Patents

Literature

42results about How to "Good moisture management" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

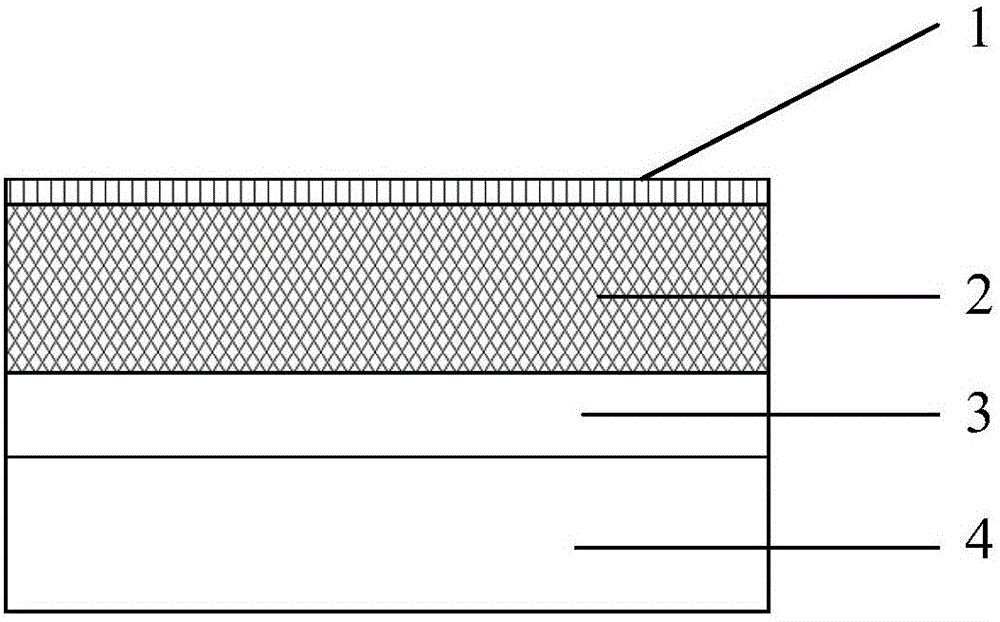

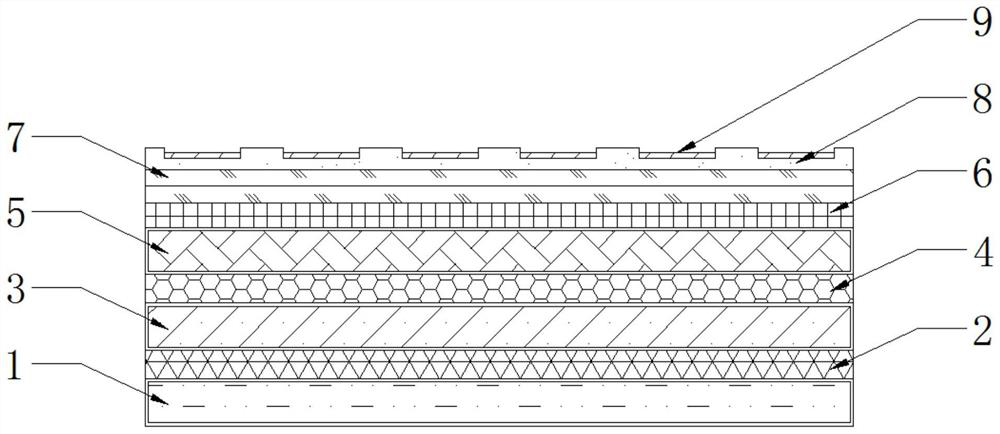

Preparation method of one-way wet conduction nano-fiber multilayer composite membrane with wettability gradient

InactiveCN107059251AExcellent unidirectional moisture transfer performanceWaterproofNon-woven fabricsFiberHydrophobic polymer

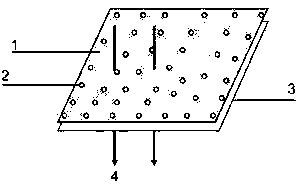

The invention discloses a preparation method of a one-way wet conduction nano-fiber multilayer composite membrane with the wettability gradient. The method comprises the following steps that hydrophilic nano materials are dispersed in solvent, the nano materials are dispersed uniformly through ultrasound, a hydrophilic polymer is dissolved in the dispersing agent, a spinning solution A1 is obtained, and a hydrophilic nano-fiber membrane is deposited on a receiving base material through an electrostatic spinning method; hydrophilic nano materials are dispersed in solvent, the nano materials are dispersed uniformly through the ultrasound, a hydrophilic polymer is dissolved in the dispersing agent, and a spinning solution A2 is obtained; a hydrophobic polymer is dissolved in solvent, and a spinning solution B1 is obtained; the two spinning solutions are deposited on the hydrophilic nano-fiber membrane to form at least one diversion layer through the electrostatic spinning method; a hydrophobic polymer is dissolved in solvent, a spinning solution B2 is obtained, a hydrophobic nano-fiber membrane is deposited on the diversion layers through the electrostatic spinning method, and the one-way wet conduction nano-fiber multilayer composite membrane with the wettability gradient is obtained.

