Patents

Literature

40results about How to "Reduced compression energy consumption" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

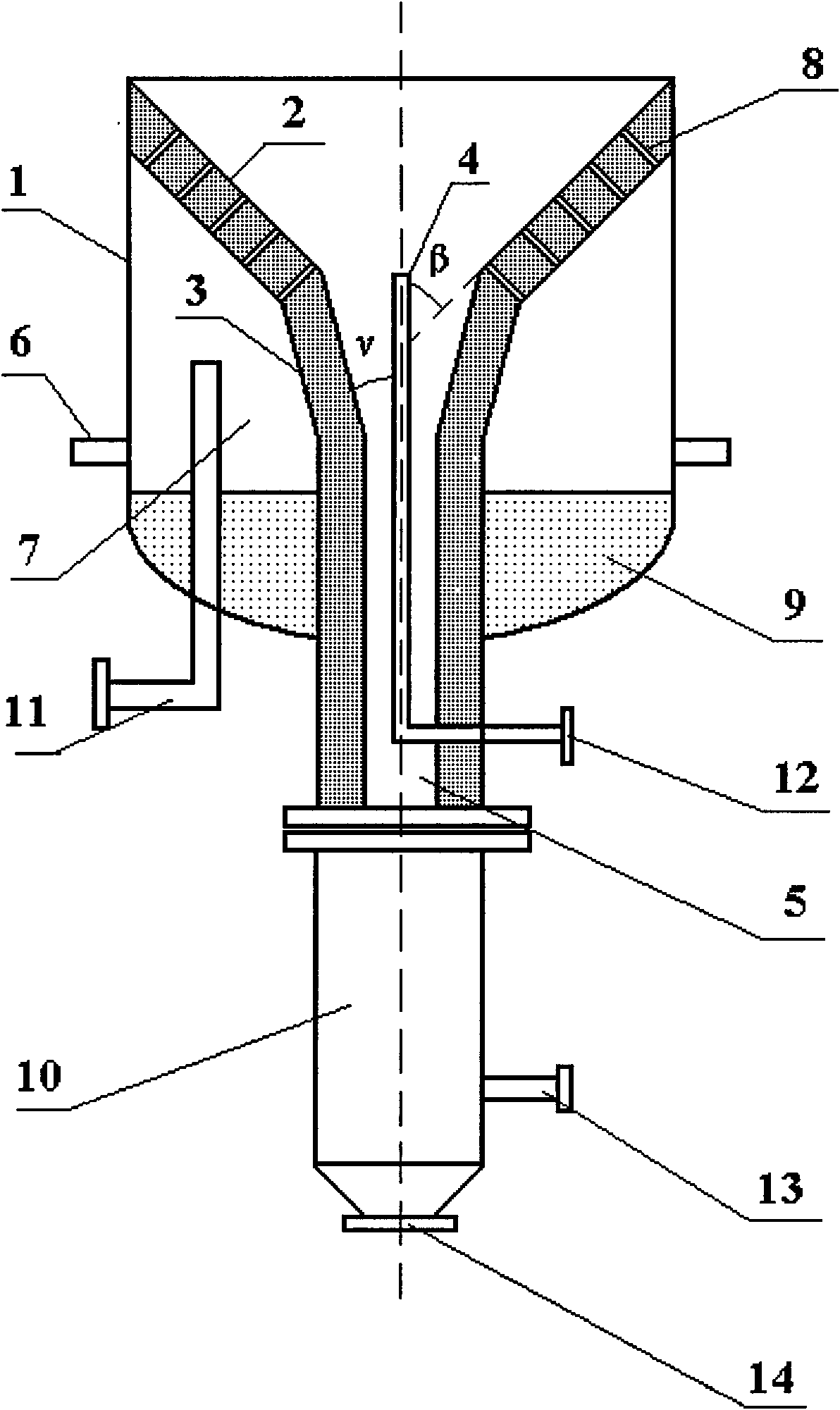

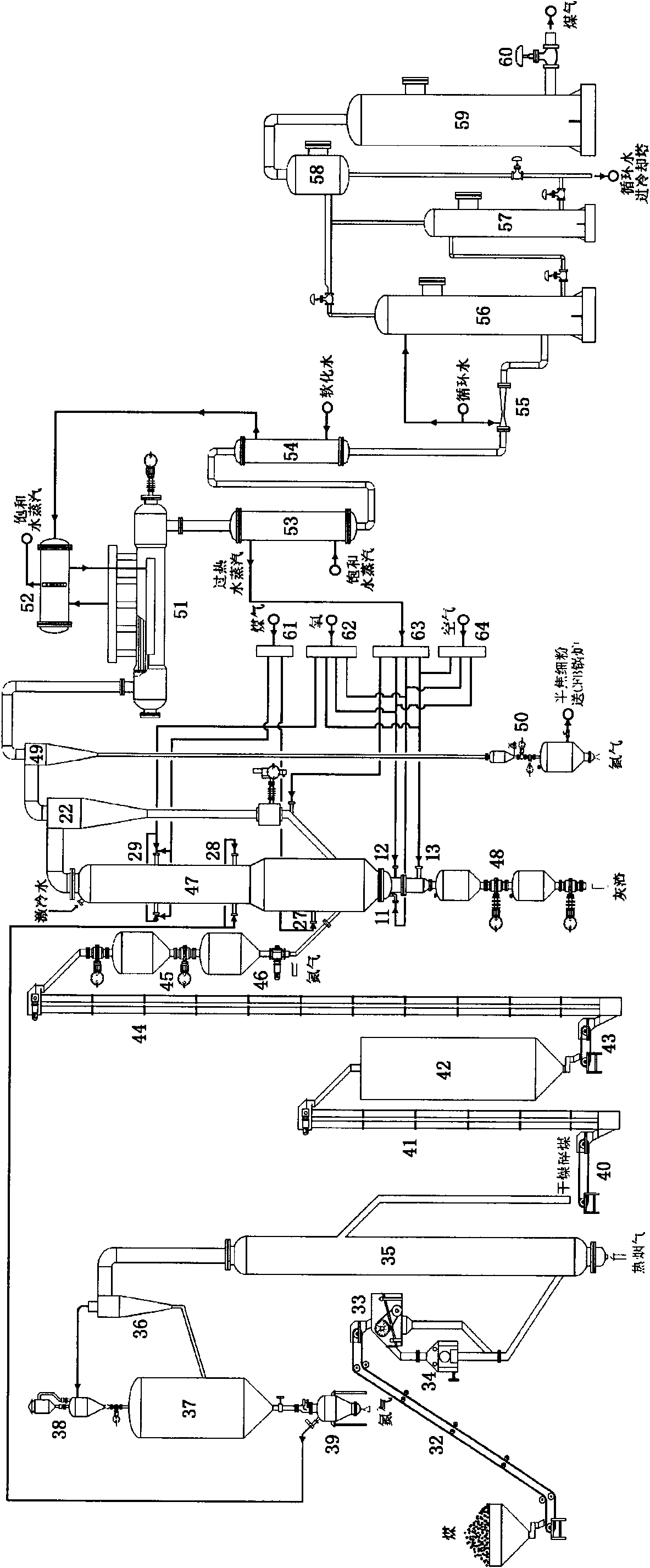

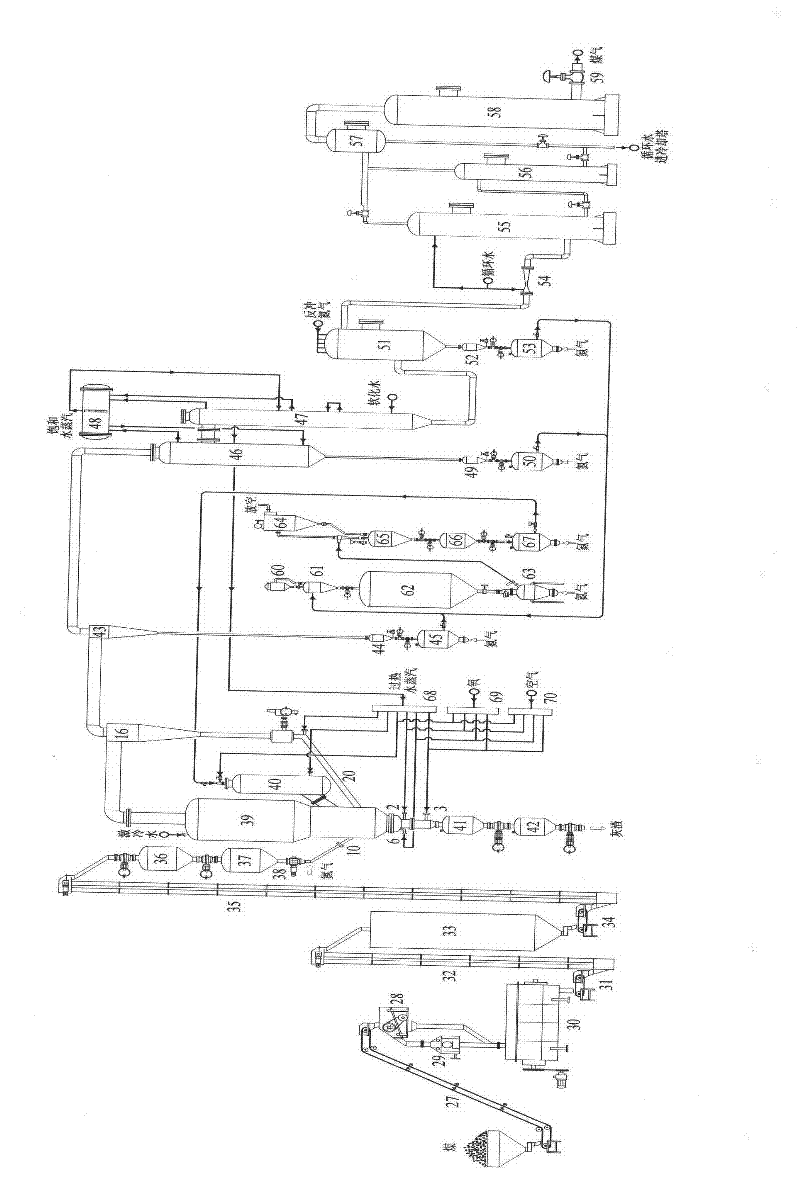

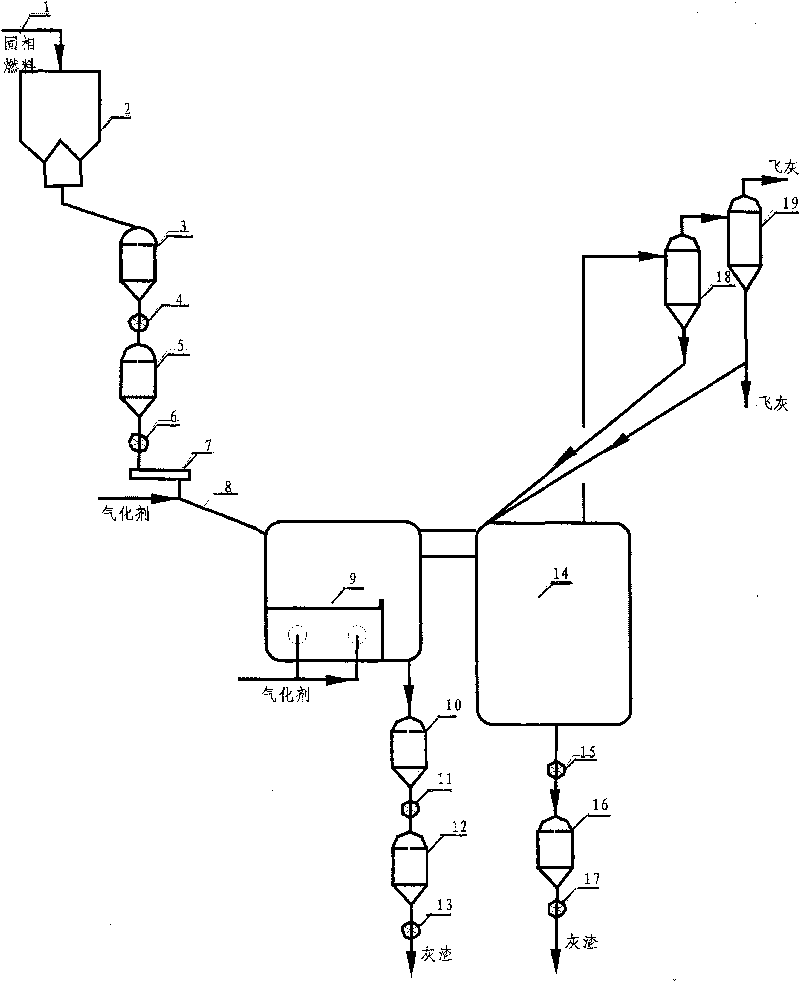

Method and device for gasifying multi-segment staged converted fluidized bed

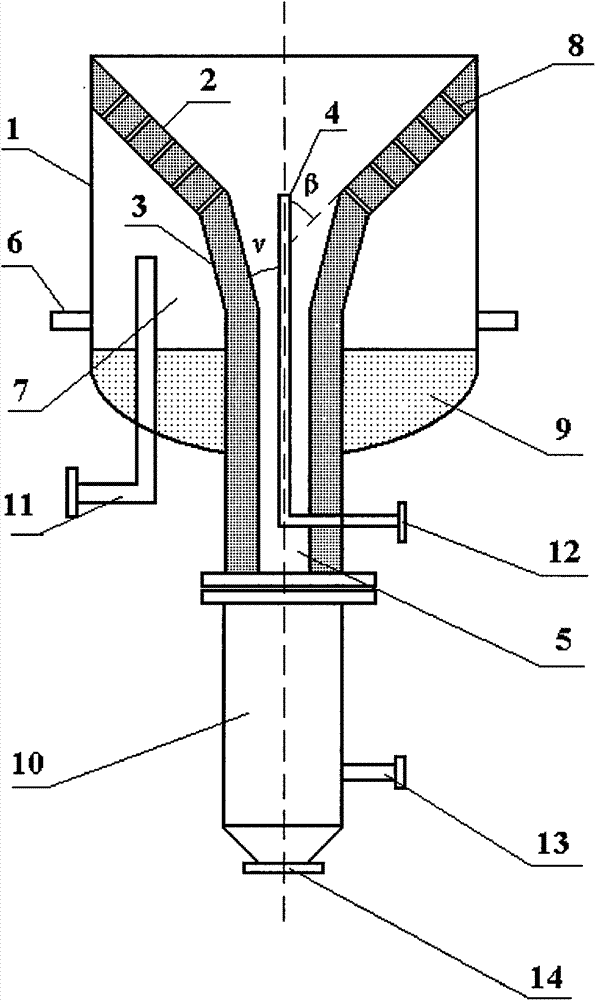

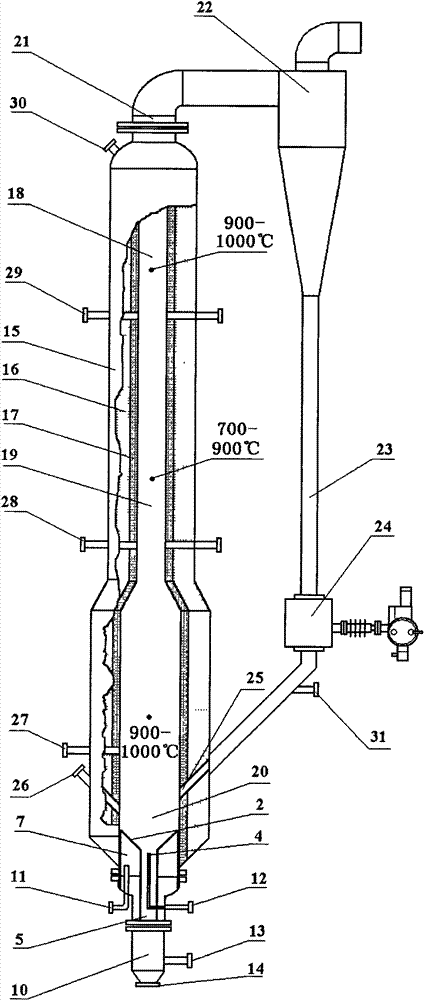

ActiveCN101942344ALow ash carbon contentExtended stayEnergy inputCombined combustion mitigationFluidized bedProcess engineering

