Patents

Literature

160 results about "Polyester matrix" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

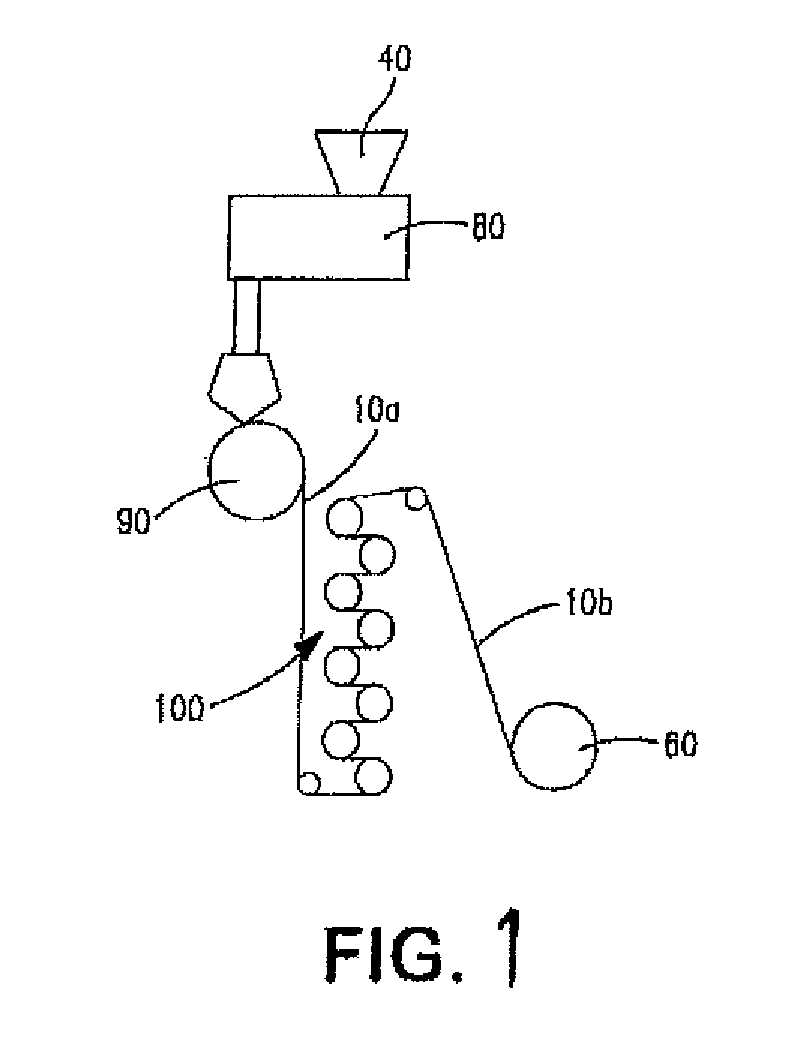

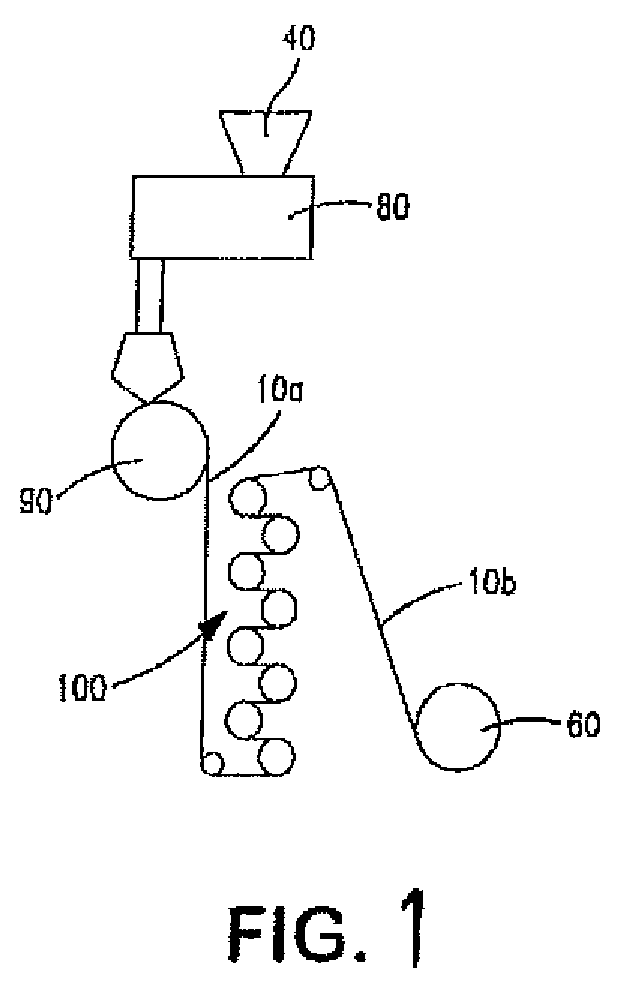

Process for the production of polyester nanocomposites

InactiveUS20080315453A1Increase polyester molecular weightHigh molecular weightMaterial nanotechnologyRotary stirring mixersCompound aMasterbatch

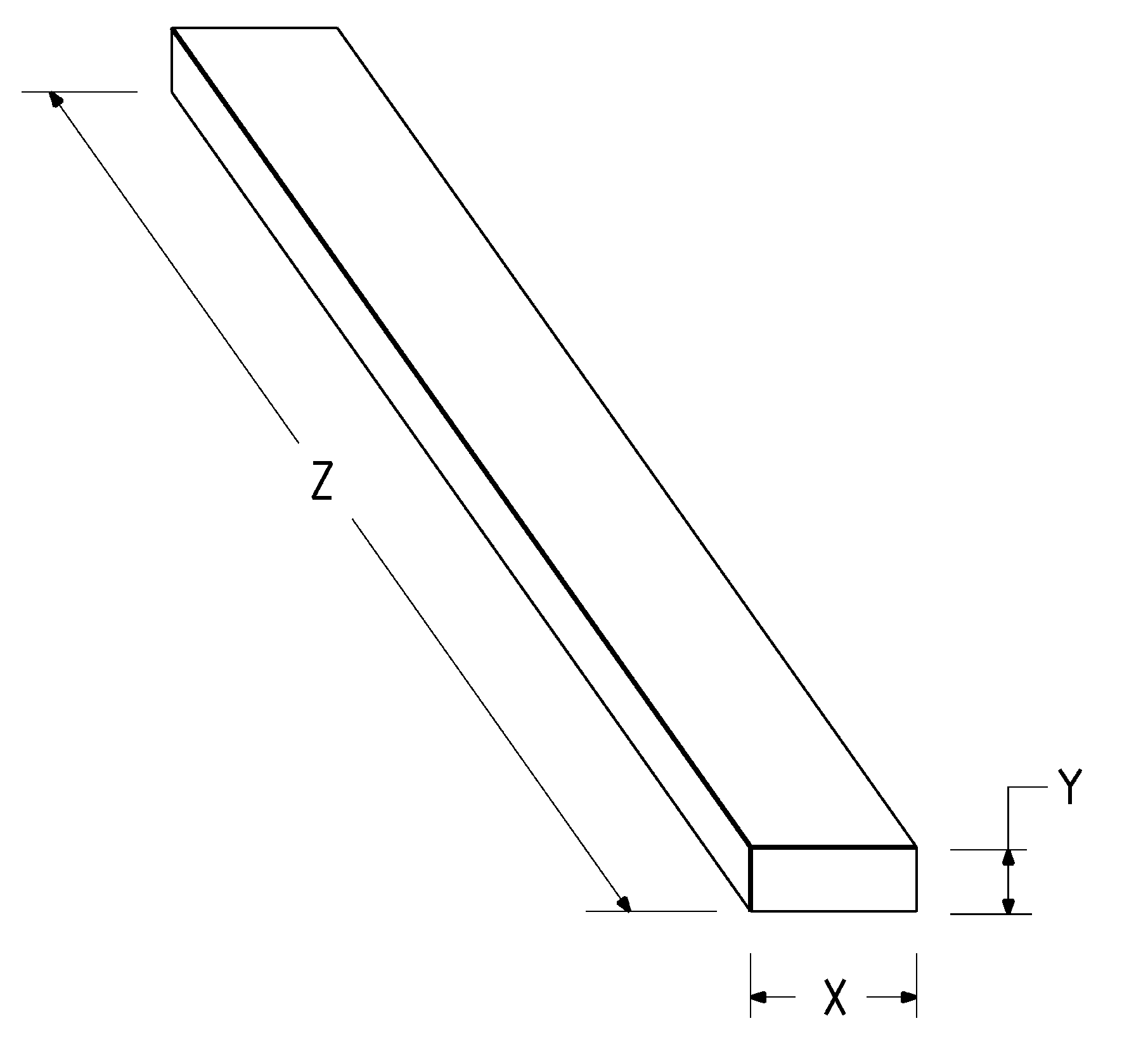

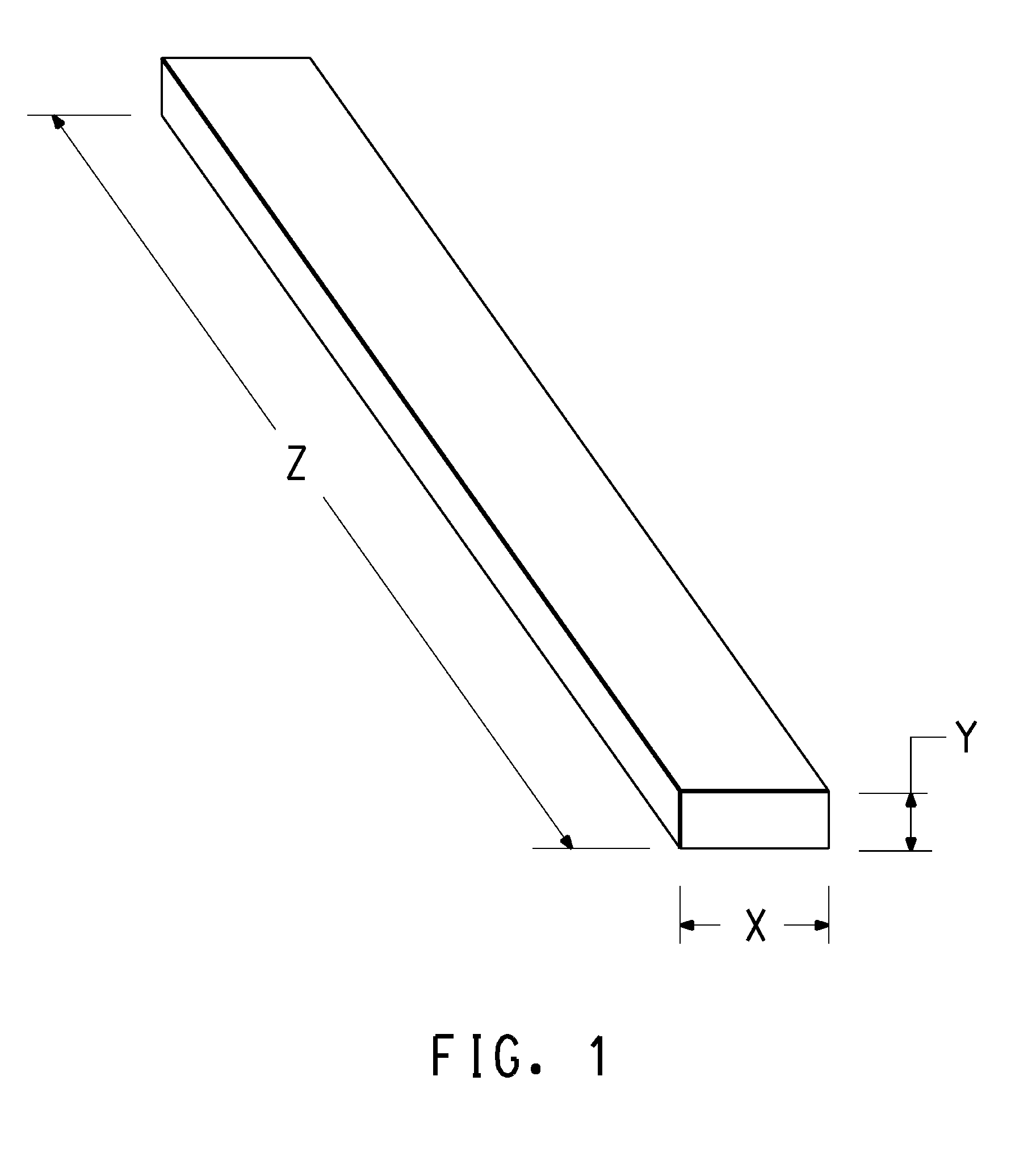

A method for dispersing sepiolite-type clay particles in a polyester matrix by melt-compounding a mixture of: sepiolite-type clay, at least one linear polyester oligomer, and at least one polyester polymer to produce a nanocomposite composition; and, optionally, subjecting said nanocomposite composition to solid state polymerization to increase polyester molecular weight. Further described is a method for preparing a polyester nanocomposite composition from a masterbatch, comprising melt-compounding a mixture of: sepiolite-type clay, at least one polyester oligomer, and at least one polyester polymer to produce a nanocomposite composition containing a greater concentration of sepiolite-type clay than is desired in the final resin composition; optionally, subjecting said nanocomposite composition to solid state polymerization to increase the polyester molecular weight; and further melt compounding said nanocomposite composition with polyester polymer and, optionally, additional ingredients.

