Six-way valve

A technology of six-way valve and valve body, applied in the field of six-way valve, can solve the problems of complicated operation, complicated structure and high cost, and achieve the effects of good sealing effect, lower cost and easy installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

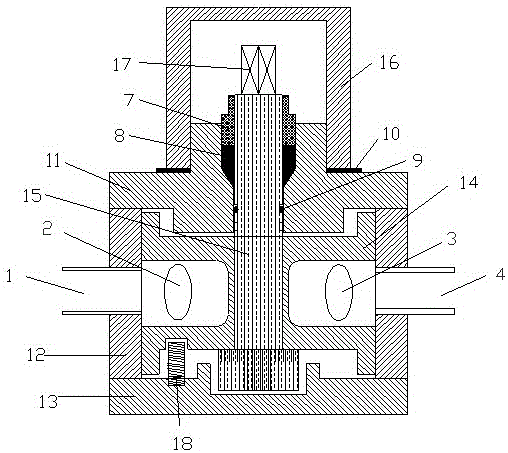

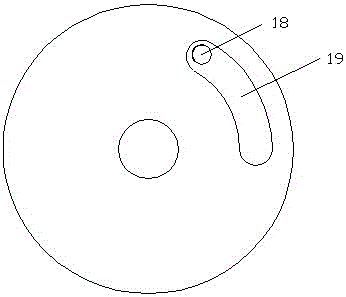

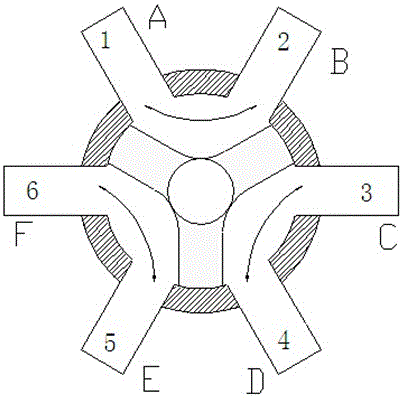

[0018] Example 1, see figure 1 , 2 According to the design requirements, the valve body 12 and the valve core 14 are processed, and pits or holes are set on the inner wall of the valve body 12; There are six channels 1, 2, 3, 4, 5, and 6 of A, B, C, D, E, and F; the cross section of the valve core 14 is Y-shaped, and the lower part of the valve core 14 is provided with a fan-shaped positioning ring groove 19; 12 The valve core 14 is installed inside, and the limit screw 18 is installed on the upper surface of the lower cover 13, and the upper part of the screw 18 is installed in the positioning ring groove 19; there is a hole in the middle of the valve core 14, and the valve stem 15 is installed, and the valve stem 15 is connected with the valve core 14 , and can be driven by the valve stem 15, the lower end of the valve stem 15 is installed in the blind hole in the lower cover 13; the upper surface of the upper cover 11 protrudes to form a boss, with a through hole in the mi...

Embodiment 2

[0021] Example 2, see Figure 7 , Same as the embodiment, the difference is that in order to make the valve rotate more flexibly, a bearing 20 is installed at the lower end of the valve stem 15, and the outer ring of the bearing 20 is installed in the blind hole of the lower cover 13.

Embodiment 3

[0022] Example 3, see Figure 8 , With embodiment 1, the difference is that a pit groove or hole is set on the inner wall of the valve core 14, and there is no pit groove or hole on the inner wall of the valve body 12; a check valve is installed on the E passage 5.

[0023] A kind of six-way valve of the present invention, when working, see Figure 5 , during normal operation, channel A communicates with channel B, channel C communicates with channel D, and channel E communicates with channel F. The refrigerant is discharged through the compressor 21, flows into the B channel through the A channel, and then flows into the condenser 22. The condensed refrigerant enters the liquid receiver 23, passes through the expansion valve 24 and flows into the aluminum row evaporator 25, and the evaporated refrigerant passes through The D channel flows into the C channel and then enters the compressor 21 .

[0024] E channel and F channel are closed because of being connected with check ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com