Artificial jade dishware and preparation method thereof

A jade and artificial technology, which is applied in the field of artificial jade tableware and its preparation, can solve the problems of no technical data retrieved, low thermal expansion coefficient, thermal shock stability, etc., and achieve the effect of moist and smooth appearance and high thermal shock resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

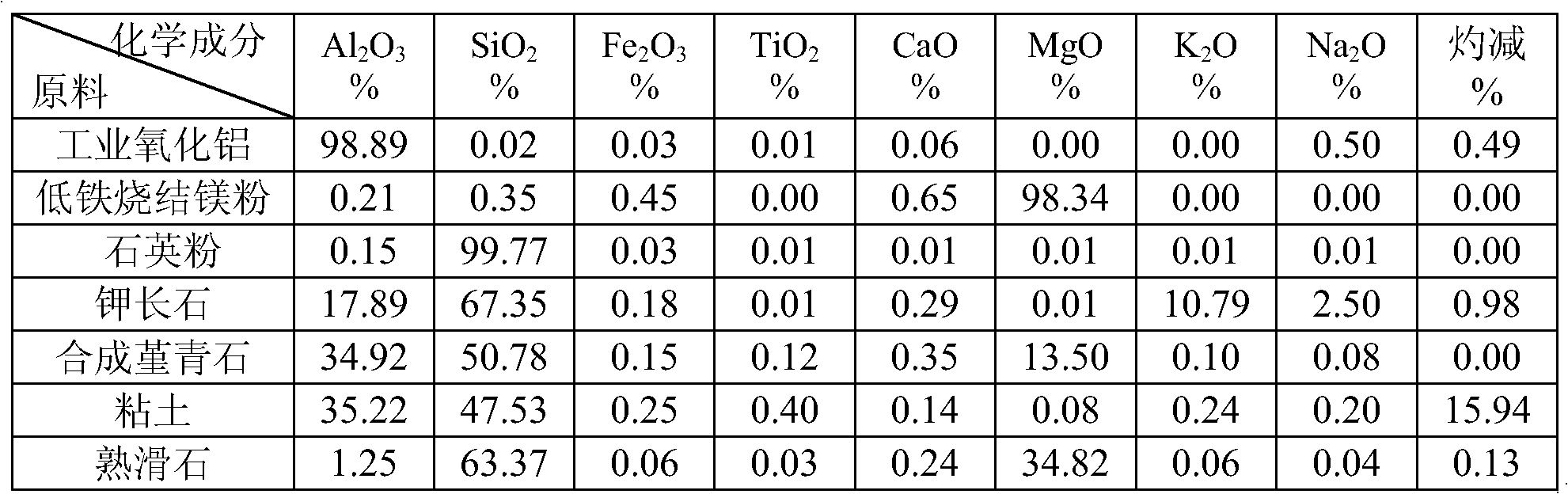

Method used

Image

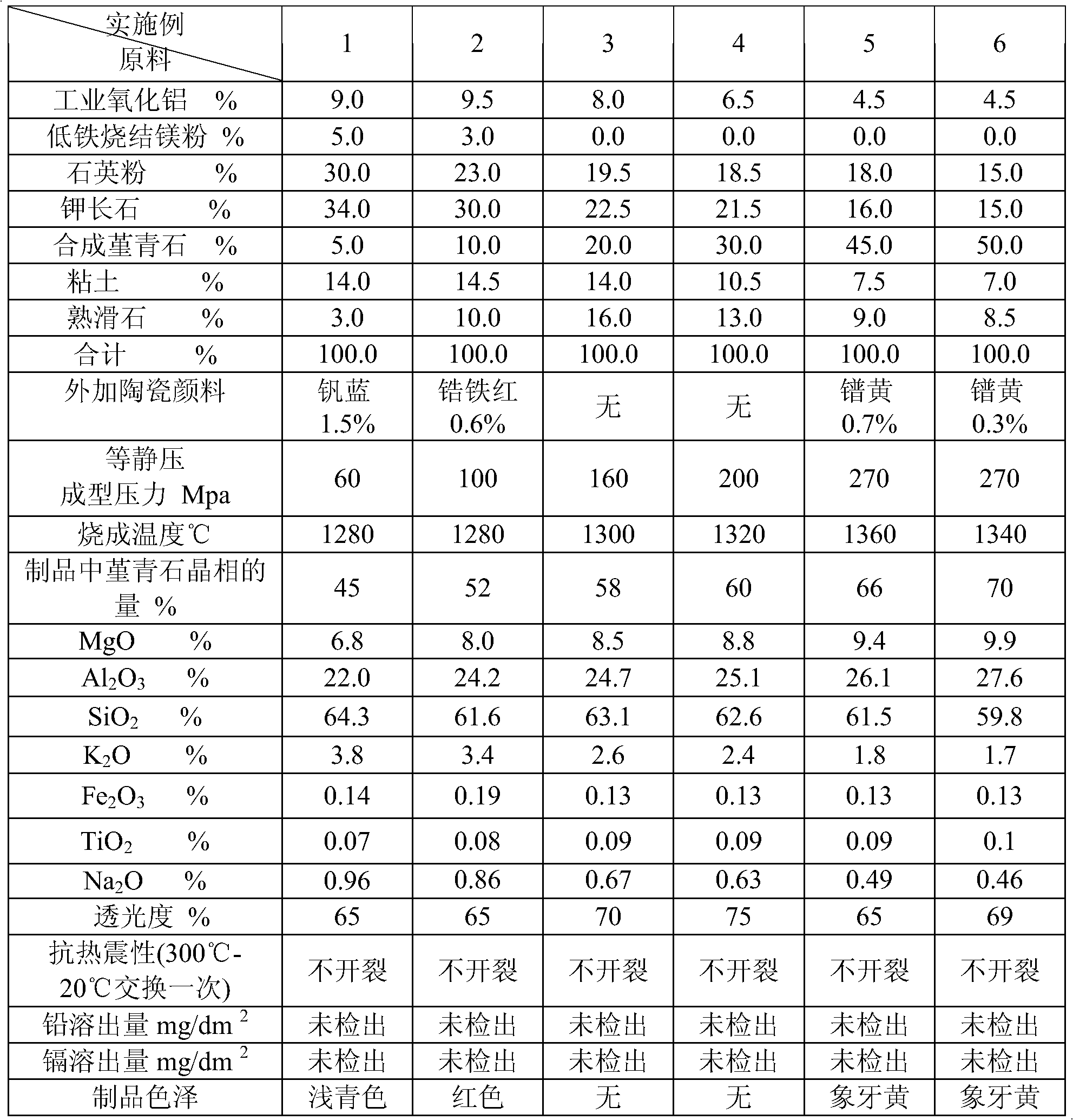

Examples

Embodiment 1

[0035] Embodiment 1: add the vanadium blue of 1.5% of raw material gross weight, spray and granulate into 16-100 mesh particle, the granularity of particle is: 16-40 mesh sieve residue: 30%; 40-80 mesh sieve residue: 48%; 80 -100-mesh sieve: 20%; 100-mesh sieve accounted for 2%; isostatic pressing forming green body, the pressure of isostatic pressing is 60Mpa. After 3 days of natural drying, the green body is fired in a kiln at a firing temperature of 1280°C and a firing holding time of 45 minutes.

Embodiment 2

[0036] Example 2: adding 0.6% of the total weight of the raw materials to the iron red, spraying and granulating into 16-100 mesh particles, the particle size of the particles is: 16-40 mesh sieve residue: 35%; 40-80 mesh sieve residue: 40%; Remainder of 80-100 mesh sieve: 18%; 100 mesh sieve accounted for 7%; the green body obtained by isostatic pressing, the pressure of isostatic pressing is 100Mpa. The green body is naturally dried for 3 days and then fired in a kiln at a firing temperature of 1280°C and a firing holding time of 120 minutes.

Embodiment 3

[0037] Embodiment 3: Spray granulation into 16-100 mesh particles, the particle size of the particles is: 16-40 mesh sieve: 20%; 40-80 mesh sieve: 48%; 80-100 mesh sieve: 19%; 100 Under the mesh sieve, it accounts for 13%; the green body is obtained by isostatic pressing, and the pressure of isostatic pressing is 160Mpa. The green body is naturally dried for 2 days and then fired in a kiln at a firing temperature of 1300°C and a firing holding time of 90 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mohs hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com