Owner:EI DU PONT DE NEMOURS & CO

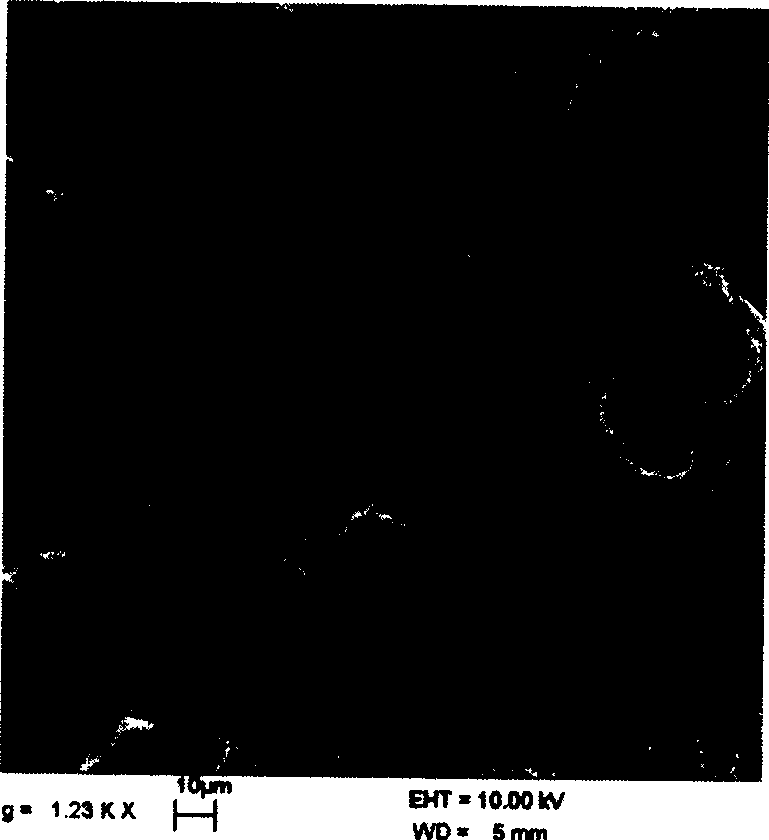

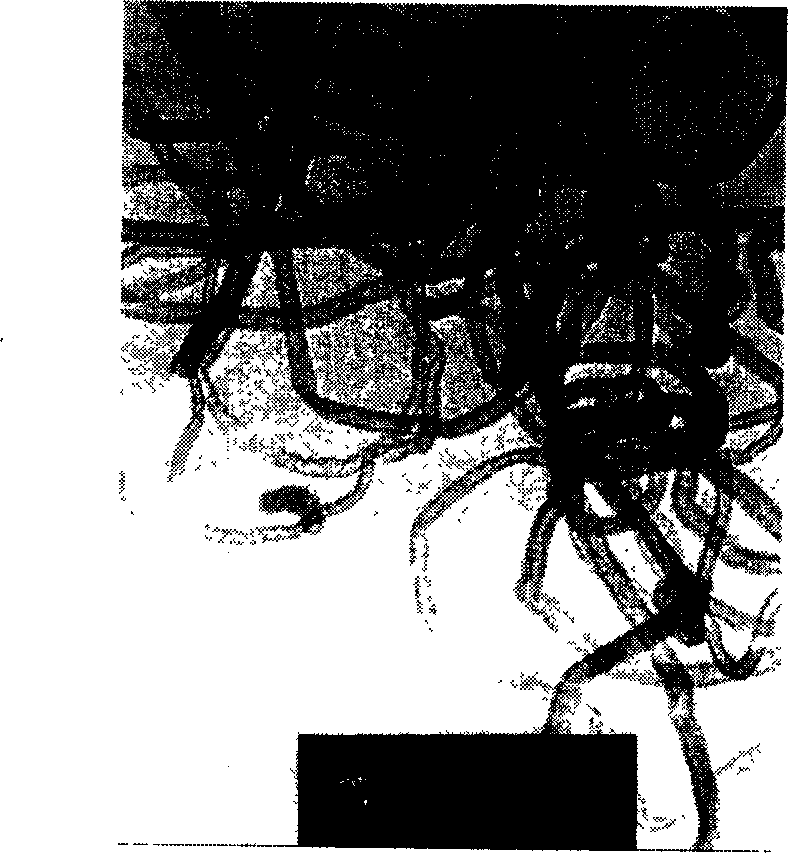

Conducting fiber containing nano car bon tube and its prepn. method

ActiveCN1563526AGood electrical conductivityReduce volume resistanceElectroconductive/antistatic filament manufactureMonocomponent polyesters artificial filamentElectrically conductivePolyester

A conducting fiber containing carbon nm tubes includes the following three components polyester, carbon nm tube and coupler with the weight ration of polyester 80-94.9, carbon nm tube 0.05-10, the coupler 0.05-10. The three components are prepared to conducting fibers via mix, extrusion and fiber spinning having the composite shapes of interlayer, sheath-core and island, characterizing in utilizing the fine conductivity of the carbon nm tubes and extremely length-diameter ratio to prepare conducting fibers, Special coupler is selected to strongthen the interaction of carbon nm tube and the polyerter to open the coacervates of the tube in the blend process by cutting.

