Patents

Literature

180results about How to "Meet heating requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

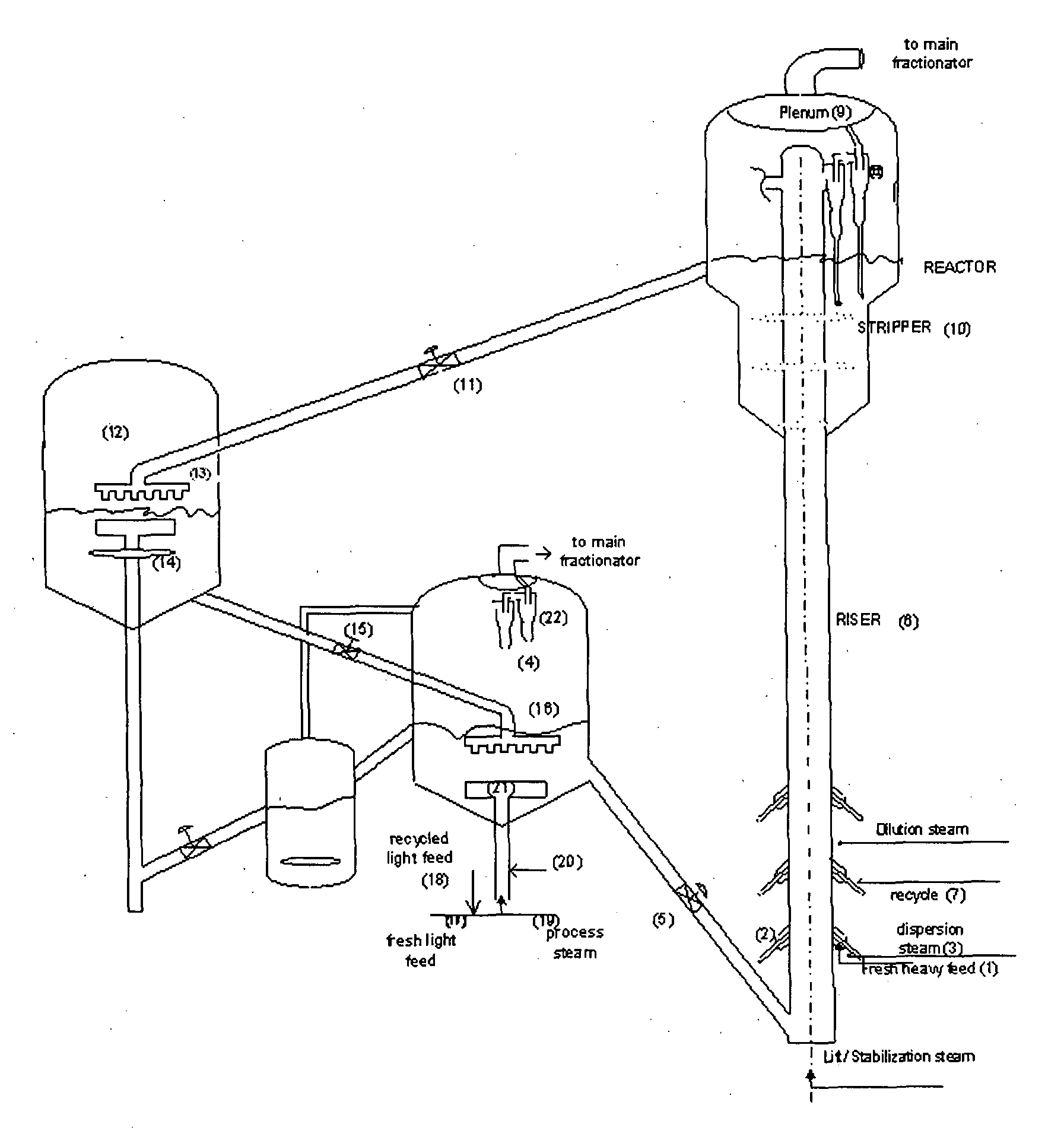

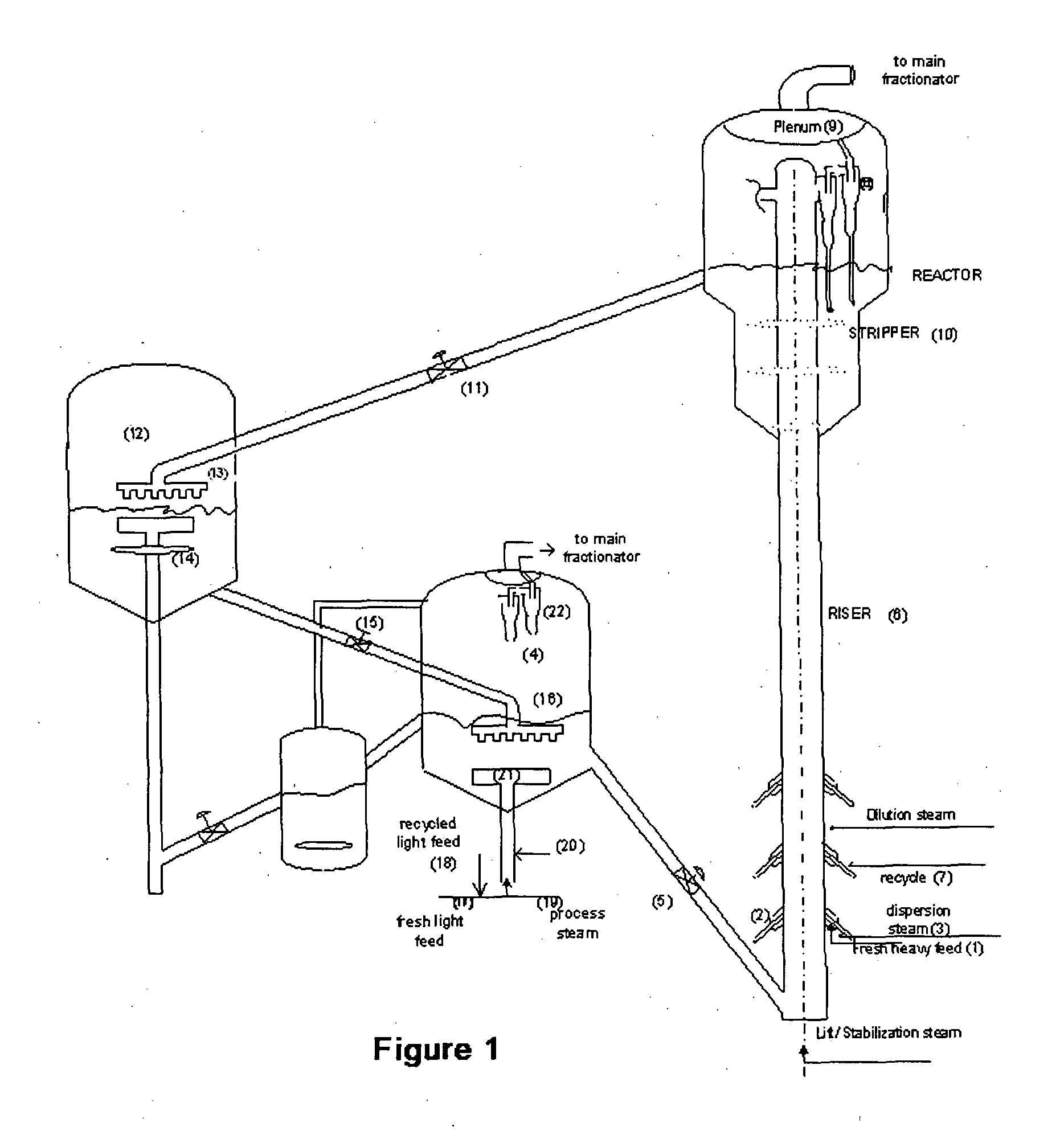

Process for simultaneous cracking of lighter and heavier hydrocarbon feed and system for the same

ActiveUS20130056393A1Reduce sulfur contentEfficient use ofTreatment with plural serial cracking stages onlyCatalytic crackingProcess conditionsHydrocarbon

The invention provides for a process and apparatus for simultaneous conversion of lighter and heavier hydrocarbon feedstocks into improved yields of light olefins in the range of C2 to C4, liquid aromatics in the range C6 to C8 mainly benzene, toluene, xylene and ethyl benzene and other useful products employing at least two different reactors operated in series with respect to catalyst flow and parallel with respect to feed flow under different regimes and process conditions with same catalyst system.

Owner:INDIAN OIL CORPORATION

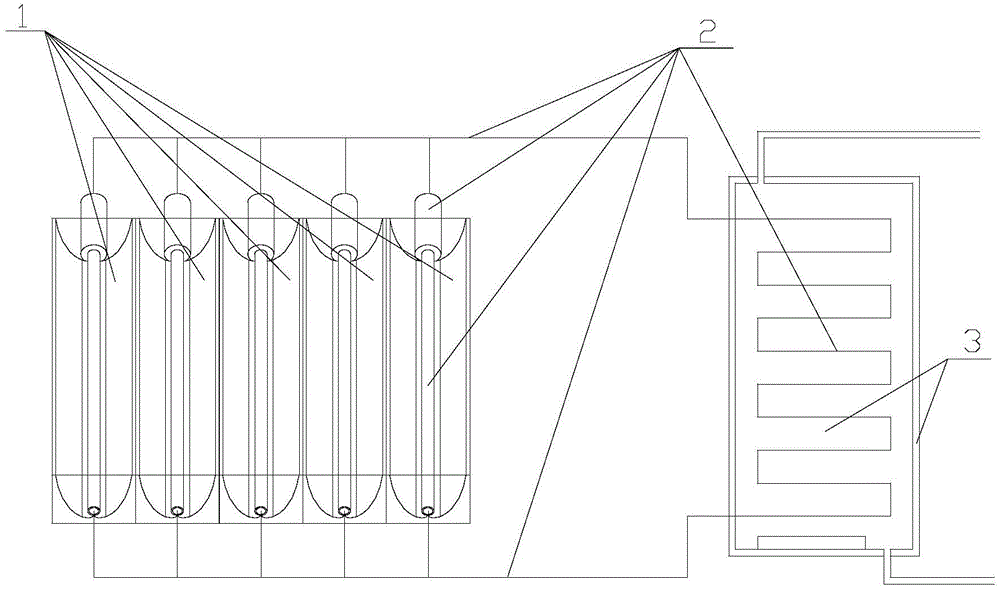

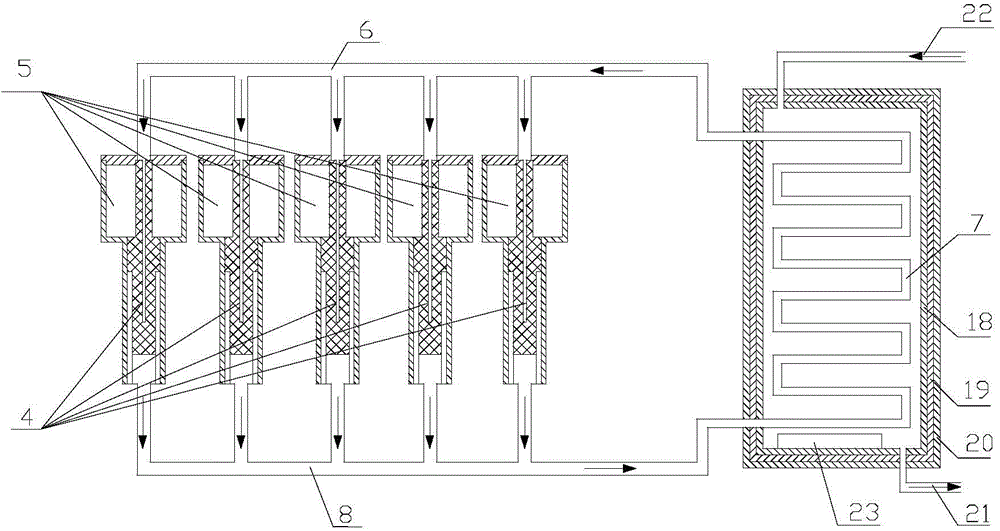

Solar heat collecting and transporting device

InactiveCN103954048AReduce complexityImprove economySolar heating energySolar heat devicesHeat transfer efficiencyEvaporator

Solar heating is an environment-friendly and effective means for reducing building energy consumption which is increased day by day and enabling a city and a village to enjoy the same heating comfort, but an existing heat collecting way is large in heat collecting area, low in heat transfer efficiency and low in building integration flexibility. The invention provides a novel solar building heating, heat collecting and transmitting system without mechanical work consumption. The solar building heating, heat collecting and transmitting system mainly consists of a composite paraboloid light condensation heat collector, a loop-circuit heat pipe and a user hot water system, wherein the loop-circuit heat pipe is formed by connecting multiple evaporators in parallel. According to the solar building heating, heat collecting and transmitting system provided by the invention, the composite paraboloid light condensation heat collector is adopted, and efficient collecting of solar energy is realized through pure light condensation; efficient collecting of heat is realized through the multiple evaporators of the loop-circuit heat pipe which are connected in parallel; solar heat driving without the mechanical work consumption is realized by utilizing capillary suction forces of capillary cores of the multiple evaporators of the loop-circuit heat pipe; efficient, long-distance and multi-angle transmission of high-load solar heat energy is realized by utilizing the circulation phase change of a working medium in a closed space, and thus efficient collection and transmission of low-temperature solar energy are realized.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Heating system

ActiveCN102734857AReduce initial investmentControl Heating CostsLighting and heating apparatusSpace heating and ventilation detailsProcess engineeringHeating system

The invention discloses a heating system, comprising a heat source (1) for supplying a high-temperature working medium and heating tail ends with at least more than two forms, wherein the heating tail ends with various forms are connected in parallel, are connected in series or are arranged in a combined parallel and serial connection manner, and are respectively communicated with the heat source (1) through pipelines so as to form a loop; and the heating tail ends specially are at least two of a heat radiator, a heating coil pipe and an air blower coil pipe. Compared with the prior art, in the heating system provided by the invention, on one hand, the heating tail ends with the corresponding forms can be arranged according to rooms with different functions, and the property indexes of comfort, warming speed and the like can be met simultaneously, so that the heating requirements of the rooms with the different functions can be met, and the flexible arrangement is realized; and on the other hand, the heating tail ends with various forms use one heat source, so that the initial system of the system is greatly reduced, and the heating cost is effectively controlled.

Owner:浙江和际投资管理有限公司

Method and device for heating by heat electric heating pump phase-change thermal storage

InactiveCN101298925AImprove heating efficiencyReduce usage costsCentral heating with accumulated heatLighting and heating apparatusThermal energyHeat storage material

Disclosed is a thermoelectric heat pump phase change heat storage heating method and a device. When in energized heat storage during the trough electrovalency phase, the thermoelectric chip set is connected with one end of the phase change heat storage materials as the fire end, and the heat energy generated is transferred to the phase change heat storage materials for storage, while the other end of the thermoelectric chip set becomes the cool end and adsorbs the waste heat from the surrounding air. When in heat emission heating, there is provided with two working modes, the first working mode is an energy saving mode, wherein the surrounding air directly exchange the heat with the regenerative phase change heat storage materials to realize the heat release warm; when the first working mode can not satisfy the warm request, the current direction of the thermoelectric chip set is changed, to make the cold and heat end faces changed; one end of the thermoelectric chip set connected with the phase change heat storage materials becomes the cold end, which adsorbs the heat energy of the phase change heat storage materials, and the heat of the other end of the thermoelectric chip set is released for the warm.

Owner:HUNAN UNIV

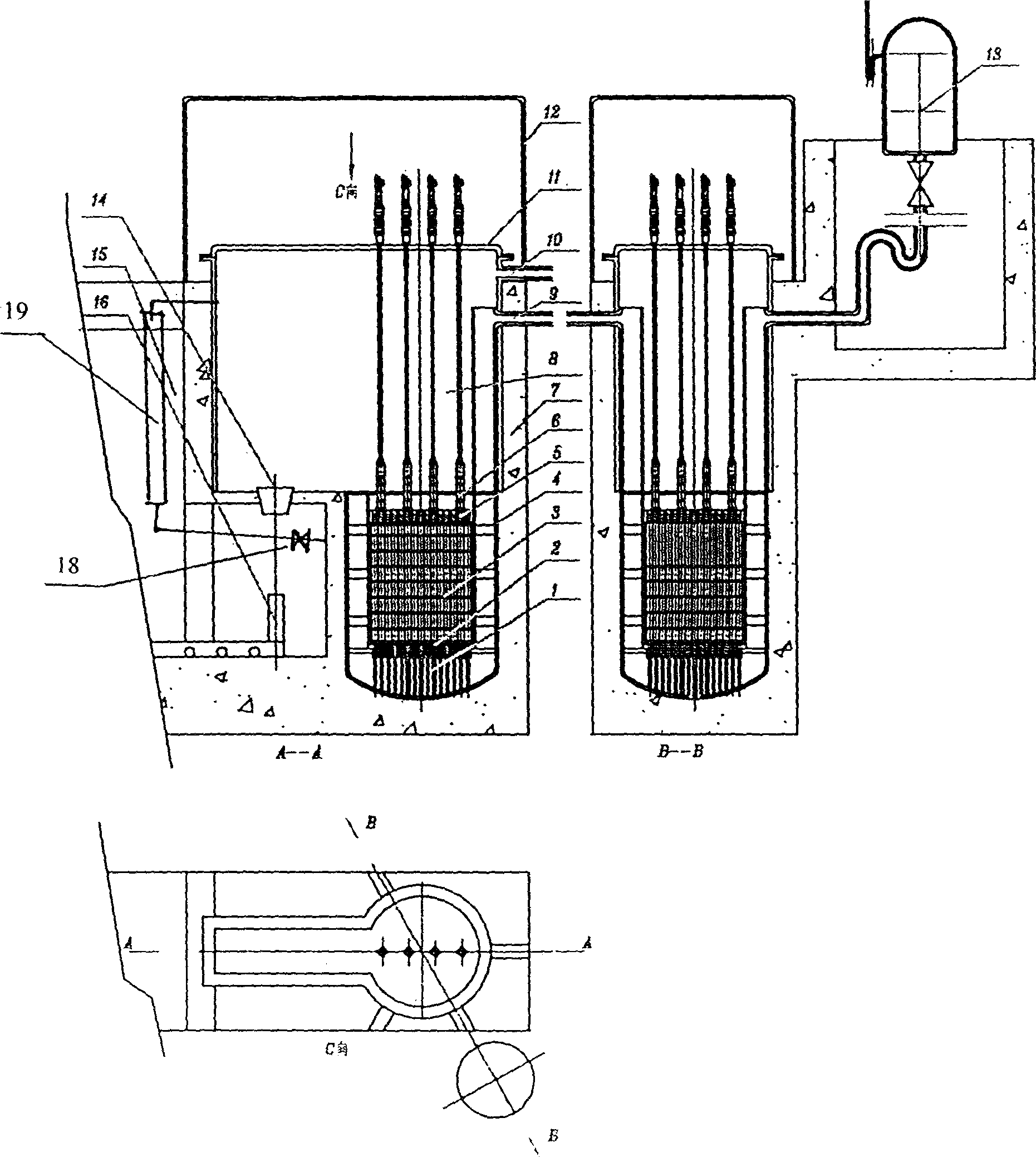

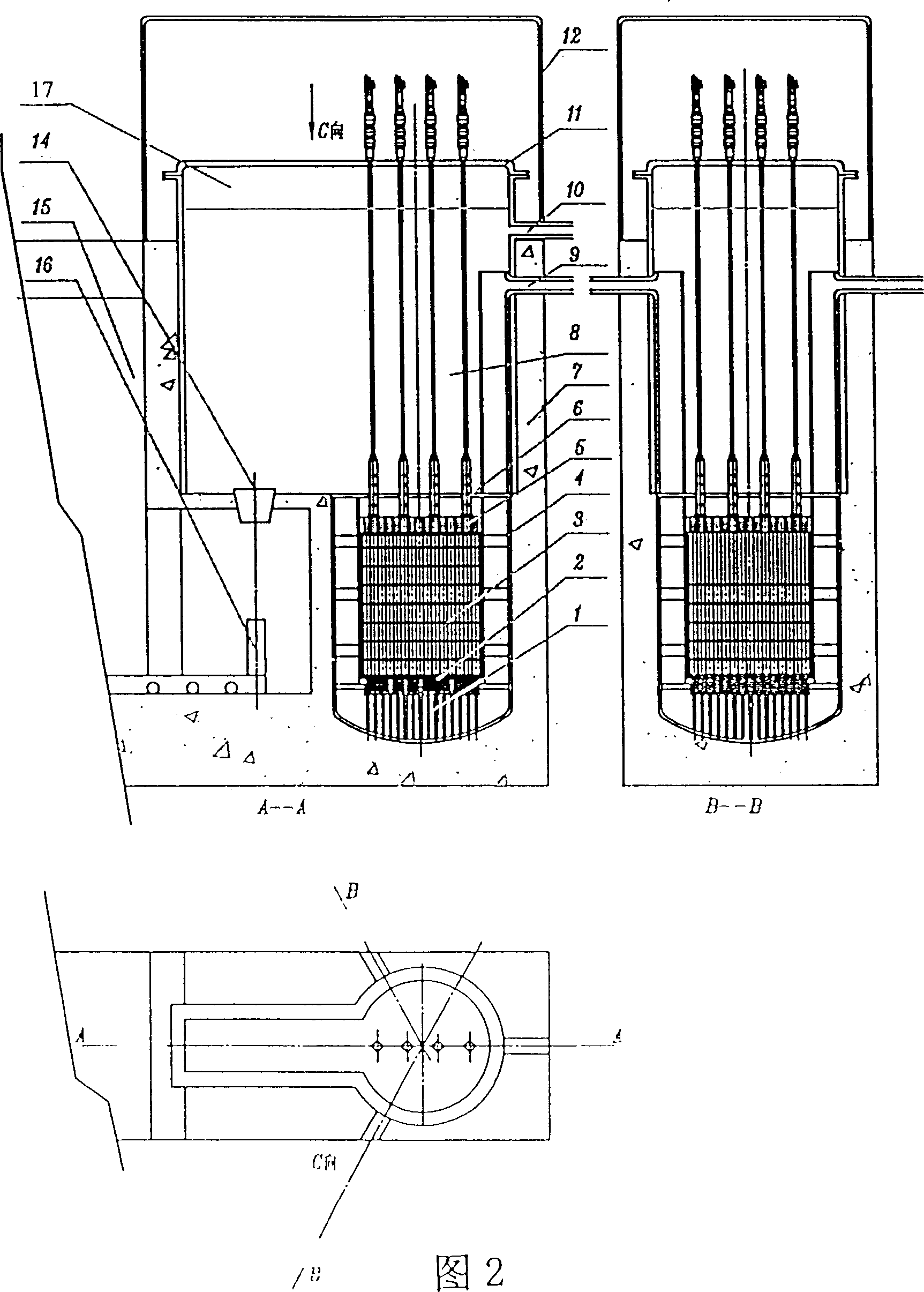

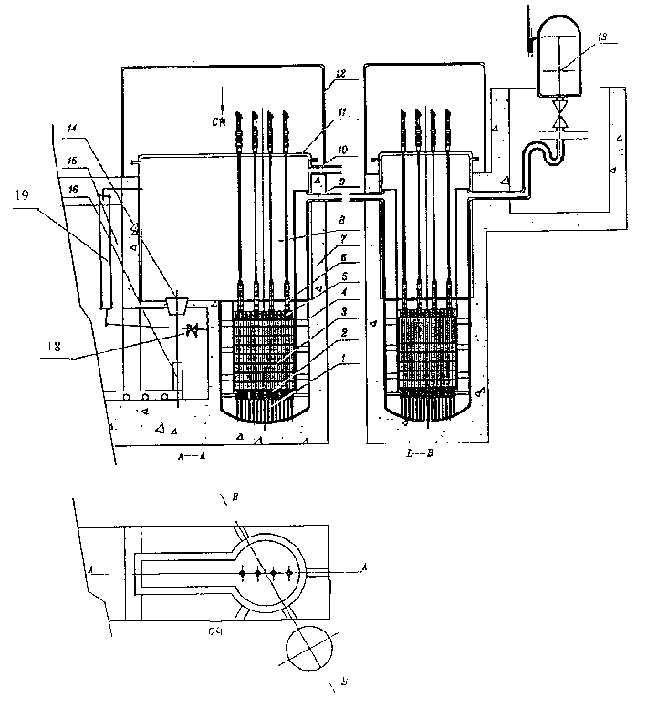

Low-temp nuclear reactor with hypofuel for nuclear power station

InactiveCN1396603AImprove use valueSave fuelNuclear energy generationNuclear engineering problemsRadioactive gasNuclear reactor

A low-temp. nuclear reactor using the deleted fuel of nuclear power station has a reactor core in its water pool with a sealing cover. The gas with a certain pressure is aerated in the water pool via the sealing cover. At the side of the water pool, there is a fuel loading-unloading channel communicated with the water pool where the deleted fuel is stored. Its advantages are low cost, high utilization rate of U-resource, and no radioactivity pollution.

Owner:李玉仑 +2

Heat pump system for air conditioning adaptable to cold regions

InactiveUS20020129615A1Increase costSimple structureHeat pumpsDomestic cooling apparatusThermal expansionEngineering

A heat pump system for air conditioning adaptable to cold regions, comprising a compressor, a condenser, a thermal expansion valve and an evaporator and forms a closed circuit. The structure features that said compressor is a scroll compressor, and a supplementary inlet is provided on the inlet side of the compressor. A subcooler is provided between the condenser and the expansion valve, thus forming a closed circuit with an electromagnetic valve and an electronic expansion valve for supplementary refrigerant vapor to the supplementary inlet of the compressor. Compared to the prior art, the present invention is simple in structure, easy to manufacture and assemble, highly effective in energy utilization and low cost, and the system can operate in low temperature environment with stability and reliability. Therefore, it is particularly suitable for popularization and application in cold regions.