Owner:DONGHUA UNIV

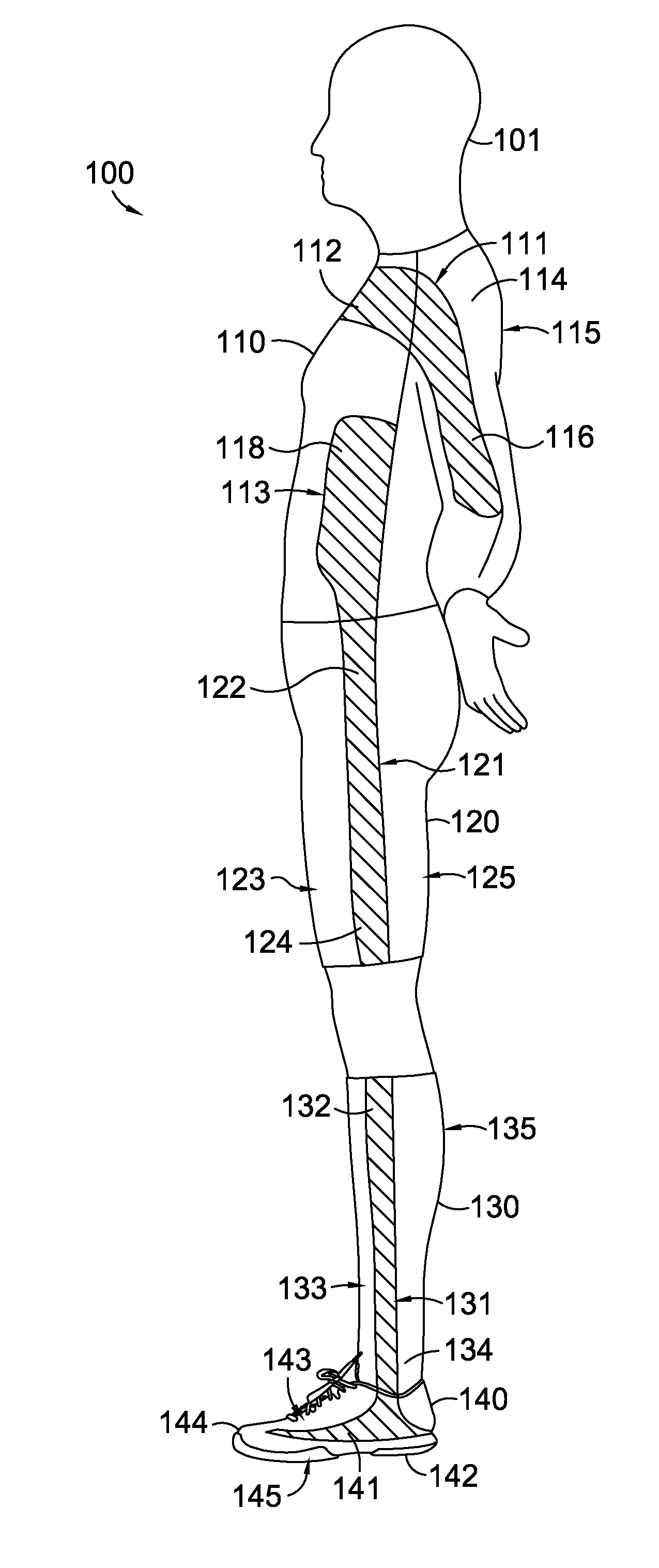

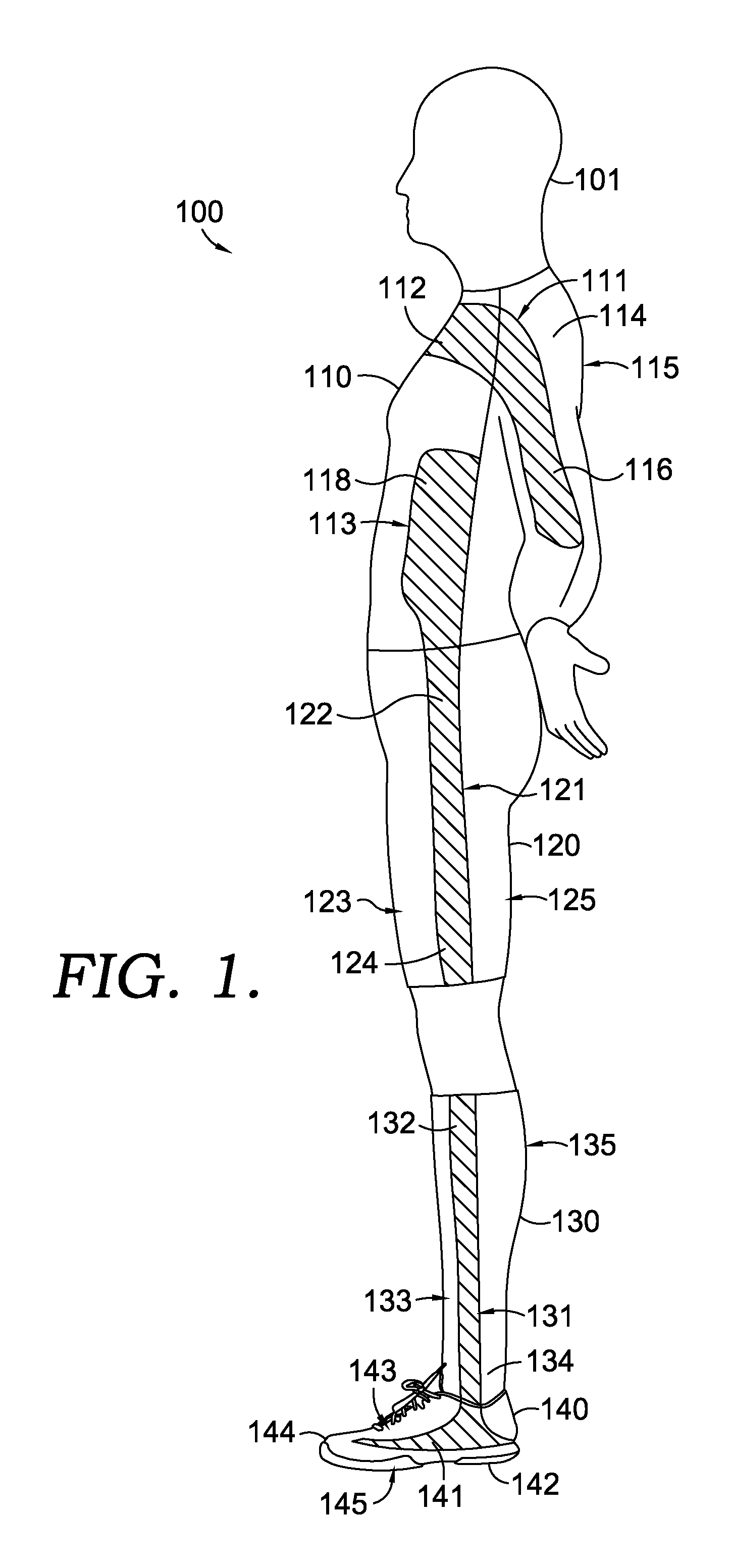

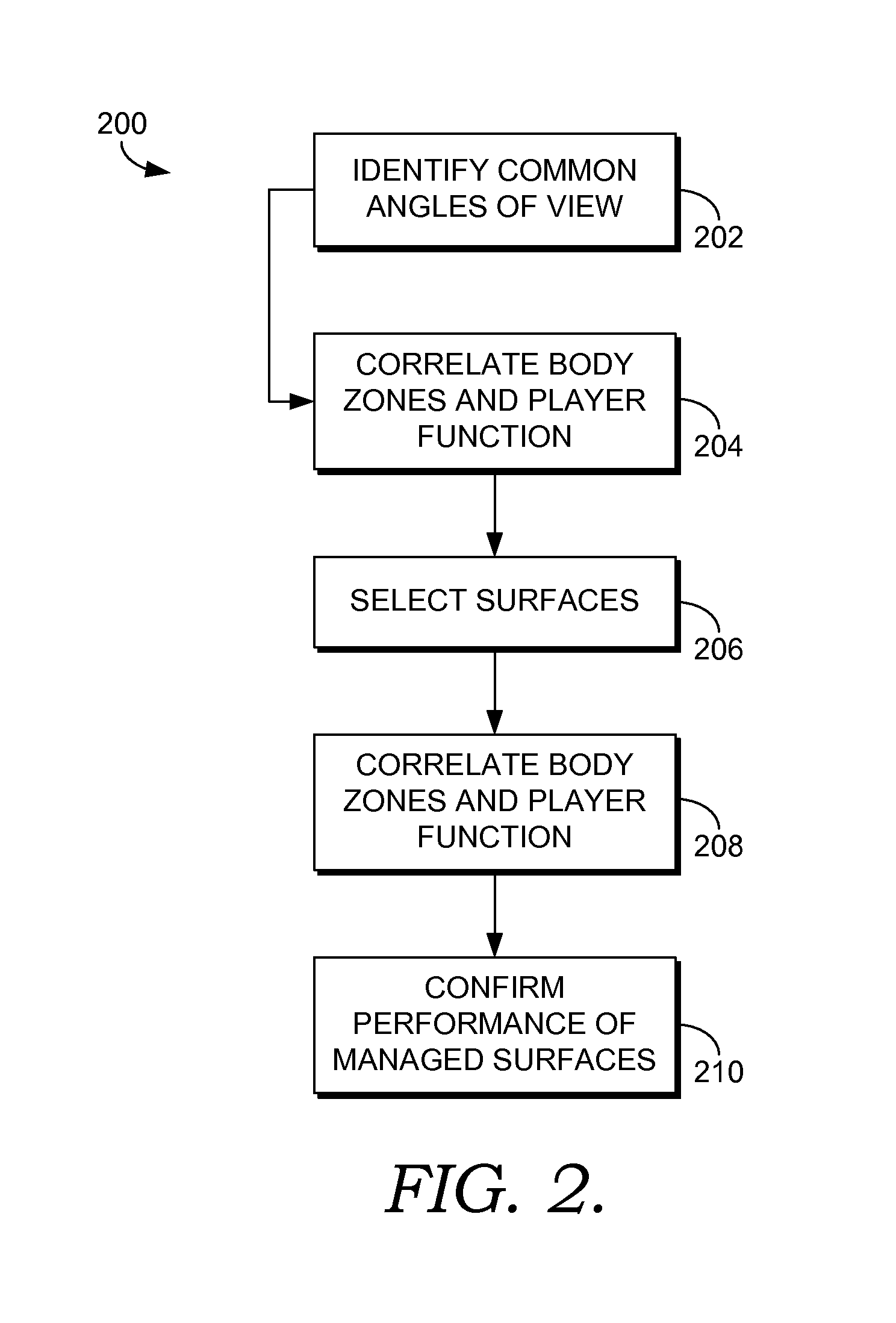

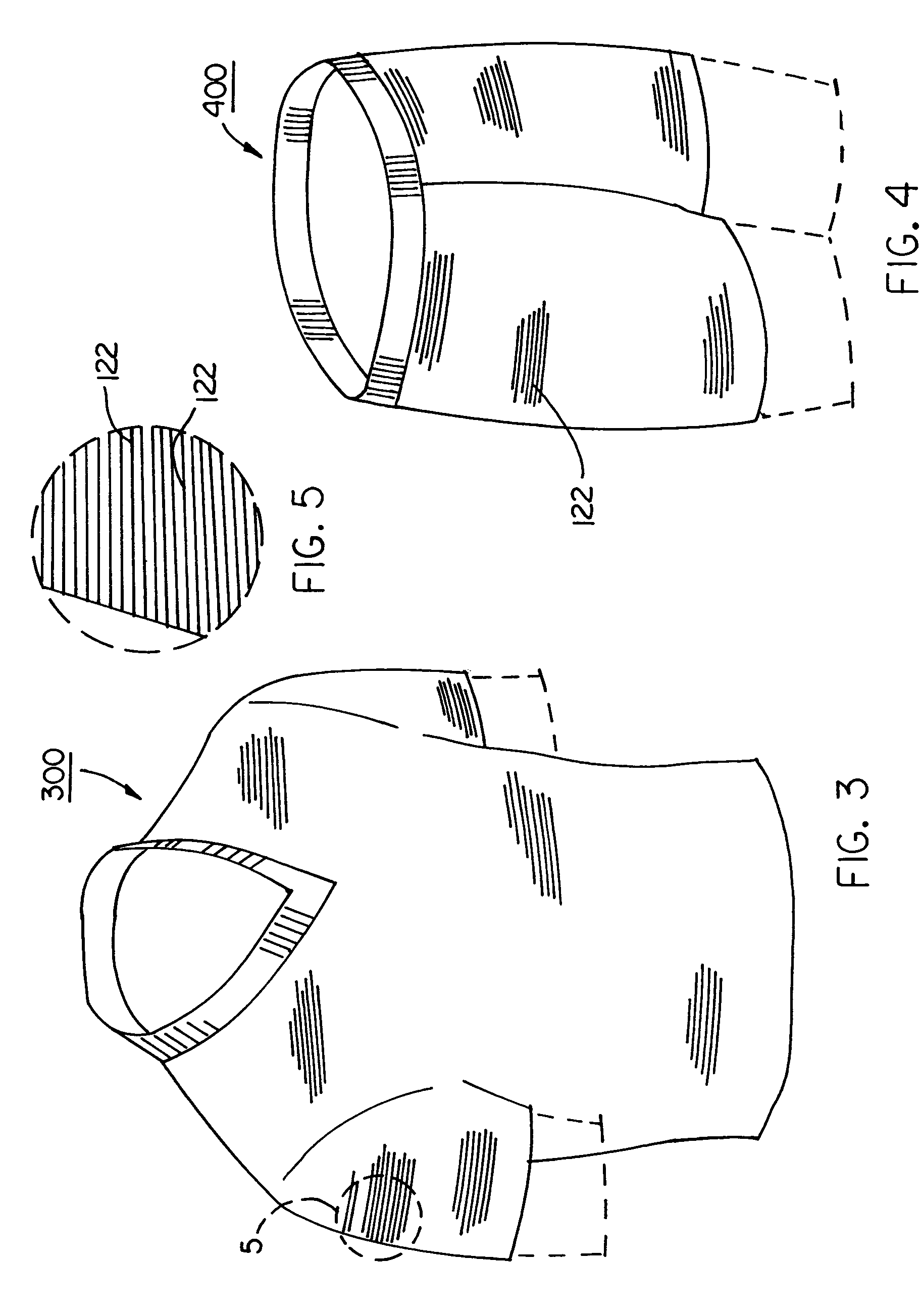

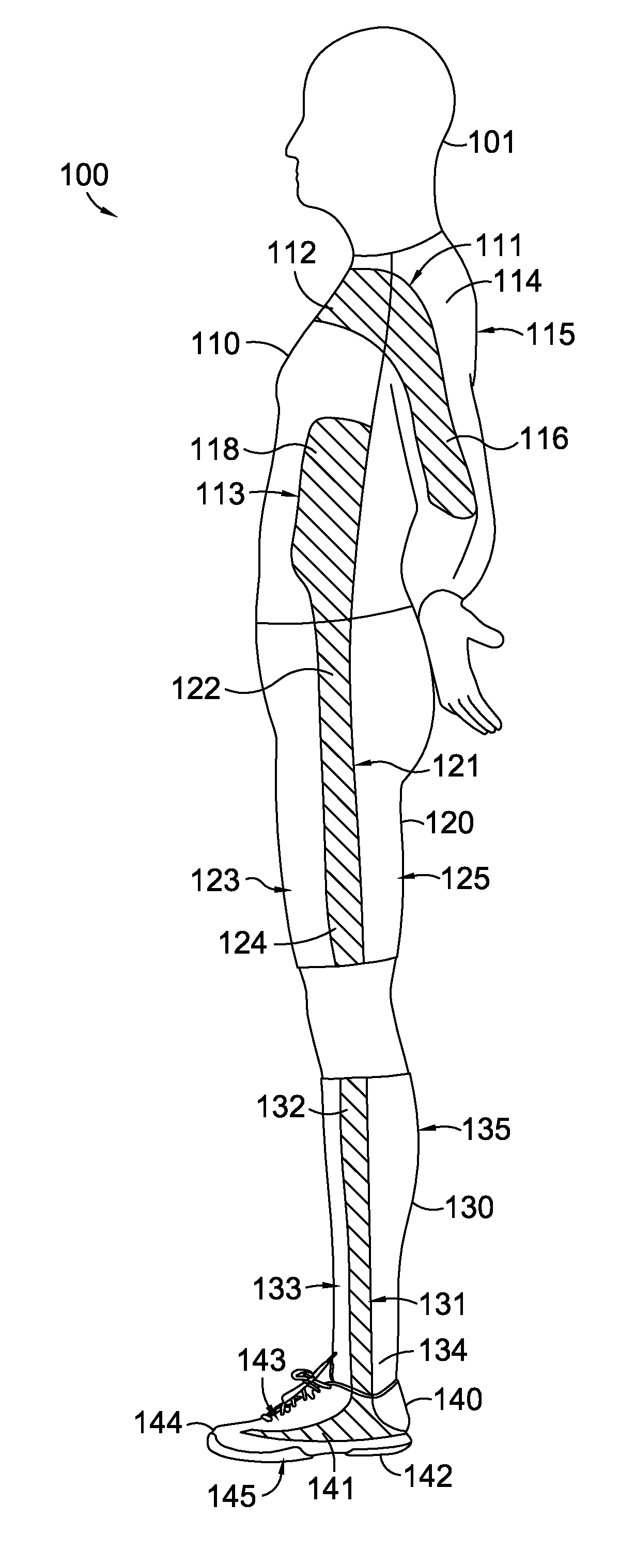

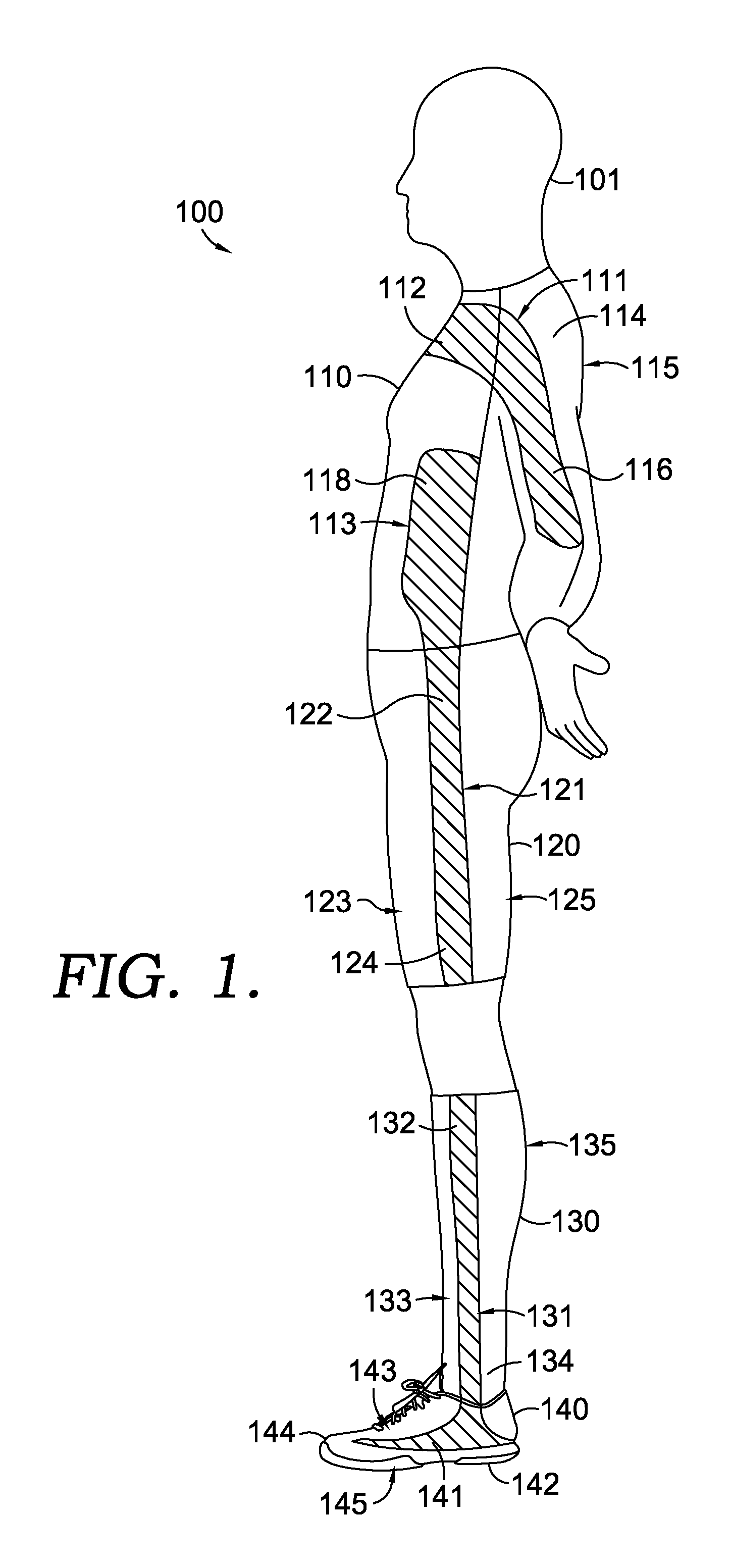

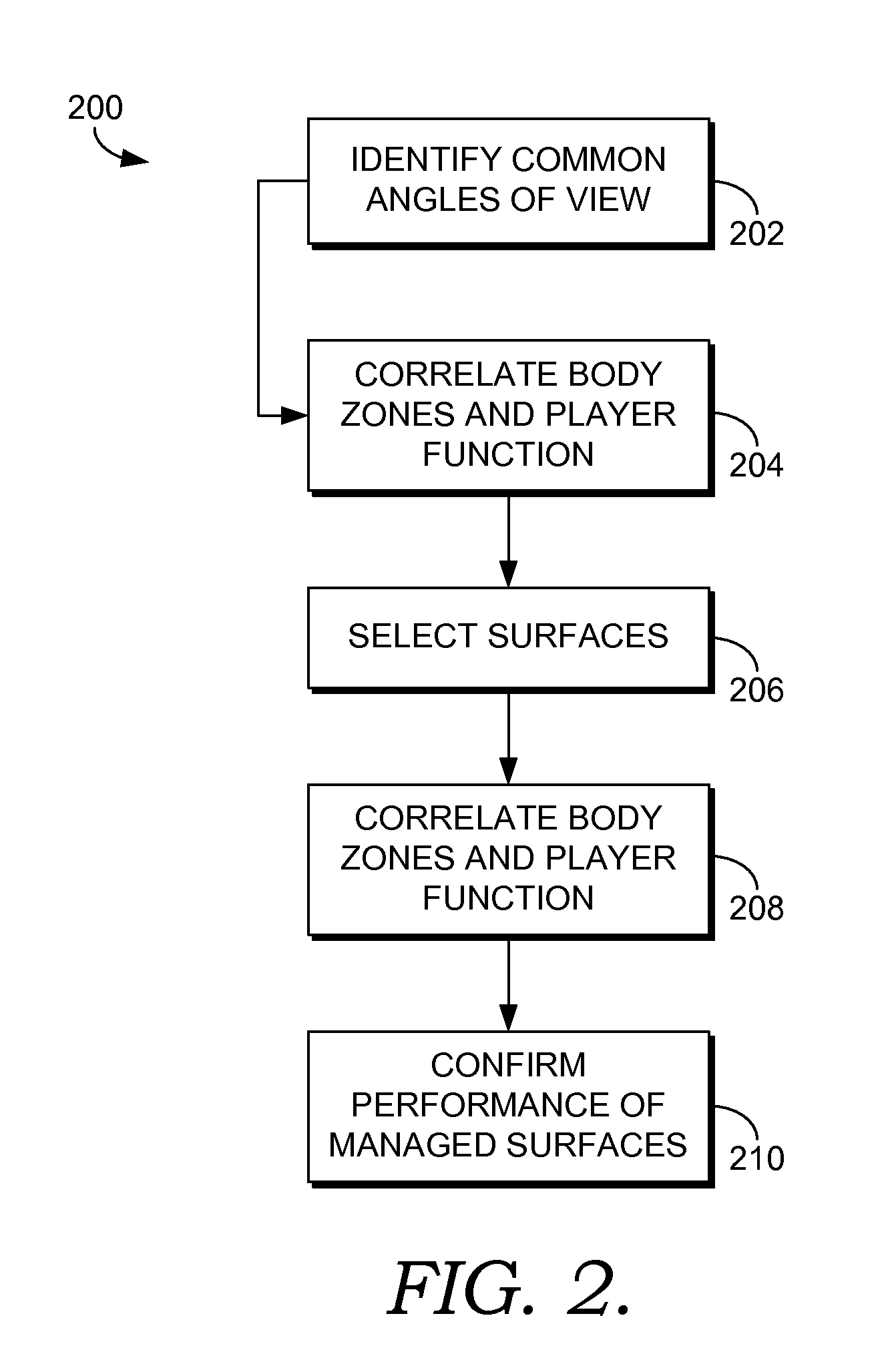

Sports Garments With Enhanced Visual And/Or Moisture Management Properties

ActiveUS20120222189A1Enhance visibilityIncrease awarenessGarment special featuresBall sportsVisibilityEngineering

A garment, such as a sports uniform, may provide visibility zones and / or flicker zones to enhance the ability of teammates to perceive the wearer. Different zones on a garment may have different sets of visual properties that may contrast with one another and / or a visual background. A denier differential between layers of a garment may facilitate moisture transport across the layers of the garment. Flicker zones may be discrete from or combined with visibility zones. One or more zones of a garment may also be substantially non-reflective at wavelengths associated with the visual background encountered while wearing the garment.

Owner:NIKE INC

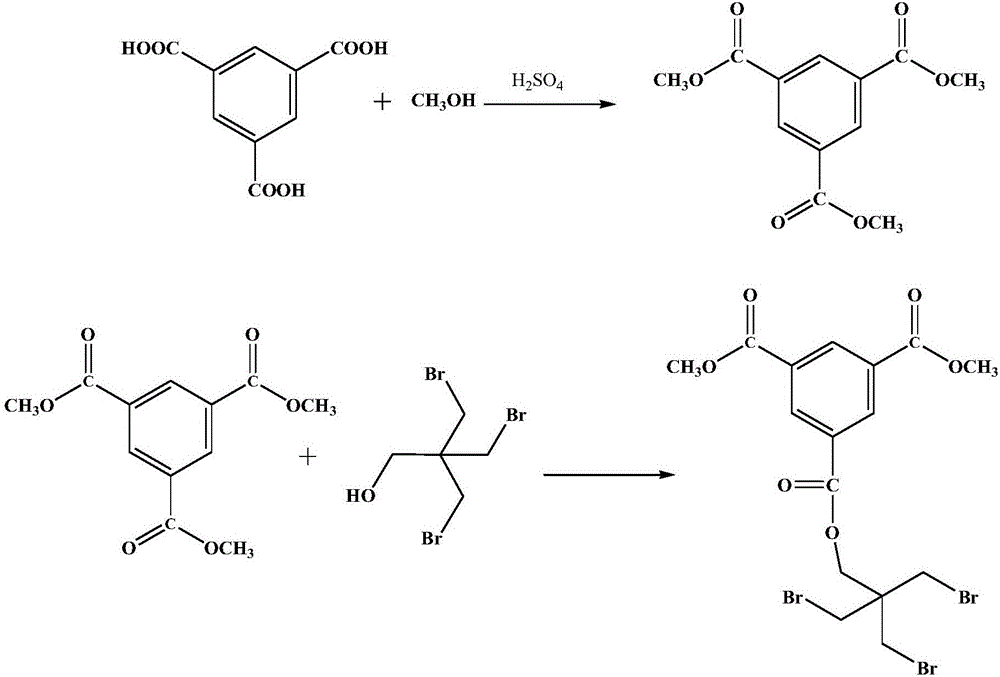

Method for preparing silver metallized organic fiber and textile

This is a argent metallization producing method of organic fibre and fabric, which belongs to vacuum membrane plating and electroplating technologic field and mainly solves the problems of quality and producing batches of silver-gilt organic and fabric. Through physical vapour phase deposition technology, it firstly arranges smoothly and rolls up tidily the organic fibre bundle and fabric; lay them in the vacuum room, plate silver by magnetic controlling and sputtering, and monolayer or multilayer continuously plate membrane; then plate mulriple argent membrane according to different using demands. The binding force of the metallic argentic ion and organ fibre of the present invention is strong, it has no pollution, low costs and can be continuously produced. The products are applied in such industry as electronics, war industry communication, medical treatment, special type of spinning and so on. For instance, electric shielded products, military used shielded tent, special type of spinning antibacterial materials and civil health care spinning products.