Owner:TSINGHUA UNIV

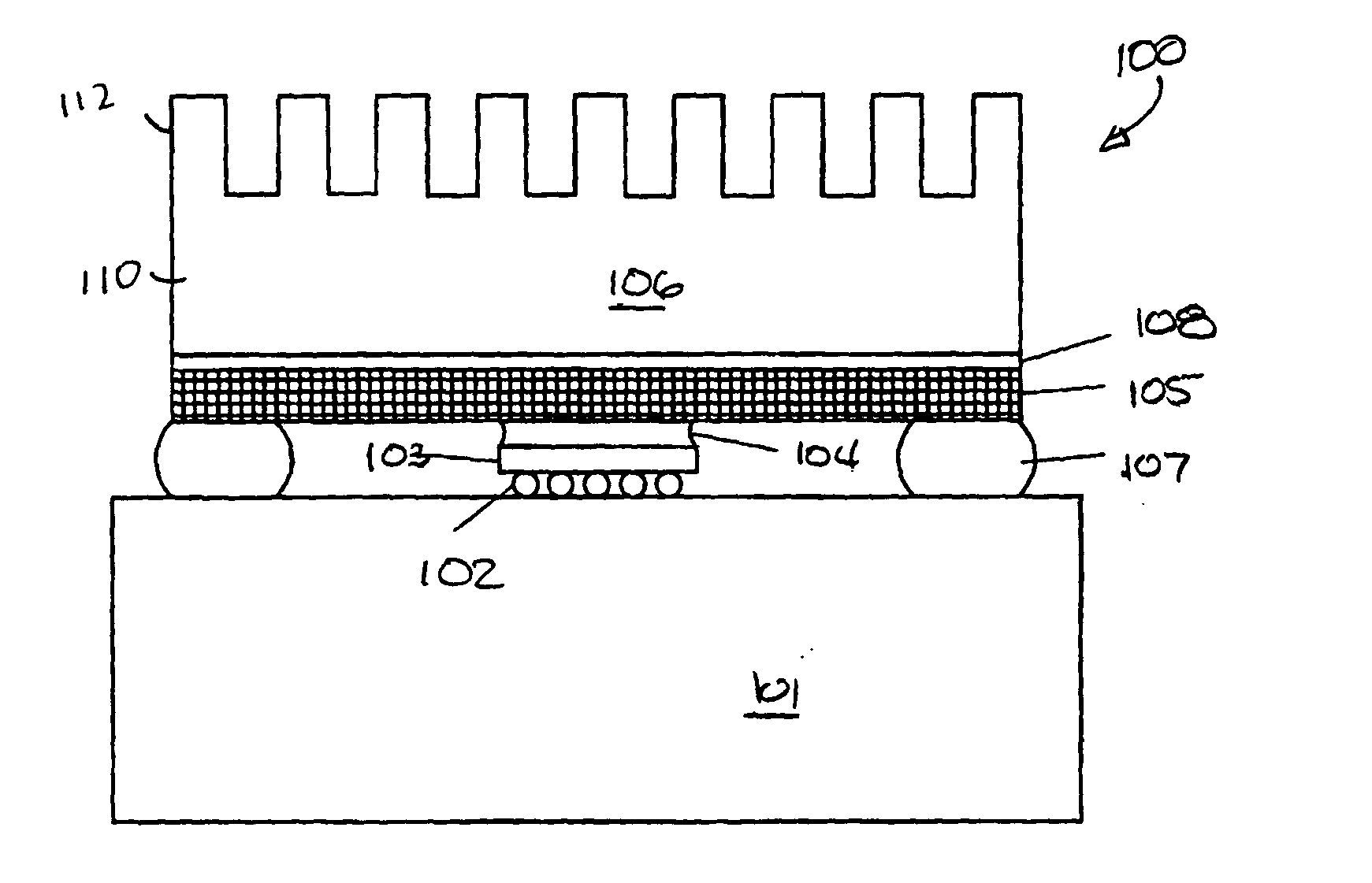

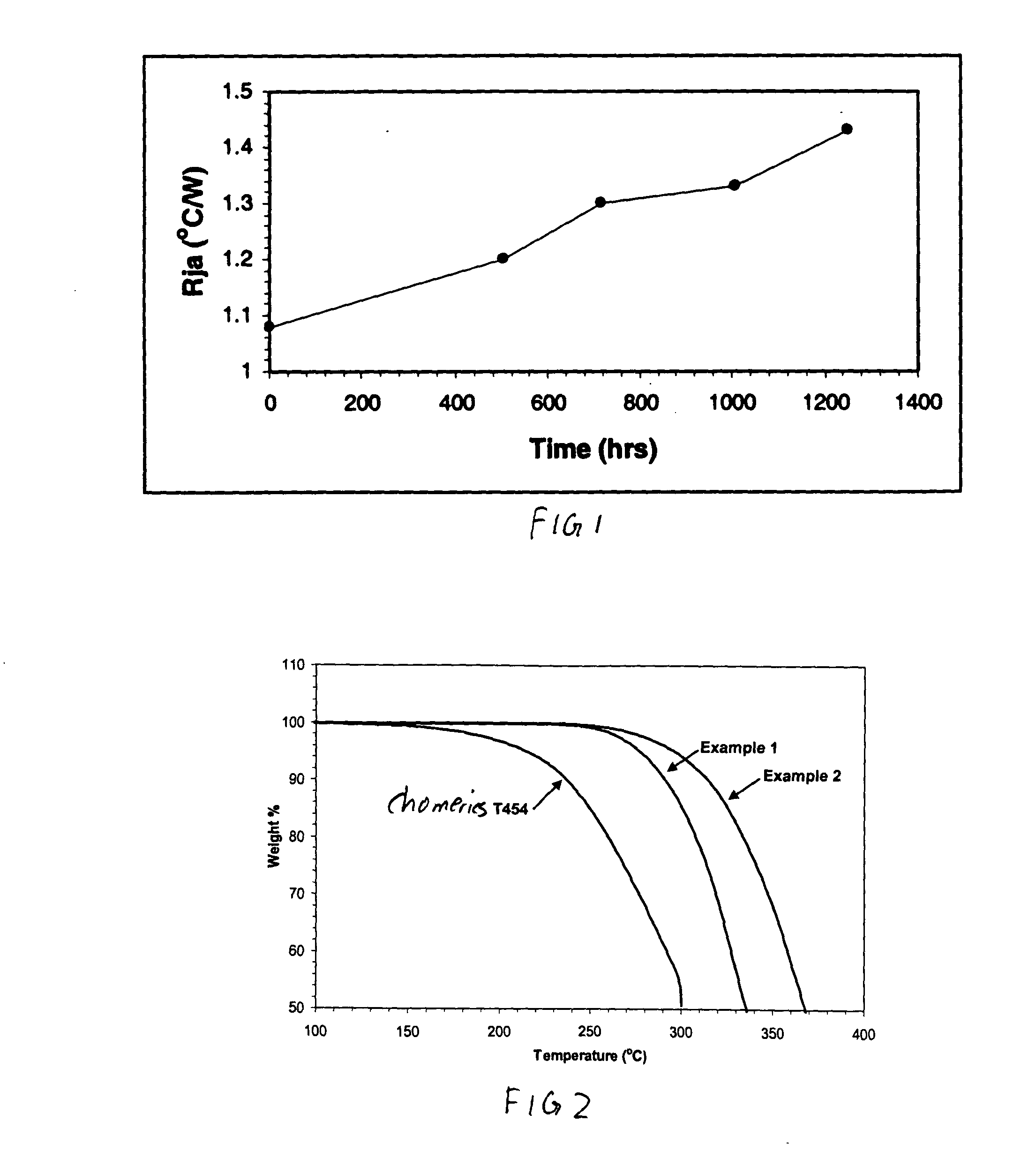

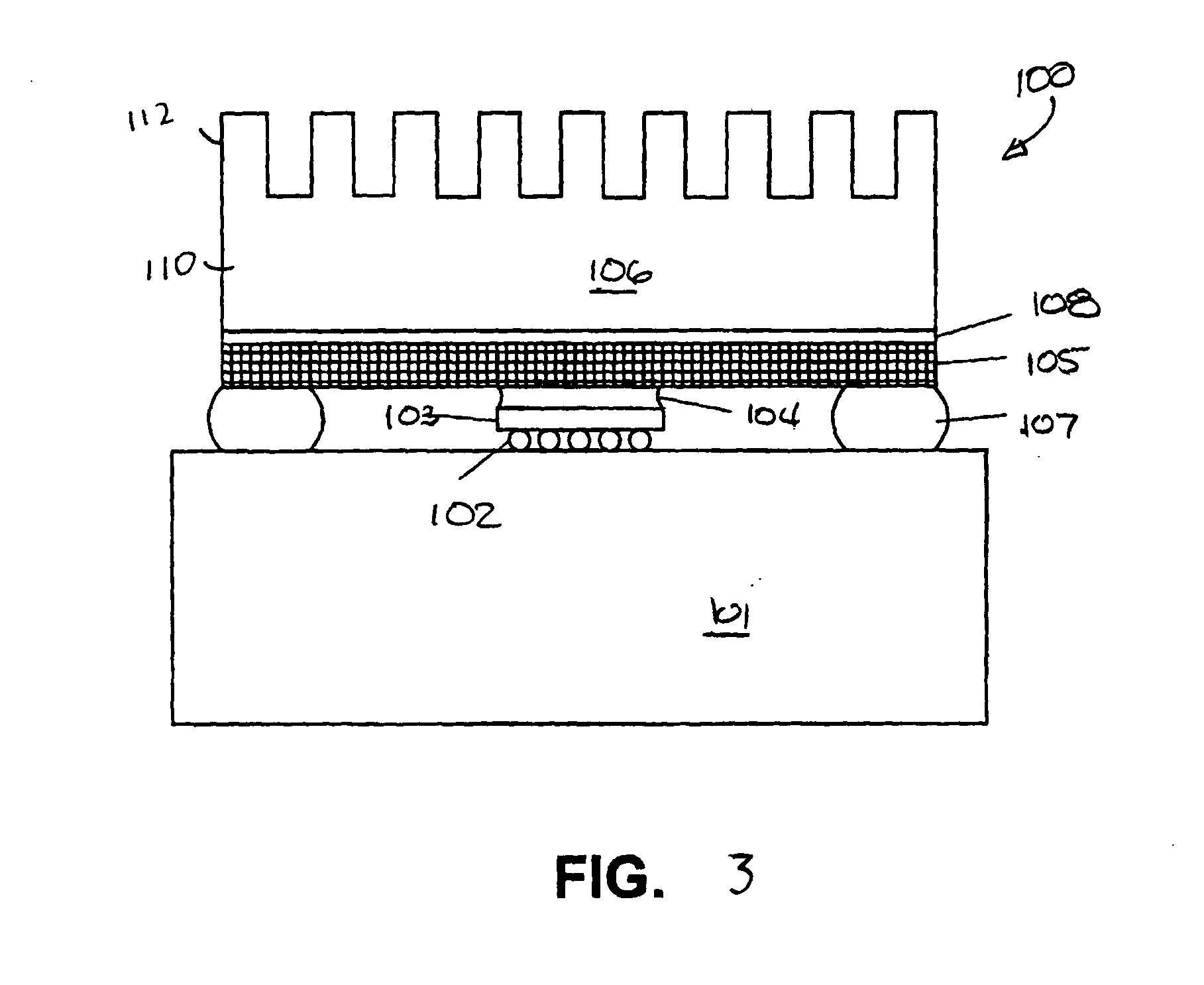

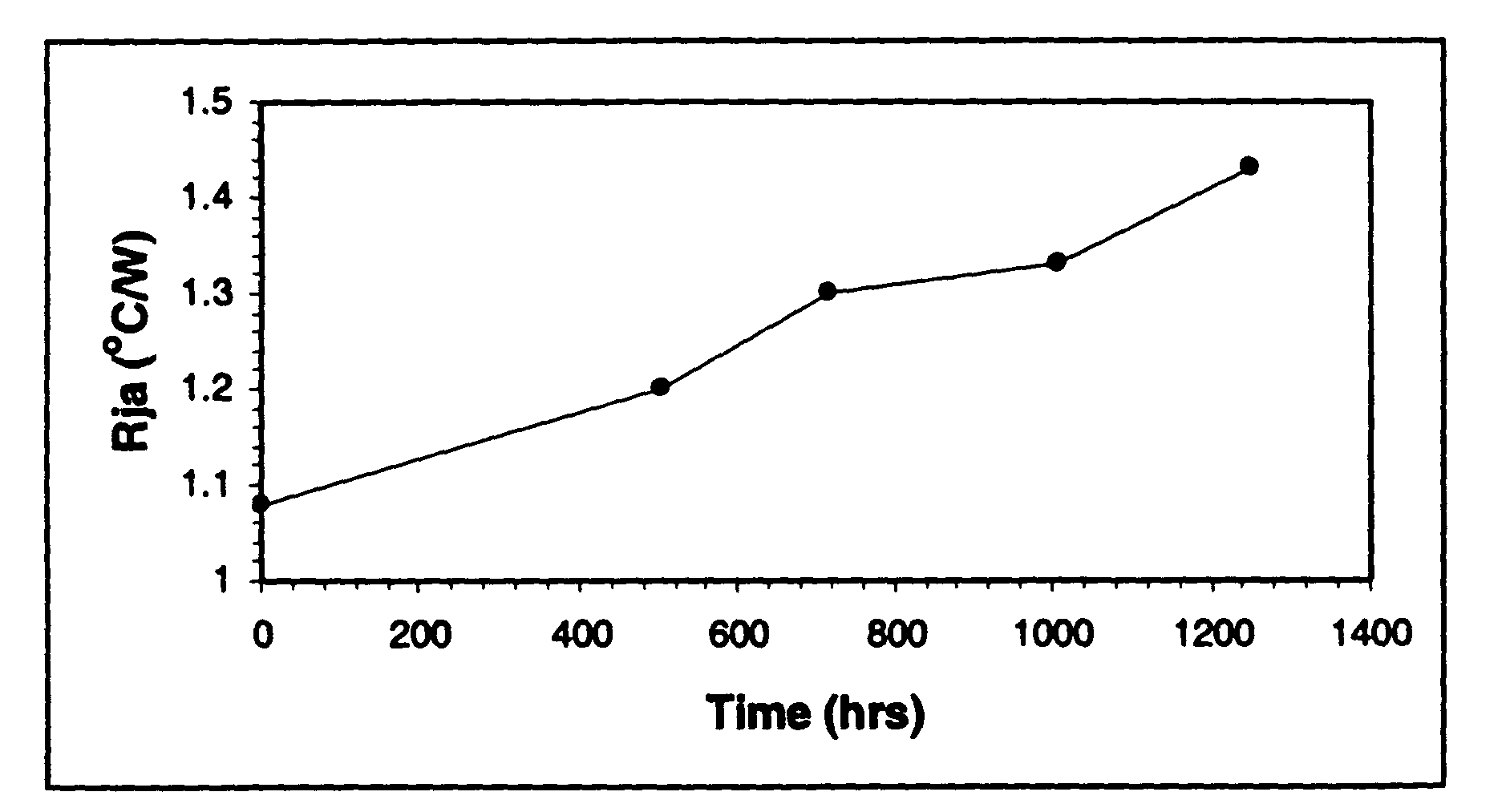

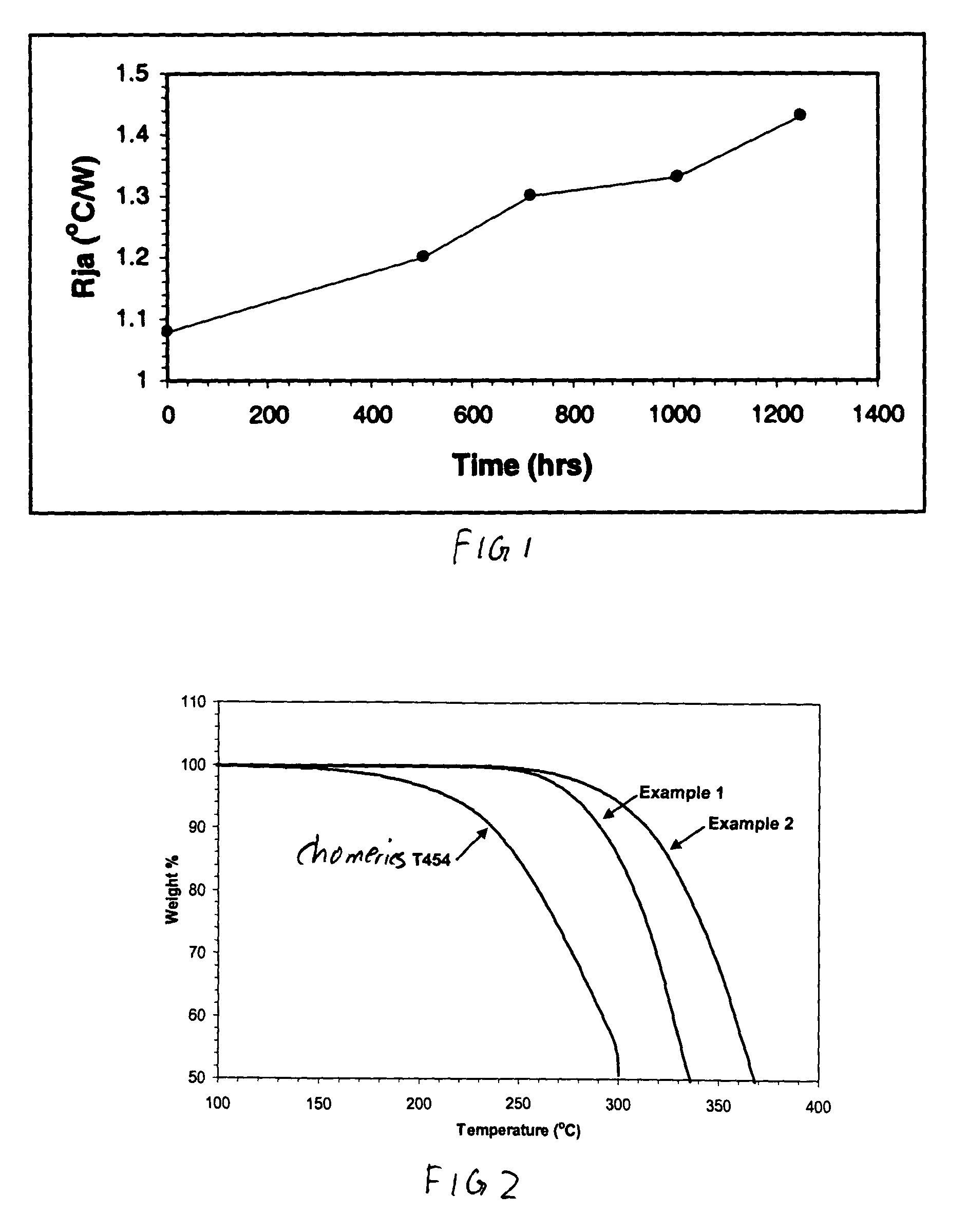

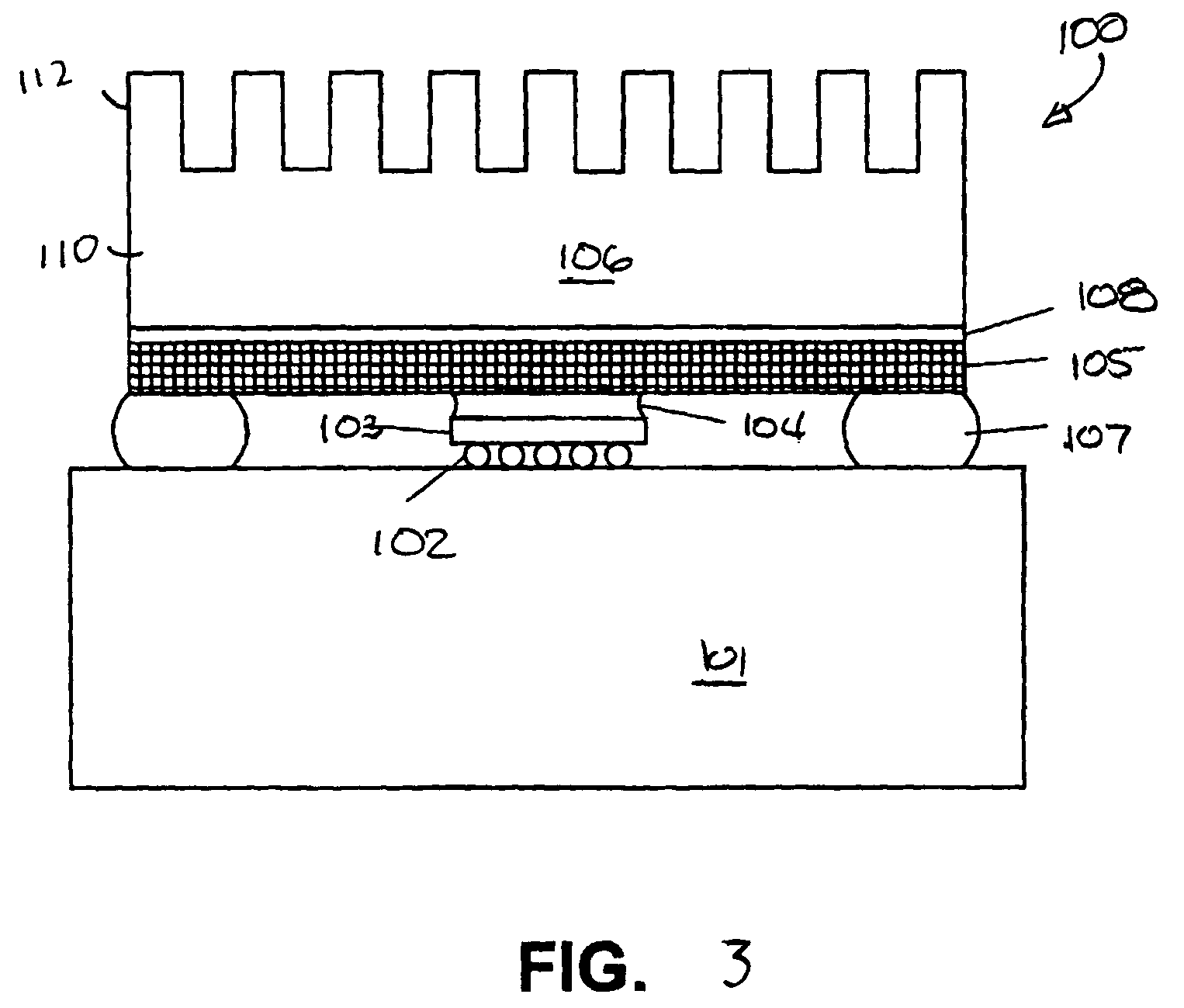

Phase change thermal interface materials including polyester resin

InactiveUS20050041406A1Improve thermo-oxidative stabilityImprove reliabilitySemiconductor/solid-state device detailsSolid-state devicesPolyolefinPolyester resin

An embodiment of a phase change TIM of this invention comprises a polyester matrix with melting temperature near or below operating temperature (typically less than about 130° C.), thermally conductive filler with bulk thermal conductivity greater than about 50 W / mK, and optionally other additives. The polyester resin has improved thermo-oxidative stability compared to the polyolefin resins, thereby providing improved reliability performance during test.

Owner:INTEL CORP

Breathable Film Formed from a Renewable Polyester

PendingUS20130210621A1Lamination ancillary operationsOther chemical processesGlass transitionToughening

A breathable film formed from a thermoplastic composition that contains a rigid renewable polyester and has a voided structure is provided. To achieve such a structure, a thermoplastic composition that contains a renewable polyester and polymeric toughening additive is extruded onto a surface to form a precursor film in which the toughening additive can be dispersed as discrete physical domains within a continuous matrix of the renewable polyester. The precursor film is thereafter stretched or drawn at a temperature below the glass transition temperature of the polyester (i.e., “cold drawn”). Without intending to be limited by theory, the present inventors believe that the deformation force and elongational strain of the drawing process causes debonding to occur in the renewable polyester matrix at those areas located adjacent to the discrete domains. This creates a network of voids located adjacent to the discrete domains.

Owner:KIMBERLY-CLARK WORLDWIDE INC

Inorganic-filling material full-biodegradation composite material with high compatibility and preparation method thereof

InactiveCN104059342AGood compatibilityReduce manufacturing costBiodegradable polyesterInorganic filler

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

