Method and system for exhaust aftertreatment

A technology of exhaust system and exhaust flow, which is applied in the direction of exhaust treatment, electronic control of exhaust treatment device, exhaust device, etc., and can solve problems such as boost pressure loss and turbo lag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

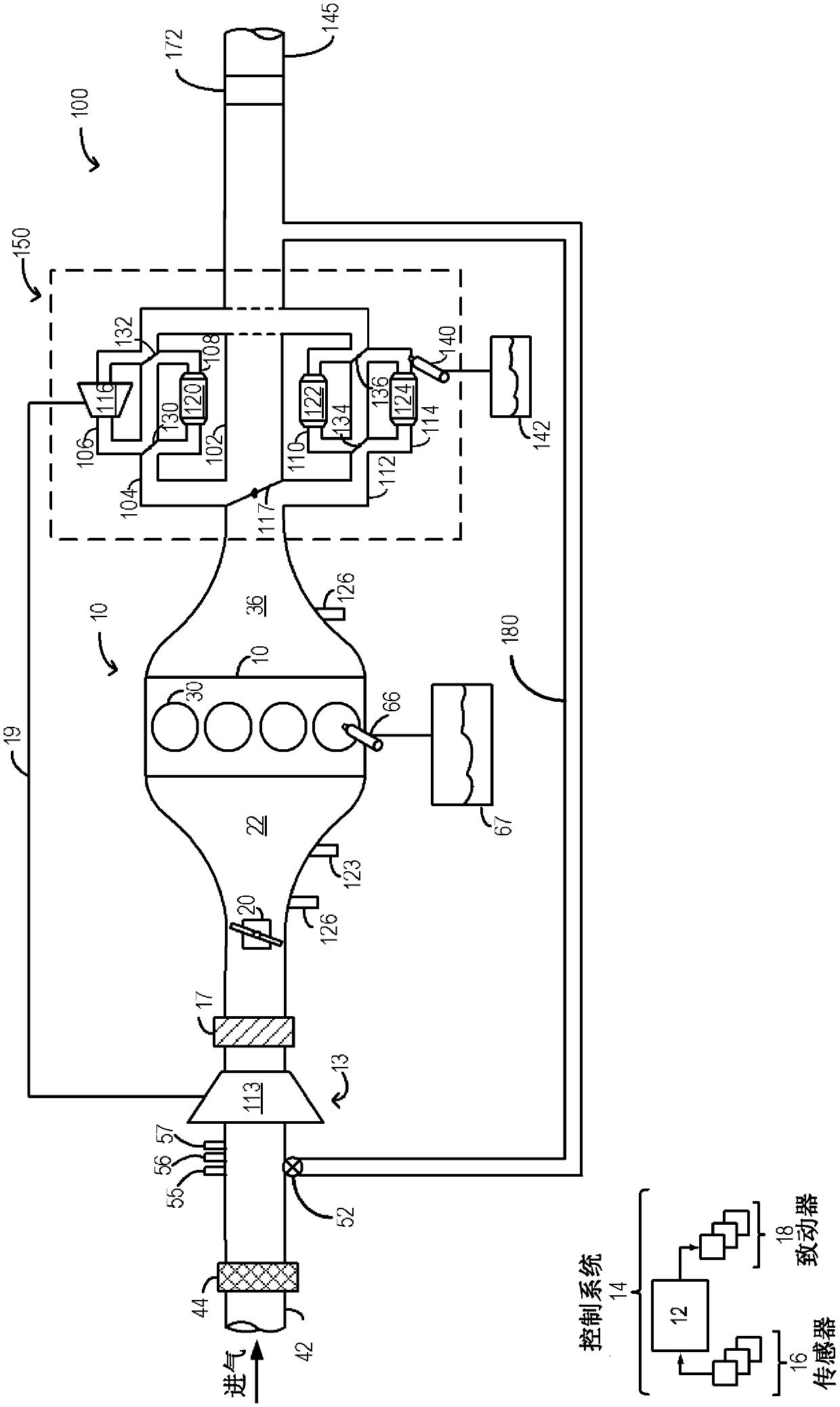

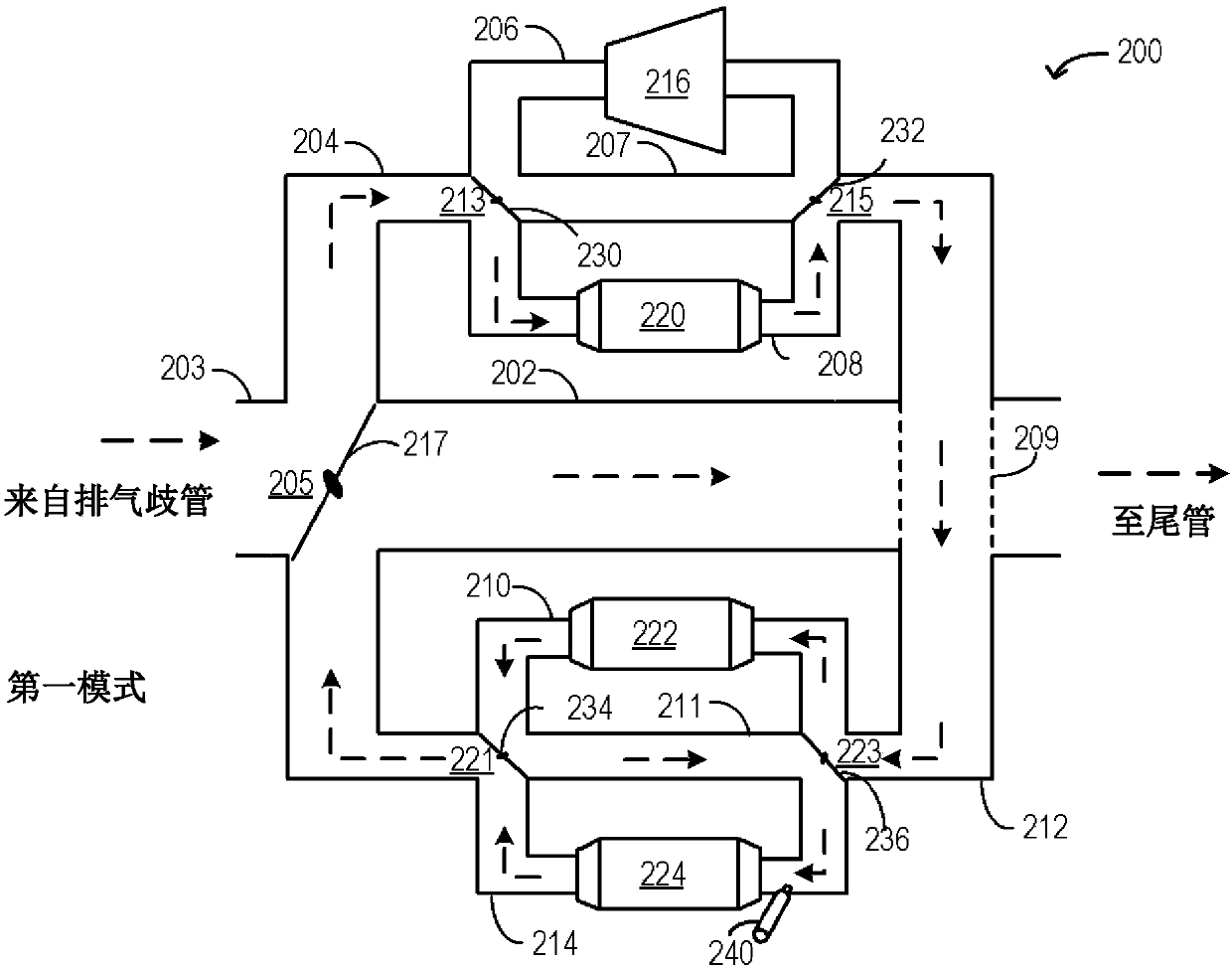

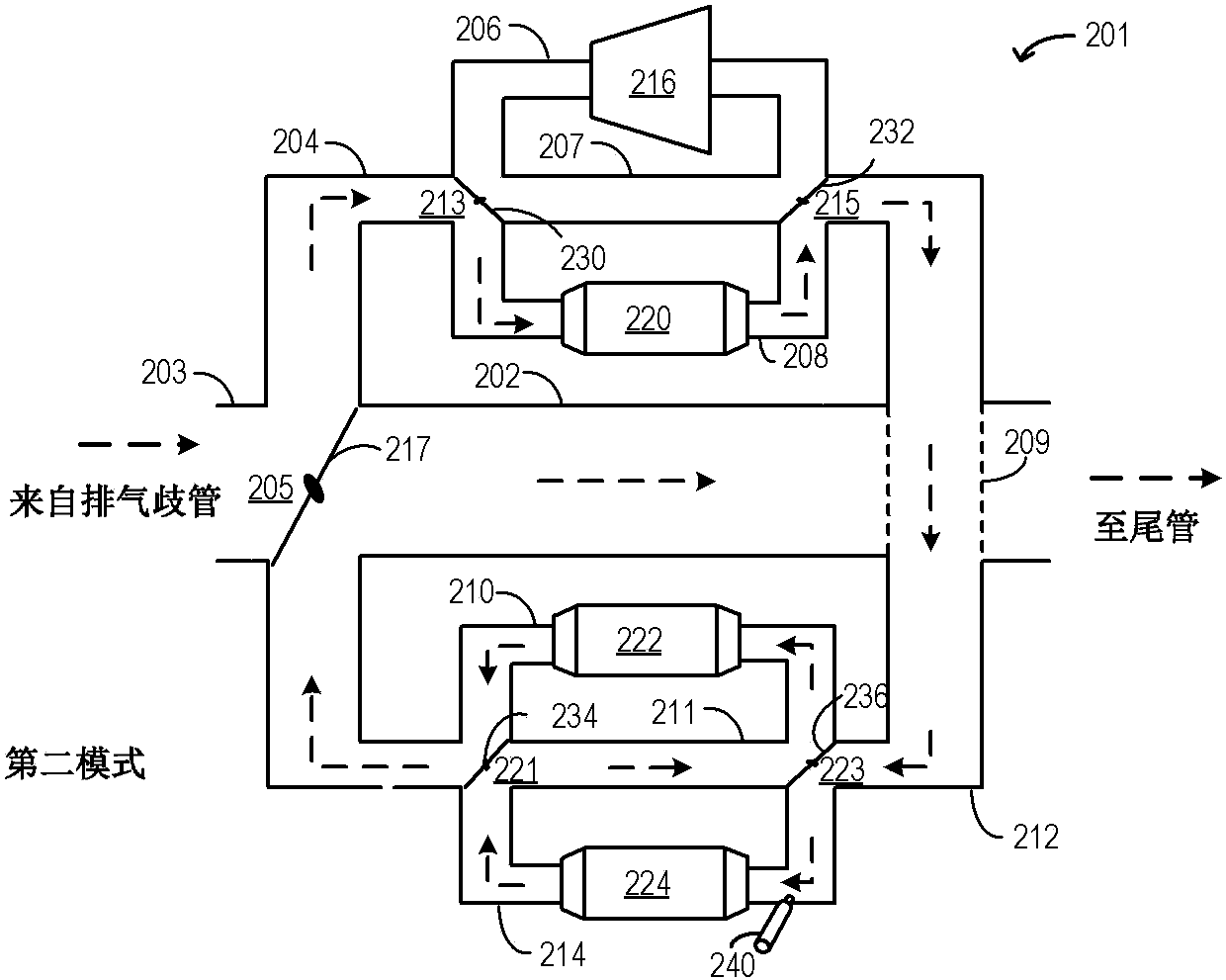

[0028] The following description relates to systems and methods for operating a branch exhaust aftertreatment system to increase the efficiency of exhaust system components and reduce engine emissions. figure 1 An example engine system including a branched exhaust assembly is shown. Different exhaust manifold components, such as the turbo, diesel oxidation catalyst (DOC), diesel particulate filter (DPF), and selective catalytic reduction (SCR) catalyst, may be housed in different branches of the assembly. Figure 7 A cross-sectional view of a DPF showing views of alternating passages. refer to Figure 2A to Figure 2J The different modes of operation of the branch exhaust assembly are detailed. The engine controller can be configured to execute control programs such as image 3 with Figure 4 An example procedure for directing exhaust gas through different branches of a branched exhaust assembly based on the engine operating conditions and temperature requirements of the re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com