Owner:夏芝林

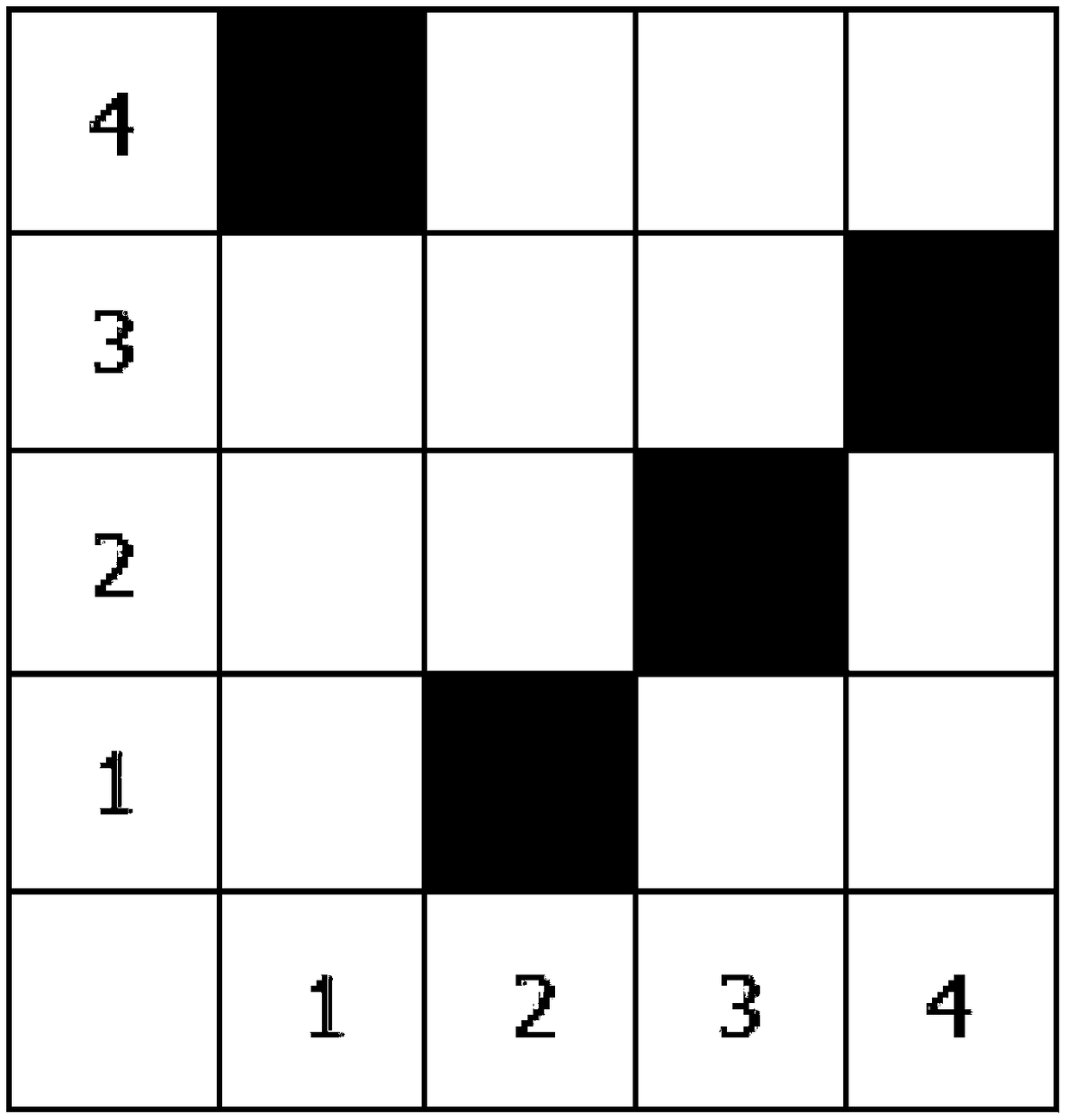

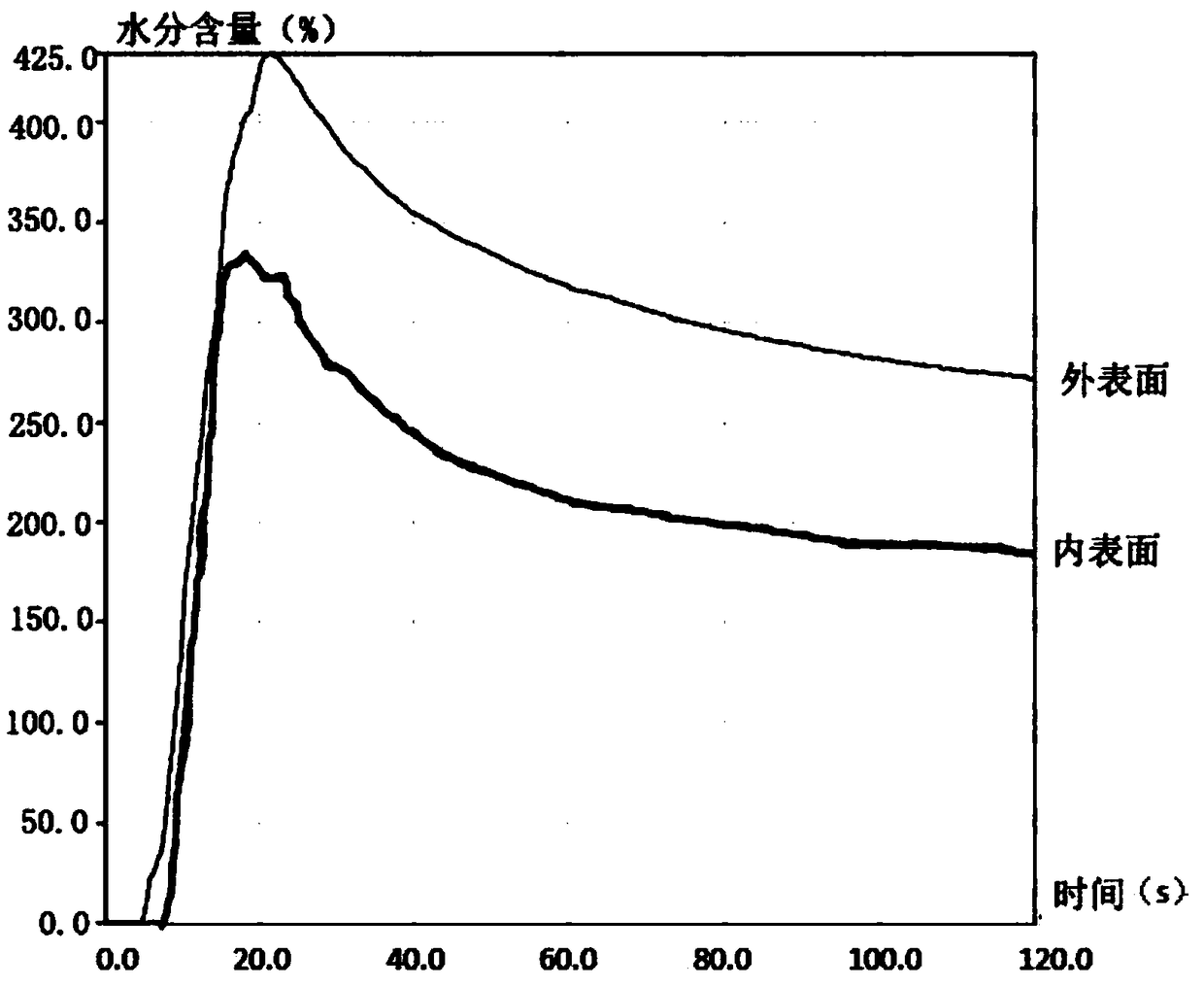

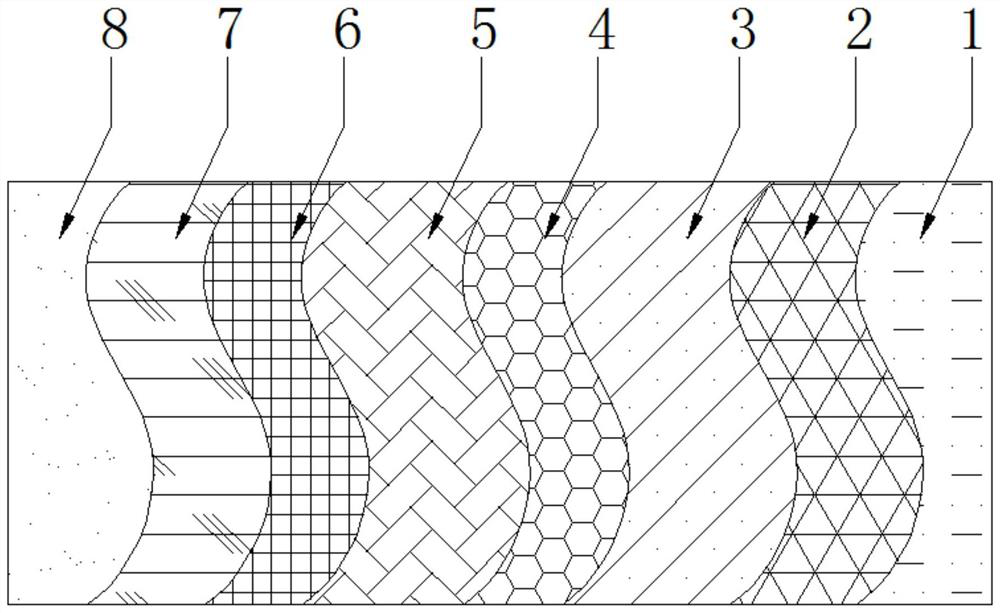

One-way moisture-transferring fabric and processing method thereof

The invention discloses a one-way moisture-transferring fabric and a processing method thereof. The fabric is in a double-layer double-side mesh structure, wherein one side of the fabric which is close to the skin i.e., an internal layer uses polypropylene fibers while the other side i.e., an external layer uses terylene fibers, and the internal layer and the external layer are connected by terylene macrofibers with recesses on the surface and special-shaped cross sections. The processing method of the fabric comprises: that in the process of weaving the fabric, polypropylene fibers are selected as internal layer materials, polyester fibers are selected as external layer materials, and terylene macrofibers with recesses on the surface and special-shaped cross sections are selected as connecting material, thereby weaving the double-layer double-side mesh structured fabric whose internal layer is polypropylene fibers, external layer is terylene fibers, and the internal layer and the external layer are connected by the terylene macrofibers with recesses on the surface and special-shaped cross sections; that connection points which are evenly arranged are established between the internal and the external layers, wherein the connection points of the internal and the external layers are connected to each other through the terylene macrofibers; and that in a dyeing after-finishing process, the fabric is processed to be hydrophilic, quick-drying, and soft. The fabric in the invention is well in hygroscopic property and moisture-transferring property, and has the effects of one-way moisture transferring and quick drying.

Owner:SHANGHAI JIALE

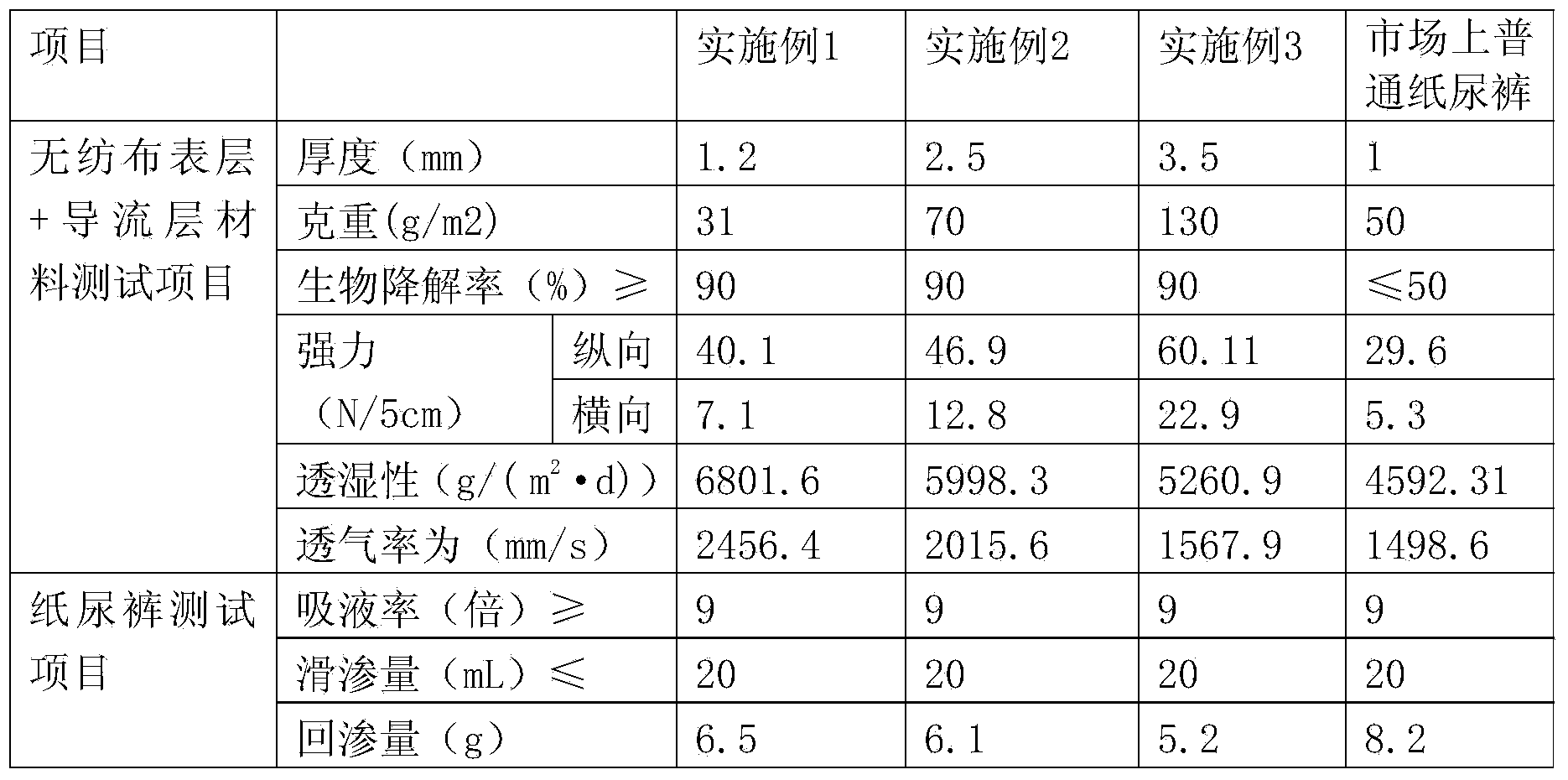

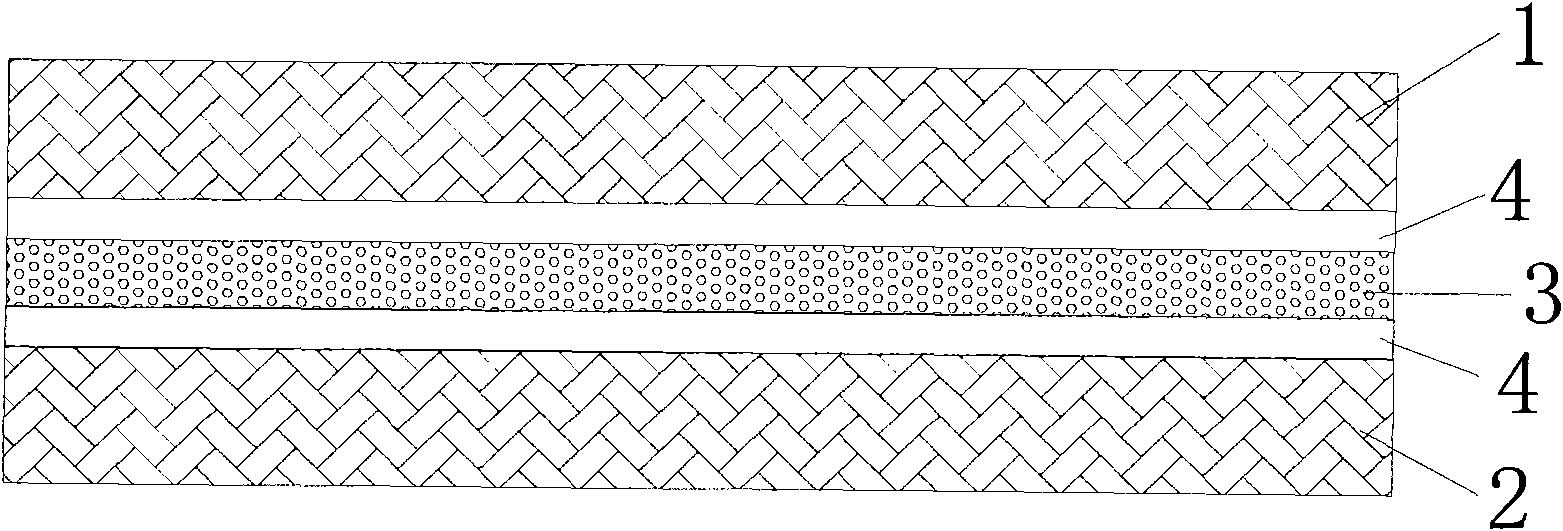

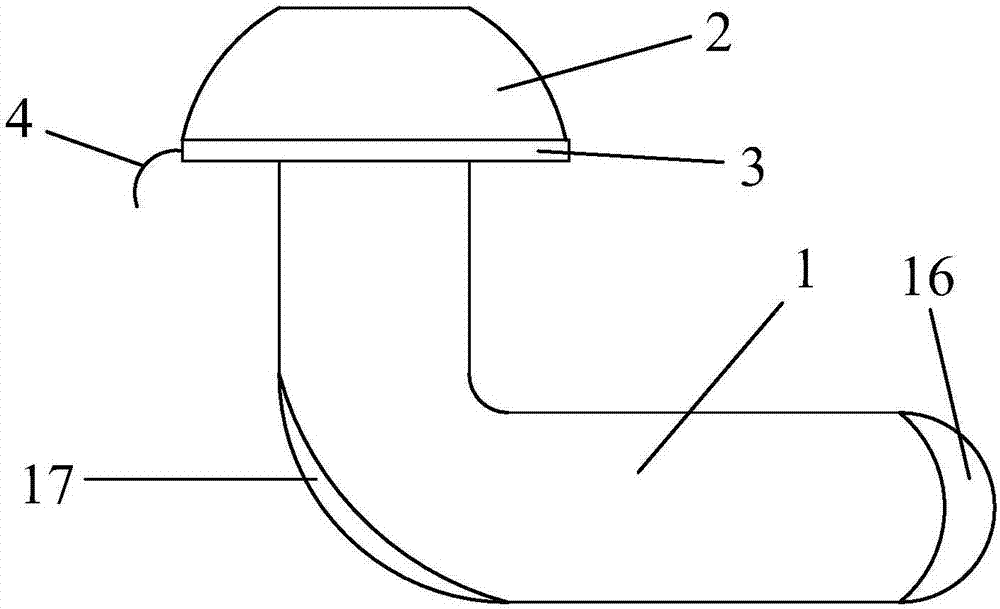

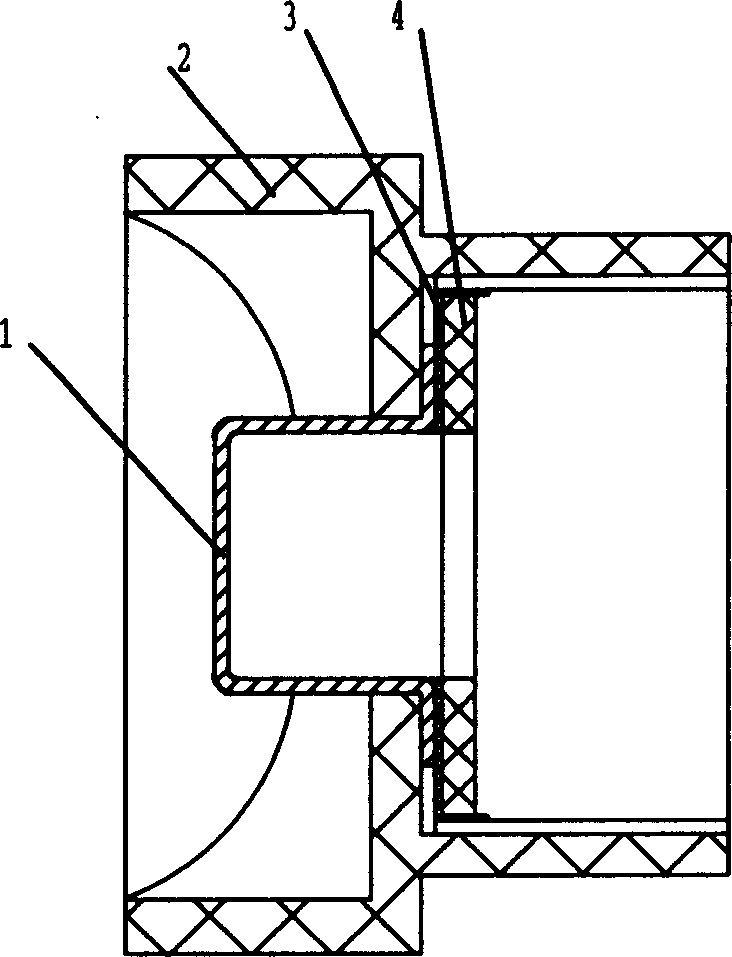

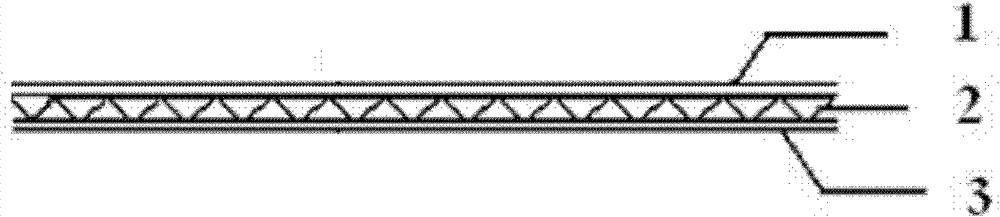

PLA (polylactic acid) non-woven fabric diaper with high breathability and preparation method thereof

ActiveCN104138310AImprove breathabilityGood moisture managementAbsorbent padsNon-woven fabricsSurface layerEngineering

The invention discloses a PLA (polylactic acid) non-woven fabric diaper with high breathability. The PLA non-woven fabric diaper comprises a surface material, a water absorption core layer and a bottom membrane from inside to outside, wherein the surface material adopts a three-layer structure consisting of an upper layer, a middle layer and a lower layer, PLA short fiber webs are arranged on the upper layer and the lower layer, PLA long fiber non-woven fabric is arranged on the middle layer, and guide holes with pore diameters of 10-30 meshes are distributed on the PLA long fiber non-woven fabric. According to the diaper with the high breathability, upper-layer PLA short fiber non-woven fabric in three-layer PLA fiber webs is adopted as a surface layer, lower-layer PLA short fiber non-woven fabric is adopted as a guide layer, middle PLA filament non-woven fabric is adopts as an isolated layer, the three layers are bonded into integral non-woven fabric in a hot melting compound manner, the method for compounding the guide layer and the non-woven fabric on the surface layer through glue spraying in the production process of conventional diapers is not required, and the breathability between the surface layer and the non-woven fabric on the guide layer is greatly improved.

