Patents

Literature

55results about How to "Improve electromechanical performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Double-electret mems actuator

InactiveUS20060066934A1Improve electromechanical performanceElectrostatic/electro-adhesion relaysElectrets selectrostatic transducerEngineeringActuator

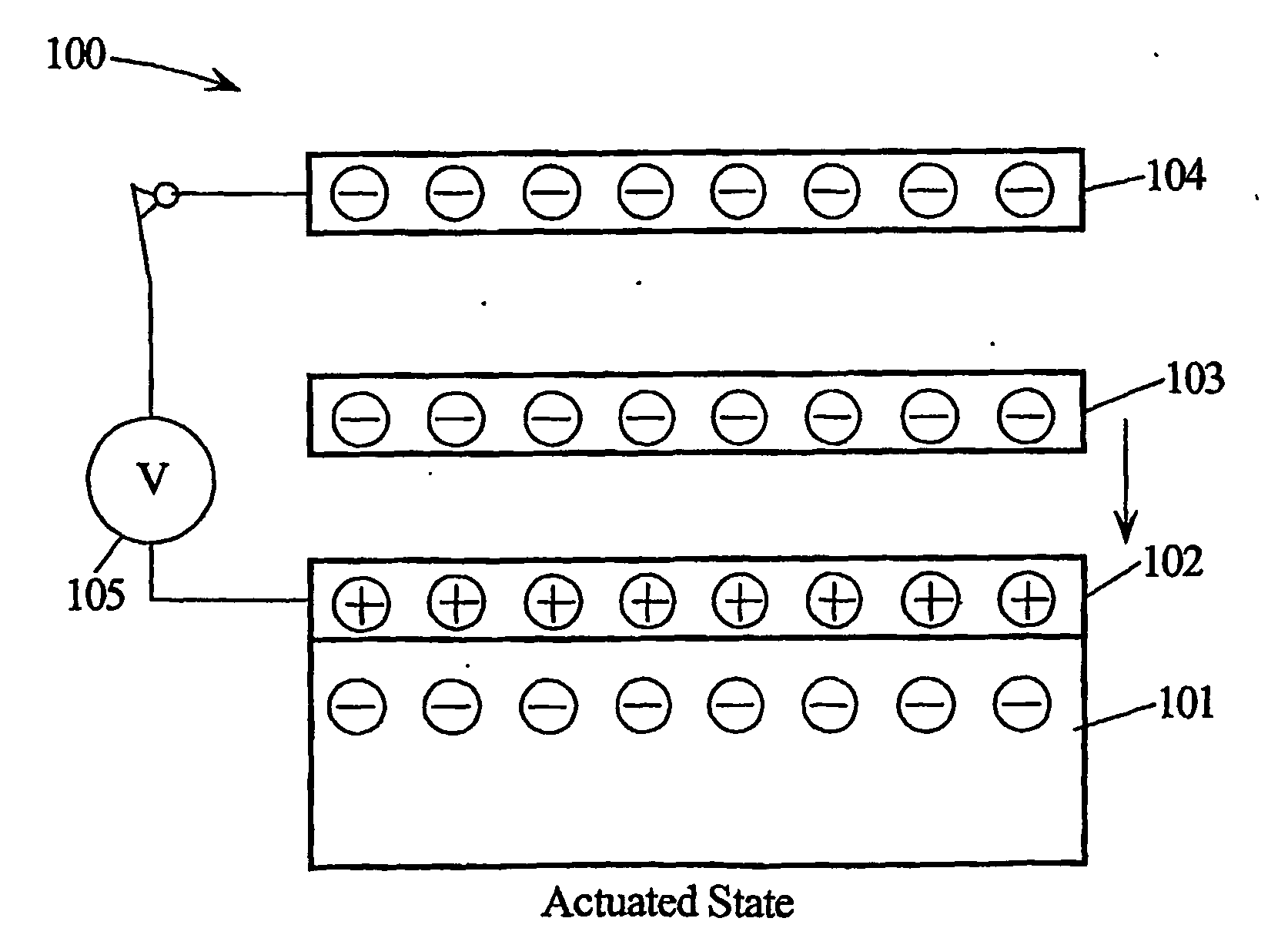

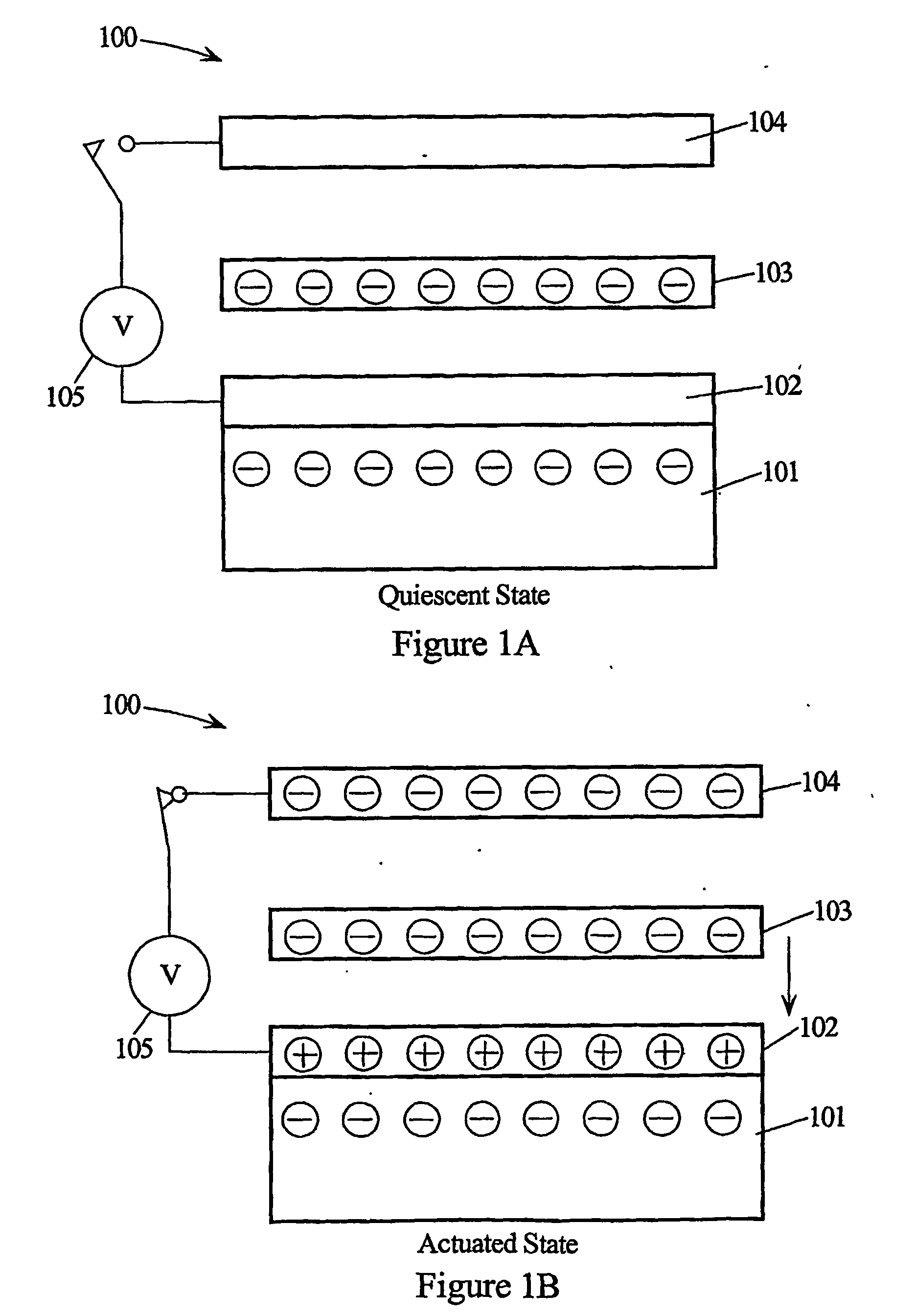

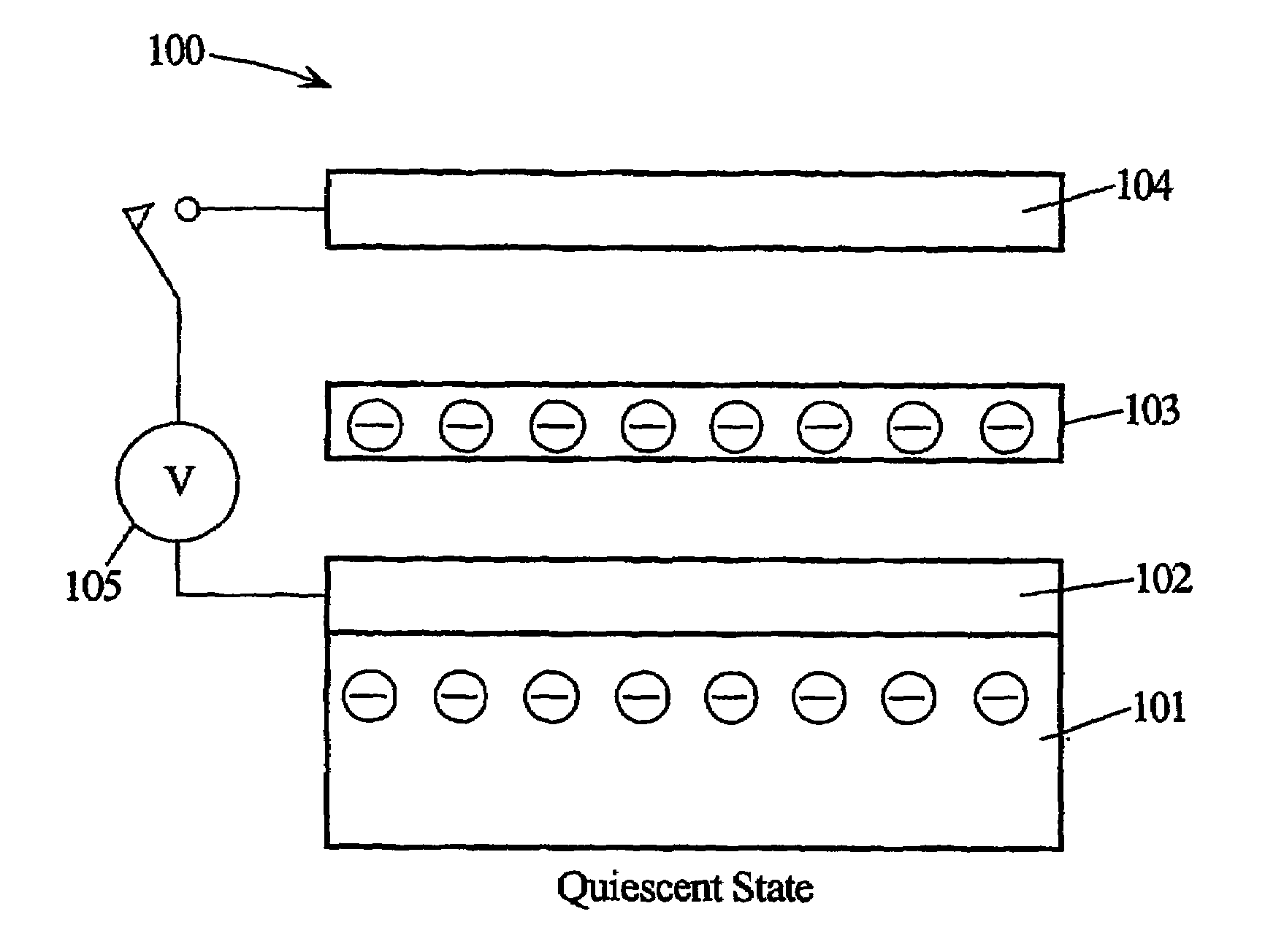

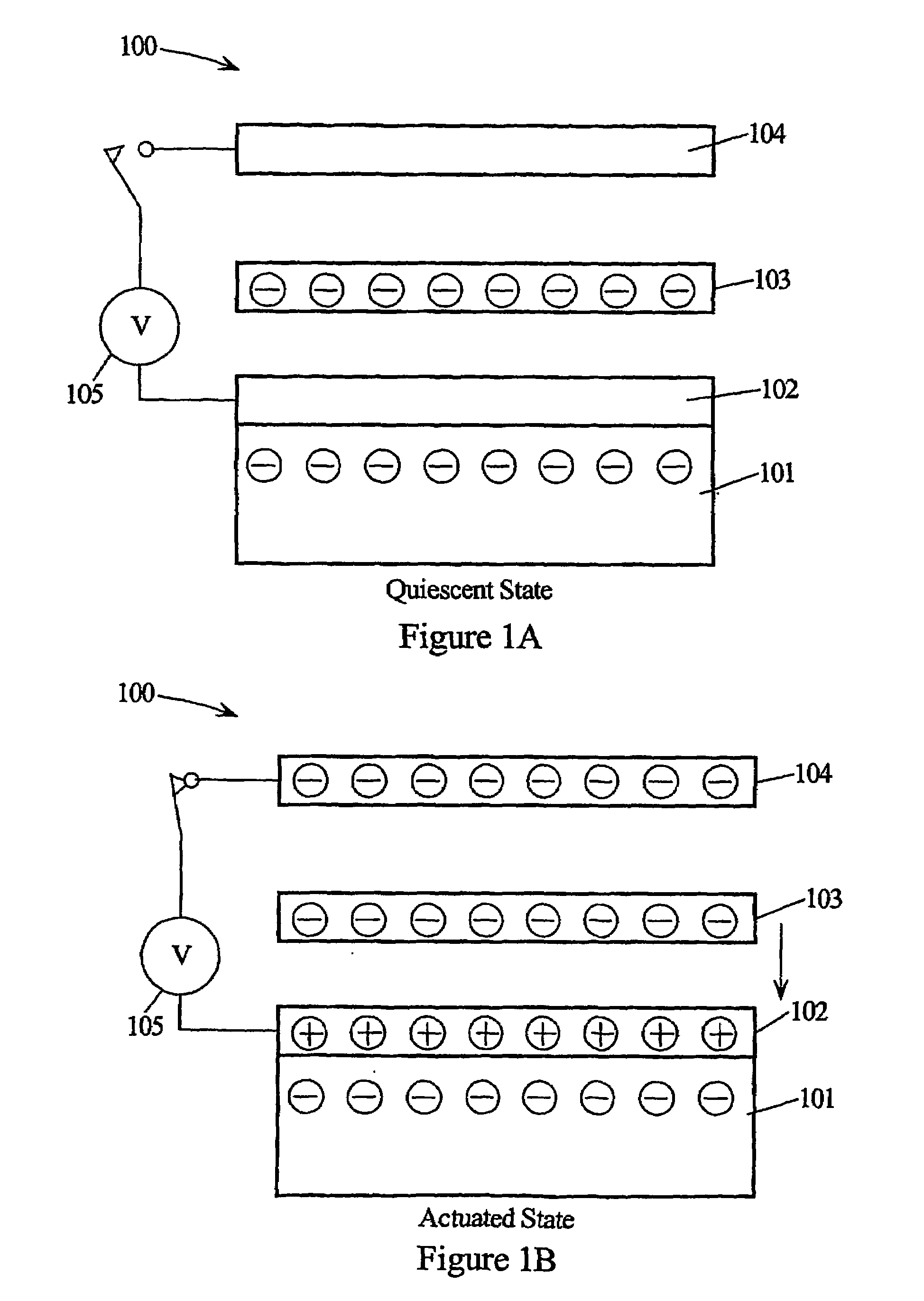

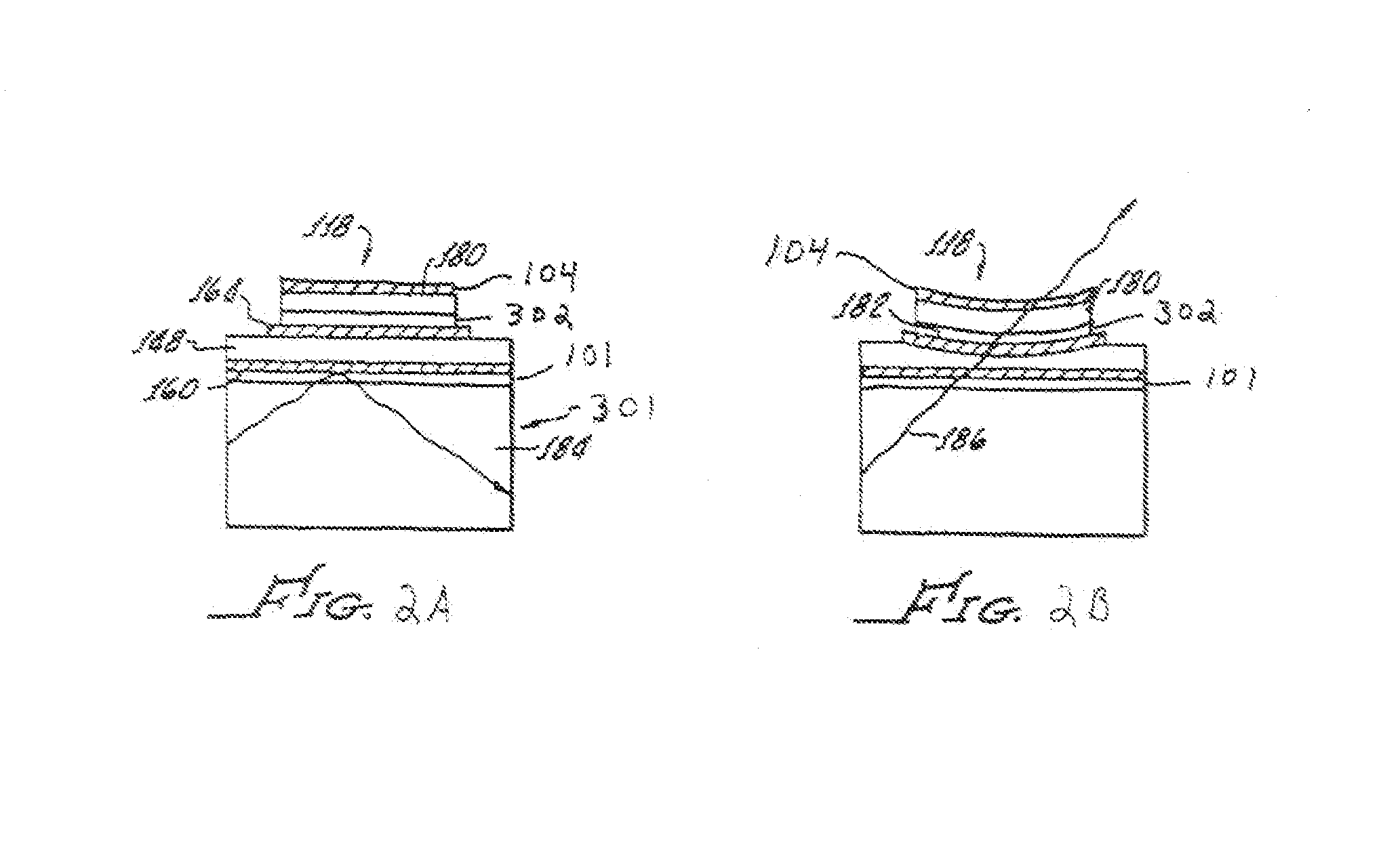

An actuator (100) taking advantage of ponderomotive forces to enhance its electromechanical performance as a function of input energy. An actuator (100) may include a first conductive layer (102) residing on a first electret layer (101). The actuator (100) may further include a moveable second electret layer (103) which is spaced apart in relation to the first conductive layer (102) when the second electret layer (103) is in a quiescent state. The actuator (100) may further include a second conductive layer (104) in a spaced apart relation to the second electret layer (103) when the second electret layer (103) is in the quiescent state. The actuator (100) may further include a voltage source (105) configured to selectively apply a voltage between the first (102) and second (104) conductive layers thereby propelling the second electret layer (103) to either the first (102) or second (104) conductive layer.