Owner:TSINGHUA TONGFANG CO LTD +2

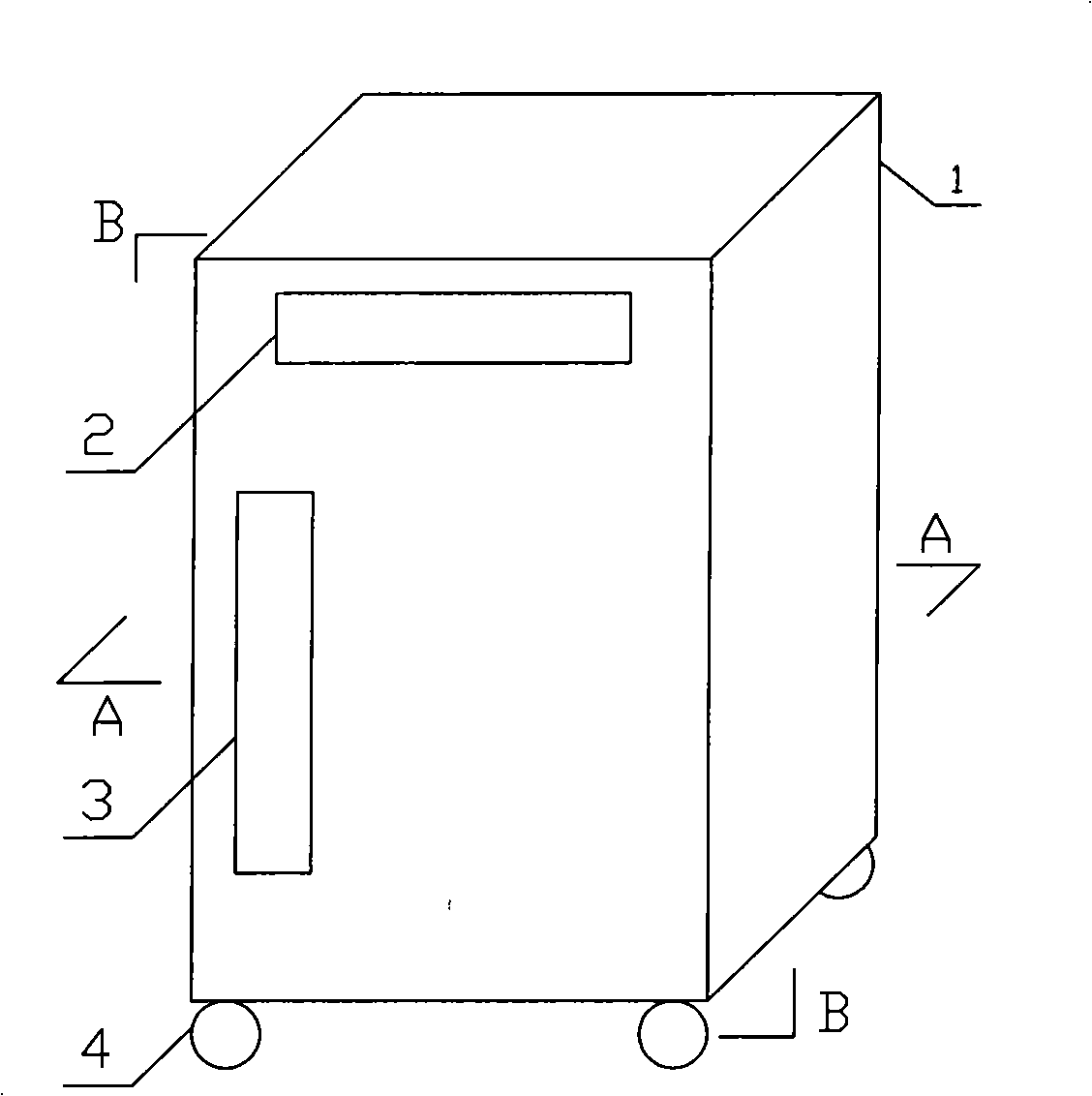

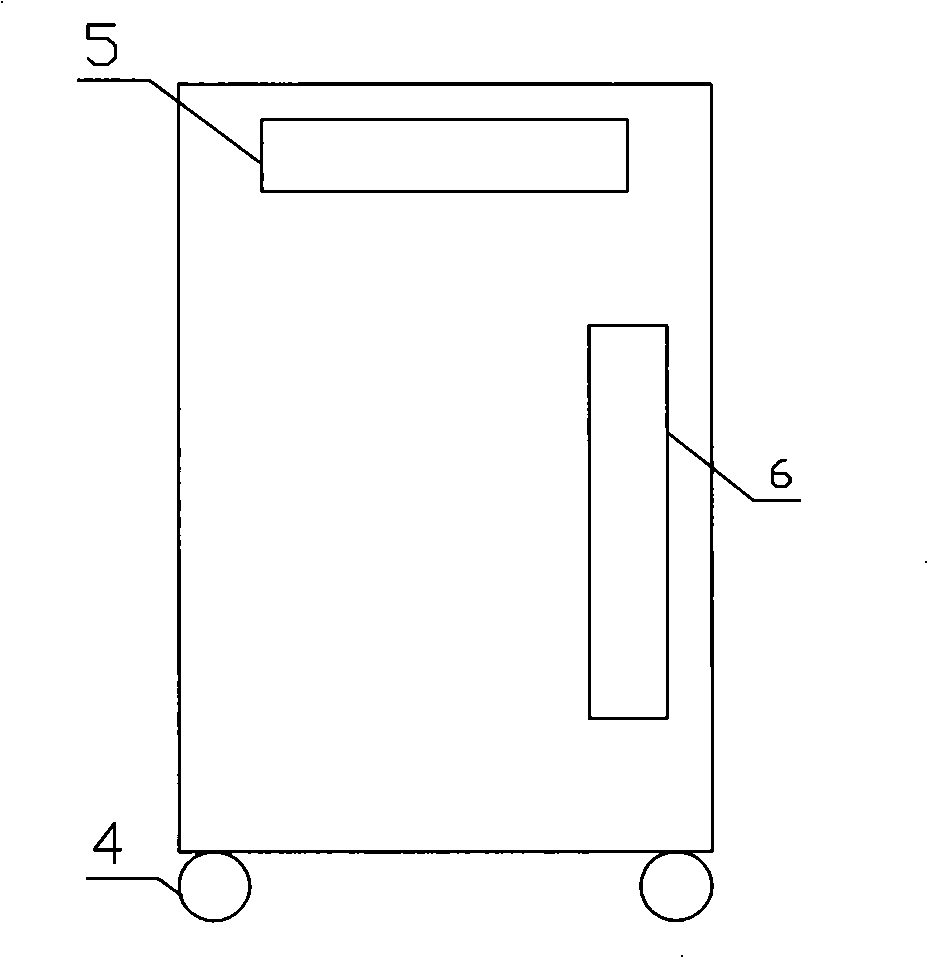

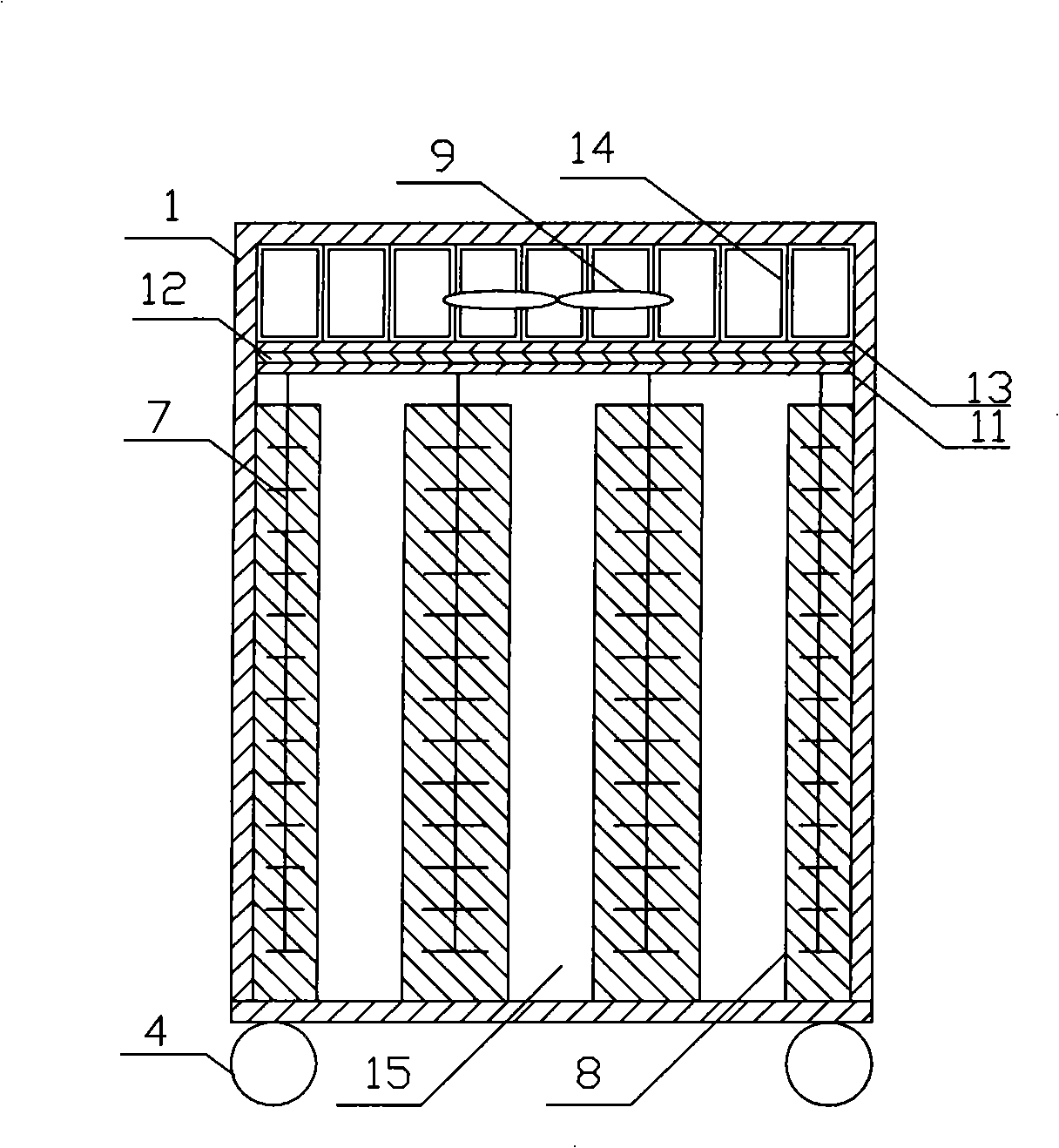

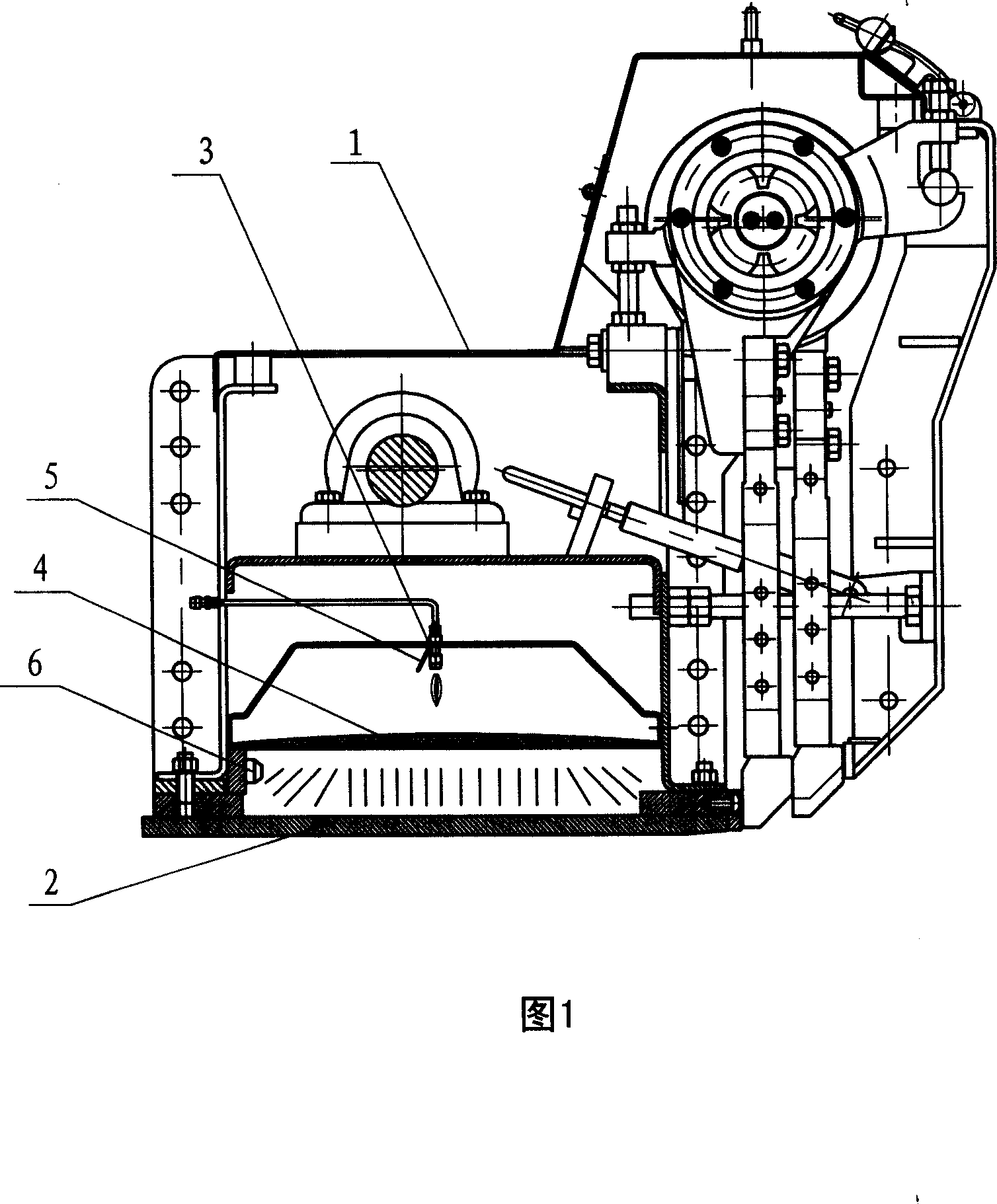

Movable greenhouse water and fertilizer irrigator

InactiveCN106508509ASave electricitySave waterClimate change adaptationPressurised distribution of liquid fertiliserTemperature controlGreenhouse

The invention provides a movable greenhouse water and fertilizer irrigator which comprises a tank body and an irrigator body. A feeding port, a stirring shaft, a hand crank, a water inlet, a temperature sensor, a water outlet pipe and a heating cavity are arranged on the tank body. The stirring shaft penetrates through the middle of the upper end of the tank body, a bearing is arranged at the position where the stirring shaft is in contact with the upper end of the tank body, and a stirring rod is arranged on the stirring shaft. A water outlet pipe is arranged at the slightly lower portion of the right end of the tank body, a filter screen and a valve are arranged in the water outlet pipe, and a plurality of branch pipes are arranged at the outer end. The branch pipes are symmetrically distributed at two ends of the water outlet pipe and are provided with spray heads. Heating cavities are formed in walls of the left and right ends of the tank body, and electrical heating wires are arranged in the heating cavities. A handle, a water tank and supporting legs are arranged on the irrigator body. The handle is fixed to the left end of the irrigator body, and a fixing ring is arranged on the handle. The water tank is fixed to the irrigator body, and a water pump is arranged on the water tank. The movable greenhouse water and fertilizer irrigator facilitates irrigation, fertilizer application, pesticide spraying, heating and temperature control, is diversified in function and convenient to move and can achieve manual stirring.

Owner:HENAN TIMECLOUD COMM TECH CO LTD

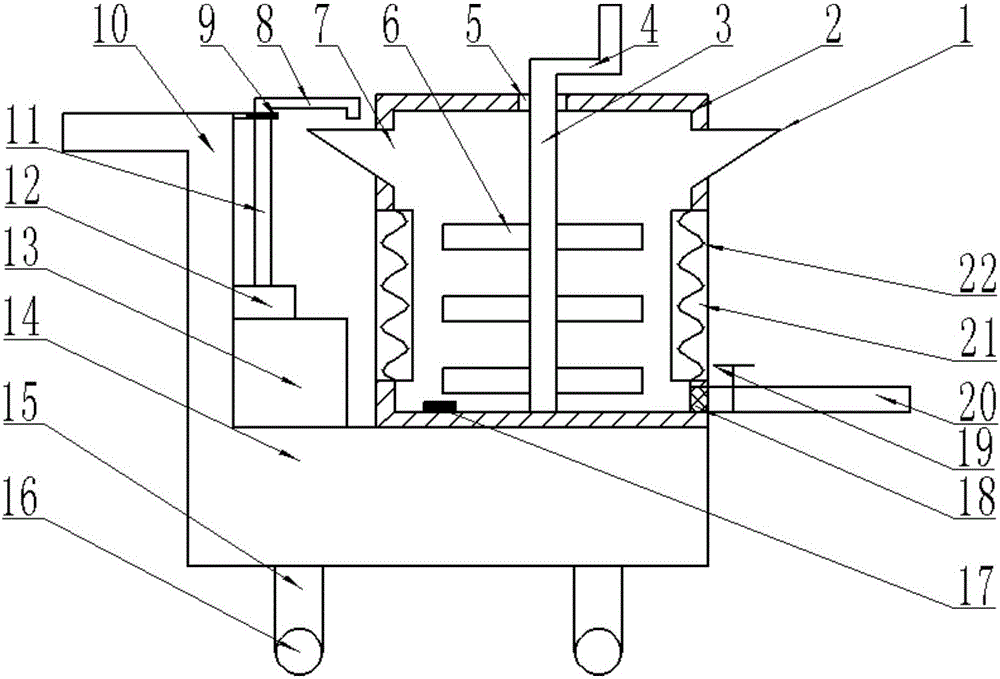

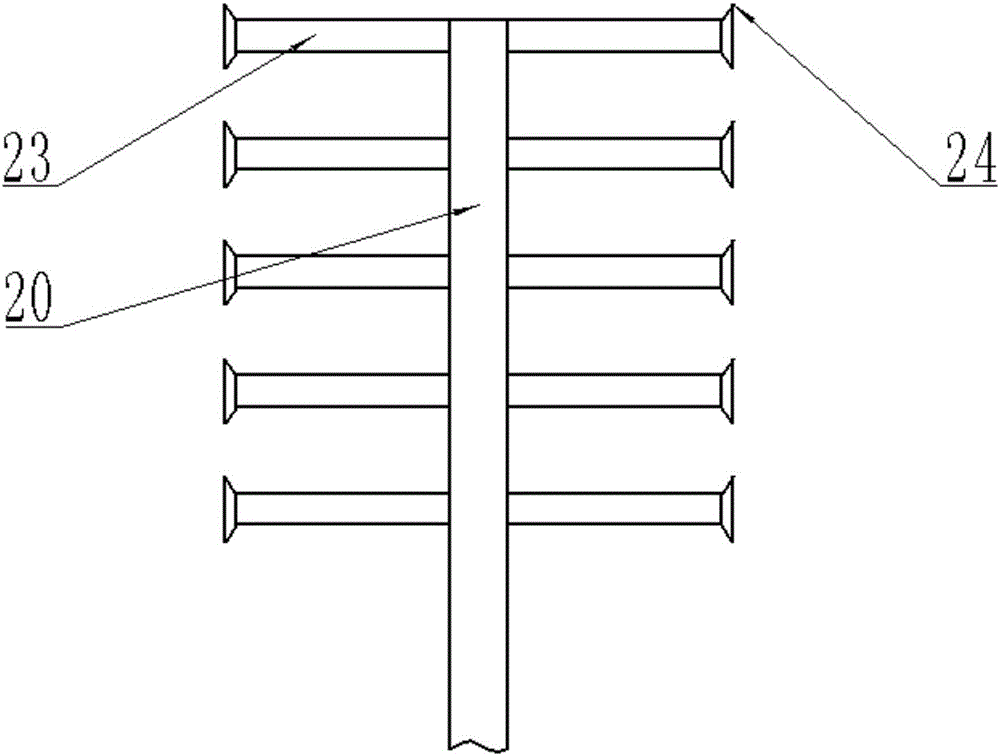

Intelligent heater for ironing plate of asphalt spreader

InactiveCN101046083AMeet heating requirementsHeating up fastRoads maintainenceCombustorPavement engineering

The present invention belongs to the field of road engineering machinery, and is especially one kind of intelligent heater for ironing plate of asphalt spreader. The intelligent heater includes several ironing plates comprising one cover and one bottom plate inside the cover each, burner nozzles controlled with the combustion control system and set over the bottom plates, and one far infrared radiation layer made of far infrared radiating material set between the nozzle and the bottom. The intelligent heater has high temperature raising speed, homogeneous temperature, high heat efficiency and capacity of resulting in high asphalt spreading quality.

Owner:ZHENJIANG HUACHEN HUATONG ROAD MASCH CO LTD

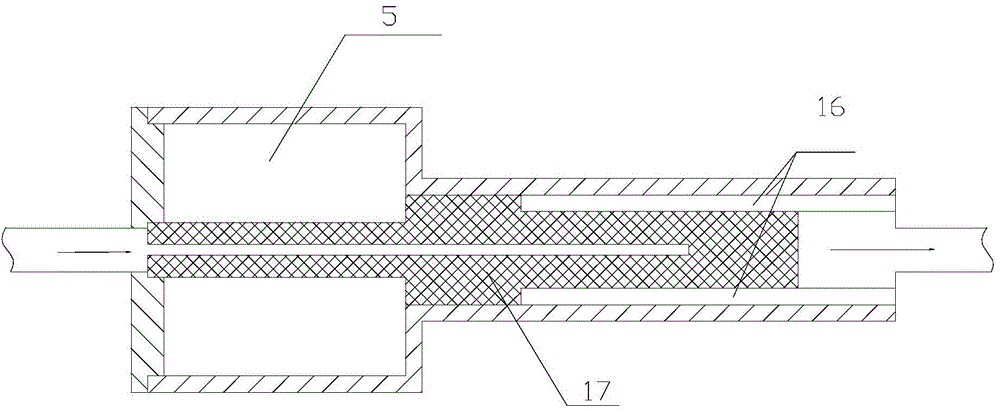

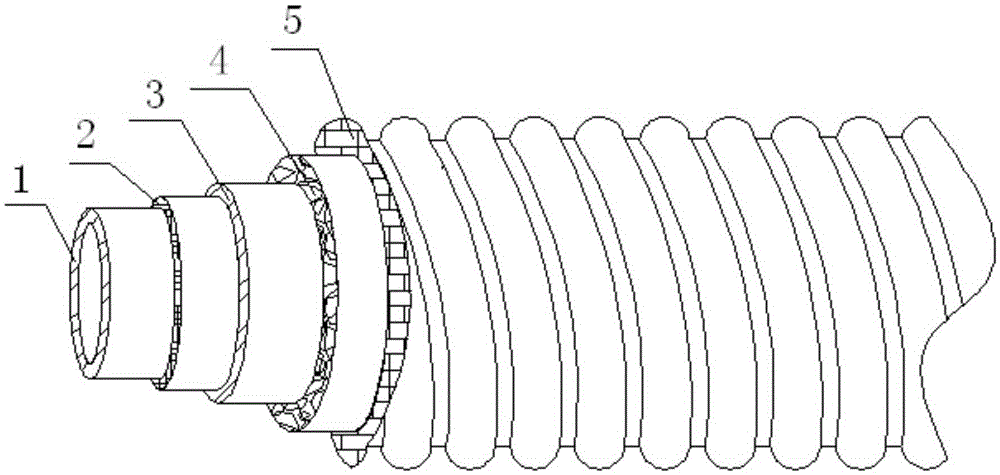

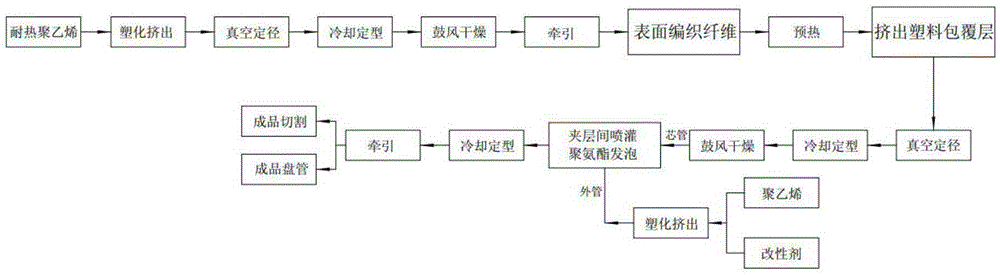

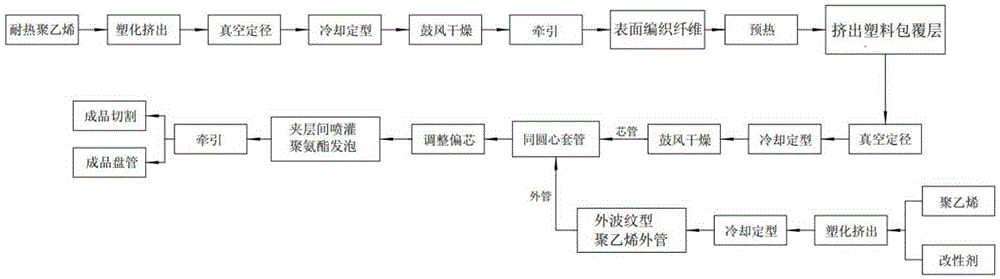

Production technique for external corrugated reinforced plastic heat-preservation heating/cooling pipe

ActiveCN105402502ALow thermal conductivityGood temperature resistanceThermal insulationFlexible pipesEngineeringMechanical engineering

The invention belongs to the technical field of building pipe materials and particularly relates to a production technique for an external corrugated reinforced plastic heat-preservation heating / cooling pipe. The production technique for the external corrugated reinforced plastic heat-preservation heating / cooling pipe comprises the steps that a heat-resistant polyethylene inner pipe body is prepared; a fiber reinforced layer is prepared; a plastic cladding layer is prepared; a foamed heat-preservation layer is prepared; and a polyethylene outer pipe body is prepared. The using temperature of the corrugated reinforced plastic heat-preservation heating / cooling pipe produced through the technique is -40-85 DEG C, the heating requirement of the plastic pipe can be met, and the pipe can also be used as a centralized cooling pipeline.

Owner:盘锦建硕管业有限公司

Heating method of motor rotor

InactiveCN101841216AMeet the needs of mass productionReduce volumeManufacturing dynamo-electric machinesHeating timeIntermediate frequency

The invention relates to a heating method of a motor rotor, which changes the traditional heating method of the motor rotor, and changes the original heating of a tunnel furnace to the heating of a middle-frequency generator, and adopts appropriate technical parameters to realize the heating requirement. The size of the equipment is greatly reduced, and the space is saved. At the same time, by adopting the middle-frequency generator to heat, the electric power consumption is reduced, and a single work piece consumes the electric power about 0.07 degrees; and the heating time is also greatly shortened. The heating method can be widely applied to the mass production process of the motor.

Owner:HARBIN DONGAN ENGINE GRP

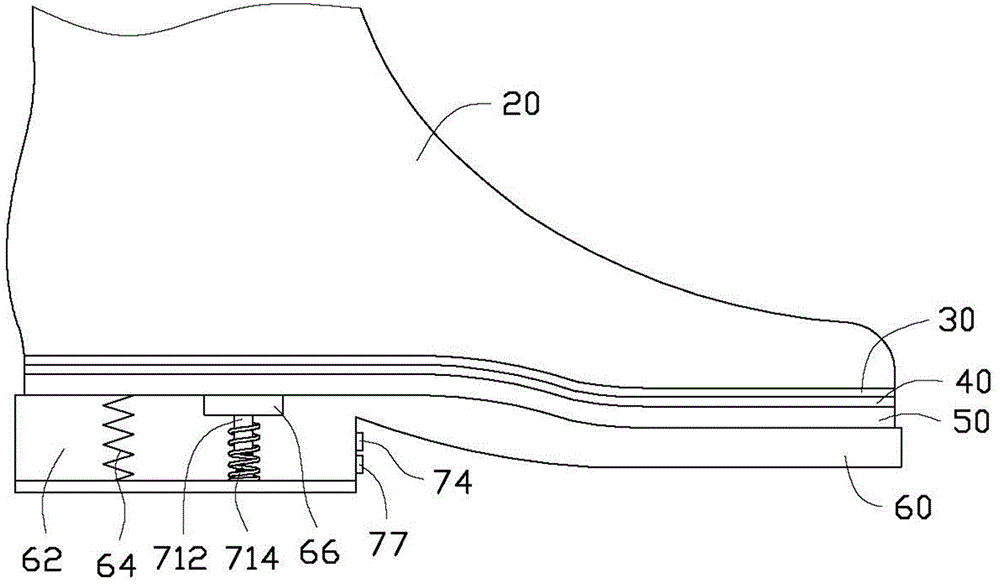

Heat insulation shoes

InactiveCN102742963AMeet heating requirementsBatteries circuit arrangementsSolesPower flowEngineering

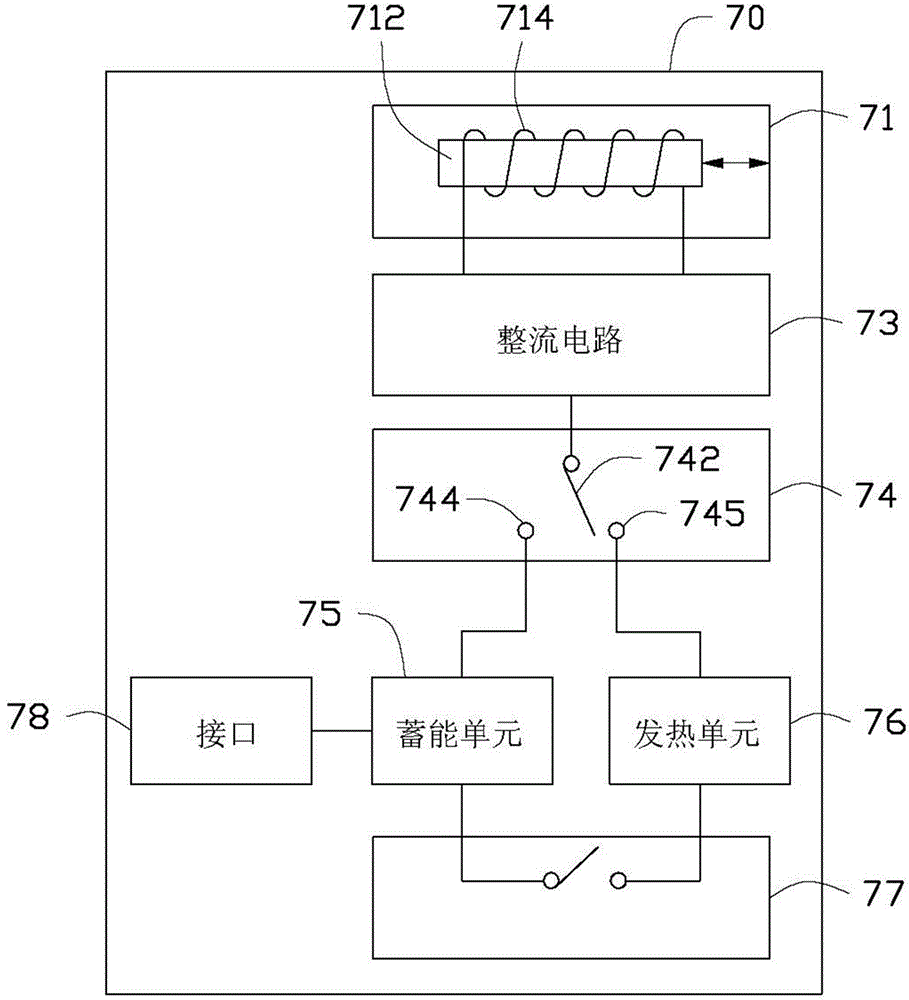

The invention provides a pair of heat insulation shoes. Each shoe comprises a main body part, a sole part, a heating layer and a heating module, wherein the sole part is arranged at one side of the main body part, the heating module is arranged at the sole part and is arranged between the main body part and the sole part, the heating module comprises a power generating unit, a rectifying circuit and a heating unit which are sequentially and electrically connected, the power generating unit generates induction current, the rectifying circuit carries out rectifying processing on the induction current output by the power generating unit, and the heating unit is arranged in the heating layer, converts electric energy output by the rectifying circuit into heat energy and outputs heat through the heating layer.