Polyester composite filled with lignin and preparation method thereof

InactiveCN102070891AReduce manufacturing costDoes not affect goodnessEconomic benefitsMixed materials

The invention discloses a polyester composite filled with lignin and a preparation method thereof. The preparation method comprises the following steps: mixing polyester and lignin evenly, wherein the weight percentages of polyester and lignin are separately 60-95% and 5-40%; and performing melt extrusion granulation to the mixed material with a twin screw extruder to obtain the polyester composite filled with lignin. The preparation method of the invention uses rich, cheap and renewable biological resource lignin to fill biodegradable polyester material, thus the production cost of the material can be reduced extremely without affecting the good performances of the polyester matrix; and the preparation process is simple and has a certain social and economic benefits.

Owner:GUANGZHOU CHEM CO LTD CHINESE ACADEMY OF SCI

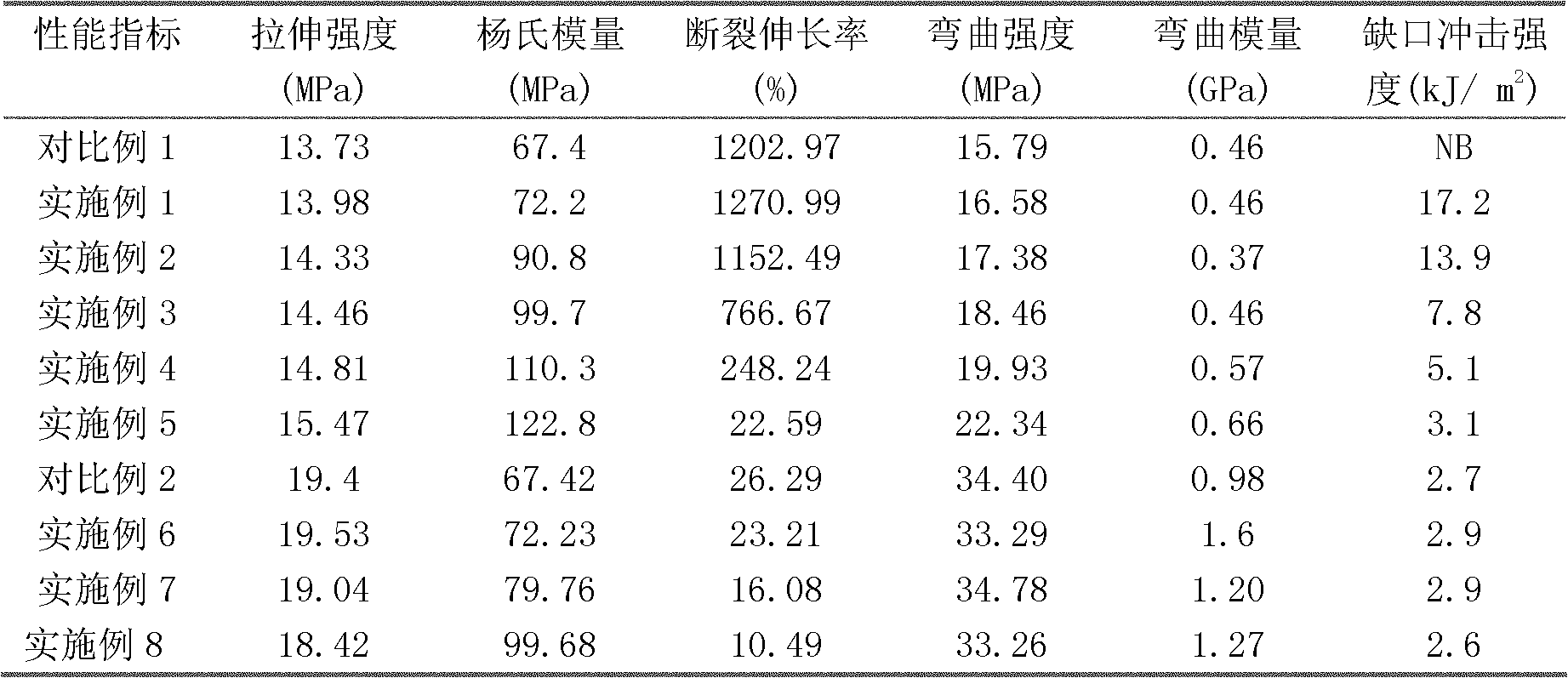

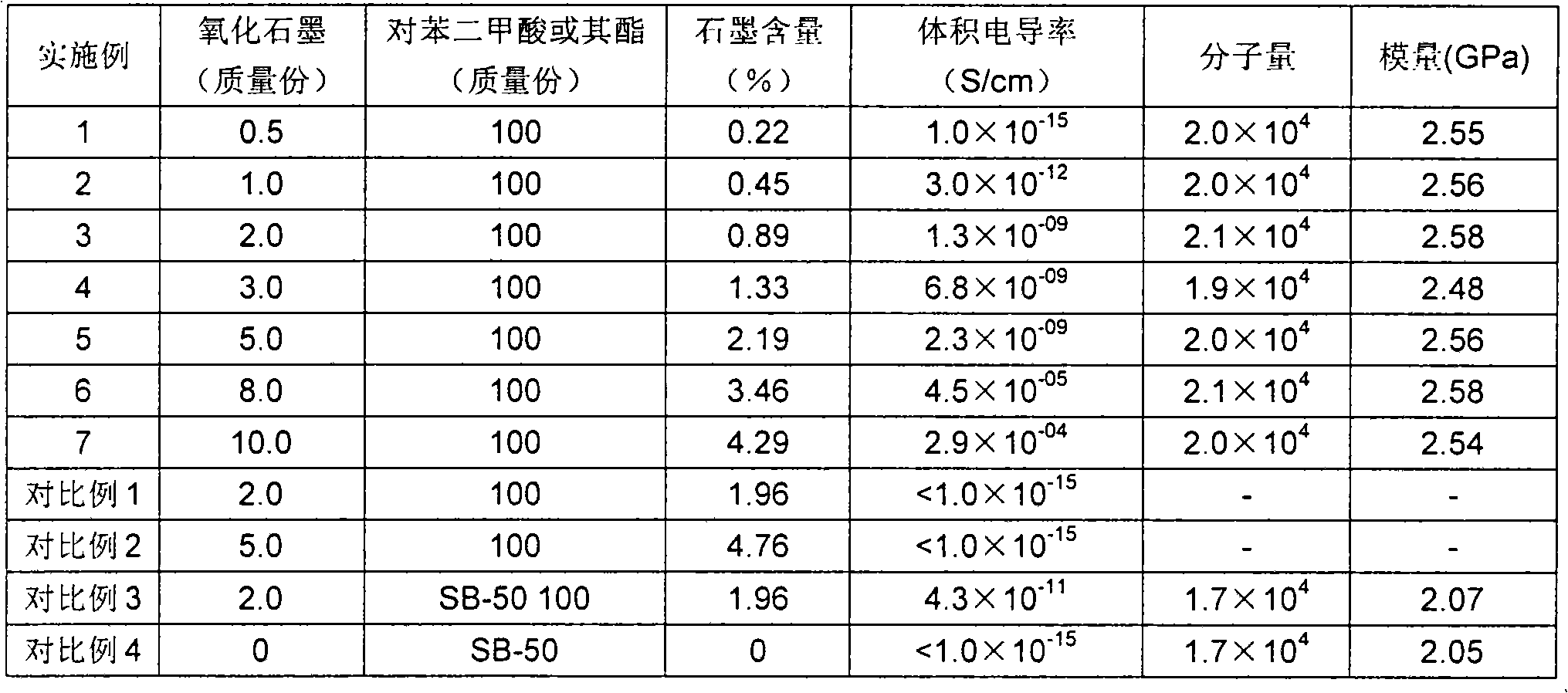

Conductive polyester/graphite oxide composite material and preparation method thereof

InactiveCN101875718AImprove conductivityReduce the amount of fillerConductive polymerElectromagnetic shielding

The invention discloses a conductive polyester / graphite oxide composite material and a preparation method thereof. The composite material is prepared from the following raw materials in part by mass: 0.25 to 10 parts of graphite oxide, 100 parts of terephthalic acid or ester thereof, 60 to 200 parts of alkaline glycol, 0.01 to 3 parts of catalyst, 0.01 to 0.5 part of stabilizing agent and 0 to 100 parts of dispersant. The polyester / graphite oxide composite material of the invention is prepared by polymerizing a polyester substrate and a nano-graphite packing in situ, has the percolation threshold of 0.5 to 1.0 weight percent, can achieve the electric conductivity of 10 to 5 S / cm when graphite content is 3.5 weight percent, and compared with a conventional natural graphite conductive composite material and an expanded graphite conductive composite material, can achieve the high properties of low packing amount and high electric conductivity without adding an auxiliary substrate, and can be widely applied in the fields of conductive materials, antistatic materials, electromagnetic shielding materials, microwave absorption and the like.

