Wool-imitated tricot lace fabric

A technology of warp knitting and wool, which is applied in the direction of warp knitting, hollow filament manufacturing, fireproof and flame retardant filament manufacturing, etc. It can solve the problems of fluffing and poor antistatic property

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

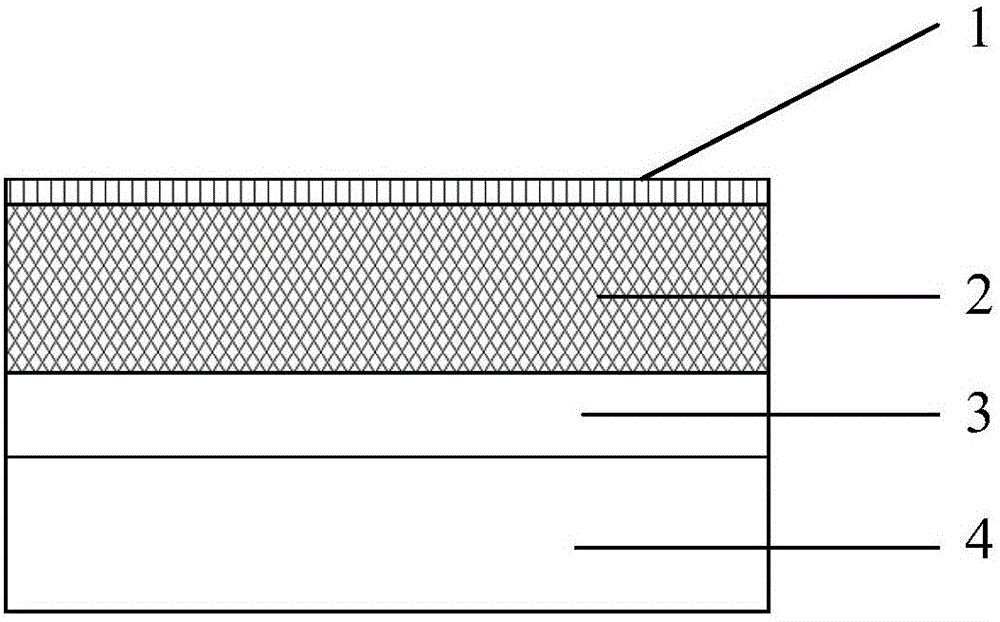

[0053] Such as figure 1 , 2, 3, 4 and Figure 5 As shown, a wool-like warp-knitted lace fabric is divided into four layers, from top to bottom are antistatic layer, wool-like layer, hollow thermal insulation layer and functional thermal insulation layer; the raw material of antistatic layer is antistatic polyester fiber, the raw material of the wool-like layer is acrylic fiber, the raw material of the hollow thermal insulation layer is hollow polyester fiber, and the raw material of the functional thermal insulation layer is modified nylon fiber; the antistatic polyester fiber of the antistatic layer and the acrylic fiber of the wool-like layer are processed The acrylic fibers of the wool-like layer and the hollow polyester fibers of the hollow thermal insulation layer are warp-knitted and interwoven; the hollow polyester fibers of the hollow thermal insulation layer are warp-knitted and interwoven with the modified nylon fibers of the functional thermal insulation layer.

[...

Embodiment 2

[0082]A kind of wool-like warp-knitted lace fabric, which is divided into four-layer structure, from top to bottom are antistatic layer, wool-like layer, hollow thermal insulation layer and functional thermal insulation layer; the raw material of antistatic layer is antistatic polyester fiber, imitation The raw material of the wool layer is acrylic fiber, the raw material of the hollow thermal insulation layer is hollow polyester fiber, and the raw material of the functional thermal insulation layer is modified nylon fiber; the antistatic polyester fiber of the antistatic layer and the acrylic fiber of the imitation wool layer are warped and interwoven The acrylic fibers of the wool-like layer and the hollow polyester fibers of the hollow thermal insulation layer are warp-knitted and interwoven; the hollow polyester fibers of the hollow thermal insulation layer are warp-knitted and interwoven with the modified nylon fibers of the functional thermal insulation layer.

[0083] Th...

Embodiment 3

[0108] A kind of wool-like warp-knitted lace fabric, which is divided into four-layer structure, from top to bottom are antistatic layer, wool-like layer, hollow thermal insulation layer and functional thermal insulation layer; the raw material of antistatic layer is antistatic polyester fiber, imitation The raw material of the wool layer is acrylic fiber, the raw material of the hollow thermal insulation layer is hollow polyester fiber, and the raw material of the functional thermal insulation layer is modified nylon fiber; the antistatic polyester fiber of the antistatic layer and the acrylic fiber of the imitation wool layer are warped and interwoven The acrylic fibers of the wool-like layer and the hollow polyester fibers of the hollow thermal insulation layer are warp-knitted and interwoven; the hollow polyester fibers of the hollow thermal insulation layer are warp-knitted and interwoven with the modified nylon fibers of the functional thermal insulation layer.

[0109] T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com