Waterproof and antifouling fabric and preparation method thereof

A technology of anti-fouling fabrics and fabrics, applied in the direction of fabrics, textiles, textiles and papermaking, etc., can solve the problems of inability to wash at will, loss of locked down, etc., and achieve good moisture conduction, avoid shedding, and good bonding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

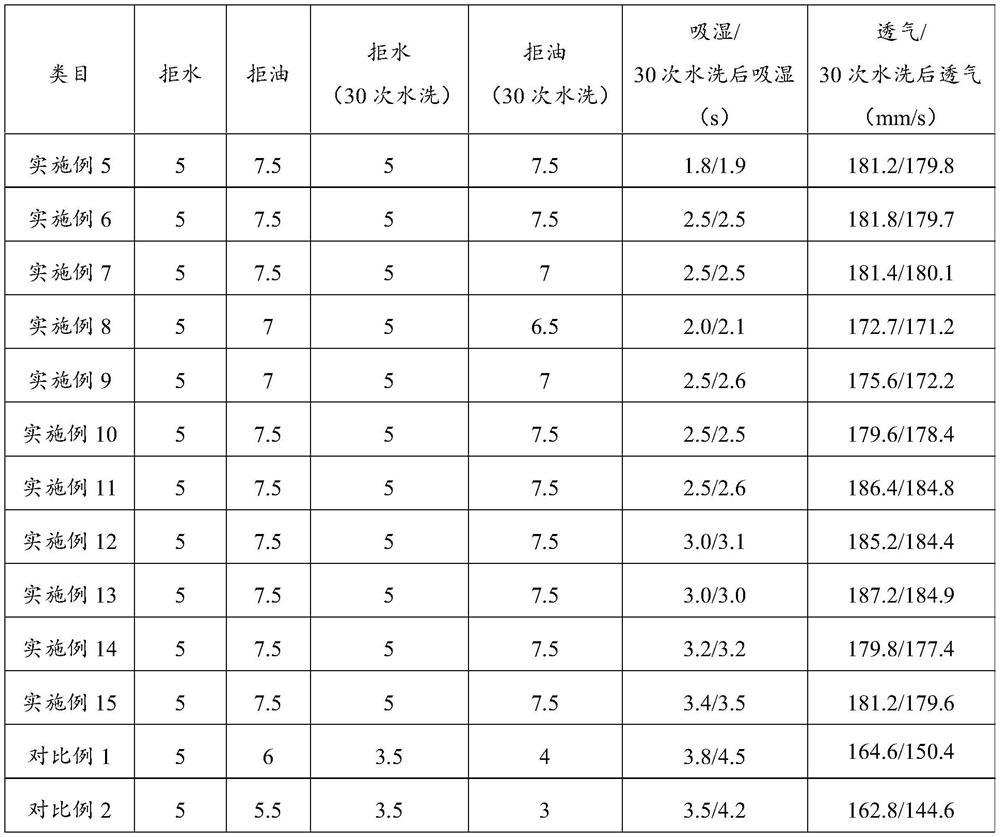

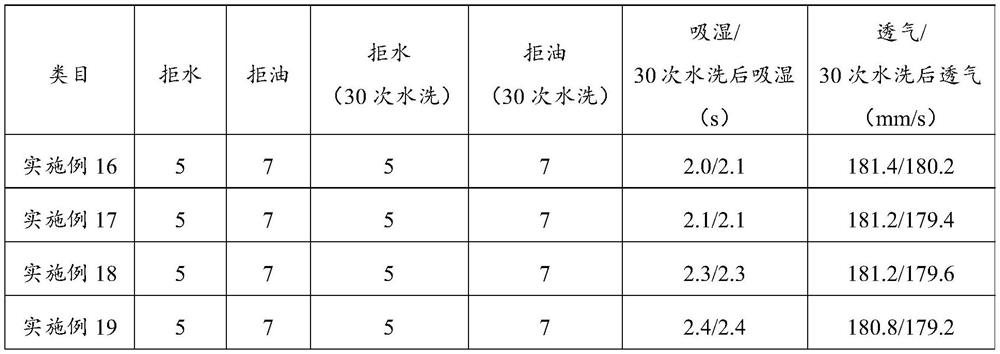

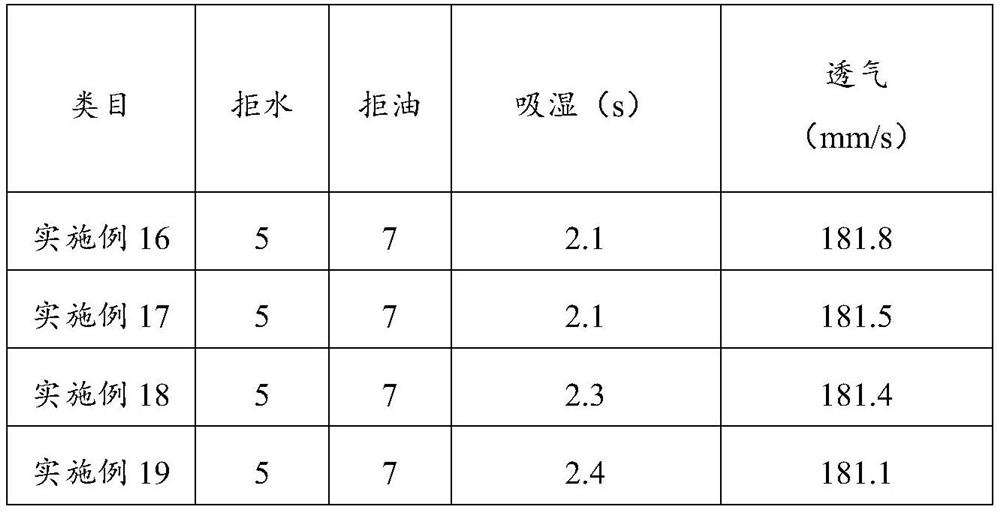

Examples

preparation example Construction

[0029] The waterproof and antifouling fabric of the present invention, the specific preparation method, comprises the following steps:

[0030] S1. Preparation of core yarns: According to the ratio of core yarns, short fiber raw materials are used, and the raw materials are processed into yarns by picking cotton, cotton blending, combing and anti-static treatment, and then the processed yarns are treated with a softening finishing agent, and then dehydrated. , The core wire is obtained after drying;

[0031] S2. Preparation of outer thread: According to the ratio of outer thread, short fiber raw material is used, and the raw material is processed into thread by cotton picking, cotton blending, combing and anti-static treatment, and then the processed thread is treated with perfluorinated finishing agent and cross-linking agent. After soaking treatment, dehydration and drying, the outer wire is obtained;

[0032] S3, fabric preparation thread: the core wire and the outer threa...

Embodiment 1

[0048] The fabric of this embodiment is prepared by the following steps:

