Insulating structure for 2MW wind driven generator

A wind power generator and insulation structure technology, applied in the shape/style/structure of winding insulation, laying solid insulation, etc., can solve the problems of high production cost, inability to run stably for a long time, low performance of motor insulation structure, etc., and achieve electromechanical performance Improve, improve the ability to prevent moisture and other media intrusion, and improve the effect of heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with accompanying drawing:

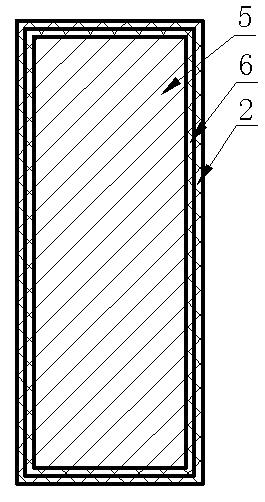

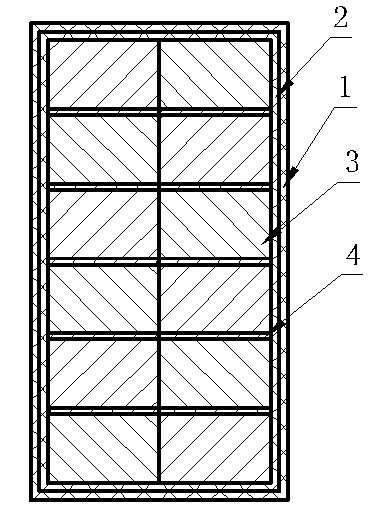

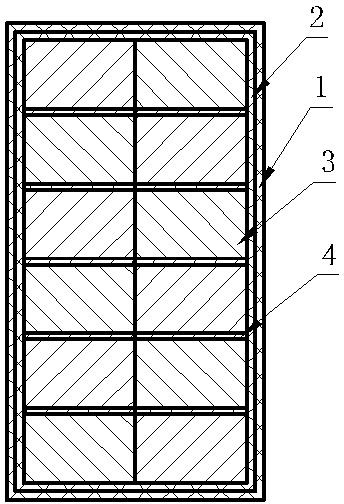

[0014] 2MW wind turbine insulation structure, which includes stator core, rotor core, stator coil 3 embedded in the stator core, rotor coil 5 embedded in the rotor core, mica tape wrapped on the stator coil 3, NHN insulation 1 and the mica tape wrapped on the rotor coil 5, the inter-turn liner 4 is provided between the stator coil 3, the stator core, the stator coil 3, the mica tape, and the NHN insulation 1 are bonded together by solvent-free impregnation resin and vacuum pressure impregnation , the rotor core, the rotor coil 5, and the mica tape are bonded together by solvent-free impregnating resin and vacuum pressure impregnation, and the mica tape includes a less-adhesive mica tape 2 and a less-adhesive mica tape 6 reinforced with a CR film.

[0015] like figure 1 The stator coil 3 is sequentially provided with two layers of less-adhesive mica tape 2 wrapped in a half...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com