Owner:SHENZHEN FUTAIHONG PRECISION IND CO LTD

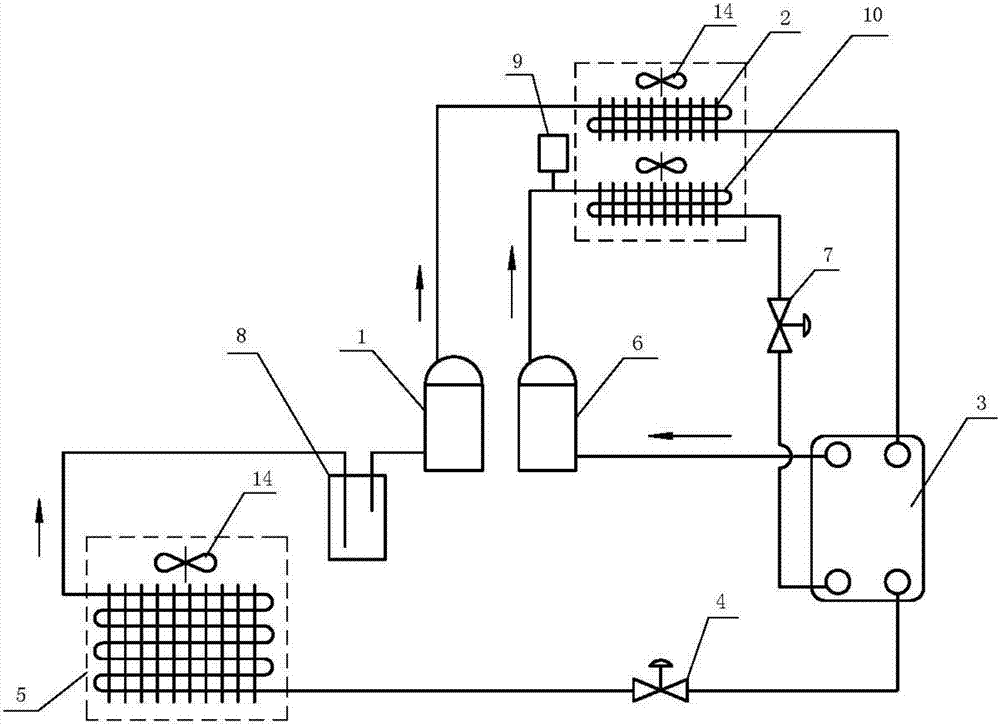

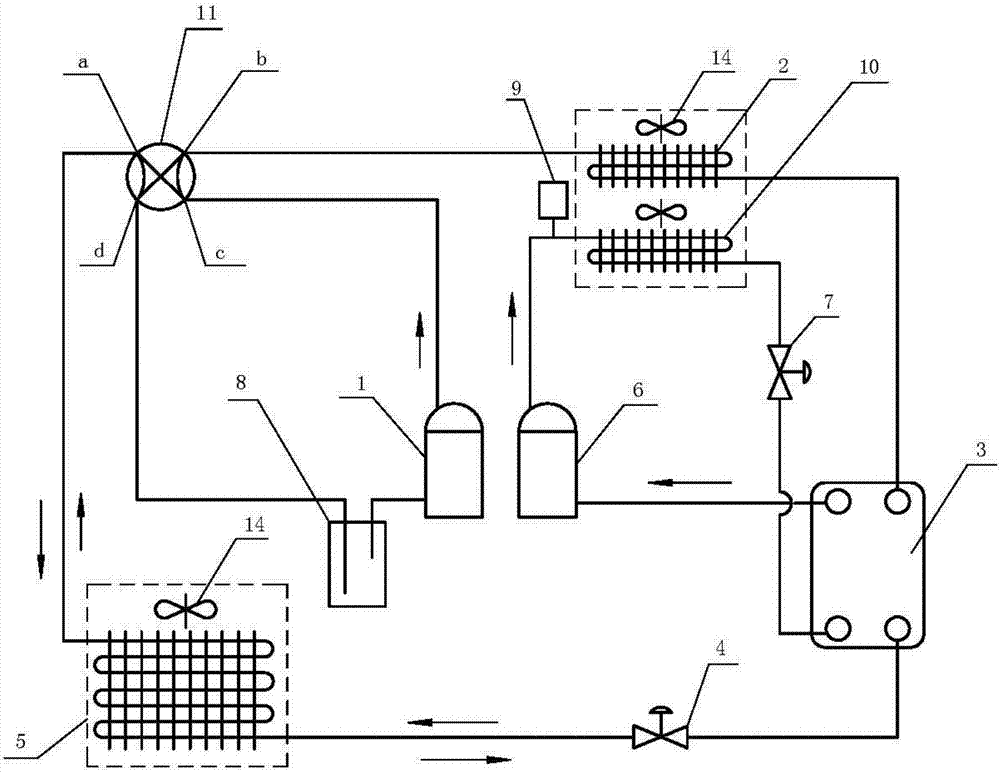

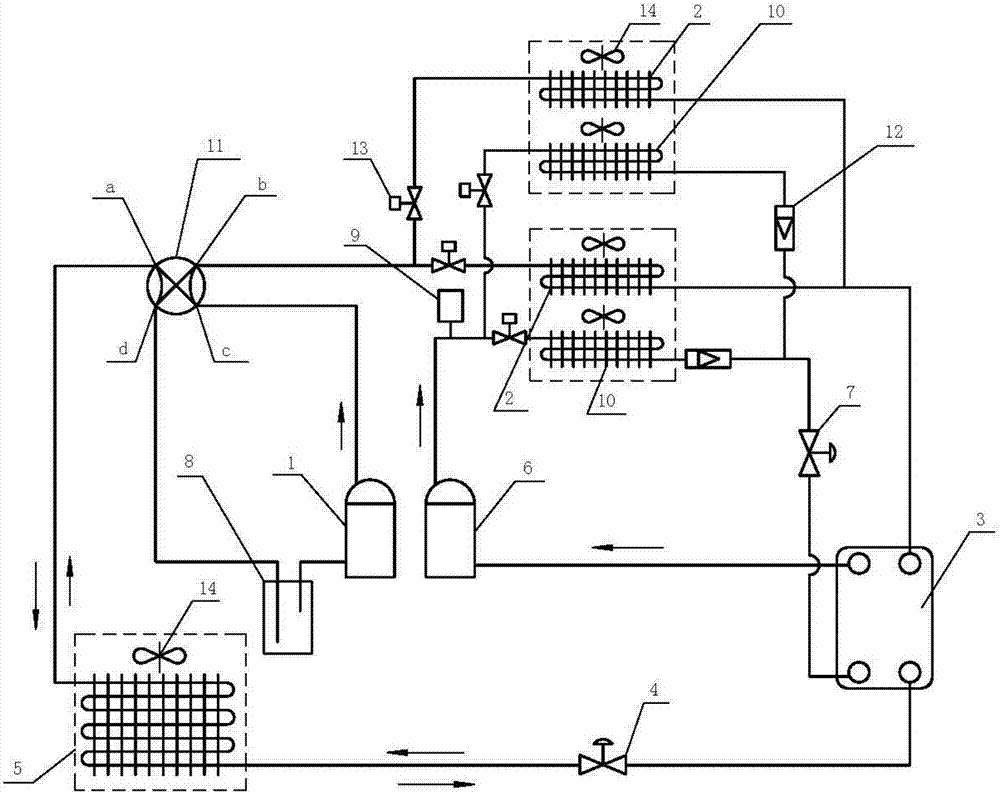

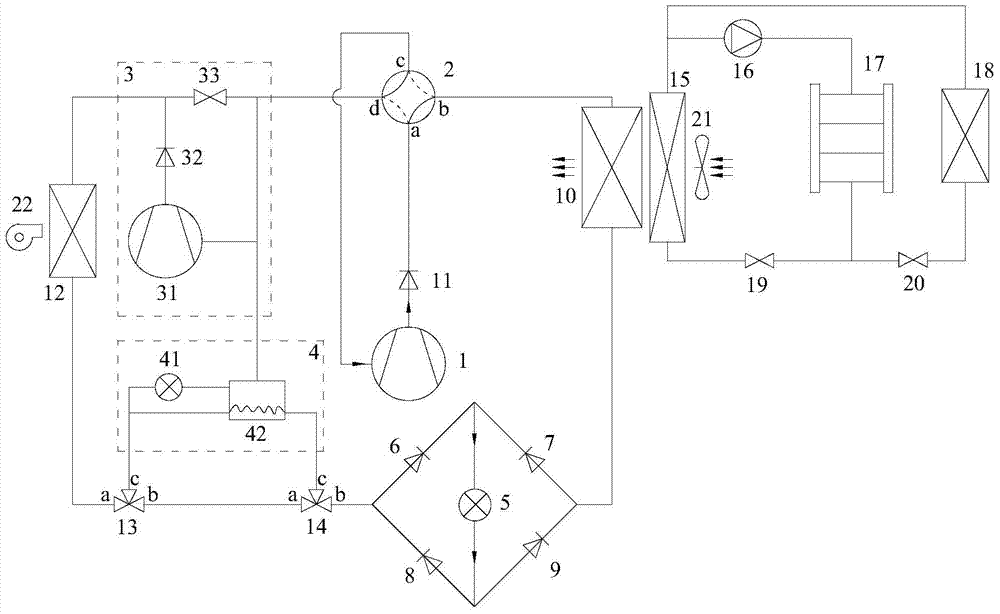

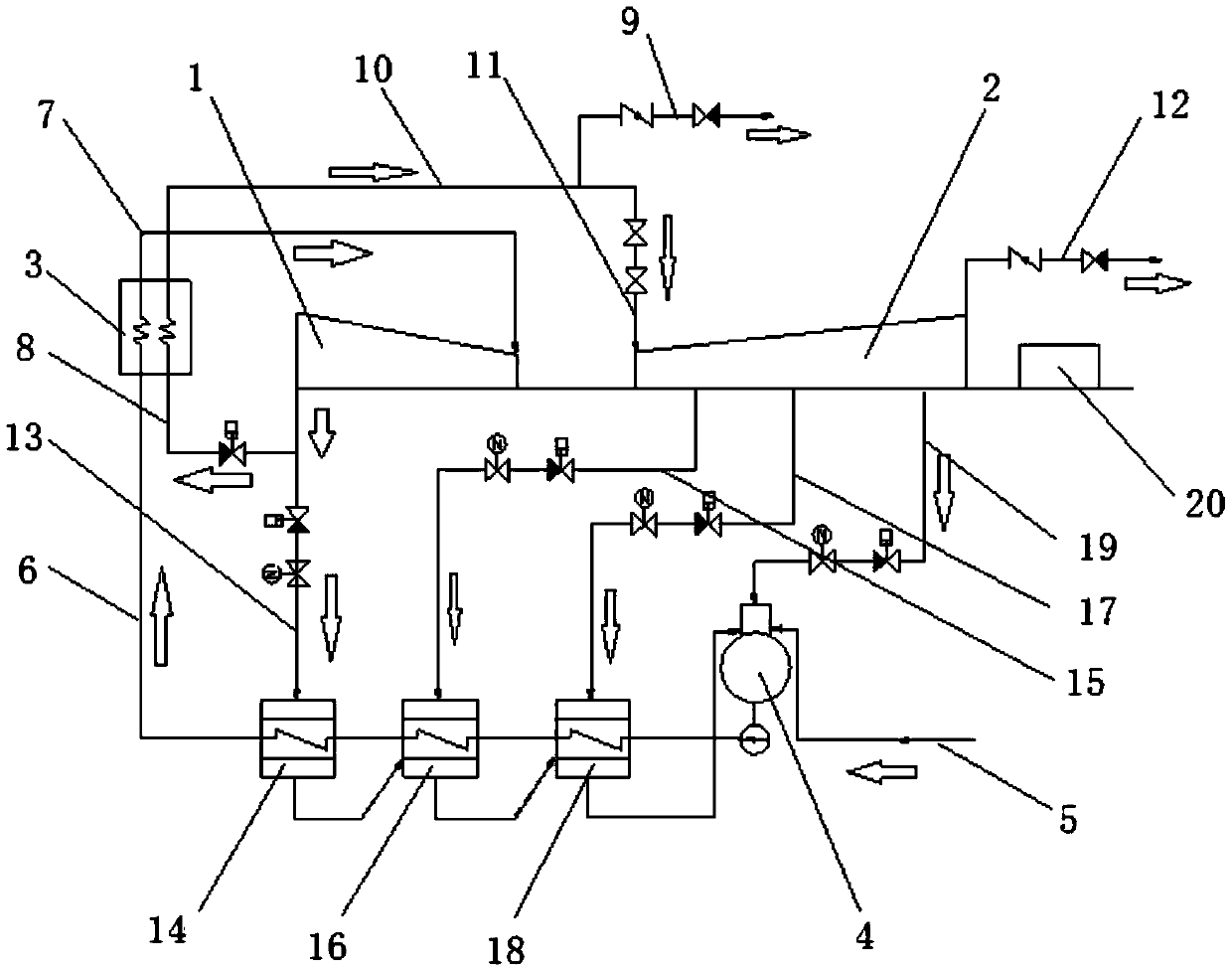

Air-energy two-stage heat pump air-conditioning system

PendingCN107278253AEasy to useSolve the problem of abnormal heatingCompressorMechanical apparatusFour-way valveBuffer tank

An air-energy two-stage heat pump air-conditioning system comprises first loop which is formed by an outdoor low temperature evaporator (5), a liquid storage tank (8), a low temperature compressor (1), an indoor low temperature condenser (2), a first path of a heat exchanger (3) and a first expansion valve (4) sequentially connected to each other, and a second loop which is formed by a high temperature compressor (6), an indoor high temperature condenser (10), a second expansion valve (7) and a second path of the heat exchanger (3) sequentially connected to each other. A buffer tank (9) is arranged between the high temperature compressor (6) and the indoor high temperature condenser (10), and an indoor low temperature condenser (2) and an indoor high temperature condenser (6) forms an indoor condenser set. The air-energy two-stage heat pump air-conditioning system consumes air energy to supply heat for a room in winter and cools a room in summer after installing a two-position four-way valve. The air-energy two-stage heat pump air-conditioning system has the advantages of high efficiency, easy installation and easy use. No water is used and freezing is not a problem, so that the system is more secure and reliable.

Owner:EVER SOURCE SCI & TECH DEV GRP CO LTD

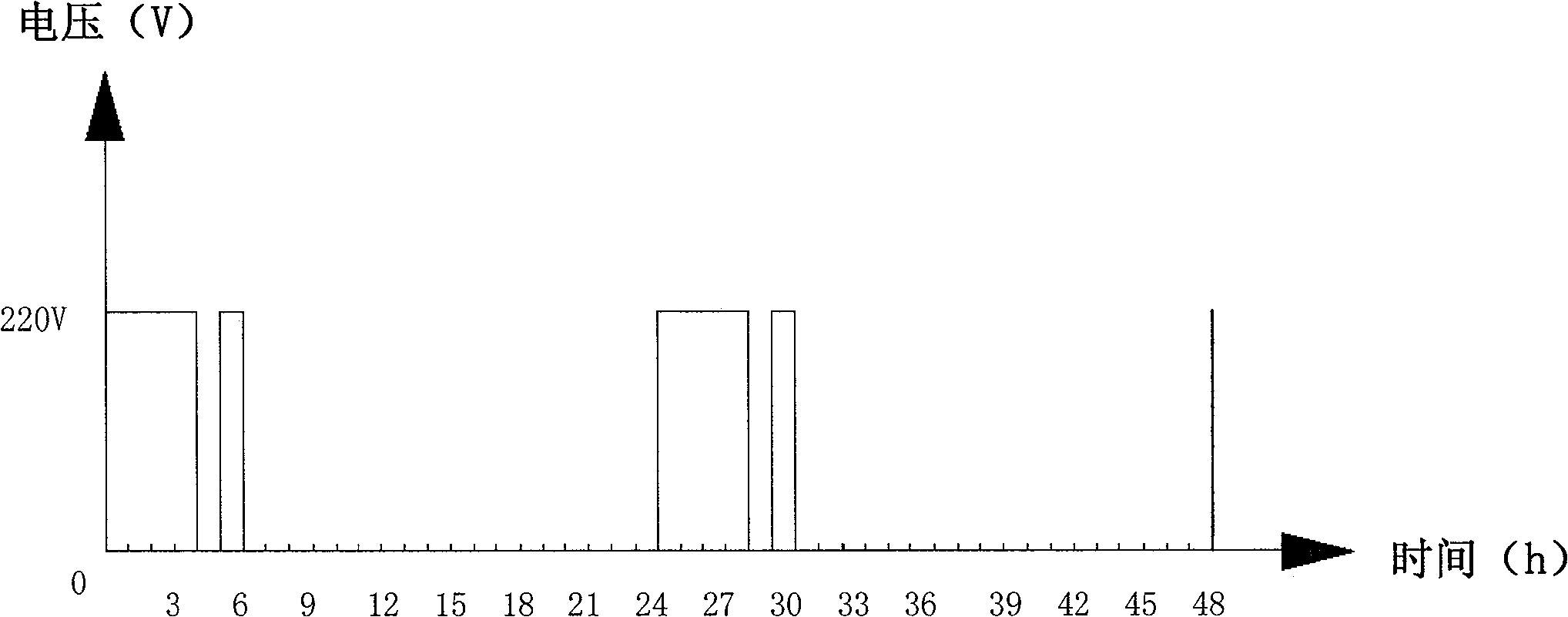

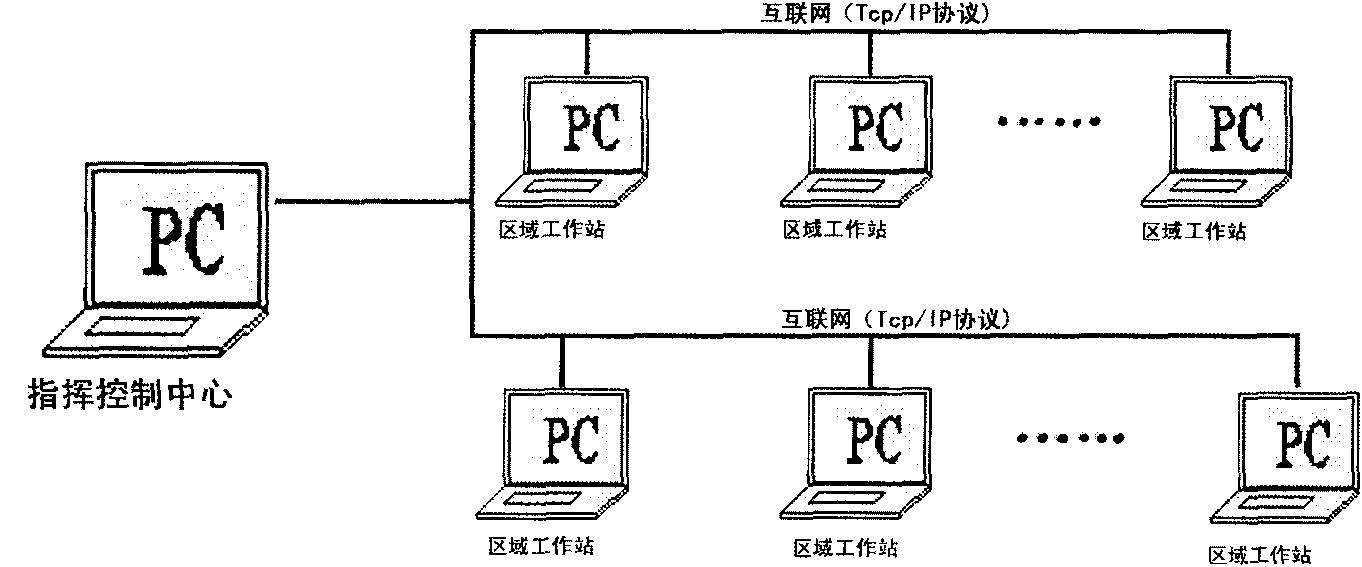

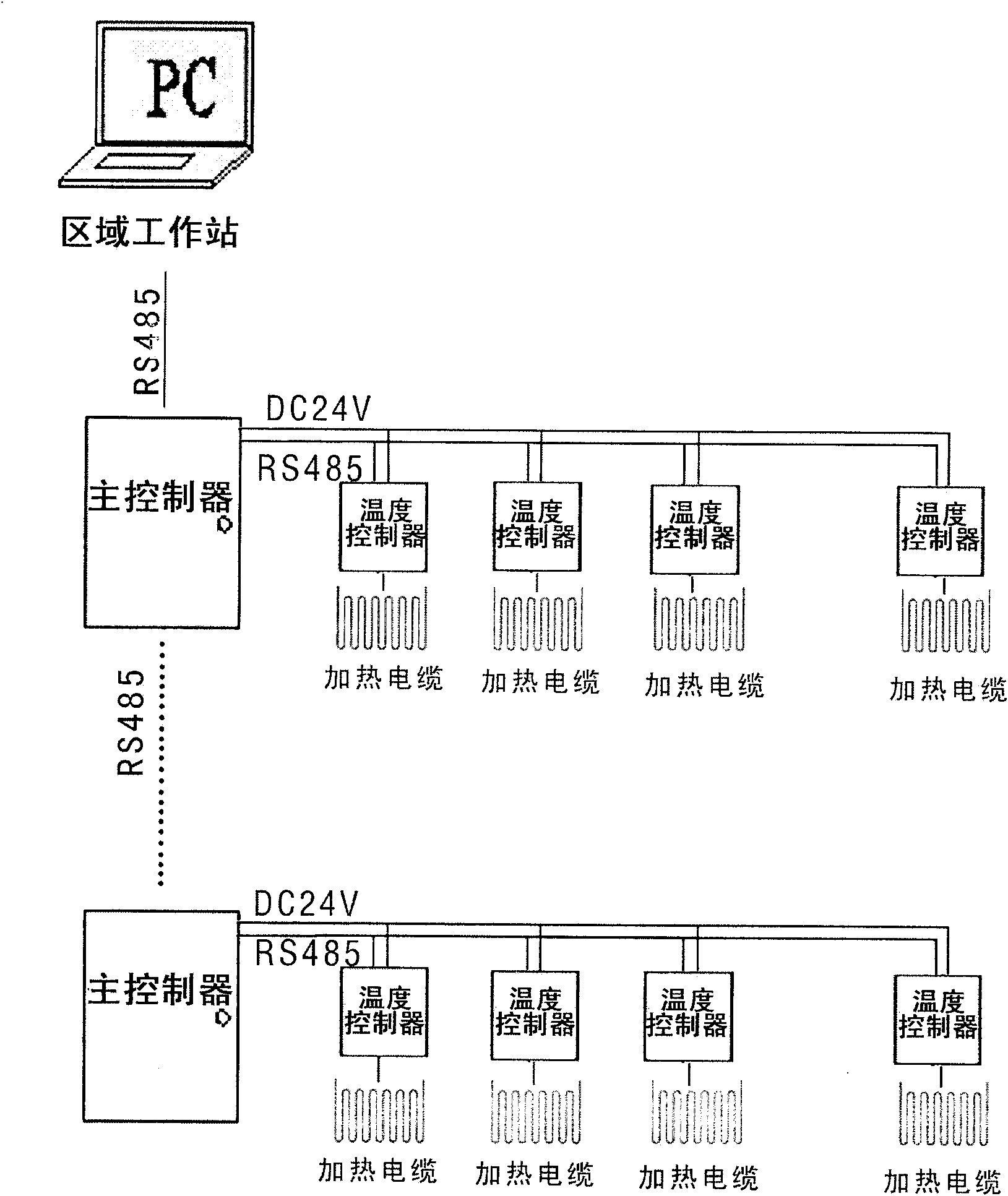

Computer control system for urban electric power central heating and control method thereof

ActiveCN101876824AIncrease profitSimple network structureTransmissionTotal factory controlPower gridThermal energy

The invention relates to the technical field of urban electric power heating, in particular to a computer control system for urban electric power central heating and a control method thereof. The control system comprises a command control center, a region work station and a main control system; the command control center is connected with the region work station through internet, and the region work station is connected with the main control system of a user terminal. The control method comprises the following steps of: (1) starting a program and verifying; (2) reading data from a service center, and meanwhile starting a data server; and (3) waiting for a control command of a user, if the command of the user exists, executing the command of the user, and uploading an execution result to the data server, if no command of the user exists, executing a routing inspection command and uploading a routing inspection result to the data server. The invention can realize the interaction between electric energy and heat energy and central control of the system, is beneficial to peak load shifting of a power grid, has low electricity consumption cost, realizes the utilization of electricity at the valley period while solving the problem of urban heat supply, and achieves the aim of peak shaving and valley filling.

Owner:辽宁省鑫源温控技术有限公司

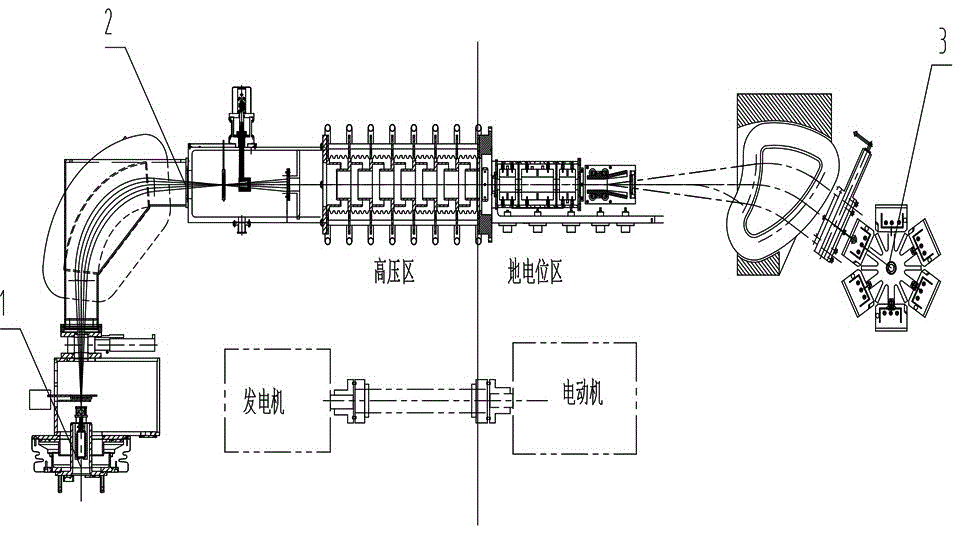

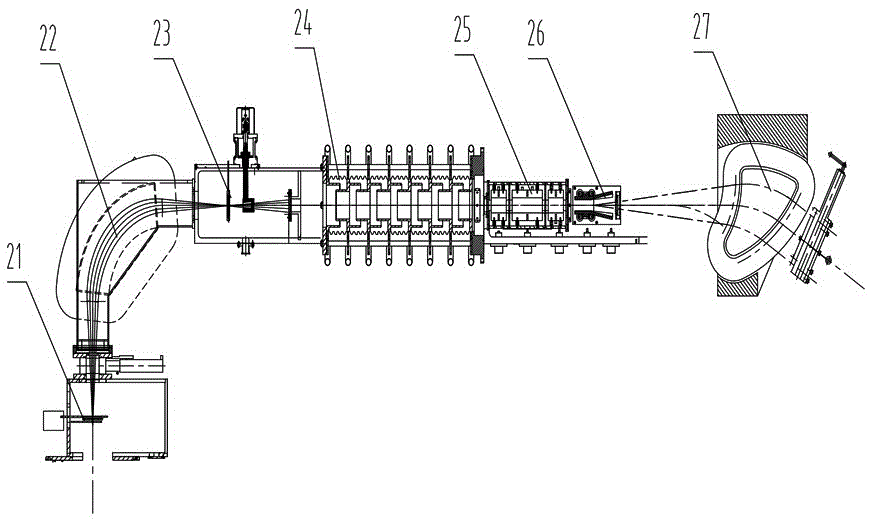

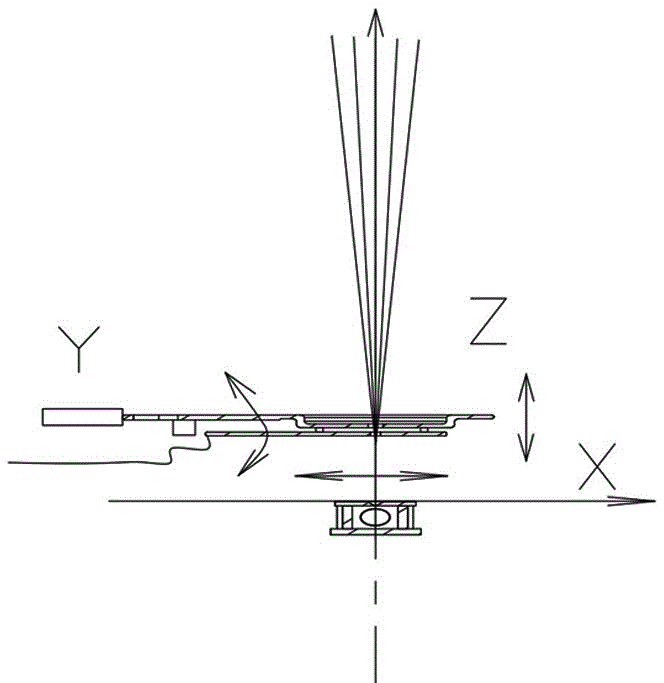

SiC high-temperature high-energy aluminum ion implantation machine

ActiveCN105551922AGuaranteed optionalGuaranteed accuracyElectric discharge tubesAluminum IonShaped beam

The invention discloses a SiC high-temperature high-energy aluminum ion implantation machine. The SiC high-temperature high-energy aluminum ion implantation machine includes an ion source used for generating aluminum-containing ions, and an ion beam transmission system used for transmitting aluminum ion beams; the ion beam transmission system comprises an extraction system, a mass analyzer, an analysis diaphragm, an accelerating tube, a vertical scanning electrode plate and a parallel beam lens which are arranged sequentially; the extraction system extracts out ions generated by the ion source and generates an ion beam; the ion beam passes through the mass analyzer and the analysis diaphragm sequentially and then is accelerated by the accelerating tube; the shape of the accelerated ion beam spot is corrected through a lens; the ion beam spot passes through the vertical scanning electrode plate, and thereafter, the ion beam spot can be scanned to a fan-shaped beam belt; the fan-shaped beam belt passes through the parallel beam lens so as to form parallel belt-shaped beams; the parallel belt-shaped beams enter a high-temperature target chamber system; the high-temperature target chamber system is used for bearing wafers to be subjected to implantation; and the wafers are heated to meet high-temperature process requirements of aluminum implantation. With the SiC high-temperature high-energy aluminum ion implantation machine of the invention adopted, choosability and energy precision of the charges of implanted aluminum ions can be ensured, and wafer heating requirements of aluminum implantation process can be satisfied.