The invention relates to method and device for gasifying a multi-segment staged converted fluidized bed. The method comprises the following steps of: supplying coal; supplying gas; gasifying; slagging; and conveying fine powder. The device for gasifying the multi-grade staged converted fluidized bed comprises an agglomerating ash separating unit, a pyrolyzing and gasifying reactor of the multi-segment staged fluidized bed and a semicoke fine powder cyclic feeding unit. The invention has the advantages of high volume utilization rate of a gasifying oven, great handling capacity and high utilization rate of total carbon, is suitable for a coal staging and converting system and can be singly used for producing gas for mass coal-based methane synthesis and coal chemical industry.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

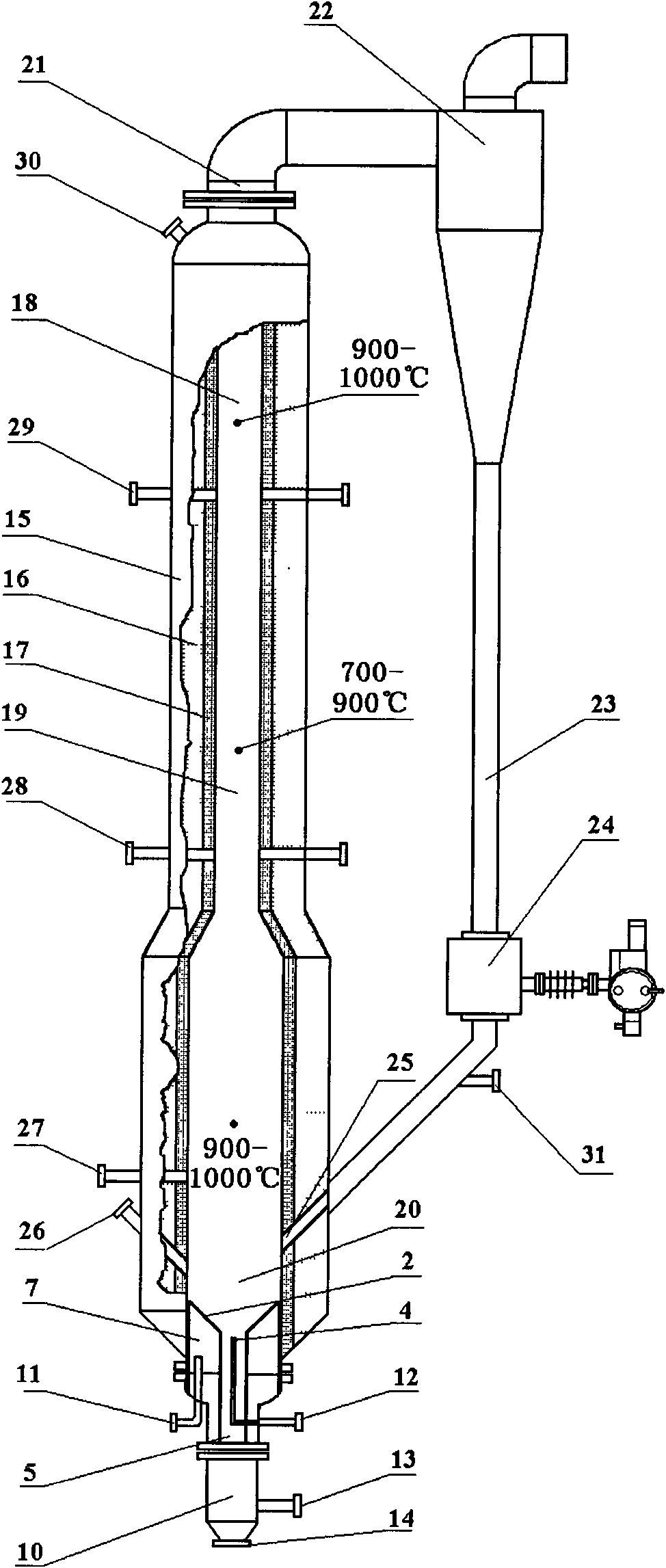

Method and device for coal gasification in combined type fluidized bed

ActiveCN102533345AImprove gasification efficiencyEasy to handleEnergy inputGranular/pulverulent flues gasificationRetention timeSlag

The invention discloses a method for coal gasification in a combined type fluidized bed, which comprises coal preparation, gas supply, gasification, slag discharge, dedusting, waste heat recovery and fine powder conveying. An ash agglomeration fluidized bed realizes gasification of large-particle coal; the non-completely converted carryover fine powder enters an entrained flow bed gasifier in a dense phase pneumatic conveying manner; secondary gasification is carried out by using a short retention time high temperature gasification manner; the produced ash slag is carried into an intersection segment of the fluidized bed and the entrained flow bed with high temperature coal gas, and rapidly mixed with ''low temperature'' large-particle partially carbonized coal in the fluidized bed and the produced ''low temperature'' coal gas; and partial ash slag is selectively discharged out of the gasifier in the form of solid. The method and the device of the invention have the advantage of being suitable for various coal types and high in carbon conversion rate.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

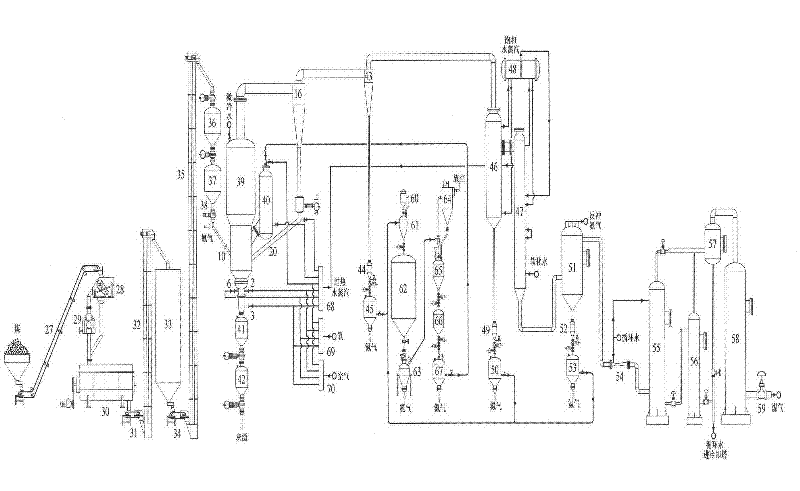

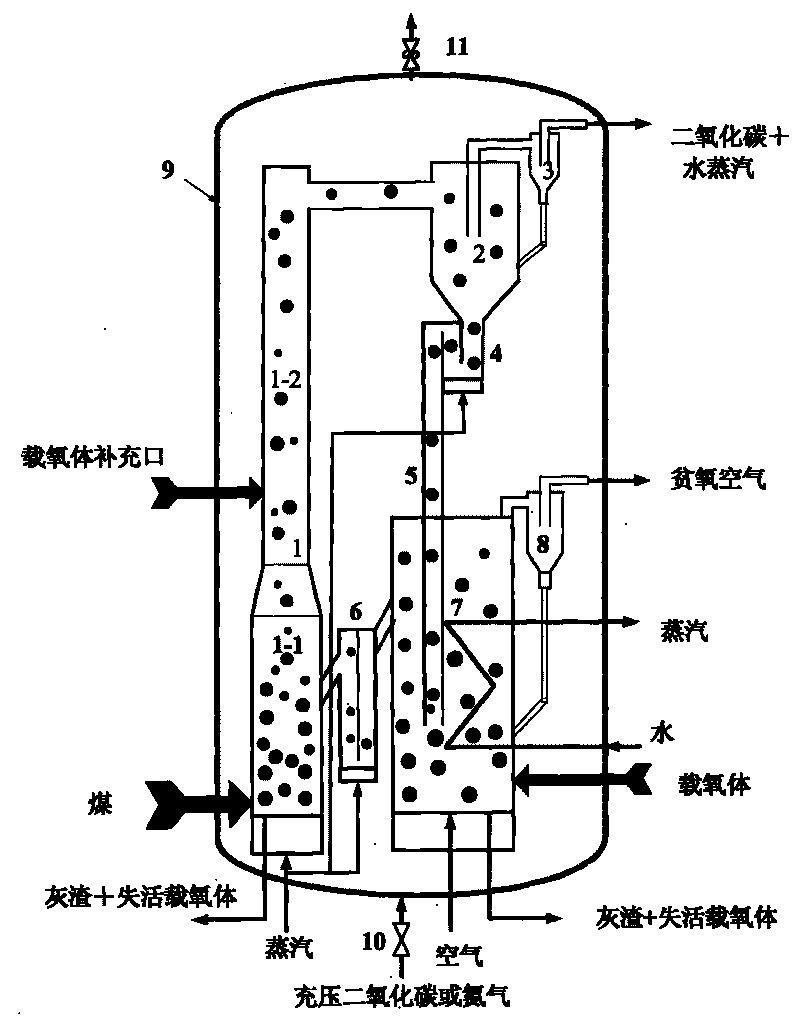

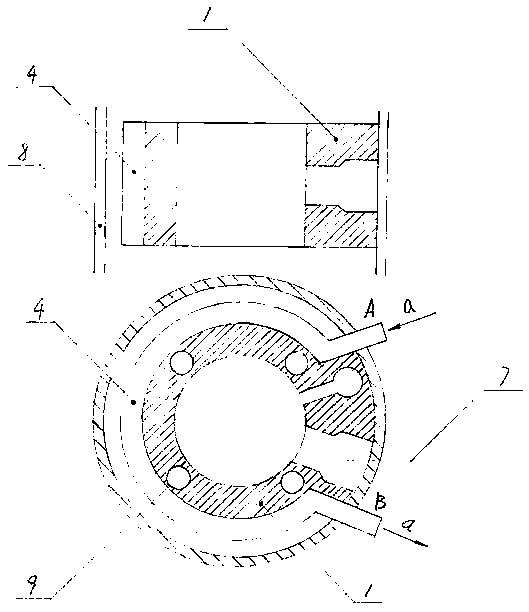

Coal combustion apparatus capable of separating carbon dioxide and separation method thereof

InactiveCN101699187AEasy to handleReduced compression energy consumptionExothermal chemical reaction heat productionCarbon compoundsCycloneEngineering

The invention provides a coal combustion apparatus capable of separating carbon dioxide, which is mainly formed by connecting a fuel reactor, a primary cyclone separator, a dipleg and an air reactor in series; wherein the lower part of the fuel reactor is provided with a mixing chamber with large cross section, and the upper part thereof is provided with a lifting tube with small cross section; and the height of the lifting tube is over three times higher than that of the mixing chamber. The invention also provides a method using the coal combustion apparatus capable of separating the carbon dioxide to separate the carbon dioxide. The fuel reactor adopts the structure of a reactor with long residence time, internal circulation can be formed by granules, and the gas-solid turbulence is improved; the air reactor adopts a moving fluidized bed to ensure the operation to be stable, so that the heat can be evenly released; meanwhile, a heat exchanger is arranged inside the bed, so that coking caused by local overheating since a great deal of heat is released in a centralized way in oxidation reaction can be avoided. Furthermore, the fuel reactor and the air reactor run under the pressure, so that the equipment can be compact, the utilization efficiency of system energy is high, and the subsequent carbon dioxide compression energy consumption is reduced.

