Solution-spraying type air-conditioner heat pump unit

A heat pump unit, spray type technology, applied in air conditioning systems, space heating and ventilation, household heating and other directions, can solve the problems of discontinuous heating, reduced heating energy efficiency ratio, low cooling energy efficiency, etc. Frost problem, reduction of metal material, effect of large heat transfer coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

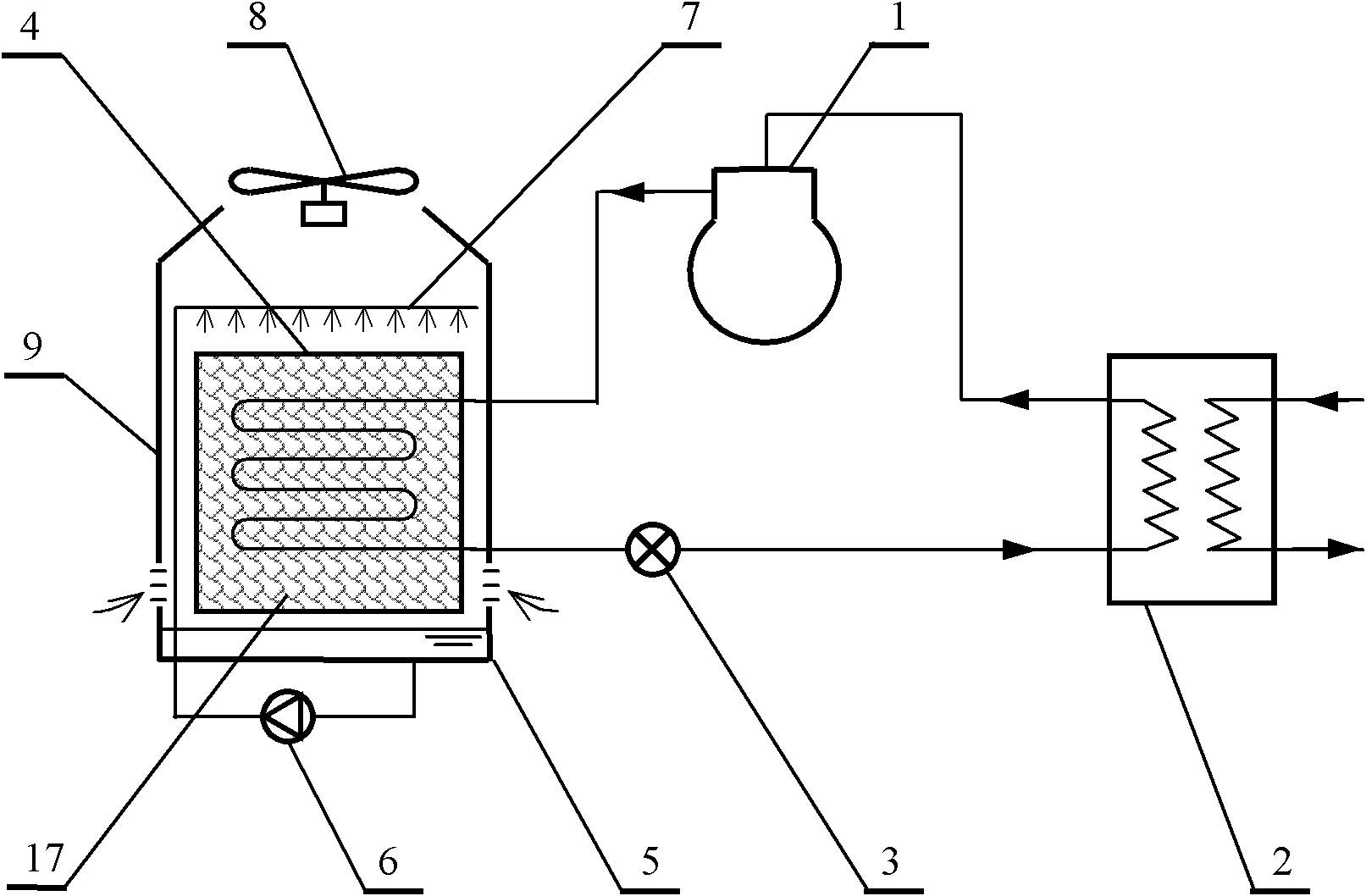

Embodiment 1

[0029] image 3 It is the structural principle diagram of the first embodiment of the solution spray type air conditioner heat pump unit provided by the present invention. In this embodiment, the exhaust gas of the compressor is used as the heat source for the solution regeneration, and it includes a compressor 1, a first heat exchanger 2, The throttling device 3, the second heat exchanger 4, the solution regenerator 14 arranged above the second heat exchanger 4, the first shower 7a and the first sprayer 7a arranged above the second heat exchanger 4 and the solution regenerator 14 respectively The second sprayer 7b, solution collection tray, four-way valve 10 and solution pump 6; described solution collection tray 5, second heat exchanger 4, first shower 7a, solution regenerator 14 and second sprayer The shower 7b is sequentially arranged in the heat exchanger housing 9 from bottom to top.