[0049] S1. Core yarn preparation: According to the ratio of 50% cotton, 25% nylon, 20 polyester and 5% polypropylene fibers, the above four kinds of short fibers are weighed, put into the cotton grabbing machine for cotton processing, and then into the mixed cotton Machine-blended cotton into rolls, and then carded and combed by a carding machine to form yarns. After finishing the yarns with antistatic finishing agent, dewatering treatment, and then drying at 100 °C for 5 minutes, the core yarns are finally obtained. The diameter of the prepared core wire is controlled at 60 μm.

[0050] S2. Preparation of outer thread: According to the ratio of 35% cotton, 30% wear-resistant polyester, 25% polyester-cotton and 10% hemp, the above four kinds of short fibers are weighed, put into the cotton grabbing machine for cotton processing, and then enter the The cotton blender mixes cotton into rolls, and then is...

Embodiment 2

[0056] The fabric of this embodiment is prepared by the following steps:

[0057] S1. Core yarn preparation: According to the ratio of 50% cotton, 25% nylon, 20 polyester and 5% polypropylene fibers, the above four kinds of short fibers are weighed, put into the cotton grabbing machine for cotton processing, and then into the mixed cotton Machine-blended cotton into rolls, and then carded and combed by a carding machine to form yarns. After finishing the yarns with antistatic finishing agent, dewatering treatment, and then drying at 100 °C for 5 minutes, the core yarns are finally obtained. The diameter of the prepared core wire is controlled at 64 μm.

[0058] S2. Preparation of outer thread: According to the ratio of 35% cotton, 30% wear-resistant polyester, 25% polyester-cotton and 10% hemp, the above four kinds of short fibers are weighed, put into the cotton grabbing machine for cotton processing, and then enter the The cotton is mixed with a cotton blender to form a rol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com