Owner:SOUTHEAST UNIV

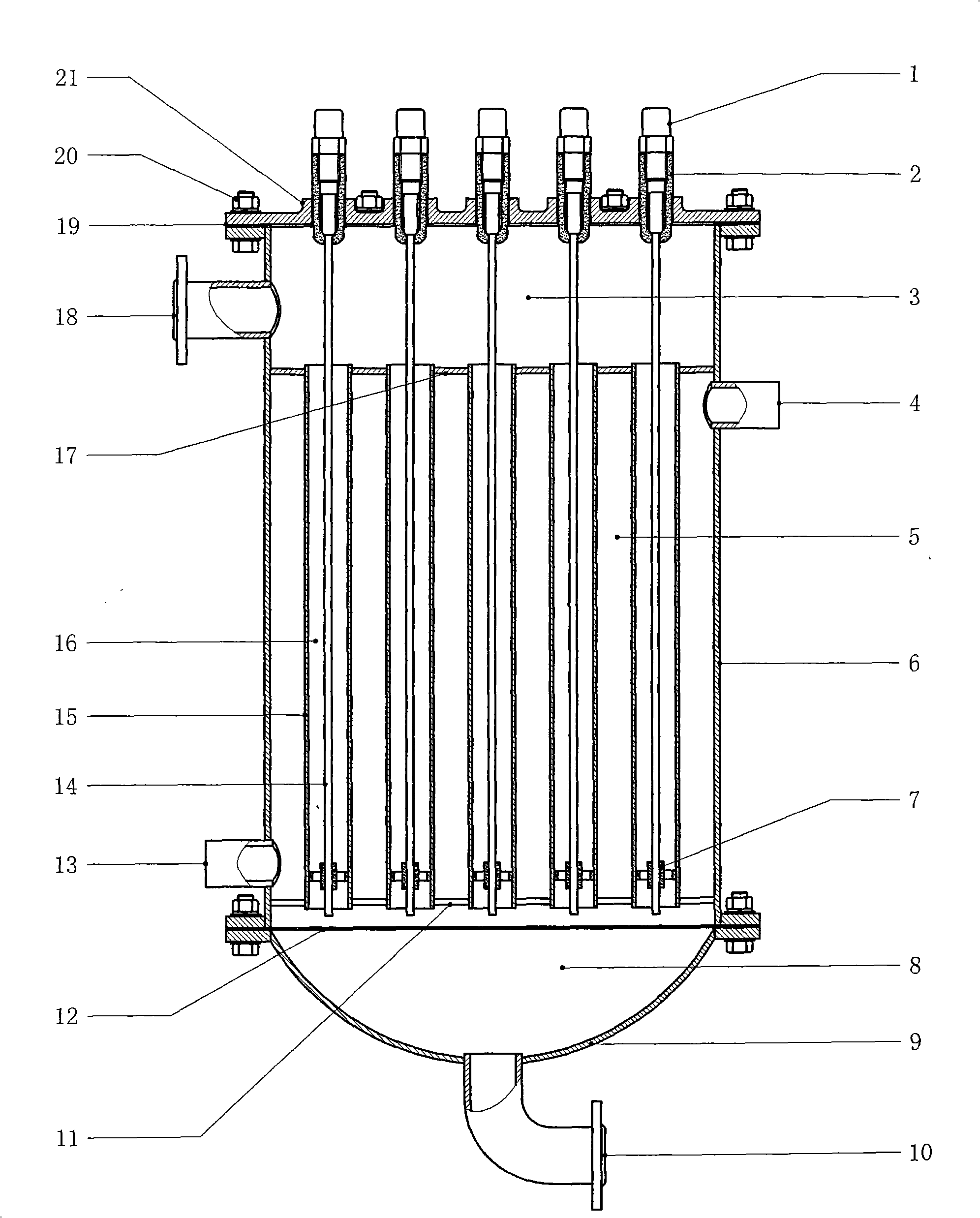

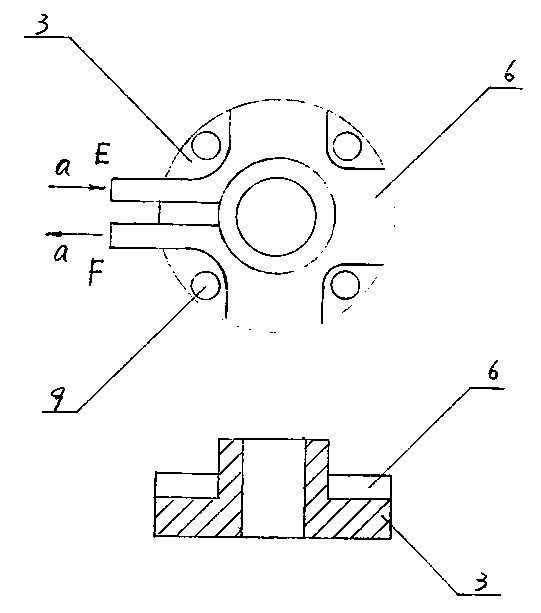

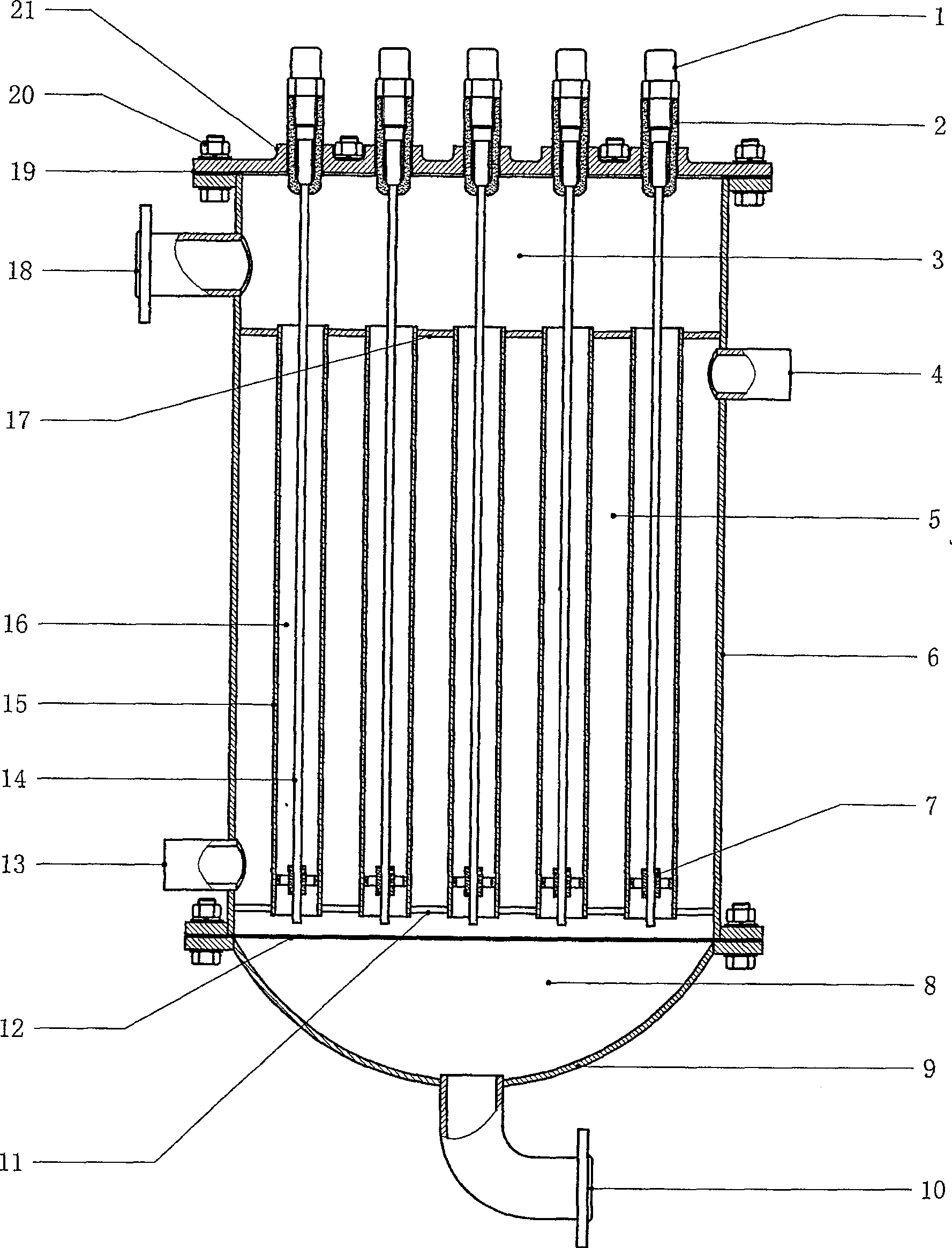

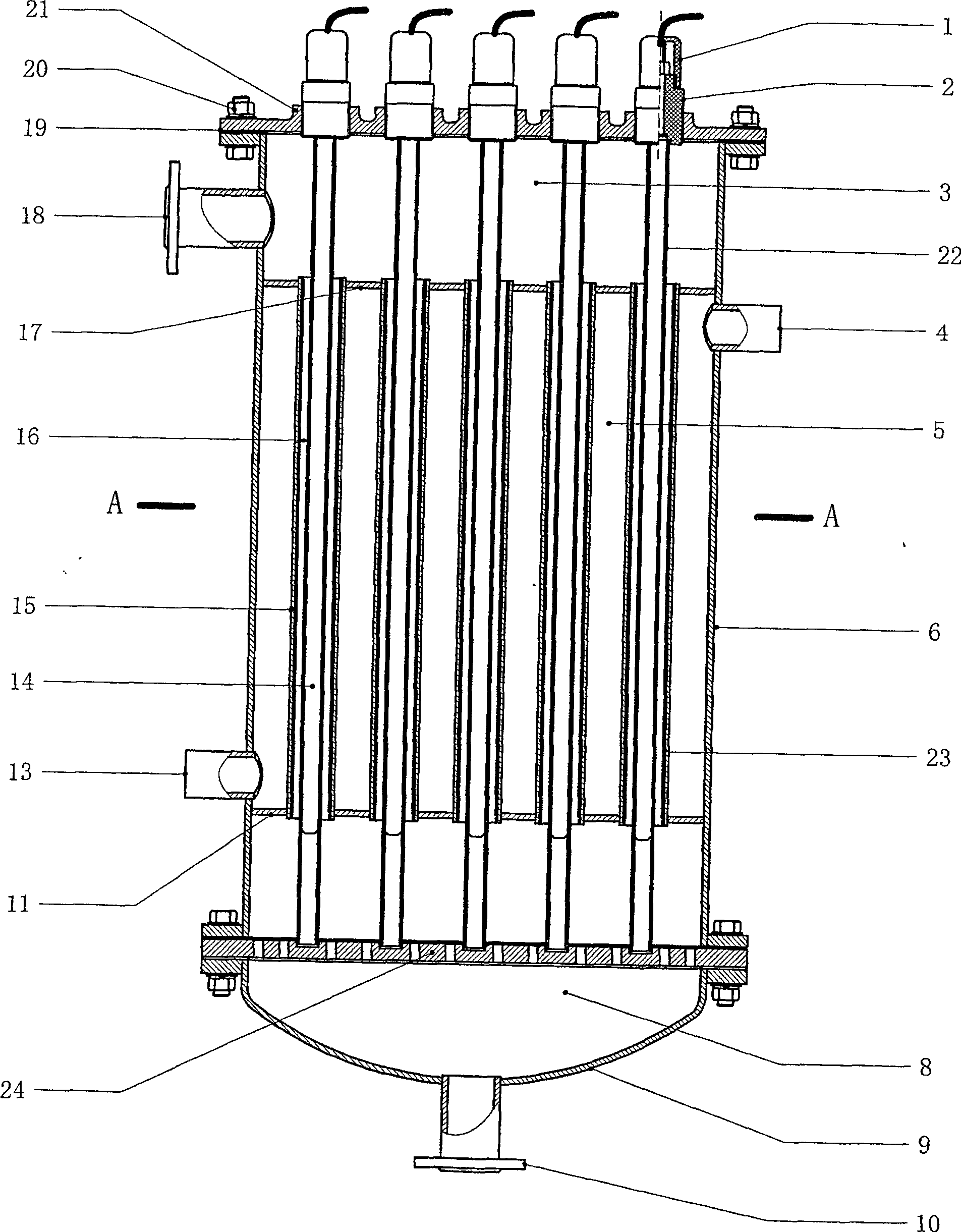

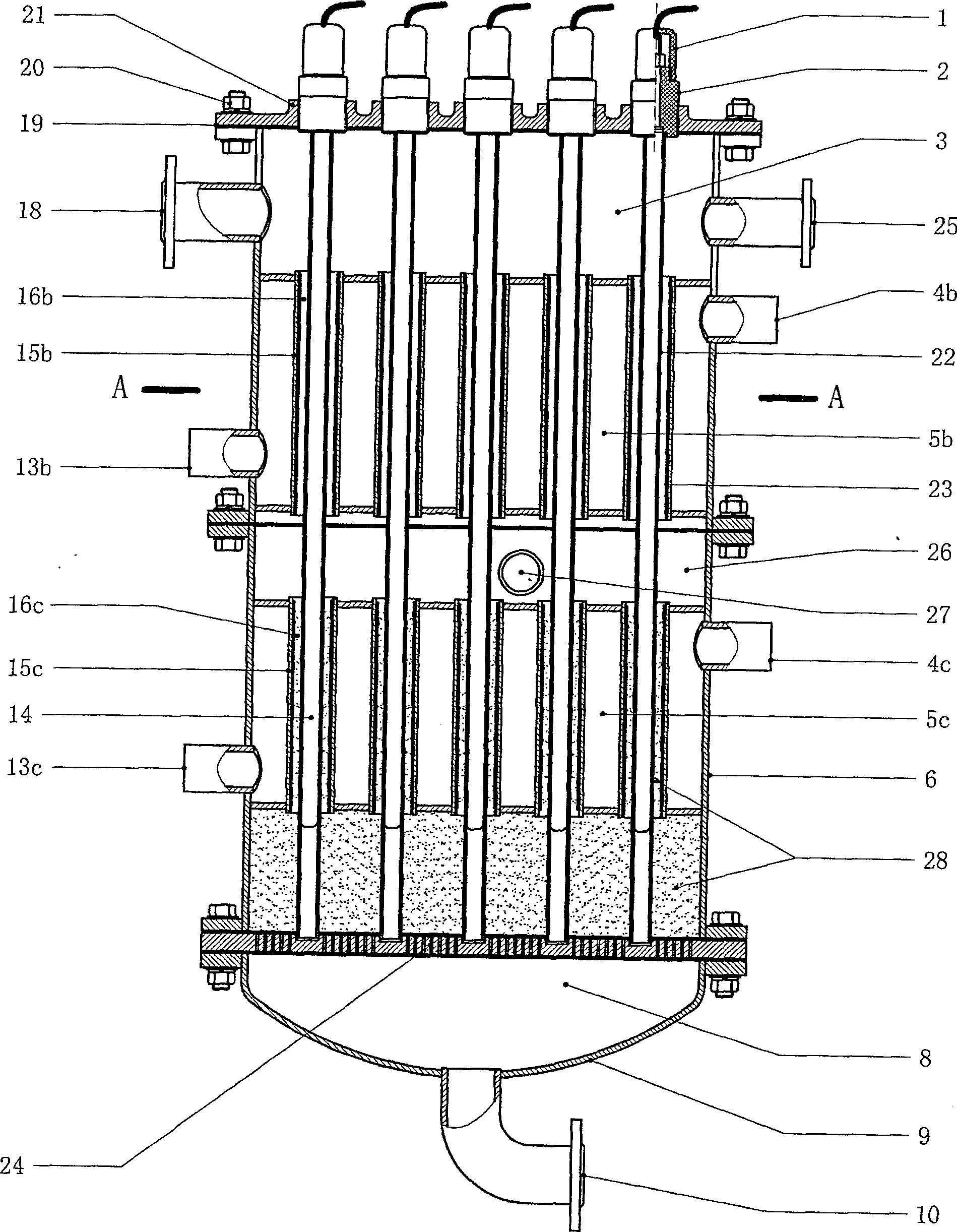

Electrocatalysis synthesis reactor

InactiveCN101254452AGood choiceControllable reaction speedEnergy based chemical/physical/physico-chemical processesLiquid-gas reaction processesChemical synthesisElectricity

An electrocatalytic synthesis reactor is provided, which relates to a reactor for chemical synthesis and mainly comprises a gas distribution chamber, a tubular electrocatalysis chamber, a collection chamber, a product discharge port, a cooling medium chamber and a housing, wherein a material gas inlet is provided on the side wall of the gas distribution chamber, the gas distribution chamber communicates with the collection chamber through the tubular electrocatalysis chamber, the product discharge port is provided at the bottom of the collection chamber, each unit of the tubular electrocatalysis chamber is defined by the inner space of an external electrode tube bundle and provided inside with a central electrode, and the periphery of the external electrode tube bundles is the cooling medium chamber. The synthesis reactor realizes synthetic reactions based on the synergetic catalysis of low-temperature plasmas and catalysts, allows the synthetic reactions to perform under approximately normal pressure, and allows the raw gases to enter the synthesis reactor without compression, thereby reducing energy consumption. Additionally, the synthesis reactor has the advantages of good selectivity, controllable reaction speed, and workability of producing methanol, dimethyl ether and synthetic ammonia by inputting raw gases related to the target product and selecting the relevant catalytic electrodes or catalysts.

