Liquid heat exchange type air source heat pump

An air source heat pump and heat exchange technology, which is applied in the field of liquid heat exchange air source heat pump to achieve the effects of improving heat exchange efficiency, low structural cost and high degree of popularization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] The following is a description of Embodiment 1.

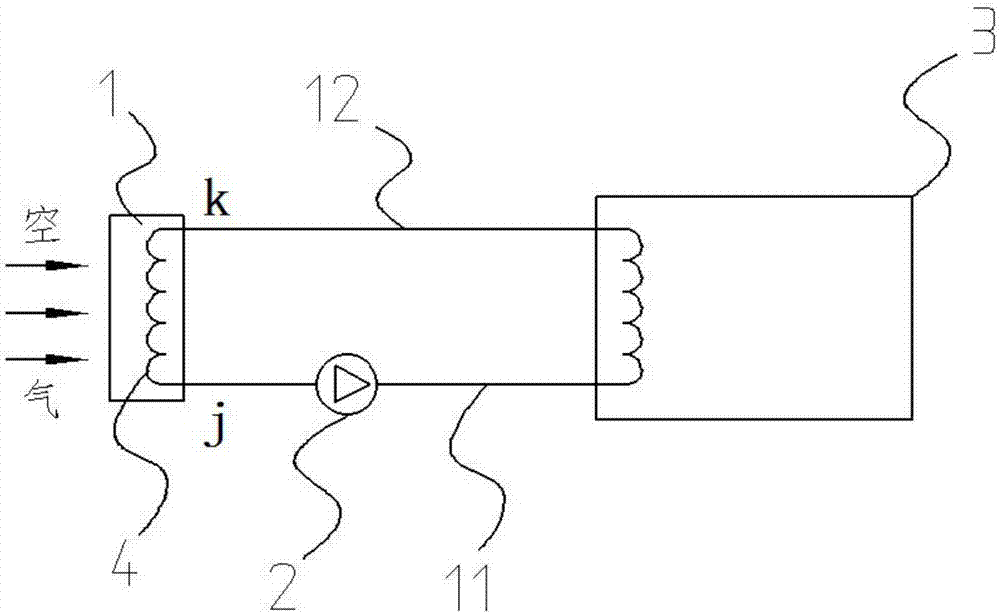

[0047] Such as figure 1 As shown, a liquid heat exchange type air source heat pump is characterized by comprising an air-liquid heat exchanger 1, a heat source liquid inlet pipeline 11, a heat source liquid return pipeline 12, a circulating pump 2, a liquid heat source heat pump 3, and a heat exchange tube Road 4, the air-liquid heat exchanger 1 is provided with a set of heat exchange pipelines 4, and the liquid outflow end j of the heat exchange pipeline 4 in the air-liquid heat exchanger 1 communicates through the heat source liquid inlet pipeline 11 To the inlet end j of the circulation pump 2, the outlet end of the circulation pump 2 is connected to the liquid inflow end of the heat exchange pipeline provided in the liquid heat source heat pump 3 through a pipeline, and the liquid of the heat exchange pipeline in the liquid heat source heat pump 3 flows out The end is connected to the liquid inflow end k of the heat...

Embodiment 2

[0049] The following is a description of Embodiment 2.