Owner:UNIPIXEL DISPLAY

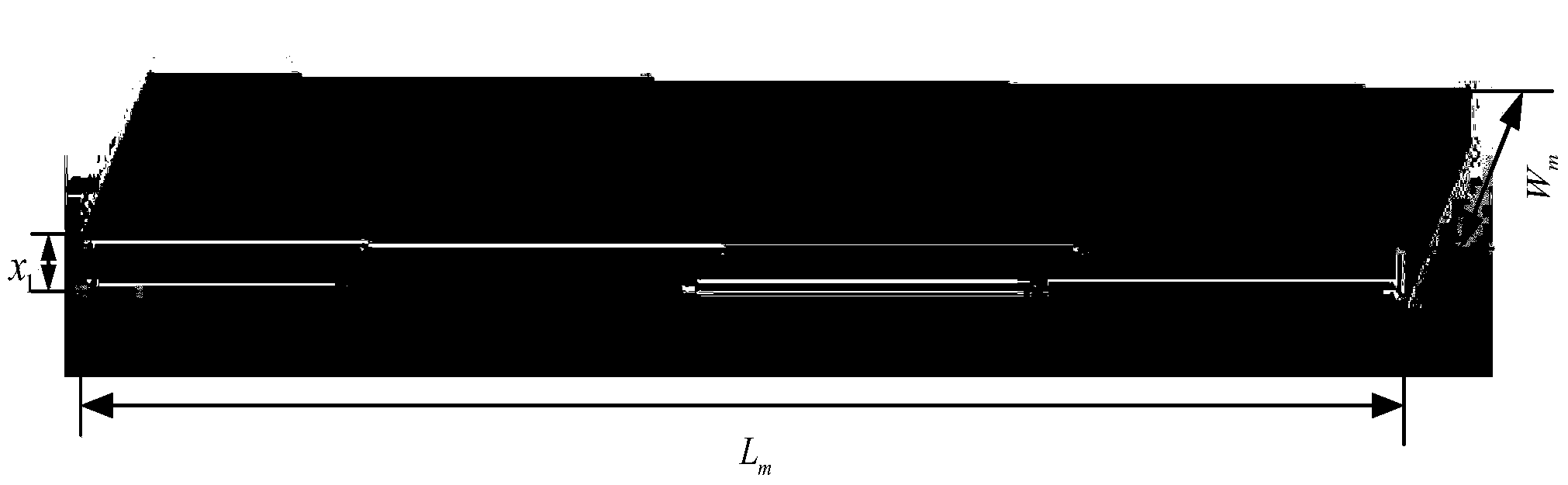

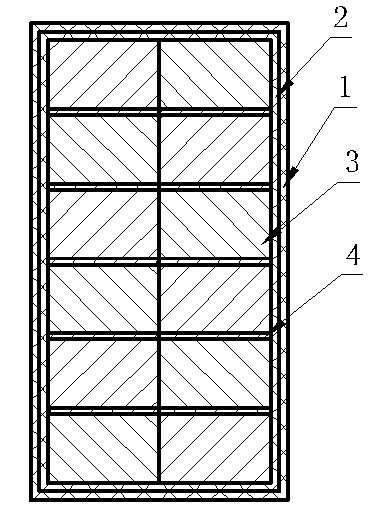

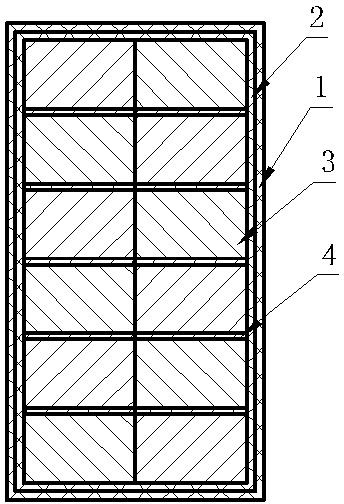

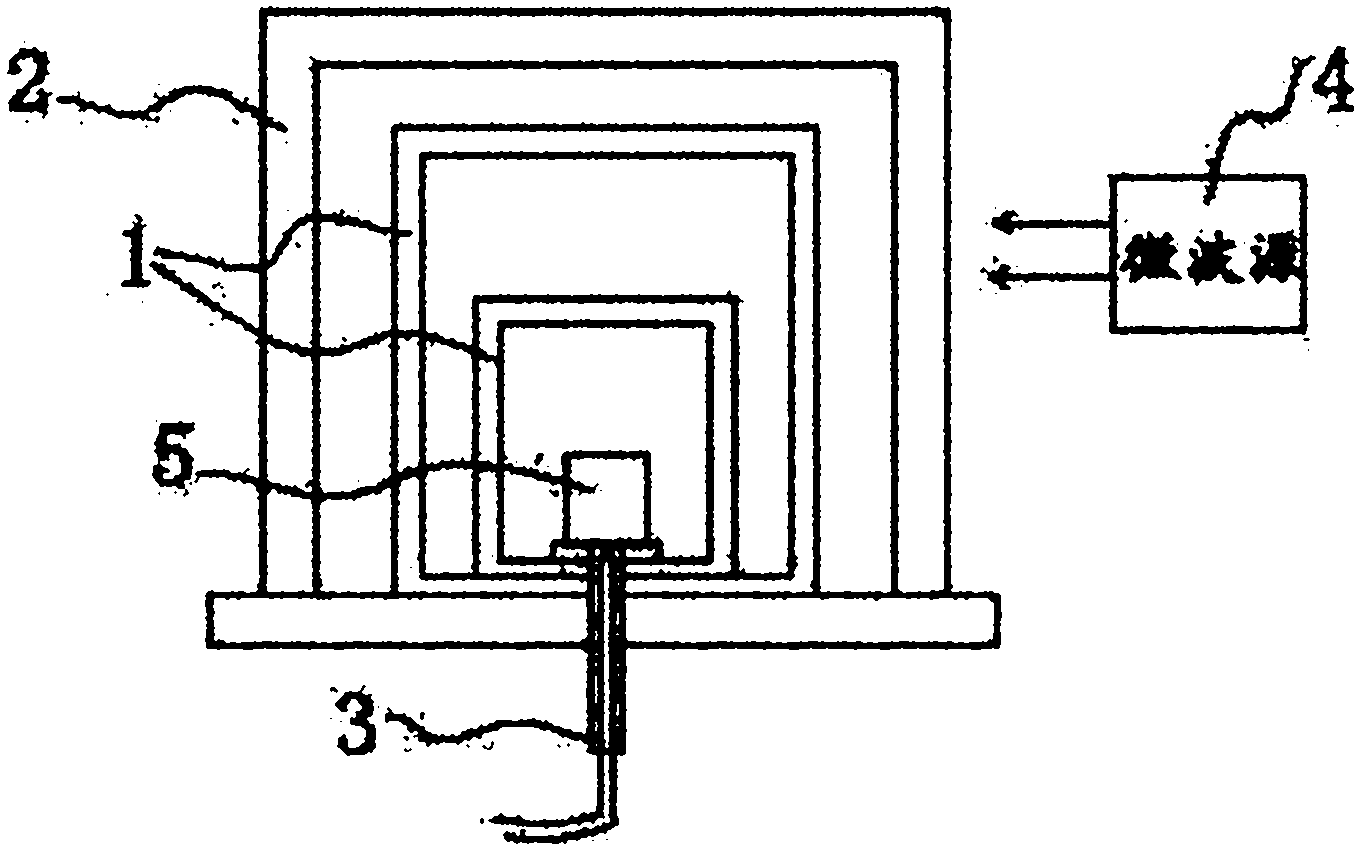

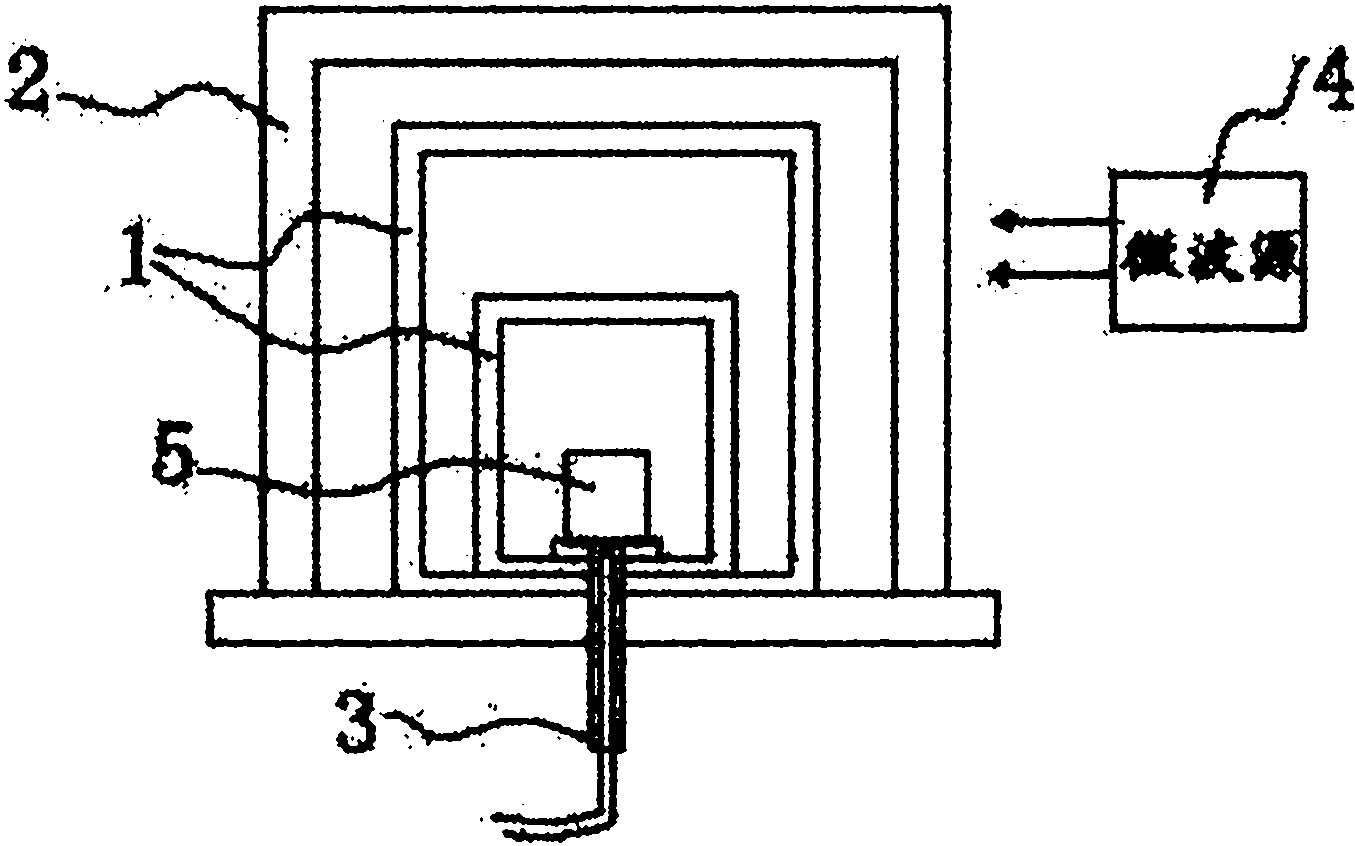

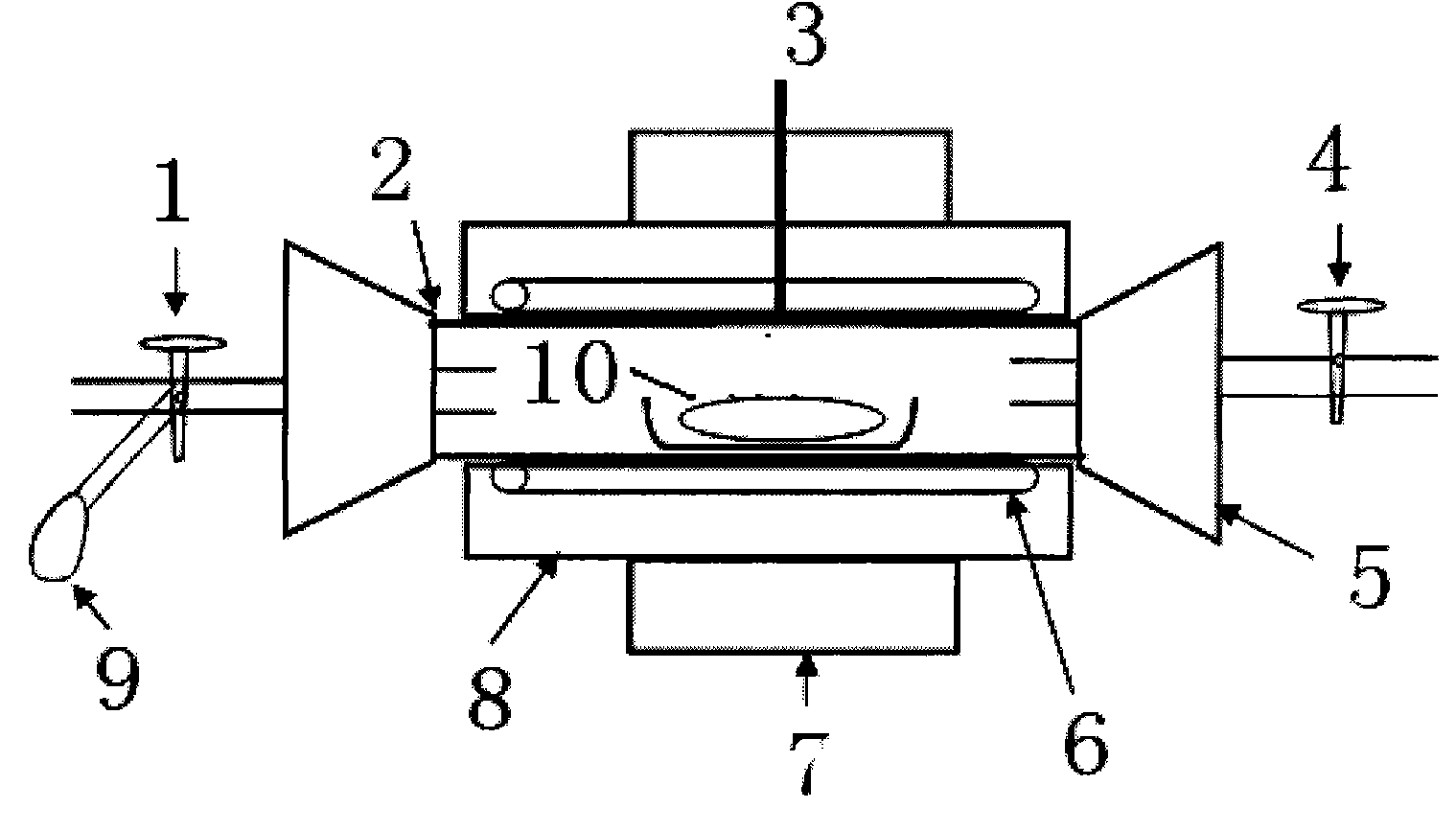

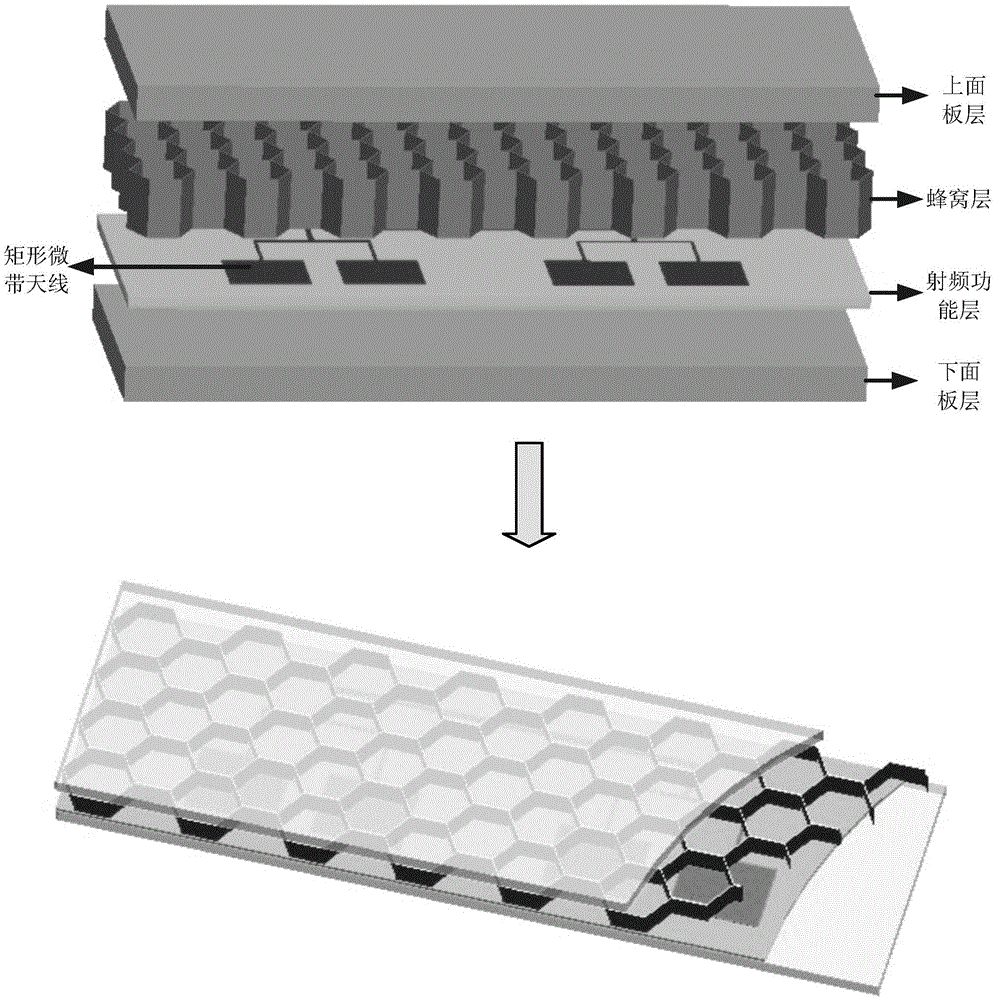

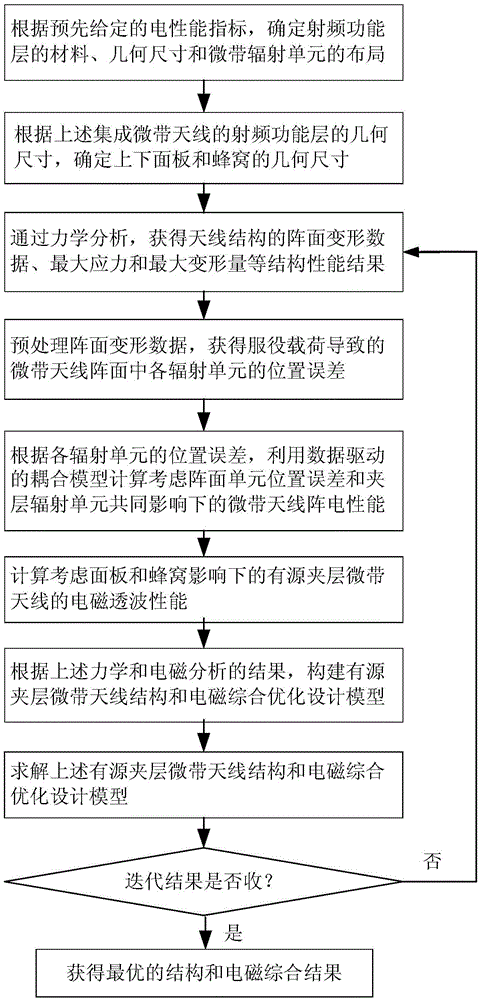

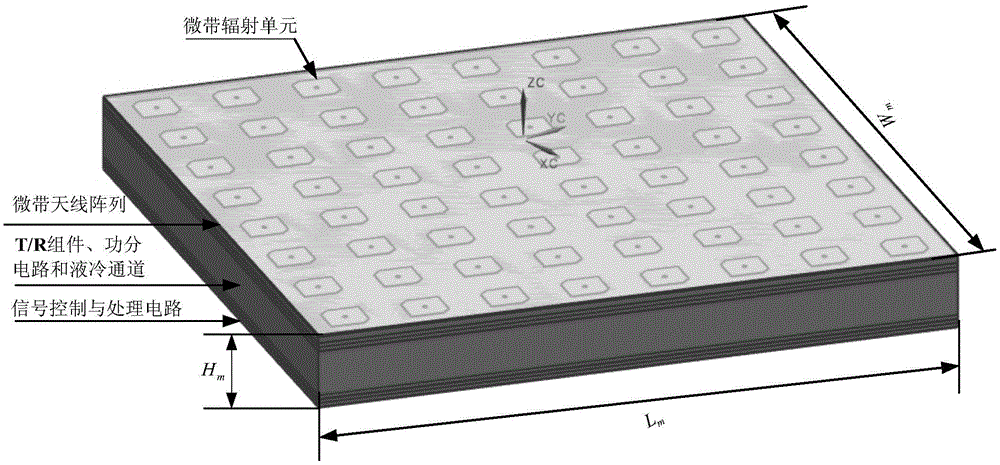

Data-driven design method integrating active interlayer microstrip antenna structure and electromagnetism and antenna

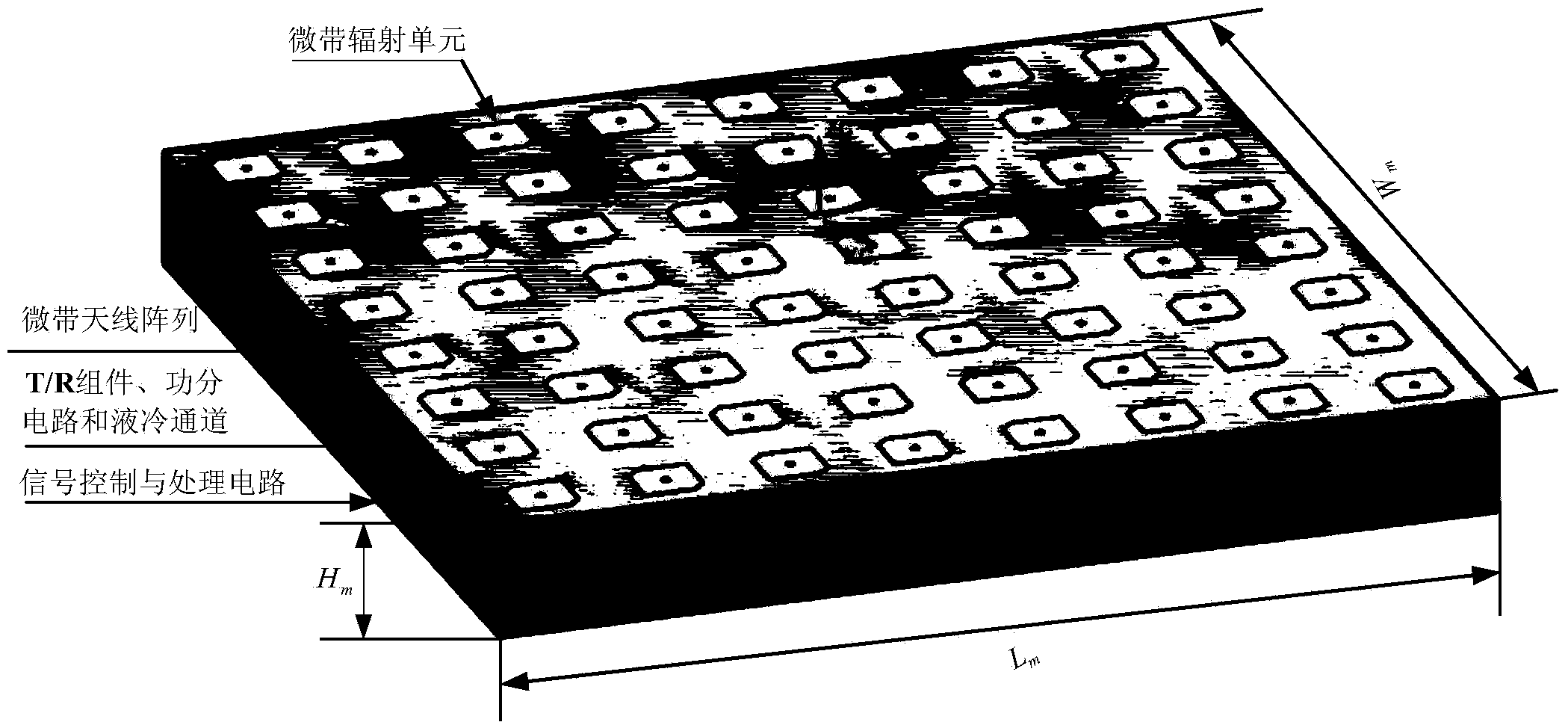

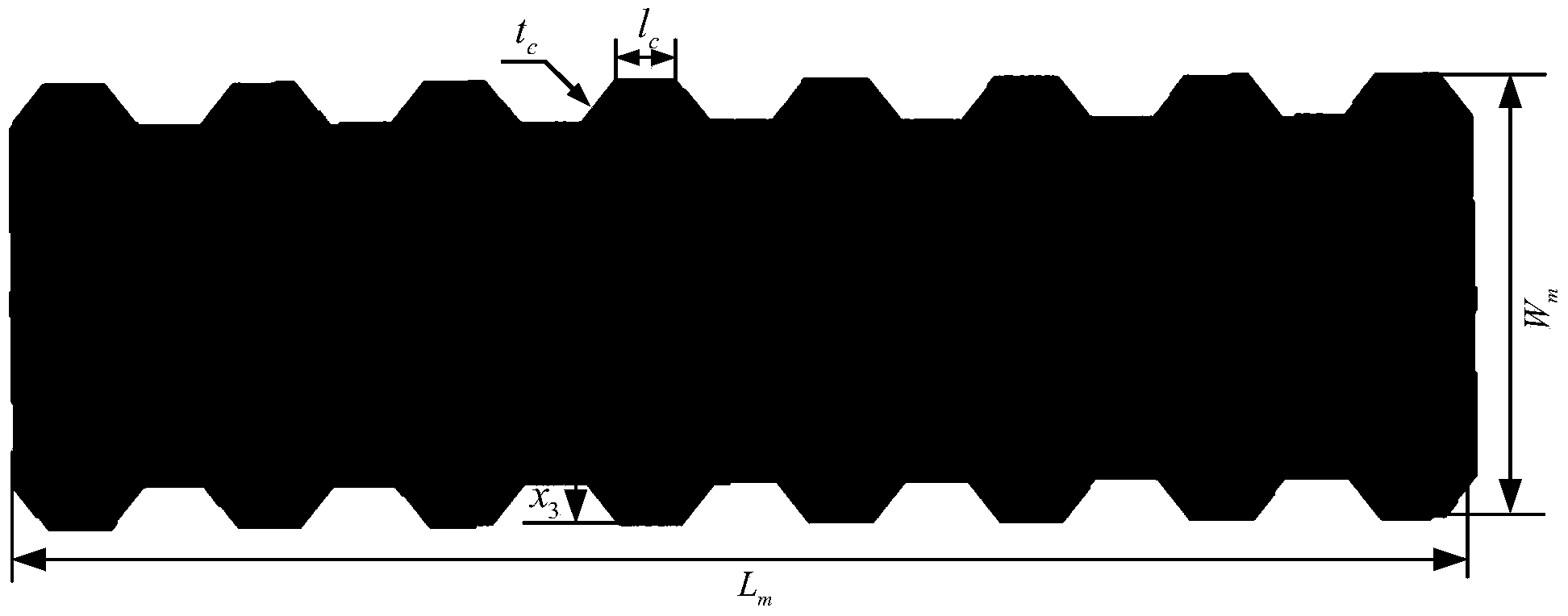

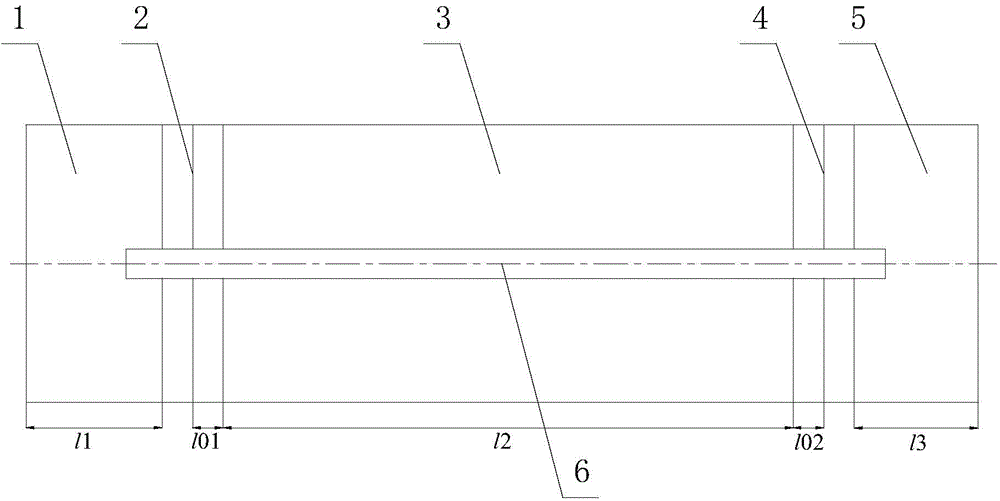

ActiveCN103353904ATo overcome the difficulty in realizing the design of electromechanical integrationRealize the structureSpecial data processing applicationsInformation technology support systemEngineeringRadio frequency