Owner:衢州市广源生活垃圾液化技术研究所

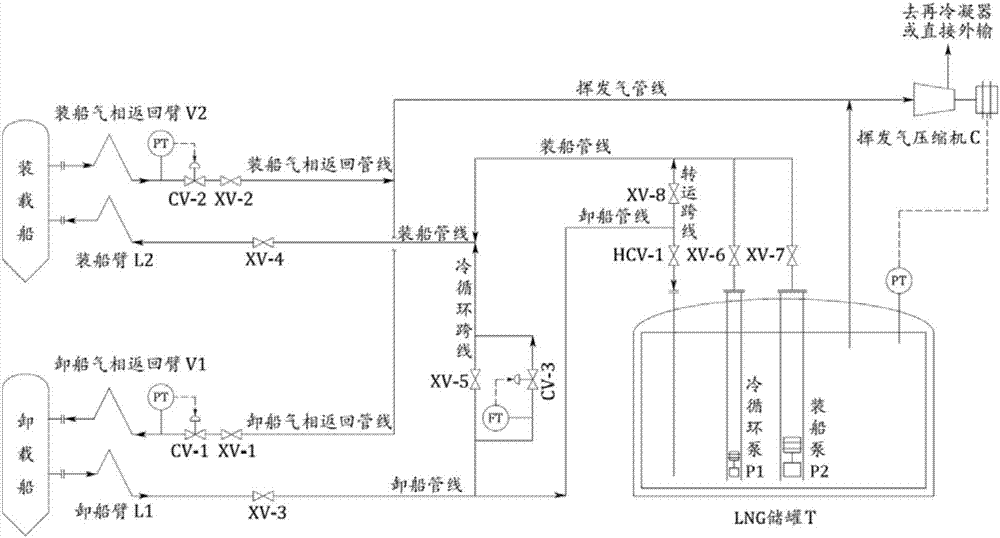

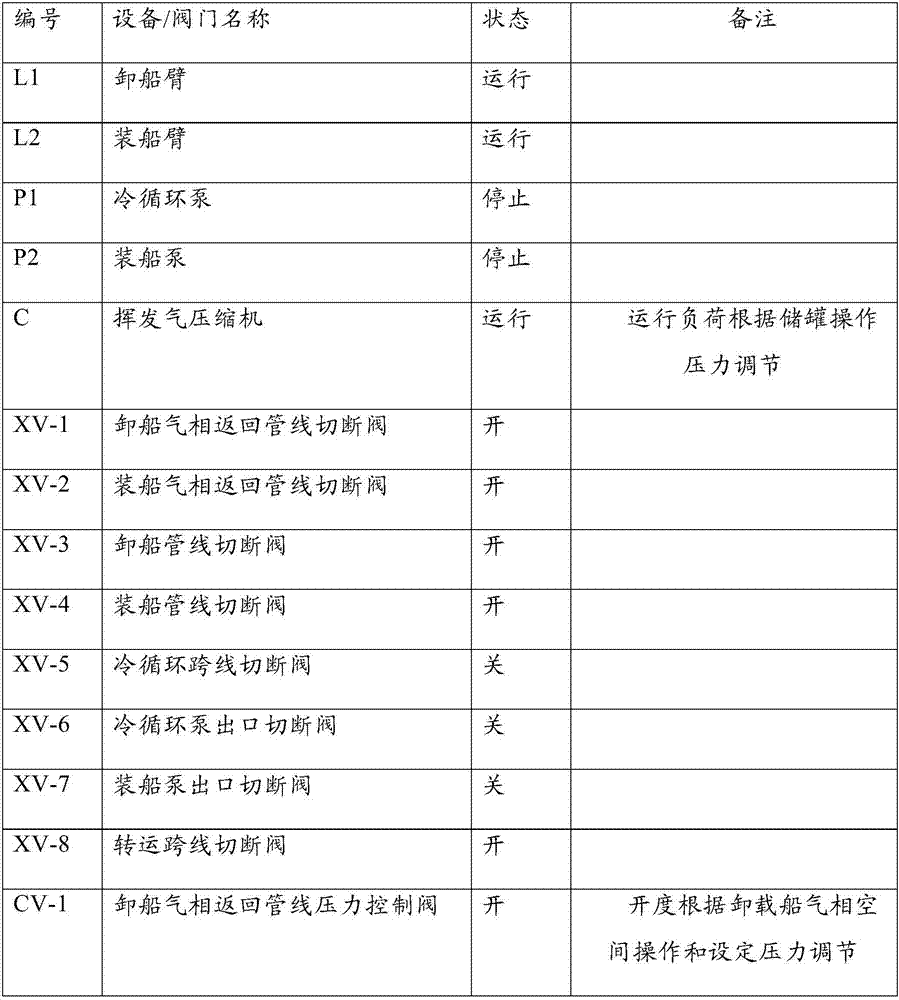

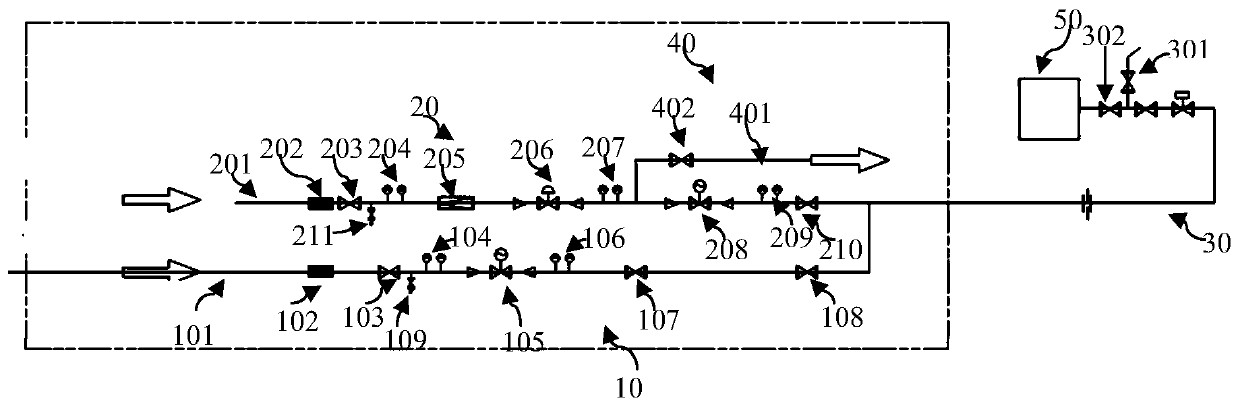

Ship-to-ship transfer system based on shore-based liquefied natural gas receiving station

ActiveCN106907570AReduce dependenceRealize the transfer functionWaterborne vesselsLiquid transferring devicesGas phaseGas compressor

Disclosed is a ship-to-ship transfer system based on a shore-based liquefied natural gas receiving station. The ship-to-ship transfer system based on the shore-based liquefied natural gas receiving station comprises a ship unloading arm L1, a ship unloading gaseous-phase return arm V1, a ship loading arm L2, a ship loading gaseous-phase return arm V2, an LNG storage tank T, a cold circulating pump P1, a ship loading pump P2, a volatile gas compressor C, a ship loading pipeline, a ship unloading pipeline, a volatile gas pipeline, a ship unloading gaseous-phase return pipeline, a ship loading gaseous-phase return pipeline, a cold circulating crossing line and a transfer crossing line. A ship unloading pipeline stop valve XV-3 is arranged on the ship unloading pipeline, and a ship loading pipeline stop valve XV-4 is arranged on the ship loading pipeline. A ship unloading gaseous-phase return pipeline stop valve XV-1 and a ship unloading gaseous-phase return pipeline pressure control valve CV-1 are arranged on the ship unloading gaseous-phase return pipeline. A ship loading gaseous-phase return pipeline stop valve XV-2 and a ship loading gaseous-phase return pipeline pressure control valve CV-2 are arranged on the ship loading gaseous-phase return pipeline. A cold circulating crossing line stop valve XV-5 is arranged on the cold circulating crossing line. A cold circulating pump outlet stop valve XV-6 is arranged in an outlet of the cold circulating pump P1. A ship loading pump outlet stop valve XV-7 is arranged in an outlet of the ship loading pump P2.