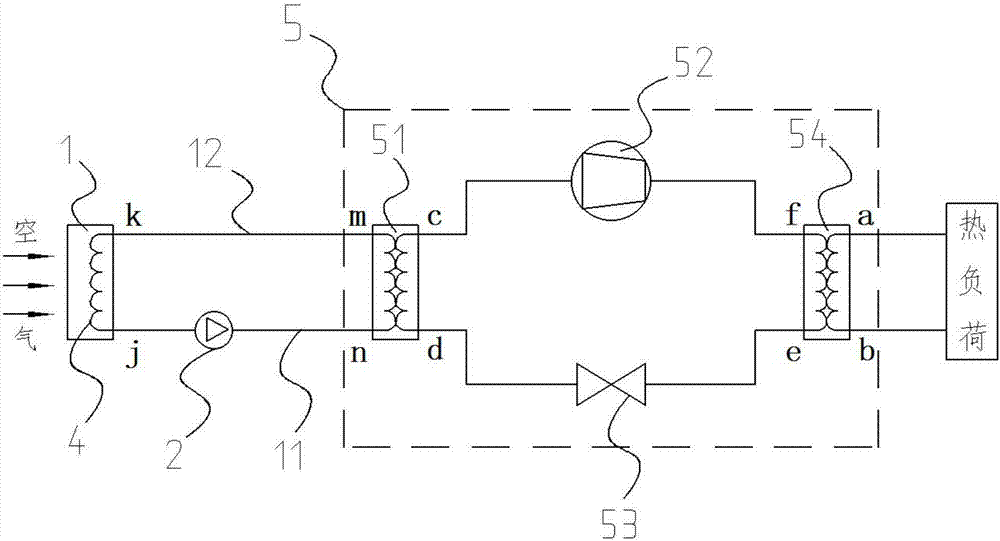

[0050] In Embodiment 2, the same symbols are assigned to the same structures as in the above-mentioned embodiments, and the same descriptions are omitted. Embodiment 2 is an implementation case of using compression heat pump 5 on the basis of embodiment 1. Such as figure 2 As shown, the compression heat pump 5 includes a first evaporator 51, a steam compressor 52, a throttle valve 53, and a first condenser 54. The port j of the air-liquid heat exchanger 1 passes through the heat source liquid inlet pipeline 11 is connected to the inlet port of the circulating pump 2, and the outlet port of the circulating pump 2 is connected to the port n on the first evaporator 51 in the compression heat pump 5 through pipelines. The first evaporator 51 is provided with two sets of heat exchange pipelines , one group communicates with port m and port n on the first evaporator 51, the other group communicates with port c and port d on...

Embodiment 3

[0052] The following is a description of Embodiment 3.

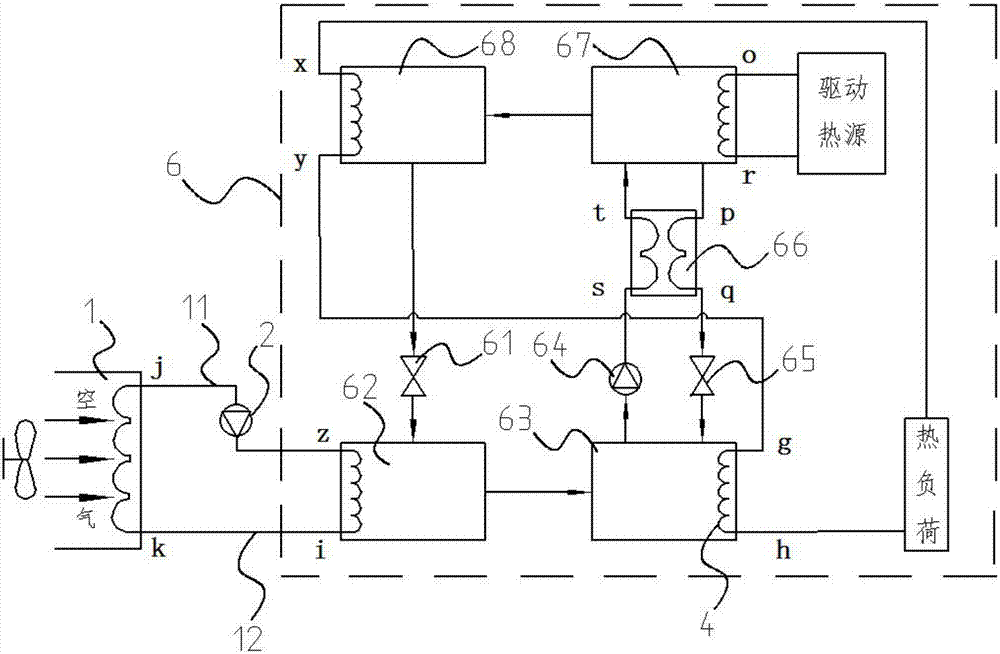

[0053] In Embodiment 3, the same symbols are assigned to the same structures as those in the above-mentioned embodiments, and the same descriptions are omitted. Embodiment 3 provides the embodiment that absorption heat pump 6 realizes embodiment 1, as image 3 As shown, the absorption heat pump 6 includes a solvent throttling valve 61, a second evaporator 62, an absorber 63, a solution pump 64, a solution throttling valve 65, a solution heat exchanger 66, a generator 67, a second condenser 68, the port j of the air-liquid heat exchanger 1 is connected to the inlet end of the circulation pump 2 through the heat source liquid inlet pipeline 11, and the outlet end of the circulation pump 2 is connected to the second evaporator in the absorption heat pump 6 through a pipeline Port z on 62, the second evaporator 62 is provided with a heat exchange pipeline to communicate with port z and port i, and port i of the second evapo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com