Owner:BEIJING SHUOKE ZHONGKEXIN ELECTRONICS EQUIP CO LTD

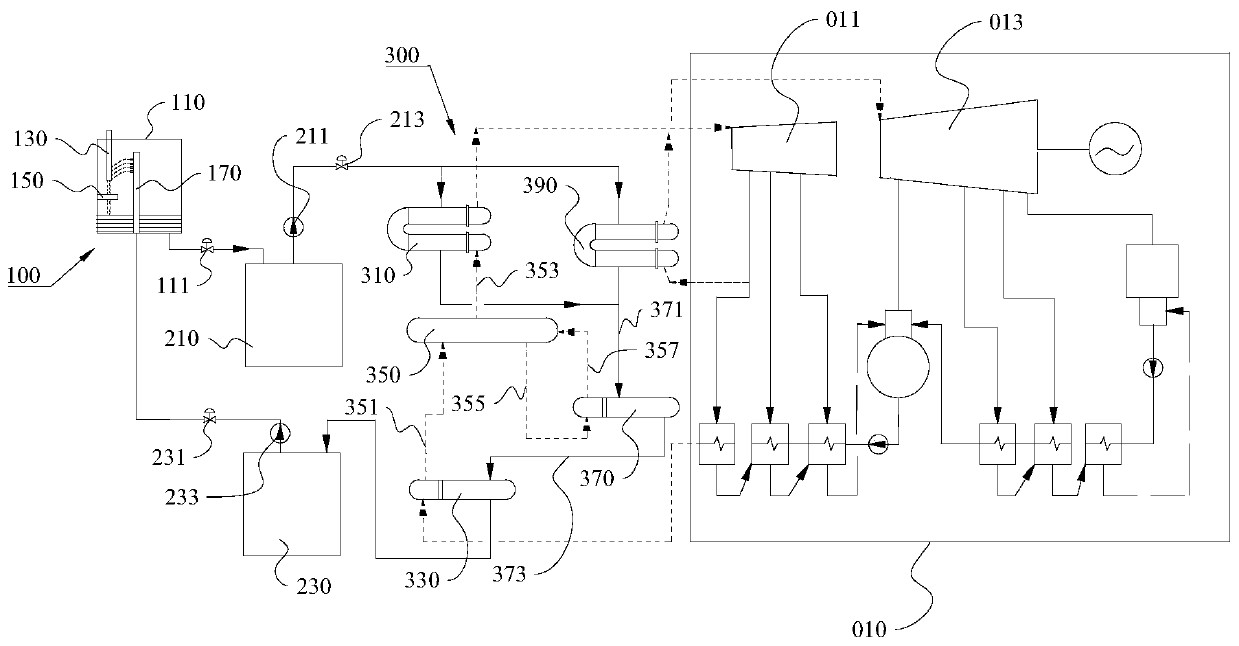

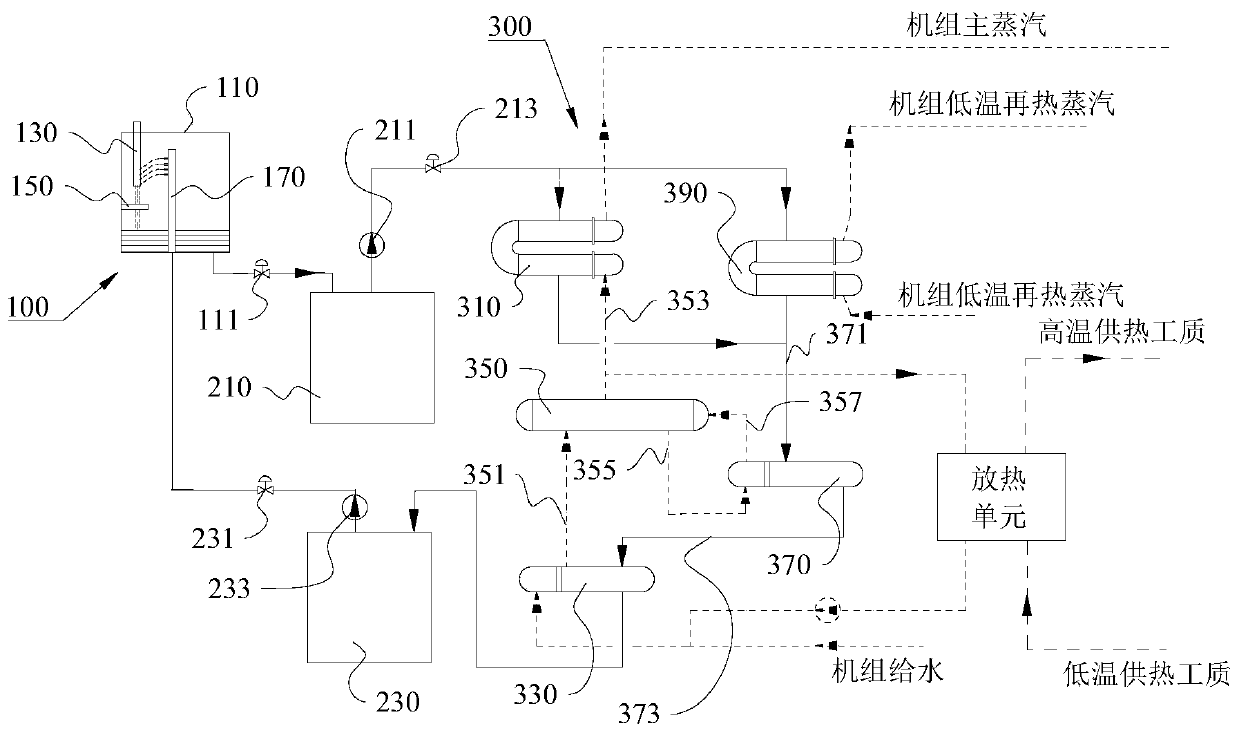

Molten salt electrode boiler heat storage and power generation system

InactiveCN111288428AAchieve large-scale storageImplement schedulingHeat storage plantsEnergy storageElectric powerBoiler (power generation)

The invention provides a molten salt electrode boiler heat storage and power generation system, and belongs to the field of energy storage. The system involves a heating part, a high-temperature molten salt storage tank and a heat utilization part; the heating part comprises a boiler body, a high-voltage electrode, a neutral electrode and a low-temperature molten salt supply head, wherein the high-voltage electrode, the neutral electrode and the low-temperature molten salt supply head are arranged in the boiler body, the high-voltage electrode is used for being connected with a power generation system, and the low-temperature molten salt supply head is used for filling the boiler body with low-temperature molten salt; one end of the high-temperature molten salt storage tank is connected with the bottom of the boiler body, and the other end of the high-temperature molten salt storage tank is connected with the heat utilization part; and the heat utilization part is used for carrying outheat exchange on the molten salt sent out by the high-temperature molten salt storage tank and a water working medium for pushing the steam turbine to act, and sending the cooled molten salt back tothe boiler body. Wind power photovoltaic curtailed electricity is used for heating the molten salt and storing heat in the off-peak period of electricity utilization, and high-temperature molten saltis used for heating feed water to generate high-temperature and high-pressure steam in the peak period of electricity utilization, so that the steam turbine is pushed to act, he stored heat is converted into electric energy to be output, and the curtailed wind and light can be effectively consumed to realize large-scale storage and scheduling of non-water renewable energy power.

Owner:DONGFANG BOILER GROUP OF DONGFANG ELECTRIC CORP

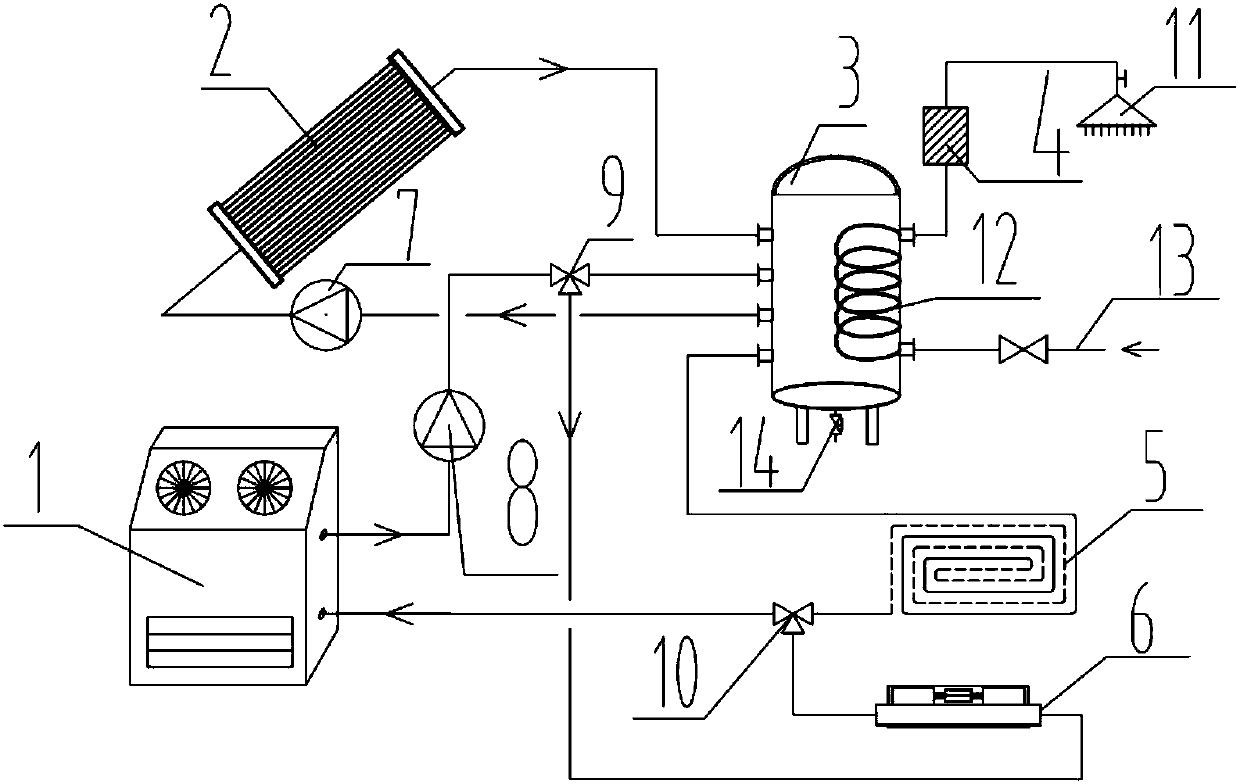

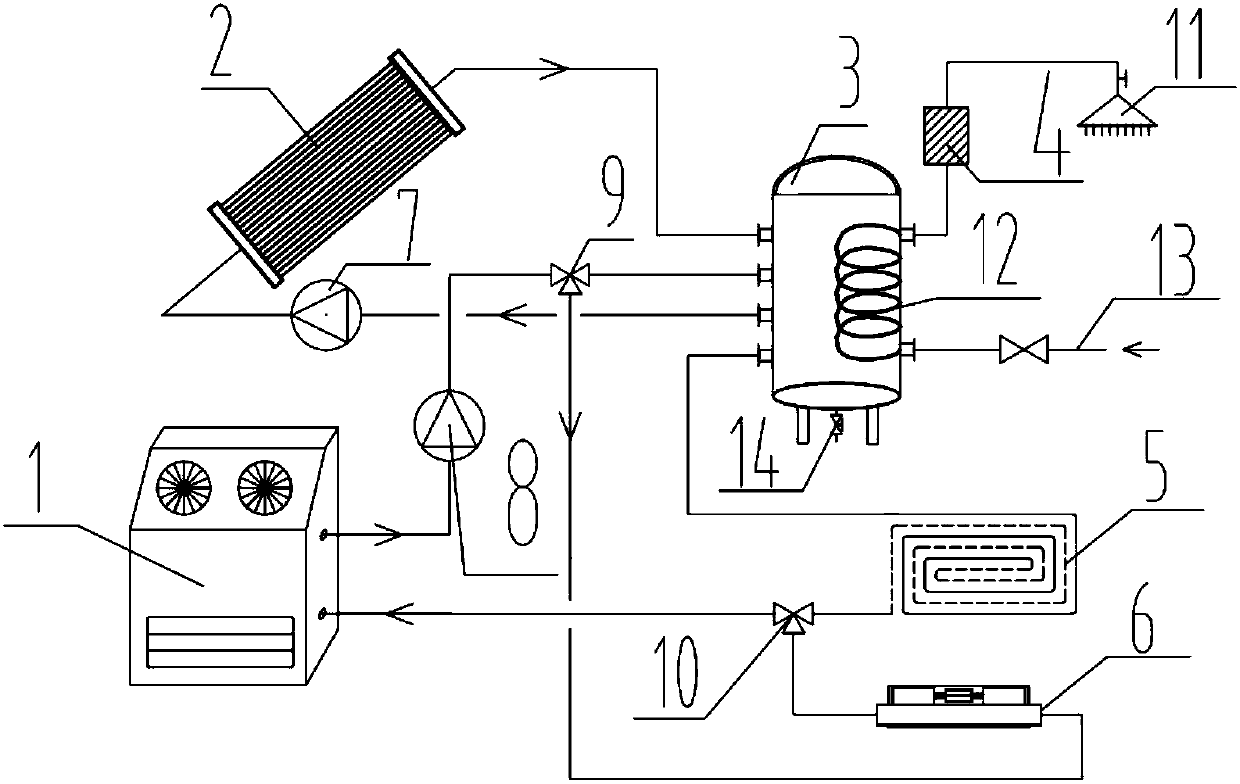

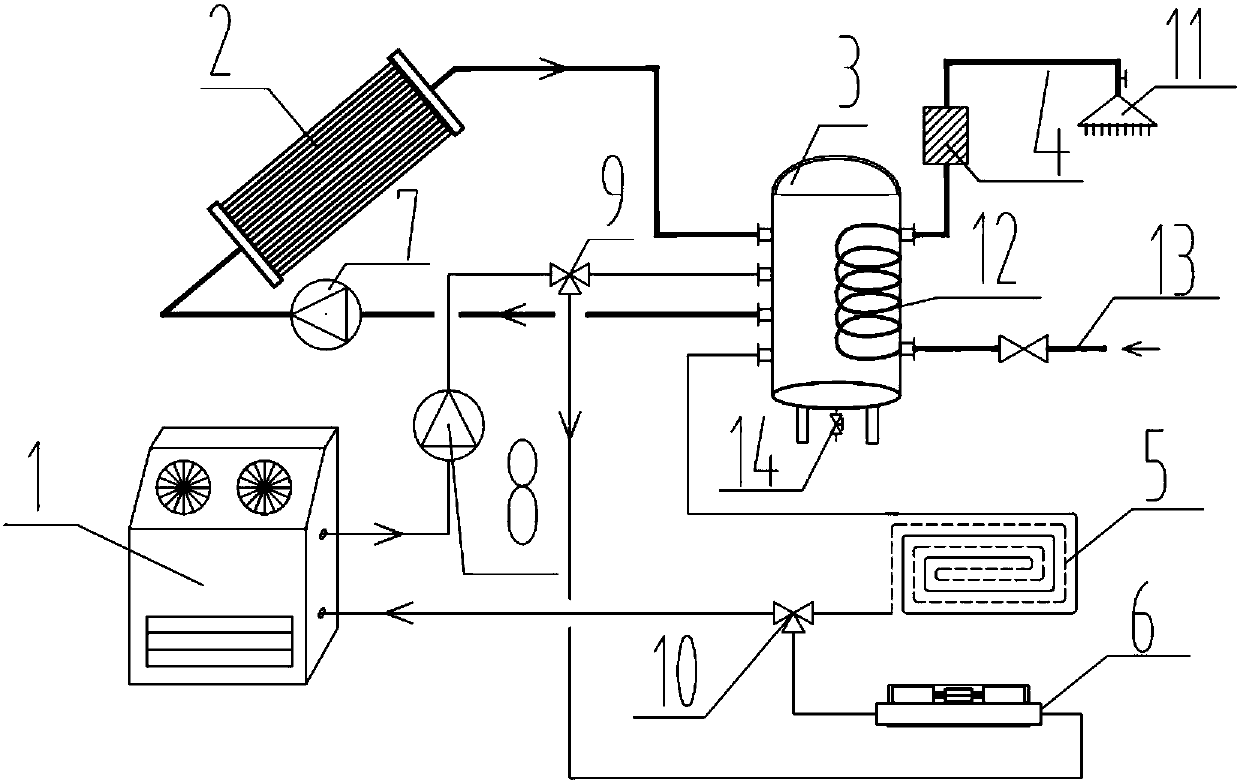

Household heating air-conditioning system and method combining electric energy with solar energy

InactiveCN109751684AMeet heating requirementsGuaranteed supplyLighting and heating apparatusClimate change adaptationThermal energyNew energy

The invention relates to a household heating air-conditioning system and method combining electric energy with solar energy. The household heating air-conditioning system comprises an air source heatpump unit, a solar domestic-hot-water-supply system and an indoor terminal device, wherein a solar heat collector heats water in a heat-accumulation water tank by heating a domestic-hot-water coiled pipe to supply hot water to a user; and the air source heat pump unit is connected with a user terminal and the heat-accumulation water tank to improve the heating efficiency and provide heat energy for a user side device. The invention focuses on the problem on using new energy resources for heating in buildings in villages and towns; renewable energy sources such as solar energy and air energy are adopted to ensure the year-round supply of hot water and meet the need for heating in winter in buildings in villages and towns; and the household heating air-conditioning system is simple, economical, environment-friendly, efficient and worthy of strong promotion in vast rural regions.

Owner:SHANDONG JIANZHU UNIV

Effective-flexible cogeneration system in supercritical carbon dioxide

ActiveCN107355265AIncreased power cycleImprove waste heat qualityCompression machinesSteam useElectrolysisPower cycle

The invention discloses an effective-flexible cogeneration system in supercritical carbon dioxide, which comprises a power-cycle power generating system in supercritical carbon dioxide, a reverse circulation heating system in supercritical carbon dioxide and a shunt water heating system for heating water. Based on the existing power-cycle power generating system in supercritical carbon dioxide, the effective-flexible cogeneration system adds the reversing circulation in supercritical carbon dioxide, thereby the residual heat quality of the driving force circulating cold end can be improved, then the residual heat can meet the requirement of heating, and the aims of the cogeneration system can be achieved and the comprehensive utility efficiency can be highly improved. By shunting the shunt water heating system, one part of the water can be heated directly by the residual heat in higher temperature of the driving force circulating cold end, and the other part of the water absorbs the residual heat in lower temperature by the heat pump technology and heat the shunting water. The cogeneration system realizes the classification using of the energy, and by adjusting proportion of shunting, the cogeneration system adjusts the proportion of external power supply and heat supply, and then the system can realize the totally hot electrolytic coupling.

Owner:XIAN THERMAL POWER RES INST CO LTD

Integrated intelligent heating microlite plate

The invention relates to an integrated intelligent heating microlite plate. The integrated intelligent heating microlite plate is characterized by comprising a floor board body and a thermal wafer, wherein the floor board body is prepared by 45-60 parts of microlite, 15-20 parts of PVC (Polyvinyl Chloride) resin, 5-10 parts of compound stabilizer, 1-10 parts of CPE (Chlorinated Polyethylene) and 1-5 parts of aluminium oxide, the compound stabilizer is a preparation with an organic auxiliary stabilizer and calcium as main ingredients; a rectangular installation hole is arranged on the cross section of the narrow side of the floor board body or a rectangular groove is arranged on the bottom surface of the floor board body; and the thermal wafer is arranged on the installation hole of the floor board body or the rectangular groove of the floor board body. The integrated intelligent heating microlite plate has the advantages of simple structure and convenience in use, can reach the effects of ground heating by switching on a power supply, is waterproof, fireproof, free of poisonous gases and uneasily deformed; simultaneously, the integrated intelligent heating microlite plate has decoration effects for the floor board.