Owner:CHINA HUANQIU CONTRACTING & ENG CO LTD

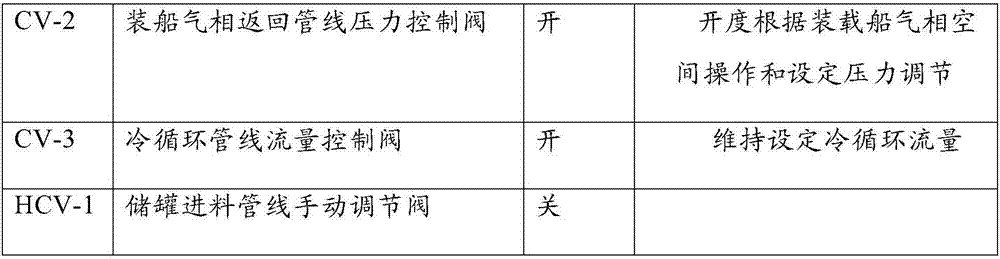

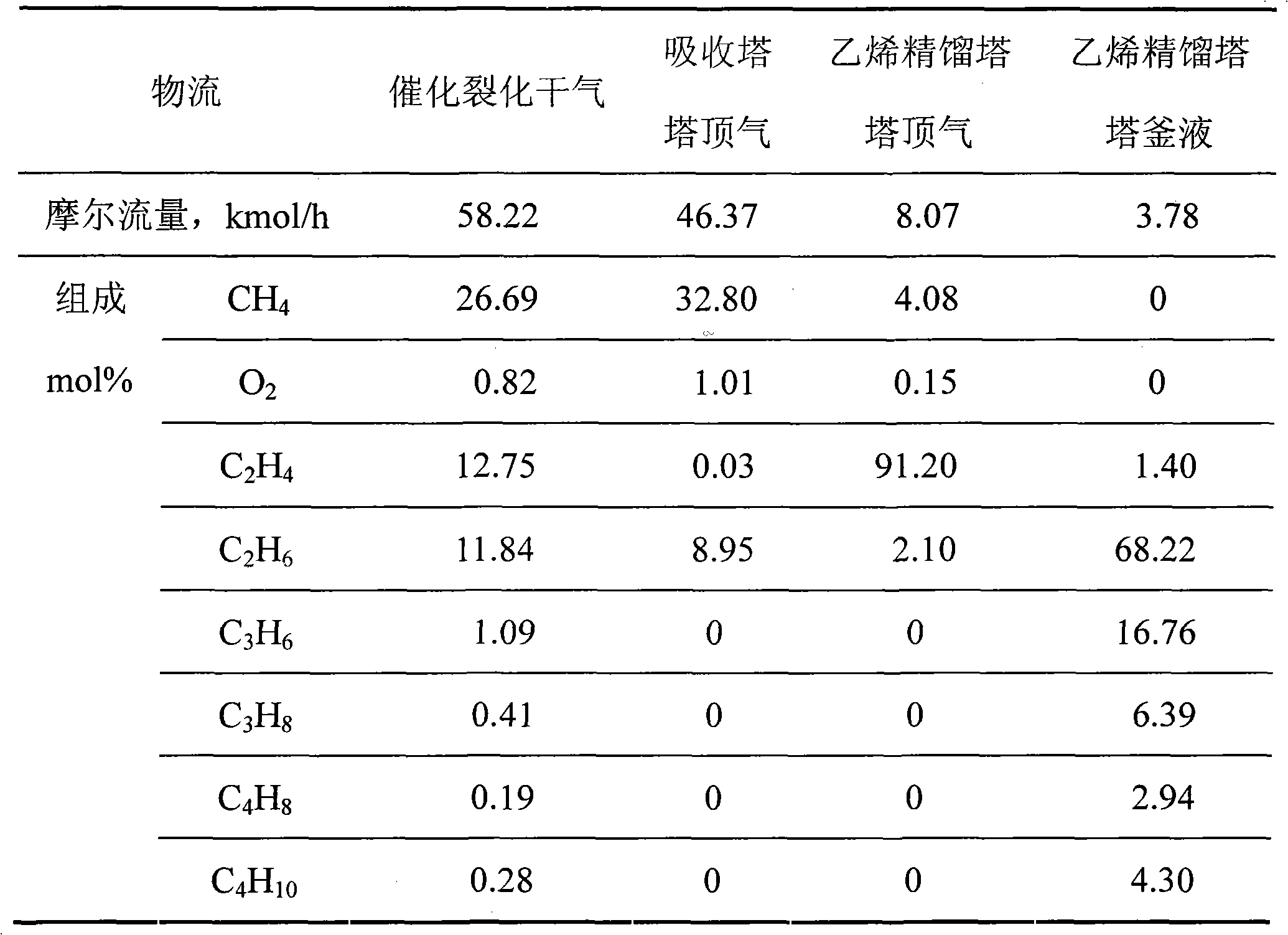

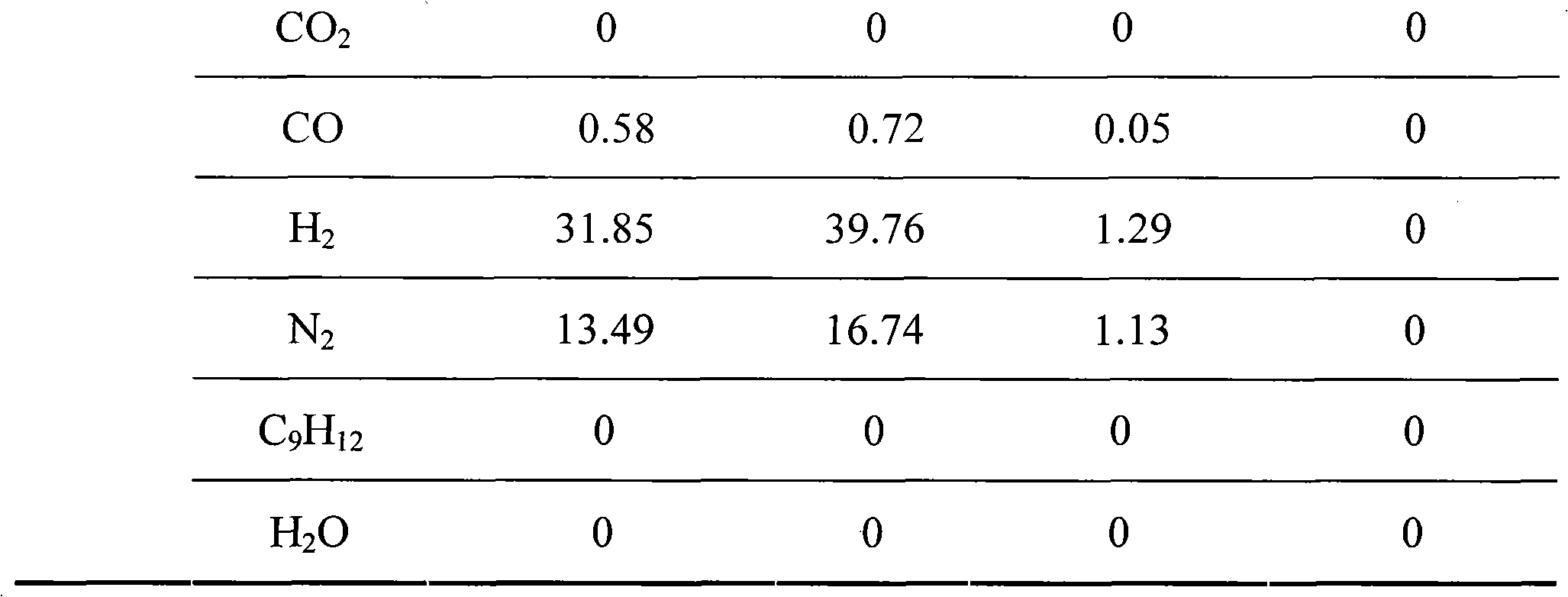

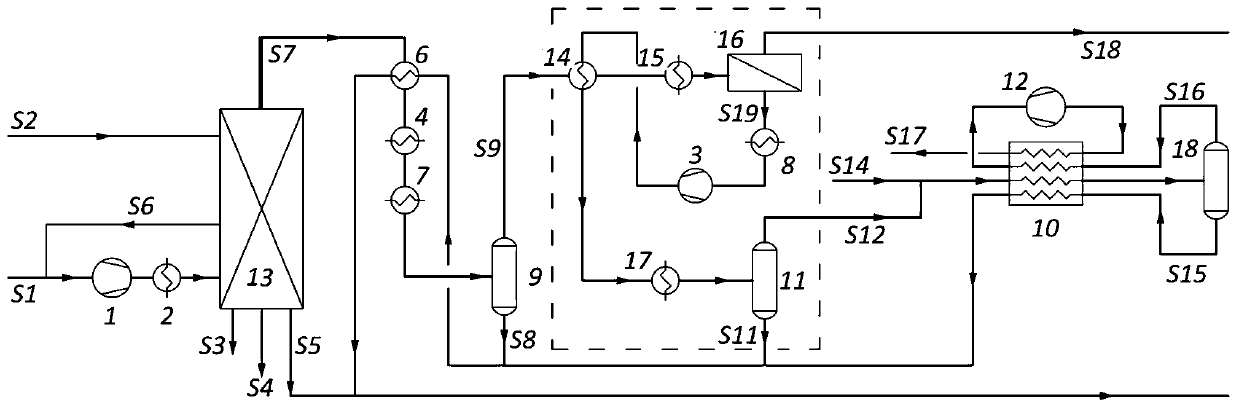

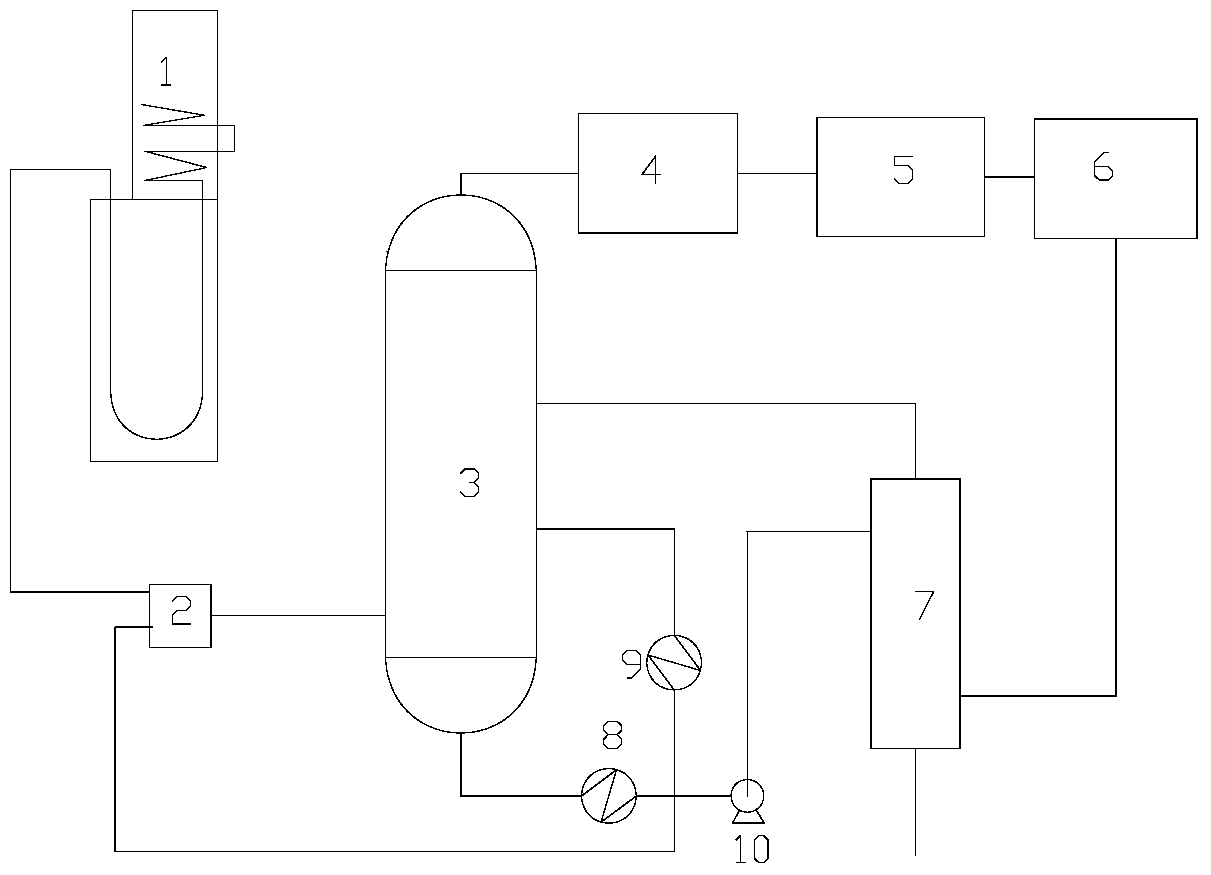

Technical method for recovering ethylene from ethylene containing mixed gas

InactiveCN101565348AImprove absorption efficiencyAchieve thermal integrationEnergy inputAbsorption purification/separationReboilerDesorption

The invention provides a technical method for separating ethylene from ethylene containing mixed gas. The technical method comprises a gas pretreatment process, an absorption process, a desorption process and an ethylene refining process, wherein a novel absorbing agent of trimethylbenzene is adopted, the heat integration methods such as a desorption tower, a middle reboiler, refrigeration of poor ethylene current by pressure recovery turbine and refrigeration recovery are adopted, so that the recovery and the purity of the ethylene can reach more than 99 percent and 91 percent respectively. The technical method can lower power consumption of compression of a system as well as consumption of throttling and low-temperature cooling capacity. Compared with the common ethylene high-pressure cryogenic separation process, the technical method of the invention is easier and is suitably used for recovering and enriching the ethylene from the ethylene containing mixing gas such as refinery dry gas, and the like.

Owner:BEIJING UNIV OF CHEM TECH

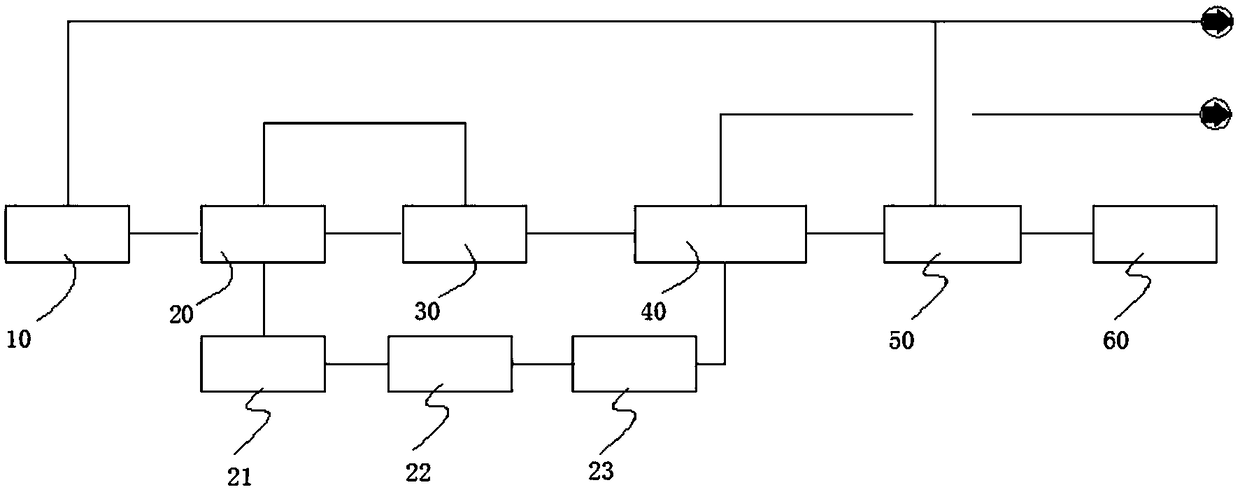

Production method and production equipment for sodium bicarbonate

PendingCN108726542AReduce manufacturing costLow costBicarbonate preparationSodium carbonateCarbonation

Relating to the field of sodium bicarbonate preparation, the invention provides a production method and production equipment for sodium bicarbonate. The production method of sodium bicarbonate includes the steps of: a) providing solid-liquid mixture containing crude sodium bicarbonate as the reaction raw material, and decomposing the reaction raw material to obtain a decomposition solution containing sodium carbonate and decomposition gas containing CO2; b) subjecting the decomposition gas to purification treatment to obtain carbonization gas, and then introducing the carbonization gas into the decomposition solution for carbonation crystallization reaction, and then conducting solid-liquid separation to obtain sodium bicarbonate and recovered mother liquor. The production method providedby the invention can solve the problems of waste of resources, environmental pollution, high energy consumption and high cost caused by existing sodium bicarbonate production methods, and achieves thetechnical effects of increasing CO2 utilization rate, reducing environmental pollution, and lowering energy consumption and cost.

Owner:BEIJING EDGEIN TECH +1

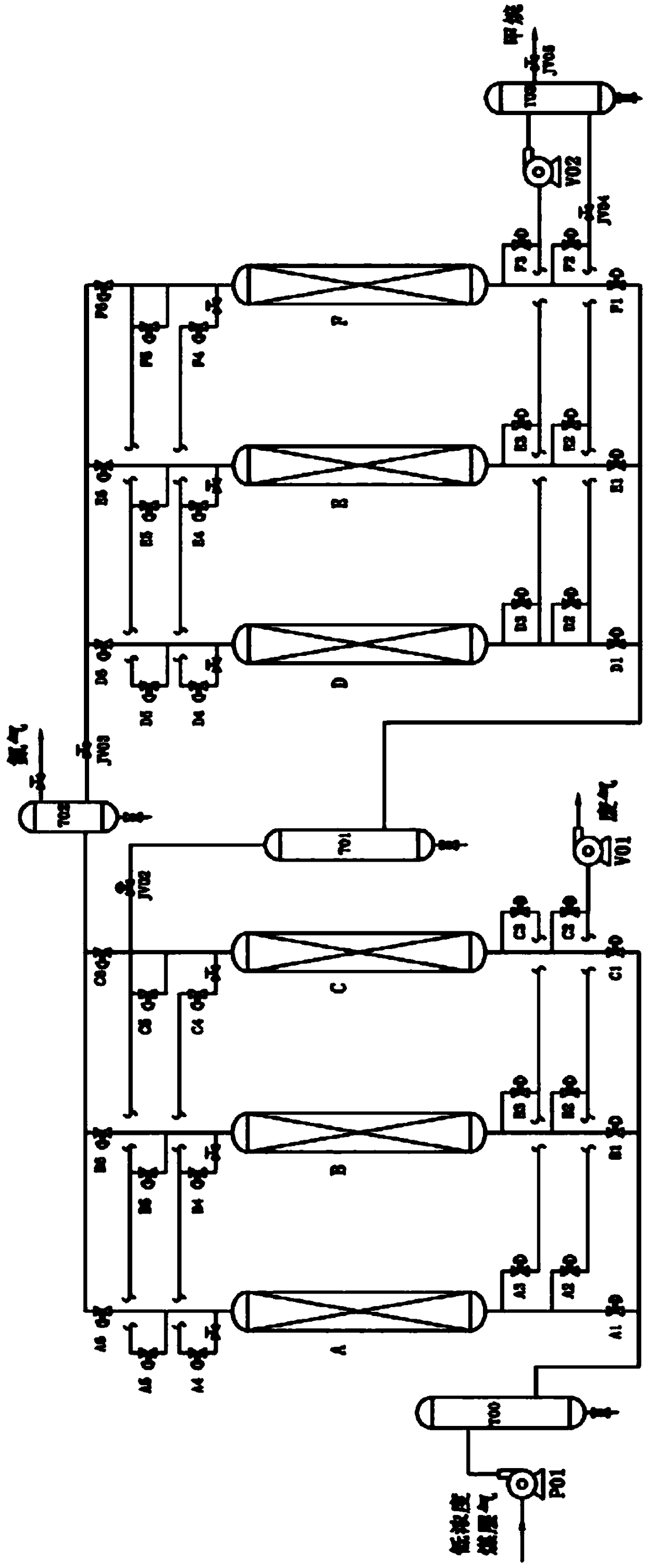

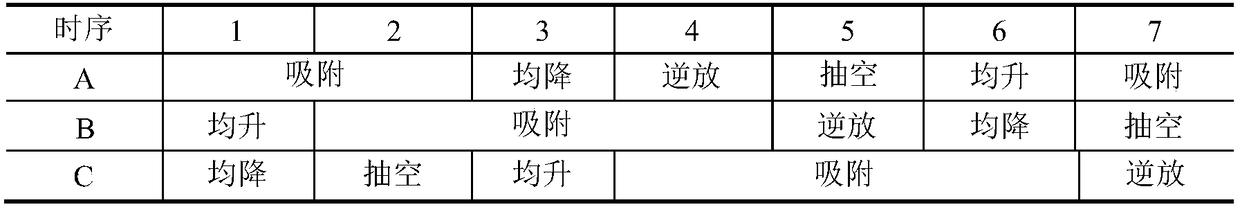

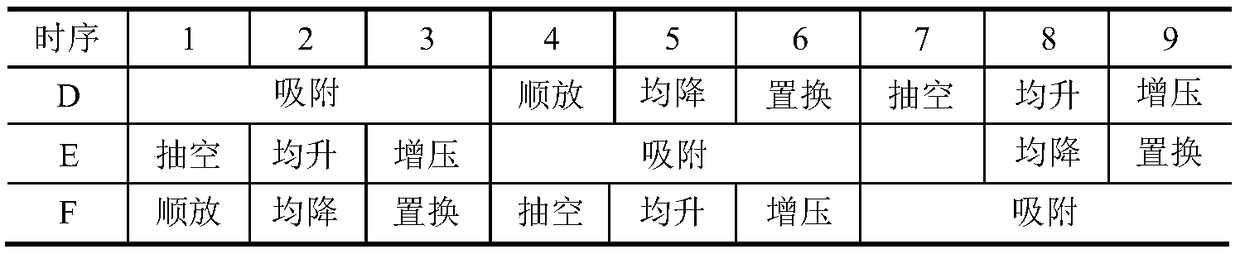

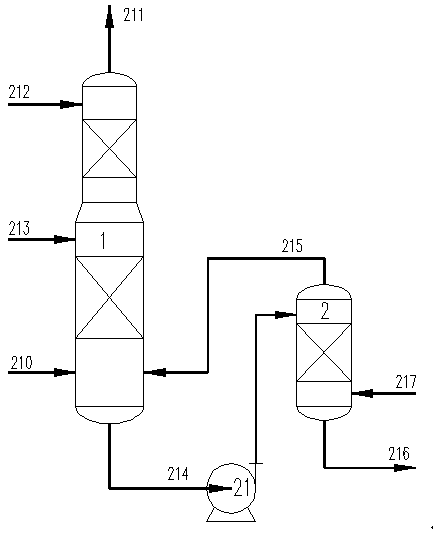

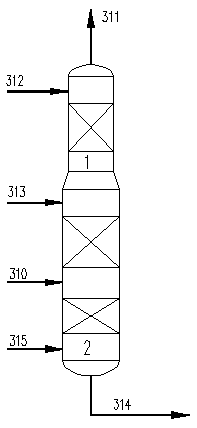

Coal bed gas deoxidation, nitrogen removal, concentration method based on product gas methane replacement and device thereof