Owner:马鞍山同杰良生物材料有限公司

Mildewproof and mothproof composite fabric

InactiveCN102058189AImprove breathabilityKeep warmLayered productsProtective garmentKapok fiberEngineering

The invention discloses a mildewproof and mothproof composite fabric, which comprises an outer layer, an inner layer and a middle layer, wherein both the outer layer and the inner layer are made of fabric blended with kapok fibers and other fibers; the middle layer is a membrane layer; and the two sides of the membrane layer are combined with the outer layer and the inner layer through glue layers. The composite fabric disclosed by the invention is a kapok fiber-containing fabric, has excellent breathing, warming, dampness conducting, mildewproof and mothproof effects, is environmentally-friendly, has the characteristic of being softer, lighter and more environmentally-friendly than fabrics made of other fibers, and mainly solves the problem that the mildewproof and mothproof effects of other fibers are undesirable.

Owner:CHANGSHU HUABO WOOLEN TEXTILE

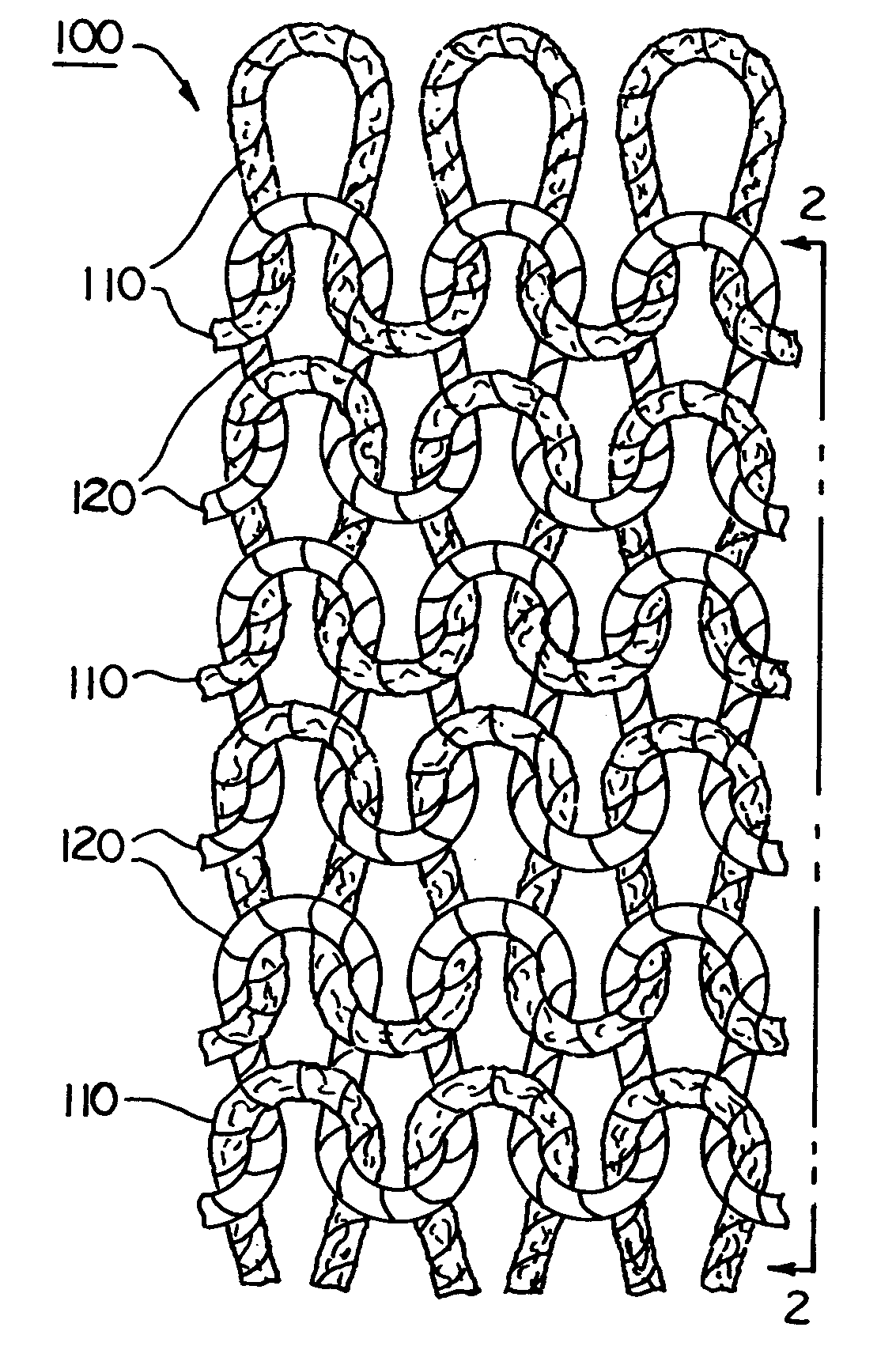

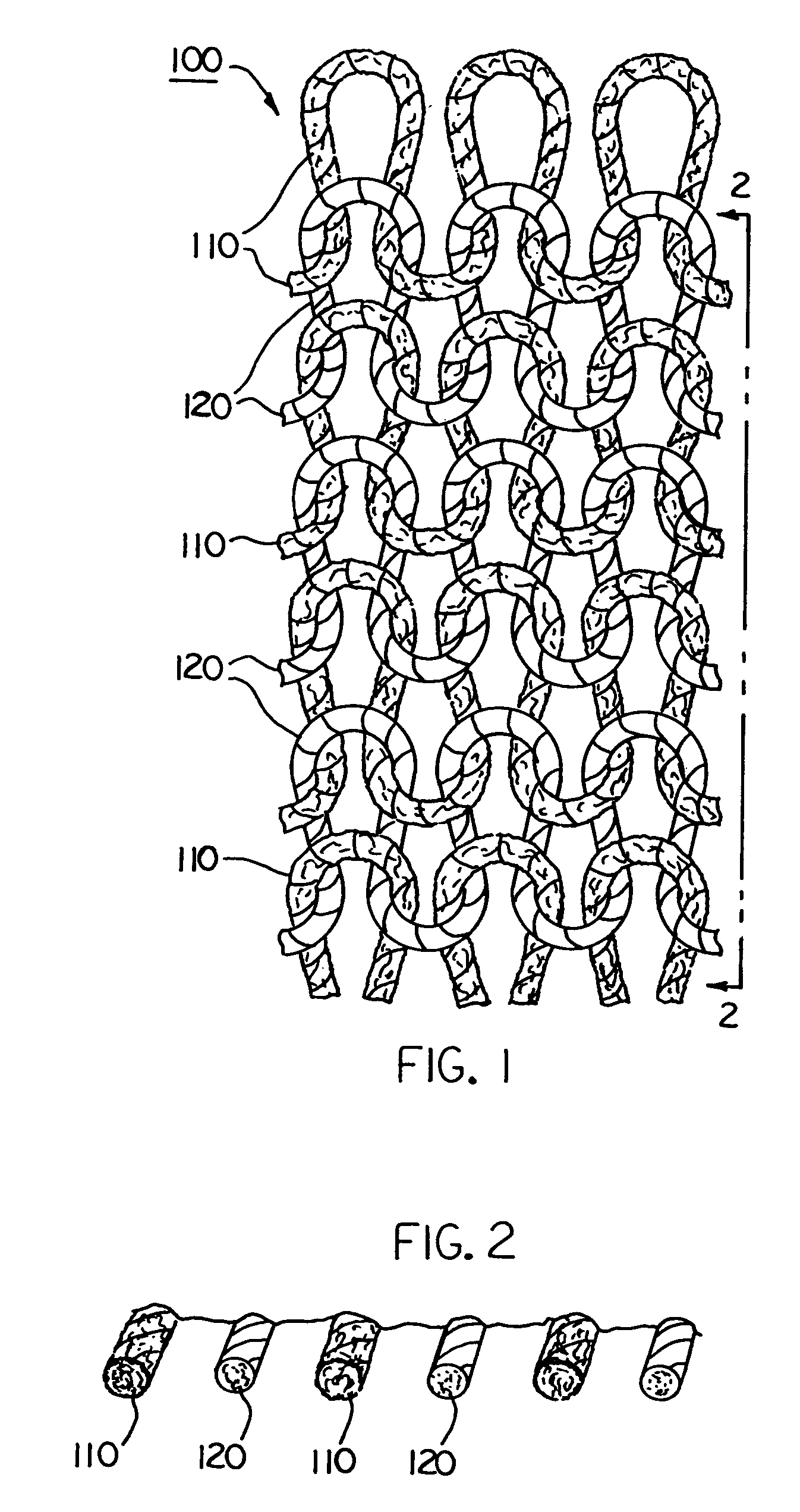

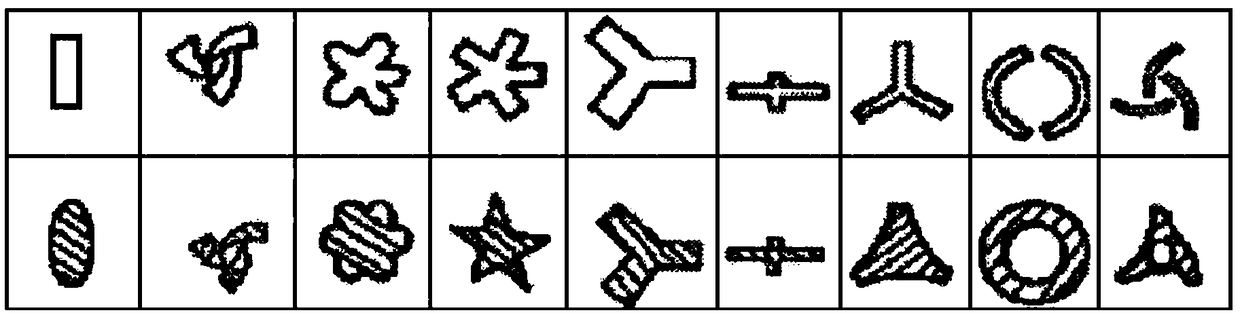

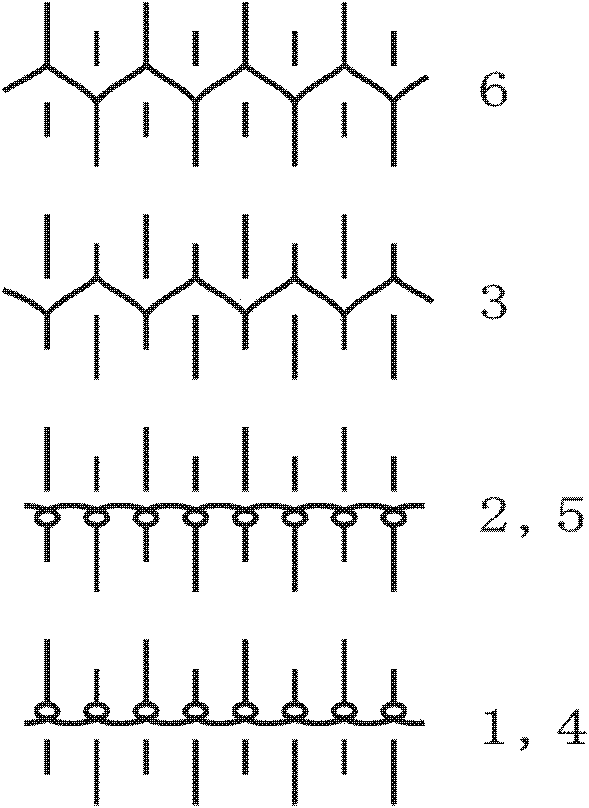

Knitted fabric construction with improved moisture management

ActiveUS6986270B2Good moisture managementTransportation is highLiquid transferring devicesCircular knitting machinesYarnMoisture management

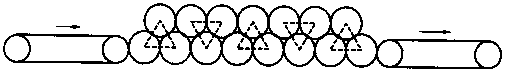

A knitted fabric having moisture management properties. The fabric is formed from filamentary yarns and spun yarns, both the filamentary and spun yarns having substantially the same weight per unit of length. The fabric is knitted with so that the courses alternate between a filamentary yarn and a spun yarn.

Owner:HBI BRANDED APPAREL ENTERPRISES

Knitted fabric with one-way moisture guide function

InactiveCN103726204AGood moisture absorption and air permeabilityStrong wearing comfortWeft knittingWarp knittingPolyesterFiber

The invention relates to knitted fabric with the one-way moisture guide function. Raw materials of the knitted fabric are high-hydrophilic biological-base polyester fibers. A production method comprises the specific steps of high-hydrophilic biological-base polyester fiber preparation, knitting of the knitted fabric, execution of the dyeing technology, execution of the printing technology and acquisition of the one-way moisture knitted fabric. The novel high-hydrophilic full-biological-base polyester fibers used by the fabric are good in moisture absorbing breathable performance, so that the prepared knitted fabric is good in moisture absorbing breathable performance and wearing comfort. The adopted high-hydrophilic biological-base polyester fibers serve as the raw materials of the fabric and due to the special molecular structure of modified fibers, the one-way moisture guide function of the knitted fabric is durable. The high-hydrophilic biological-base polyester fibers with the environment protection performance, the renewable performance, the good moisture absorbing and sweat discharging performance are adopted to serve as the raw materials of the fabric, so that environment protection and the sustainable development are facilitated.

Owner:QUANZHOU HAITIAN MATERIAL TECH CORP

Process for producing controllable micropore polyester fiber fabric

InactiveCN101956275AControllable specific surface areaGood moisture managementWoven fabricsYarnPolyesterYarn

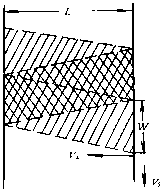

The invention discloses a process for producing a controllable micropore polyester fiber fabric. The process comprises a weaving process and a dyeing and finishing process, wherein warps are warped, drawn in, dented, subjected to a sizing process and woven into a gray fabric together with wefts; a blended yarn comprises the following raw materials in percentage by weight: 65 percent of micropore polyester fiber and 35 percent of raw cotton fiber or 65 percent of micropore polyester fiber and 35 percent of viscose fiber; a sizing agent adopted in the sizing process comprises polyvinyl acetate (PVA)-1799, PVA-205M and polyacrylic ester; a texture structure adopts a plain texture; and the ratio of the warp to the weft is 2:2 in the aspect of yarn arrangement. A product produced by the process has the advantages of keeping the original quick drying and stiffness and smoothness of polyester, reducing the rigidity of the polyester fiber, enhancing flexibility, eliminating polar light of the polyester, achieving sense of touch closer to the texture of natural fibers and fundamentally improving the wet permeability, ventilation property, fuzz resistance and pilling resistance of fibers.

Owner:ZHEJIANG ZHONGFANG XINTIANLONG TEXTILE SCI & TECH

Biodegradable needling warmth retention flocculus and preparation method thereof

InactiveCN108330612AGood moisture managementImprove breathabilityNon-woven fabricsTextile shapingFiberEnvironmental resistance

The invention provides a biodegradable needling warmth retention flocculus and a preparation method thereof. Viloft fibers are carded into nets; nets are laid in an intersected manner; the laid nets are drawn by the aid of a plurality of rollers; needling is reinforced to form the warmth retention flocculus. By a pre-needling reinforcement method, high-temperature treatment is omitted, and the fibers are intersected each other by the aid of crimp indexes of the fiber and needling friction force, so that fiber nets have a certain strength and keep a certain filling power. The needling reinforcement method is simple in process, energy consumption is low as compared with a hot air reinforcement method, production cost of flocculus products is reduced, chemical gas emission is reduced, and themethod for processing the flocculus is environmentally friendly.

Owner:HENAN INST OF ENG

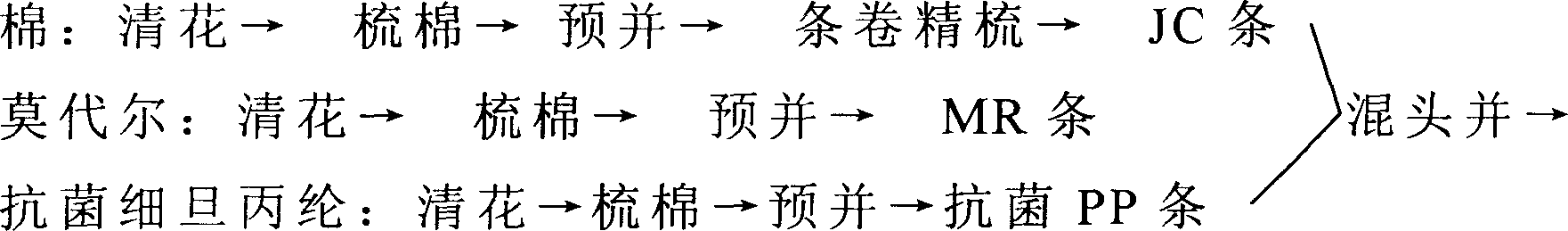

Cotton, model and nano silver-series antibacterial fine-denier poly propylene fiber scribbled and processing method thereof

InactiveCN1508308AImprove antibacterial propertiesGood moisture managementYarnNanotechnologyPolypropylene fiber

The invention relates to a cotton-Modaier-nano silver-system antibacterial fine polypropylene fiber blend spinning and processing method, the blending ratio: combed cotton JC 30-40%; Modaier MR 20-30%; nano silver system antibacterial fine polypropylene fiber PP 40-60%. The processing flow: gin and comb-precombine or roll-comb three fibers, blend and combine JC strip, MR and antibacterial PP strip, and then rove and spin to be able to make knit underwaist.