Owner:深圳必图新型材料科技有限公司

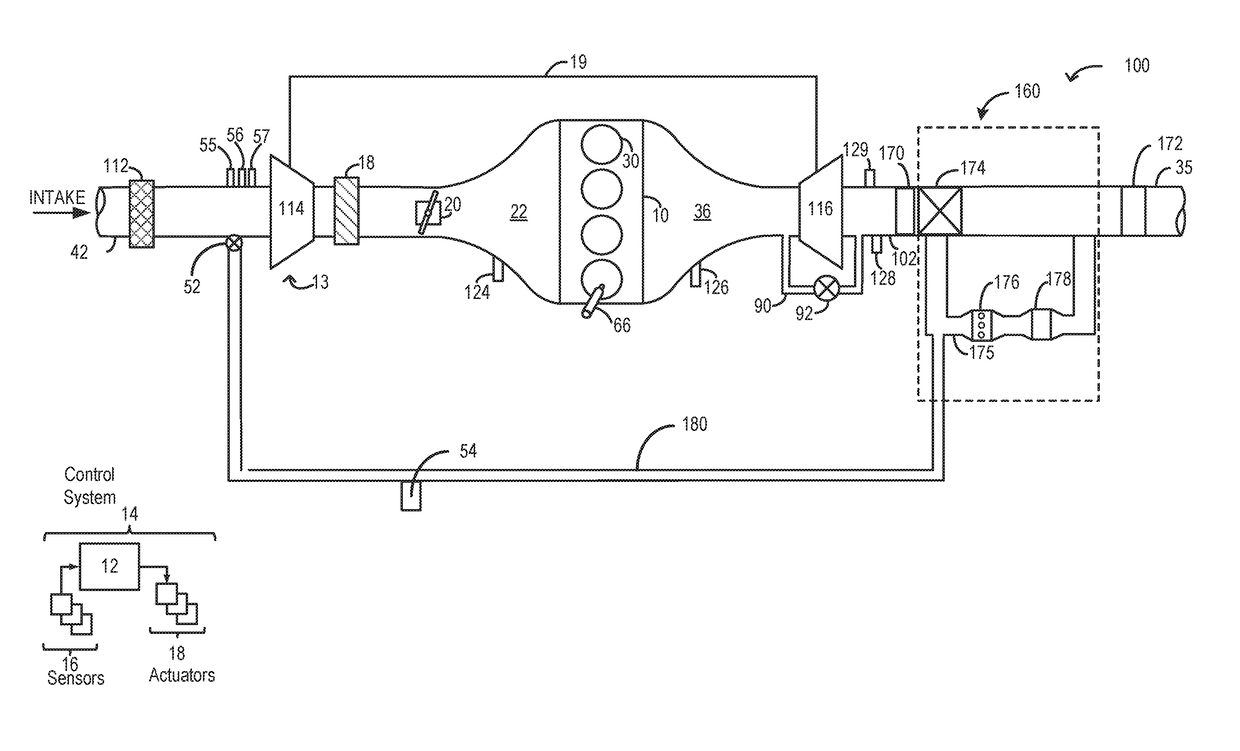

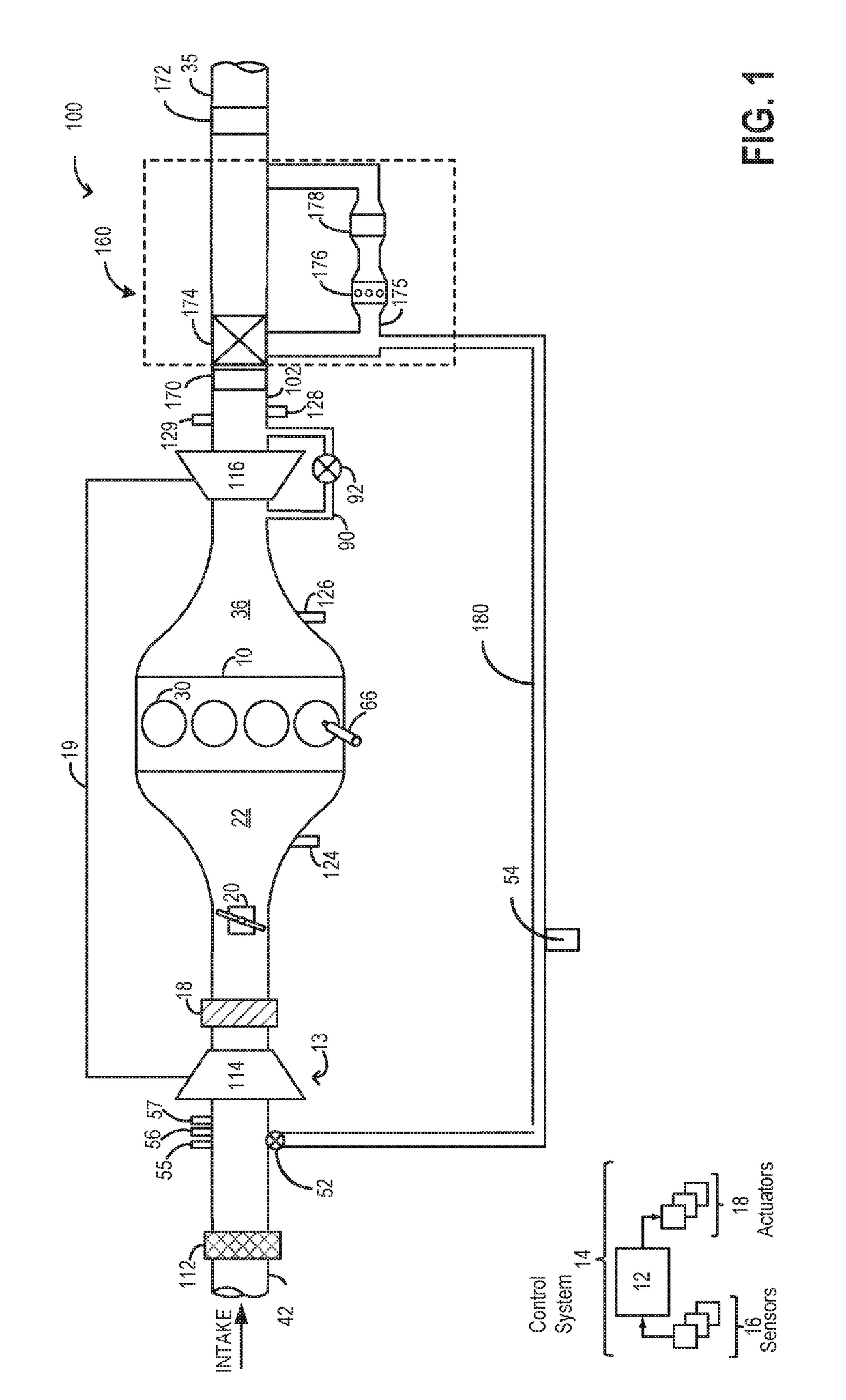

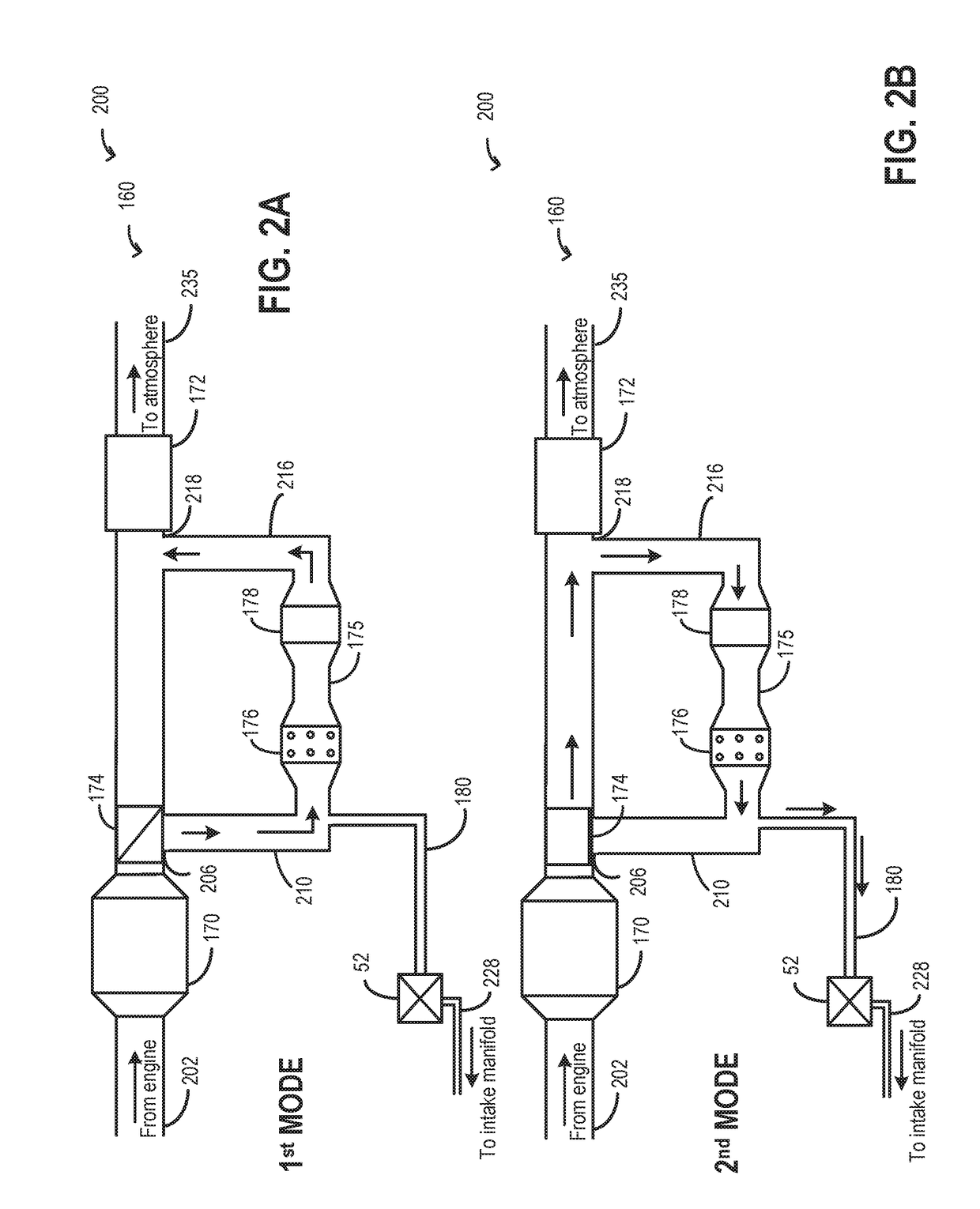

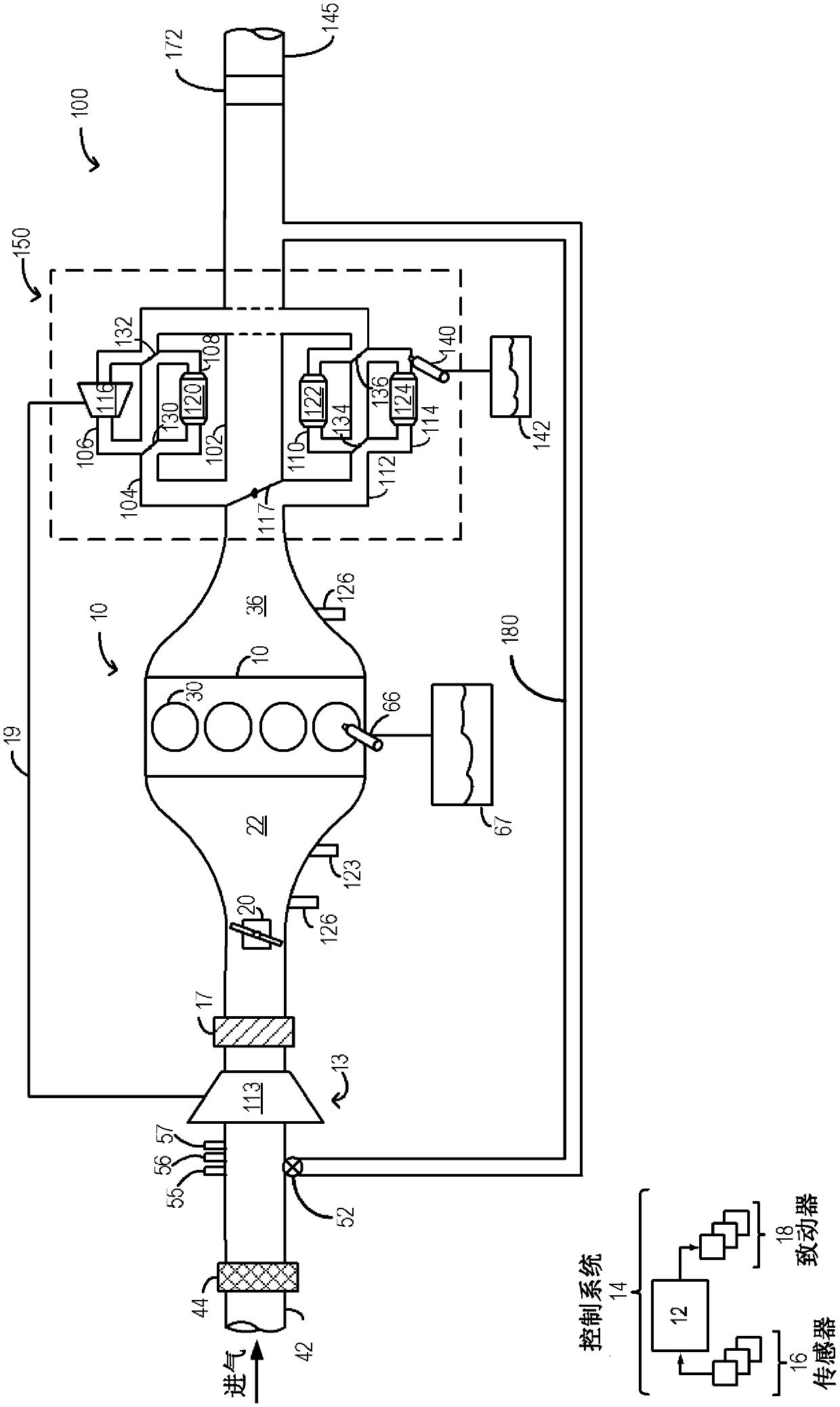

Exhaust heat recovery and hydrocarbon trapping

InactiveUS20170218826A1Improve fuel economyImprove engine efficiencyElectrical controlInternal combustion piston enginesTrappingExhaust fumes

Methods and systems are provided for exhaust heat recovery and hydrocarbon trapping at an exhaust bypass assembly. Exhaust gas may flow in both directions through an exhaust bypass passage and each of a HC trap and a heat exchanger coupled to the bypass passage. The HC trap may be purged with the hot exhaust and heat from the exhaust may be recovered at the heat exchanger.

Owner:FORD GLOBAL TECH LLC

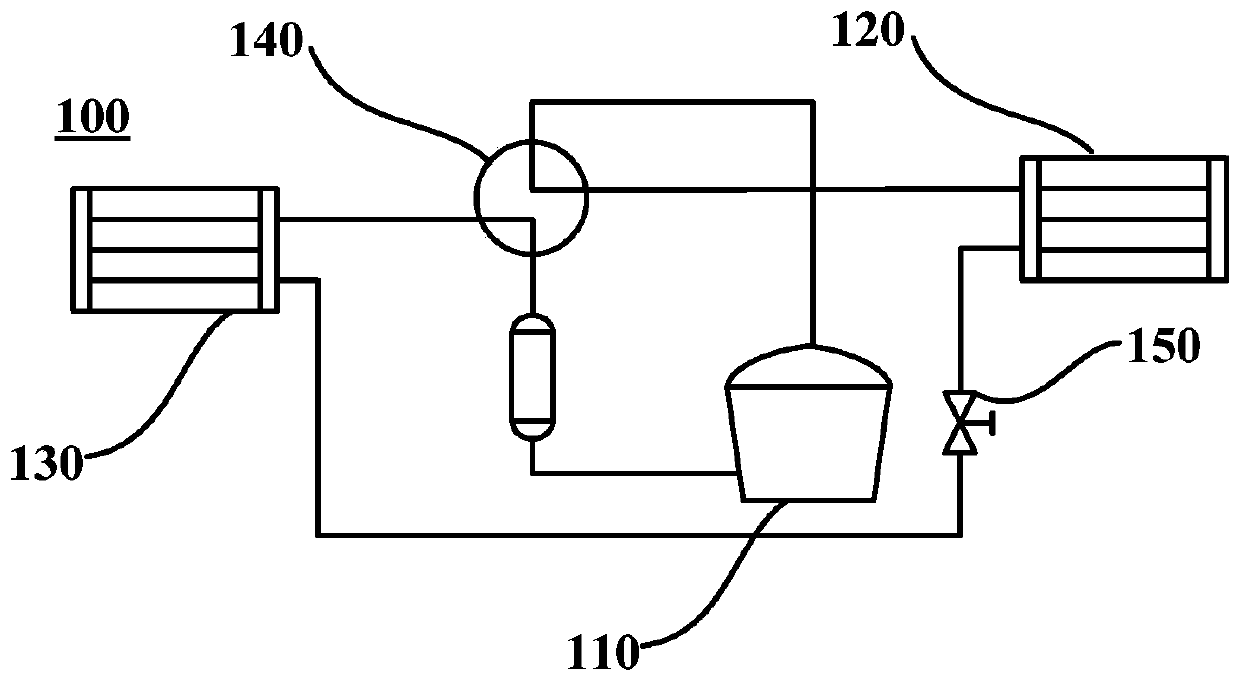

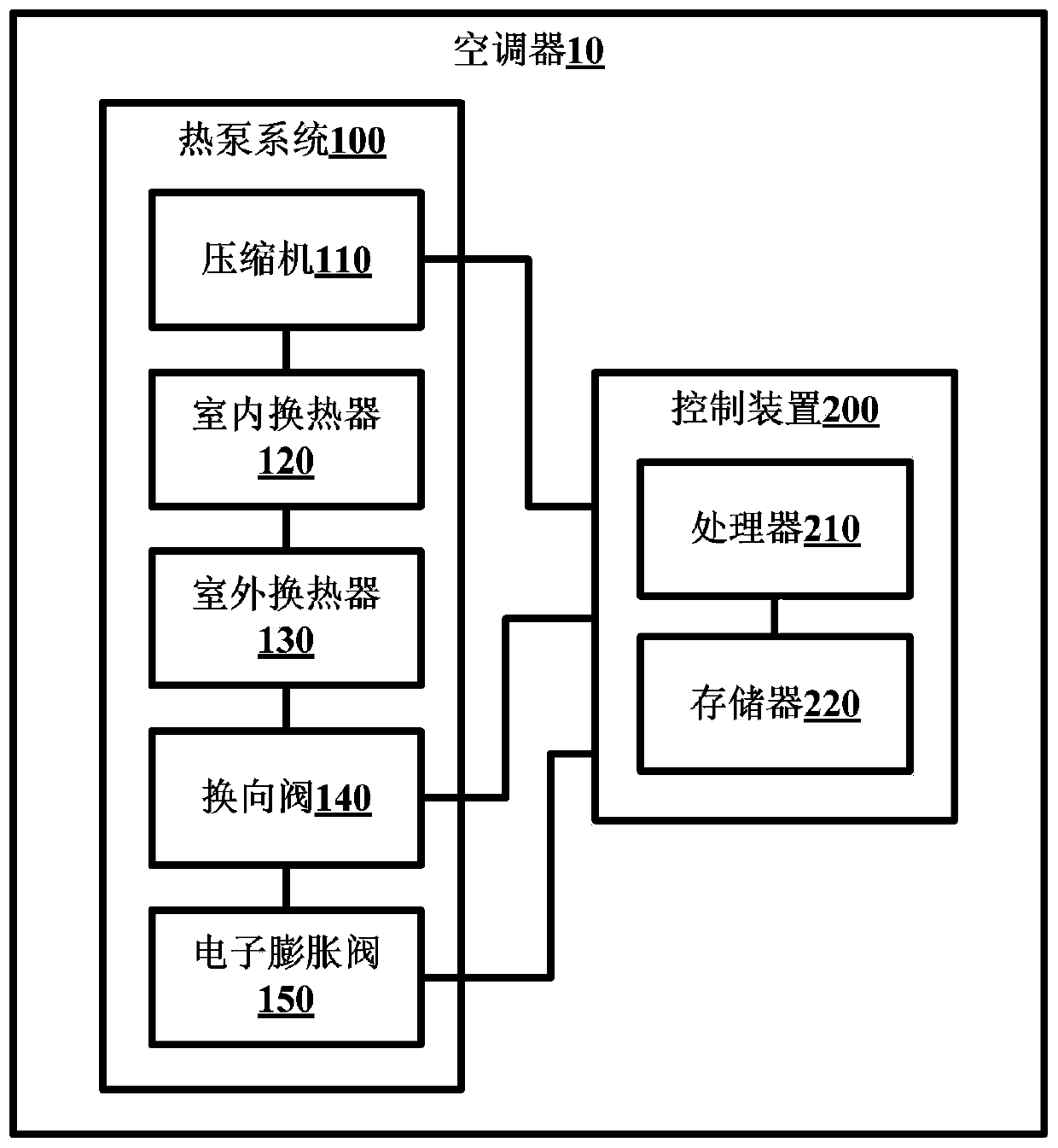

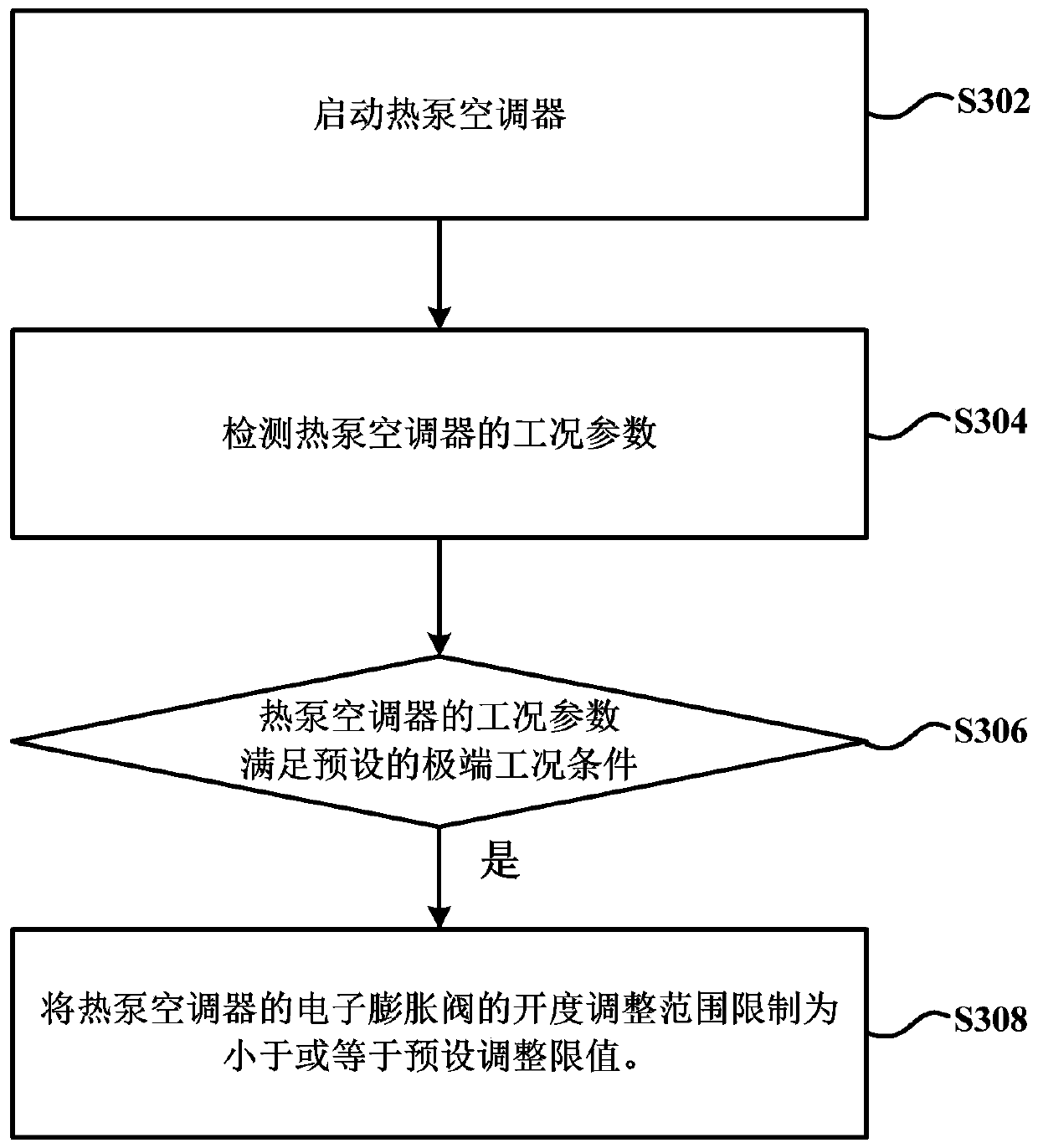

Control method of heat pump air conditioner and air conditioner

InactiveCN110160228AGuaranteed uptimeAvoid volatilityMechanical apparatusSpace heating and ventilation safety systemsOpen adjustmentEngineering

The invention provides a control method of a heat pump air conditioner and the air conditioner. The control method of the heat pump air conditioner comprises the following steps of starting the heat pump air conditioner to release heat by utilizing an indoor unit of the heat pump air conditioner; detecting working condition parameters of the heat pump air conditioner; judging whether a working condition parameter of the heat pump air conditioner meets a preset extreme working condition; and if so, limiting the opening adjustment range of an electronic expansion valve of the heat pump air conditioner to be smaller than or equal to a preset adjustment limit value. According to the scheme, under the extreme working condition that the opening degree of the electronic expansion valve has greatinfluence on the exhaust temperature, large fluctuation of the exhaust temperature caused by excessive adjustment of the electronic expansion valve is avoided, and stable operation of a heat pump system is guaranteed.

Owner:QINGDAO HAIER AIR CONDITIONER GENERAL CORP LTD +1

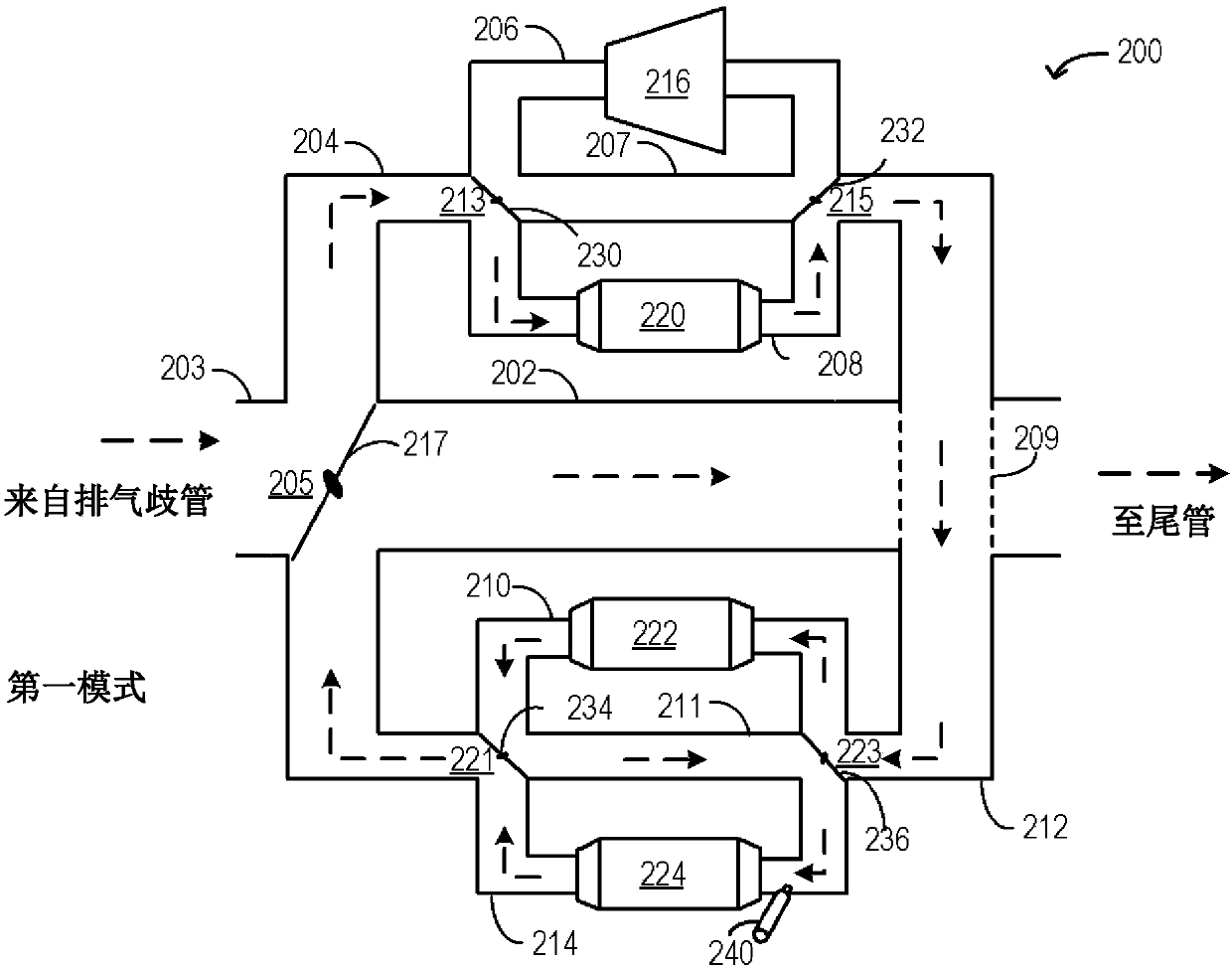

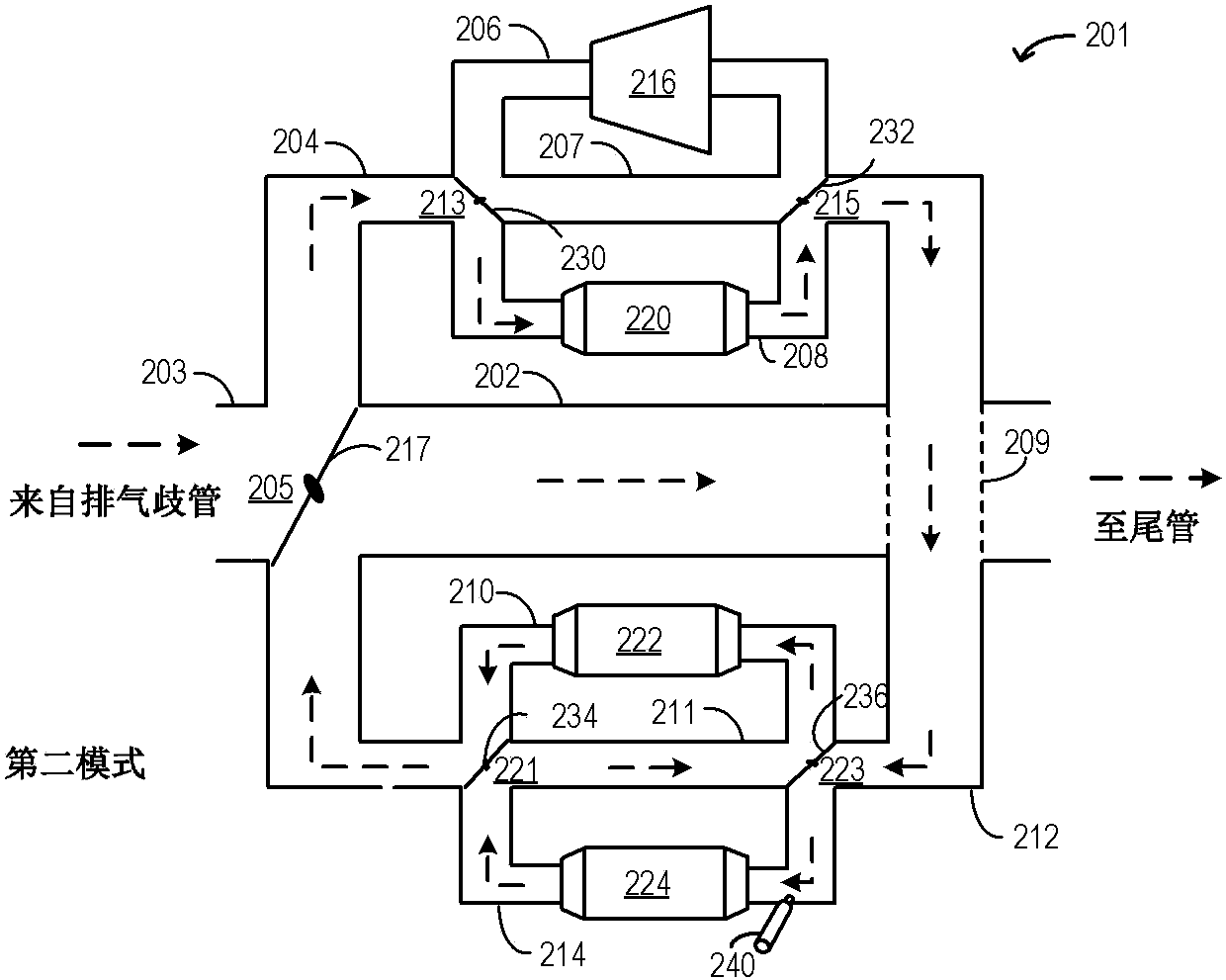

Method and system for exhaust aftertreatment

InactiveCN107654278ARaise the ignition temperatureAccelerates reaching light-off temperatureInternal combustion piston enginesExhaust apparatusAerospace engineering

Methods and systems are provided for reducing engine emissions using a branched exhaust system. In one example, a branched exhaust system may include a plurality of sub-branches each housing a distinct exhaust component, and an order of exhaust flow through each of the exhaust components may be adjusted based on engine operating conditions and temperature demand of the distinct components.