InactiveCN109012030AIncrease concentrationExcluding the danger of entering the explosive limitMethane captureDispersed particle separationHigh concentrationNitrogen gas

The invention relates to the technical field of a pressure swing adsorption gas separation technology, and especially relates to a coal bed gas deoxidation, nitrogen removal, concentration method based on product gas methane replacement and a device thereof. The method comprises the following two-stage process: a first stage is a deoxidation process, and a second stage is a denitrification process; the oxygen concentration in a final product gas obtained by the above concentration method is below 0.3%, and the concentration of methane is above 90%, so that a purpose of purifying coal bed gas can be achieved. The method realizes the purpose of purifying low-concentration coal bed gas to obtain high-concentration methane; a separation process uses methane replacement to replace part of the nitrogen in an adsorption tower, and the methane concentration is increased; the nitrogen produced by a second-stage separation process is used as the purge gas for regeneration of the first-stage adsorption tower, the concentration of methane and oxygen at a first-stage regeneration outlet can be reduced, the danger of the regeneration gas entering the explosion limit can be eliminated, and the safety of the adsorption process can be ensured.

Owner:ZHENGZHOU FULONG NEW MATERIAL TECH

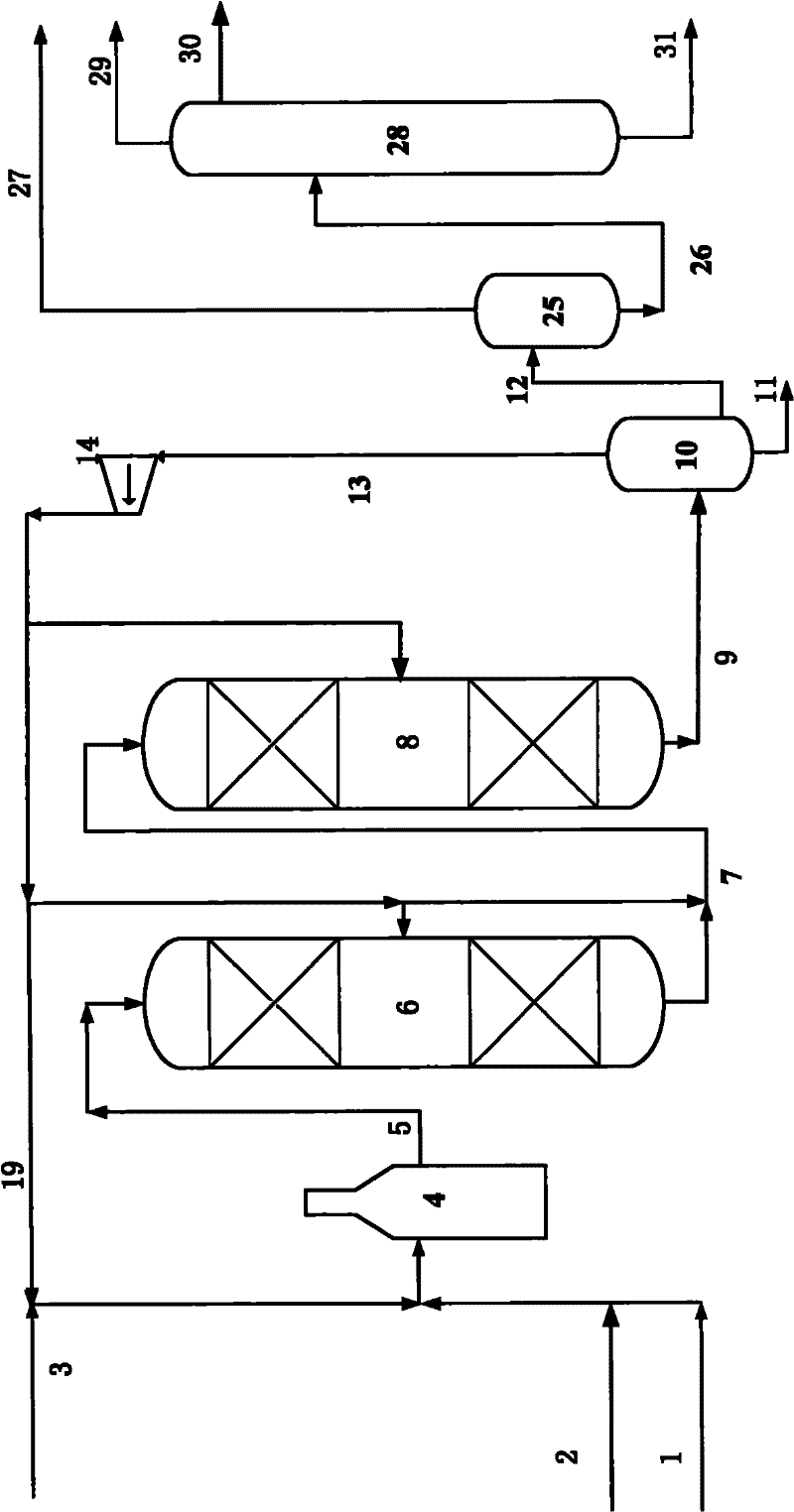

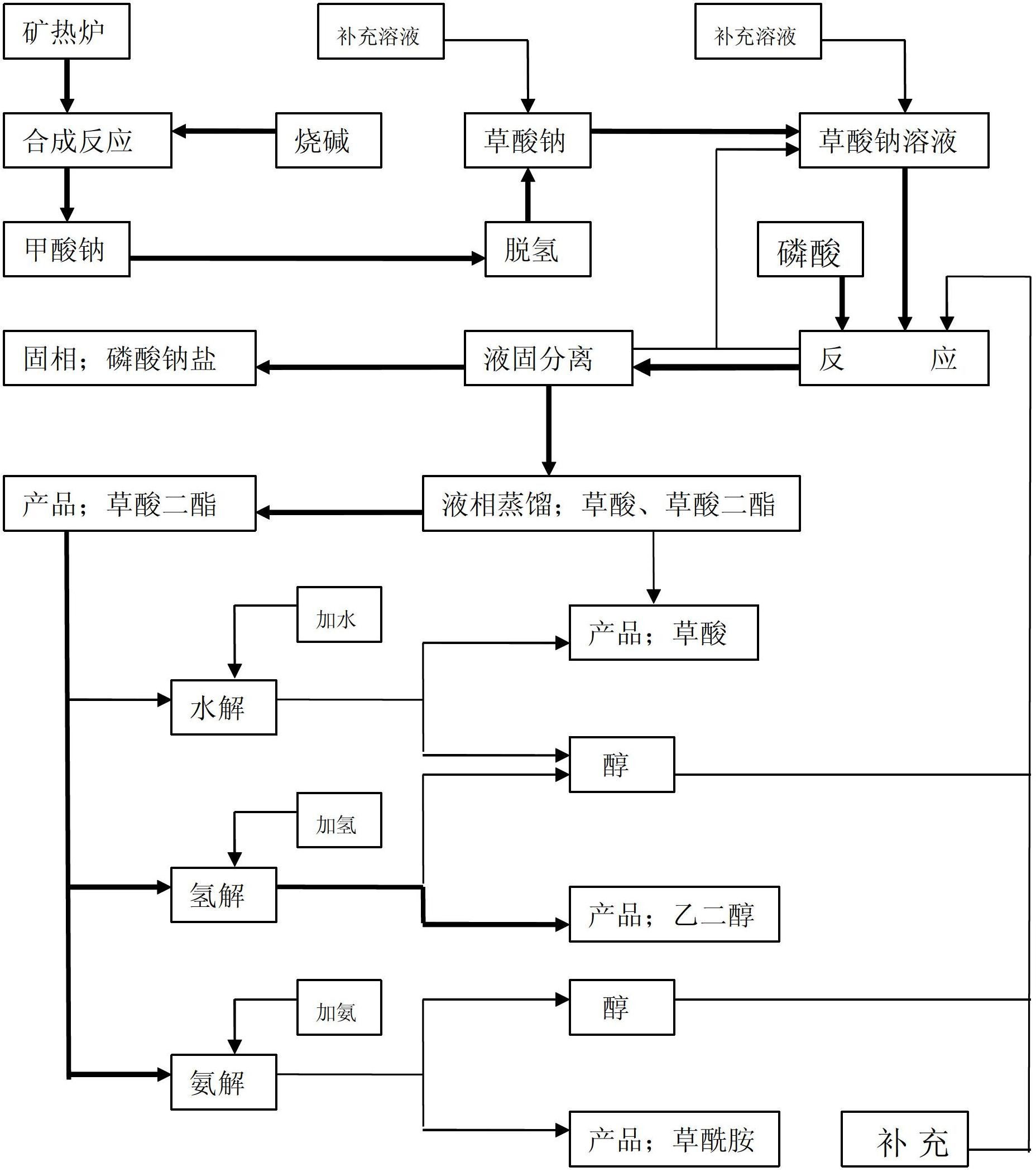

Integrated hydrogenation method for producing clean diesel

ActiveCN102453536AHigh selectivityHigh yieldTreatment with hydrotreatment processesFractionationHigh pressure

The invention discloses an integrated hydrogenation method for producing clean diesel. The method comprises the following steps of: performing hydrogenation refining on a diesel material with high cetane number in a first hydrogenation reaction area; separating in a thermal high-pressure separator, mixing the separated hydrogen-rich gas and a diesel material with low cetane number, allowing the mixture to enter a second hydrogenation reaction area, performing hydrodesulfurization, hydrodenitrogeneration, aromatics saturation and cycloalkane opening reaction under the action of hydrogenation refining and a hydrocracking catalyst, mixing a liquid-phase material flow obtained by the thermal high-pressure separator and a liquid material in the second hydrogenation reaction area, and allowing the mixture to enter a fractionation system; and finally obtaining the clean diesel and a small amount of naphtha with high aromatic hydrocarbon. By the method, a clean diesel product having the sulfur content of less than 10ppm and the cetane number of more than 51 can be produced. On one set of device, two technological processes are implemented, the flow is relatively simple, the hydrogen utilization rate is high, device investment and operating cost are low, and the process selectivity and economic efficiency are high.