Owner:SHANGHAI NO 17 COTTON TEXTILE MILL

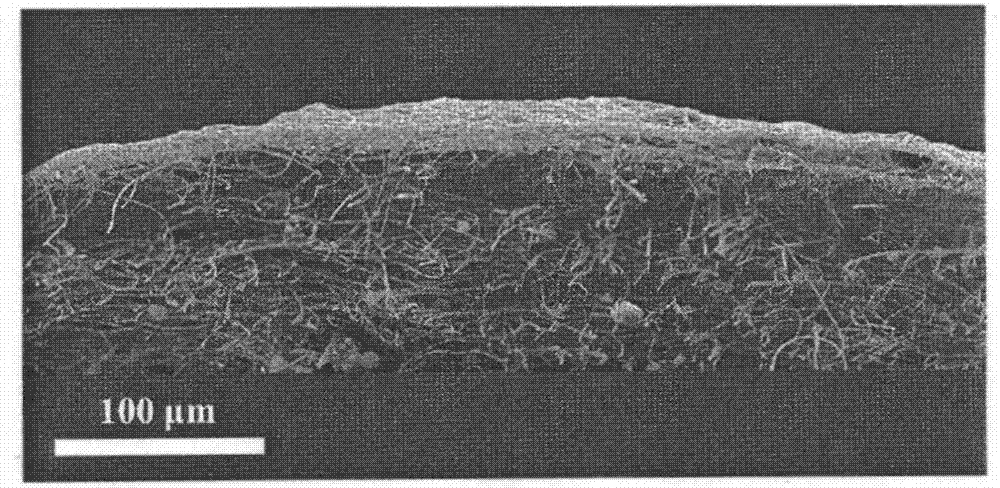

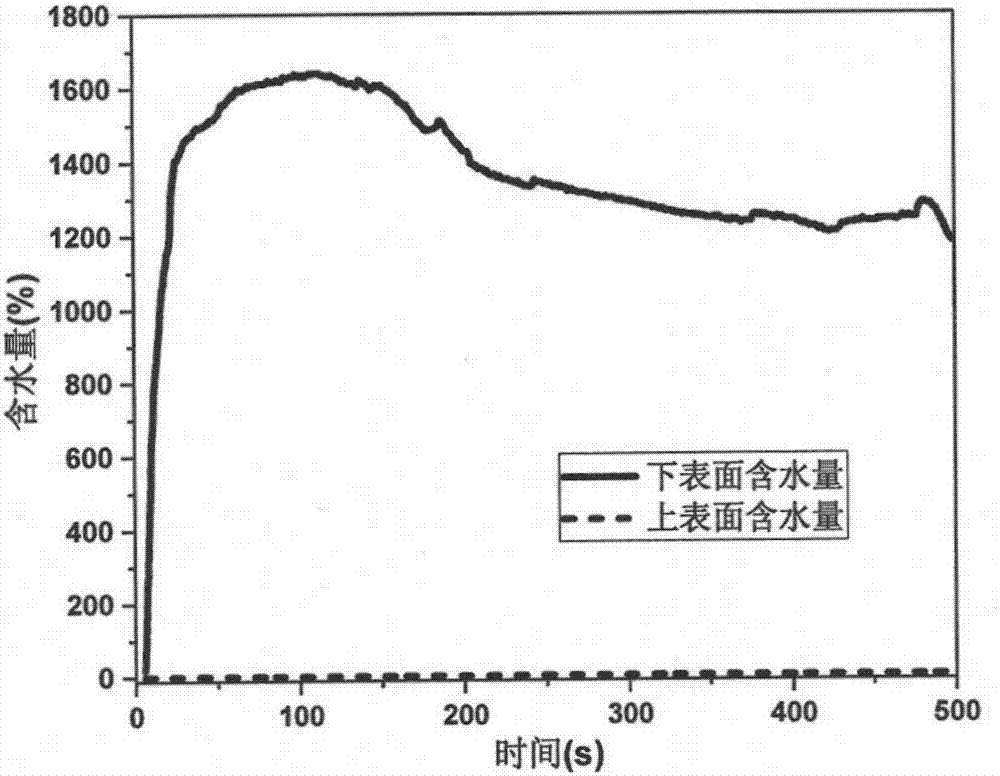

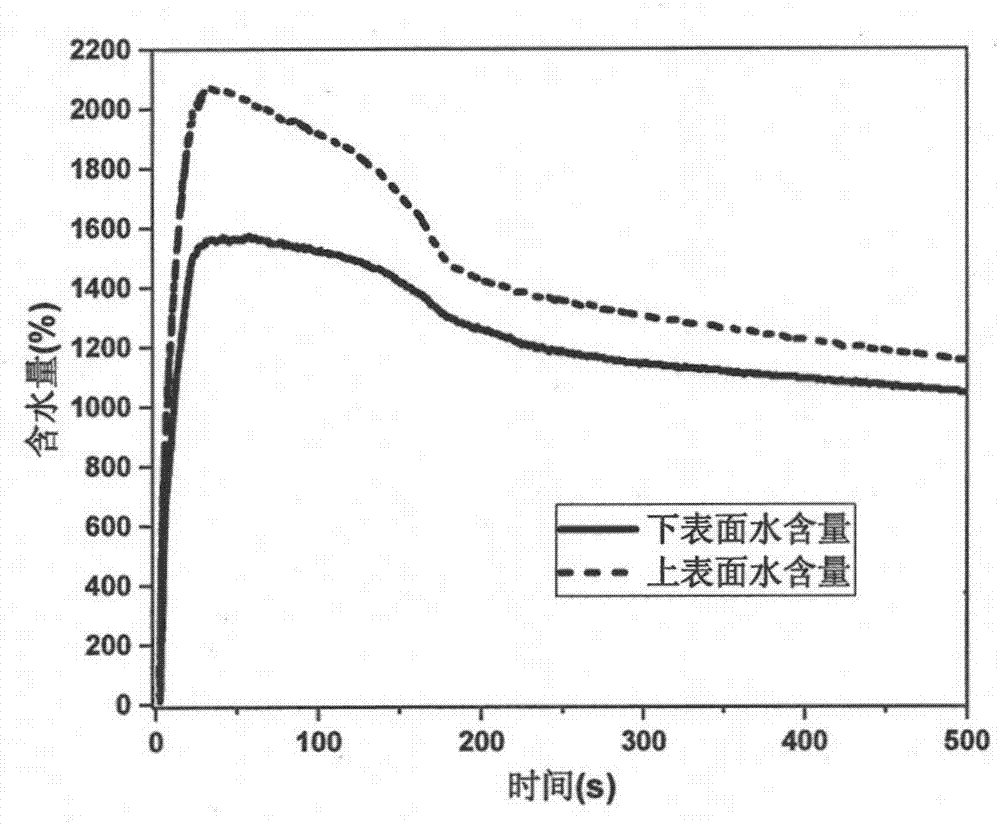

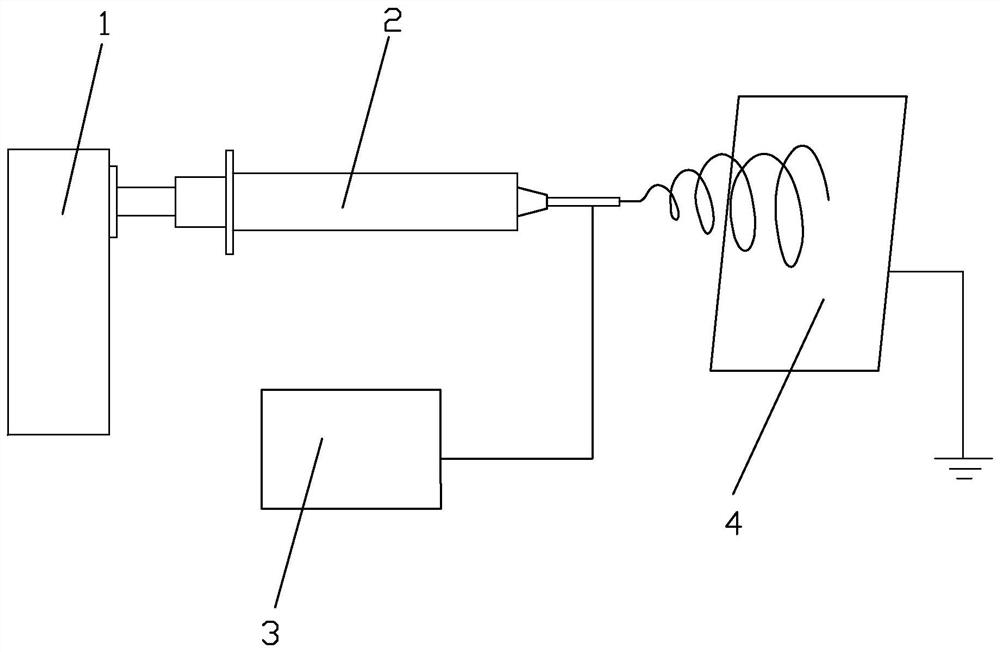

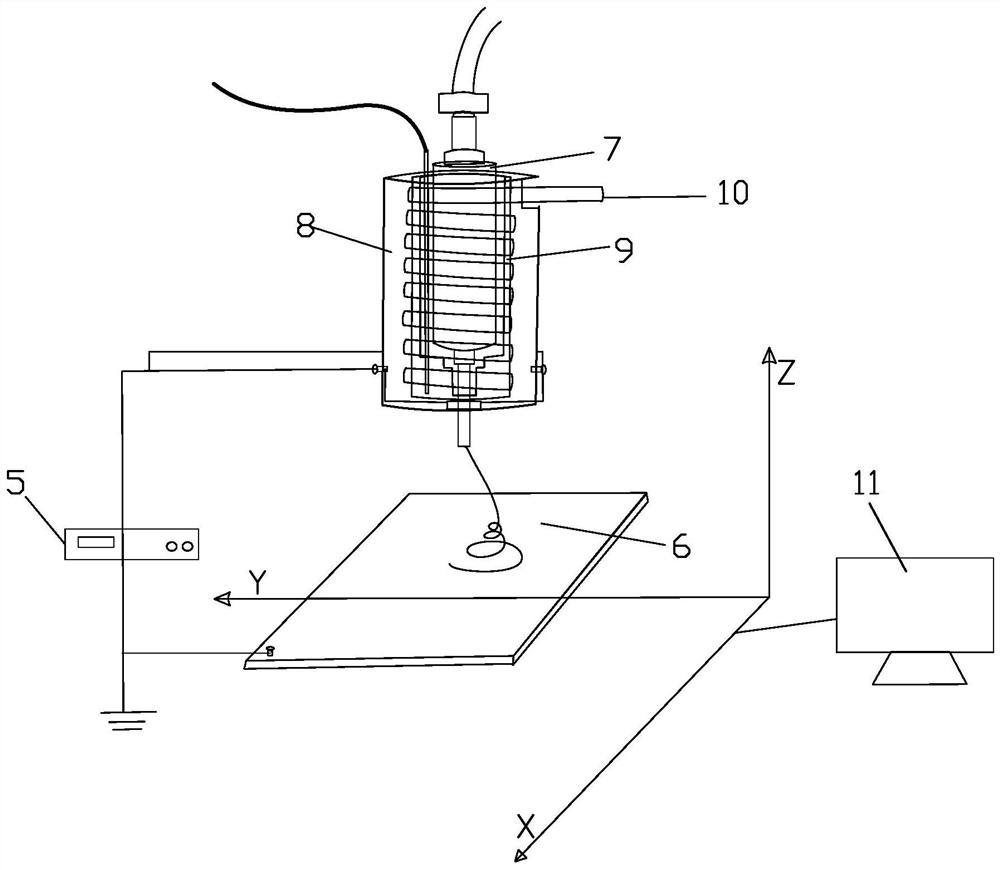

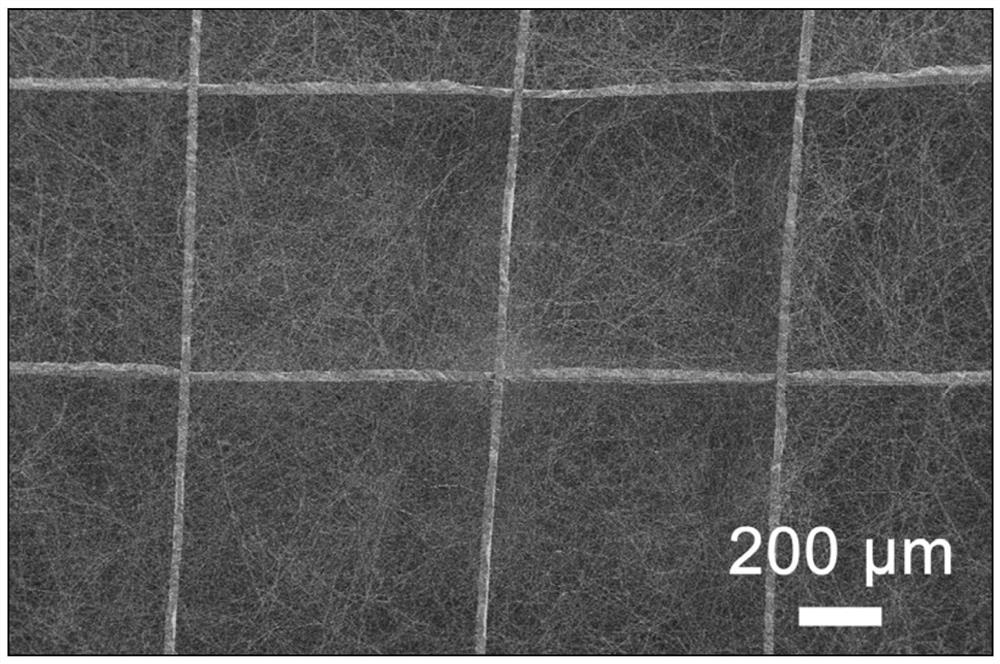

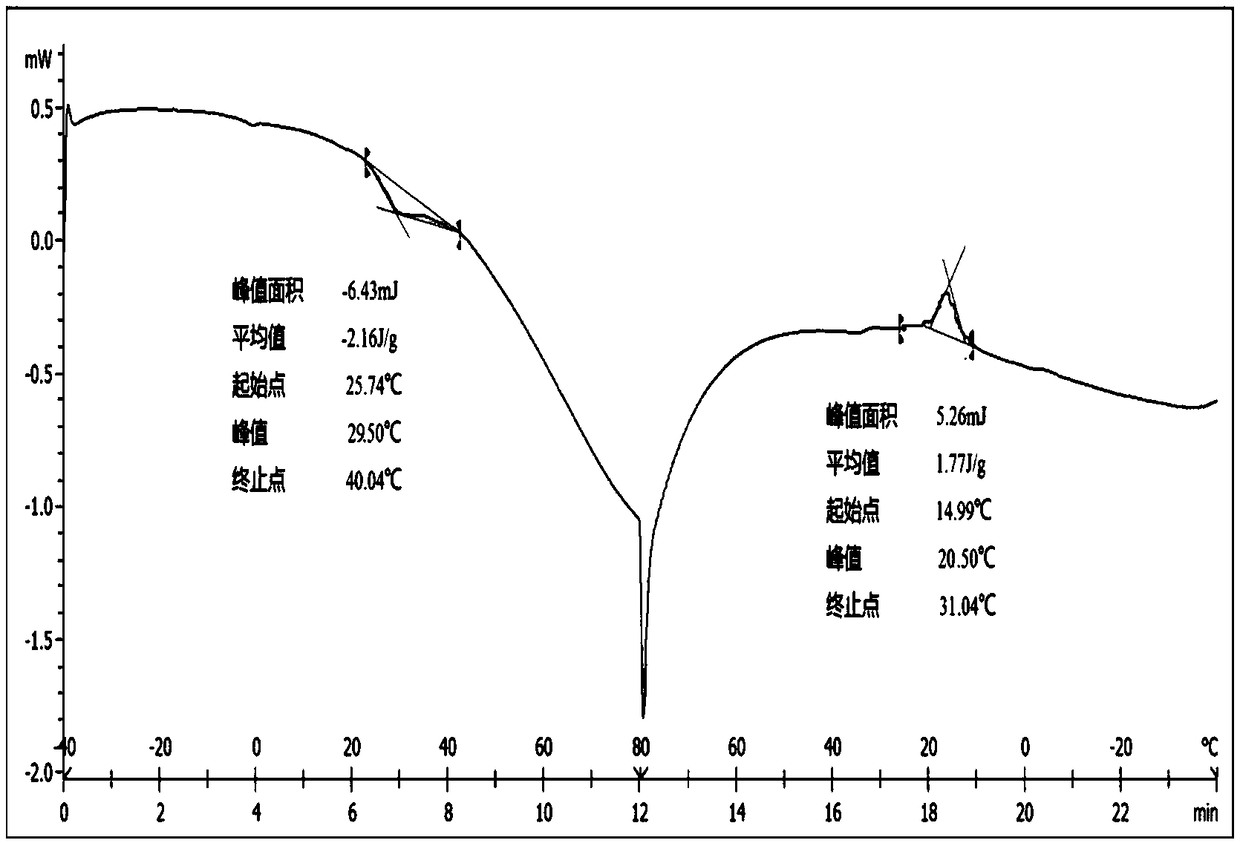

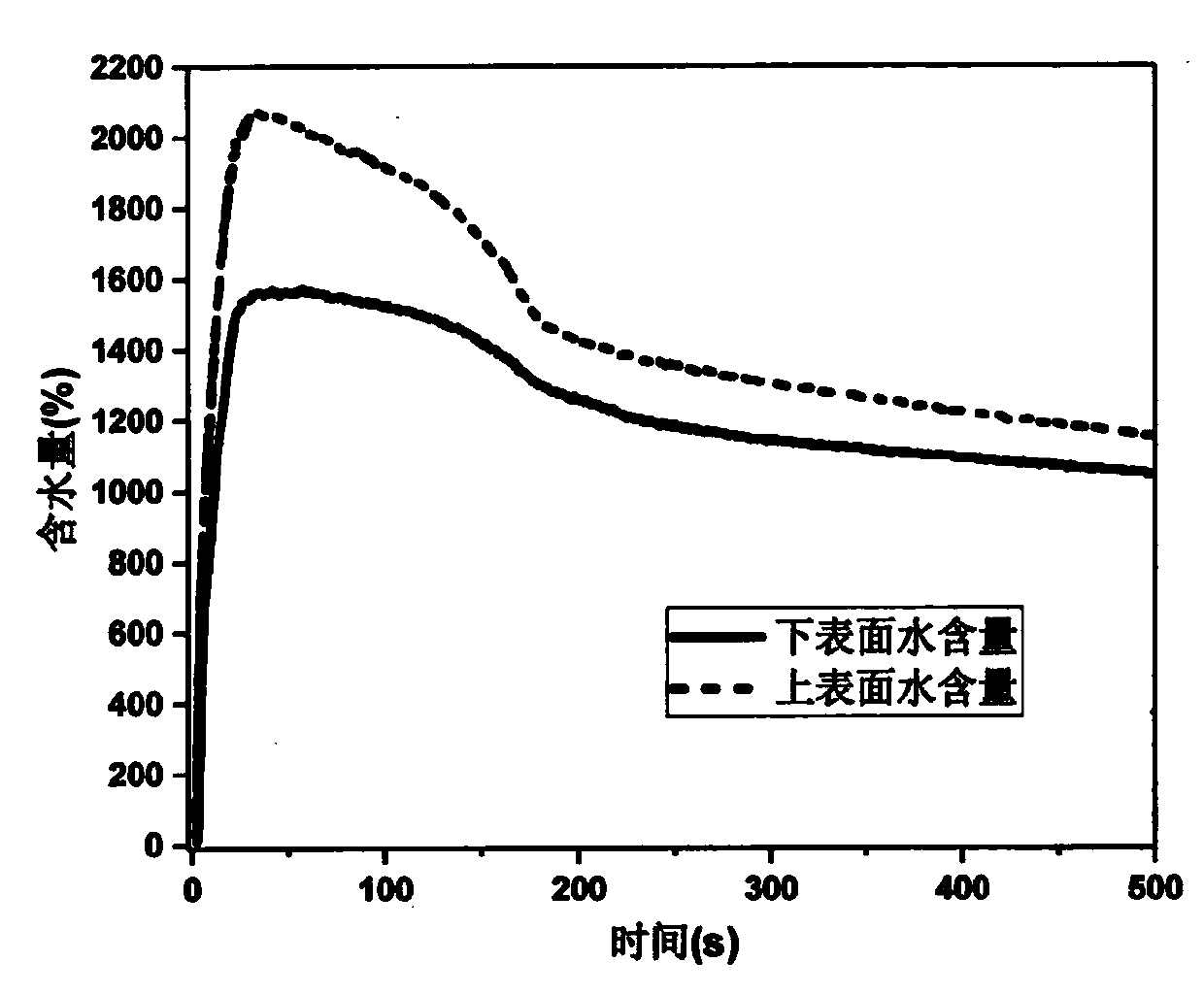

Preparation method of double-layer one-way moisture-conducting micro-nano fiber membrane based on near-field direct writing and solution electrospinning technology