Owner:FORD GLOBAL TECH LLC

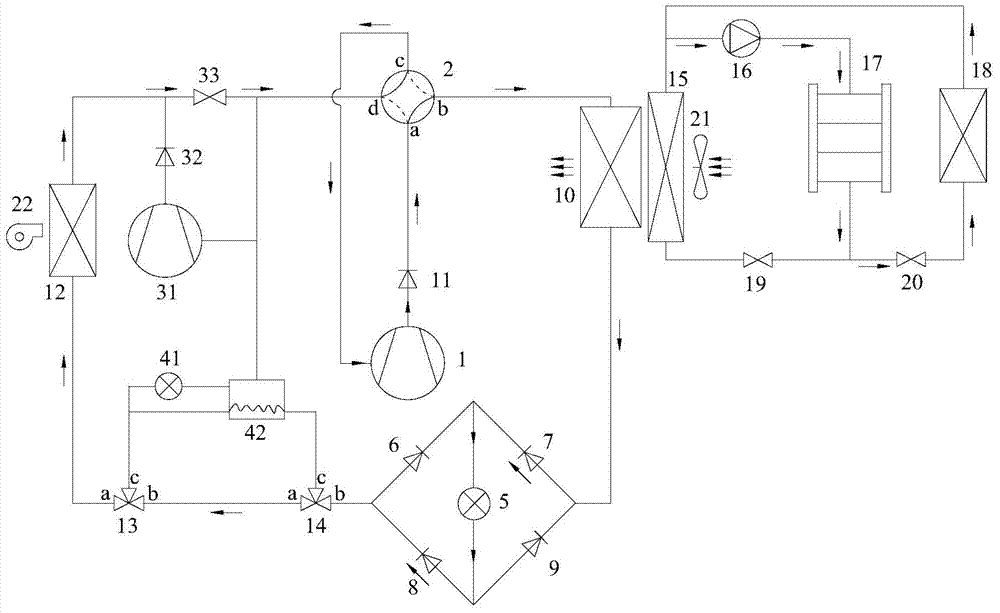

Electric vehicle waste heat utilization variable-frequency thermal pump air conditioning system and method thereof

InactiveCN104501445AGuaranteed working lifeGuaranteed service lifeMechanical apparatusClimate change adaptationDual stageEngineering

The invention discloses an electric vehicle waste heat utilization variable-frequency thermal pump air conditioning system and a method thereof. The electric vehicle waste heat utilization variable-frequency thermal pump air conditioning system comprises a low-pressure-stage variable-speed horizontal vortex compressor driven by an internal alternating current motor, a high-pressure-stage compressor, an internal heat exchanger, an external heat exchanger, an internal fan, an external fan, a intercooler, a waste heat recovering loop and the like, wherein the waste heat recovering loop consists of a waste heat recovering radiator, a waste heat discharging radiator, an electric water pump, an electric element water cooling device and the like; the waste heat recovering radiator is arranged in front of the external heat exchanger; in a heating cycle, the temperature around the external heat exchanger is raised through heat discharged by the waste heat recovering radiator, so that the working condition of a thermal pump is improved. By adopting the system, cooling in an optimal way in summer and single-stage heating under a general working condition and dual-stage heating under a low-temperature condition in winter are realized for an electric vehicle; meanwhile, the waste heat of electric elements on the electric vehicle can be used for melting frost on the external heat exchanger, so that the running condition of an air conditioner during heating is improved, and the running efficiency of the air conditioning system is increased.

Owner:SOUTH CHINA UNIV OF TECH

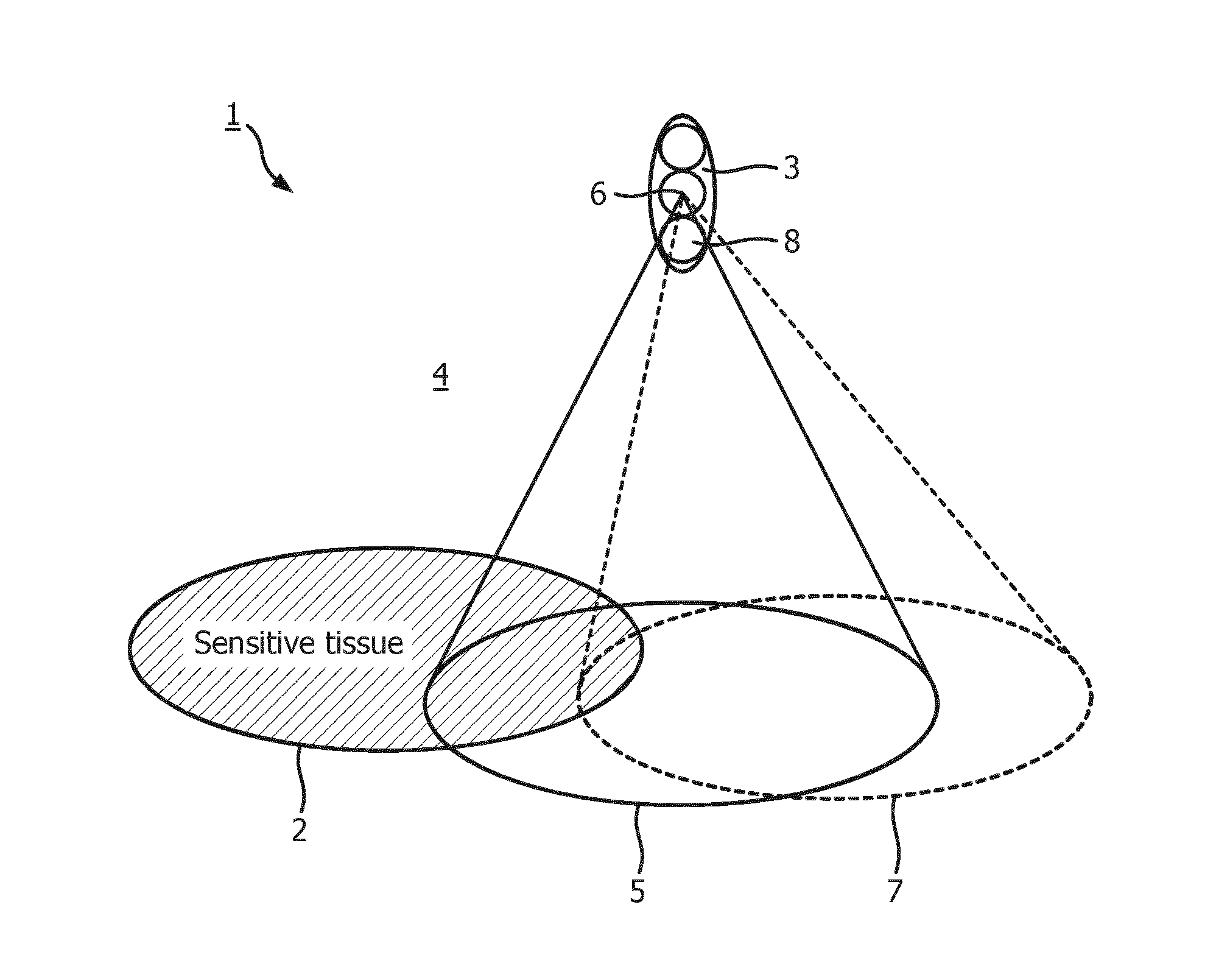

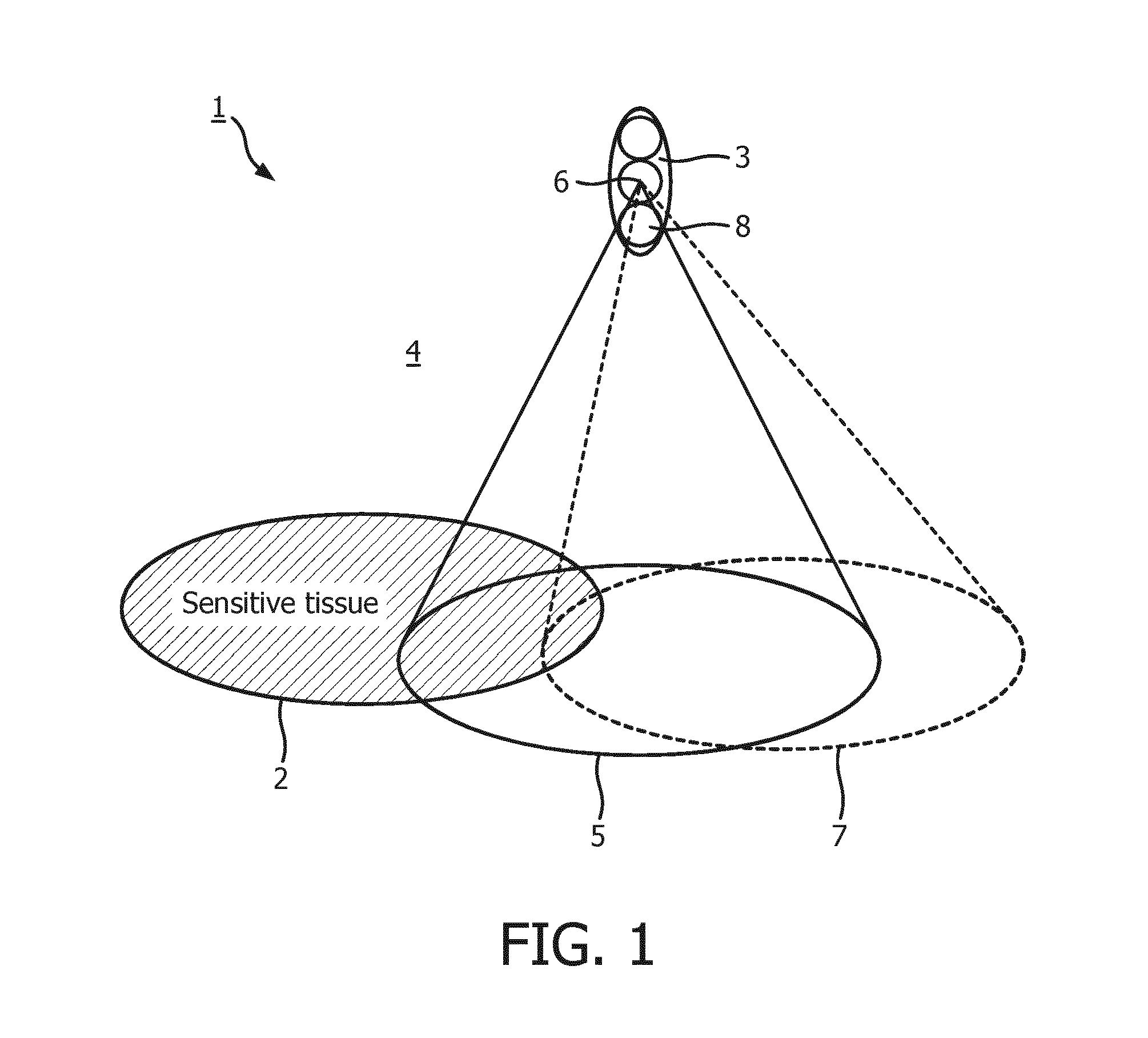

Hifu treatment optimization in vicinity of sensitive zones

InactiveUS20160082293A1Minimize exposureEffective monitoringUltrasound therapyDiagnosticsEngineeringUltrasound Radiation

The present invention provides a method for heating a target zone (3) of a subject of interest (1) according to pre-defined heating requirements using ultrasonic irradiation, comprising the steps of providing an ultrasonic irradiation device comprising a set of individually controllable transducer elements in vicinity of the target zone (3), defining at least one sensitive zone (2) within an area (4) covered by ultrasonic irradiation device, and controlling the ultrasonic irradiation device to apply sonications of ultrasonic energy to the target zone (3) to achieve the desired heating thereof, wherein the transducer elements are individually controlled in phase and amplitude to provide the sonications as a beam (5) directed towards the target zone (3), wherein the beam (5) has a energy distribution so that the pre-defined heating requirements of the target zone (3) are met and the exposure of the at least one sensitive zone (2) is minimized The present invention further provides an ultrasonic irradiation device adapted to perform the above method. By individually controlling the transducer elements, beam shaping of the ultrasonic irradiation can be applied over sensitive zones like scars, bones, bowels, spines or others without associating an intensity limit or energy exposure limit thereto. Such a configuration of active elements is sought, that the exposure on the sensitive zone is minimized, without compromising focal properties or violating restrictions on the number of active elements.

Owner:KONINKLJIJKE PHILIPS NV

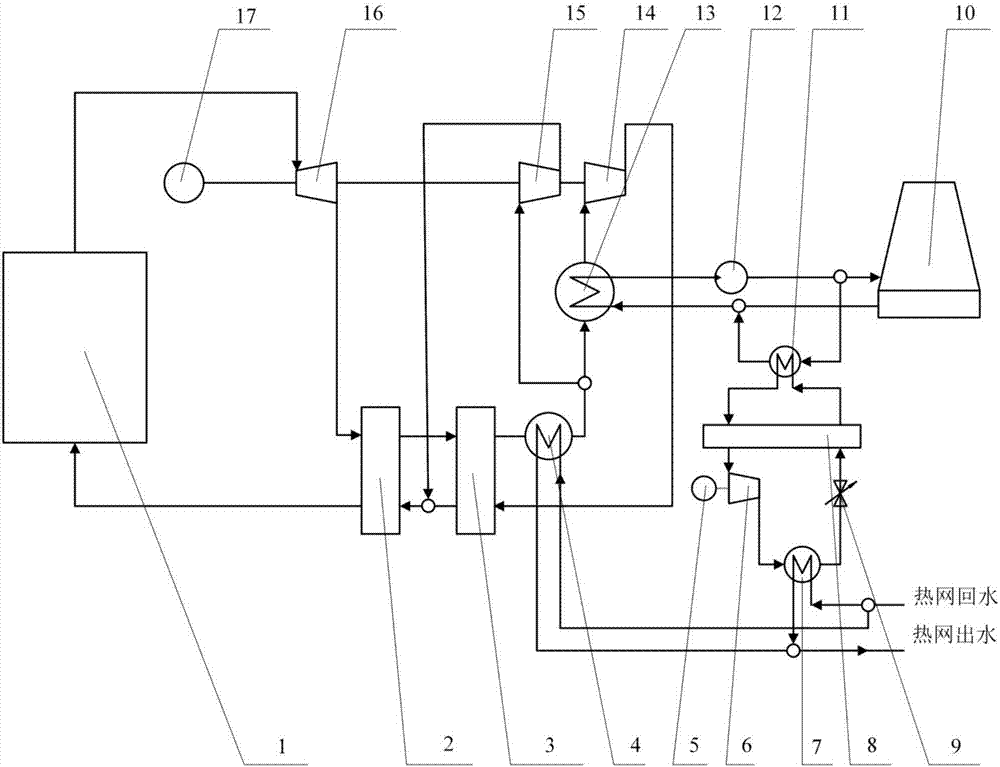

Two-stage backpressure machine reheating steam extraction heating supply system and method

InactiveCN109653818AImprove utilization efficiencyReduce energy consumptionLiquid degasificationSteam engine plantsPipingPower capability

The invention discloses a two-stage backpressure machine reheating steam extraction heating supply system and method. The two-stage backpressure machine reheating steam extraction heating supply system comprises a deaerator water inlet pipe, a deaerator, a boiler water inlet pipe, a boiler water outlet pipe, a high-pressure backpressure machine and a high-pressure steam supply pipe. A boiler is arranged on the boiler water inlet pipe. The high-pressure steam supply pipe communicates with a low-pressure steam inlet pipe. The low-pressure steam inlet pipe communicates with a low-pressure backpressure machine. The low-pressure backpressure machine communicates with a low-pressure steam supply pipe. The two-stage backpressure machine reheating steam extraction heating supply system has the beneficial effects that the requirement of users for high-parameter steam is met through unit reheating; the power capability of reheated steam is greatly improved; waste steam generated from acting by the low-pressure backpressure machine is supplied to low-pressure heat users; the requirements of the users for high-pressure steam supply and low-pressure steam supply are both met; and the utilization efficiency of heat energy is improved.

Owner:DONGFANG TURBINE CO LTD

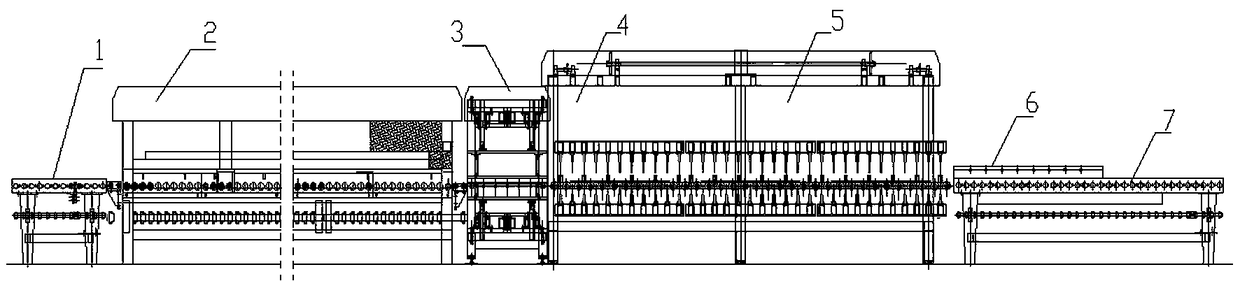

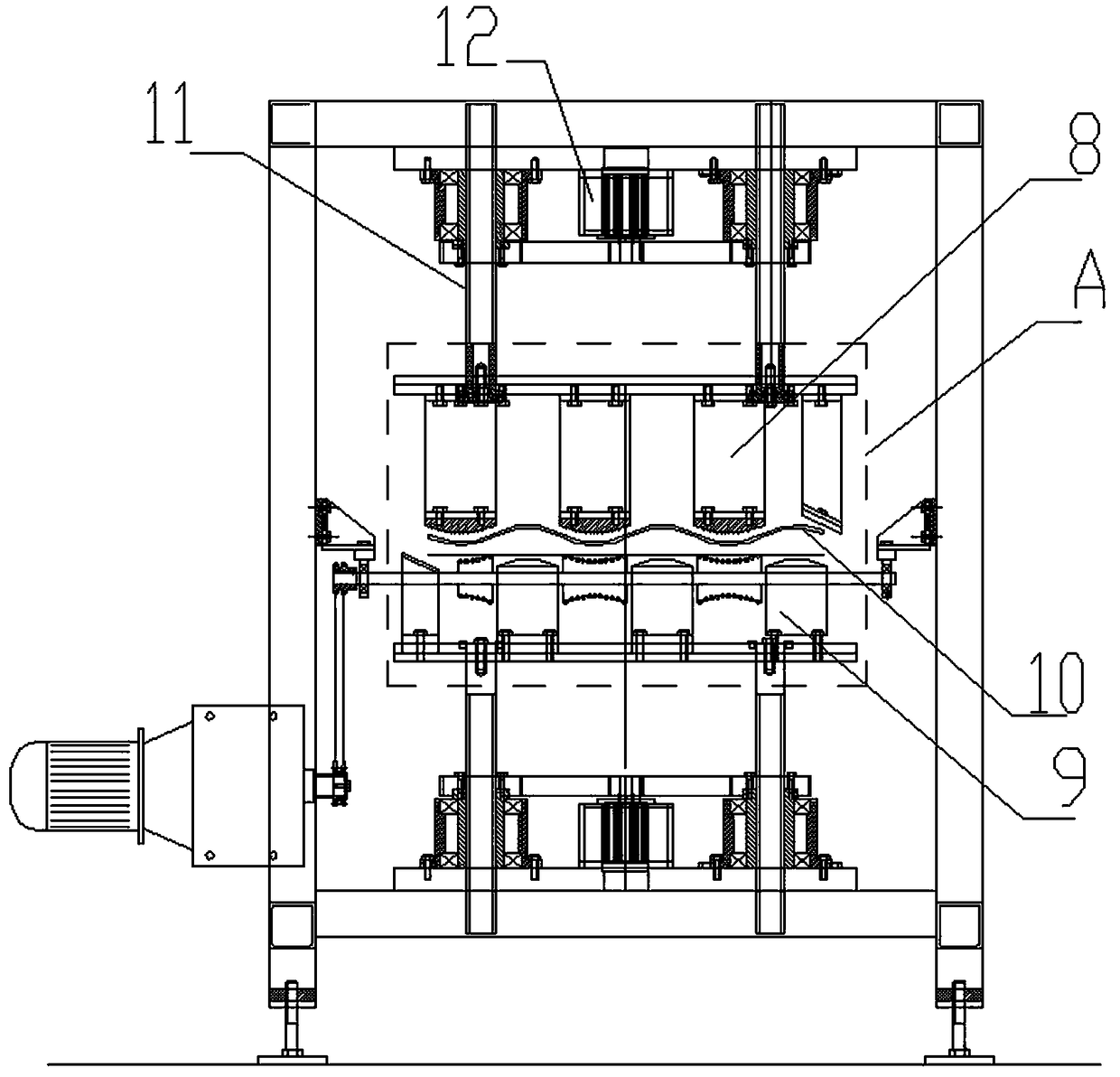

Production equipment of wave-shaped tempered glass

ActiveCN108328911ASolve bottlenecksIncrease power generation capacityGlass reforming apparatusGlass tempering apparatusWave shapeFusiform shape

The invention relates to production equipment of wave-shaped tempered glass. The production equipment comprises a sheet charging table, a heating furnace, a primary shaping section, a rolling pressingcorrection section, a tempering section and a sheet discharging table in sequential arrangement along the process progress direction, wherein the primary shaping section comprises an upper module, alower module and a plurality of rows of shaping rollers; the upper module and the lower module are in vertical arrangement; the shaping rollers are arranged in the glass conveying direction; a plurality of upper molds used for wave-shaped concave surface part shaping are arranged in the upper module; the upper molds and the shaping rollers are in vertical correspondence; a plurality of lower moldsused for wave-shaped glass convex surface part shaping are arranged in the lower module; the bus lines of the shaping rollers are anastomotic with the lower surface sectional line of the concave surface part after the glass shaping; the rolling pressing correction section is mainly formed by a roller way which are ranged in the glass conveying direction and is provided with a plurality of fusiform rollers; the bus lines of the fusiform rollers are anastomotic with the interface sectional lines of the wave-shaped glass in contact with the fusiform rollers. The equipment has the advantages thatthe production of the wave-shaped tempered glass becomes possible; the bottleneck problem of the wave-shaped curve surface photovoltaic solar panel production is solved.

