Production process of rod-shaped porcelain insulator for high-speed rail overhead contact system

A porcelain insulator and production process technology, applied in the field of rod-shaped porcelain insulator production process, can solve the problems of low product qualification rate, poor anti-fouling performance, small bending damage load, etc., and achieve good anti-fouling performance and plastic packaging pass rate High, stable production quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below in conjunction with specific embodiments.

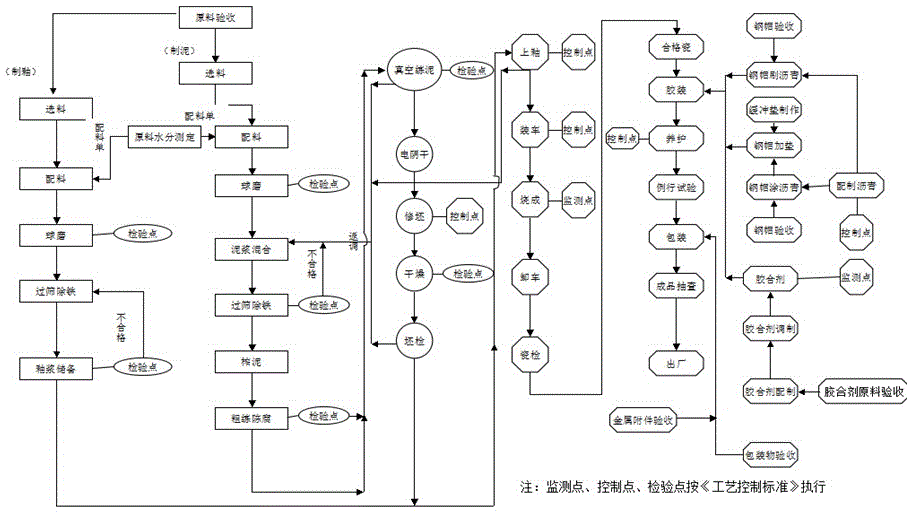

[0023] Porcelain rod insulators are key components in electrified high-speed railway catenary. Pollution-resistant electrified railway catenary rod-shaped porcelain insulators for high-speed railways are used for power frequency single-phase 25kV (27.5kV) electrified railway catenary contact wire insulation and fixed wires. With the gradual speed up of high-speed railways, higher requirements are put forward for the electromechanical performance of rod-shaped porcelain insulators for catenary. In order to satisfy 350Km / h and above high-speed railways with safe and reliable driving, improve the qualified rate of products, and increase benefits, the present invention proceeds from the following links to produce rod-shaped porcelain insulators for high-speed railway catenary.

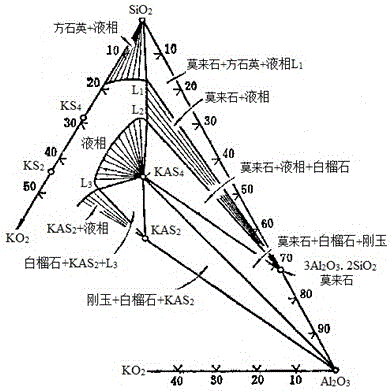

[0024]1. Raw material optimization and control: the present invention starts with the raw...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

| Refractoriness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com