Flame-retardant glass fiber reinforced PBT (polybutylene terephthalate) with high glow wires and high CTI (comparative tracking index) value and method for preparing flame-retardant glass fiber reinforced PBT

A technology of high glow wire and glass fiber, applied in the field of high glow wire, high CTI value flame retardant glass fiber reinforced PBT and its preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

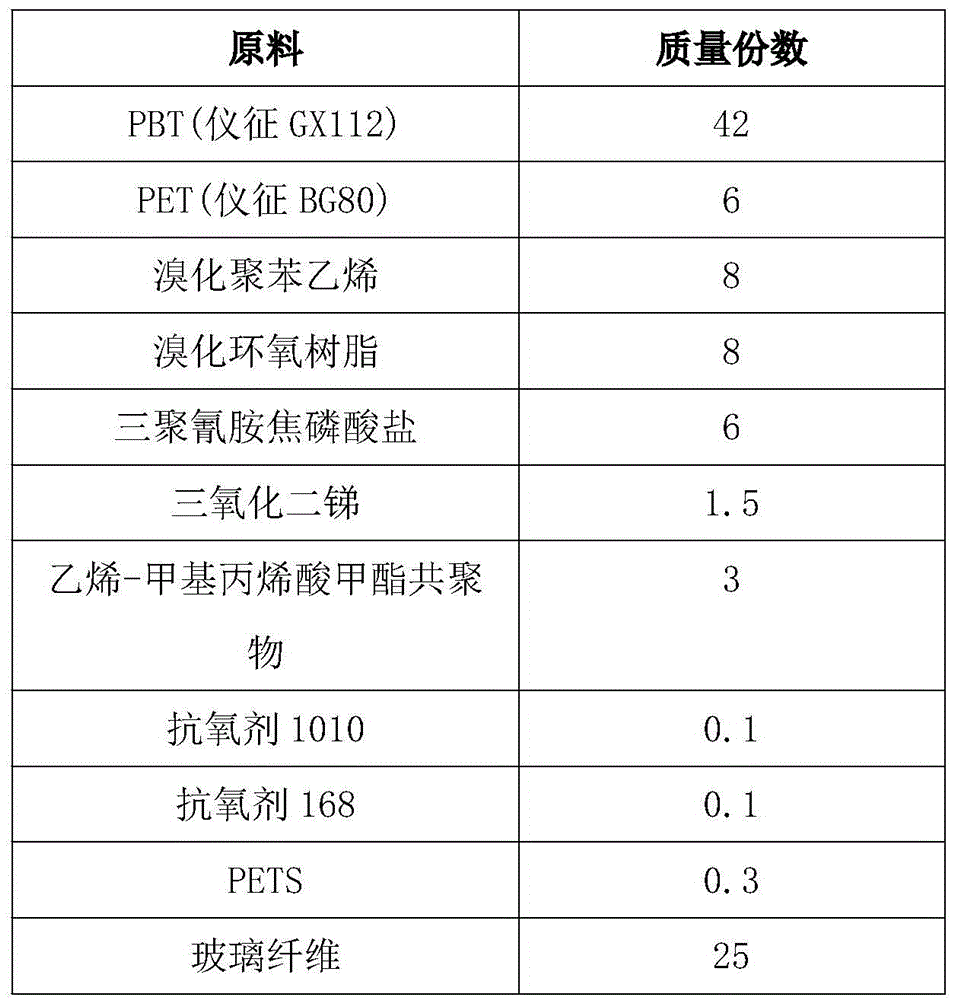

[0023] Example 1: Preparation of flame retardant glass fiber reinforced PBT with high glow wire and high CTI value

[0024] Table 1 Example 1 used each component dosage table (parts by mass)

[0025]

[0026] Mix all components in the formula except glass fiber evenly; put the mixed material in a twin-screw extruder to melt and extrude, and granulate; the processing technology is as follows: the temperature in the first zone of the twin-screw extruder is 230-250°C , The temperature in the second zone is 235~255℃, the temperature in the third zone is 240~260℃, the temperature in the fourth zone is 240~260℃, the temperature in the fifth zone is 220~240℃, the temperature in the sixth zone is 220~240℃, the temperature in the seventh zone is 230~250℃, the temperature in the eighth zone The zone temperature is 240-260°C, the die head temperature is 250-270°C, the screw speed: 380-420 rpm, the glass fiber is added from the glass fiber port of the twin-screw extruder, and the screw...