Owner:CHINA PETROLEUM & CHEM CORP +1

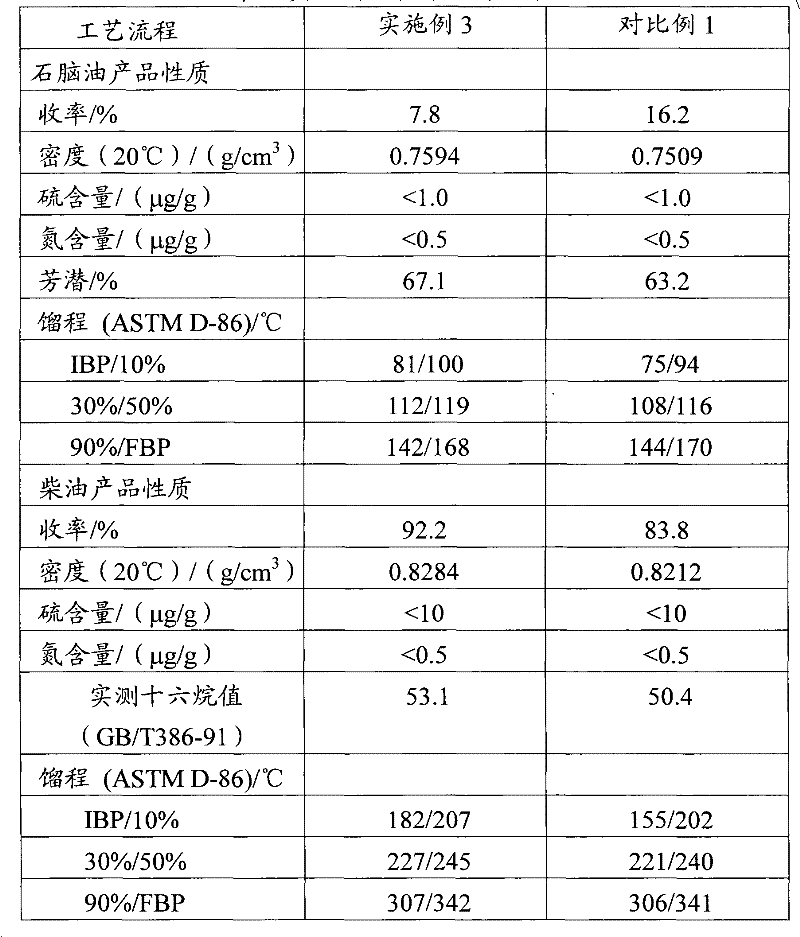

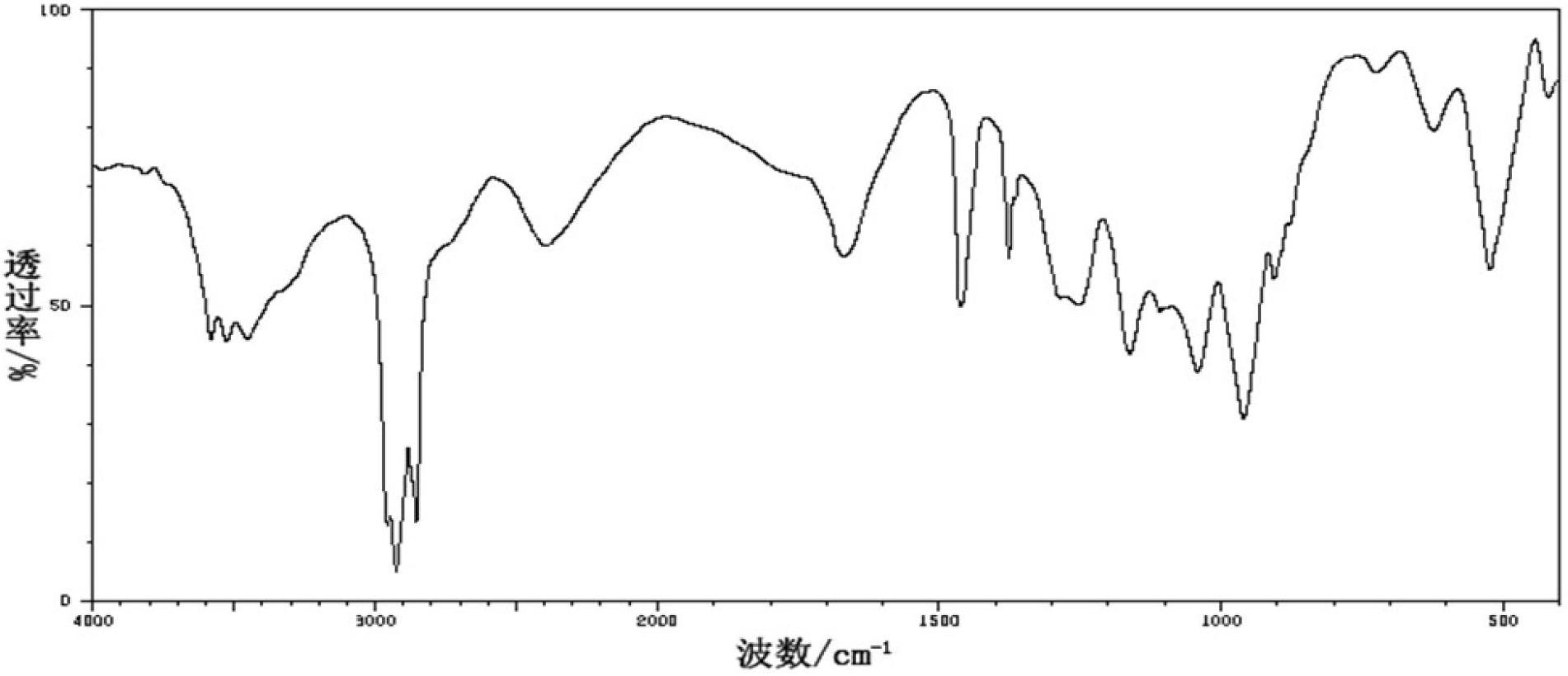

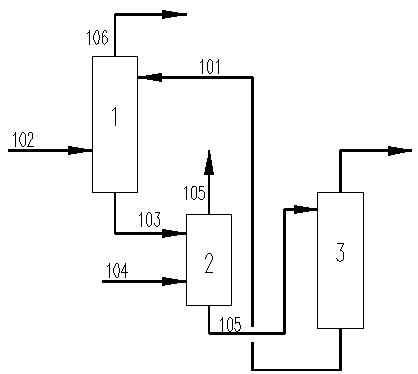

Chemical reaction system for producing oxalic acid diester and oxalic acid as main products by using sodium formate as raw materials

InactiveCN102659556ANo pollution to the environmentReduced compression energy consumptionPreparation from carboxylic acid saltsOrganic compound preparationChemical reactionDistillation

The invention discloses a chemical reaction system for producing oxalic acid diester and oxalic acid as main products by using sodium formate as raw materials. The chemical reaction system comprises a first reaction unit, a second reaction unit and a third reaction unit, wherein the sodium formate is subjected to dehydrogenation reaction to generate sodium oxalate in the first reaction unit; in the second reaction unit, the sodium oxalate is mixed with solvents, then, the oxalic acid is added, the reaction is carried out, and then, the solid and liquid separation is carried out, wherein the solid phase is phosphate, and the oxalic acid diester is rich in the liquid phase; and in the third reaction unit, the oxalic acid diester-rich liquid phase is subjected to distillation separation, then, the oxalic acid diester is respectively subjected to hydrolysis, hydrogenolysis and ammonolysis, and oxalic acid, alcohol, glycol and oxamide are obtained. The chemical reaction system disclosed by the invention has the advantages that the influence on environment is avoided, the environment problems of lead-containing sewage and other waste discharge do not exist, phosphates from sodium ions and with higher additional values are generated, the process separation becomes simple, the implementation is easy, and the production process reaches the requirements of clean production and energy saving environment-friendly type production process.

Owner:天津市碳一有机合成工程设计有限公司

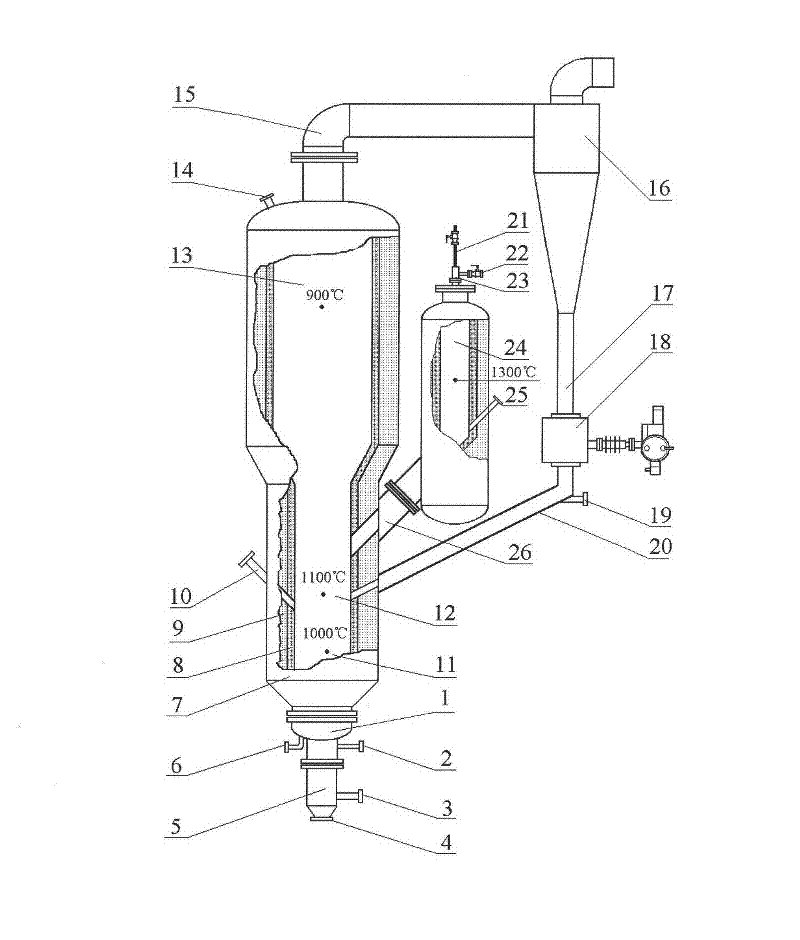

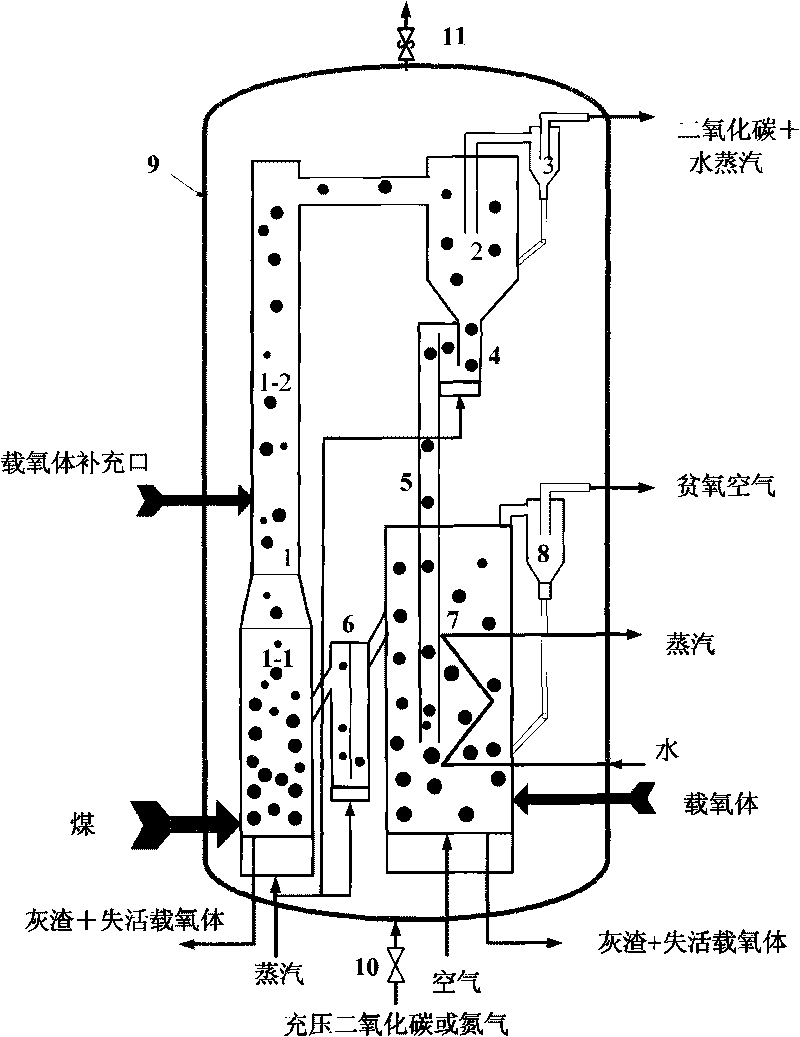

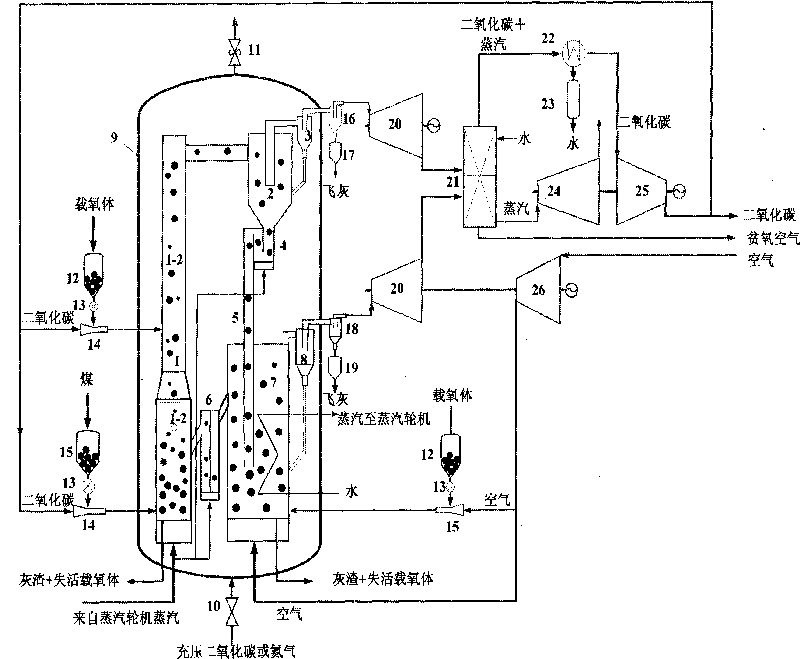

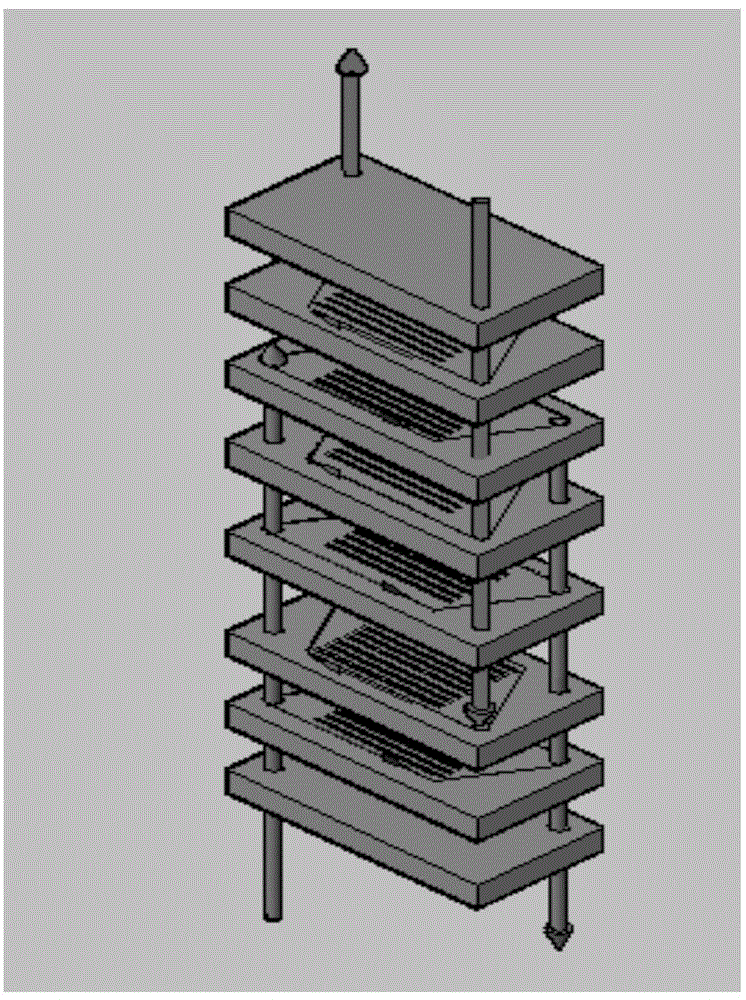

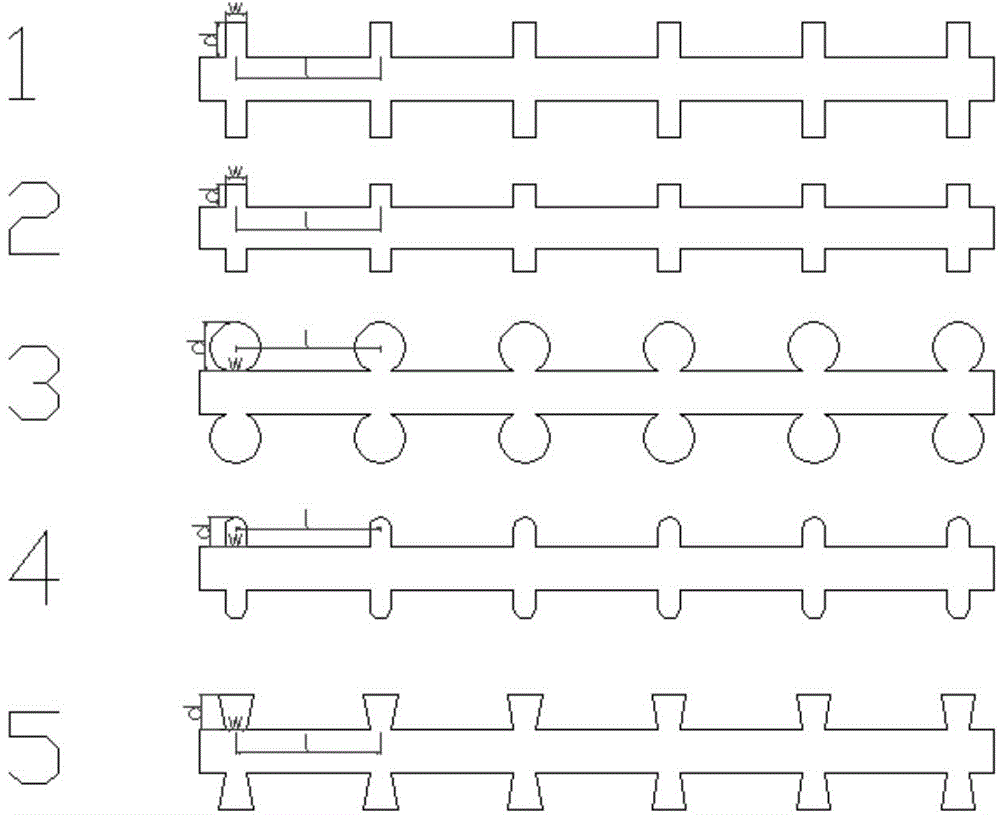

Solid fuel combustion and gasification device for horizontal pressurized fluidized bed or spouted bed