ActiveCN113249875AFast evaporationThin diameterAdditive manufacturing apparatusElectro-spinningMicro nanoPolymer science

The invention discloses a preparation method of a double-layer one-way moisture-conducting micro-nano fiber membrane based on a near-field direct writing and solution electrospinning technology. The preparation method comprises the following steps of (1) preparing a layer of disordered hydrophilic micro-nano fiber membrane A through a solution electrospinning method; and (2) carrying out melt spinning by using melt direct writing equipment, and preparing an inner-layer hydrophobic micro-nano fiber membrane B on the hydrophilic micro-nano fiber membrane A. On the basis of solution electrostatic spinning, melt direct-writing spinning is added, so that accurate control over the pore size of the fiber membranes is facilitated, the topological structures of the fiber membranes can be constructed by printing preset grid patterns, then the requirement for permeation of liquid drops with different diameters is met, and the moisture absorption efficiency is improved. The micro-nanofiber membrane with an excellent one-way moisture guiding function can be prepared by combining the solution electrostatic spinning and the melt direct-writing spinning, the moisture absorption rate is adjusted, and the one-way moisture guiding performance of the micro-nano fiber membrane is further improved. The composite fiber membrane has a huge application prospect in the aspects of sportswear, paper diapers and medical dressings.

Owner:ZHEJIANG SCI-TECH UNIV

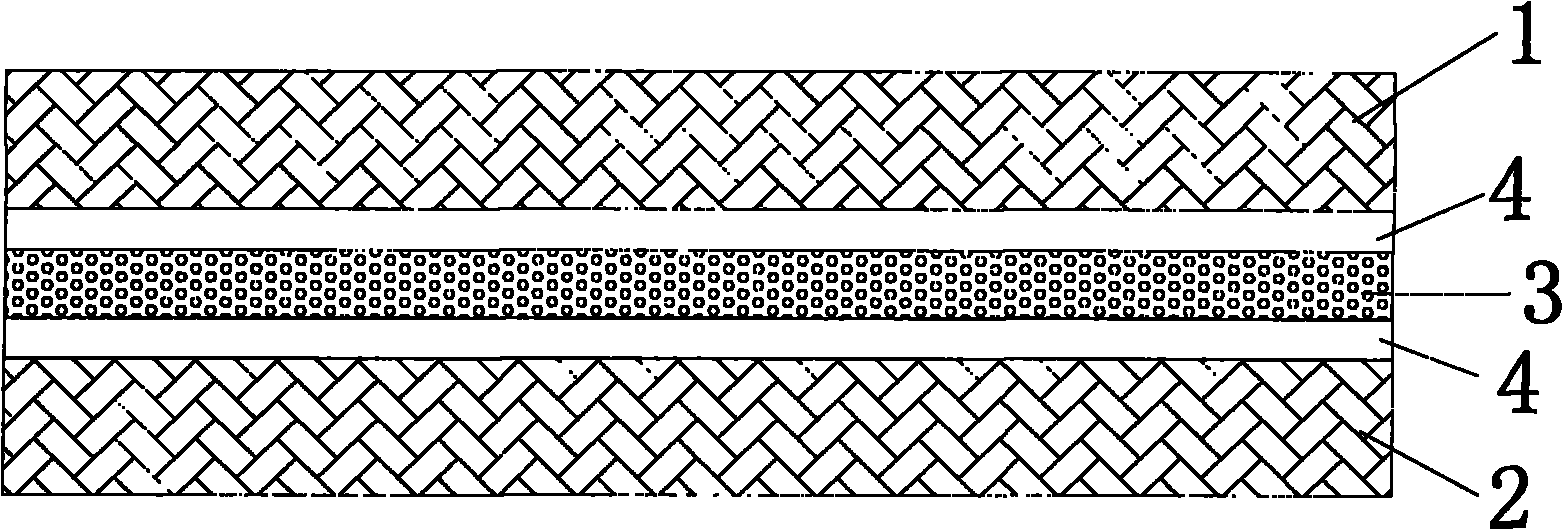

Three-layer heat insulation material

InactiveCN106585021AIt has the effect of windproof and breathableLow thermal conductivitySynthetic resin layered productsProtective garmentInsulation layerInter layer

The invention discloses a three-layer heat insulation material. The three-layer heat insulation material comprises a surface layer, a middle layer and a lining layer, and the surface layer and the lining layer are respectively compounded to the upper surface and the lower surface of the middle layer. The surface layer is a coated layer, the coated layer is attached with a plastic film through a coating technology, and the surface of the coated layer is uniformly provided with a plurality of small holes, and has windproof and breathable effects; the middle layer is a heat insulation material, the heat insulation layer is a multilayer structured fabric, polyimide fabric layers and heat insulation filler layers are selected at intervals in the heat insulation layer, the heat conduction coefficient of every polyimide fabric layer is low, and the 300 DEG C heat conduction coefficient is 0.03 w / (m*k), so the heat insulation material has good heat insulation performance; and the lining layer is a comfortable layer, and the material of the comfortable layer adopts a fabric with skin-friendly, moisture absorbing, moisture guiding and moisture dissipating performances, so the integral heat insulation material has good moisture absorbing and breathing functions.

Owner:南通盛园色织有限公司

Sheath-core natural antibacterial healthcare ultraviolet-proof polypropylene fiber

InactiveCN103710778AGood moisture managementImprove perspirationFilament/thread formingMonocomponent polypropylene artificial filamentTransdermal absorptionPolypropylene fiber

The invention provides a sheath-core natural antibacterial healthcare ultraviolet-proof polypropylene fiber. The sheath-core natural antibacterial healthcare ultraviolet-proof polypropylene fiber comprises a core layer and a sheath layer, wherein the core layer is completely wrapped by the sheath layer and is not exposed; the component of the sheath layer is polypropylene; the component of the core layer is a mixture of plant extracts and polypropylene, the weight of the plant extracts accounts for 35-65% of the total weight of the core layer component, the weight of the polypropylene accounts for 35-65% of the total weight of the core layer component; the weight ratio of the sheath layer component to the core layer component is (70-35): (30-65). Therefore, the sheath-core natural antibacterial healthcare ultraviolet-proof polypropylene fiber has the advantages that the plant extracts can be effectively prevented from being lost in storage and processing processes, the polypropylene fiber has high antibacterial efficiency, strong transdermal absorption capacity and good skin affinity, when the polypropylene fiber is in direct contact with the skin of a human body, the polypropylene fiber is antibacterial and ultraviolet-proof and meanwhile releases nutritional ingredients to be adsorbed by the skin, the perfect combination among the fiber, skin care, body building, life cultivation and health preservation is realized, and by using the polypropylene fiber, the human body can obtain more health benefits. Waste resources are recycled; the sheath-core natural antibacterial healthcare ultraviolet-proof polypropylene fiber has enormous social, ecological, environmental and economic benefits.

Owner:绍兴东盛京纺织服装有限公司

Sports garments with enhanced visual and/or moisture management properties

ActiveUS9241516B2Increase awarenessGood moisture managementGarment special featuresBall sportsVisibilityEngineering

A garment, such as a sports uniform, may provide visibility zones and / or flicker zones to enhance the ability of teammates to perceive the wearer. Different zones on a garment may have different sets of visual properties that may contrast with one another and / or a visual background. A denier differential between layers of a garment may facilitate moisture transport across the layers of the garment. Flicker zones may be discrete from or combined with visibility zones. One or more zones of a garment may also be substantially non-reflective at wavelengths associated with the visual background encountered while wearing the garment.

Owner:NIKE INC

Production method of moisture-absorption, moisture-conduction and temperature-adjusting fabric

InactiveCN109112700AGood moisture managementGood moisture absorptionMulti-ply fabricsCotton fibreYarn

The invention discloses the production method of a moisture-absorption, moisture-conduction and temperature-adjusting fabric. The fabric is formed through interweaving moisture-conduction performanceyarns, moisture-absorption performance yarns and temperature-adjusting performance yarns. The moisture-conduction performance yarns are formed through blending coolmax fibers and cotton fibers. Moisture-absorption function yarns are pure viscose yarns. The temperature-adjusting performance yarns are made through blending the cotton fibers and Outlast fibers. In the invention, the fabric has moisture-absorption, moisture-conduction and temperature-adjusting functions, through adopting single-layer, double-layer and three-layer structures, different structure fabrics have the different degrees of moisture-absorption, moisture-conduction and temperature-adjusting functions, the different demands of people can be satisfied, practicality is high, and a suitable range is wide.

Owner:XI'AN POLYTECHNIC UNIVERSITY

Moisture-management in hydrophilic fibers

ActiveUS20080128044A1Improved moisture-management performanceImprove performanceMechanical impurity removalLubricating devicesHydrophilizationPolymer science

Provided is a fabric having improved moisture-management performance and being resilient to repeated washing, as well as a process for manufacturing the fabric. The process, employing consecutive steps of hydrophilization and hydrophobization, includes defatting cotton or cellulose fibers and their coating with silicone nanoparticles.

Owner:DELTA GALIL INDUSTRIES

Organic fiber surface chromium-plating method

An organic fiber surface chromium-plating method belongs to the field of a vacuum coating and electroplating technology. According to the invention, quality and production lot-sizing problems of chromium-plated organic fiber are mainly solved. By a physical vapor deposition technology and a composite coating technology, organic fiber tow and organic fiber fabric are firstly arranged to be smooth and packaged to be tidy; the materials are put into a vacuum chamber to undergo magnetron sputtering chromium-plating and single-layer or multi-layer continuous coating; and according to different usage requirements, composite chromium film electroplating is carried out. The method has advantages of strong binding force between metallic chromium ions and organic fiber, no pollution, low cost and continuous production. The product is used in the industries such as electron, military communication, medical treatment and special textile, etc. By the method, products such as manufacture products such as electronic screening products, military screening tents, special textile antibacterial materials and health-care textile products for civil use can be manufactured.

