Axial heterogeneous structure moisture-absorption quick-dry yarn

A hygroscopic, quick-drying, non-uniform technology, used in the field of textile product manufacturing to achieve uniform appearance, control of adhesion and coldness, and controllable amount of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] In this implementation, the basic specifications of the yarn: twist coefficient 360, yarn count 40s, cotton fiber / Coolsmart moisture-conducting polyester 70 / 30.

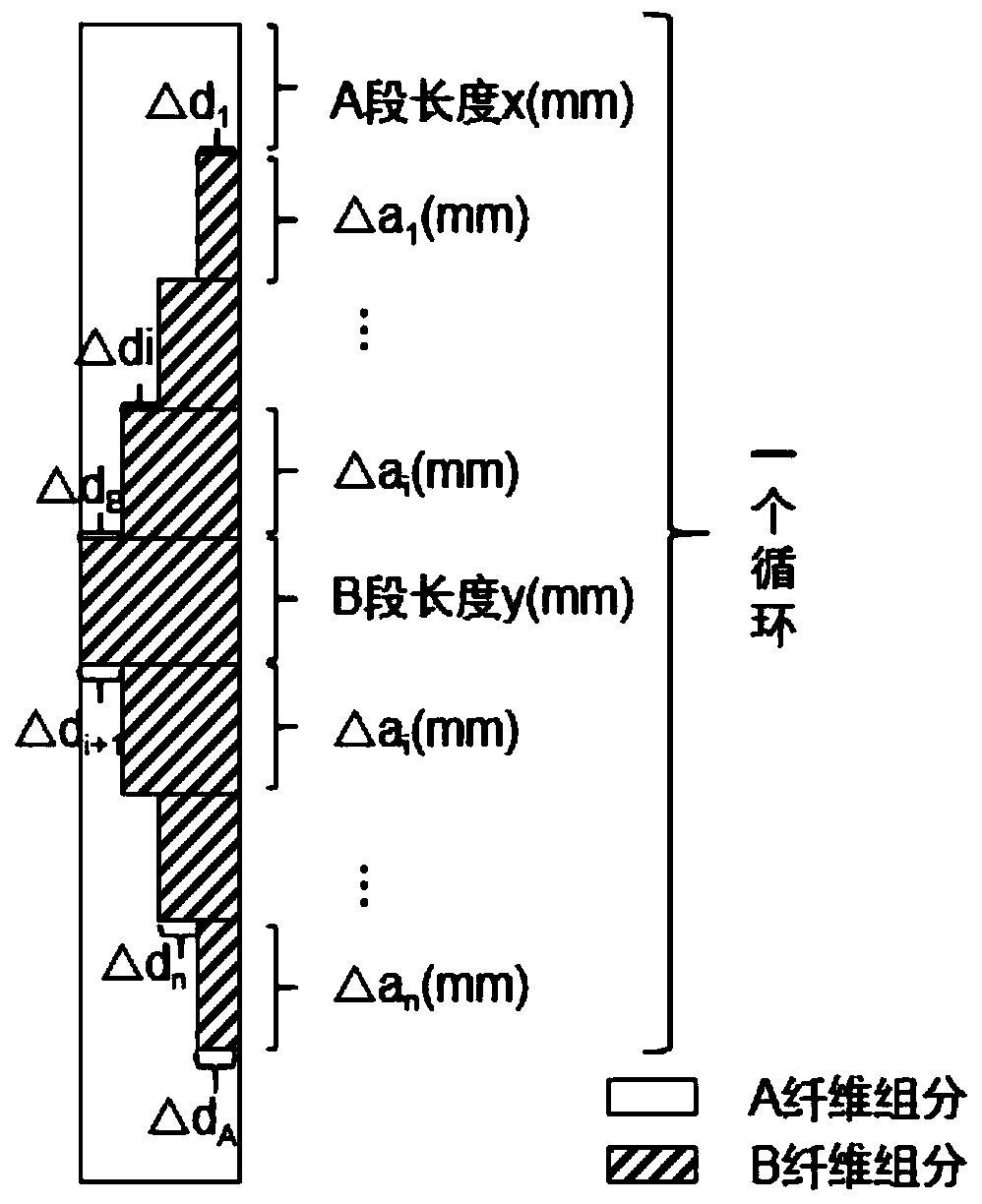

[0032] Distribution law of fiber components: A is cotton fiber, B is Coolsmart moisture-wicking polyester, △d=0.5, z=40mm, length of section B is y=z=40mm, length of section A is x=147mm.

[0033] Compared with the uniform blended yarn of the same raw material and specification, the yarn has better moisture management performance. Meet the requirements of general moisture absorption and quick-drying fabrics.

Embodiment 2

[0035] In this implementation, the basic specifications of the yarn: twist coefficient 360, yarn count 40s, cotton fiber / Coolsmart moisture-conducting polyester 50 / 50;

[0036] Distribution law of fiber components: A is cotton fiber, B is Coolsmart moisture-conducting polyester, △d=0.5, z=40mm, section B length y=z=40mm, section A length x=40mm.

Embodiment 3

[0038] In this implementation, the basic specifications of the yarn: twist coefficient 360, yarn count 40s, cotton fiber / Coolsmart moisture-conducting polyester 50 / 50;

[0039] Distribution law of fiber components: A is cotton fiber, B is Coolsmart moisture-conducting polyester, △d=0.2, z=40mm, section B length y=z=40mm, section A length x=40mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com