Hydrate temperature-controlled energy storage magnetic composite material and preparation method thereof

A magnetic composite material and hydrate technology, applied in the direction of inorganic material magnetism, heat exchange materials, chemical instruments and methods, etc., can solve the problems of affecting the container, easy to leak, large fluidity, etc., achieve high latent heat, convenient transportation, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

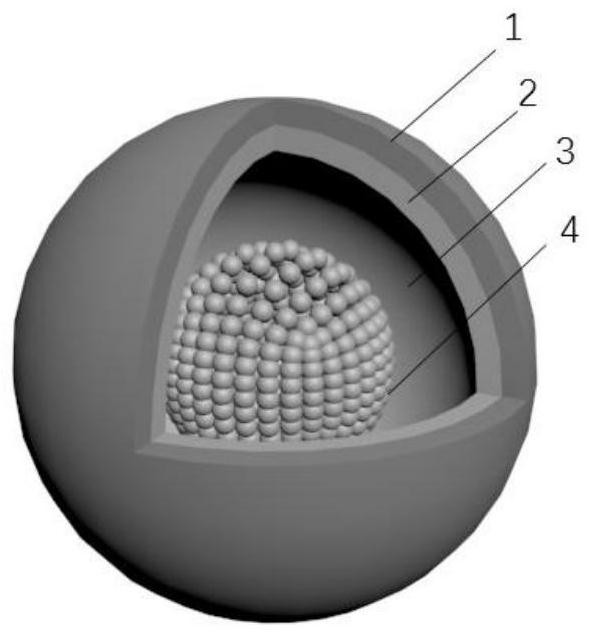

[0025] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0026] (1) 0.6g ferrocene Fe(C 5 h 5 ) 2 Dissolve in 30 mL of acetone and sonicate vigorously for 10 min. After sonication, slowly add 3 mL of HO 2 o 2 , stirred vigorously for 30 minutes. The solution was then transferred to a polytetrafluoroethylene-lined stainless steel autoclave with a total capacity of 50 ml and a pressure of 1.2 MPa. The temperature in the kettle was adjusted to 210°C and kept for 24 hours. After the reaction, the solution was cooled to room temperature and treated with ultrasonic dispersion for 15 minutes. The precipitate in the solution was separated by centrifugation with a magnet, and then washed with acetone to obtain a carbon support containing The starting material of ferroferric oxide.

[0027] (2) The magnet collects the initial material and washes it with 1mol / L hydrochloric acid at room temperature to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com