Owner:TORAY IND INC

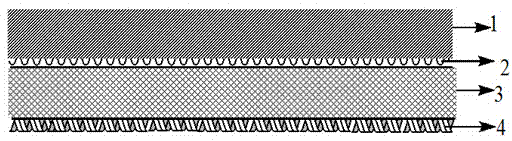

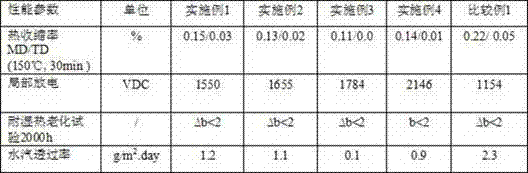

High-partial-discharge-voltage photovoltaic backplane

ActiveCN104494263APlay a protective roleHigh partial discharge voltageSynthetic resin layered productsWeather resistanceEngineering

The invention discloses a high-partial-discharge-voltage photovoltaic backplane, which is formed by sequentially bonding an olefin copolymer layer, a weather-proof bonding layer, a polyester matrix layer and a weather-proof layer. The prepared backplane has high partial discharge voltage, and also has the good water vapor barrier property and the excellent mechanical strength and outdoor weather resistance. The photovoltaic backplane has excellent performances and is suitable for photovoltaic modules of large systems.

Owner:HANGZHOU FIRST APPLIED MATERIAL CO LTD

Universal fully-biodegradable color masterbatch and preparation method thereof

The invention belongs to the technical field of high-molecular materials, and relates to a universal fully-biodegradable color masterbatch and a preparation method thereof. The universal fully-biodegradable color masterbatch comprises the formula compositions in parts by weight: 30-80 parts of biodegradable polyester, 10-40 parts of a pigment, 10-30 parts of a filler, 0.5-3 parts of a compatilizer, 5-20 parts of a lubricant and 0.1-0.6 part of an anti-oxidant. The fully-biodegradable color masterbatch is obtained through melt blending, extrusion, strip pulling and pelletizing by employing a double screw extruder. The fully-biodegradable color masterbatch is completely biodegradable, good in processing performance and good in dispersing effect in a matrix, and has extremely good compatibility with a polyester matrix even a masterbatch carrier and a biodegradable polyester matrix are different polyesters. The masterbatch gives play to extremely good coloring effect on a product when being applied to a biodegradable polyester.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

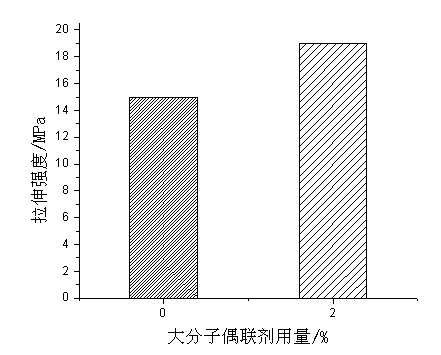

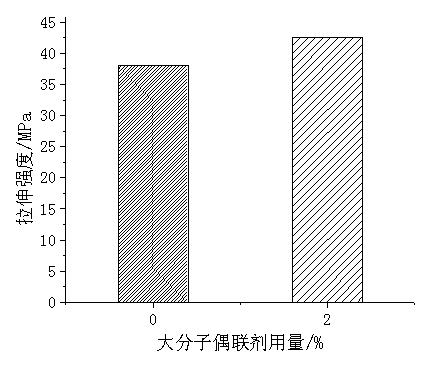

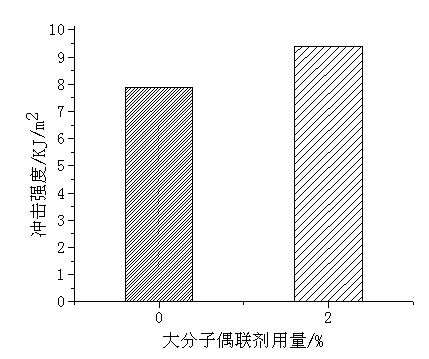

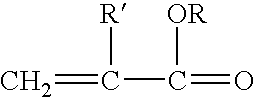

Preparation method and application for biomass fibre-aliphatic polyester composite material macromolecular coupling agent

The invention discloses a preparation method and application for a biomass fibre-aliphatic polyester composite material macromolecular coupling agent. The preparation method comprises the following steps: (1) synthesis for a biomass constituent-based macromolecular coupling agent; (2) surface hydrophobic modification for biomass fibre raw materials; (3) compounding for the modified biomass fibre raw materials and an aliphatic polyester matrix. The method can be used for various aliphatic polyester matrixes and is low in raw material limit; moreover, the composite material product is wide in application and can be used for the fields of household appliances, automobile industry, packaging, daily necessities and the like. The method is low in production cost, beneficial to popularize and apply, and has great significance in the aspects of improving the utilization level of biomass raw materials, alleviating petroleum resource crisis, protecting environment, and the like.