Embodiment 2

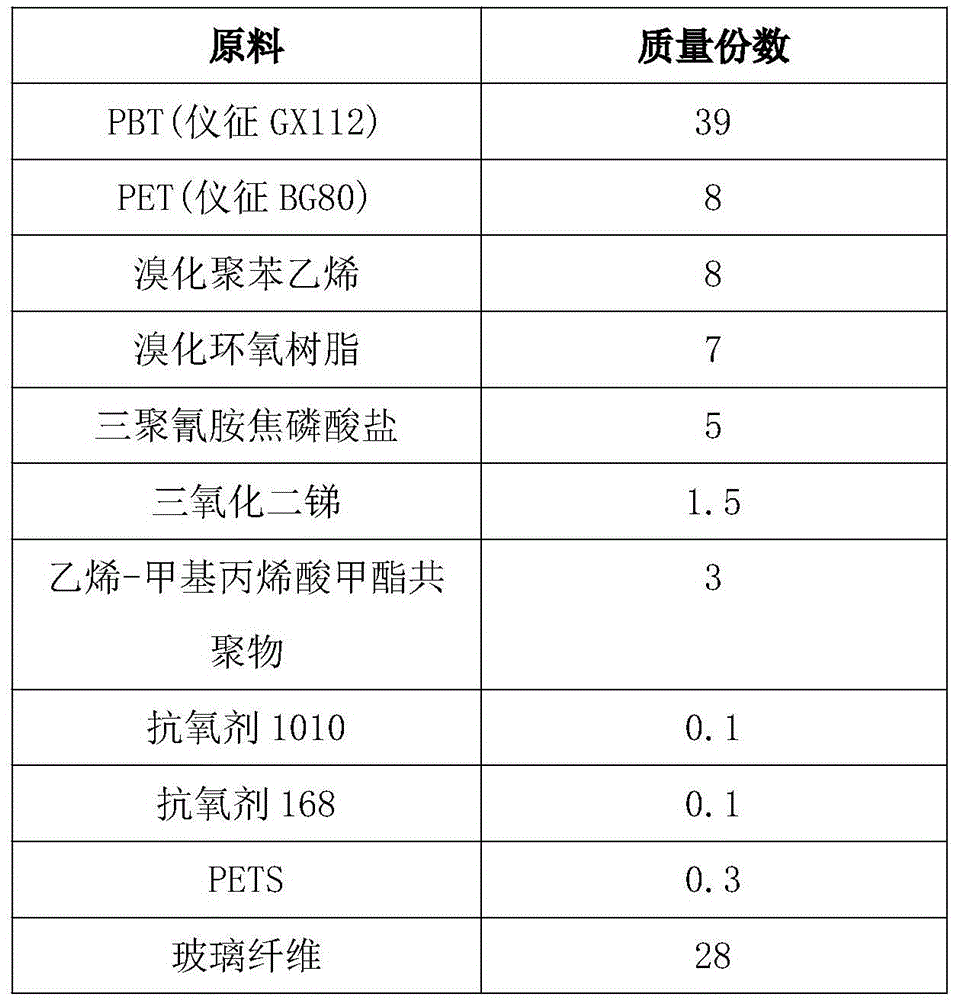

[0027] Example 2: Preparation of flame retardant glass fiber reinforced PBT with high glow wire and high CTI value

[0028] Table 2 Example 2 used each component dosage table (parts by mass)

[0029]

[0030] Preparation method: Same as Example 1 to obtain high glow wire and high CTI value flame retardant glass fiber reinforced PBT pellet II.

Embodiment 3

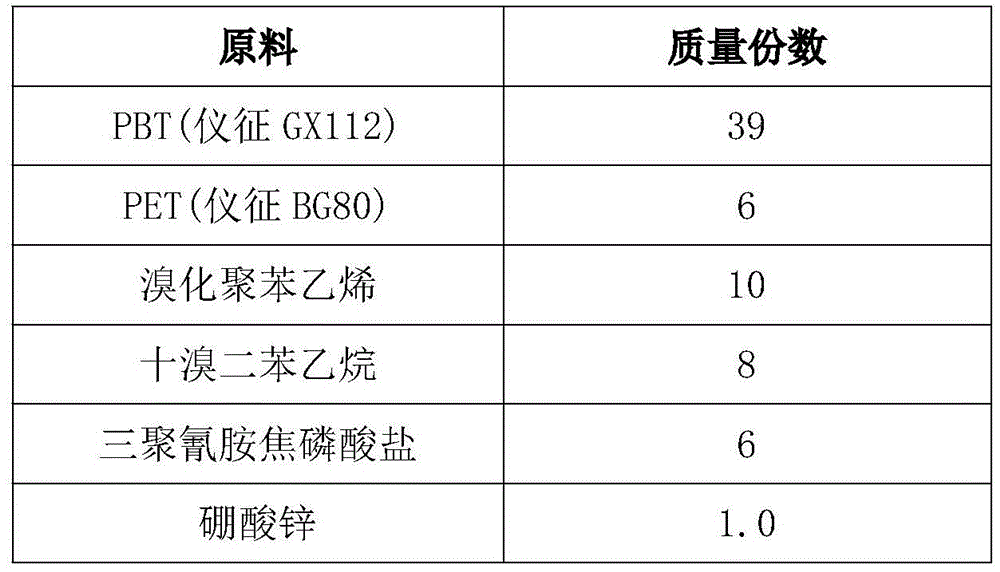

[0031] Example 3: Preparation of flame retardant glass fiber reinforced PBT with high glow wire and high CTI value

[0032] Table 3 Example 3 used each component dosage table (parts by mass)

[0033]

[0034]

[0035] Preparation method: Same as Example 1 to obtain high glow wire, high CTI value flame retardant glass fiber reinforced PBT pellet III.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Notched impact strength | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com