The invention discloses a data-driven design method integrating an active interlayer microstrip antenna structure and electromagnetism and an antenna, and solves the problem that the prior art can not realize the integrated design of the structure and electromagnetism. The method comprises the following steps: firstly, fixing the material, size, panel and cellular size of a radio frequency function layer according to electrical property indexes, secondly, obtaining front deformation data and stress data of the antenna structure through mechanical analysis, thirdly, preprocessing the front deformation data, so as to obtain the position error of each radiating element, fourthly, calculating a far-field pattern of an interlayer microstrip antenna according to a data-driven coupling model, fifthly, calculating and considering the wave-transparent performance influenced by the panel and cellular, sixthly, establishing an optimization design model integrating the interlayer microstrip antenna structure and electromagnetism, and seventhly, solving the optimization design model, so as to obtain an optimal integrating result. The method can realize the simultaneous optimal design of the active interlayer microstrip antenna structure and electromagnetism, shortens the development period, and improves force-electricity properties of products.

Owner:XIDIAN UNIV

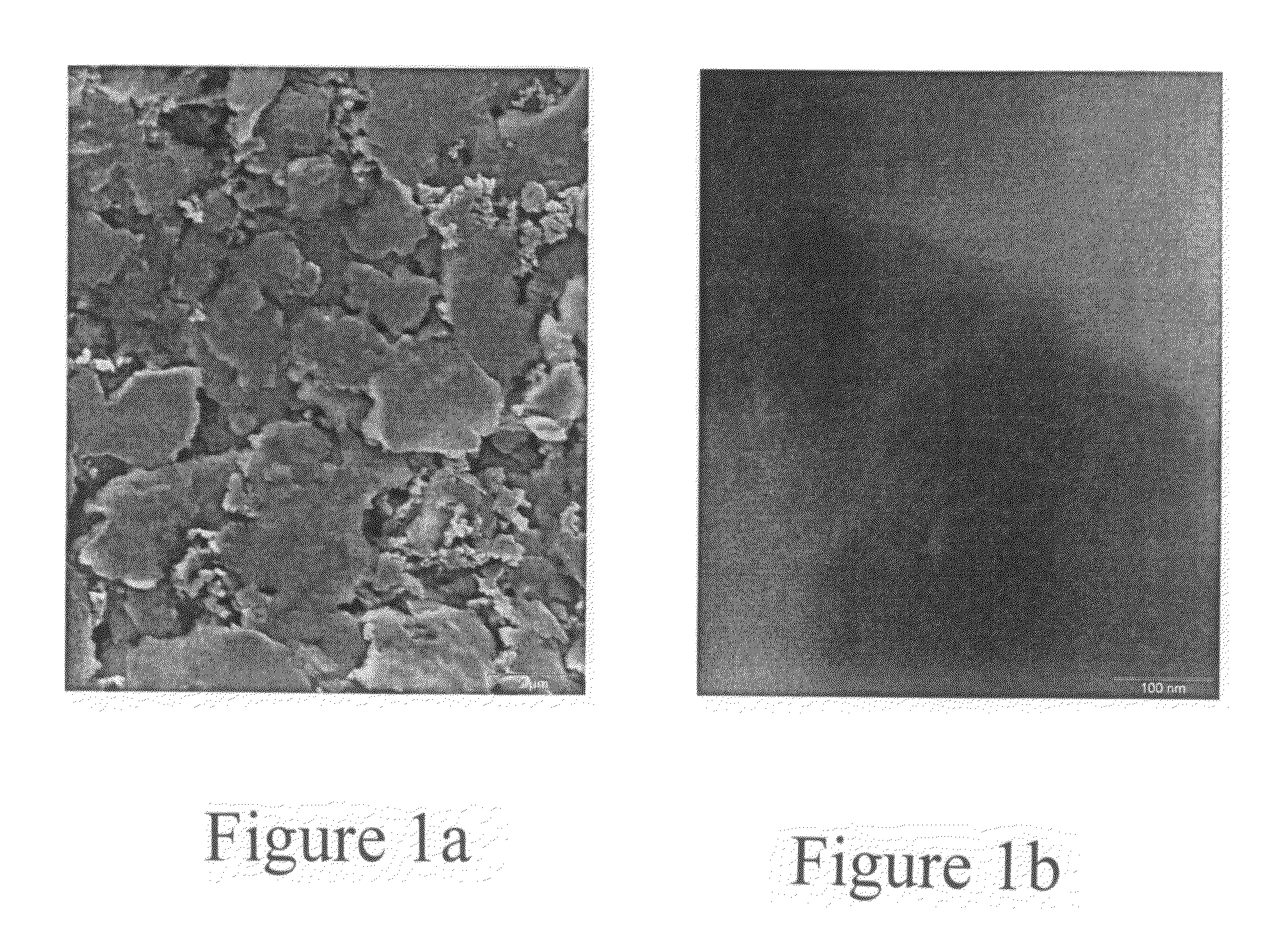

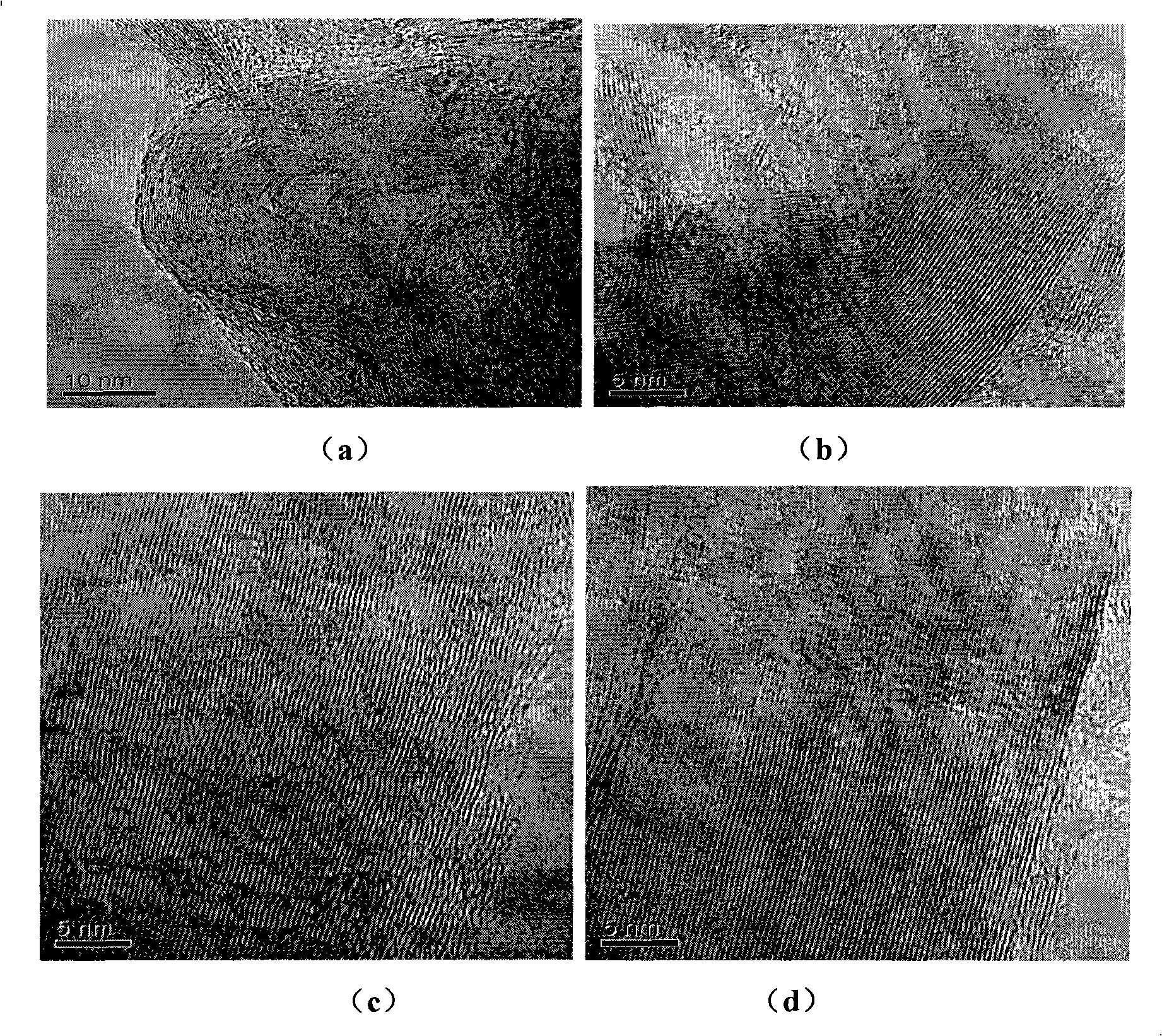

Carbon nanotubes-reinforced conductive silver ink

InactiveUS7763187B1Improve conductivityIncreased durabilityNon-metal conductorsPrinted circuit aspectsSilver inkSolvent

Conductive silver ink is reinforced using carbon nanotubes. Carbon nanomaterials are stabilized and uniformly dispersed in a solvent and mechanically mixed with conductive silver ink. The reinforcement material bridges the gap between separated silver flakes in the conductive silver ink. The carbon nanotubes reinforced conductive silver ink exhibits superior performance over unreinforced silver ink in its mechanical, electrical and thermal properties without significantly greater weight.

Owner:OCEANIT LAB

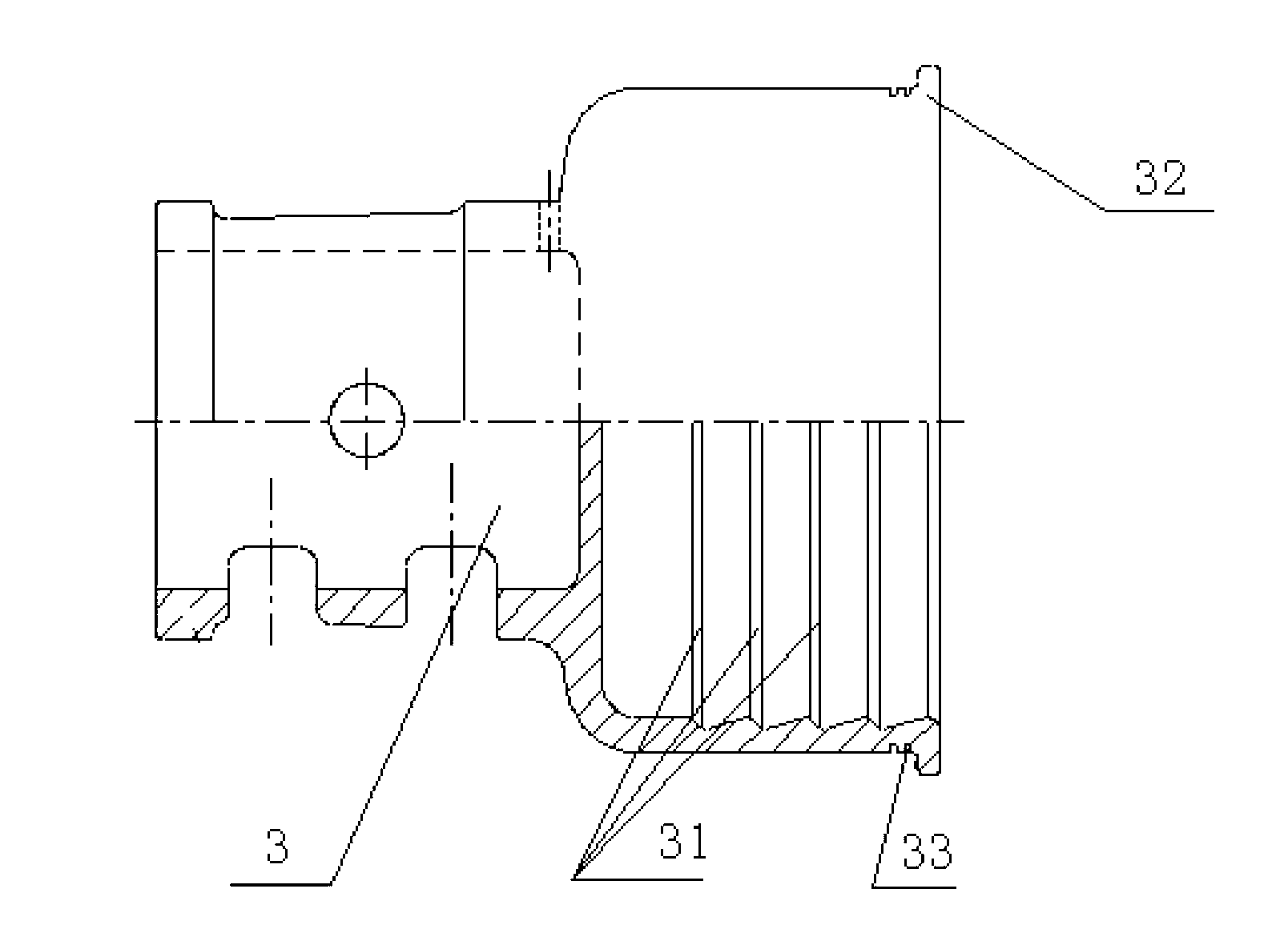

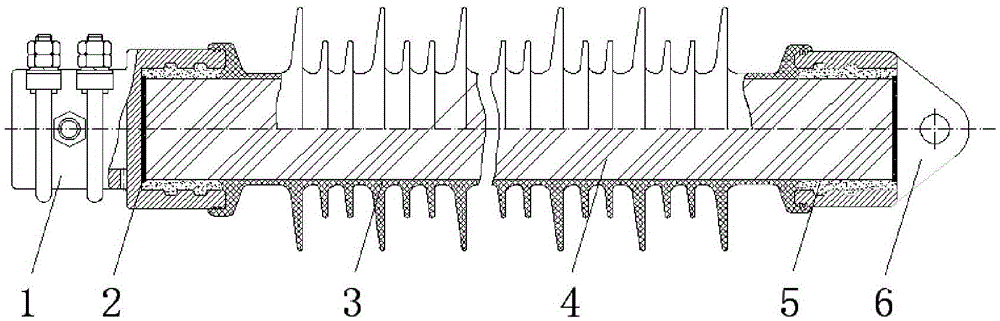

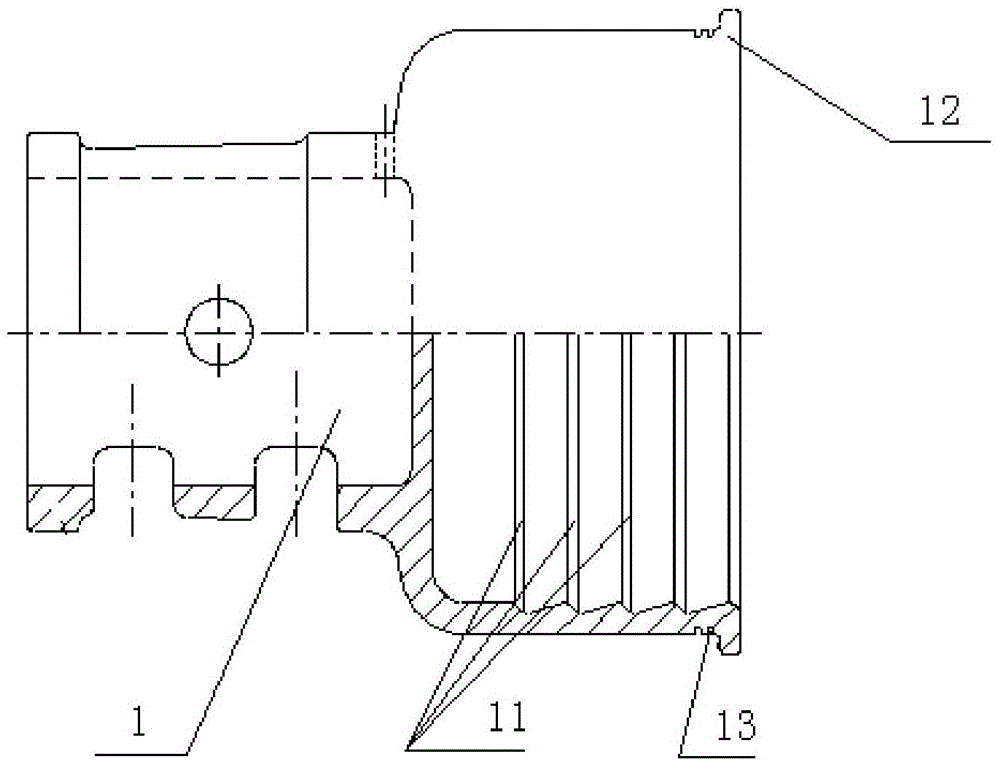

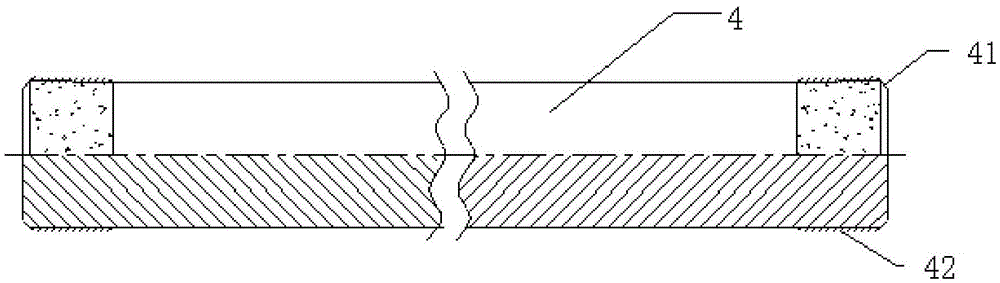

Novel long rod type porcelain composite insulator and manufacturing method thereof

ActiveCN103165247AImprove pass rateHigh mechanical strengthInsulatorsComposite insulatorsEngineering

The invention discloses a novel long rod type porcelain composite insulator. The long rod type porcelain composite insulator comprises an insulator body, wherein an outer insulating umbrella skirt sheath is arranged outside the insulator body; hardware fittings are cemented at two ends of the body; a mounting inner hole of each hardware fitting is in a sawtooth shape; and the outlet end of each hardware fitting is in a circular arc shape, and a rectangular groove is formed outside the outlet end. Due to the adoption of reasonable structural design and high-quality production raw materials and the selection of an advanced manufacturing process, the long rod type porcelain composite insulator has high electromechanical properties. According to the long rod type porcelain composite insulator, high-temperature vulcanized silicon rubber is used as the outer insulating umbrella skirt sheath, high-strength ceramic is used as internal insulation, and the end fittings are cemented by using high-strength silicates through a amplitude varying process to manufacture the porcelain composite insulator. By the porcelain composite insulator, the accidents of brittle failure and string breakage can be avoided, and the problem of external insulation pollution flashover of the porcelain insulator is solved, so that the long rod type porcelain composite insulator is high in mechanical and electrical properties and is suitable for various extremely severe work conditions.

Owner:JIANGSU SOUTH PORCELAIN INSULATOR CO LTD

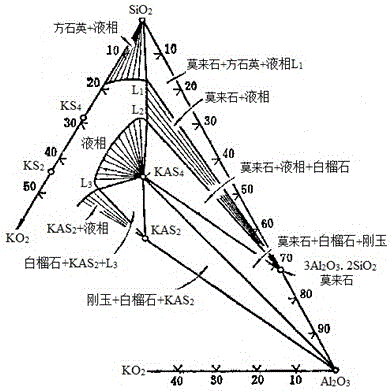

Method for selection and preparation of raw materials of high-strength suspension porcelain insulator glaze

InactiveCN101514114AImprove electromechanical performanceImprove insulation performanceKaoliniteGranularity

The invention discloses a method for the selection and the preparation of the raw materials of a high-strength suspension porcelain insulator glaze. The raw materials comprise kaolinite type clay, talcum, feldspar, refined quartz, carbonate, porcelain powder, water glass and calcined alumina. The invention is characterized in that the kaolinite type clay is 10 to 15%, the talcum is 10 to 15%, the feldspar is 25 to 35%, the refined quartz is 25 to 35%, the carbonate is 5 to 10%, the porcelain powder is 1 to 8%, the water glass is 0.1 to 0.5% and the calcined alumina is 10 to 15%. The particle size of each clay raw material is 20 to 40 mushes, the particle size of other raw materials is 180 to 200 mushes. The bending strength of porcelain blank can be improved by 25 to 40% after being glazed by the glaze, the sintering temperature of the porcelain insulator after being glazed is 1200 to 1350 DEG C.