Owner:SHAANXI HUAHAOXUAN NEW ENERGY TECH DEV CO LTD

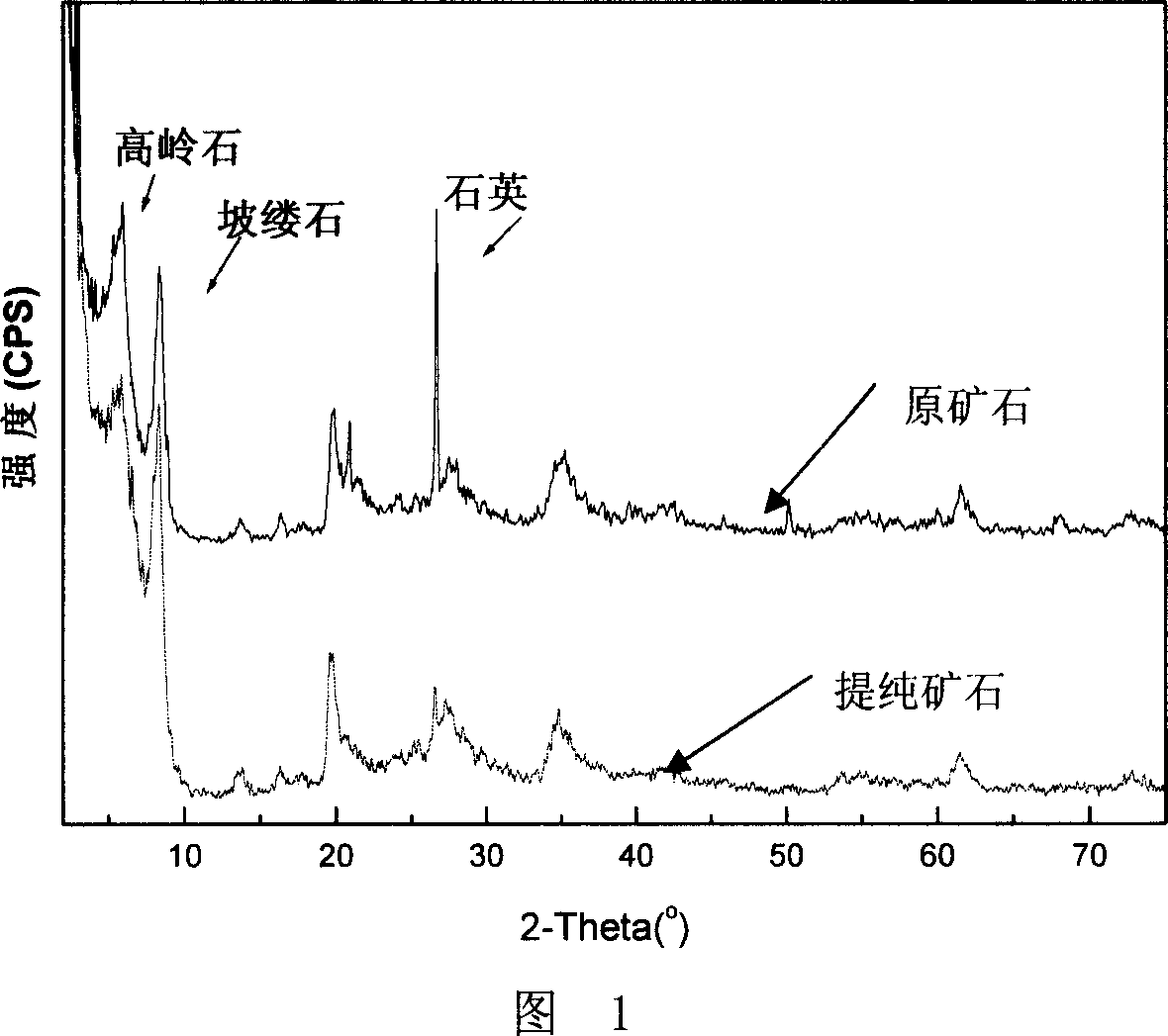

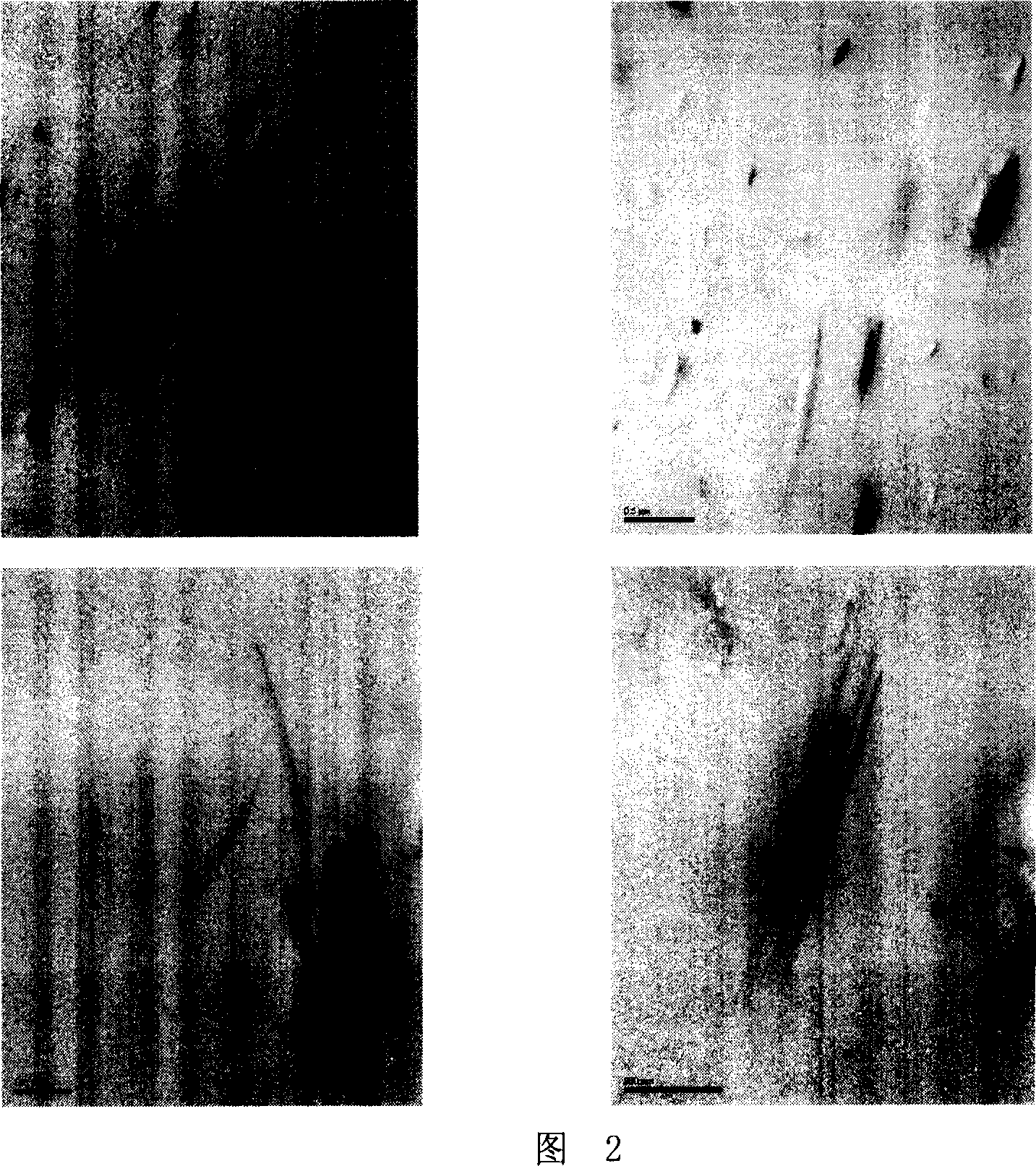

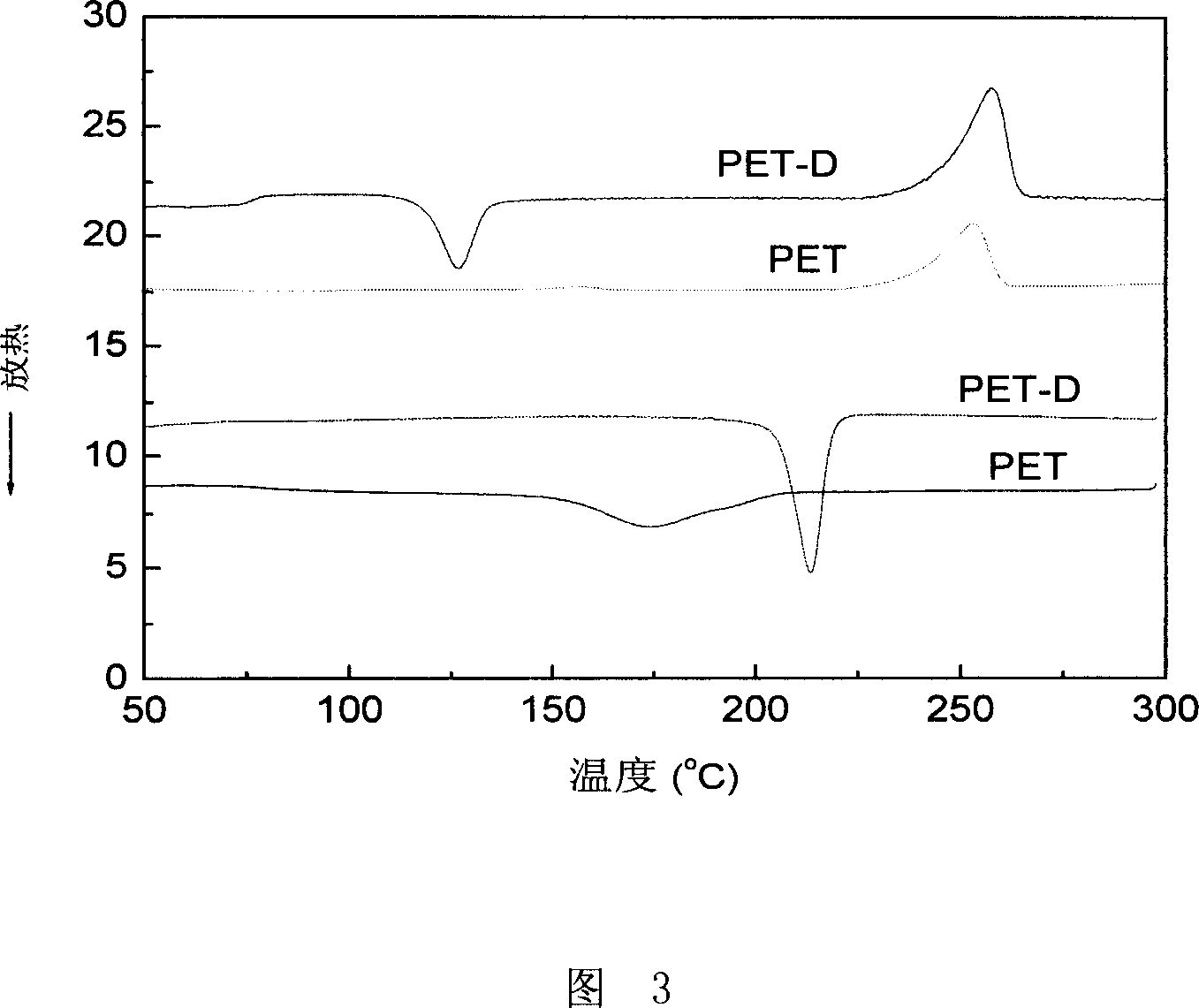

Polyester/fibrous clay nano composite material, preparation method and application thereof

The present invention discloses one kind of nanometer polyester / fibrous clay composite material and its preparation process and application. The nanometer polyester / fibrous clay composite material consists of polyester base and fibrous clay, which accounts for 0.1-10 wt% of the composite material and is rod crystals of 10-500 nm size dispersed in the polyester base. The nanometer polyester / fibrous clay composite material has relatively great molecular weight and less degradation after melt spinning. After the fiber of the composite material is drafted and oriented, the clay rod crystals with high length / diameter ratio are arranged in the drafting direction to strength the polyester fiber and raise the mechanical performance greatly. In addition, the clay rod crystals serve as the physical cross-linking points to limit the motion of great molecular chain, raise the heat resistance of the fiber and lower the dry heat shrinkage of the fiber.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Optical-scale polyester film and preparation method thereof

ActiveCN102825885AEnsure transparencyReach optical grade requirementsSynthetic resin layered productsPolyurea/polyurethane coatingsPolymer sciencePolyethylene terephthalate glycol

The invention relates to an optical-scale polyester film, which comprises a polyester base film and bottom coatings, wherein the polyester base film only contains polyethylene glycol terephthalate; the bottom coatings are coated on two surfaces of the polyester base film; the thickness of each bottom coating is 0.05-0.3mu m; and each bottom coating contains colloidal silicon dioxide and crosslinking polystyrene microspheres. The polyester base film in the optical-scale polyester film does not contain silicon dioxide, and the transparency of the polyester base film can be guaranteed; the bottom coatings contain the crosslinking polystyrene microspheres serving as organic anti-adhesion agent and the colloidal silicon dioxide serving as inorganic anti-adhesion agent; rough surfaces can be formed on two surfaces of the polyester film, and the surface of the polyester film has good smooth property, anti-adhesion property, anti-scratching property and anti-falling property, thereby being convenient to process; the refractive index of the crosslinking polystyrene microspheres is similar to the refractive index of the polyethylene glycol terephthalate; therefore the refraction and the diffuse reflection of ray on a phase boundary of the anti-adhesion agent and polyester matrix can be effectively inhibited; and the ray transmittance is improved.

Owner:JIANGSU YUXING FILM TECH

Microbead and immiscible polymer voided polyester for inkjet imaging medias

InactiveUS6863939B2Promote absorptionEnhance the imageSynthetic resin layered productsCoatingsCrosslinked polymersRecord element

The present invention relates to an inkjet recording element comprising a microvoided layer comprising a continuous phase polyester matrix having dispersed therein crosslinked organic microbeads and non-crosslinked polymer particles that are immiscible with the polyester matrix of said microvoided layer.

Owner:EASTMAN KODAK CO

Non-transparent microvoided axially stretched film, production process therefor and process for obtaining a transparent pattern therewith

InactiveUS20080241769A1Loss in opacityHigh opacityX-ray/infra-red processesPhotosensitive materialsAdditive ingredientAntioxidant

A film consisting essentially of a continuous phase linear polyester matrix having dispersed therein a non-crosslinked random SAN-polymer and dispersed or dissolved therein at least one ingredient from the group of ingredients consisting of inorganic opacifying pigments, whitening agents, colorants, UV-absorbers, light stabilizers, antioxidants and flame retardants, wherein the film is white, microvoided, non-transparent and axially stretched; the linear polyester matrix has monomer units consisting essentially of at least one aromatic dicarboxylic acid, at least one aliphatic diol and optionally at least one aliphatic dicarboxylic acid; and the weight ratio of the linear polyester to the non-crosslinked SAN-polymer is in the range of 2.0:1 to 19.0:1, wherein one of the said at least one aliphatic dimethylene monomer units is selected from the group consisting of neopentylene and 1,4-cyclohexanedimethylene in a concentration of 30 mole % or less of all aliphatic dimethylene monomer units; the use of the film as or in synthetic paper; an image recording element comprising the film; a process for the preparing of the non-transparent microvoided axially stretched film; and a process for obtaining a transparent pattern therewith.

