Heating system

A heating system and pipeline technology, applied in the field of multi-form terminal heating systems, can solve the problems of low maintainability, large differences in initial investment in heating terminals, and increased construction and maintenance costs, so as to reduce initial investment, control heating costs, and arrange layout. flexible effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

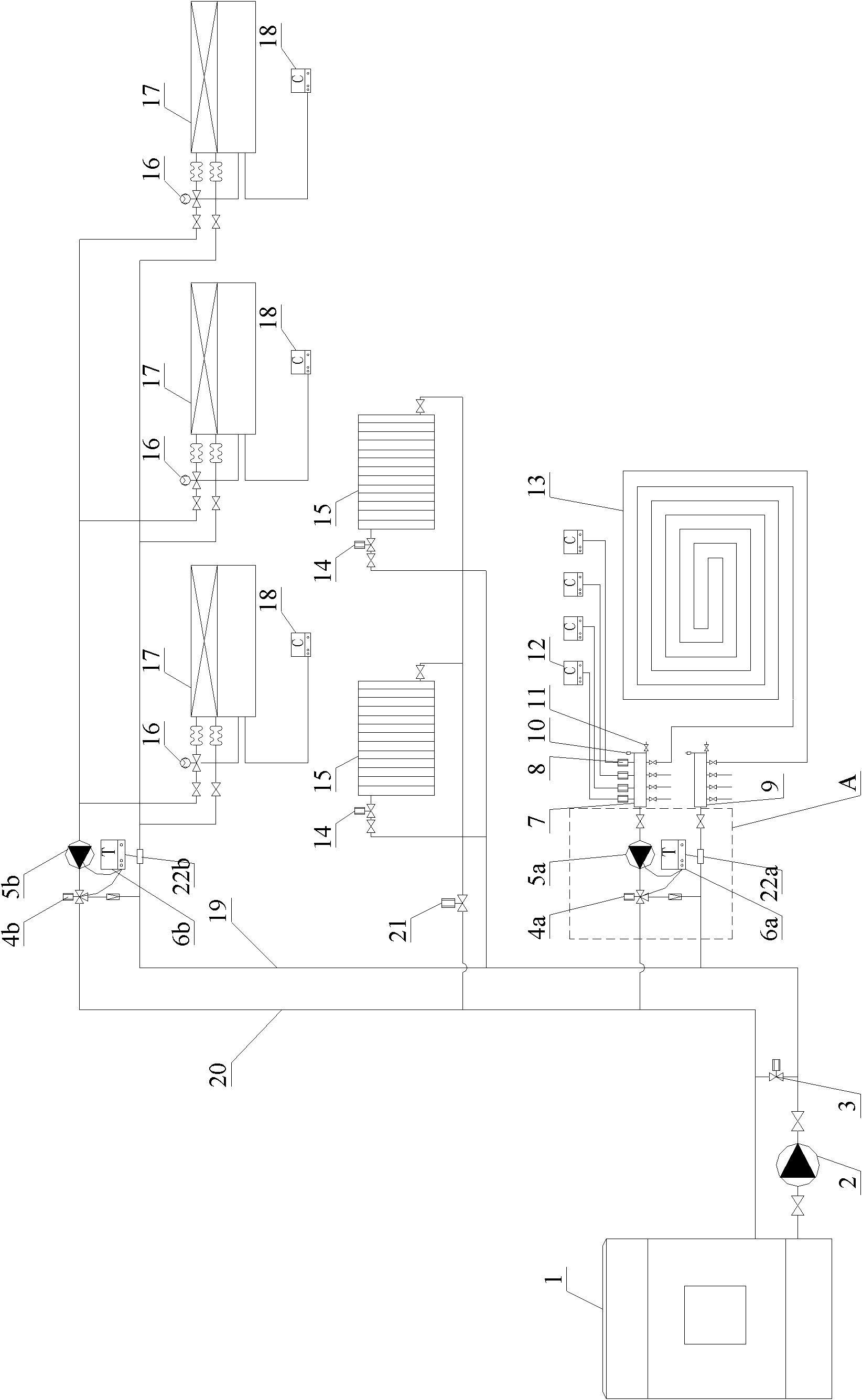

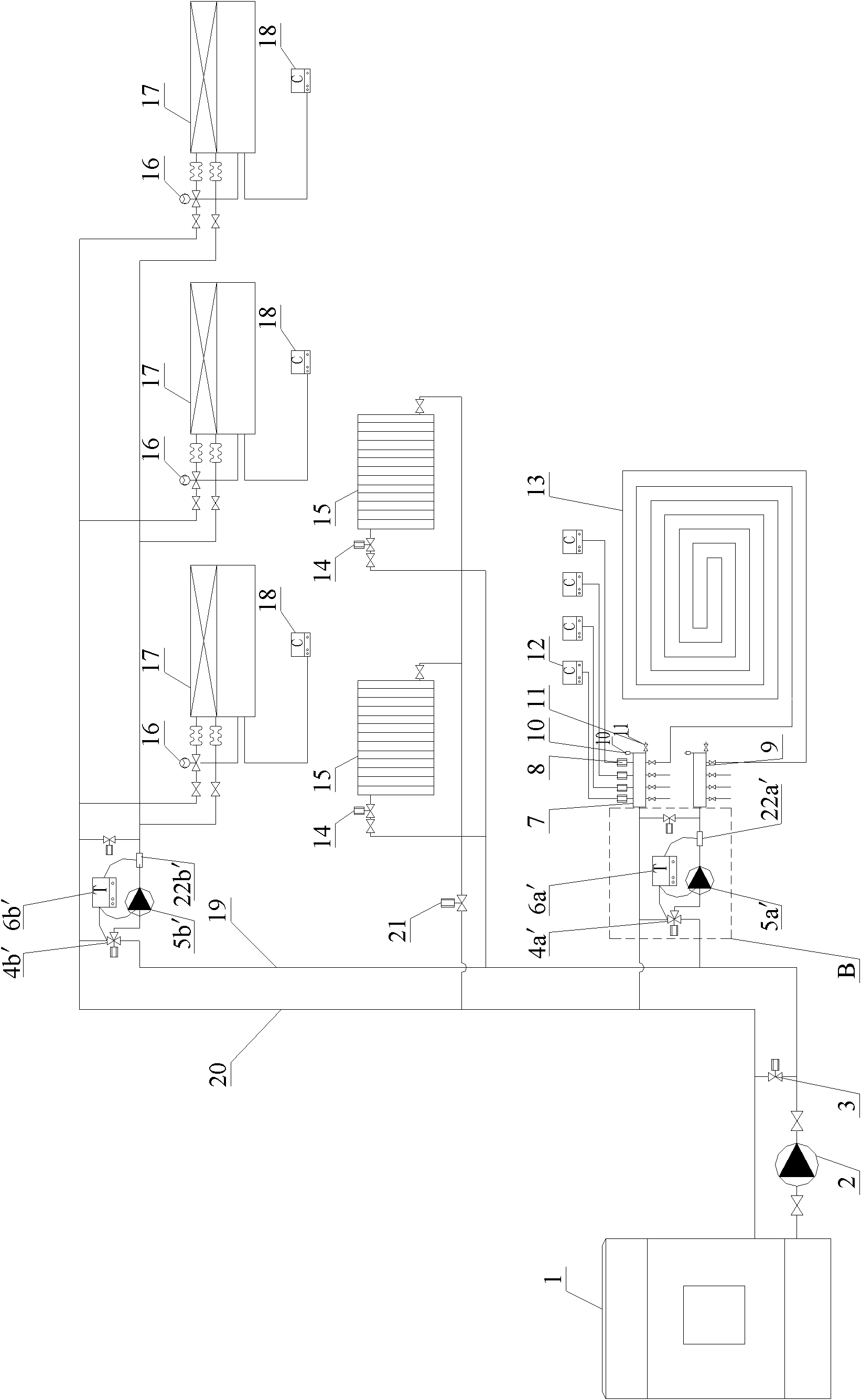

[0030] The core of the present invention is to provide a heating system, including a heat source that provides high-temperature working fluid and various forms of heating terminals; the various forms of heating terminals are arranged in parallel, in series, or in series and parallel, respectively through pipes and heat sources connected to form a circuit. On the basis of meeting the heating requirements such as comfort and heating speed of each space to be heated, it can effectively control the initial investment of the system; it has the characteristics of energy saving, high efficiency and flexible layout.