Owner:INST OF GEOCHEM CHINESE ACADEMY OF SCI +1

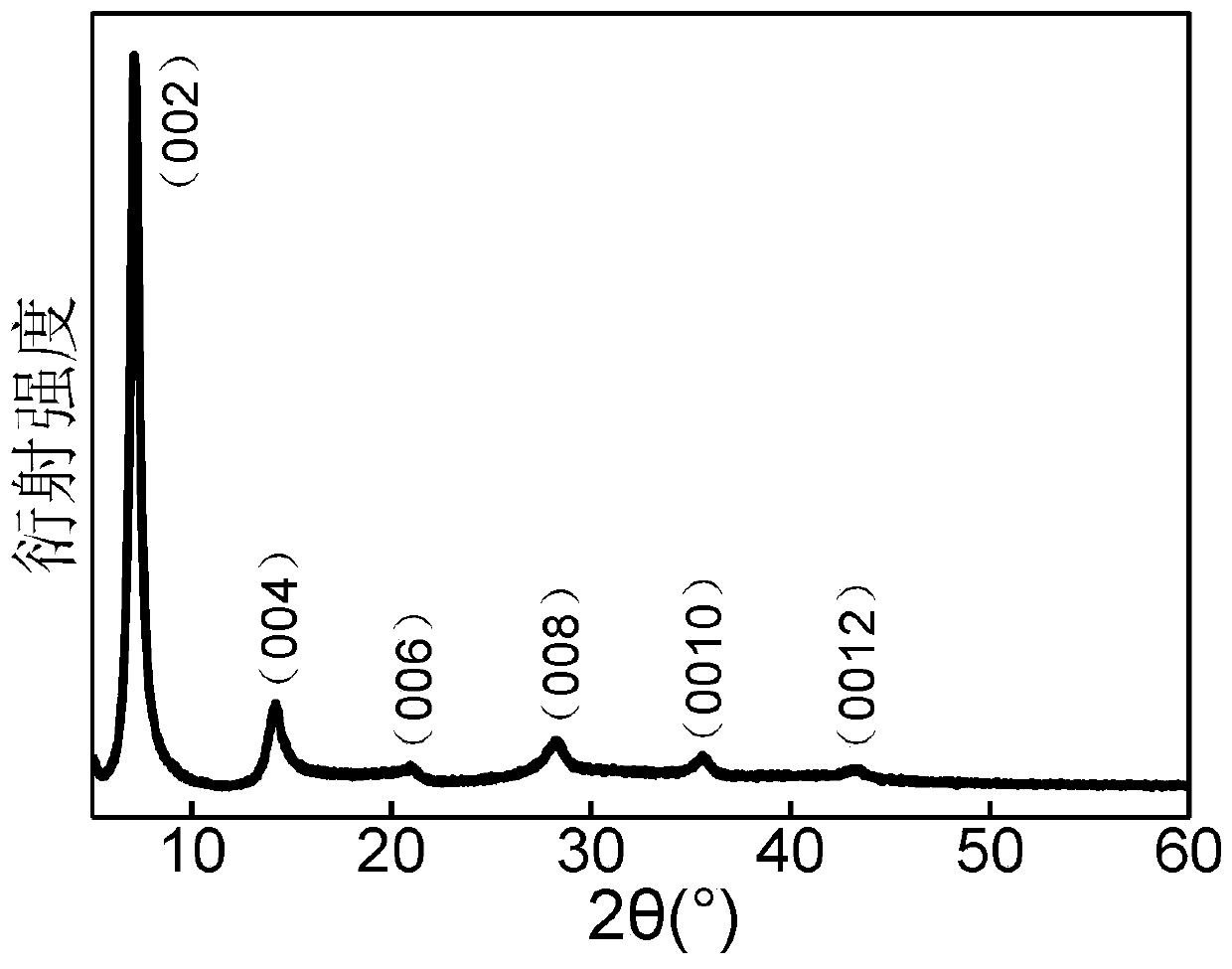

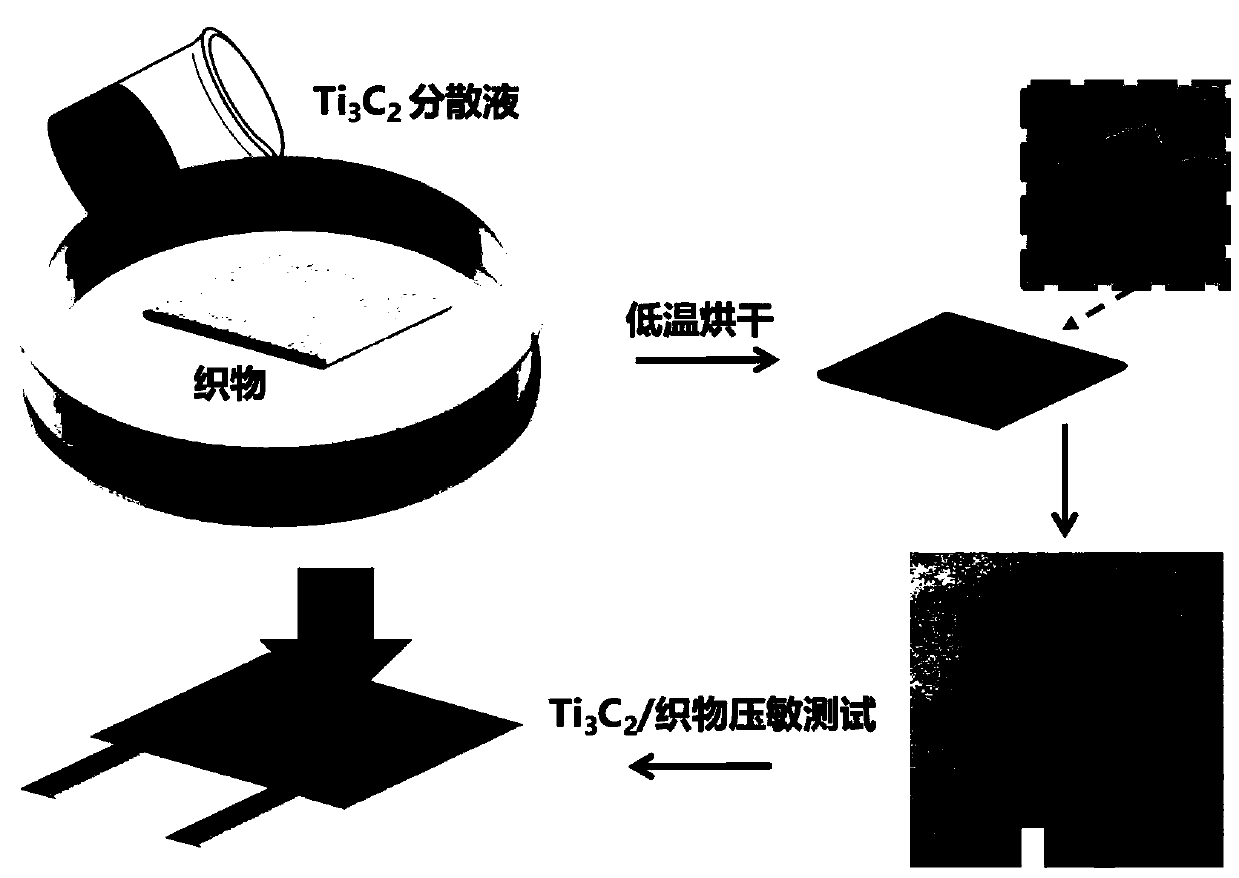

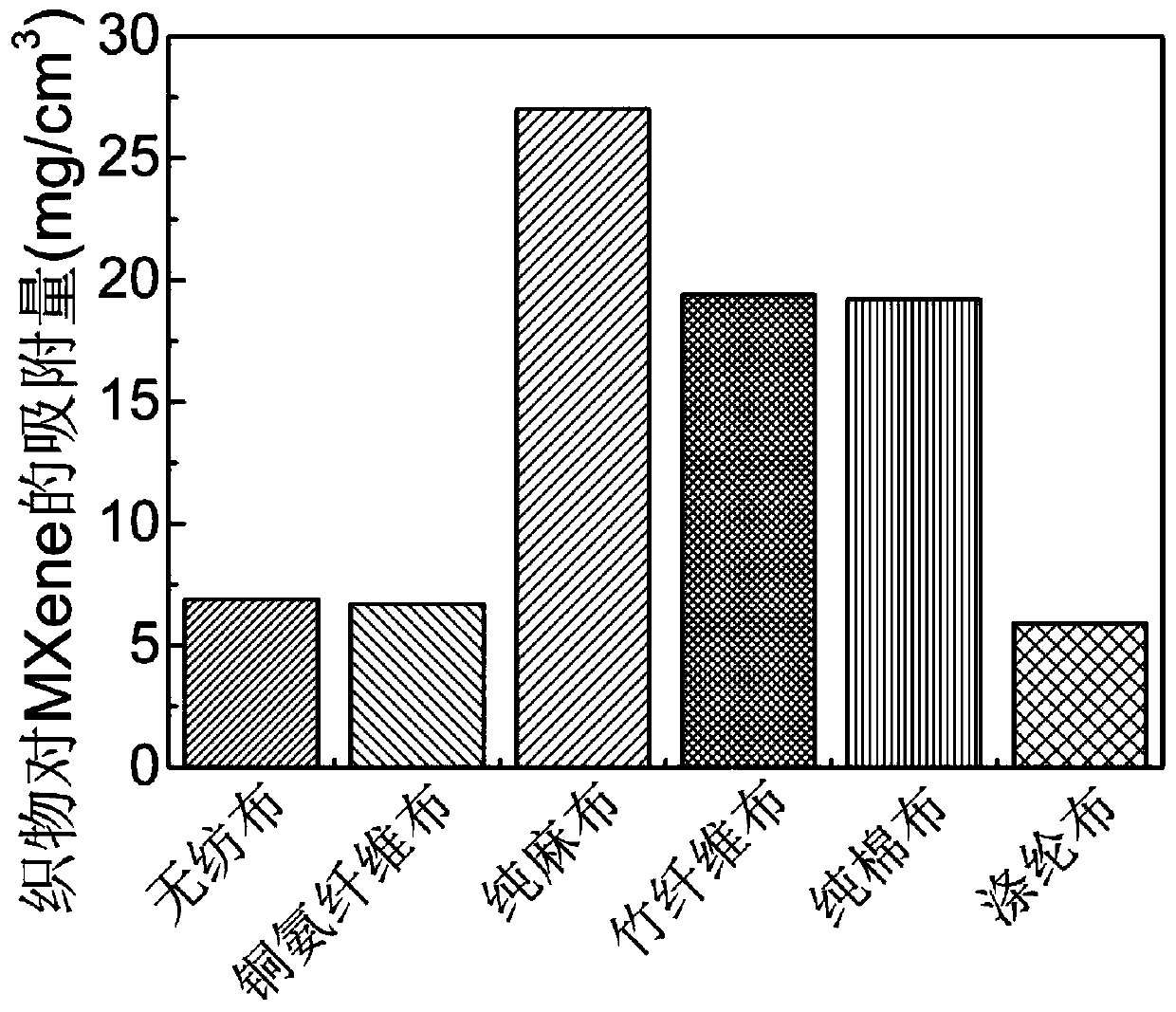

MXene coating textile force sensor and fabrication method thereof

InactiveCN110726496AGood flexibilityImprove responsivenessFluid pressure measurement by electric/magnetic elementsForce measurementPhysicsWoven fabric

The invention relates to an MXene coating textile force sensor and a fabrication method thereof. The MXene coating textile force sensor comprises a flexible substrate layer and a response transmissionlayer, wherein the material of the response transmission layer is MXene. Corresponding current response can be rapidly shown under different external pressures, the fabrication method is simple, andthe force-sensitive response device is high in sensitivity, low in cost and high in strength, has relatively good flexibility and can have very wide application prospect in the field of wearable smartclothing.

