Method for preparing aliphatic polyester composite material by means of alkyl ketene dimer surface modification biomass fibers

A technology of alkyl ketene dimer and biomass fiber, which is applied in the field of cellulose modification and polymer composite materials, to achieve the effects of improving comprehensive performance, good reinforcement, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] (1) Preparation of AKD emulsion and its surface treatment of poplar wood powder:

[0065] Surface treatment of 80-100 mesh poplar wood powder with commercial series AKD emulsion (product of a company in Shandong, solid content 15%, AKD content 12%). The amount of AKD relative to poplar wood powder is 2% (mass fraction). Stir at 2000r / min for 15min in a high-speed mixer.

[0066] (2) Drying and curing treatment of poplar wood powder modified fiber:

[0067] According to the above surface modification, the poplar wood powder modified fiber was air-dried at 105° C. for 4 hours, and sealed for later use.

[0068] (3) Composite of poplar wood powder modified fiber and PBS:

[0069] The materials are proportioned according to the following mass percentages: 30% modified poplar wood powder fiber after drying treatment, 70% PBS, processed in an internal mixer at 120°C for 10 minutes, and hot pressed to form a PBS / poplar wood powder composite material. .

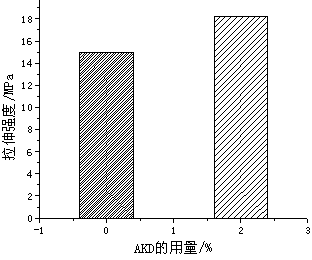

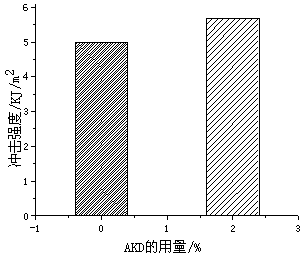

[0070] by Figure 1a , Figure 1...

Embodiment 2

[0072] (1) Preparation of AKD emulsion and its surface treatment of bamboo powder:

[0073] Surface treatment of 60-80 mesh bamboo powder with commercial series AKD emulsion (product of a company in Shandong, solid content 15%, AKD content 12%), the amount of AKD relative to bamboo powder is 2% (mass fraction), in a high-speed mixer Stir at 2000r / min for 15min.

[0074] (2) Drying and curing treatment of bamboo powder modified fiber:

[0075] The obtained modified bamboo powder fiber was air-dried at 90°C for 24 hours, and sealed for later use.

[0076] (3) Compound of bamboo powder modified fiber and PLA:

[0077] The materials are proportioned according to the following mass percentages: 35% of bamboo powder modified fiber after drying and curing treatment, 65% of PLA, processing at 200℃ for 8 minutes on a mill, and hot pressing to prepare PLA / bamboo powder composite material.

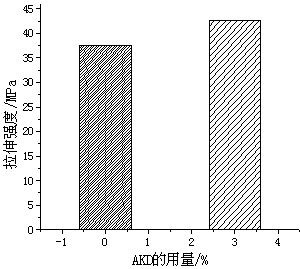

[0078] Compared with the composite material without AKD, the composite material prepared with AKD surface-t...

Embodiment 3

[0080] (1) Preparation of AKD emulsion and surface treatment of bamboo powder:

[0081] Weigh 15 grams of cationic starch, 1.5 grams of lignosulfonate, 17.5 grams of aluminum sulfate, and 846 mL of water, mix them thoroughly under stirring, and heat at 80°C for 60 minutes to form an emulsifier and place in an incubator. Heat 120 grams of AKD wax powder (product of a company in Shandong, chain length: C14-C16) to melt, and fully mix the emulsifier and AKD wax powder to prepare an emulsion with a mass fraction of 15%.

[0082] The surface treatment of 60-80 mesh bamboo powder is carried out with the emulsion, and it is stirred for 20 minutes with a high-speed mixer at 2000 r / min.

[0083] (2) The curing treatment of bamboo powder modified fiber:

[0084] The obtained bamboo powder modified fiber was air-dried at 100°C for 24 hours and sealed for later use.

[0085] (3) Compound of bamboo powder modified fiber and PBS:

[0086] The materials are proportioned according to the following mass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com