Owner:WUXI HUIMING ELECTRONICS TECH

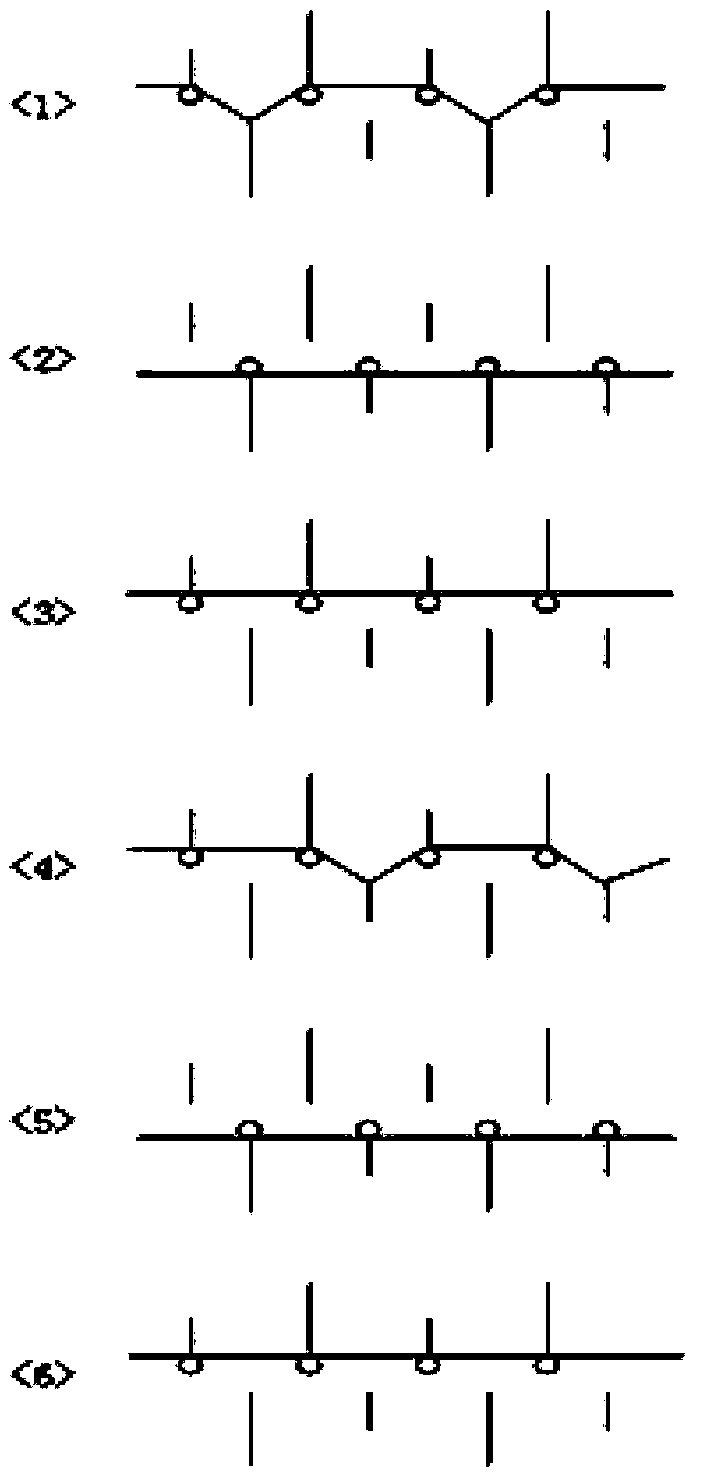

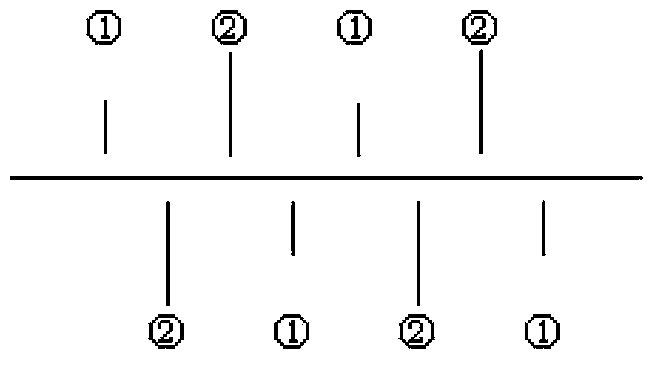

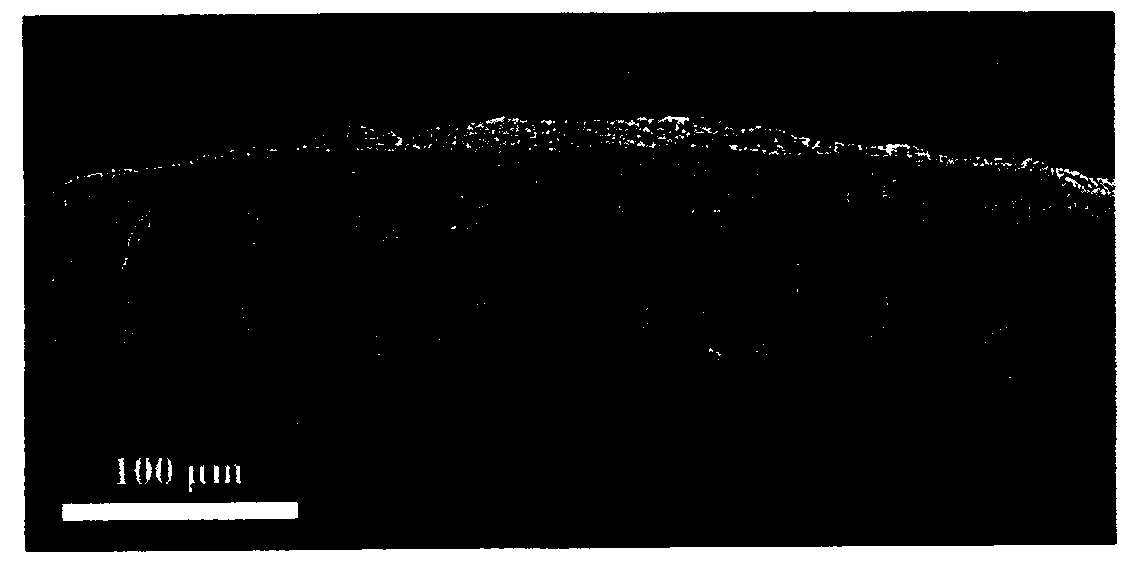

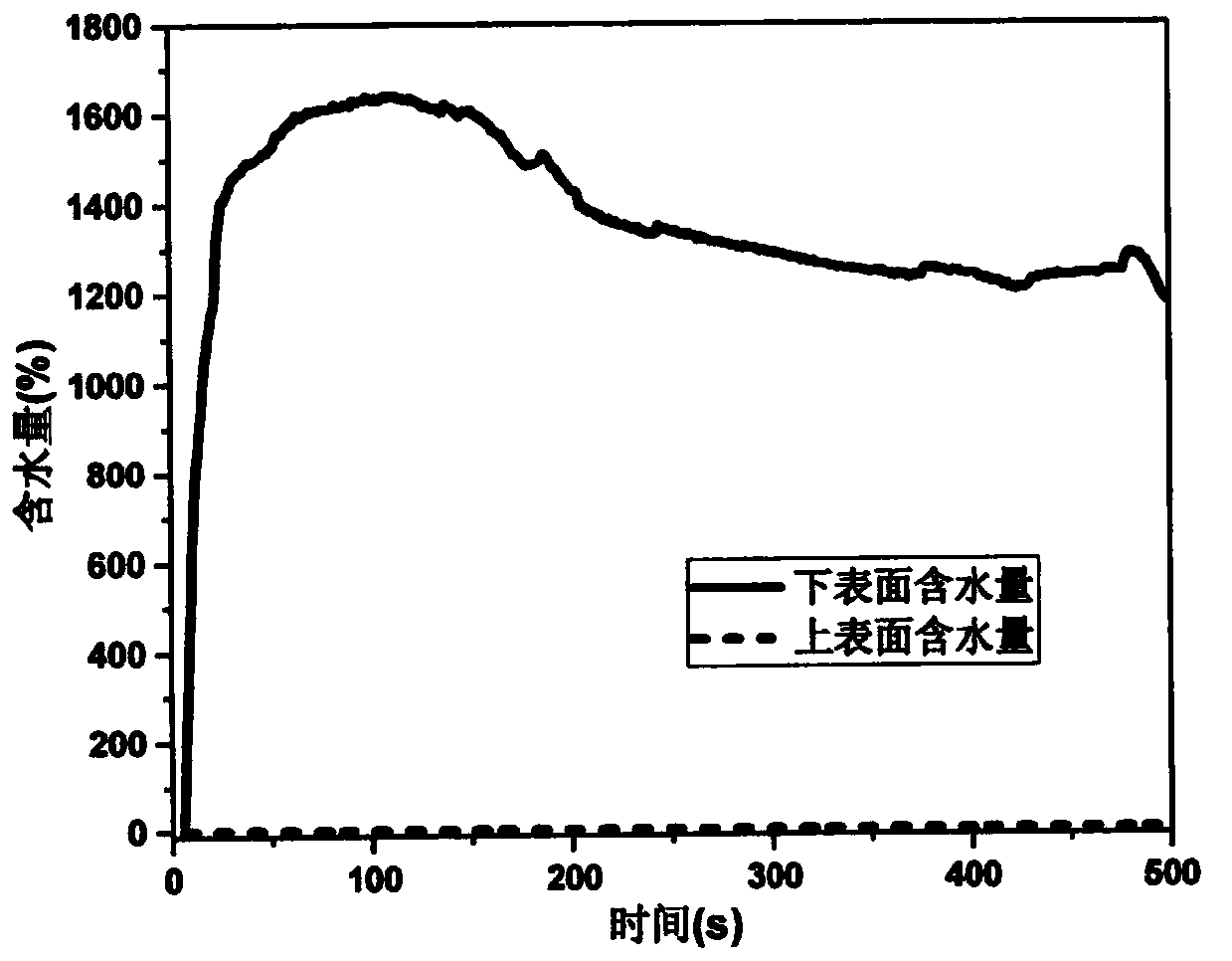

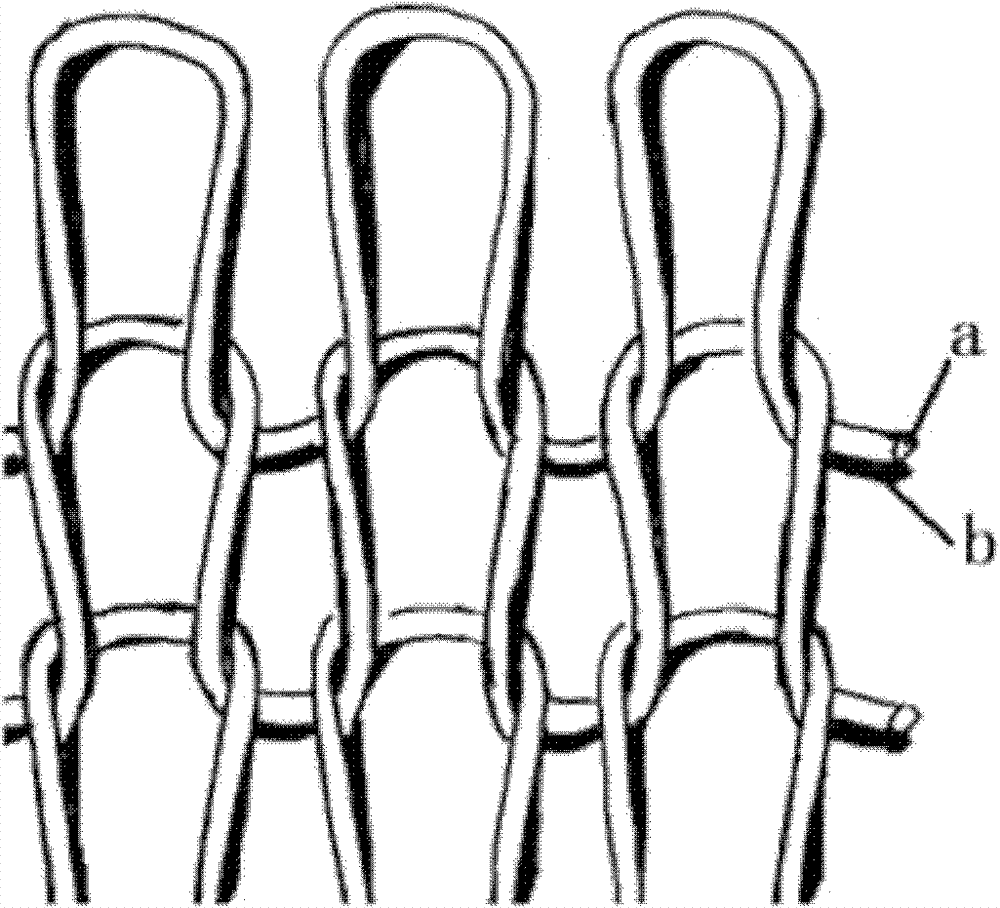

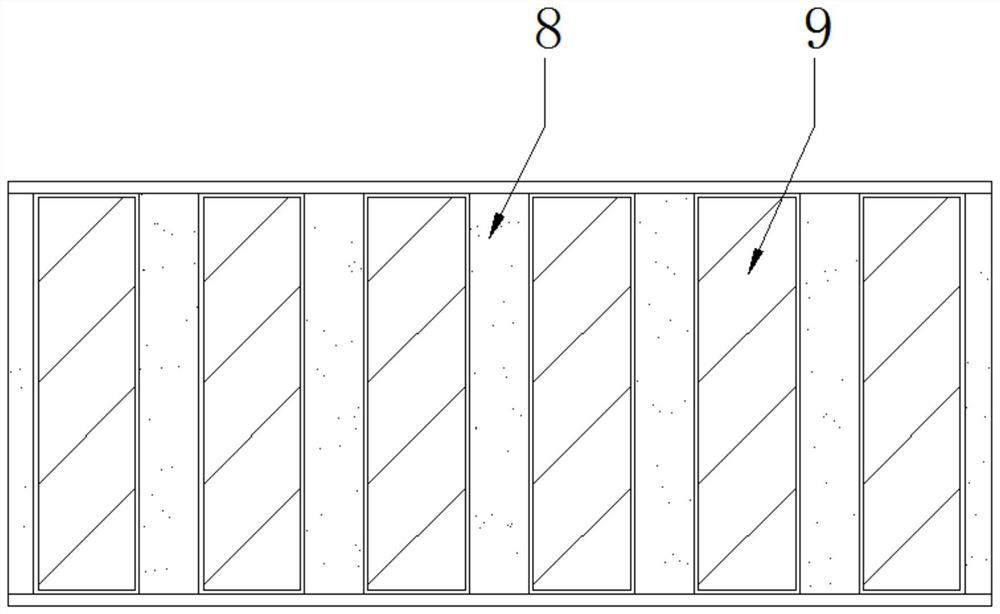

Damp guiding breathable alkali-free mercerizing fabric having germanium ion healthcare function and processing method thereof

ActiveCN103572484AWith germanium ion health functionGood moisture absorption and air permeabilityMercerising of indefinite length fabricsWeft knittingAlkali freeCotton fibre

The invention discloses damp guiding breathable alkali-free mercerizing fabric having a germanium ion healthcare function and a processing method thereof. The fabric is in a double-layer double-sided mesh structure; a next-to-skin side of the fabric namely an internal layer is germanium ion functional fibers; the other side namely an external layer is pure cotton fabric; the internal layer and the external layer are connected through deformed sectional dacron long fibers with the surfaces provided with grooves. A weaving method comprises weaving through a double-sided machine, enabling ribs to be arranged in a facing mode, upper stitches to be in a low-high arrangement and lower stitches to be in a high-low arrangement and enabling a weaving process to be cycled by six routes. A threading method comprises threading a second route and a fifth route with the germanium ion functional fibers to weave the internal-layer mesh structure, threading a third route and a sixth route with the cotton fibers to weave the external-layer mesh structure, threading a first route and a fourth route with the deformed sectional dacron long fibers with the surfaces provided with the grooves to weave connecting portions between the internal layer and the external layer. The damp guiding breathable alkali-free mercerizing fabric having the germanium ion healthcare function has smooth touch and silkiness gloss after non-alkali mercerizing finishing agent DGF processing. The fabric has the germanium ion healthcare function, is good in damp guiding and air breathable performance and has soft and smooth touch.

Owner:SHANGHAI JIALE

Preparation method of unidirectional moisture-guiding nanofiber multilayer composite membrane with wetting gradient

InactiveCN107059251BHas super hydrophilic/hydrophobic propertiesStructural regulationNon-woven fabricsFiberPolymer science

The invention discloses a preparation method of a one-way wet conduction nano-fiber multilayer composite membrane with the wettability gradient. The method comprises the following steps that hydrophilic nano materials are dispersed in solvent, the nano materials are dispersed uniformly through ultrasound, a hydrophilic polymer is dissolved in the dispersing agent, a spinning solution A1 is obtained, and a hydrophilic nano-fiber membrane is deposited on a receiving base material through an electrostatic spinning method; hydrophilic nano materials are dispersed in solvent, the nano materials are dispersed uniformly through the ultrasound, a hydrophilic polymer is dissolved in the dispersing agent, and a spinning solution A2 is obtained; a hydrophobic polymer is dissolved in solvent, and a spinning solution B1 is obtained; the two spinning solutions are deposited on the hydrophilic nano-fiber membrane to form at least one diversion layer through the electrostatic spinning method; a hydrophobic polymer is dissolved in solvent, a spinning solution B2 is obtained, a hydrophobic nano-fiber membrane is deposited on the diversion layers through the electrostatic spinning method, and the one-way wet conduction nano-fiber multilayer composite membrane with the wettability gradient is obtained.

Owner:DONGHUA UNIV

Single face moisture-conductive antibacterial sock

The invention provides a single-sided moisture-conducting antibacterial sock, which comprises a sock main body, a storage decorative border, a hemming edge and a storage pull wire; the sock main body includes a dust-proof outer layer, an antibacterial layer, an elastic layer, a one-way moisture-conducting Fabric layer, thermal insulation layer and thickening layer; dustproof outer layer, elastic layer and antibacterial layer are seamed sequentially through seams from outside to inside, and the unidirectional moisture-wicking layer and mesh fabric layer are seamed through seams and passed through seams Connected to the sole opening of the sock structure, the mesh fabric layer is located on the inner side of the one-way moisture-wicking layer; the insulation layer is wrapped on the outer end surface of the sock structure, and the thickened layer is wrapped on the outer end surface of the sock structure, and the decorative edge and socks are stored In the main body, the wrapping edge has a ring structure and is arranged at the lower end edge of the storage decoration surround, and the storage pull wire is arranged in the wrapping edge. The invention has the advantages of good heat preservation, anti-wear, antibacterial and moisture conduction, etc., can keep the feet warm and dry, improves wearing comfort, and is beneficial to the health of the feet.

Owner:HAINING HAD SOCKS

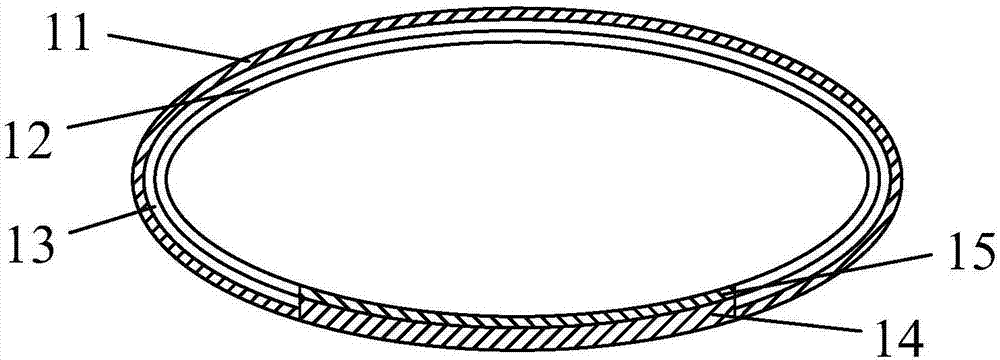

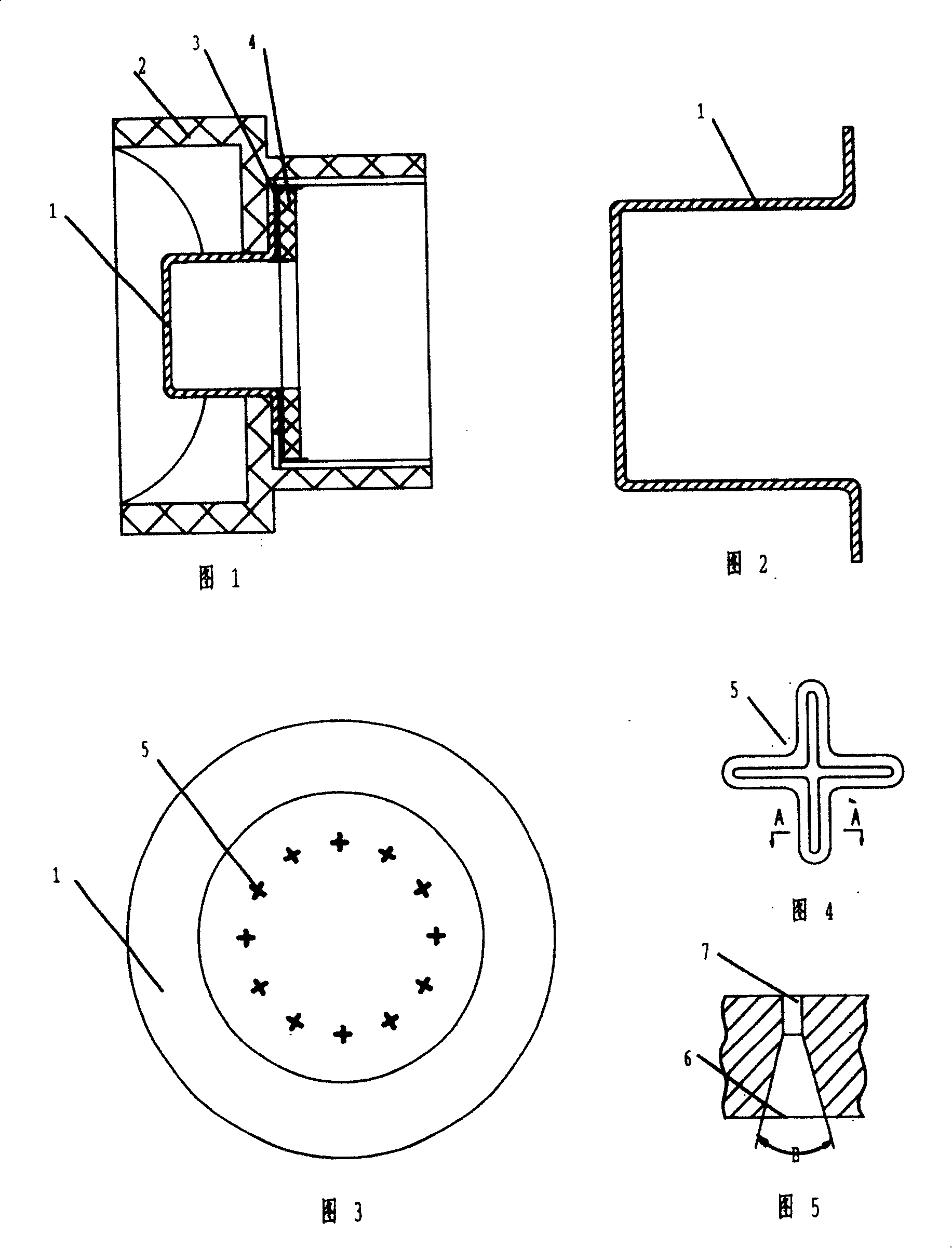

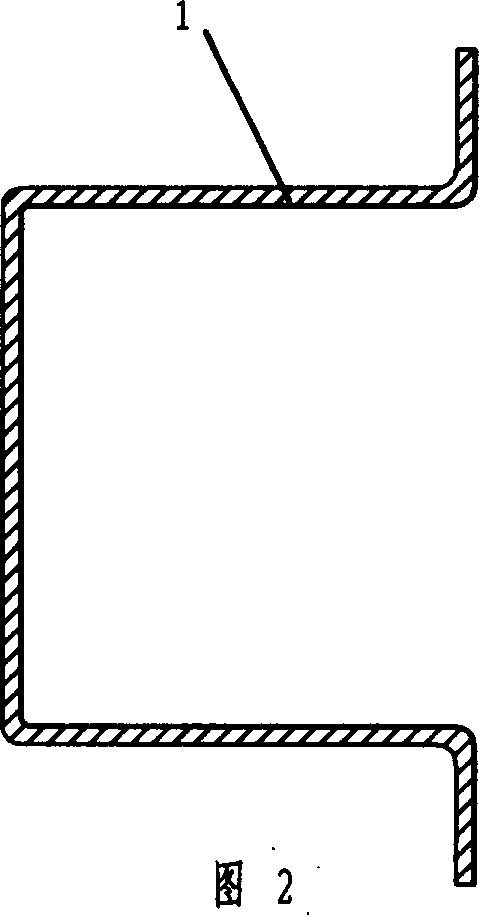

Viscose filament with abnormal section, preparation method thereof and spinneret assembly

InactiveCN100402712CIncrease air volumeGood moisture managementWet spinning methodsTextile technologyYarn

The invention relates to an abnormal section mucilage glue filament and the method to manufacture, and the thread spurting component that is used to solve the manufacture problem of crisscross mucilage glue filament. It belongs to weave technology field. The process is that: there are four ramifications on the section of the mucilage glue, which are crisscrossed, and the length-width ratio of the ramification is from 3 to 10:1. The invention has crisscrossed section, thus its wet-transmitting capability, sweating capability, and gas permeability are better than that of flat silk and trilobite silk. It is the ideal material for comfortable and functionality textile.