Owner:DONGHUA UNIV

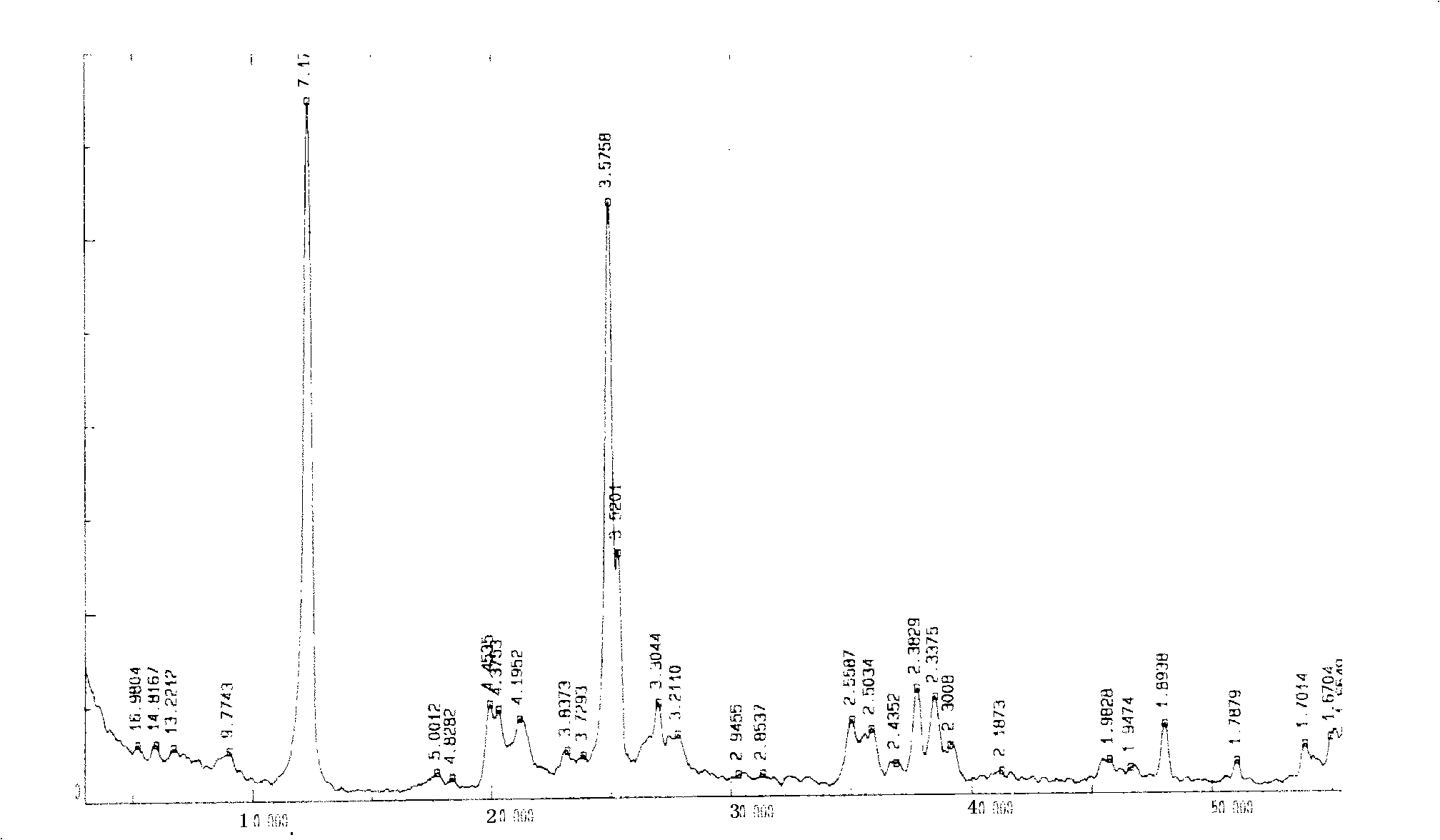

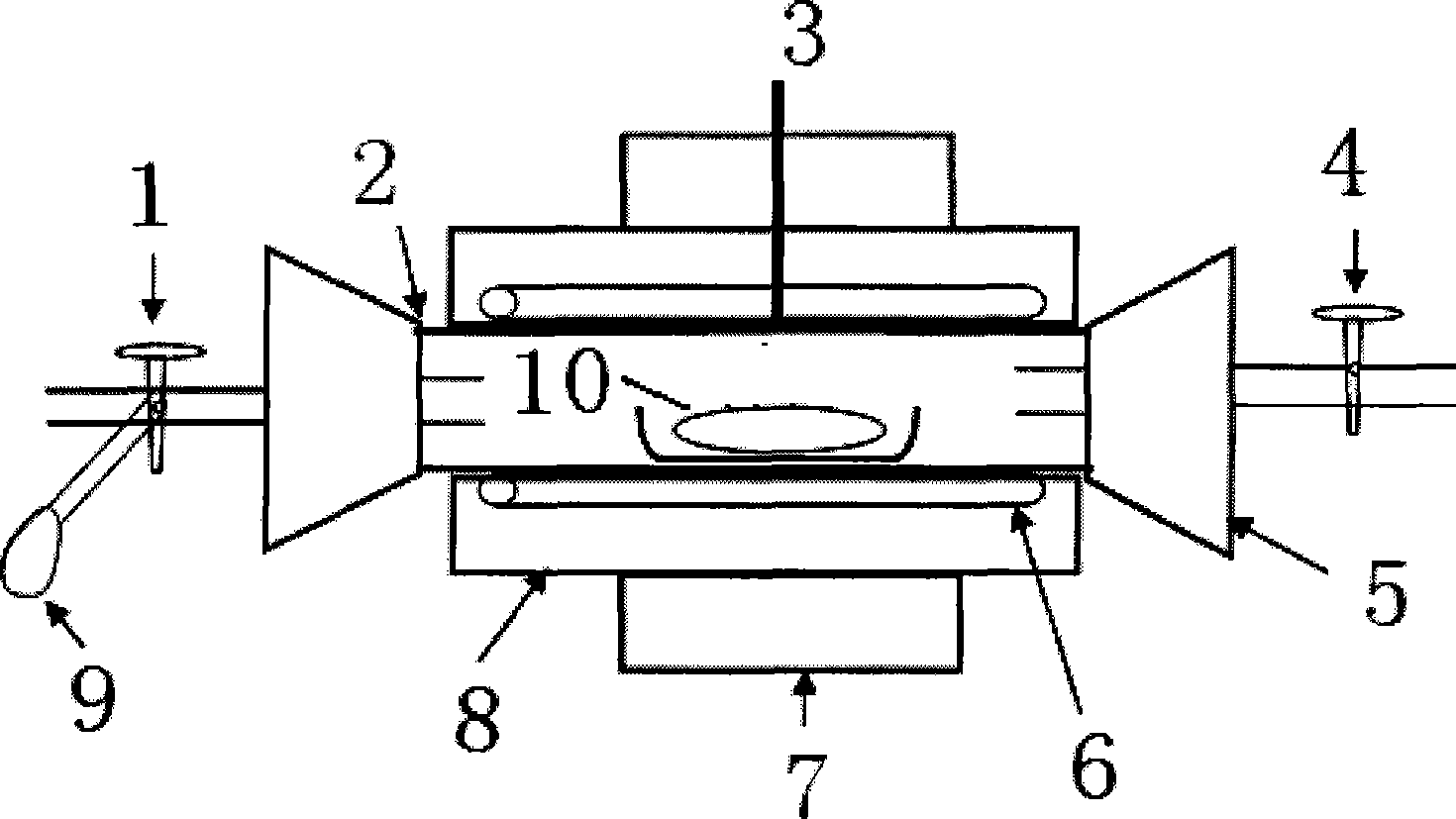

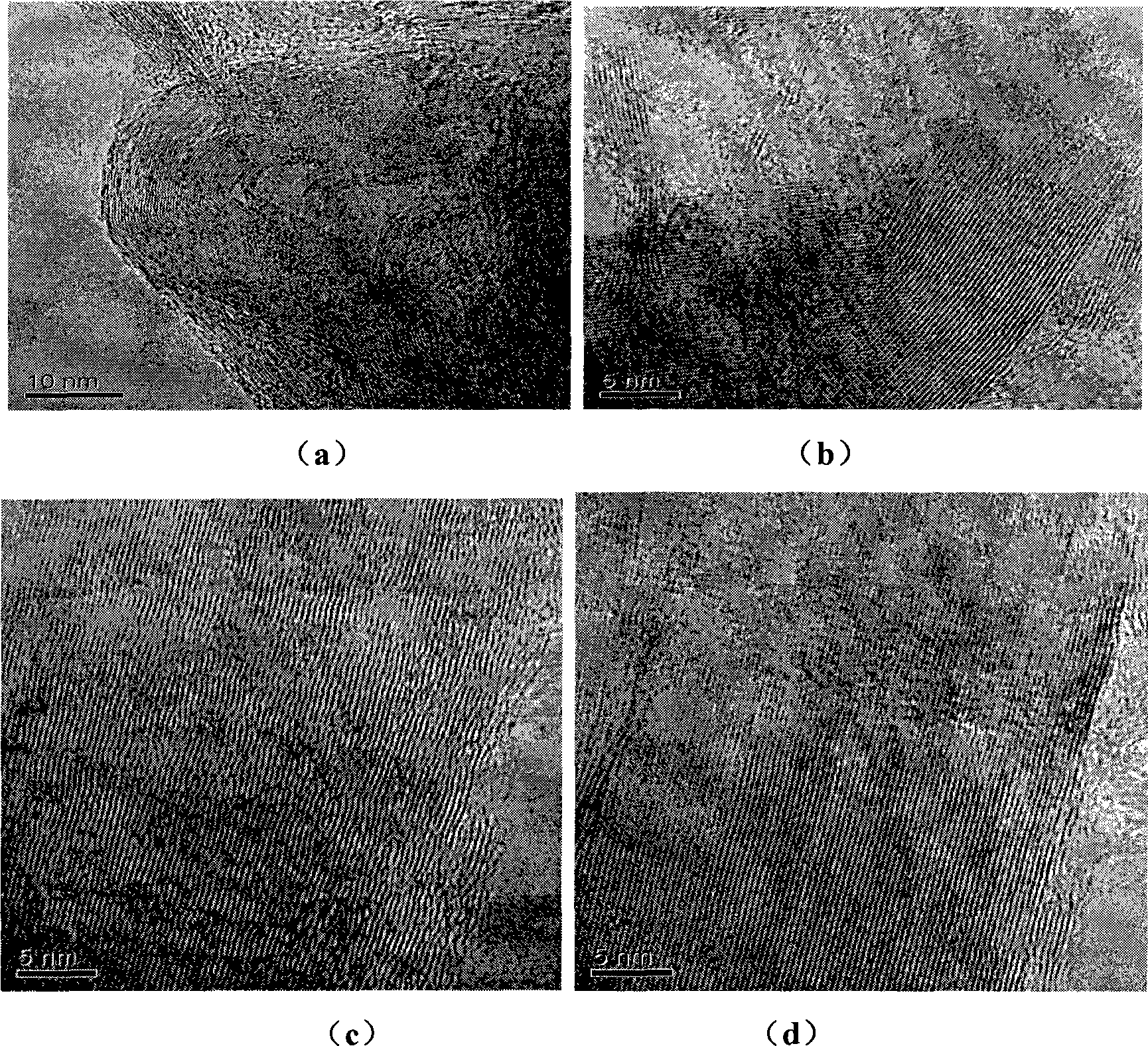

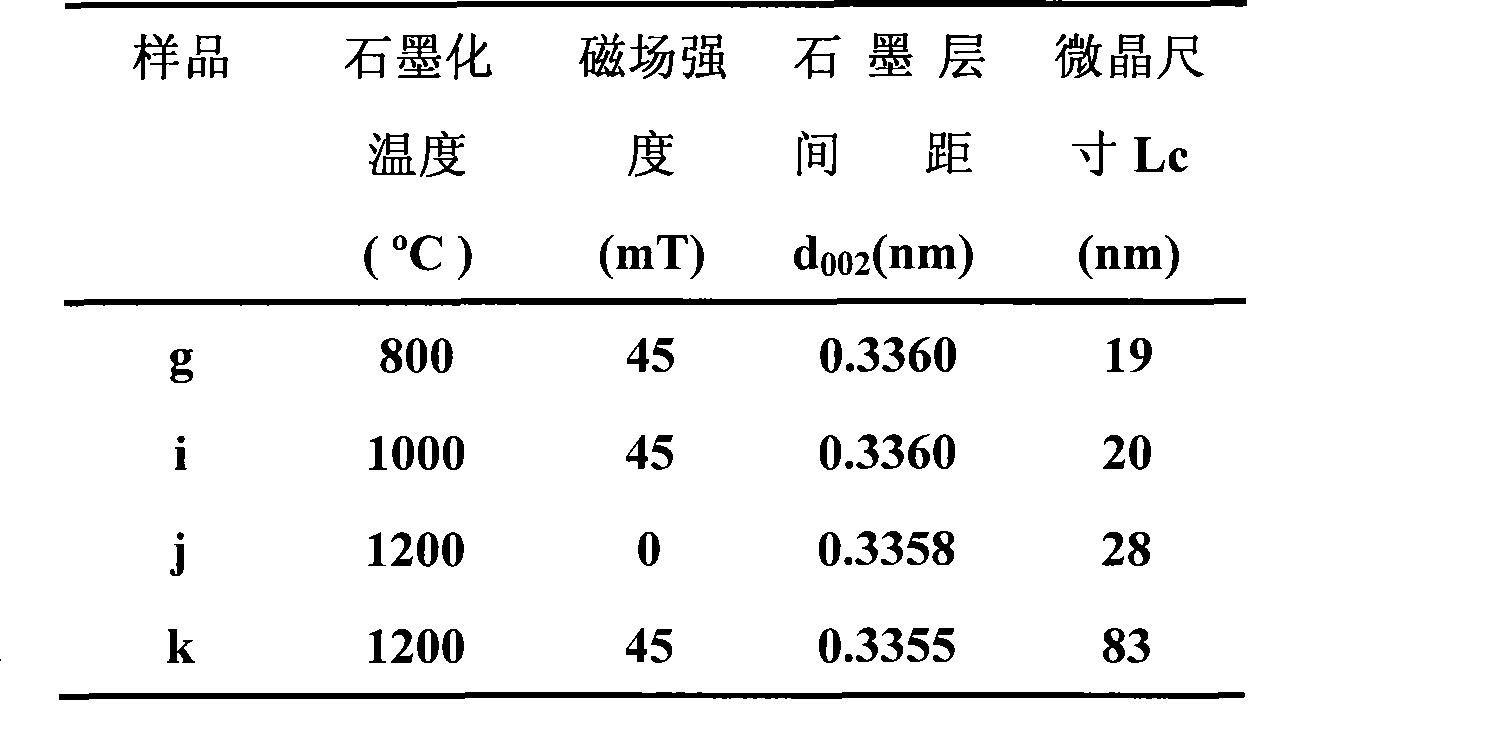

Method for improving graphitization and carbonizing degree of carbon material based on magnetic field and catalysis

The invention discloses a method for improving the graphitization of a carbon material and the carburization degree based on a magnetic field and the catalysis. The method aims to apply the magnetic field induction and control the structural orientation of a newly generated graphite layer to ensure that the carbon material grows according to the preset orientation, thereby achieving the aim of improving the electromechanical properties of the carbon material. A proper amount of ferromagnetic catalyst is added into the carbon material, and then the high temperature carbonization and graphitization treatment is performed under the action of an externally-applied magnetic field; and the graphitization based on the carbon material is performed on the surface of the catalyst, and the ferromagnetic catalyst can directionally move on a molten carbon matrix under the action of the magnetic field to ensure that the graphitization is performed according to the direction of the magnetic field, thereby achieving the aim of controlling and affecting the structural orientation of the newly generated graphite layer to produce the carbon material with high orientation degree and high graphitization degree, and playing an active role in the increase and improvement of the electromechanical properties of the carbon material.

Owner:HUNAN UNIV

Method for selecting and preparing raw materials of 550kN-grade suspension-type porcelain insulator glaze

InactiveCN101921137AImprove electromechanical performanceImprove insulation performanceFlexural strengthTalc

The invention relates to a method of selecting and preparing raw materials of 550kN-grade suspension-type porcelain insulator glaze. A 550kN-grade porcelain insulator glaze green body can be prepared by selecting 6-20 percent of kaolinite clay, 7-15 percent of talc, 20-40 percent of feldspar, 25-40 percent of refined quartz, 10-20 percent of calcined bauxite, 3-15 percent of calcium carbonate, 0-10 percent of medium porcelain powder and 0.001-1 percent of sodium silicate. The granularity of the clay is 20-40mu, and the granularity of other raw materials is 180-200mu.The glaze is prepared by using the raw materials and the method has good flowability and little multiviscosity, and is convenient for glazing operation; and the glazed and sintered porcelain green body has bending strength of being improved by 25-40 percent, therefore, the electromechanical properties and the insulating property of a porcelain insulator are improved and the quality of the porcelain insulator product is guaranteed.

Owner:INST OF GEOCHEM CHINESE ACADEMY OF SCI +1

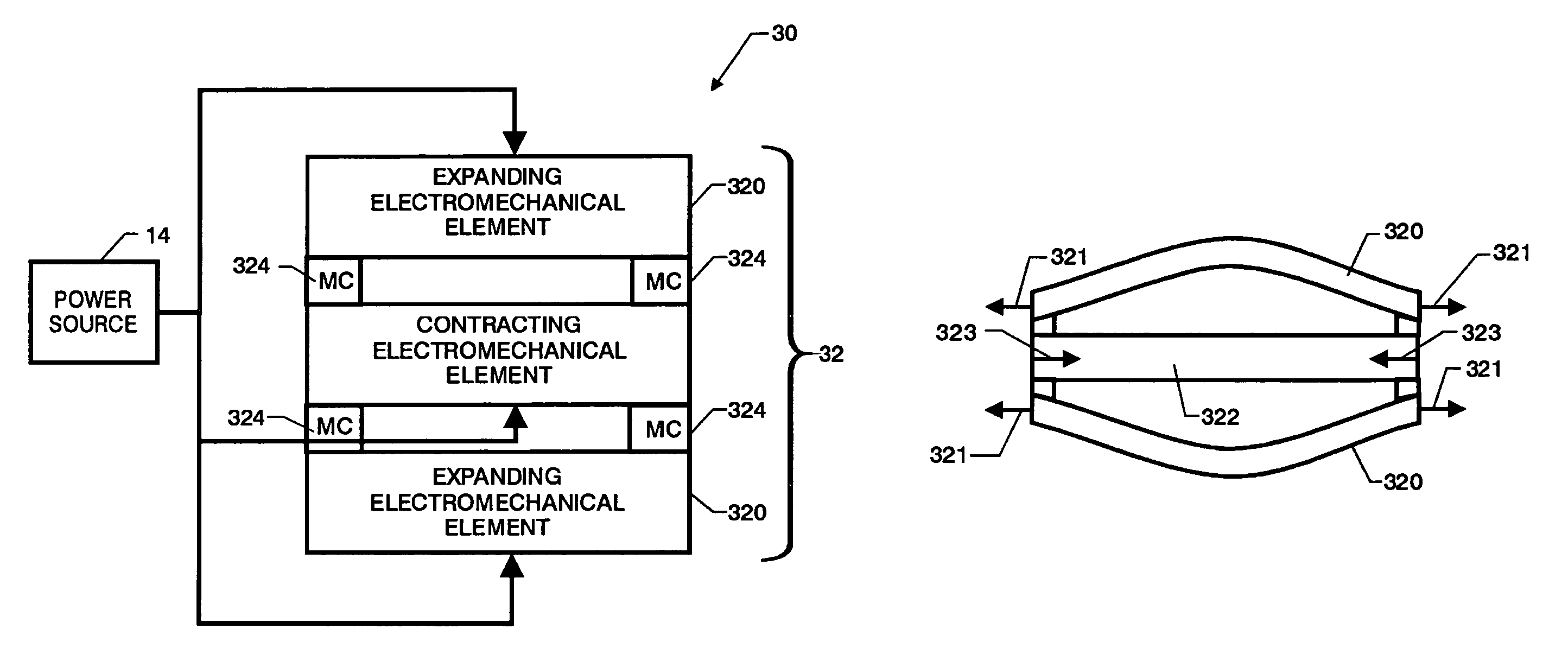

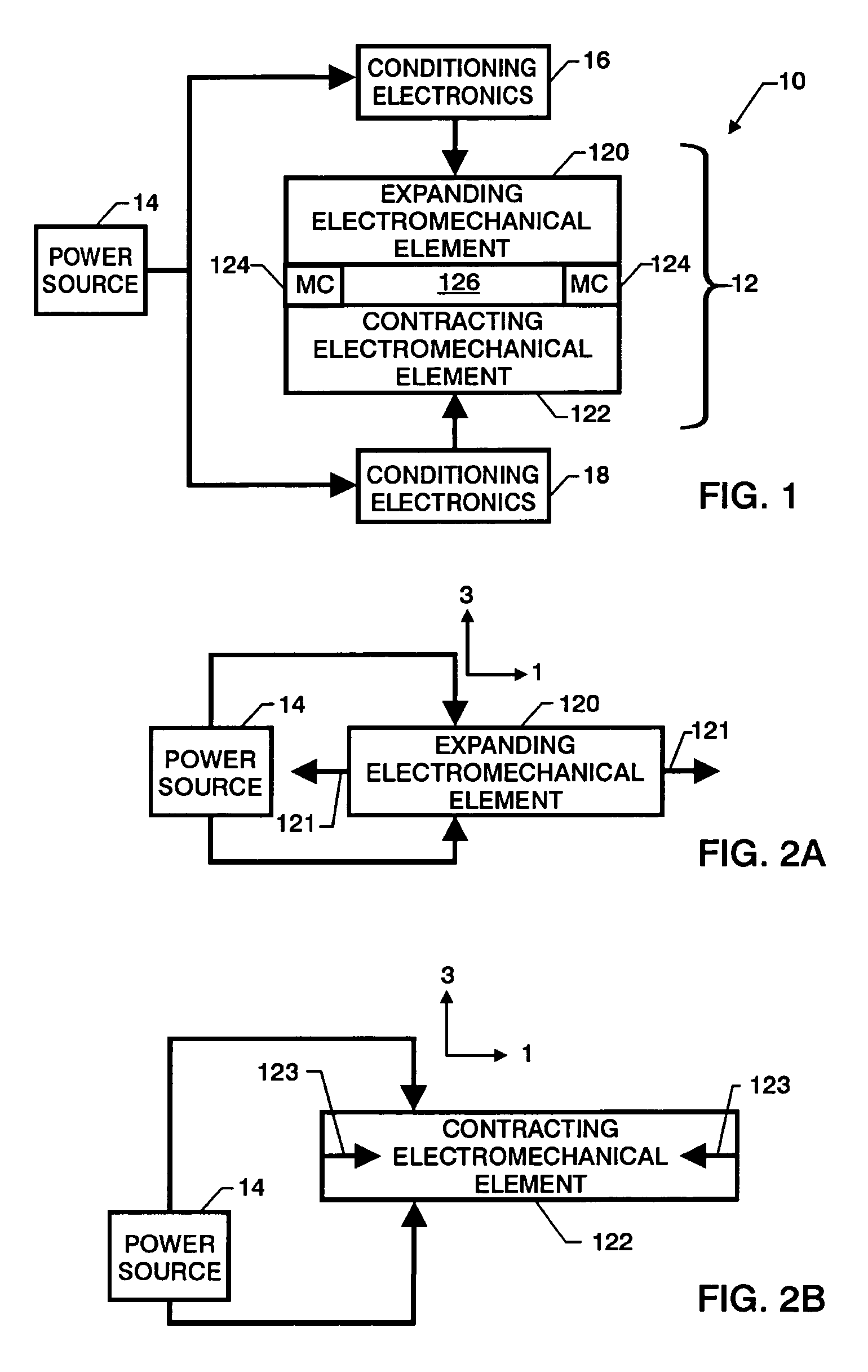

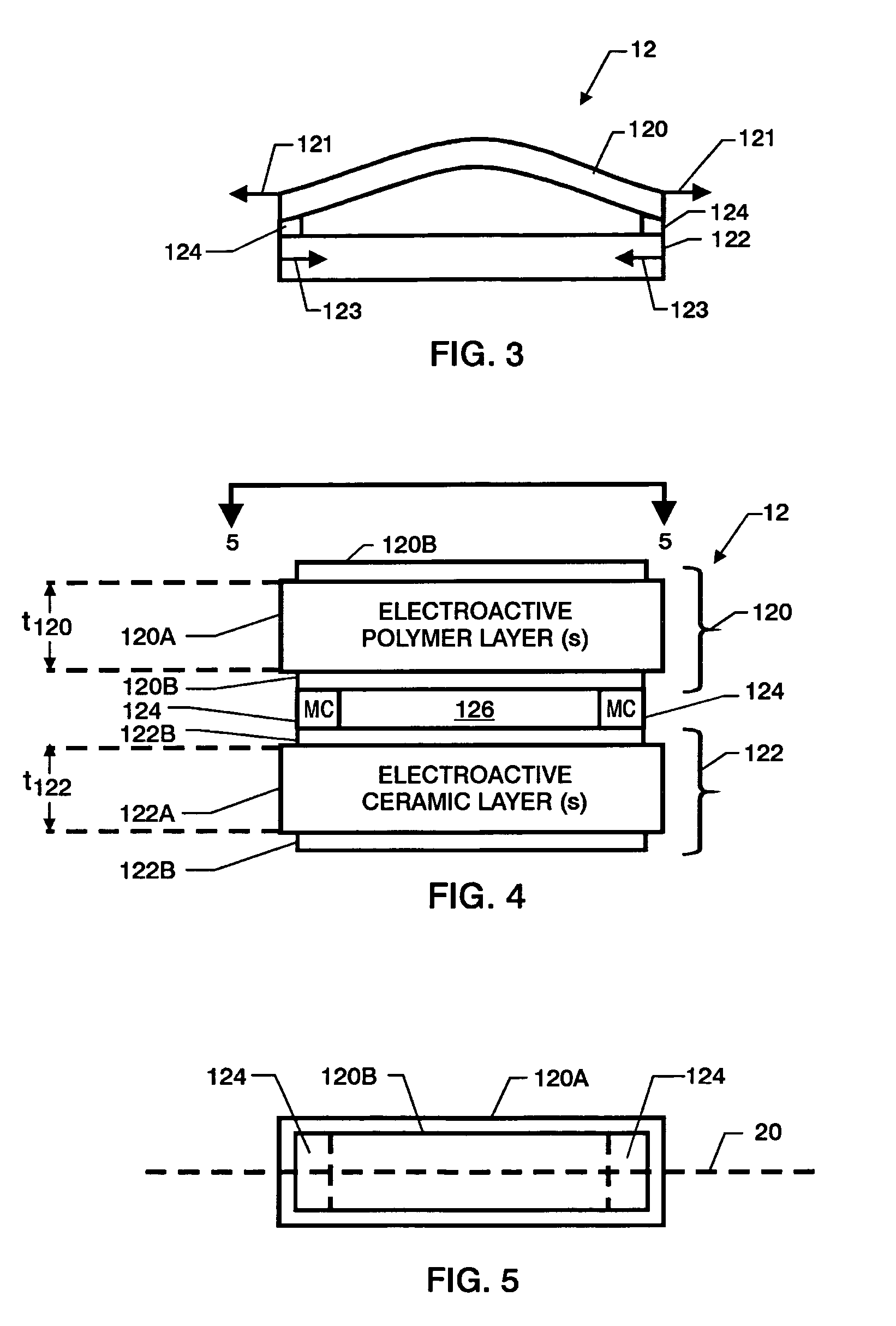

Hybrid eletromechanical actuator and actuation system

InactiveUS7394181B2Improve electromechanical performanceImprove consumption efficiencyPiezoelectric/electrostriction/magnetostriction machinesPiezoelectric/electrostrictive device detailsEngineeringElectric power

A hybrid electromechanical actuator has two different types of electromechanical elements, one that expands in a transverse direction when electric power is applied thereto and one that contracts in a transverse direction when electric power is applied thereto. The two electromechanical elements are (i) disposed in relation to one another such that the transverse directions thereof are parallel to one another, and (ii) mechanically coupled to one another at least at two opposing edges thereof. Electric power is applied simultaneously to the elements.

Owner:NASA

Process for sintering and infiltration preparation of tungsten chrome-copper composite materials

A sintering and infiltration method for manufacturing tungsten-chromium-copper composite materials. The tungsten-chromium-copper composite materials are composed of the following components by weight percentage: tungsten 32%-50%, chromium 11%-23%, copper 27%-57% , the sum of the weight of each component is 100%. The method includes the following steps: first mix tungsten powder and chromium powder, granulate, press into a billet, then sinter and infiltrate copper liquid, after homogenization treatment and aging treatment be made of. The manufacturing method and process are easy to control, and the prepared tungsten-chromium-copper composite material has stable structure and performance, high density, low oxygen content, moderate hardness, high electrical conductivity, and excellent electromechanical comprehensive performance.

Owner:XIAN UNIV OF TECH

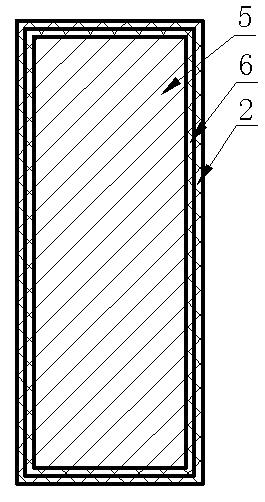

Insulating structure for 2MW wind driven generator

InactiveCN102185407AImprove electromechanical performanceThinningWindings insulation shape/form/constructionApplying solid insulationWind drivenVacuum pressure

The invention discloses an insulating structure for a 2MW wind driven generator. The insulating structure comprises a stator iron core, a rotor iron core, stator coils (3) embedded in the stator iron core, rotor coils (5) embedded in the rotor iron core, a mica tape coated and wound on the stator coils (3), nickel hydrazine nitrate (NHN) insulation (1) and a mica tap coated and wound on the rotor coils (5); inter-turn pads (4) are arranged among the stator coils (3); the stator iron core, the stator coils (3), the mica taps and the NHN insulation (1) are bonded together through solvent-free impregnated resin and vacuum pressure impregnation; and the rotor iron core, the rotor coils (5) and the mica tapes are bonded together through the solvent-free impregnated resin and the vacuum pressure impregnation. The invention has the advantages that: the electromechanical properties of the insulating structure can be improved, the aging speed of the insulating structure is slowed down, the service life of the insulating structure is long, the production cost is greatly reduced, and the problem of inter-turn insulation impact caused by a frequency converter is solved.

Owner:DONGFANG ELECTRIC CORPLESHAN NEW ENERGY EQUIP

Method and equipment for synthesizing lithium tantalite doped potassium sodium niobate ceramic

InactiveCN102173799AImprove electromechanical performanceSolve the problem of environmental loadLighting and heating apparatusFiberPolyvinyl alcohol

The invention provides a method for synthesizing lithium tantalite doped potassium sodium niobate ceramic. The method comprises the following steps of: ball-milling and mixing 5 to 15 molar percent of lithium tantalite, 42.5 to 47.5 percent of potassium niobate, and 42.5 to 47.5 molar percent of sodium niobate, adding 5 percent polyvinyl alcohol (PVA) and pelleting, and performing dry pressing and forming under the pressure of 200 MPa to obtain green blank; preserving heat at the temperature of 450 DEG C for 5 hours and removing adhesion of the green blank, filling a sample which is subjected to adhesion removal into multimode cavity microwave sintering equipment and sintering; and polishing the sintered sample to form a wafer with a diameter of 10 to 11mm and thickness of 0.5mm, coating silver, and then applying voltage of 3 to 4KV / mm in silicone oil at the temperature of 120 DEG C and polarizing for 30 minutes. In the method, the multimode cavity microwave sintering equipment is adopted, the sample is placed in a self-developed chromic acid lanthanum inlayer heat preservation body, zirconium oxide fiber is filled between the sample and the heat preservation body, and the heat preservation body of an outer layer has a corundum structure. The lithium tantalite doped potassium sodium niobate ceramic prepared by the method has the excellent electromechanical properties and lead pollution is avoided.