Owner:AGFA GEVAERT AG

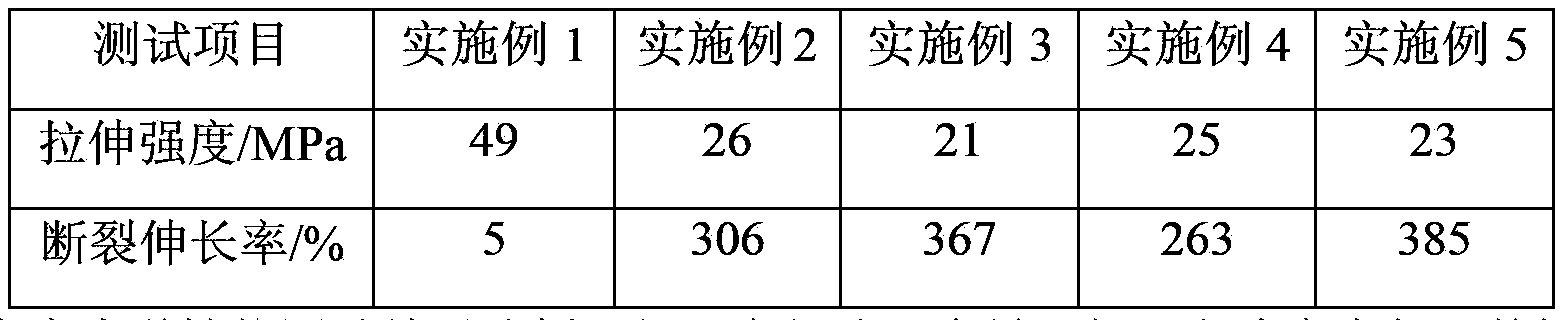

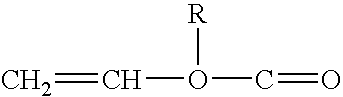

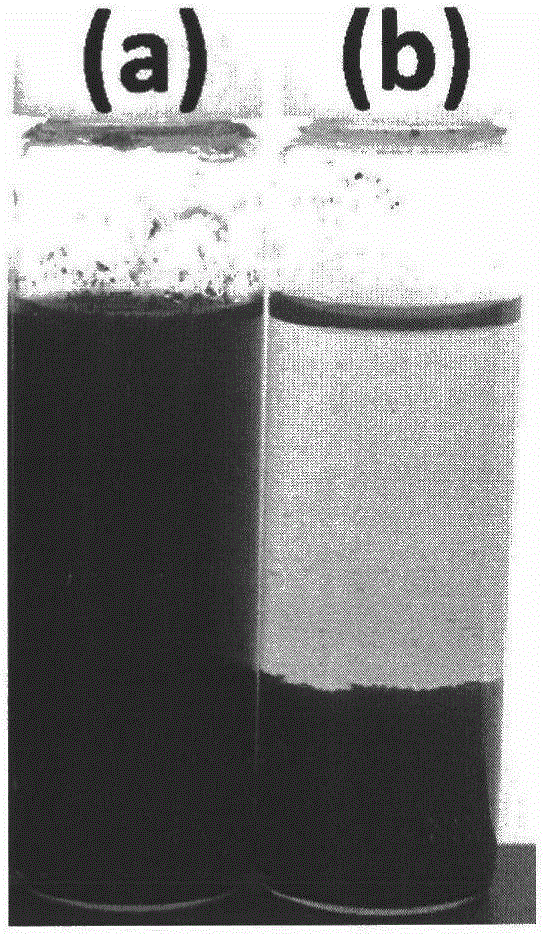

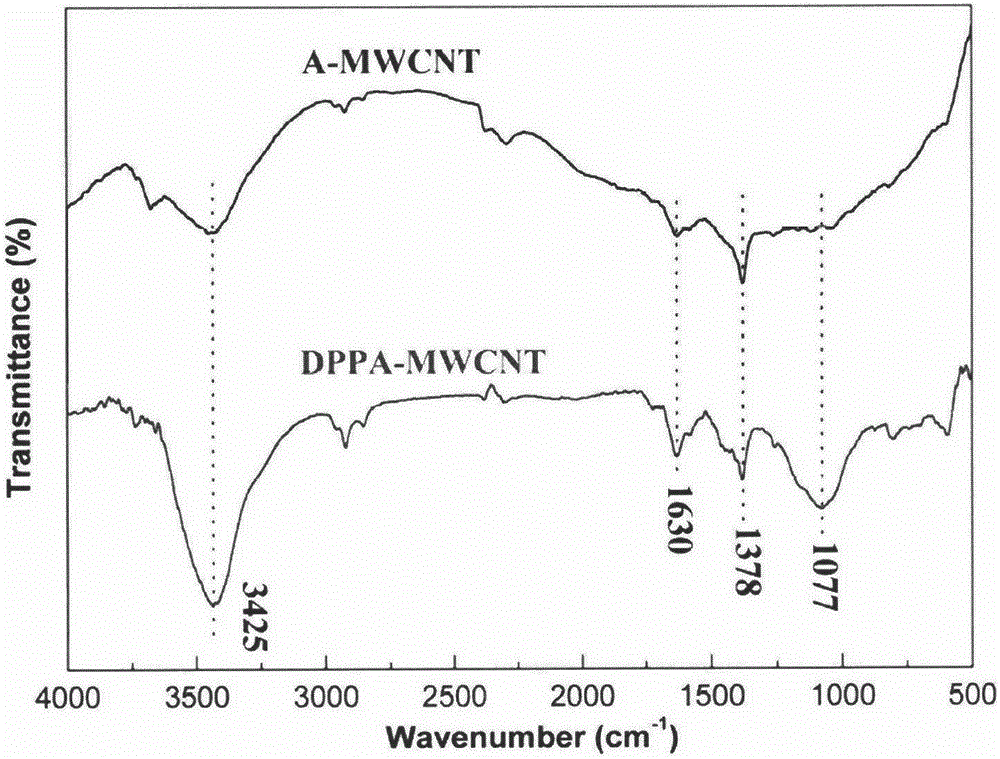

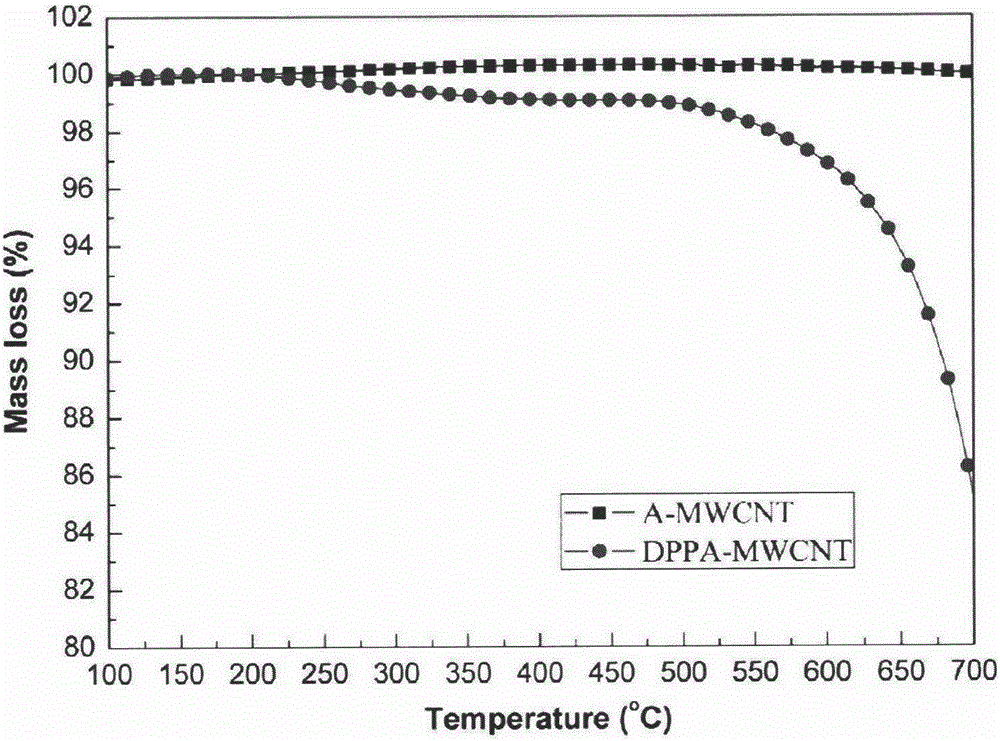

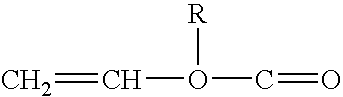

Modified carbon nanotube flame retardant reinforced polyester composite material and preparation method thereof

The invention belongs to the technical field of nano materials and plastic processing and particularly relates to a modified carbon nanotube flame retardant reinforced polyester composite material and a preparation method thereof. The composite material is prepared from, at a minimum, 31.5-99.4wt% of polyester, 0.1-2wt% of modified carbon nanotubes and 0.5-5wt% of compatilizer. The molecular structural formula of the modified carbon nanotubes can be found in specification, wherein R is ethyl or phenyl group. All raw materials are evenly mixed, heated to 220-265 DEG C, subjected to melt blending, squeezed out and subjected to bracing, cooling, pelletizing and drying. The aggregation effect of the carbon nanotubes can be lowered by the adoption of the modified carbon nanotubes, the interfacial compatibility of the carbon nanotubes and polyester materials is improved, the dispersibility of the carbon nanotubes in polyester matrix is improved, and thus the flame retardant and mechanical properties of the composite material are improved.

Owner:SUZHOU HSM TECH CO LTD

Rigid Renewable Polyester Compositions having a High Impact Strength and Tensile Elongation

A thermoplastic composition that contains a rigid renewable polyester and a polymeric toughening additive is provided. The toughening additive can be dispersed as discrete physical domains within a continuous matrix of the renewable polyester. An increase in the deformation force and elongational strain causes debonding to occur in the renewable polyester matrix at those areas located adjacent to the discrete domains. This can result in the formation of a plurality of voids adjacent to the discrete domains that can help to dissipate energy under load and increase impact strength. To even further increase the ability of the composition to dissipate energy in this manner, an interphase modifier may be employed that reduces the degree of friction between the toughening additive and renewable polyester and thus enhances the degree and uniformity of debonding.

Owner:KIMBERLY-CLARK WORLDWIDE INC

Flame-retardant anti-dripping polyester fiber and preparation method thereof

InactiveCN107557901AReduce acidityReduce the impactFlame-proof filament manufactureMonocomponent polyesters artificial filamentPolymer scienceIn situ polymerization

The invention relates to flame-retardant anti-dripping polyester fiber and a preparation method thereof. A phosphorus-based flame retardant and graphene oxide react under a certain condition to prepare a flame-retardant anti-dripping agent, then terephthalic acid and ethylene glycol are utilized as raw materials, the flame-retardant anti-dripping agent is introduced into a polyester matrix by an in-situ polymerization method to prepare flame-retardant anti-dripping polyester, and then the flame-retardant anti-dripping polyester fiber is prepared by a melt spinning assembly. A technology designed by the invention not only reduces an effect of the phosphorus-based flame retardant in a polyester polymerization process, but also utilizes excellent dispersing performance and anti-dripping performance effects of the graphene oxide to make a final product have flame-retardant anti-dripping performance. The flame retardance of the prepared flame-retardant anti-dripping polyester fiber is obviously improved, and the prepared flame-retardant anti-dripping polyester fiber can be widely applied to the fields of home textiles, clothes, sports, leisure and the like.

Owner:HUIZHOU DHOMA IND CO LTD

Nanometer composite material of polyester and inorganic matter and preparing method thereof

The invention provides a polyester and inorganic substance nano composite material and method for making it, wherein the particles of metallic oxide, inorganic non-metallic oxide or their composite oxides in nano scales is first pre-processed for reaction, then is placed in polymerization reaction device along with the intermediate of polytetramethylene terephthalate (PET) for blending, obtaining the nano composite material integrating inorganic substance and polyester base through chemical bonds dispersed in nano scales evenly.

Owner:柯扬船

Nanometer composite material of polyester and abio-silicate and preparing method thereof

InactiveCN1504509AHigh molecular weightIncreased overall crystallization rateChemical LinkagePolytetramethylene terephthalate

The invention provides a polyester and inorganic silicate nano composite material and method for making it, wherein the inorganic silicate metallic oxide prepared by porcelain clay and muscovite is first pre-processed for reaction, then is placed in polymerization reaction device along with polytetramethylene terephthalate (PET) for condensation copolymerization, thus obtaining the high-performance polyethylene glycol terephthalate alcohol and inorganic salt nano composite material integrating inorganic silicate and polyester base through chemical bonds dispersed evenly in nano scale.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Microbead and immiscible polymer voided polyester for thermal imaging medias

InactiveUS6867168B2Easy to optimizeLow graininessSynthetic resin layered productsAblative recordingPolymer scienceImage recording

The present invention relates to a thermal image recording element comprising a microvoided layer comprising a continuous phase polyester matrix having dispersed therein crosslinked organic microbeads and non-crosslinked polymer particles that are immiscible with the polyester matrix of the microvoided layer.

Owner:KODAK ALARIS INC

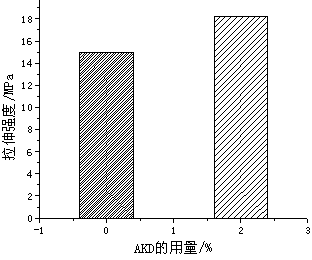

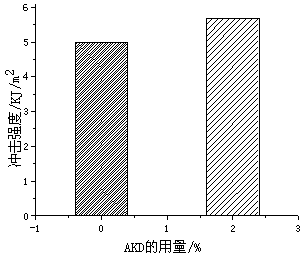

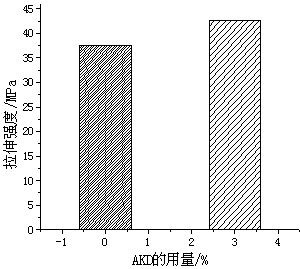

Method for preparing aliphatic polyester composite material by means of alkyl ketene dimer surface modification biomass fibers

The invention discloses a method for preparing an aliphatic polyester composite material by means of alkyl ketene dimer surface modification biomass fibers. The method comprises the steps of (1) preparation of an AKD emulsion and surface treatment of biomass fibrous raw materials through the AKD emulsion, (2) curing treatment of the surface modification fibers, and (3) composition of the surface modification biomass fibers and an aliphatic polyester matrix. The hydrogen bond bonding effect between the fibers obtained through surface hydrophobic treatment is weakened, agglomeration of the fibers in the aliphatic polyester matrix is reduced, and the interfacial strength of the composite material is improved, so that the composite material has the better comprehensive performance and particularly the mechanical performance. The composite material is wide in application range, and can be used for the fields of household electric appliances, automobile industry, packaging, daily necessities and the like, and the method is low in cost, simple in technology, convenient to implement and beneficial to application and popularization, and is of great significance in improving the utilization level of biomass raw materials, relieving the oil resource crisis, protecting the environment and the like.

Owner:SHAANXI HUAHAOXUAN NEW ENERGY TECH DEV CO LTD

Phase change thermal interface materials including polyester resin

InactiveUS7408787B2Improve thermo-oxidative stabilitySemiconductor/solid-state device detailsSolid-state devicesPolyolefinPolyester resin

An embodiment of a phase change TIM of this invention comprises a polyester matrix with melting temperature near or below operating temperature (typically less than about 130° C.), thermally conductive filler with bulk thermal conductivity greater than about 50 W / mK, and optionally other additives. The polyester resin has improved thermo-oxidative stability compared to the polyolefin resins, thereby providing improved reliability performance during test.

Owner:INTEL CORP

Polyester/unidimensional nano silicate composite materials and method for preparing same

The invention relates to a polyester / one-dimensional nanometer silicate composite material and the preparing method, comprising putting the one-dimensional nanometer silicate after decentralized processing and polyester monomer into polymerization reactor for condensation copolymerization, then getting the high property product formed through the one-dimensional nanometer silicate chemical bond combination with polyester monomer. The product is characterized by the considerable improvement in, pull resistance and contour machining property and by the complete change of the low efficiency of previous PET as engineering material. The invention discloses adapted forpolyester manufacturing technique such as direct esterification or ester exchange and can get the product with good combination property such as high crystallization velocity and high heat resistance in the precondition of not increasing the production cost.

Owner:JIANGSU NDZ TECH

Superfine polyester fluorescent fiber with high adsorption function and preparation method thereof

ActiveCN111074363ALarge specific surface areaImprove adsorption capacityConjugated synthetic polymer artificial filamentsArtifical filament manufactureFunctionalized polystyreneSulfonate

The invention relates to a superfine polyester fluorescent fiber with a high adsorption function and a preparation method thereof, in particular to a superfine polyester fluorescent fiber with the high adsorption function based on sulfonic acid functionalized polystyrene microspheres and a preparation method of the superfine polyester fluorescent fiber with the high adsorption function. The preparation method comprises the steps of blending with polyester by using polyester master batches of mixed and blended sulfonic acid group modified polystyrene microspheres when the polyester fiber is prepared, and carrying out melt spinning to obtain the polyester fiber in the shape of a Chinese character 'mi' (the part in the shape of the Chinese Character 'mi' is polyester nylon, and the rest partis polyester blended with microspheres) which radially penetrates through the cross section. The specific surface area of the fiber is large, and the sulfonic acid functionalized polystyrene fluorescent microspheres are uniformly dispersed in a polyester matrix, so that the fiber is carried with sulfonic acid groups. The difficulty of low loading rate of sodium sulfonate in polyester in the priorart is overcome, the microspheres with high loading rate are mixed and doped into the polyester, the loading rate of the polyester sodium sulfonate is improved, and the superfine fiber has a large specific surface area, so that the obtained polyester fiber has high adsorption energy.