[0030] The lower part of the heat exchanger housing 9 is provided with an air inlet, ...

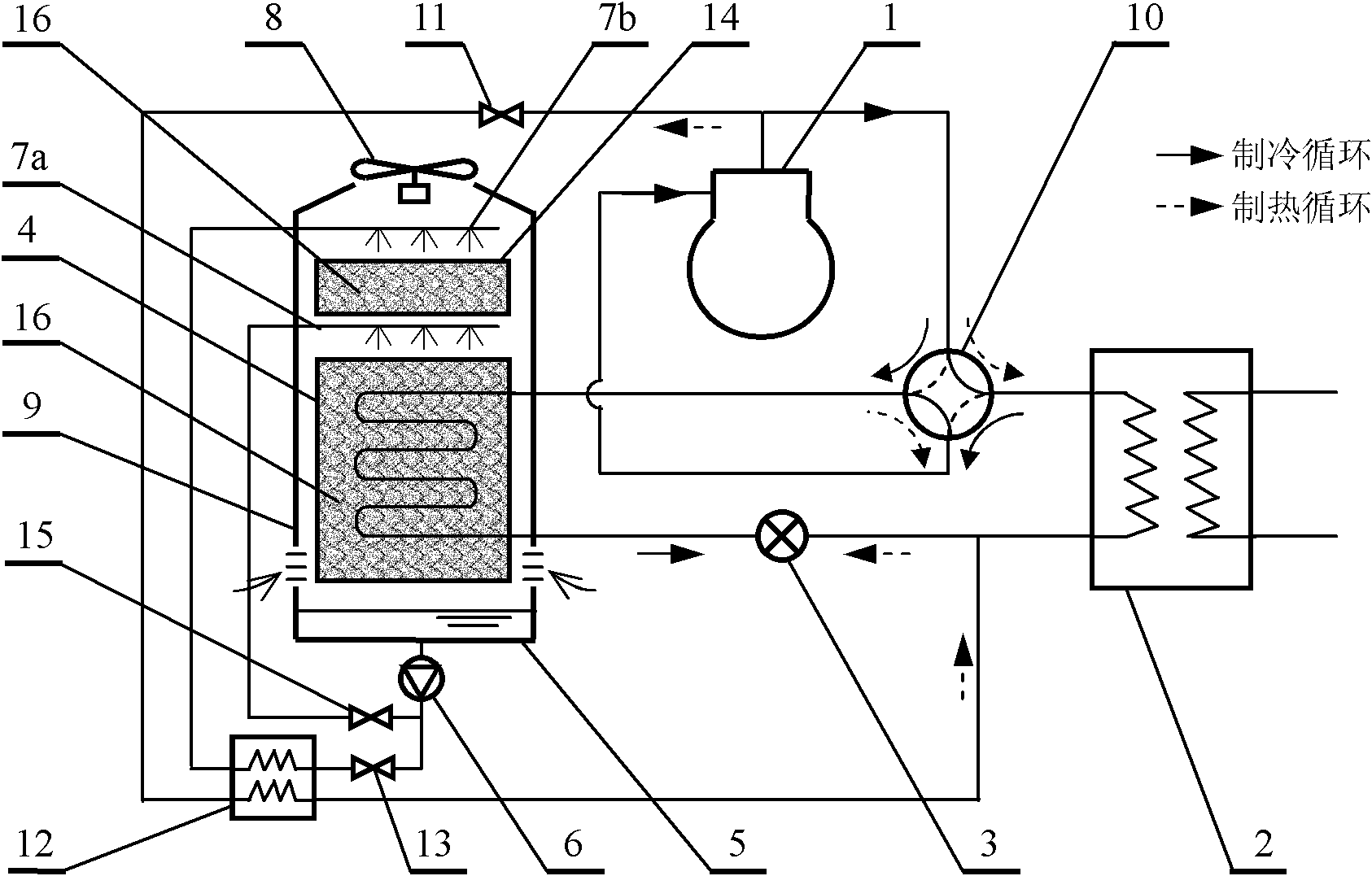

Embodiment 2

[0037] Figure 4 It is the structural principle diagram of the second embodiment of the solution spray type air-conditioning heat pump unit provided by the present invention. In this embodiment, the hot water produced by the unit is used as the heat source for solution regeneration, and it includes a compressor 1 and a first heat exchanger 2 , the throttling device 3, the second heat exchanger 4, the solution regenerator 14 arranged above the second heat exchanger 4, the first sprayer 7a arranged respectively above the second heat exchanger 4 and the solution regenerator 14 And the second sprayer 7b, solution collecting tray, four-way valve 10 and solution pump 6; Described solution collecting tray 5, the second heat exchanger 4, the first shower 7a, the solution regenerator 14 and the second The showers 7b are sequentially arranged in the heat exchanger housing 9 from bottom to top.

[0038] The lower part of the heat exchanger housing 9 is provided with an air inlet, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com