Owner:SHANGHAI MARITIME UNIVERSITY

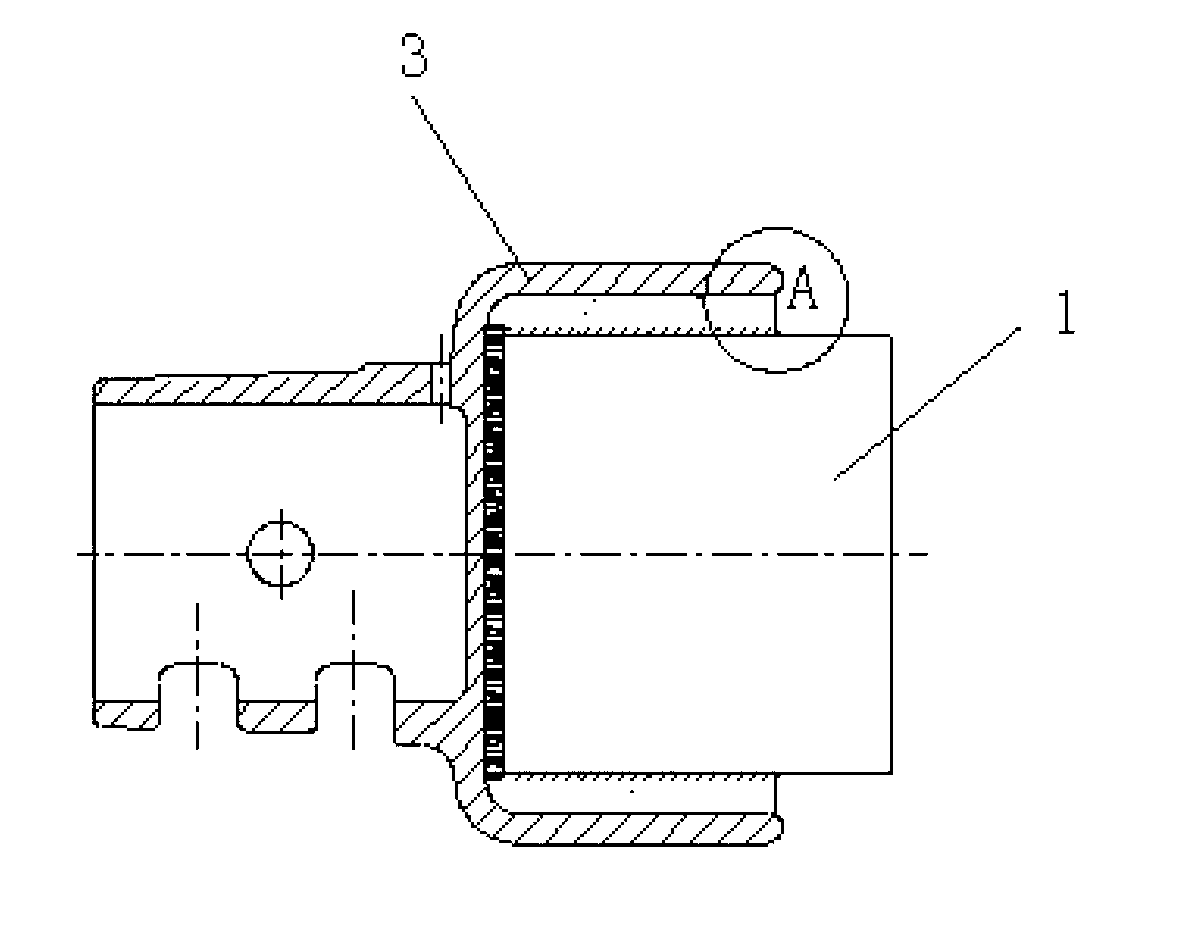

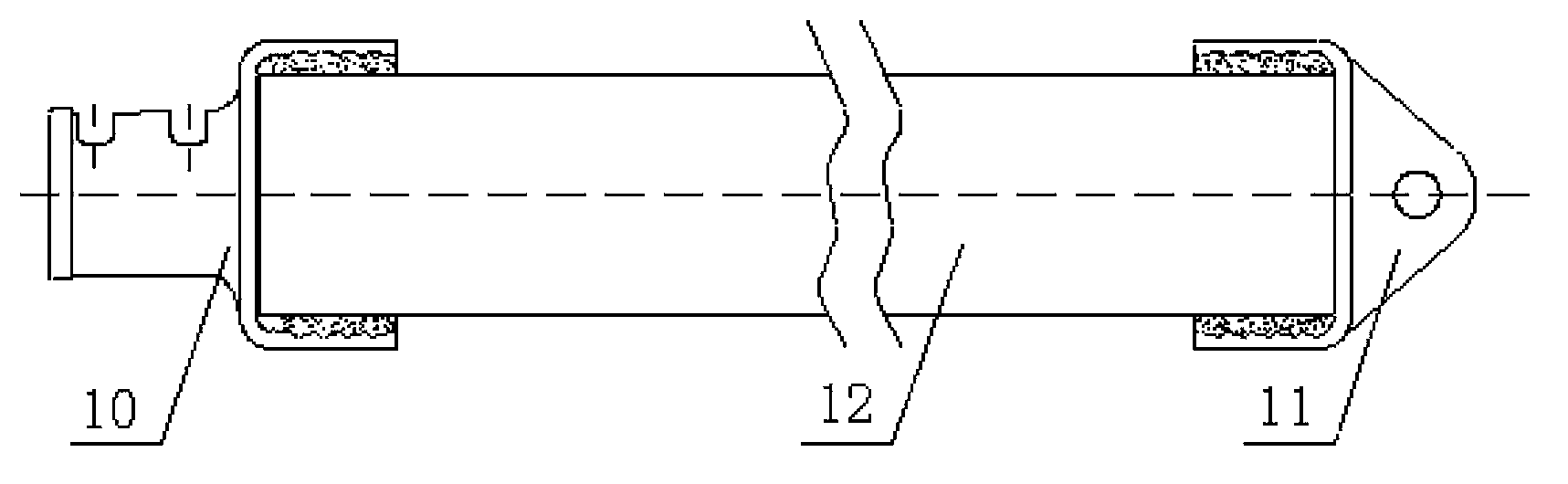

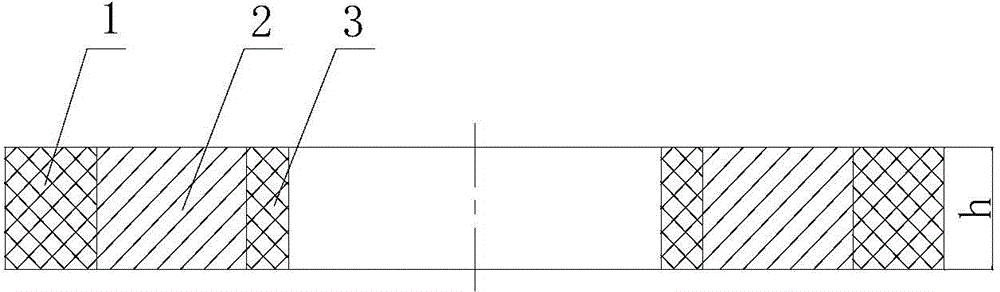

Coaxiality control tool and coaxiality control method

ActiveCN103440939AUniform thicknessImprove electromechanical performanceInsulatorsCeramic compositeComposite insulators

The invention discloses a coaxiality control tool and a coaxiality control method. The coaxiality control tool comprises a base and a screw rod. A first sliding block and a tensioning device are arranged on the base, a second sliding block is arranged on the first sliding block, and baffles are arranged on the left side and the right side of the second sliding block respectively. A stand column is arranged on the second sliding block, and an accessory limiting and clamping device and a ceramic part limiting and clamping device are arranged on the stand column. A second baffle is arranged on one side of the base, and one end of the screw rod penetrates through the second baffle and is connected with the first sliding block. The first sliding block moves on the base in a left-and-right and back-and-forth mode through the screw rod and is firmly fixed on the base through the tensioning device after moving to a proper position. The coaxiality control tool is used for controlling the vibration adhesive binding geometric tolerance of a bar type ceramic composite insulator so that the coaxiality of an adhesive binding ceramic part and an accessory can be 1mm and the coaxiality of the upper accessory and the lower accessory can be 0.5mm. Following forming process quality can be ensured, core shift of a whole product will not exist, the insulation thickness is even, the electromechanical property of the product is greatly improved, and long-term operation of the product can be stable and reliable.

Owner:JIANGSU SOUTH PORCELAIN INSULATOR CO LTD

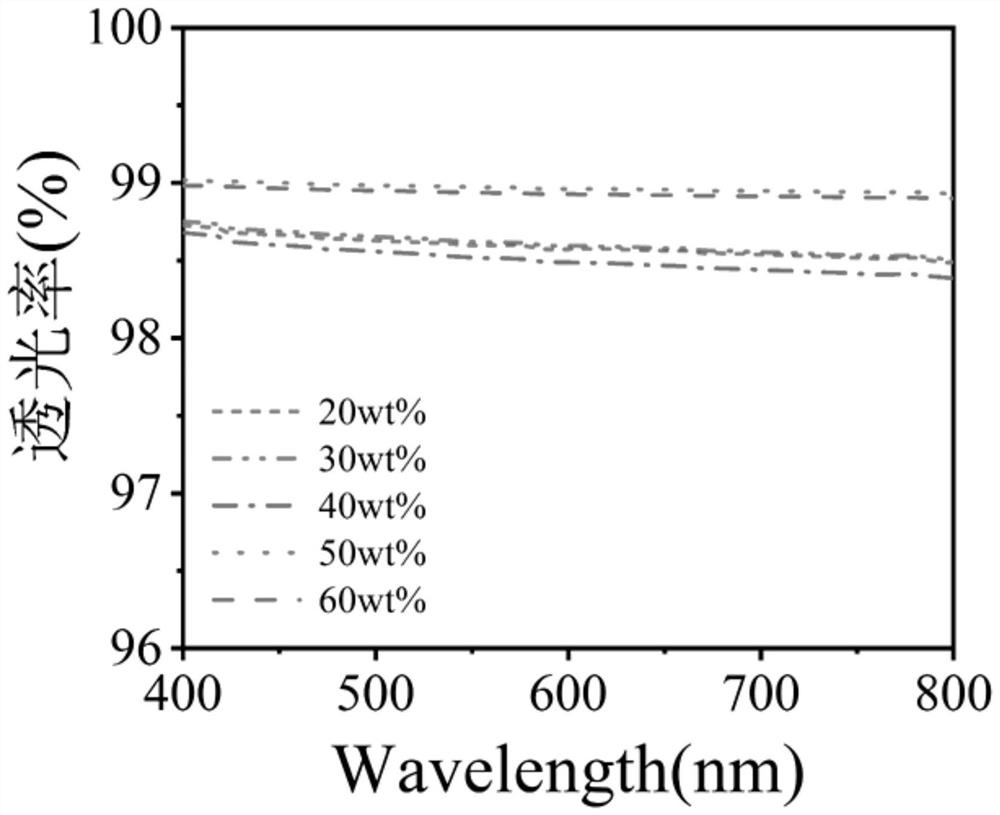

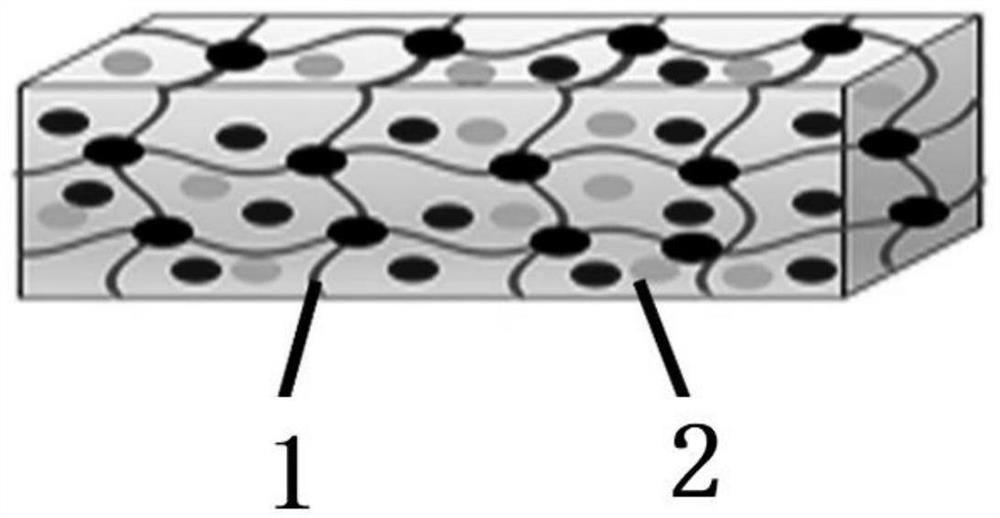

Transparent conductive ionic gel capable of realizing 3D printing as well as preparation and application of transparent conductive ionic gel

ActiveCN112080133AUnique vapor pressureNegligible vapor pressureAdditive manufacturing apparatusInksOrganic solventStrain sensor

The invention relates to a transparent conductive ionic gel composition capable of realizing 3D printing as well as preparation and application of the transparent conductive ionic gel composition. Theconductive ionic gel is prepared from a composition and comprises polyurethane urea with a linear structure, ionic liquid and an organic solvent, and the ionic liquid accounts for 5%-80% of the massfraction of the polyurethane urea with the linear structure. Ionic conductive gels of different structures can be constructed through direct writing 3D printing, and the conductive ionic gel has goodmechanical strength (the stress is as high as 2.55 MPa, and the strain is as high as 2200%), high transparency (as high as 98%), high conductivity (as high as 3.18 S.m < 1 >) and a wide working temperature range. The conductive ionic gel has excellent electromechanical properties, so that the conductive ionic gel has good strain induction capability, can be used for preparing strain sensors and isused for monitoring various motions of a human body.

Owner:浙江中特化工有限公司

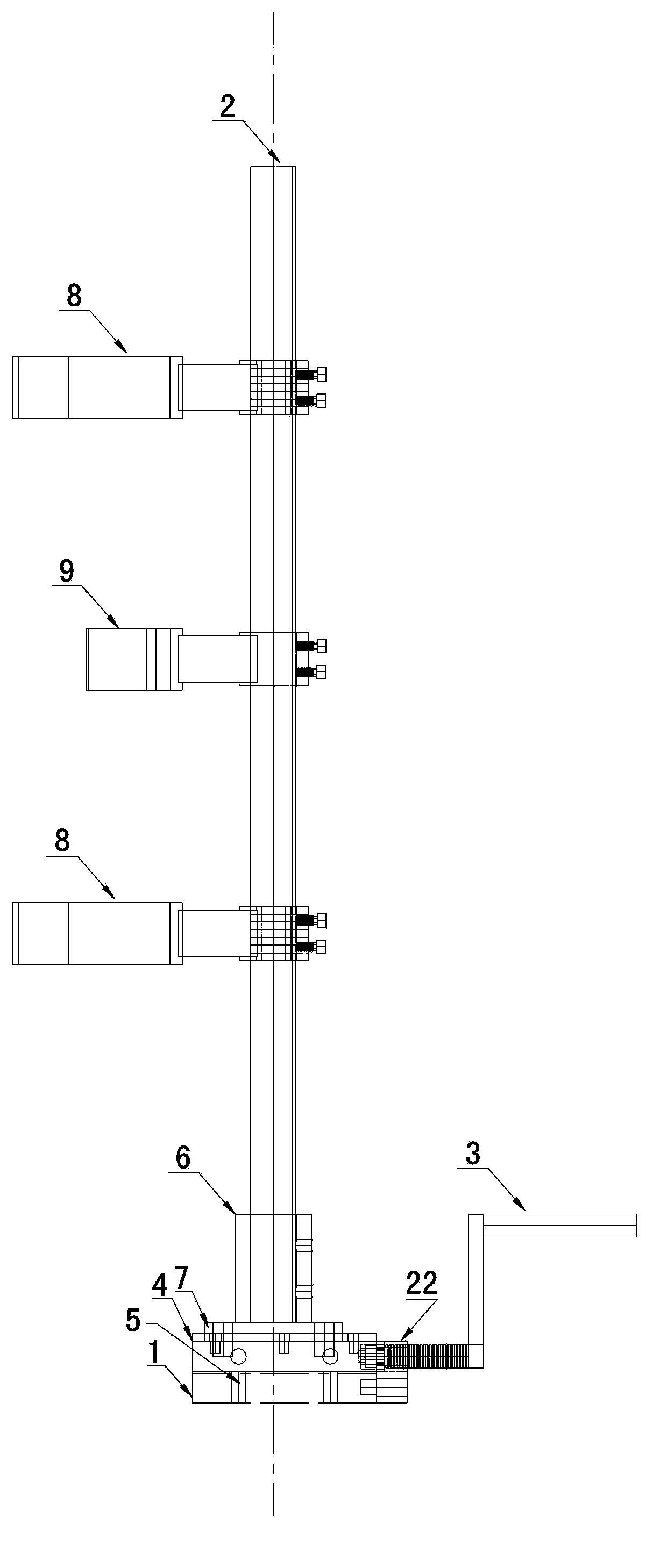

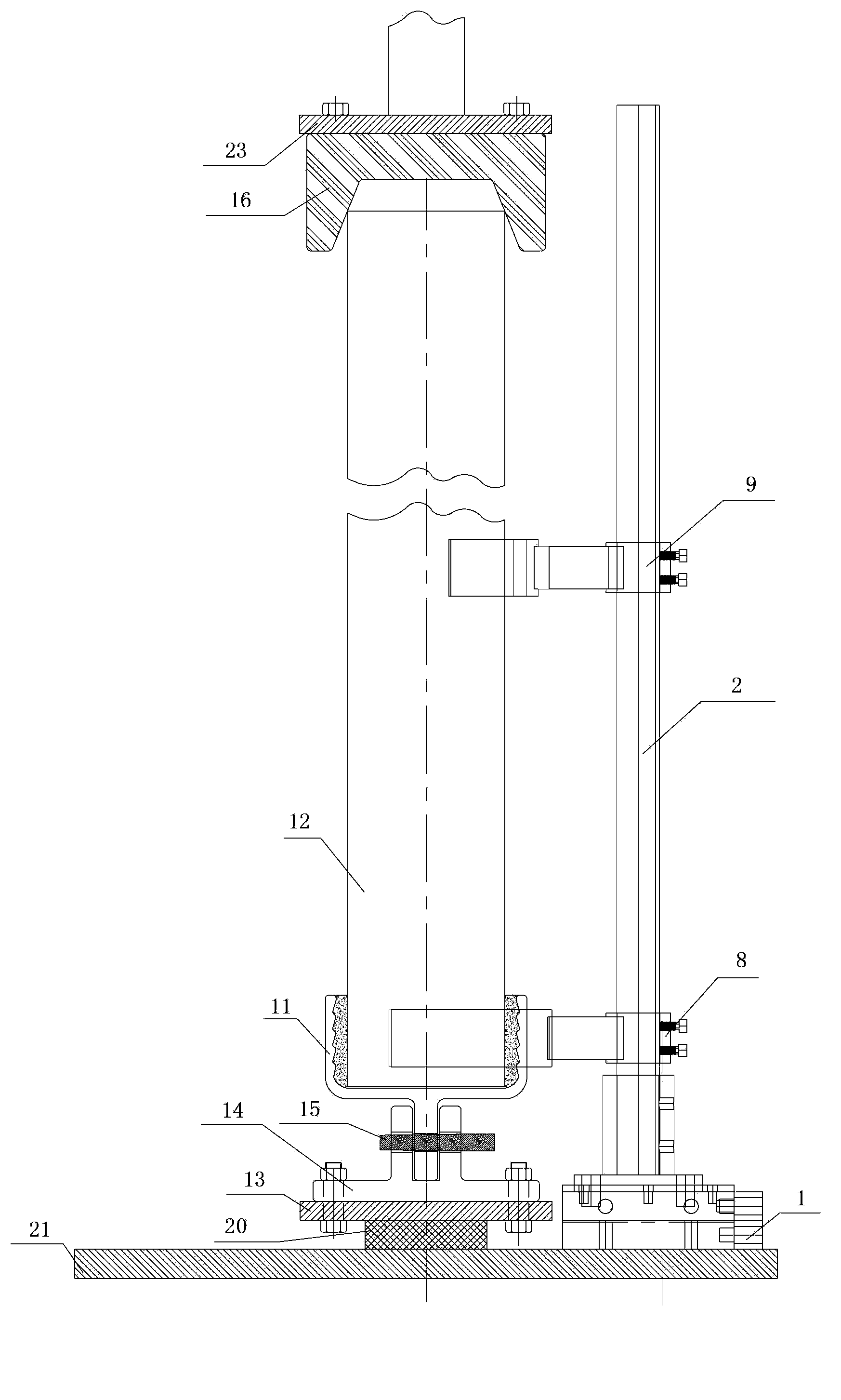

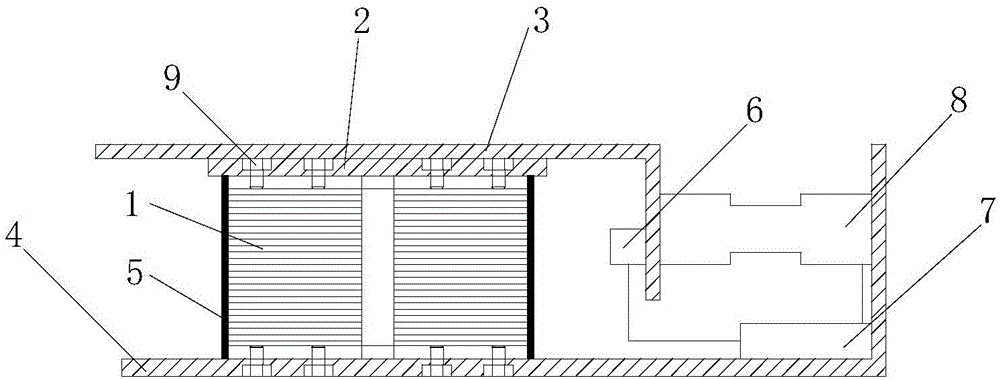

Shock isolation support with servo shock isolation system

InactiveCN106436560ARealize Active Optimal Feedback ControlMeet the isolation requirementsBridge structural detailsProtective buildings/sheltersMechanical stabilityMechanical equipment

The invention relates to the technical field of civil engineering, in particular to a shock isolation support with a servo shock isolation system. The shock isolation support with the servo shock isolation system comprises a laminated rubber support, wherein a support protective sleeve is arranged on the outer surface of the laminated rubber support in a sleeving manner; an upper flange plate is connected to the upper end of the laminated rubber support through connecting bolts, and a lower flange plate is connected to the lower end of the laminated rubber support through connecting bolts; an upper cover plate is fixedly connected to the upper surface of the upper flange plate; and a servo control system for enabling the shock isolation support with the servo shock isolation system to perform adaptive adjustment is mounted on the lower flange plate. The shock isolation support with the servo shock isolation system disclosed by the invention is simple in structure; a feedback control technology is introduced, so that the driving optimal feedback control of the shock isolation system is realized; the shock isolation support has an adaptive adjustment mechanism, so that different control targets can be realized; and the shock isolation support has an effective frequency bandwidth and an advantage of being not liable to resonate with a control structure, the mechanical stability and the electromechanical performance stability of the system can be realized, and the shock insulation requirements of engineering structures having special shock insulation requirements, mechanical equipment, valuable articles and the like can be met by the shock isolation support.