Owner:CHANGSHU POLYESTER +1

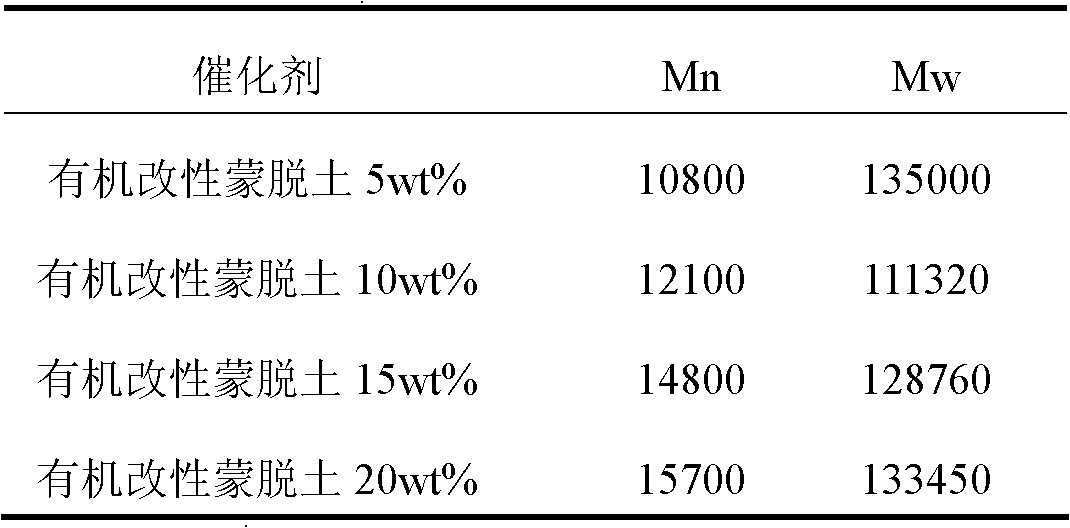

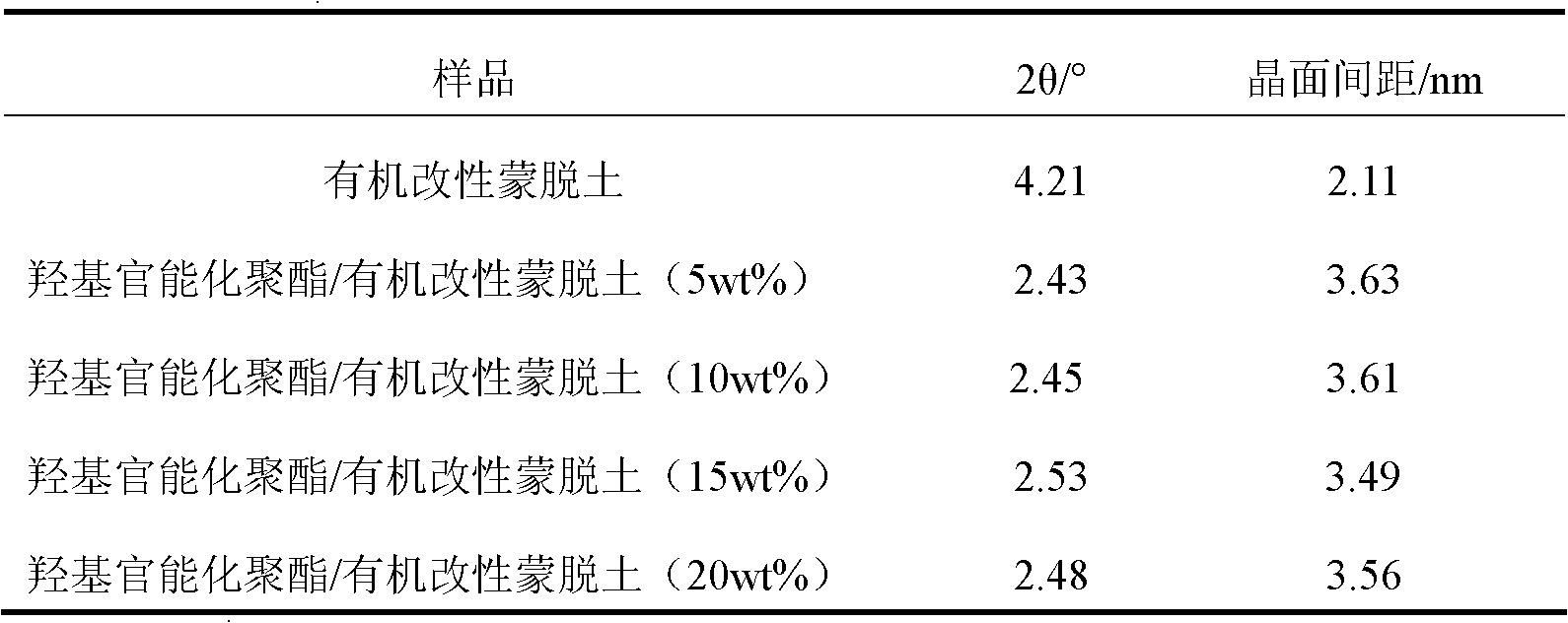

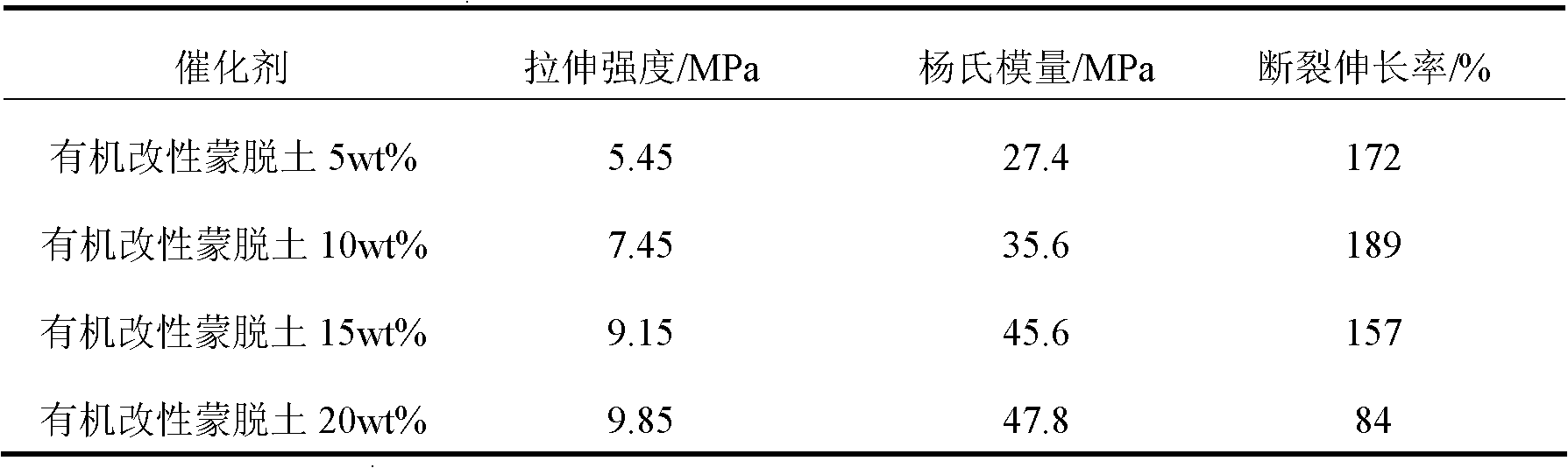

Method for preparing nano composite material of hydroxyl-functional polyester/montmorillonite

The invention relates to a method for preparing nano composite material of hydroxyl-functional polyester / montmorillonite, belonging to the technical field of polymer material. The method comprises the following steps: firstly intercalating an onium catalyst into sodium-based montmorillonite layers at 60 DEG C to 100 DEG C by adopting a cation exchange method to obtain organic modified montmorillonite; then, mixing the organic modified montmorillonite, dicarboxylic acid, dibasic epoxy compound and monocarboxylic acid for carrying out in-situ polymerization; melting a monomer dibasic epoxy compound and the dicarboxylic acid in a polymerization process for intercalating the organic modified montmorillonite; polymerizing the monomer among the montmorillonite layers and outside the montmorillonite under the action of the onium catalyst so that the montmorillonite sheet layers are pushed off; and finally uniformly distributing the sheet layers in a polyester matrix with a hydroxyl functional group so as to prepare the nano composite material of intercalating or stripping type hydroxyl functional polyester / montmorillonite. The method has the advantages of simplicity and low cost and can be applied to bulk industrial production; and the material can be widely applied to the field of biodegradable materials.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Renewable polyester film having a low modulus and high tensile elongation

Owner:KIMBERLY-CLARK WORLDWIDE INC

Antibacterial anti-mite polyester fiber and preparation method thereof

InactiveCN104264269AEasy to useImprove anti-mite and antibacterial effectMelt spinning methodsMonocomponent polyesters artificial filamentPropionatePolymer science

The invention provides an antibacterial anti-mite polyester fiber and a preparation method thereof. The antibacterial anti-mite polyester fiber comprises the following raw materials in parts by weight: 75-90 parts of polyester chips and 10-25 parts of antibacterial anti-mite master batches, wherein the antibacterial anti-mite master batches comprise the following raw materials in parts by weight: 80-95 parts of polyester chips, 5-15 parts of nano far infrared powder, 0.5-2 parts of aluminic acid ester coupling agents, 0.5-2 parts of stearic acid, 0.05-1 part of tris-(2,4-di-tert-butyl-pheny)-phosphite and 0.05-1 part of pentaerythritol tetrakis(3-(3,5-di-tert-butyl-4-hydroxyphenyl)propionate). The antibacterial anti-mite polyester fiber disclosed by the invention adopting a silver ion antibacterial anti-mite material has high-efficiency antibacterial and anti-mite effects. Moreover, due to the surface treatment, the antibacterial and anti-mite material has excellent effect of dispersing in a polyester matrix, so that the production operation is simple and convenient, and industrial production is promoted.

Owner:GUANGZHOU ZHONGCHENG NEW MATERIALS TECH

Antibacterial polyester fiber based on silver-loaded zirconium phosphate and preparation method thereof

ActiveCN105332078AValid linkStable performance and no discolorationBiocideAnimal repellantsIn situ polymerizationTerephthalic acid

The invention provides an antibacterial polyester fiber based on silver-loaded zirconium phosphate and a preparation method thereof. The antibacterial polyester fiber based on the silver-loaded zirconium phosphate is characterized in that the fiber comprises a polyester matrix, and silver-loaded zirconium phosphate powder is dispersed in the polyester matrix. The preparation method includes the steps that silver-loaded zirconium phosphate nano-powder is prepared; the silver-loaded zirconium phosphate nano-powder, terephthalic acid and dihydric alcohol are added into a polyester reaction still, silver-loaded zirconium phosphate antibacterial polyester is prepared through in-situ polymerization, and the antibacterial polyester fiber based on the silver-loaded zirconium phosphate is prepared by means of melt direct spinning; or the silver-loaded zirconium phosphate antibacterial polyester is pelleted, so that a silver-loaded zirconium phosphate antibacterial polyester master batch is obtained, and the antibacterial polyester fiber based on the silver-loaded zirconium phosphate is prepared through a master batch blended spinning method. The antibacterial polyester fiber prepared through the method has the advantages of being efficient and lasting in antibacterial action.

Owner:DONGHUA UNIV

Aliphatic polyester-nano hydroxyapatite composite material and preparation method thereof

The invention belongs to the field of preparation of a nano composite material, and especially relates to an aliphatic polyester-nano hydroxyapatite composite material and a preparation method thereof. The preparation method comprises the following steps: 1) employing coprecipitation and a hydrothermal method or a sol-gel / static spinning method, synthesizing a hydroxy apatite nano rod or nano fiber, 2) realizing surface cladding modification on nano hydroxy apatite through dopamine oxidation auto-polymerization; and 3) employing a solution blending method, the aliphatic polyester / nano hydroxy apatite composite material film or a porous support can be prepared. The method has advantages of mild modification condition, simple operation, and obvious modification effect, the aliphatic polyester-coated hydroxy apatite is uniformly dispersed in an aliphatic polyester matrix, interface bonding property is improved, the mechanical properties of the aliphatic polyester-coated hydroxy apatite composite material is obviously improved, and the composite material can be used in relative filed of bone tissue regeneration restoration.

Owner:BEIJING UNIV OF CHEM TECH

Uvioresistant high-transmitting polyester film and preparation method thereof

InactiveCN104149429ALow scattering energyPromote absorptionSynthetic resin layered productsUltraviolet lightsNano zinc oxide

The invention belongs to the field of high polymer materials and in particular relates to an uvioresistant high-transmitting polyester film and a preparation method thereof. The uvioresistant high-transmitting polyester film comprises an uvioresistant polyester layer and silica film layers, wherein the silica film layers are arranged on one surface or two surfaces of the uvioresistant polyester layer; the uvioresistant polyester layer is formed by dispersing an uvioresistant agent in a polyester matrix, and the uvioresistant agent comprises nano-titanium dioxide and nano-zinc oxide. The preparation method comprises the following steps: preparation of the uvioresistant polyester layer; corona treatment; and preparation of silica sol and film coating. According to the technical scheme, the uvioresistant agent is used; compared with current single titanium dioxide, composite powder has low scattering capacity to visible light of 400-700nm and can well absorb ultraviolet light of 200-350nm in spectrum. Sol prepared by sol-gel processing is used for improving permeability under a proper film coating condition, and finally the uvioresistant high-transmitting polyester film is prepared.

Owner:SUZHOU XILIN OPTOELECTRONICS TECH IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com