Owner:洛阳格莱斯机械设备有限公司

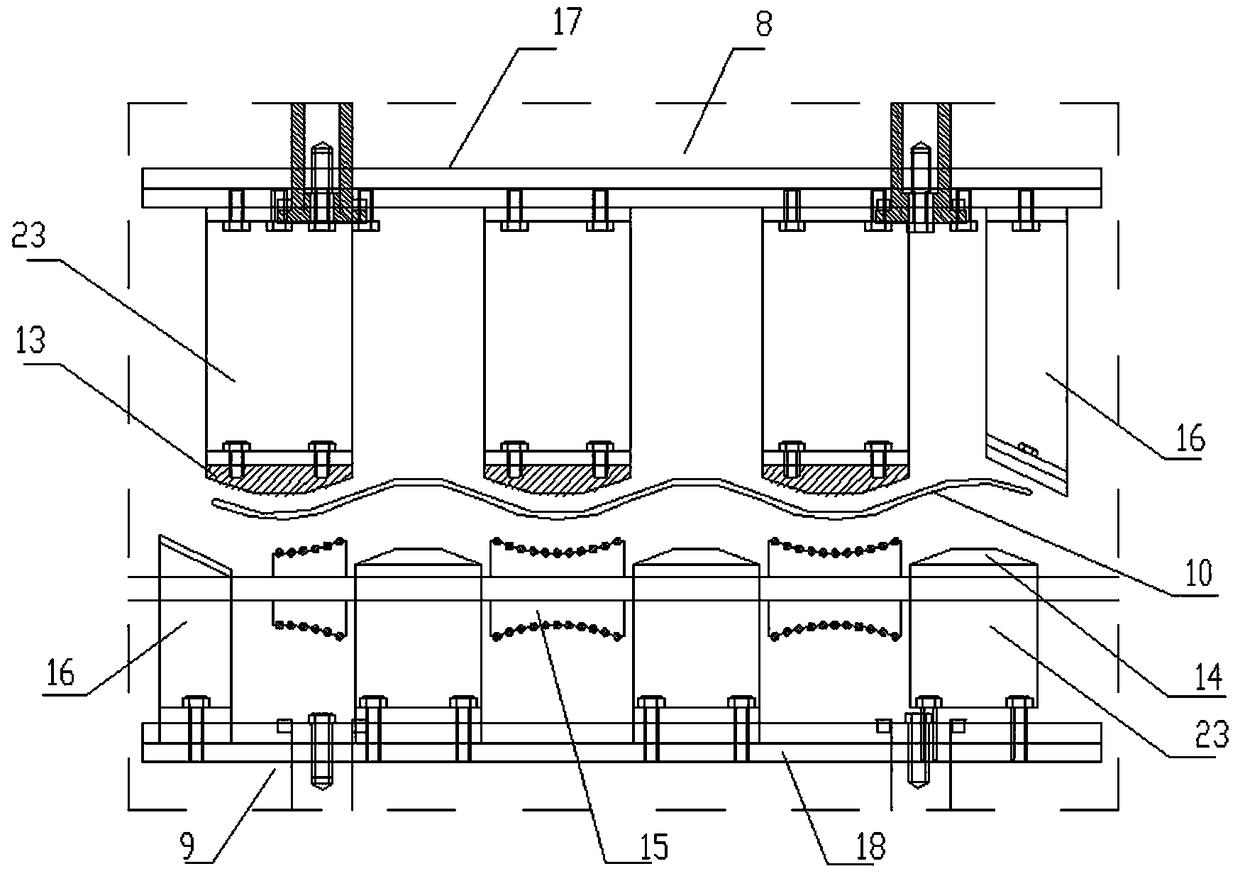

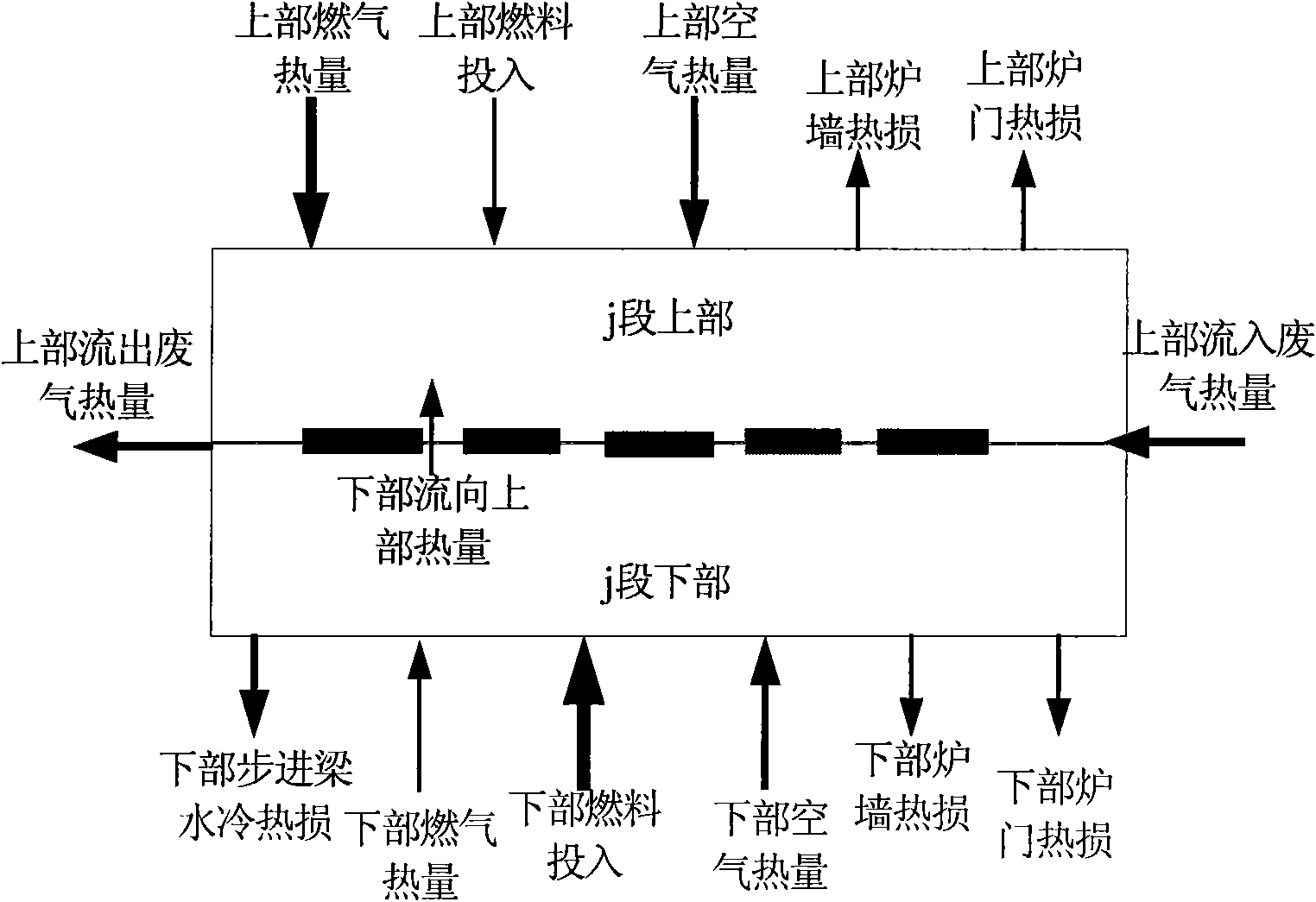

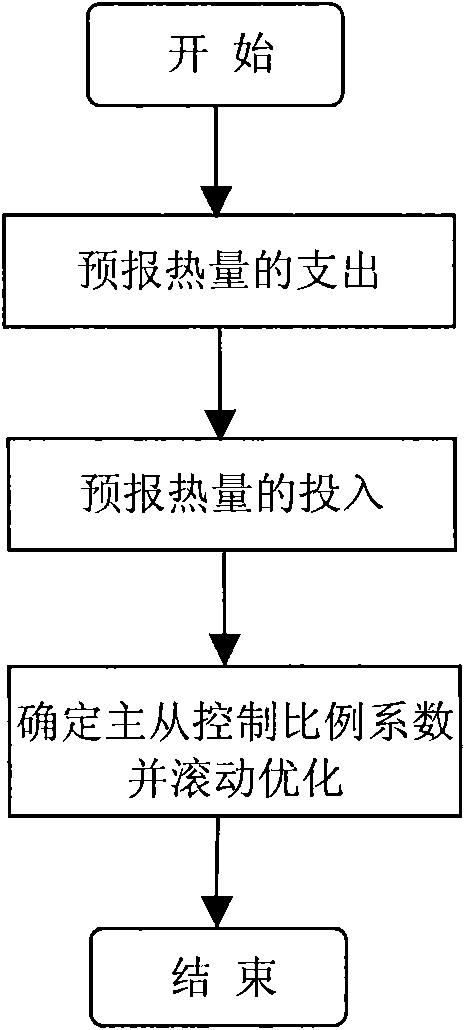

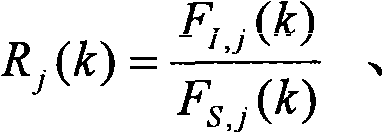

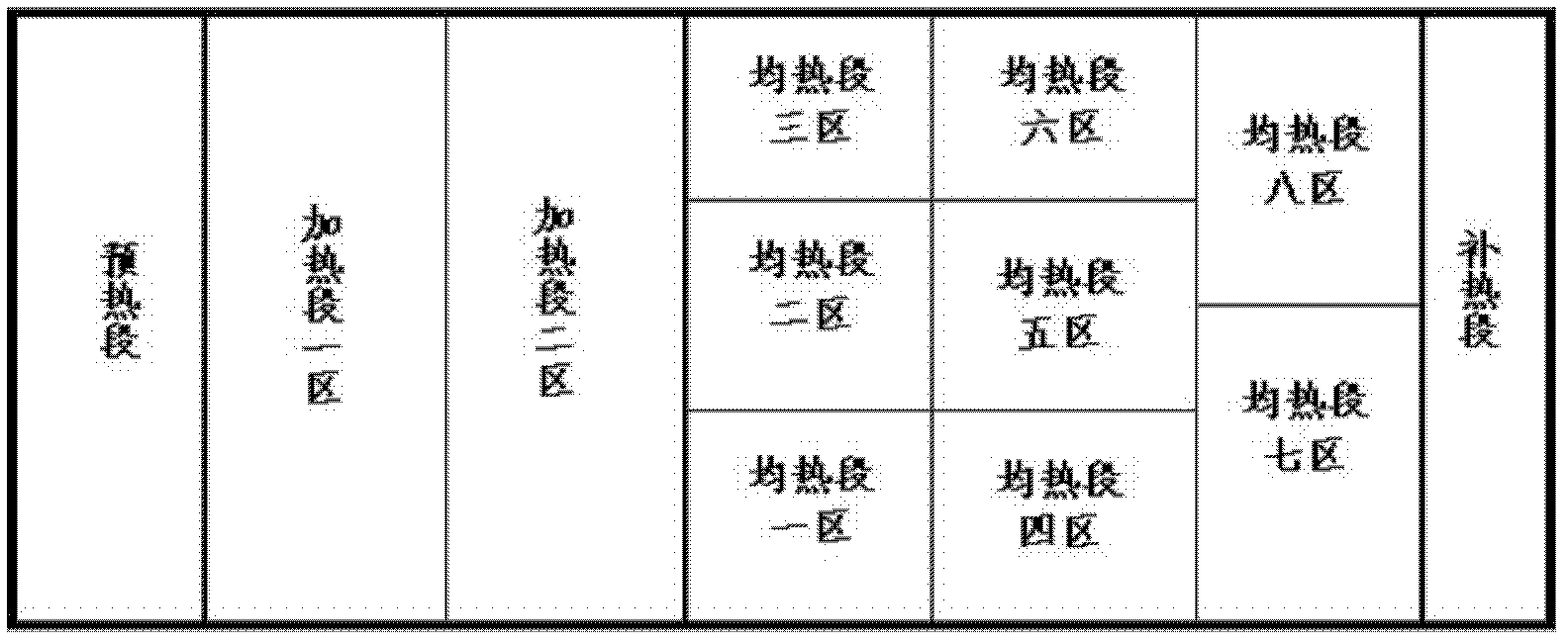

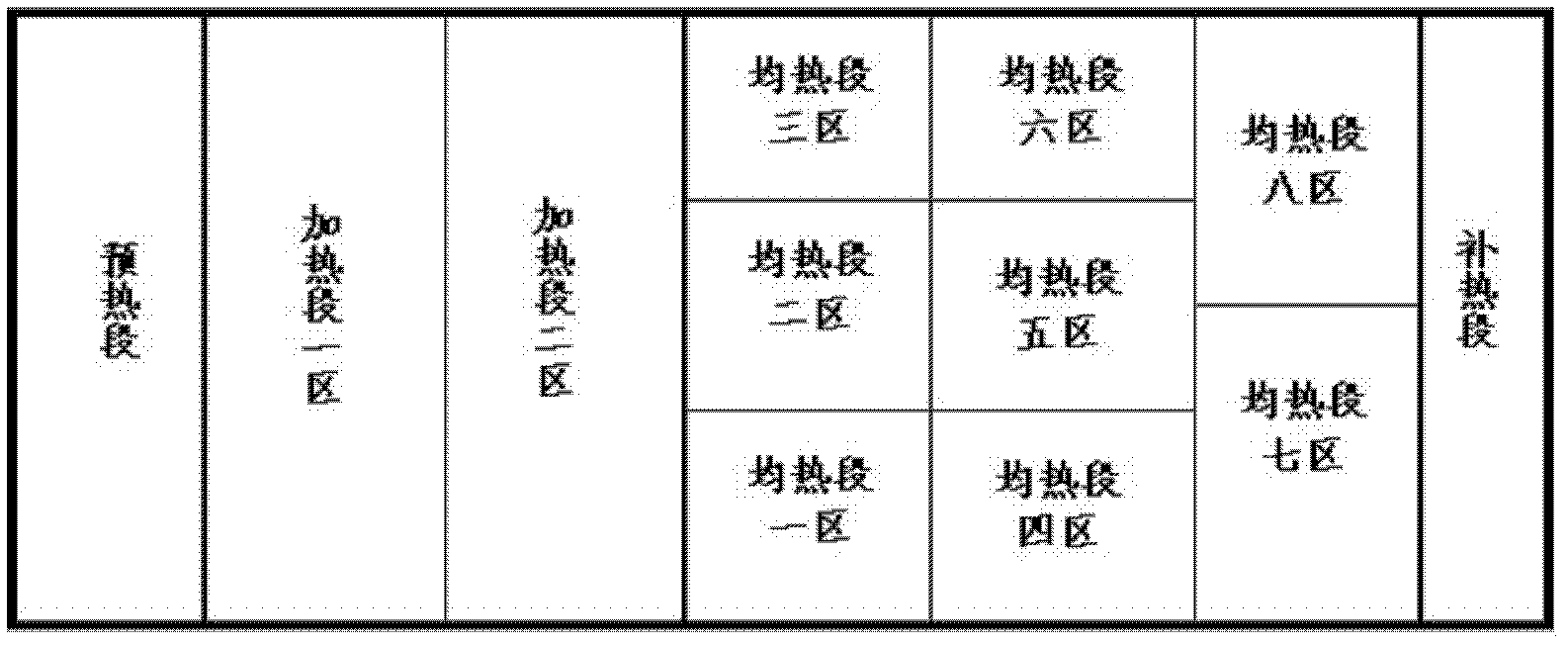

Method for determining master-slave control proportional factor of hot rolling heating furnace

ActiveCN101638717ASatisfy heating qualityMeet heating requirementsTemperature control deviceFurnace typesEngineeringHeat losses

The invention relates to the field of controlling processes of a hot rolling heating furnace, in particular to a method for determining a master-slave control proportional factor of the hot rolling heating furnace. The method comprises the following steps of: 1, determining heat energy consumed during a forecasting period of time, wherein the heat energy includes the heat energy which a plate blank needs to absorb, the heat energy lost by the furnace wall, the heat energy consumed by cold water, heat loss of a furnace door and heat loss of other parts;2, according to a forecasting model established on the basis of a thermal balance equation, working out the amount of fuel needed by the upper parts and the lower parts of all segments of the heating furnace during the forecasting period of time; and 3, according to the forecasted amount of fuel needed by the upper part and the lower part of the current segment of the heating furnace, determining the master-slave control proportional factor, and making the rolling optimization according to the actually measured flow rate of the fuel on the upper part and the lower part of the heating furnace. The method has the advantages of better meeting the requirements on heating quality and line rolling rhythm of the plate blank, saving energy, and overcoming the defects of the master-slave control of the prior hot rolling heating furnace that the upper-lower part fuel proportional factor set by artificial experience is not accurate.

Owner:BAOSHAN IRON & STEEL CO LTD

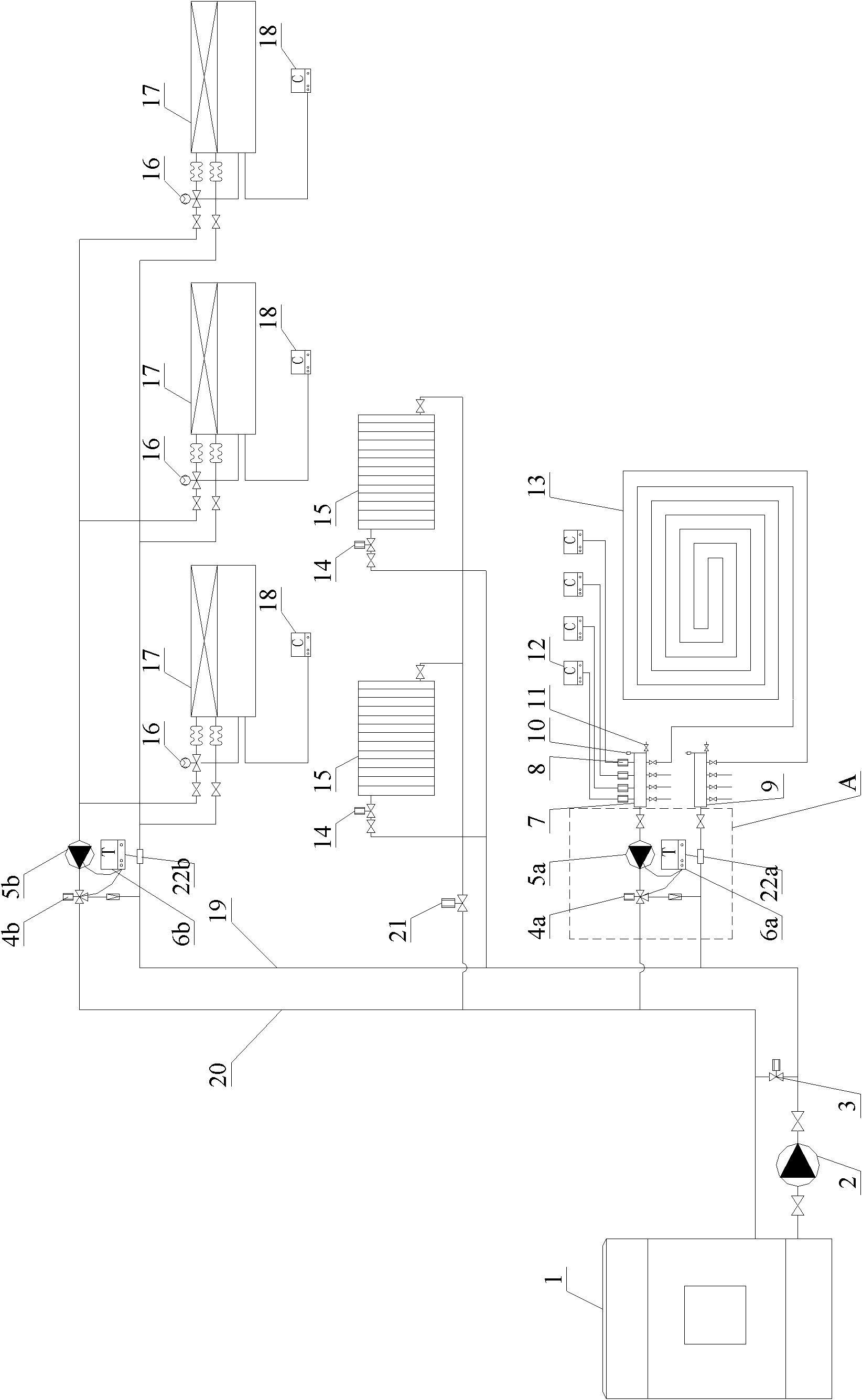

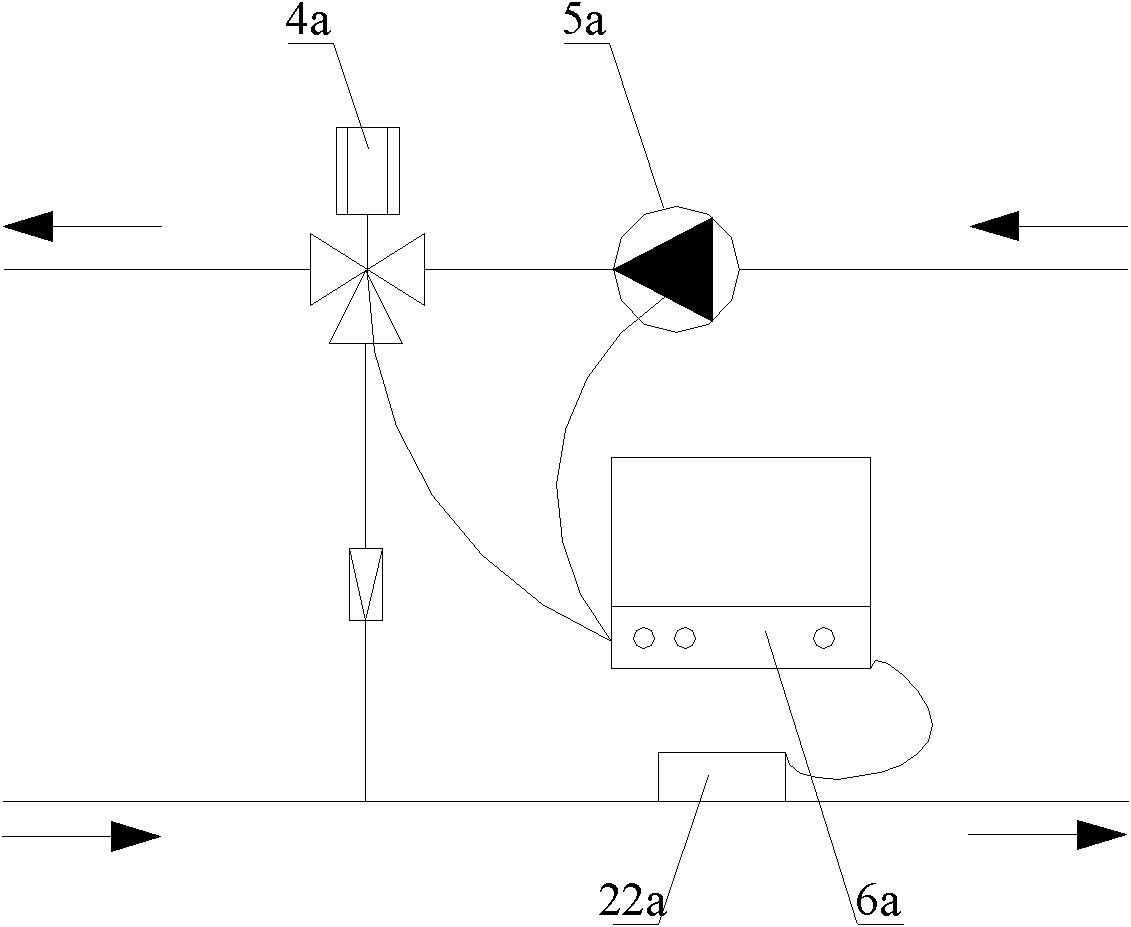

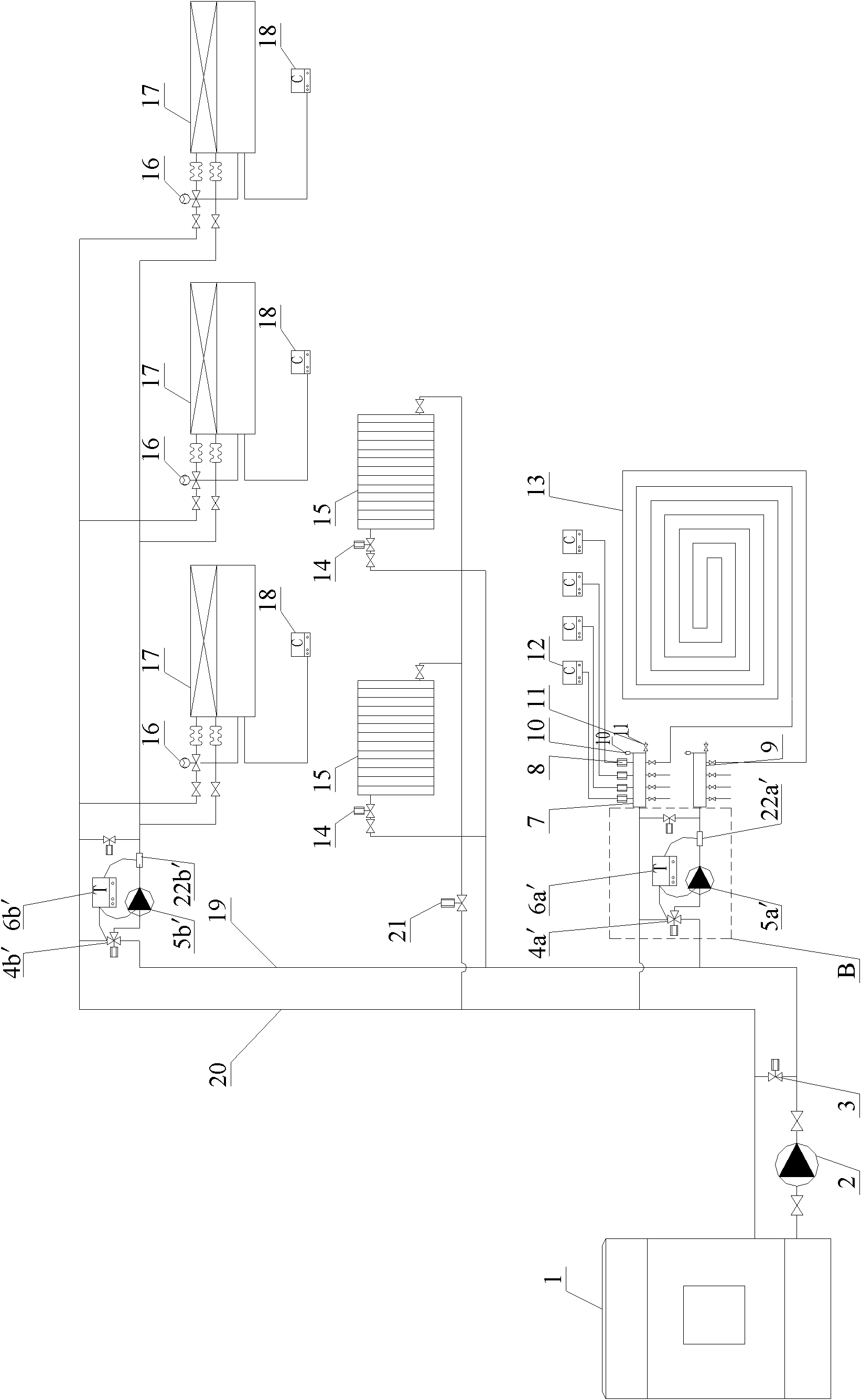

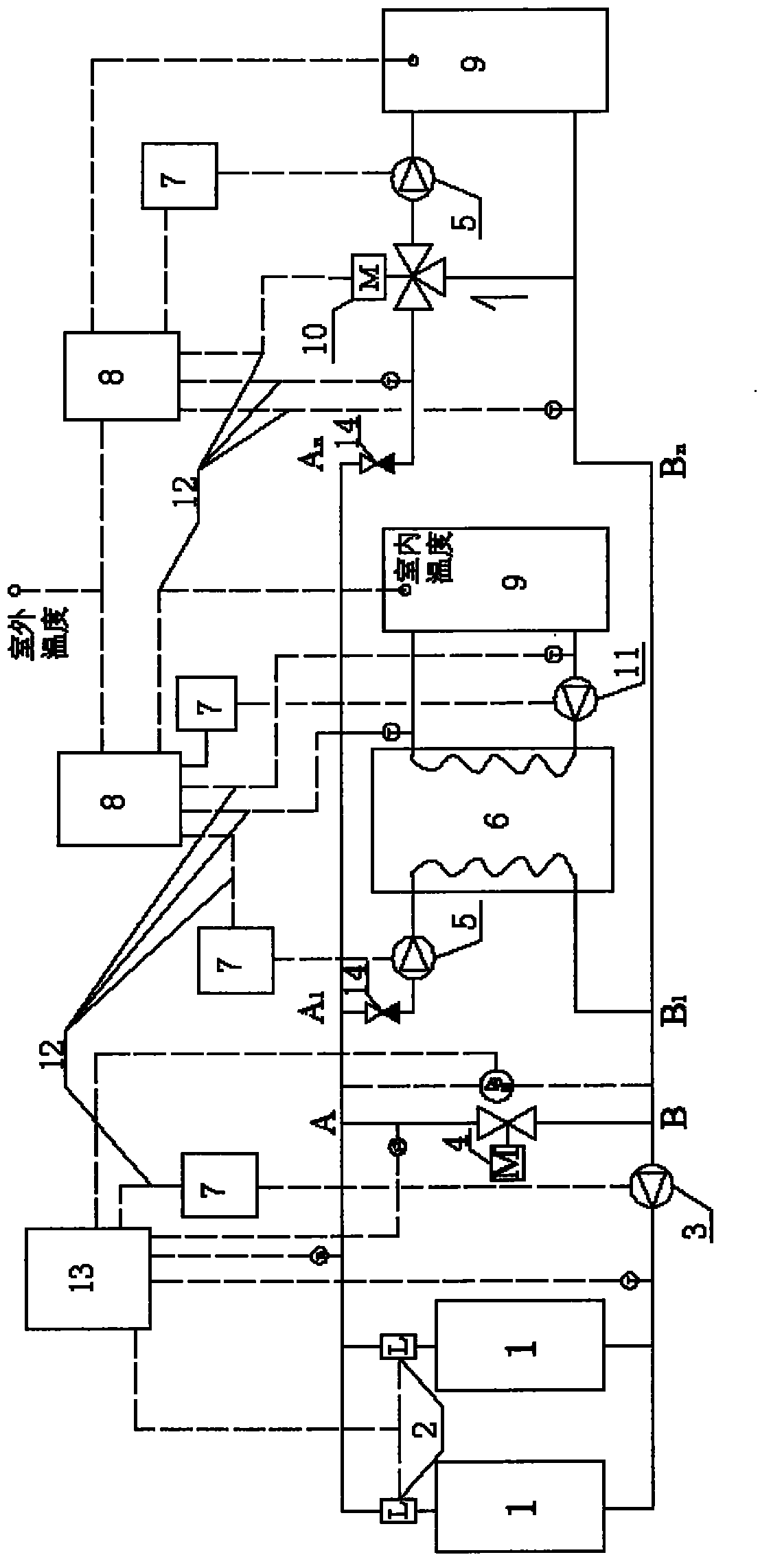

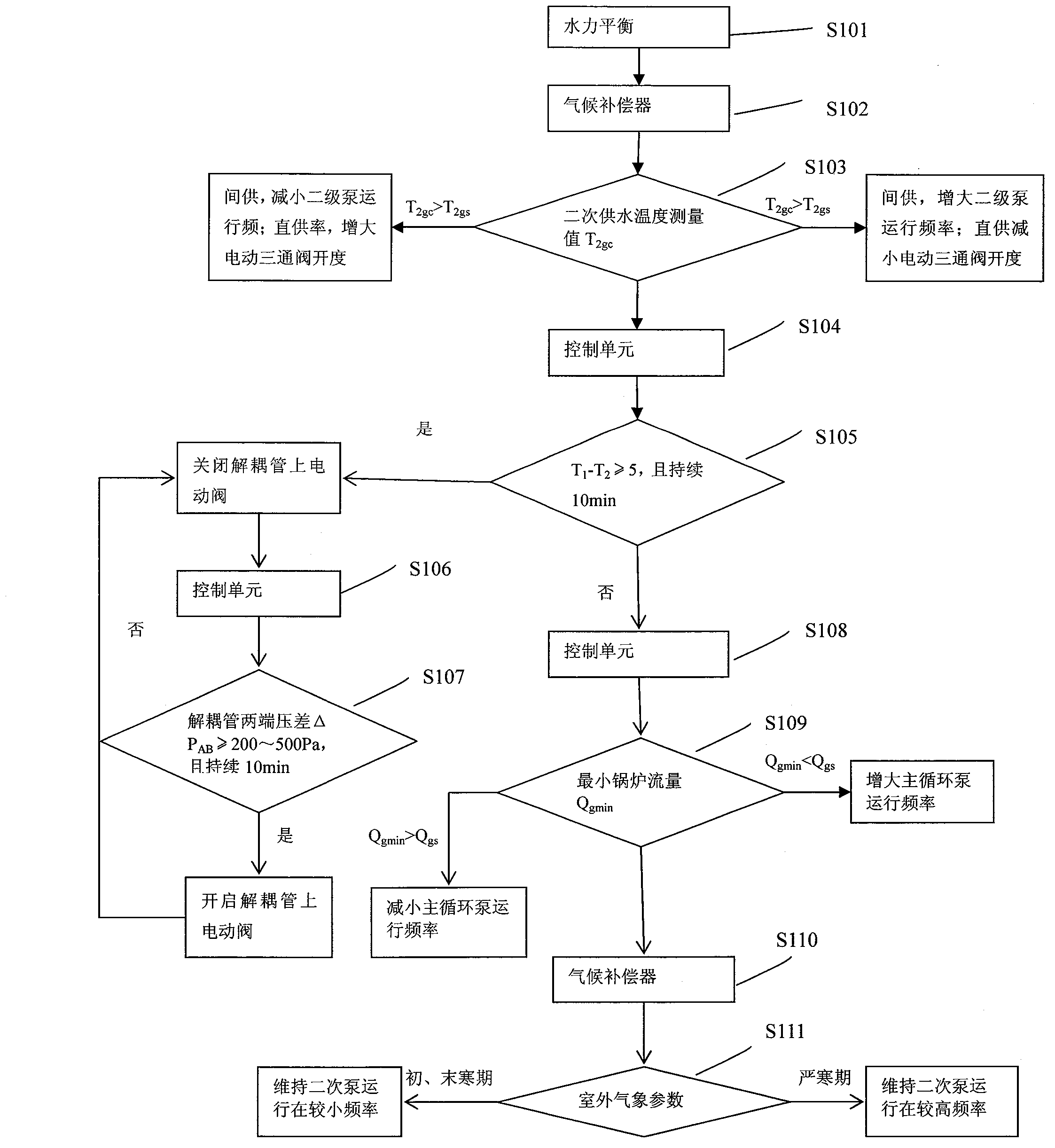

Central heating distributive frequency conversion two-stage pump system energy-saving control method

ActiveCN102913991AGuaranteed uptimeMeet heating requirementsEnergy efficient ICTLighting and heating apparatusHeat distributionFrequency conversion

The invention relates to a central heating distributive frequency conversion two-stage pump system energy-saving control method. The method comprises the following steps: adjusting the opening of an indirect heat supply form two-stage pump running frequency and an electric three-way valve arranged in front of a direct heat supply form two-stage pump according to a secondary supply water temperature, controlling the opening and closing of the electric two-way valve according to temperature difference of the electric two-way valve and a boiler outlet on a decoupling pipe and pressure difference on the two ends of the decoupling pipe, and maintaining the normal operation of a system when the two-stage pump running frequency changes or the opening of the three-way valve changes. The central heating distributive frequency conversion two-stage pump system energy-saving control method comprises a method used for controlling the running frequency of a main circulation pump according to the rated flow of each boiler and also comprises a control method used for adjusting the running frequency of a secondary pump according to outdoor meteorological parameter in a staging manner. The control method accurately adjusts the heating load of a system, the system simultaneously reduces the power consumption of a circulating water pump according to the required heat supply, the control method can carry out real-time monitoring and adjustment on a heat supply system through wireless communication, and the district heating automation level is improved.