Owner:江苏路博减振技术有限公司

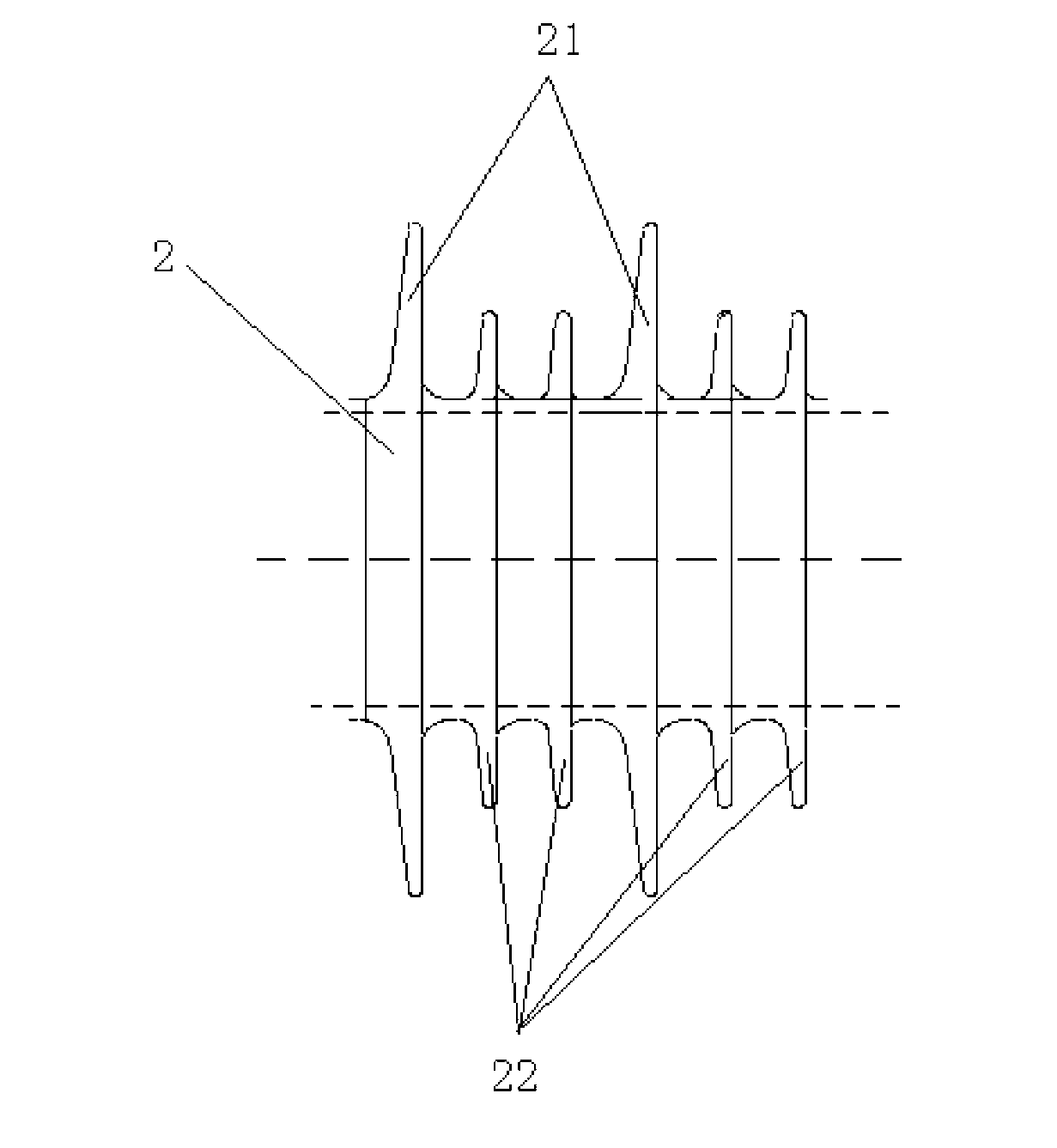

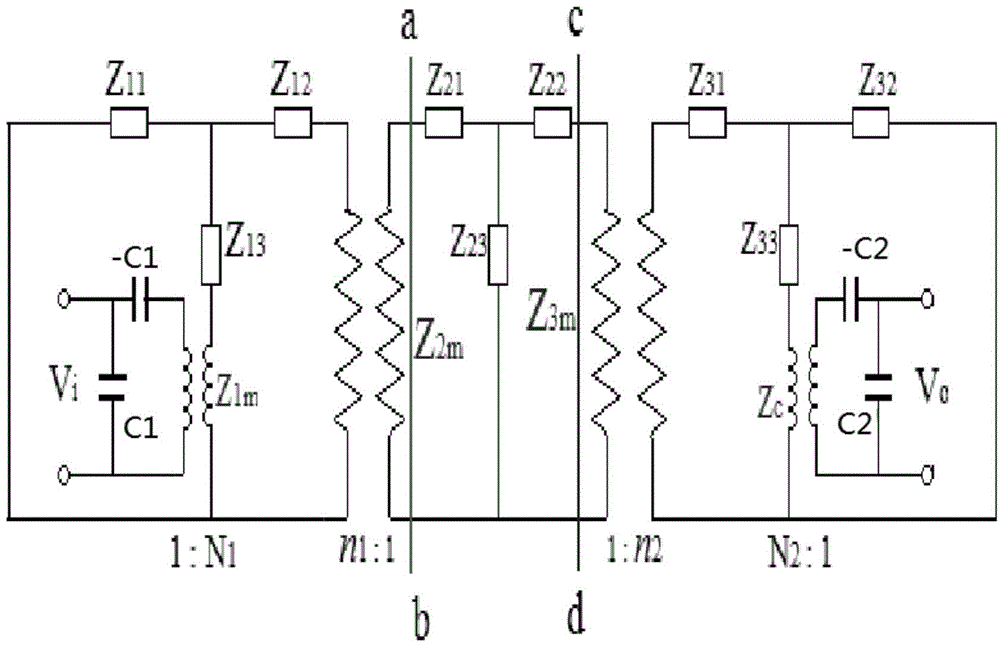

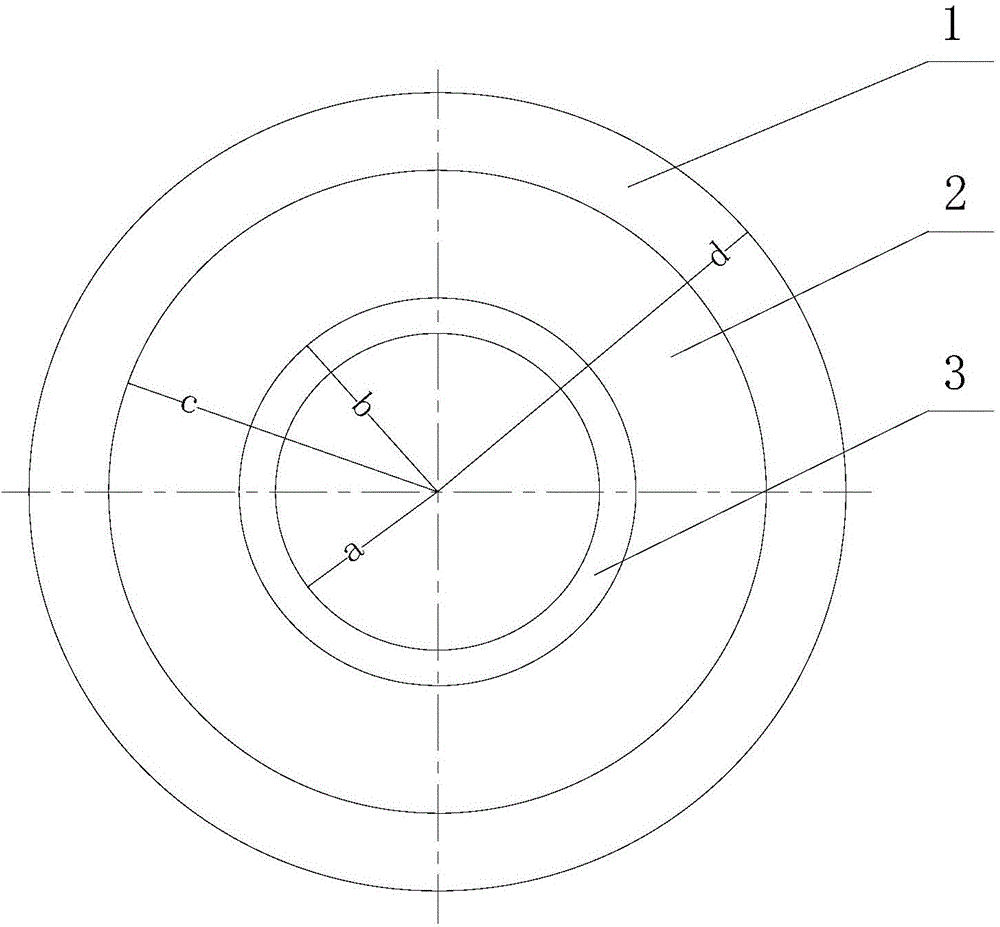

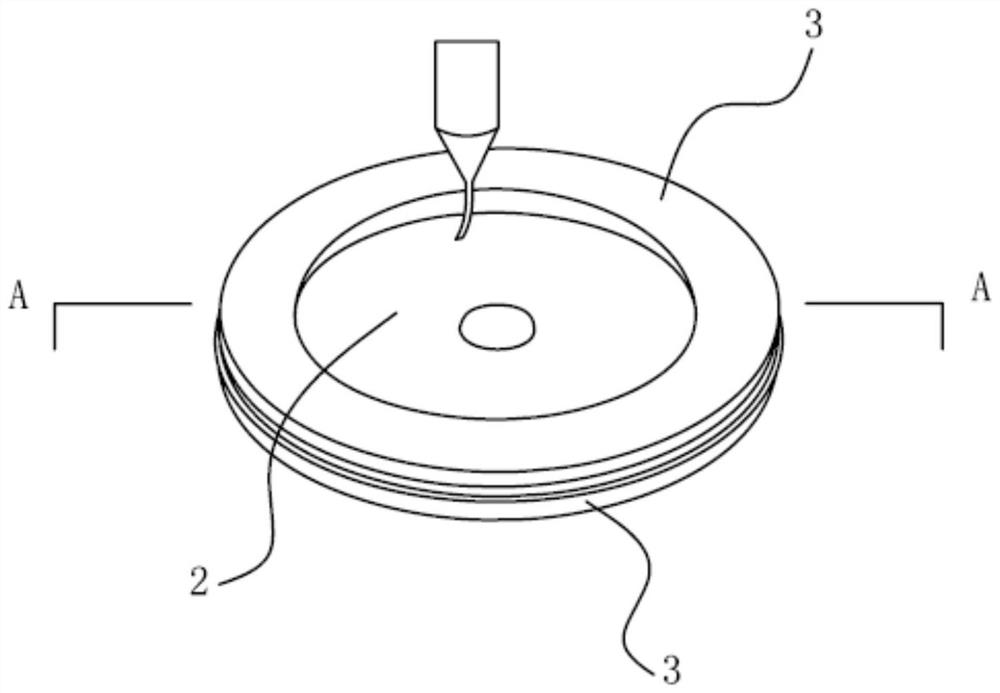

Radial vibration annular piezoelectric ceramic composite transformer

InactiveCN104538546AImprove excitation efficiencyImprove conversion efficiencyPiezoelectric/electrostrictive device detailsCeramic compositeMetallurgy

The invention relates to a radial vibration annular piezoelectric ceramic composite transformer which comprises a piezoelectric ceramic inner ring and a piezoelectric ceramic outer ring. A metal conducting ring is coaxially arranged between the piezoelectric ceramic inner ring and the piezoelectric ceramic outer ring, the piezoelectric ceramic inner ring, the piezoelectric ceramic outer ring and the upper end face and the lower end face of the metal conducting ring are placed in the same plane, and the height H of the piezoelectric ceramic inner ring, the height H of the piezoelectric ceramic outer ring and the height H of the metal conducting ring are smaller than or equal to D / 6 of the outer diameter of the piezoelectric ceramic outer ring. According to the novel radial vibration annular piezoelectric ceramic composite transformer, the metal circular ring is additionally arranged between an input piezoelectric ceramic device and an output piezoelectric ceramic device, and the effects of improving the radiating of the transformer, enlarging the power capacity of the transformer and improving the electromechanical properties of the transformer can be achieved. Meanwhile, the radial polarized piezoelectric ceramic circular rings are utilized, and the polarization and the excitation orientation of the piezoelectric ceramic circular rings are consistent. The radial vibration annular piezoelectric ceramic composite transformer belongs to a longitudinal effect vibration mode which is similar to a Kt vibration mode, and the electromechanical excitation and conversion efficiency of the piezoelectric ceramic transformer can be improved.

Owner:SHAANXI NORMAL UNIV

Production method of potassium sodium niobate/sodium bismuth titanate composite-phase piezoelectric ceramic

InactiveCN103360071AImprove electromechanical performanceSolve the problem of environmental loadPolyvinyl alcoholSodium bismuth titanate

The invention provides a production method of potassium sodium niobate / sodium bismuth titanate composite-phase piezoelectric ceramic. The ceramic is produced from the raw materials of, by molar percentages: 47-48% of potassium niobate, 47-48% of sodium niobate, 1-1.5% of sodium carbonate, 1-1.5% of bismuth trioxide, and 4-6% of titanium dioxide. The materials are mixed by call milling; 5% of polyvinyl alcohol (PVA) is added for granulation; dry-pressing molding is carried out in a mold with a diameter of 12mm under a pressure intensity of 20MPa, such that a blank is prepared; the blank is subjected to viscosity-eliminating under a temperature maintained at 500 DEG C for 1h; the obtained sample is sintered in a discharge plasma device, wherein a sintering temperature is 1100-1150 DEG C, and the temperature is maintained for 15-30min; the sintered sample is grinded and polished, such that a wafer with a diameter of 10-11mm and a thickness of 0.5mm is obtained; the wafer is coated by using silver; and the wafer is polarized for 30min in silicon oil with a temperature of 120 DEG C and with applied voltage of 3-4KV / mm. With the method, the prepared potassium sodium niobate / sodium bismuth titanate composite-phase piezoelectric ceramic has excellent piezoelectric property and no lead pollution.

Owner:SHANGHAI LONGTIAN NEW MATERIAL TECH CO LTD

Double-electret mems actuator

InactiveUS7256927B2Improve electromechanical performanceElectrostatic/electro-adhesion relaysElectrets selectrostatic transducerEngineeringActuator

An actuator (100) taking advantage of ponderomotive forces to enhance its electromechanical performance as a function of input energy. An actuator (100) may include a first conductive layer (102) residing on a first electret layer (101). The actuator (100) may further include a moveable second electret layer (103) which is spaced apart in relation to the first conductive layer (102) when the second electret layer (103) is in a quiescent state. The actuator (100) may further include a second conductive layer (104) in a spaced apart relation to the second electret layer (103) when the second electret layer (103) is in the quiescent state. The actuator (100) may further include a voltage source (105) configured to selectively apply a voltage between the first (102) and second (104) conductive layers thereby propelling the second electret layer (103) to either the first (102) or second (104) conductive layer.

Owner:UNIPIXEL DISPLAY

Axial vibration power-type piezoelectric ceramic transformer

InactiveCN104681712AReduce mechanical wear and tearImprove performancePiezoelectric/electrostriction/magnetostriction machinesPiezoelectric/electrostrictive/magnetostrictive devicesElectricityTransformer

The invention relates to an axial vibration power-type piezoelectric ceramic transformer. The axial vibration power-type piezoelectric ceramic transformer comprises an input piezoelectric ceramic body and an output piezoelectric ceramic body, wherein a metal cylinder is arranged at each of the positions between the input piezoelectric ceramic body and the output piezoelectric ceramic body, outside the input piezoelectric ceramic body and outside the output piezoelectric ceramic body. According to the axial vibration power-type piezoelectric ceramic transformer, the metal cylinders have the effects of effectively improving the radiating effect of the transformer, increasing the power capacity of the transformer, and greatly improving the electromechanical performance of the transformer; meanwhile, the working frequency of the novel piezoelectric ceramic transformer can be changed very conveniently by changing the geometric sizes of the metal cylinders in the piezoelectric ceramic transformer, so that the piezoelectric ceramic transformer can be adapted to different application places; therefore, the cost can also be reduced.

Owner:SHAANXI NORMAL UNIV

Aluminum and aluminum alloy continuous solidification and semi-solid forming process

The invention relates to a metal melting, ingot casting and plastic deformation processing process in the production field of aluminum and aluminum alloy pipe, bar, wire and section products. The invention provides a brand new metal solidification and semi-solid forming process for producing aluminum and aluminum alloy pipe, bar, wire and section products. The metal continuous solidification and semi-solid forming process provided by the invention is a new process for metal processing and forming based on the conform technology and combines casting and extrusion. In the forming process, a metal material is subjected to a crystallization solidification and plastic deformation process which is a combination of forced feeding and densification process under high pressure; and the expansion energy provided by external pressure increases the nucleation rate of the material, so that the material tissue is refined and is favorable for improving the electromechanical comprehensive performance of the aluminum and aluminum alloy products.

Owner:JIANGSU SHENGTIAN IND

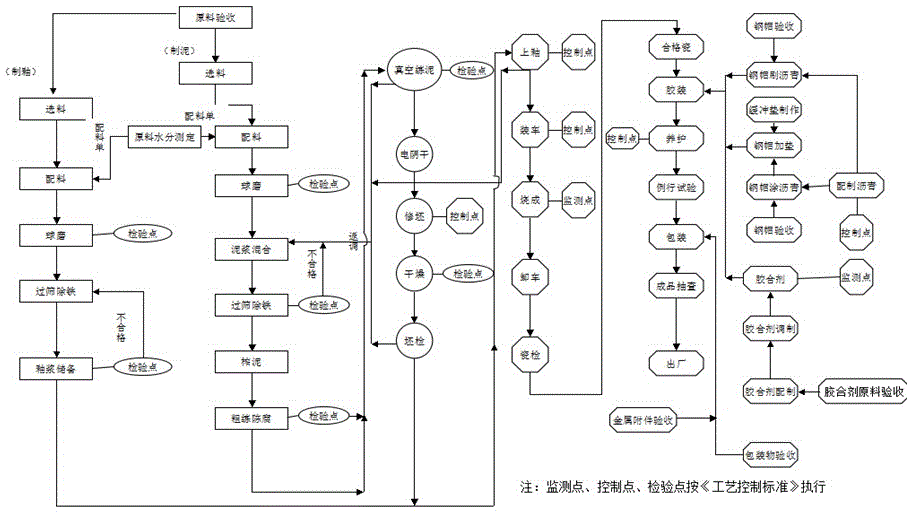

Production technique for bar shaped porcelain insulator used for overhead line system of G-series high-speed train

InactiveCN107871567AImprove electromechanical performanceGood antifoulingInsulatorsPass rateNano al2o3

The present invention disclosed a kind of high -speed rail contact network for the production process of stick -shaped porcelain insulator. In the ball milling, the total quality of the raw materials in the ball milling is as follows, and the high aluminum aluminum soil is 30-45 % WT;Yonggaolin 15-20 % WT; Jiangbei clay is 2 to 6 % WT; 3-6 % WT in Kaolin in Guizhou; 1 to 3 % WT in Bi Ji mud; 3 to 5 % WT in Changshi; 0.3 ~ 0.5 % WT of nano alumina powder.The invention has prepared a stick -shaped porcelain insulator for the high -speed rail contact network with excellent mechanical and electrical performance through the selection of the raw material in the formula.; Porcelain inspection, electrical inspection, and glue are high, and the production quality is stable; the product meets the use of 350km / h and above high -speed rail contact network.

Owner:QINGDAO DONGHAO SOFTWARE TECH CO LTD

Fully-automatic intelligent glue preparation online mixing epoxy insulation core rod injection pultrusion process

The invention discloses a fully-automatic intelligent glue preparation online mixing epoxy insulation core rod injection pultrusion process. The process specifically comprises the following steps of firstly, glass fiber positioning; secondly, intelligent glue preparation; thirdly, online mixing; fourthly, injection; fifthly, solidification; and sixthly, cutting. The utilized two-component epoxy glue injection system is different from other colloid conveying equipment, the whole glue preparation, stirring mixing and glue injection process is fully automatic, no manual operation is needed, clashmixing in a mixer can be realized, the mixing effect of raw materials is guaranteed, it can also be guaranteed that pressure output is stable, metering is accurate, and the quality of a product is guaranteed fundamentally; meanwhile the process has the characteristics that the delivery capacity and the proportion are precise and adjustable, work is stable and reliable, and the process is suitablefor continuous production; and the content of microbubbles in the obtained epoxy insulation core rod product is very few, and the electromechanical properties are good.

