Enhanced flame-retardant nylon composition with high glow wire initiation temperature and preparation method thereof

A technology of light-off temperature and high glow wire, applied in the field of polymer materials, to achieve the effect of improving light-off temperature, excellent temperature resistance and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

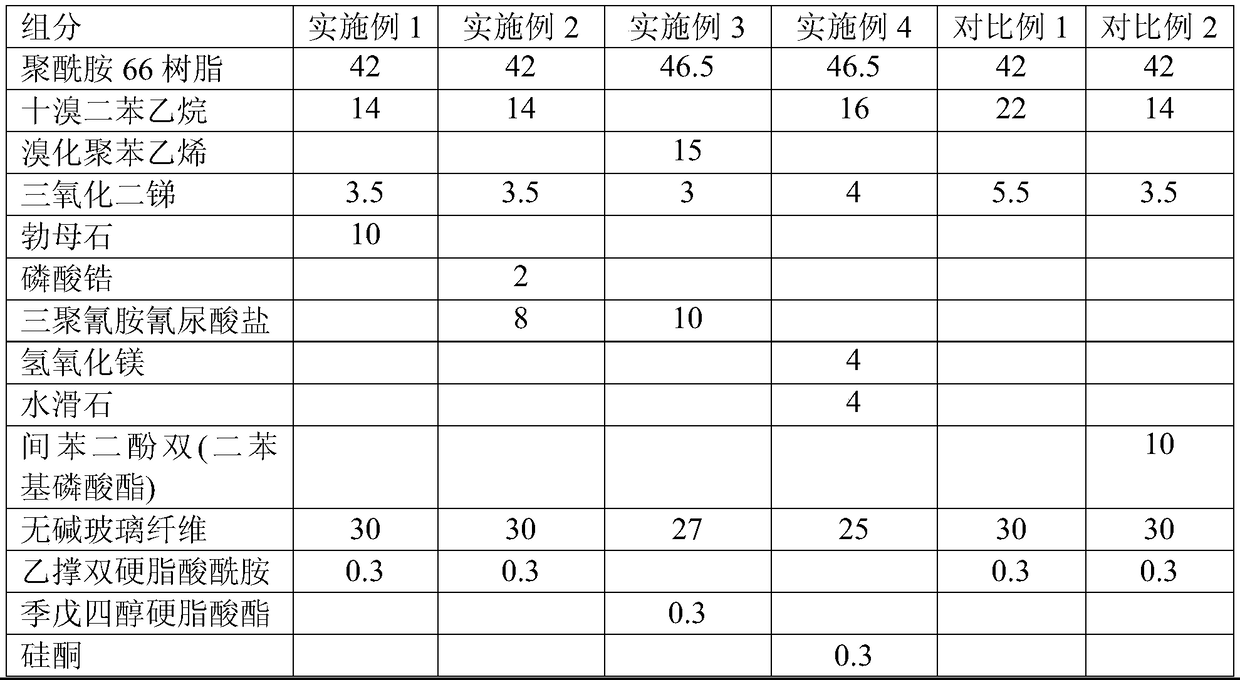

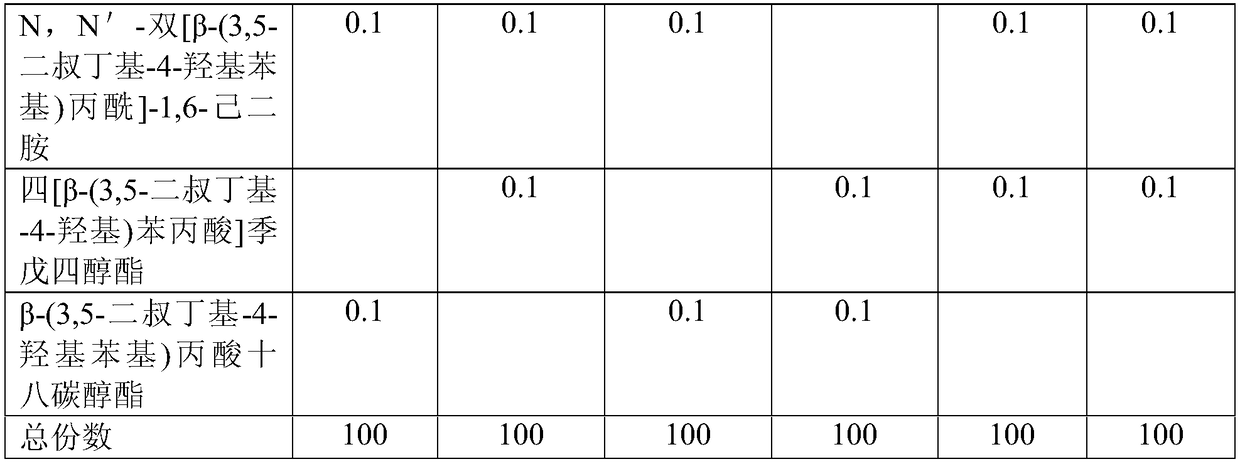

[0023] Preparation Example of Nylon Composition

[0024] The nylon composition of preparation embodiment 1-embodiment 4, comparative example 1 and comparative example 2 as shown in table 1, preparation method comprises the steps:

[0025] 1) Dry the polyamide 66 resin at 102°C for 4 hours, weigh the dried polyamide 66 resin, weigh the composite flame retardant, glow wire ignition temperature increaser antioxidant and lubricant, and add them to the high-speed mixer Mix, 4min, obtain mixed material;

[0026] 2) Add the mixed material from the main feeding port of the twin-screw extruder, add the glass fiber from the side feeding port of the twin-screw extruder, and the processing temperature of each zone of the twin-screw extruder is 220-260°C , the rotation speed of the screw is 200-250r / min, extruded into pellets, water-cooled, blow-dried, and then pelletized to obtain a reinforced flame-retardant nylon composition with a high glow-wire ignition temperature, which is injected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com