Owner:BAODING SWAN NEW FIBER MFG CO LTD

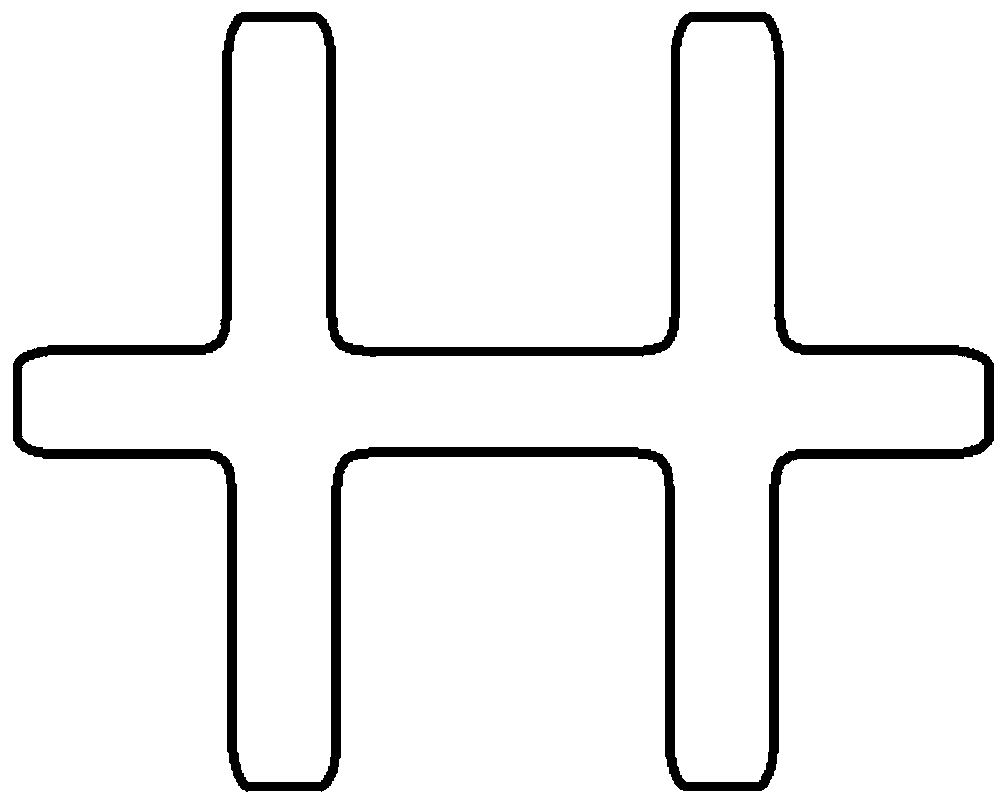

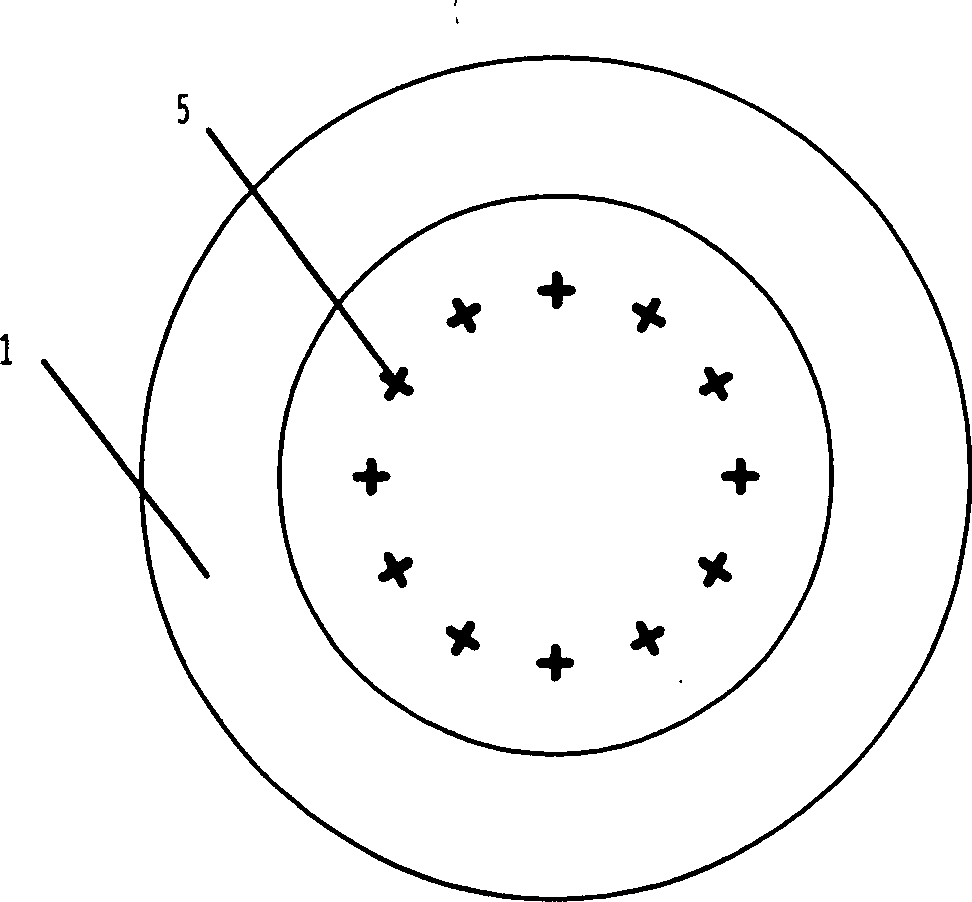

Modified cross-section fiber and moisture-absorbing and quick-drying fabric prepared from modified cross-section fiber

ActiveCN108642592AGood moisture absorptionGood moisture managementFilament/thread formingMonocomponent copolyesters artificial filamentTextile fiberPolyethylene terephthalate glycol

The invention relates to a modified cross-section fiber and a moisture-absorbing and quick-drying fabric prepared from the modified cross-section fiber, and relates to the technical field of textile fibers. The modified cross-section fiber is a non-circular modified cross-section fiber produced by spinning of a modified polyester chip, the modified cross-section fiber has at least two grooves, theratio of the height (L1) of the grooves to the width (L2) of the grooves is 0.5 or more, and the modified polyester chip is obtained by transesterification and polycondensation reaction of a reactionraw material containing terephthalic acid or polyethylene terephthalate and ethylene glycol. The moisture-absorbing and quick-drying fabric prepared from the modified cross-section fiber has good moisture absorption, moisture guiding and quick-drying effects, has good wearing comfort, no moisture-reducing phenomenon and can maintain a long-lasting antibacterial property.

Owner:JIAXING FUSHENGDA DYEING & FINISHING

Viscose filament with abnormal section, preparation method thereof and spinneret assembly

InactiveCN1667163AIncrease air volumeGood moisture managementWet spinning methodsTextile technologyYarn

The invention relates to an abnormal section mucilage glue filament and the method to manufacture, and the thread spurting component that is used to solve the manufacture problem of crisscross mucilage glue filament. It belongs to weave technology field. The process is that: there are four ramifications on the section of the mucilage glue, which are crisscrossed, and the length-width ratio of the ramification is from 3 to 10:1. The invention has crisscrossed section, thus its wet-transmitting capability, sweating capability, and gas permeability are better than that of flat silk and trilobite silk. It is the ideal material for comfortable and functionality textile.

Owner:BAODING SWAN NEW FIBER MFG CO LTD

Wool-imitated tricot lace fabric

ActiveCN106319749AImprove antistatic performanceKeep warmFlame-proof filament manufactureOrnamental textile articlesPolyesterPolymer science

The invention relates to a wool-imitated tricot lace fabric. Anti-static polyester fibers on an anti-static layer and acrylic fibers on a wool-imitated layer are connected in a warp knitted weaving manner; the acrylic fibers on the wool-imitated layer and hollow polyester fibers on a hollow heat preservation layer are connected in the warp knitted weaving manner; the hollow polyester fibers on the hollow heat preservation layer and modified nylon fibers on a functional heat preservation layer are connected in the warp knitted weaving manner. According to the wool-imitated tricot lace fabric, by the arrangement of the anti-static layer, the problem of low antistatic property of the wool-imitated tricot lace fabric is avoided; meanwhile, by adoption of the wool-imitated layer with the acrylic fibers serving as a raw material and the hollow polyester fibers serving as a material of the hollow heat preservation layer, the heat preservation effect of the fabric is enhanced on the basis of guaranteeing the wool imitation style of the fabric, and the wool imitation property of the fabric is further improved; moreover, by adoption of the functional heat preservation layer with the modified nylon fibers which serve as a raw material and have excellent in skin friendliness to a human body, the skin friendliness of the fabric is improved, and the wool imitation effect of the prepared wool-imitated tricot lace fabric is enhanced.

Owner:FUJIAN BAIKAI WARP KNITTING INDUSTRY CO LTD

Knitted fabric with multiple functions of keeping warm, absorbing moisture, releasing sweat and resisting bacteria and weaving method

The invention relates to a knitted fabric with multiple functions of keeping warm, absorbing moisture, releasing sweat and resisting bacteria. The knitted fabric comprises an outer layer, a middle layer and an inner layer, wherein the outer layer and the inner layer are connected with the middle layer through double-sided knitted structures; the outer layer has double-loop structure formed by interweaving hydrophilic yarns and elastic yarns; the inner layer has double-loop structure formed by interweaving moisture-transfer functional yarns containing antibacterial substances and elastic yarns; and the middle layer is made of elastic yarns with moisture-transfer function. A weaving method for the fabric comprises the following steps of: arranging a dial needle and a cylinder needle on a double-sided circular weft knitting machine in a double-rib arrangement mode; weaving the outer layer of the fabric by loops on the dial needle in a plaiting mode; weaving the inner layer of the fabric by loops on the cylinder needle in a plaiting mode; and finally weaving the middle layer of the fabric, and connecting the middle layer, the inner layer and the outer layer. The fabric has multiple functions of keeping warm, absorbing moisture, releasing sweat and resisting bacteria, has integral elasticity, and has the characteristics of flat appearance, massiveness, soft handfeel and the like.

Owner:上海嘉麟杰纺织科技有限公司

Preparation method of non-woven material used for wiping cloth

InactiveCN108660610AEnhance capillary wicking effectFluffy goodNon-woven fabricsPolymer scienceCarding

The invention relates to a preparation method of a non-woven material used for wiping cloth, and belongs to the technical field of the wiping cloth. In the preparation method, by adopting fine polyester filament yarn which is fine in capillary, large in amount and capable of remarkably enhancing the capillary wicking effect of a fabric and then improving the air permeability and the wet permeability of the fabric, with the combination of the structural characteristics of kawo kawo fibers and poplar floccus fibers that the longitudinal sections are cylindrical, the surface is smooth, the fibersare soft and lustrous, the cross sections are circular or elliptic, the walls of the fibers are thin, and the fibers are hollow, preparation is conducted through multi-layer laying and mixing, carding and web forming are conducted after opening, and a single-layer fiber web is prepared, wherein the single-layer fiber web is high in degree of hollowness, small in fineness, obvious in wicking effect, short in moisture sorption equilibrium time and high in wet permeability, the fiber surface contains cerolipoid, so that the fiber web has wettability resistance, and the fluffy performance and theelastic recovery performance of the fibers are high; the single-layer fiber web is combined with a single-layer wear-resistant fiber web, and the single-layer fiber web and the single-layer wear-resistant fiber web are bonded through an ultrasonic composite technology after spunlaced finishing.

Owner:史茜赟

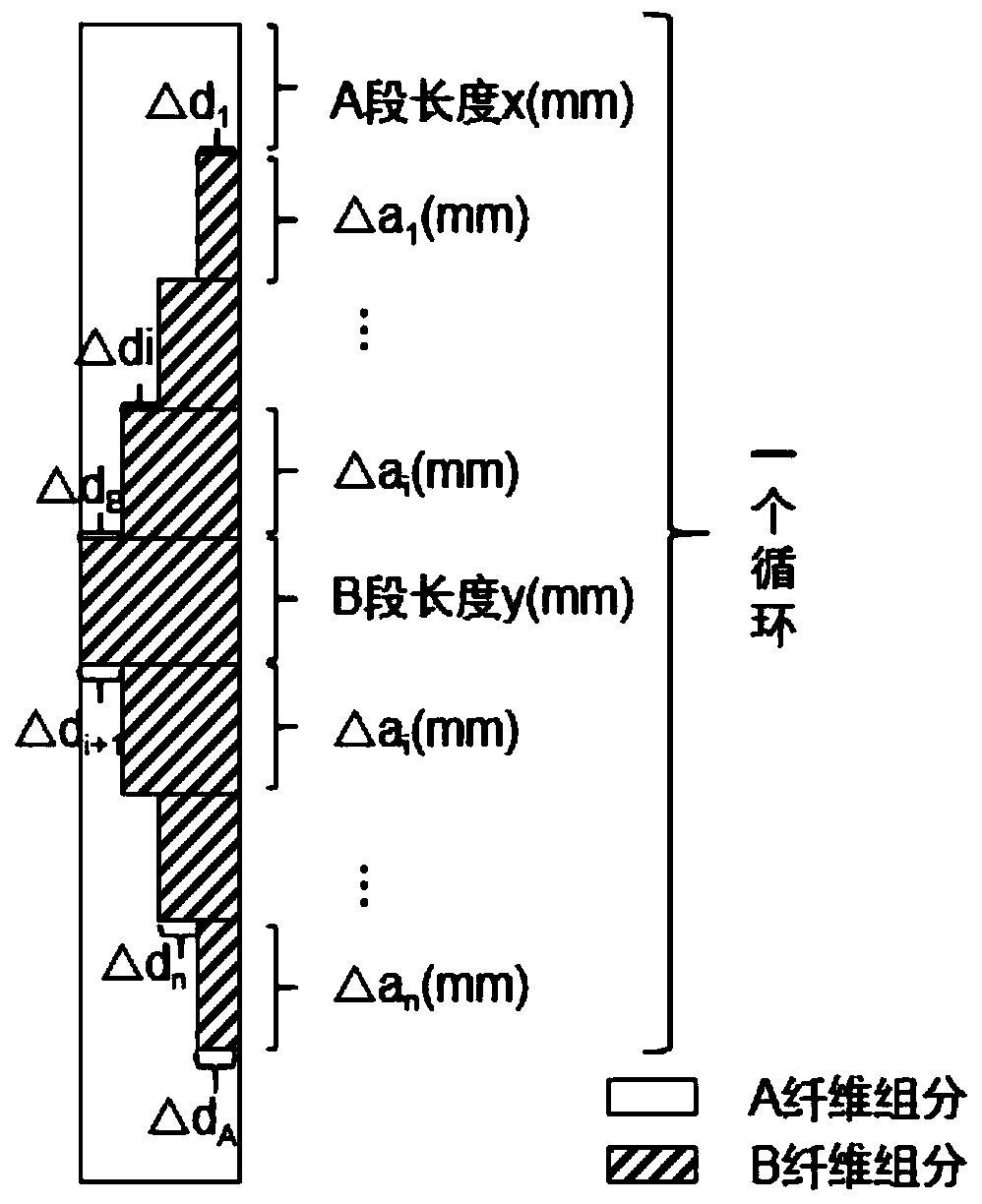

Axial heterogeneous structure moisture-absorption quick-dry yarn

The invention discloses an axial heterogeneous structure moisture-absorption quick-dry yarn. The axial heterogeneous structure moisture-absorption quick-dry yarn comprises two fiber components A and B with different performance. The two fiber components A and B, within a setting length, and in equal linear density and equal fiber component total proportion, are distributed along the fiber component in an axial direction of the yarn, and formed according to a setting rule change. The axial heterogeneous structure moisture-absorption quick-dry yarn is uniform in appearance, controllable in material amount, has good moisture management performance, and is capable of effectively controlling adhesion feel and cold moist feel caused by profuse sweating.

Owner:DONGHUA UNIV

Preparation method of sports bamboo fiber functional sock products

The invention discloses a preparation method of sports bamboo fiber functional sock products. The method comprises the following components in percentage by weight: 60-70% of bamboo pulp fibers, 10-20% of Xinjiang long stapled cotton fibers, 10-15% of antibacterial chinlon and 5-10% of spandex, and the bamboo pulp fibers, the Xinjiang long stapled cotton fibers, the antibacterial chinlon and the spandex are blended in proportion to obtain prepared fibers. The bamboo pulp fibers, the Xinjiang long stapled cotton fibers, the antibacterial chinlon and the spandex are prepared into bamboo cotton tough yarns and bamboo cotton flexible yarns by adopting air jet spinning, compact siro spinning and multi-component composite spinning technologies, and the three-layer composite interlayer comprises an inner soft layer, a middle ventilation layer and an outer comfortable and elastic layer according to a flexible inside and flexible outside structure design. The bamboo pulp fibers, the Xinjiang long stapled cotton fibers, the antibacterial chinlon and the spandex are adopted, breeding of bacteria can be effectively inhibited, the prepared sock product is divided into three layers, the comfort effect after wearing can be effectively improved, the inner layer of the sock product can be better skin-friendly and bacteriostatic, the middle layer can better conduct moisture and preserve heat, the breathable effect of the sock product is enhanced, and the outer layer is wear-resistant and tough.

Owner:湖南莎丽袜业股份有限公司

Fabric with heat-resistant and flame-retardant functions

InactiveCN114506138AIncreasing the thicknessAntibacterialSynthetic resin layered productsMetal layered productsPolyesterActivated carbon

The invention discloses a fabric with heat-resistant and flame-retardant functions, and relates to the technical field of fabrics, the fabric comprises an inner surface fabric layer, a middle fabric layer and an outer surface fabric layer, an anti-radiation fabric layer is fixed above the inner surface fabric layer, the middle fabric layer is fixed above the anti-radiation fabric layer, an anti-static layer is arranged on the upper side of the middle fabric layer, and the outer surface fabric layer is fixed above the anti-static layer. The outer surface fabric layer is fixed to the upper side of the anti-static layer, the breathable mesh cloth is arranged on the upper side of the outer surface fabric layer, the waterproof fabric layer is fixed to the upper side of the breathable mesh cloth, the jacquard layer is arranged on the upper side of the waterproof fabric layer, and the outer protective coatings are arranged on the surface of the jacquard layer at equal intervals. The fabric with the heat-resistant and flame-retardant functions is provided with a multi-layer composite structure, the fabric thickness and the cloth strength of the fabric are good, the fabric has the multiple functions of resisting bacteria, preventing ultraviolet rays, preventing static electricity and the like, and in addition, due to the arrangement of the composite chemical fiber layer, the flame-retardant polyester fiber layer, the activated carbon cloth and the like, the fabric with the heat-resistant and flame-retardant functions is good in heat-resistant and flame-retardant effect and wide in applicability.

Owner:牟向晖

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com