Owner:郑州聚成电气技术有限公司

Production process of rod-shaped porcelain insulator for high-speed rail overhead contact system

ActiveCN105070429AGood antifouling performanceHigh qualification rate of plastic packagingInsulatorsSpecific gravityAluminium

Owner:SICHUAN UNIVERSITY OF SCIENCE AND ENGINEERING

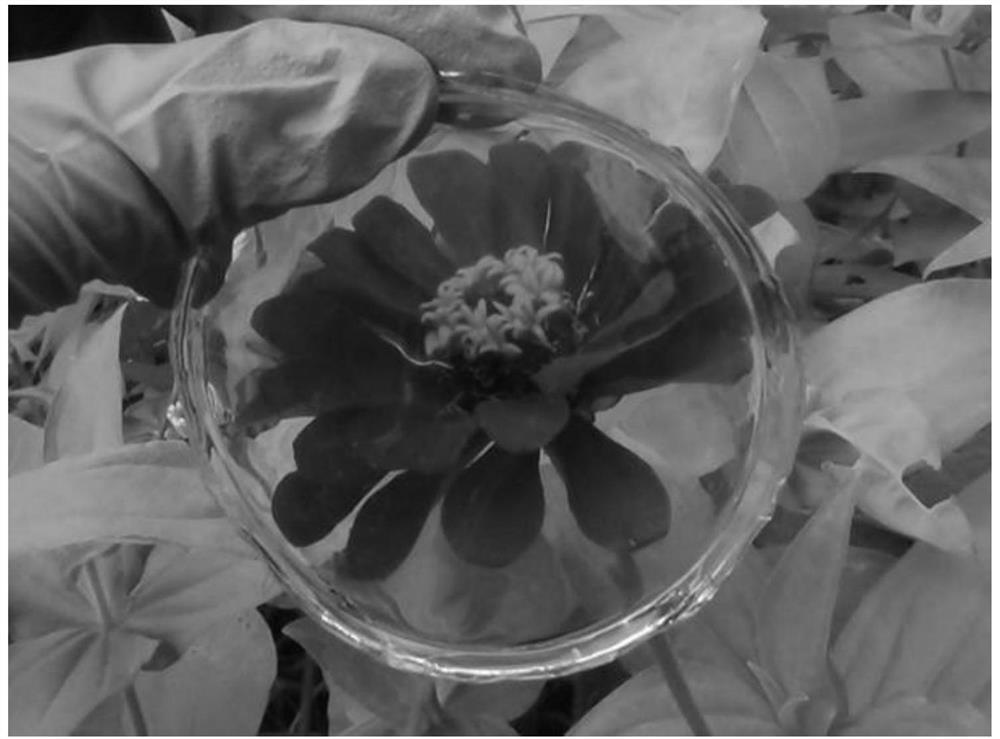

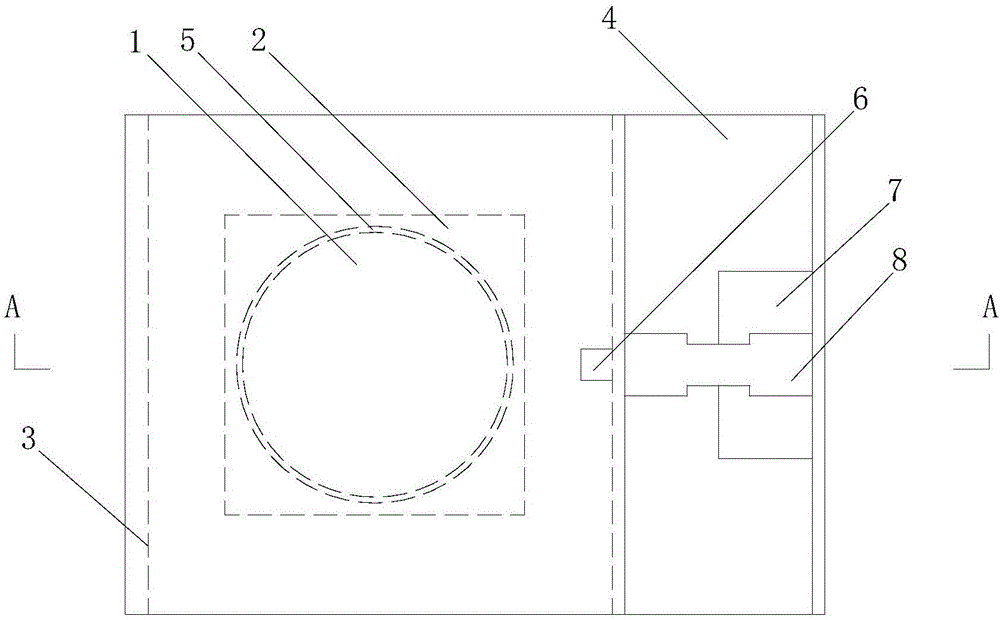

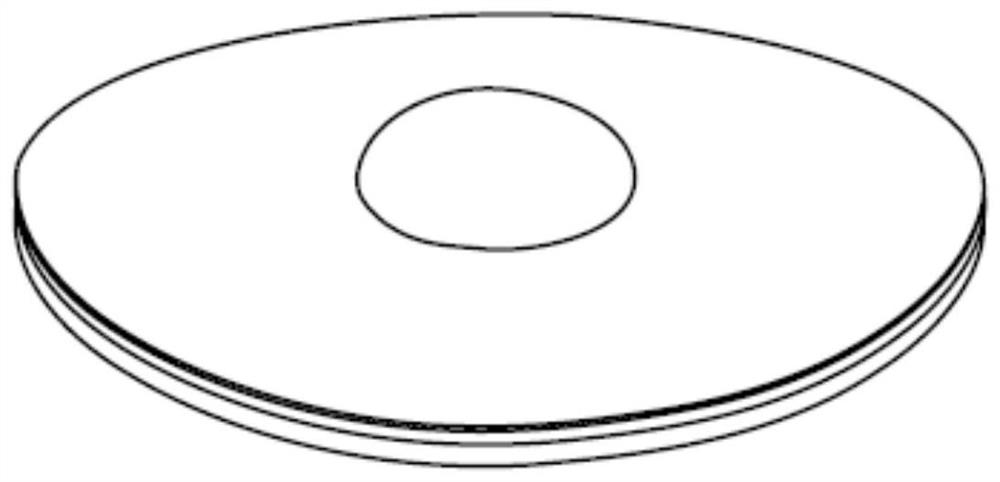

Focal length adjustable lens based on dielectric elastomer driver and preparation method thereof

ActiveCN112925052AHigh dielectric constantImprove electromechanical performanceLensLiquid mediumSilicon rubber

The invention relates to the technical field of depth-of-field 3D imaging, zoom imaging, robot vision systems and the like, in particular to a focal length adjustable lens based on a dielectric elastomer driver. The focal length adjustable lens comprises a lens body, and the dielectric elastomer driver comprises a dielectric elastomer annular film, a flexible electrode and an annular frame. The lens body comprises a lower-layer transparent silicone rubber film body which is arranged at the central position of the dielectric elastomer annular film and is integrally cured and formed with the dielectric elastomer annular film, a hemispherical cavity with an upward opening is formed in the lower-layer transparent silicone rubber film body through a vacuum suction device, the hemispherical cavity is filled with a transparent liquid medium, and an upper-layer transparent silicon rubber film body for covering and sealing the transparent liquid medium is arranged above the transparent liquid medium. The invention further discloses a method for preparing the focal length adjustable lens. According to the invention, good zoom imaging effect, high electromechanical performance, fast response speed, long service life, high automation degree, high preparation efficiency, simple process and low cost can be realized.

Owner:QINGDAO UNIV

Process for sintering and infiltration preparation of tungsten chrome-copper composite materials

A sintering and infiltration method for manufacturing tungsten-chromium-copper composite materials. The tungsten-chromium-copper composite materials are composed of the following components by weight percentage: tungsten 32%-50%, chromium 11%-23%, copper 27%-57% , the sum of the weight of each component is 100%. The method includes the following steps: first mix tungsten powder and chromium powder, granulate, press into a billet, then sinter and infiltrate copper liquid, after homogenization treatment and aging treatment be made of. The manufacturing method and process are easy to control, and the prepared tungsten-chromium-copper composite material has stable structure and performance, high density, low oxygen content, moderate hardness, high electrical conductivity, and excellent mechanical and electrical comprehensive performance.

Owner:XIAN UNIV OF TECH

Wrist arm insulator for 25kv electrified railway catenary and manufacturing method thereof

ActiveCN103400664BImprove mechanical propertiesAvoid accidentsInsulatorsComposite insulatorsPeak value

The invention discloses a wrist-arm porcelain composite insulator for a 25kV electrified railway catenary. The rated operational voltage of the insulator is 25kV, the structural height is 750 to 900mm, the largest rated mechanical bending failure load is 20kN, the largest rated mechanical tensile failure load is 160kN, the power frequency dry / wet withstand voltage is 150 / 190kV, the peak value of lightning impulse withstand voltage is 310kV, the lowest arc distance is 490mm, the smallest thickness of an outer insulating umbrella skirt sheath is 3mm, the power frequency withstand voltage is larger than 36kV in the condition that salt density is 0.35mg / cm2 or dust density is 2mg / cm2, and the overall creep distance is larger than 1600mm. The invention also discloses the manufacture method of the wrist-arm porcelain composite insulator. The wrist-arm porcelain composite insulator effectively eradicates accidents of brittle failure and bunch dropping of composite insulators, solves the problem of pollution flashover of outer insulation of the porcelain insulator, and has the advantages that mechanical and electrical performances are excellent, and the wrist-arm porcelain composite insulator is applicable to various extremely severe work condition environments.

Owner:JIANGSU SOUTH PORCELAIN INSULATOR CO LTD

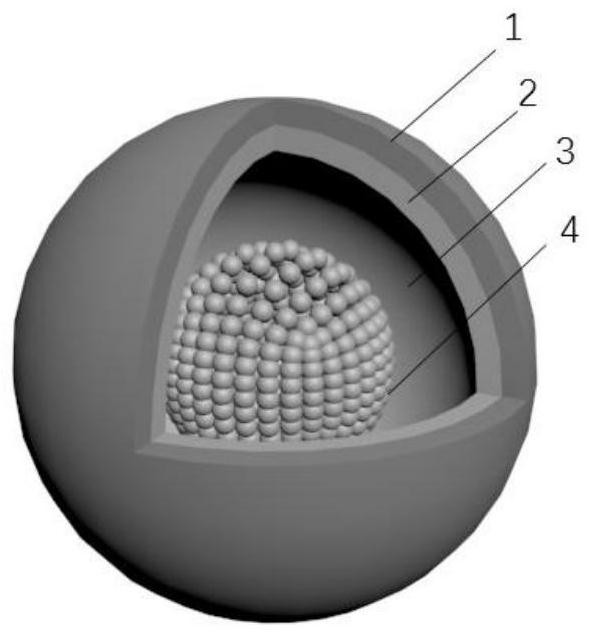

Hydrate temperature-controlled energy storage magnetic composite material and preparation method thereof

ActiveCN112592697BImprove thermal conductivityImprove uniformityMagnetic/electric field screeningInorganic material magnetismActive agentMagnetic response

The invention discloses a hydrate temperature-controlled energy storage magnetic composite material and a preparation method thereof. The hydrate temperature-controlled energy storage magnetic composite material includes a hydrate and a hydrate support, and the hydrate support has two layers. The inner layer is elemental carbon and the outer layer is polymer. The preparation process first uses an autoclave to use ferrocene particles as a template, and wraps the particles with amorphous carbon; then removes the ferric oxide in it with hydrochloric acid, and after removing part, the initial material is soaked in tetrahydrofuran aqueous solution until the material is filled with tetrahydrofuran aqueous solution to prepare base material particles; then monomers, cationic surfactants, and initiators are cross-linked on the surface of base material particles to form a polymer layer to stabilize the material structure and make the final product. The product prepared by the invention has the performance of temperature control and energy storage, can be used periodically, and has a magnetic response function, and can be used for temperature control of electronic equipment and its components with electromagnetic shielding function.

Owner:DALIAN UNIV OF TECH

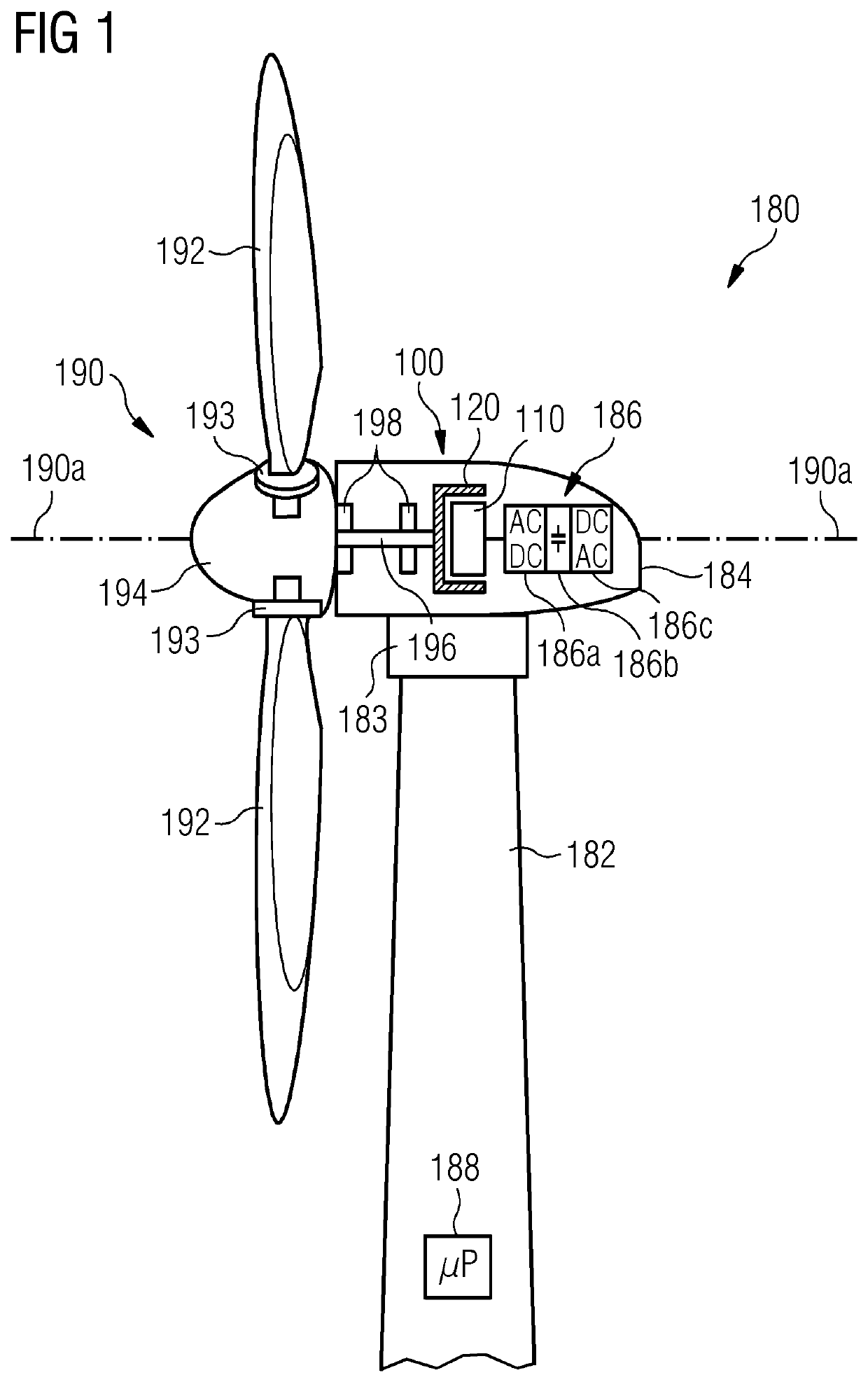

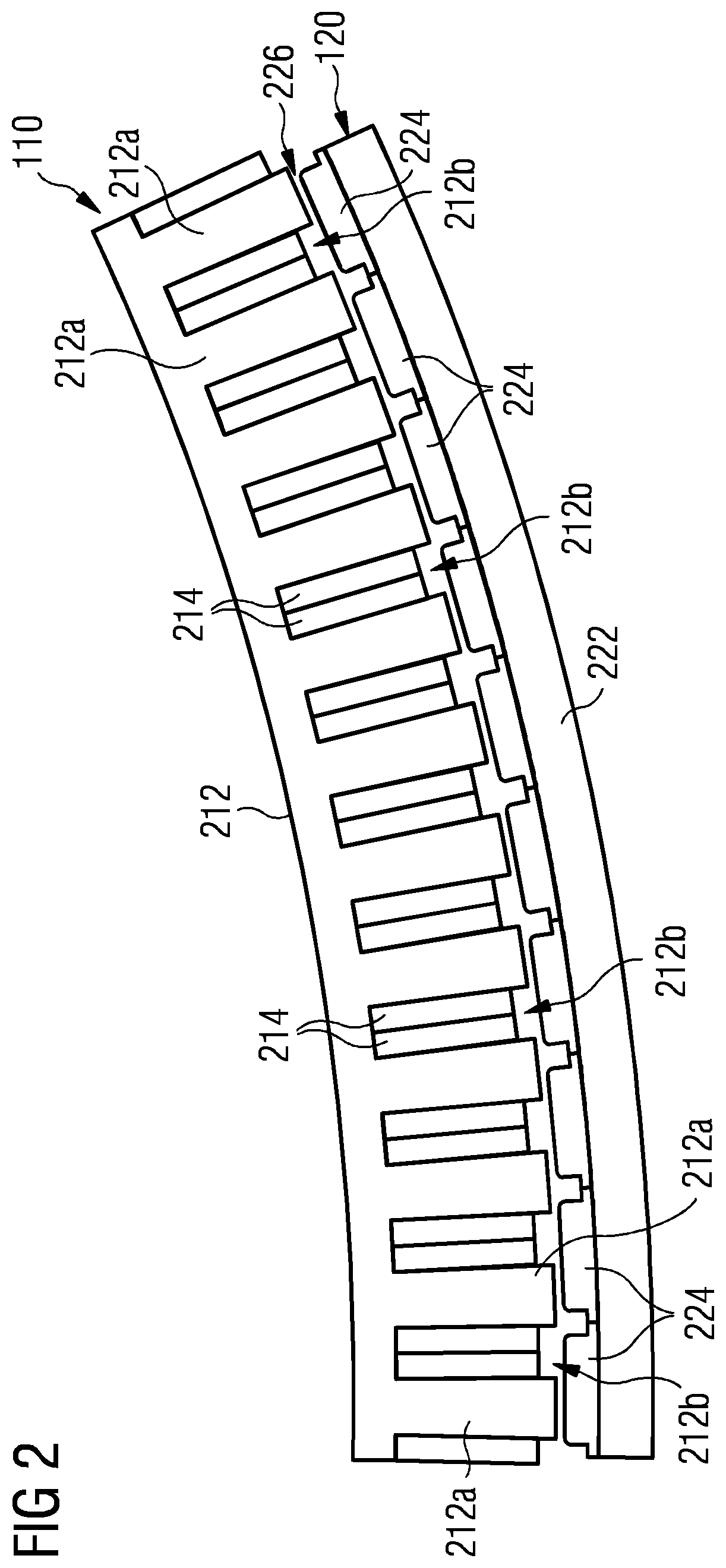

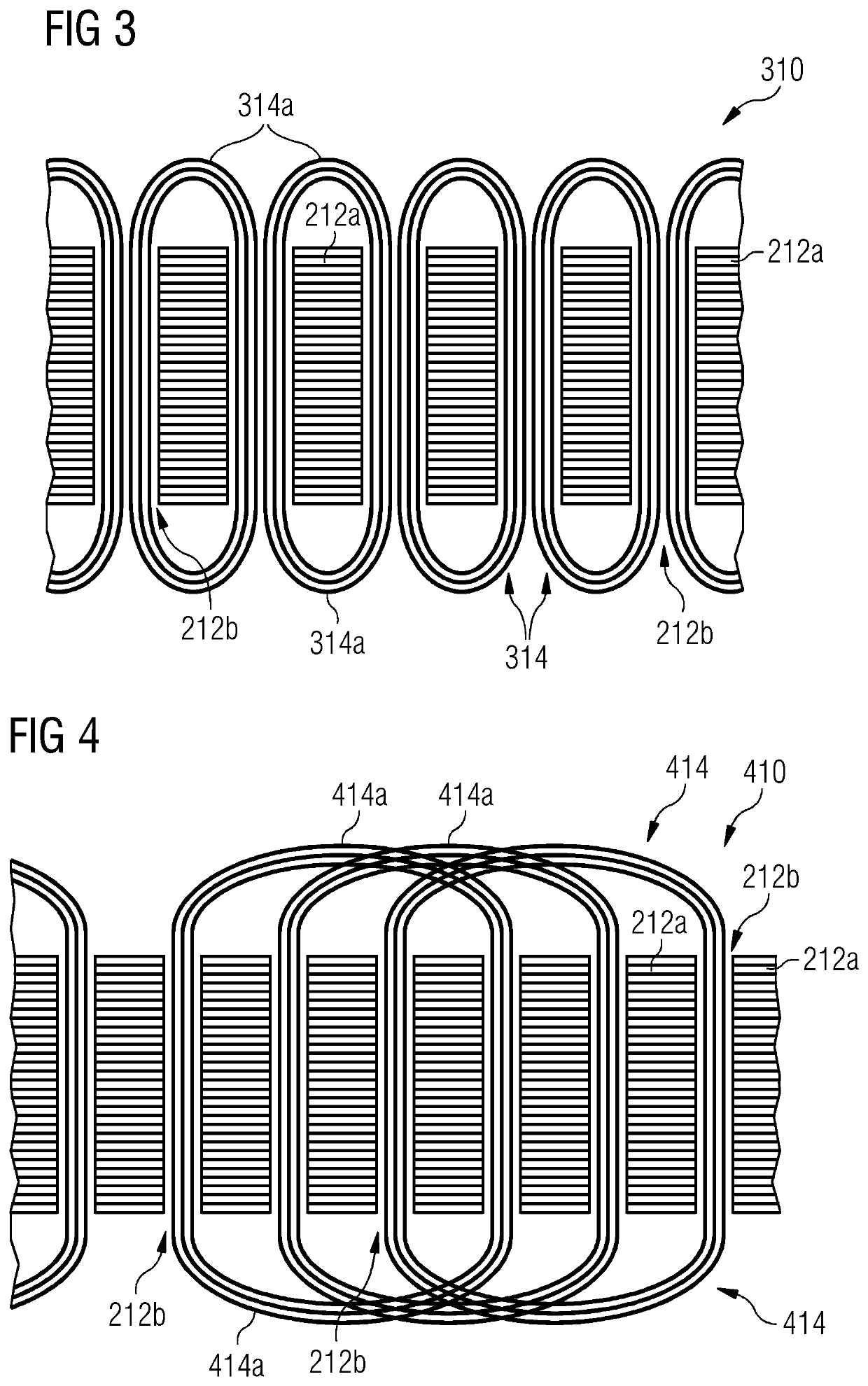

Stator assembly comprising electrical insulation devices having an outer surface with elevated surface portions

PendingUS20210126503A1Increase lengthSimple structureWindings insulation shape/form/constructionMagnetic circuit stationary partsStatorElectrical and Electronics engineering

A stator assembly including a frame structure having a stator teeth being circumferentially distributed around a longitudinal axis, wherein in between respective two neighboring stator teeth there is formed one stator slot; a winding system having a plurality of electric windings, wherein respectively one electric winding is wound around at least one stator tooth and is partially accommodated within two stator slots and each electric winding comprises an end winding portion which axially protrudes from the frame structure; and an insulation arrangement having a plurality of electric insulation devices, each insulation device surrounding a part of one electric winding is provided. Each insulation device includes an inner insulation portion being accommodated within the respective stator slot and an outer insulation portion protruding from the frame structure and surrounding a part of the respective end winding portion. The outer insulation portion includes an outer surface which includes elevated surface portions.

Owner:SIEMENS GAMESA RENEWABLE ENERGY AS

Method for improving graphitization and carbonizing degree of carbon material based on magnetic field and catalysis

The invention discloses a method for improving the graphitization of a carbon material and the carburization degree based on a magnetic field and the catalysis. The method aims to apply the magnetic field induction and control the structural orientation of a newly generated graphite layer to ensure that the carbon material grows according to the preset orientation, thereby achieving the aim of improving the electromechanical properties of the carbon material. A proper amount of ferromagnetic catalyst is added into the carbon material, and then the high temperature carbonization and graphitization treatment is performed under the action of an externally-applied magnetic field; and the graphitization based on the carbon material is performed on the surface of the catalyst, and the ferromagnetic catalyst can directionally move on a molten carbon matrix under the action of the magnetic field to ensure that the graphitization is performed according to the direction of the magnetic field, thereby achieving the aim of controlling and affecting the structural orientation of the newly generated graphite layer to produce the carbon material with high orientation degree and high graphitization degree, and playing an active role in the increase and improvement of the electromechanical properties of the carbon material.

Owner:HUNAN UNIV

Active Sandwich Microstrip Antenna and Electromagnetic Synthesis Data-Driven Design Method and Antenna

ActiveCN103353904BTo overcome the difficulty in realizing the design of electromechanical integrationRealize the structureSpecial data processing applicationsEngineeringRadio frequency

The invention discloses a data-driven design method integrating an active interlayer microstrip antenna structure and electromagnetism and an antenna, and solves the problem that the prior art can not realize the integrated design of the structure and electromagnetism. The method comprises the following steps: firstly, fixing the material, size, panel and cellular size of a radio frequency function layer according to electrical property indexes, secondly, obtaining front deformation data and stress data of the antenna structure through mechanical analysis, thirdly, preprocessing the front deformation data, so as to obtain the position error of each radiating element, fourthly, calculating a far-field pattern of an interlayer microstrip antenna according to a data-driven coupling model, fifthly, calculating and considering the wave-transparent performance influenced by the panel and cellular, sixthly, establishing an optimization design model integrating the interlayer microstrip antenna structure and electromagnetism, and seventhly, solving the optimization design model, so as to obtain an optimal integrating result. The method can realize the simultaneous optimal design of the active interlayer microstrip antenna structure and electromagnetism, shortens the development period, and improves force-electricity properties of products.

Owner:XIDIAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com