Biodegradable needling warmth retention flocculus and preparation method thereof

A technology of biodegradation and wadding, applied in the field of non-woven fabrics, can solve the problems of difficult biodegradation and high energy consumption of thermal wadding, and achieve the effects of simple process, reduced chemical gas emissions, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A biodegradable needle-punched thermal insulation flake, which is processed from Viloft fiber through carding → cross-lapping → needle-punching.

[0027] The length of the Viloft fiber is 38mm, the linear density is 2.4dtex, and the dry strength is 2.7cN·dtex -1 , wet strength 1.7cN·dtex -1 , Moisture regain 13%, dry elongation 21%, wet elongation 28%.

[0028] (1) Opening and mixing: Use automatic plucking machine or automatic weighing and mixing equipment to open the step fibers, and use multi-bin cotton blending machine or large bin cotton blending machine to mix the fibers after initial opening;

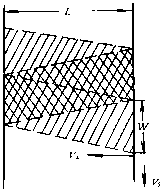

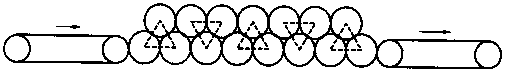

[0029] (2) Carding into a web: The fibers in step (1) are transported to the cotton box for further opening, and the opened fibers are driven by the airflow generated by the fan to pass through the exhaust fence of the lower cotton box to realize the separation of air and fiber while maintaining The horizontal distribution of fiber reserves is uniform, and the output thi...

Embodiment 2

[0036] A biodegradable needle-punched thermal insulation flake, which is processed from Viloft fiber through carding → cross-lapping → needle-punching.

[0037] The Viloft fiber length is 45mm, the linear density is 2.4dtex, and the dry strength is 2.7cN·dtex -1 , wet strength 1.7cN·dtex -1 , Moisture regain 13%, dry elongation 21%, wet elongation 28%.

[0038] (1) Opening and mixing: Use automatic plucking machine or automatic weighing and mixing equipment to open the step fibers, and use multi-bin cotton blending machine or large bin cotton blending machine to mix the fibers after initial opening;

[0039] (2) Carding into a web: The fibers in step (1) are transported to the cotton box for further opening, and the opened fibers are driven by the airflow generated by the fan to pass through the exhaust fence of the lower cotton box to realize the separation of air and fiber while maintaining The horizontal distribution of fiber reserves is uniform, and the output thickness ...

Embodiment 3

[0046] A biodegradable needle-punched thermal insulation flake, which is processed from Viloft fiber through carding → cross-lapping → needle-punching.

[0047] The Viloft fiber length is 51mm, the linear density is 2.4dtex, and the dry strength is 2.7cN·dtex -1 , wet strength 1.7cN·dtex -1 , Moisture regain 13%, dry elongation 21%, wet elongation 28%.

[0048] (1) Opening and mixing: Use automatic plucking machine or automatic weighing and mixing equipment to open the step fibers, and use multi-bin cotton blending machine or large bin cotton blending machine to mix the fibers after initial opening;

[0049] (2) Carding into a web: The fibers in step (1) are transported to the cotton box for further opening, and the opened fibers are driven by the airflow generated by the fan to pass through the exhaust fence of the lower cotton box to realize the separation of air and fiber while maintaining The horizontal distribution of fiber reserves is uniform, and the output thickness ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com