Owner:BEIJING KINGFORE HV & ENERGY CONSERVATION TECH CORP

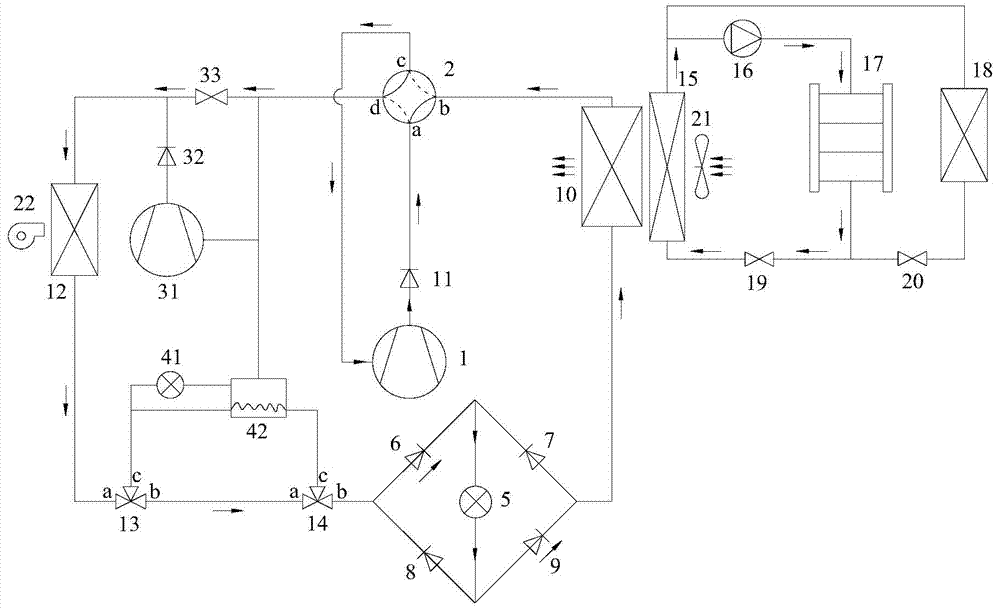

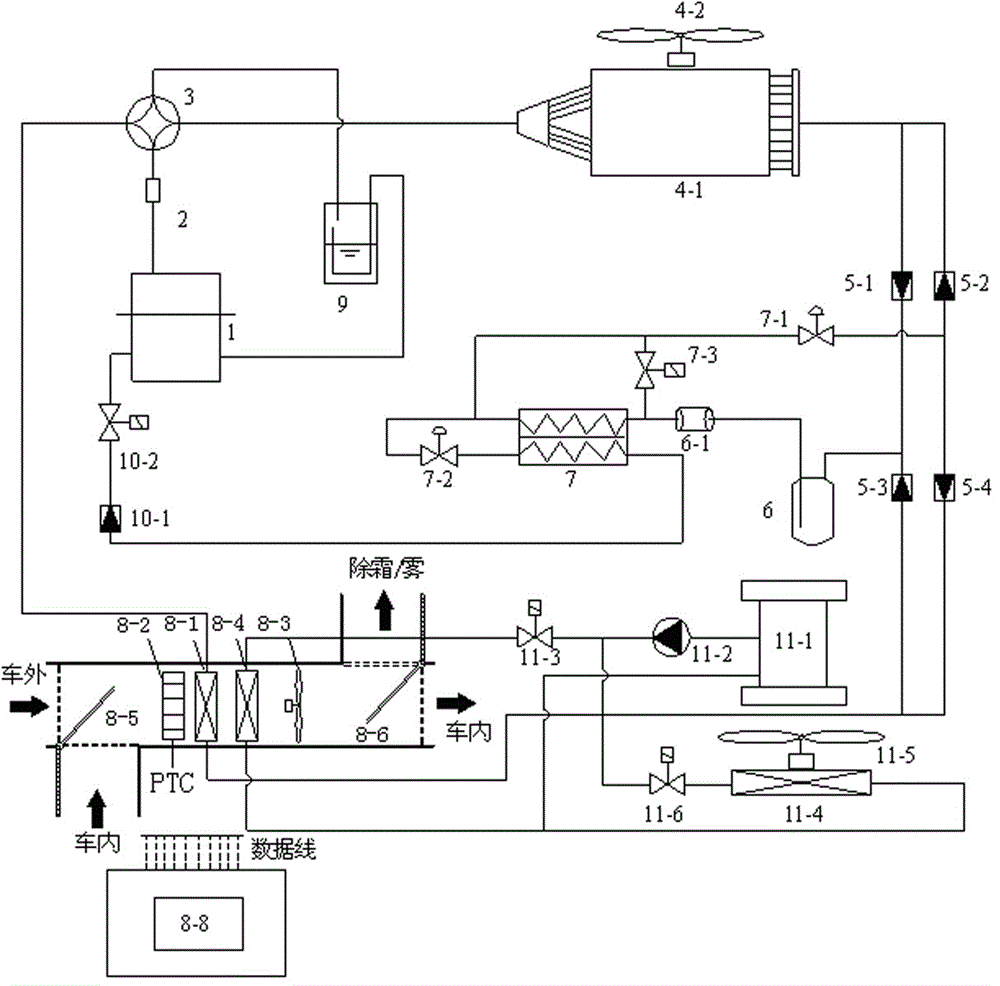

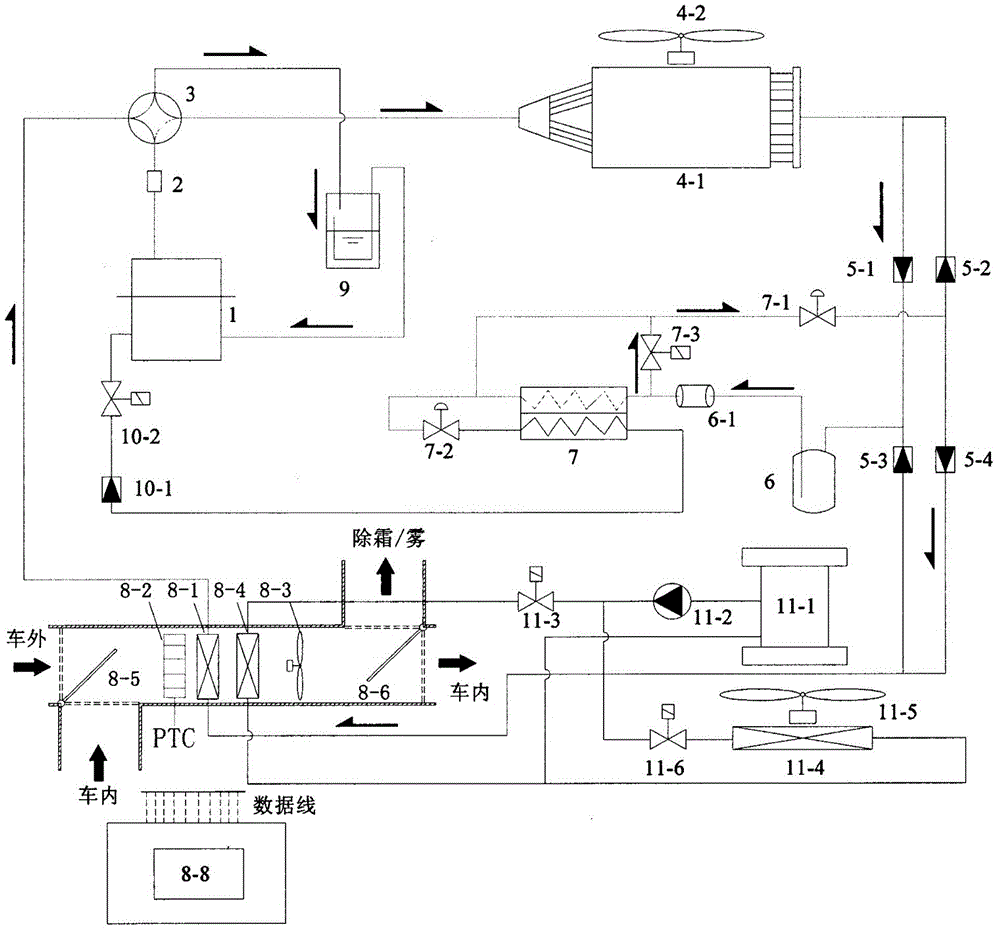

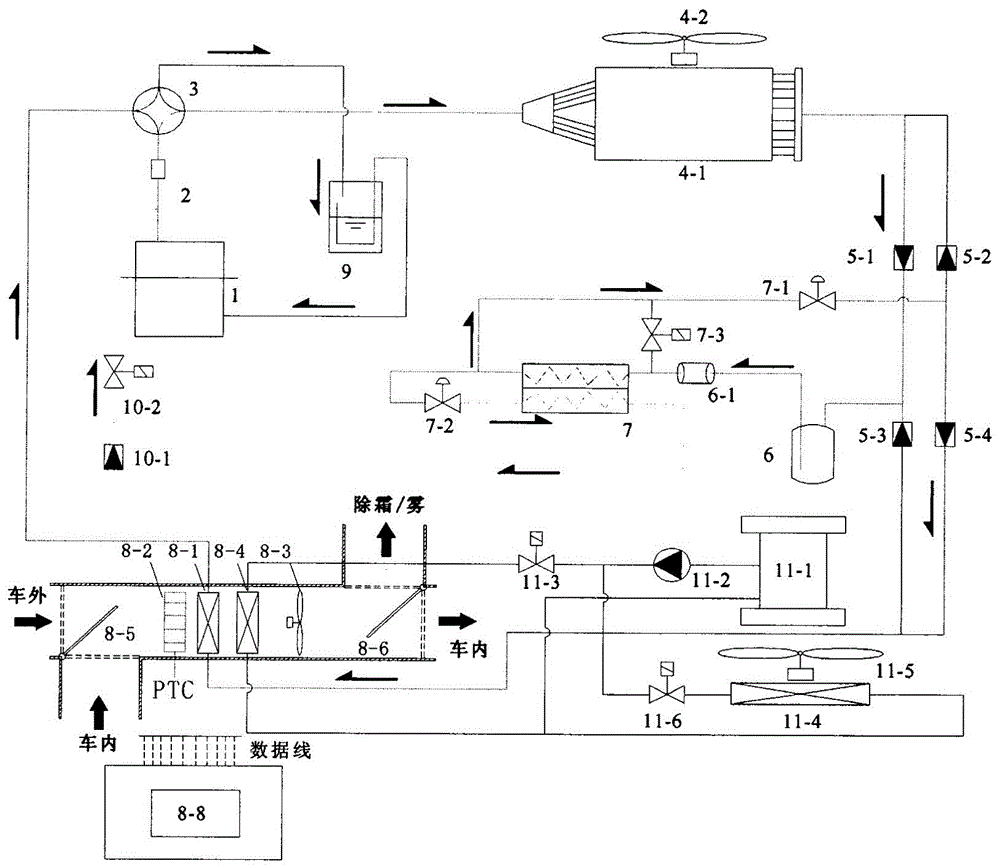

Overhead type heat pump type carriage air-conditioning system with total heat recovery apparatus

InactiveCN106585324AGuaranteed uptimeMeet heating requirementsAir-treating devicesHeat pumpsOperation modeEngineering

Disclosed is an overhead type heat pump type carriage air-conditioning system with a total heat recovery apparatus. The system is composed of an overhead type heat pump type air conditioner subsystem, a carriage power system compound total heat recovery subsystem and an operation mode switching control subsystem. The overhead type heat pump type carriage air-conditioning system with the total heat recovery apparatus, provided by the invention, through the combination of the overhead type heat pump type air conditioner subsystem, the carriage power system compound total heat recovery subsystem and the operation mode switching control subsystem, can remarkably solves such salient problems of over-high exhaust temperature of a compressor during low-temperature operation of a heat pump air conditioner, quite thick car outside heat exchanger frosting, quite difficult defrosting, low system power supply capability and heat supply efficiency, poor system operation reliability, low system energy utilization rate and the like.

Owner:ZHONGYUAN ENGINEERING COLLEGE

Method for producing beryllium-bronze flat ingot by natural-gas walking beam furnace

The invention relates to a method for producing a beryllium-bronze flat ingot by a natural-gas walking beam furnace, which is characterized in that: by using digital pulse combustion control technology, the temperature of the heating furnace is controlled by adjusting the duty cycle of the combustion time. The invention adopts a multi-segment multi-region controlled heating mold, and by using digital combustion control technology - pulse combustion control technology and by adjusting the air-fuel ratio, uniform heating and precise control of the beryllium-bronze ingot casting are realized in micro-reduction atmpsphere, and thus the purpose of batch production is reached.

Owner:CNMC NINGXIA ORIENT GRP

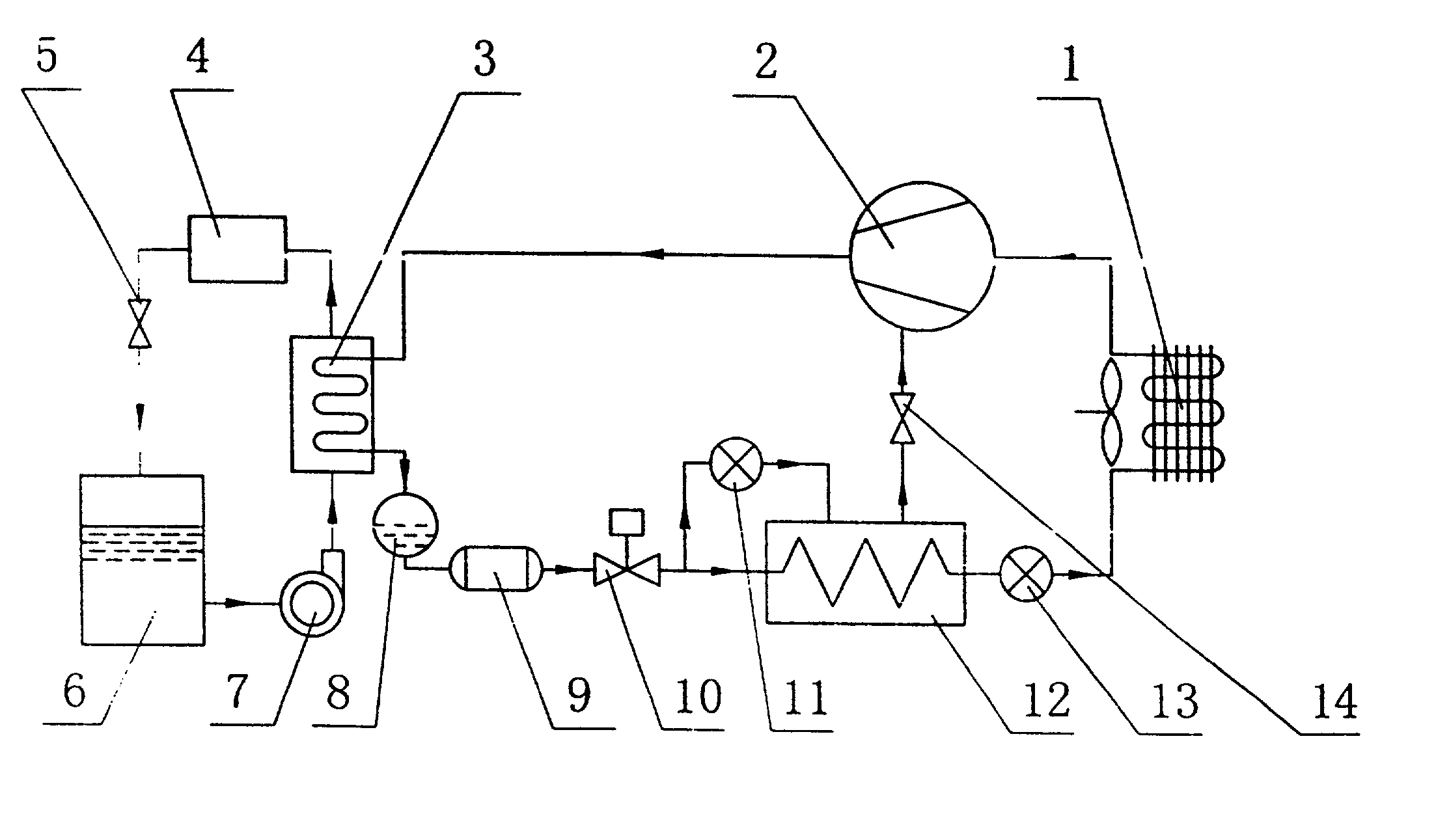

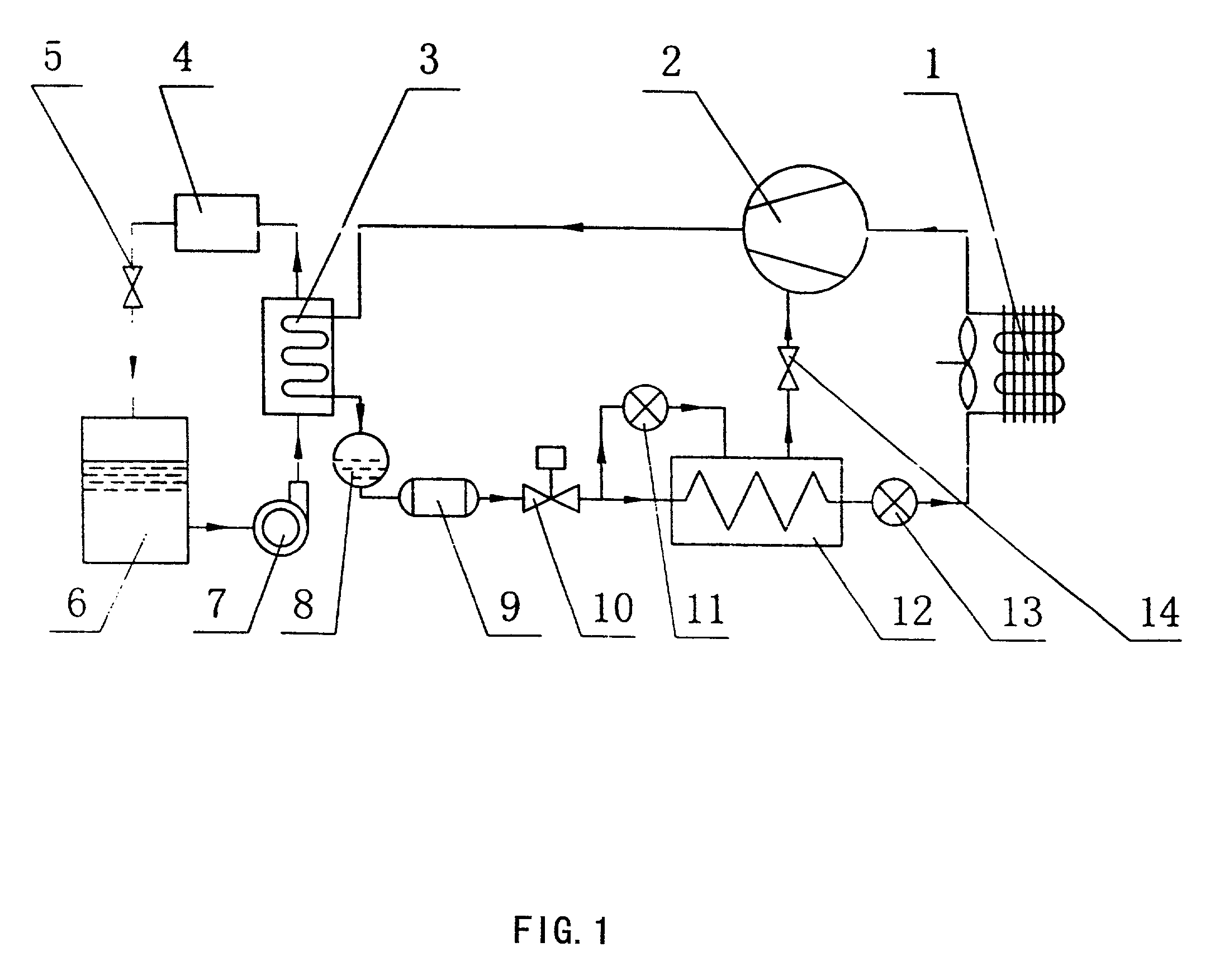

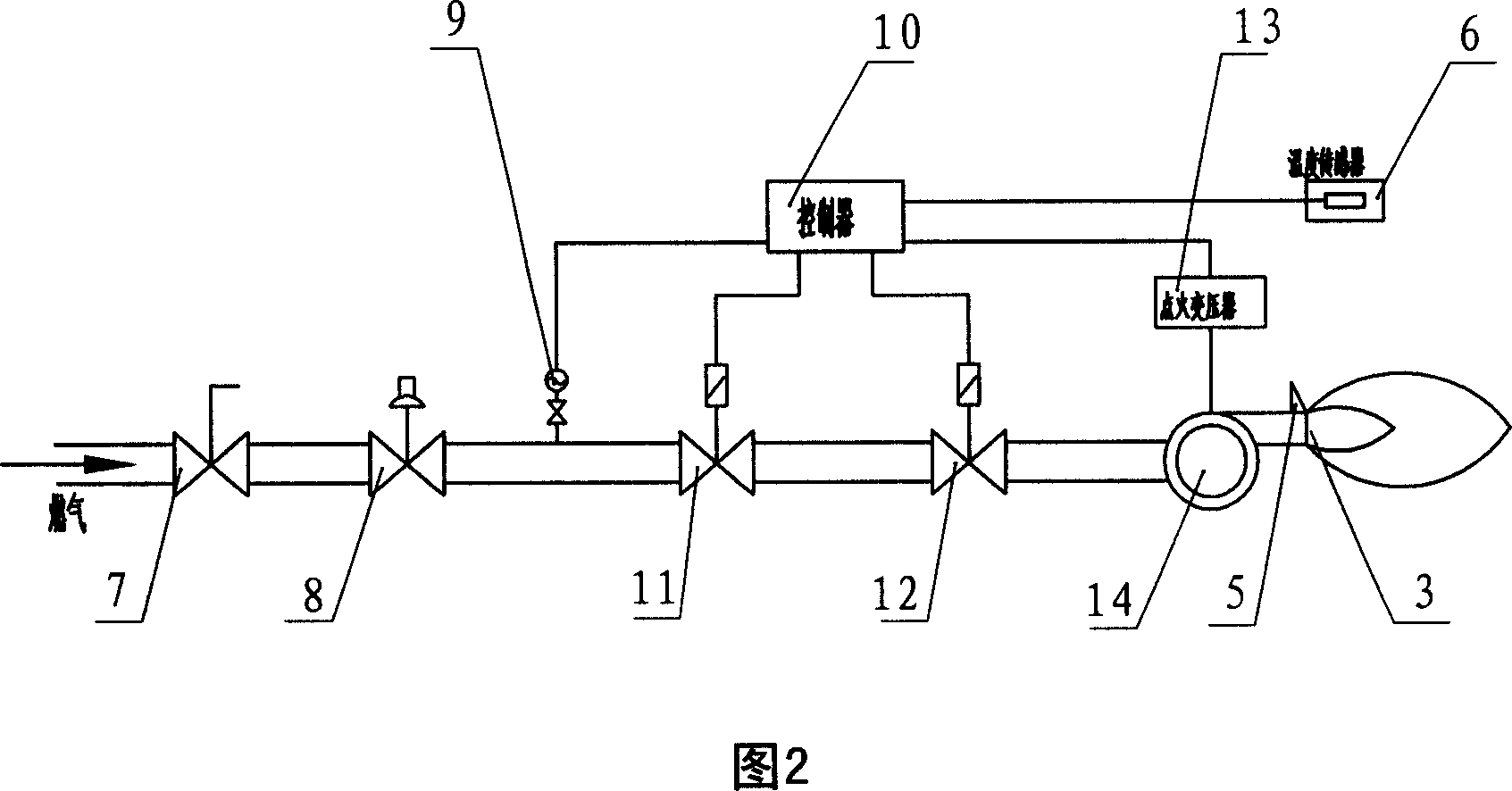

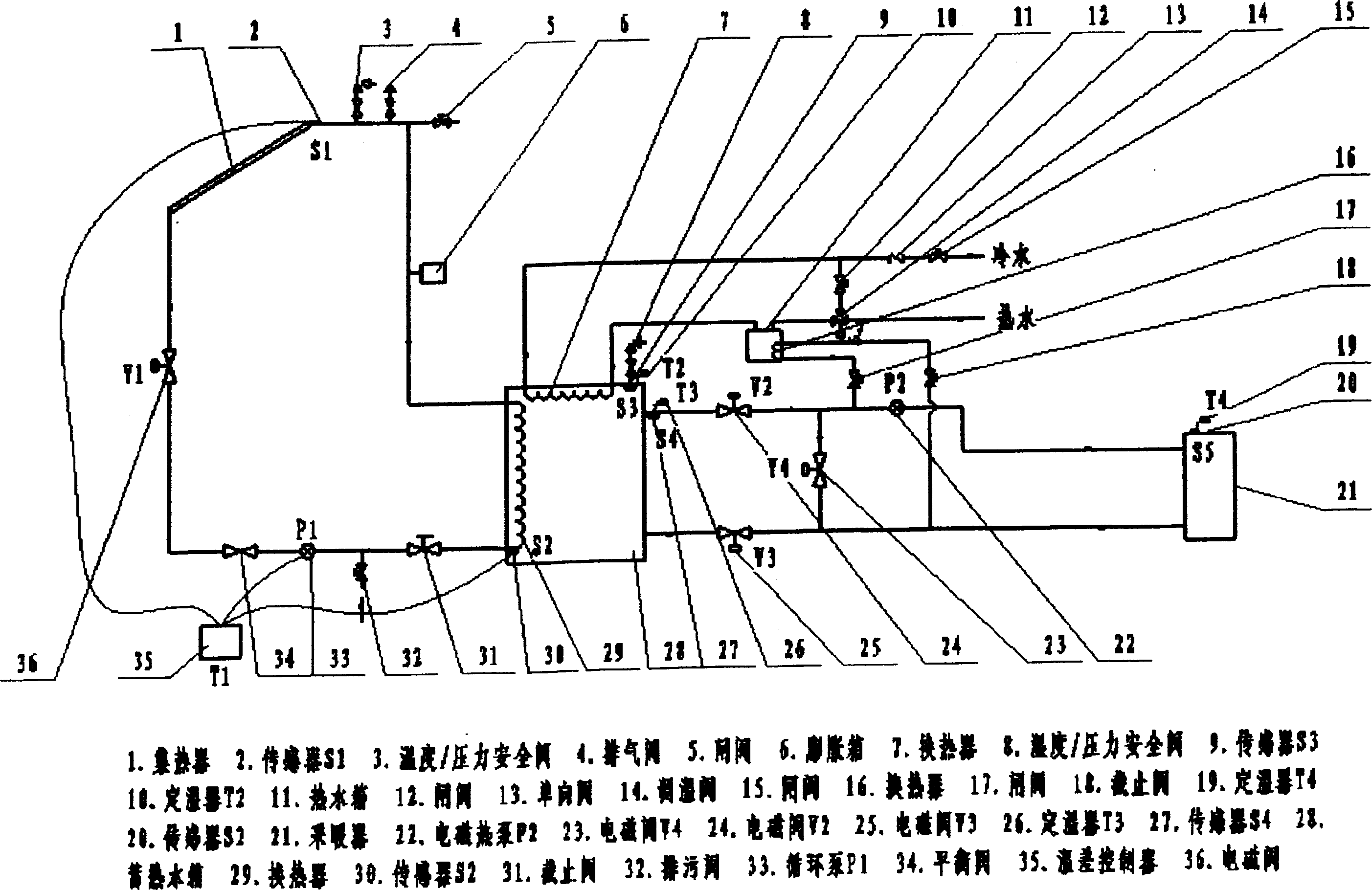

Solar electromagnetic heat pump hot-water central heating system

InactiveCN1888579AMeet heating requirementsLow running costSolar heat devicesEnergy efficient heating/coolingEngineeringHeating temperature

A solar electromagnetic heat pump hot water heating system consists of a solar heat collector, an electromagnetic heat pump, hot water storage tank, a sensor, a hot water tank, a heat exchanger, a circulating pump, a magnetic valve, a thermoelectric controller, a heating controller and a heating equipment. When the heat absorbed by the heat collector is enough to make the system run and the heating is needed in the room, the heating controller starts the electromagnetic heat pump to circulate the hot water in the hot-water storage tank to the heating equipment for heating in the room. When the heat absorbed by the heat collector is not enough to make the system run, but the heating is needed in the room, the electromagnetic heat pump is used for raising the water temperature of the system to the designed heating temperature and then it is circulated to the heating equipment for heating in the room.

Owner:唐晓江

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com