[0031] Four typical embodiments will be described in detail below in conjunction with the accompanying drawings.

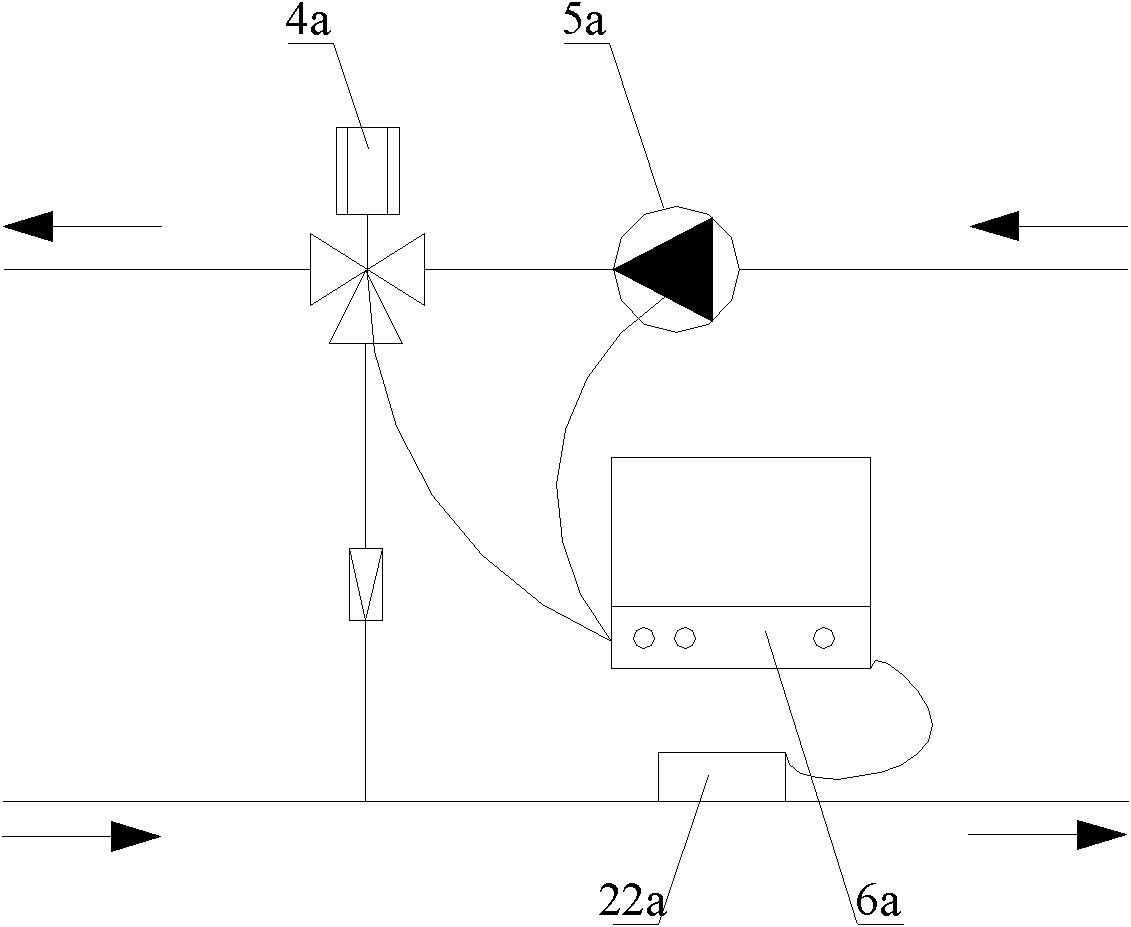

[0032] See figure 1 , which shows a schematic diagram of the heating system described in the first embodiment.

[0033] The heat source 1 of the heating system can be a wall-hung boiler, a natural gas boiler, an oil-fired boiler, a coal-fired boiler, a bio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com