InactiveCN101712890ABig investmentCompact structureFluidized bed combustionCombined combustion mitigationHigh carbonWaste treatment

The invention discloses a general combustion and gasification device for a pressurized fluidized bed or a spouted bed for a solid fuel containing carbon and hydrogen, and aims to solve the problems of much flying ash, high carbon content of the flying ash, high carbon content of discharged ash and low coal utilization rate of the solid fuel in the FBC, PFBC or fluidized bed or spouted bed solid fuel gasification device. The device consists of a gas distribution unit, a fuel feeding unit, a pressurized fluidized bed or spouted bed unit and a flying ash treating unit. The device has the remarkable characteristics that the pressurized solid fuel fluidized bed or spouted bed device is changed into a horizontal form from a vertical form so as to be more suitable for the combustion or gasification under a pressurizing condition; the structure is simplified; and a special flying ash treating device is provided for reducing the carbon content of the flying as in product gas and converting the carbon into efficient gas component. The device can be widely applied to the combustion of coal, oil shale or other organic biomass waste, three-waste treatment or production of gas, oil or ammonia and carbon chemistry. The device is particularly suitable for the pressurized fluidized bed or a spouted bed boiler (PFBC) or a coal gasifier, and can also be used in the field (IGCC) of gas-vapor combined cycle and used for boiling furnaces for producing acid from pyrite.

Owner:顾鸣海

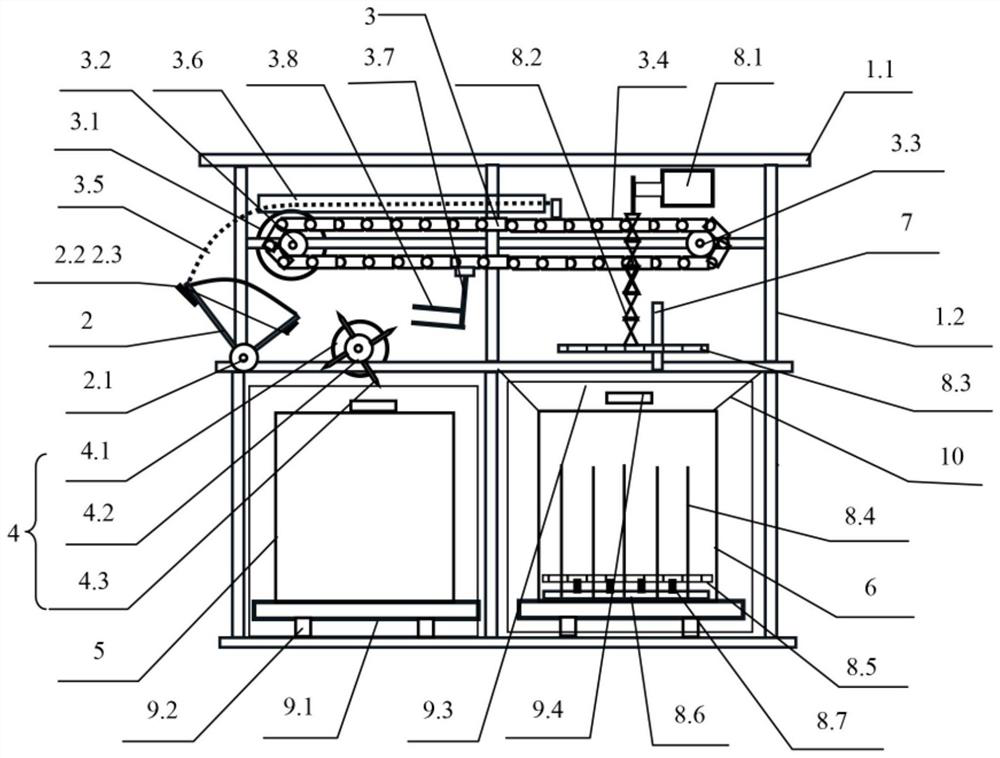

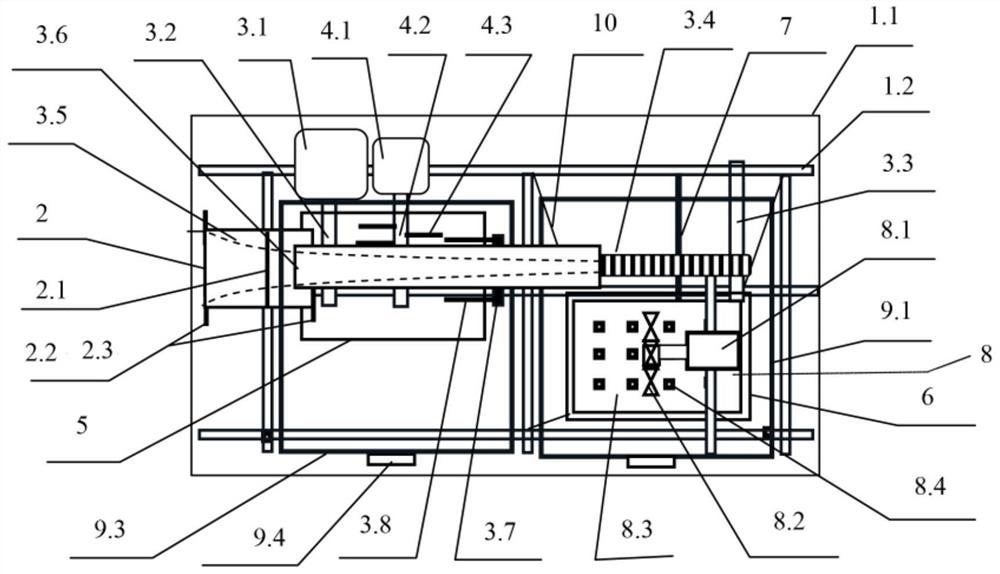

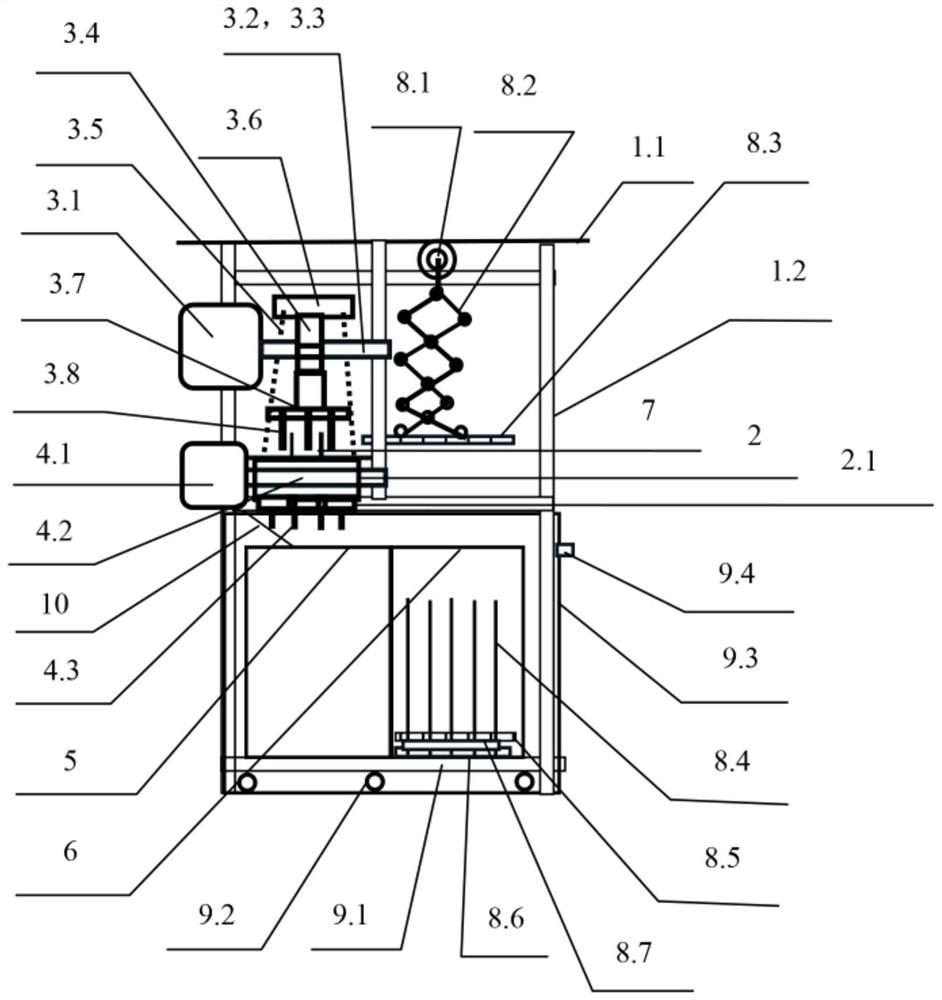

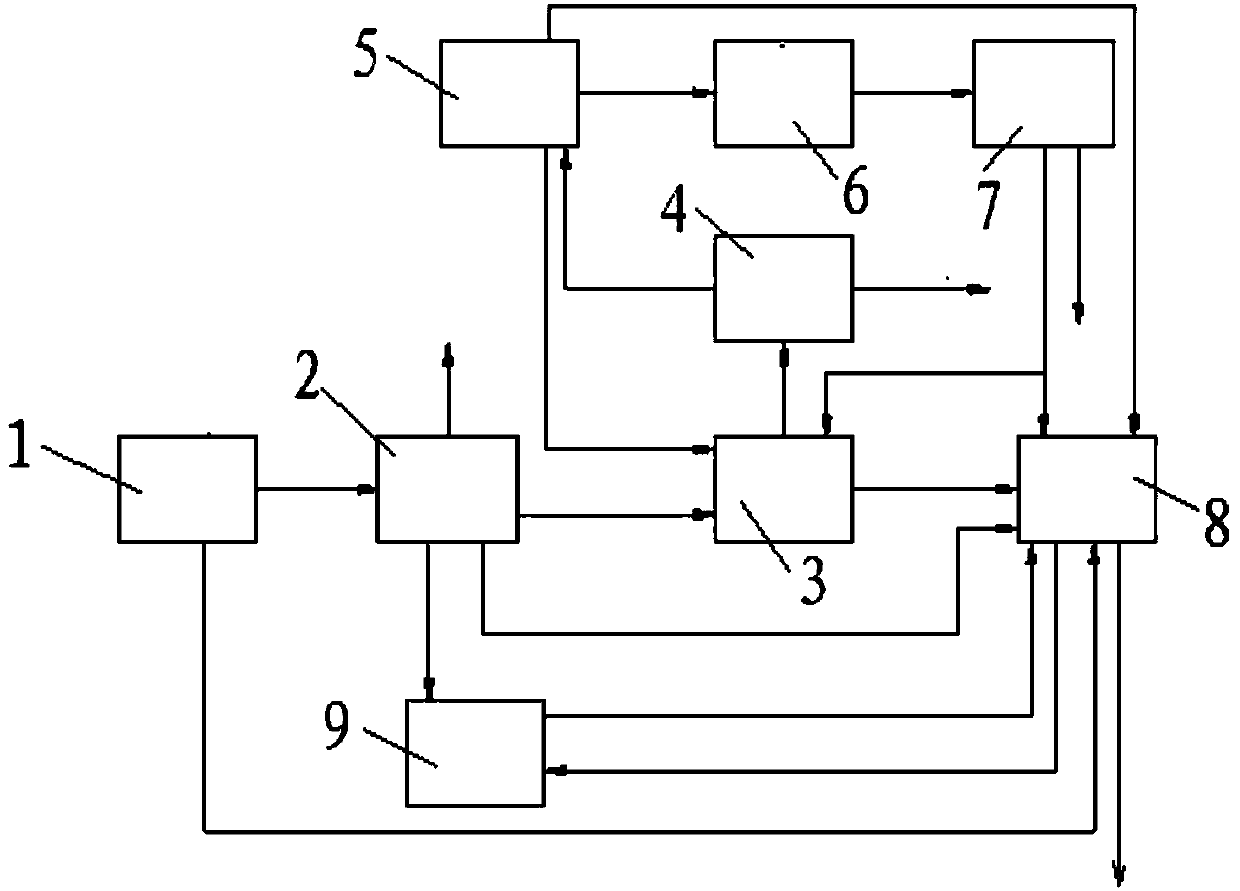

Automatic bag breaking and collecting device and method for resident household garbage

PendingCN113816045ASolve the jamAvoid entanglementRefuse receptaclesBags openingProcess engineeringDomestic waste

The invention discloses an automatic bag breaking and collecting device and method for resident household garbage. The device simultaneously has three functions of garbage classified throwing, automatic bag breaking and sorting of garbage and garbage compression and volume reduction, and an integrated scheme of manual classified throwing, automatic mechanical bag breaking and sorting, compression and volume reduction, packaging and clearing and intelligent induction is adopted. The effects of classified throwing, automatic bag breaking and sorting and classified packaging and clearing of the household garbage of community residents are achieved, meanwhile, the dual characteristics of humanization and mechanization are achieved, source classification and sorting of the household garbage are facilitated, and garbage recycling and source volume reduction are facilitated. The automatic bag breaking and collecting device and method for the resident household garbage solve the problems of high management difficulty, high management cost and difficulty in realizing effective garbage source classification in the existing community resident household garbage source only depending on the consciousness of residents, and also solves the problems that source classified garbage is not compressed and subpackaged, high garbage clearing cost, heavy pollution on the way of transportation, mixed loading and terminal mixed processing in the garbage classification process and the like are caused.

Owner:徐州无废城市技术研究院有限公司

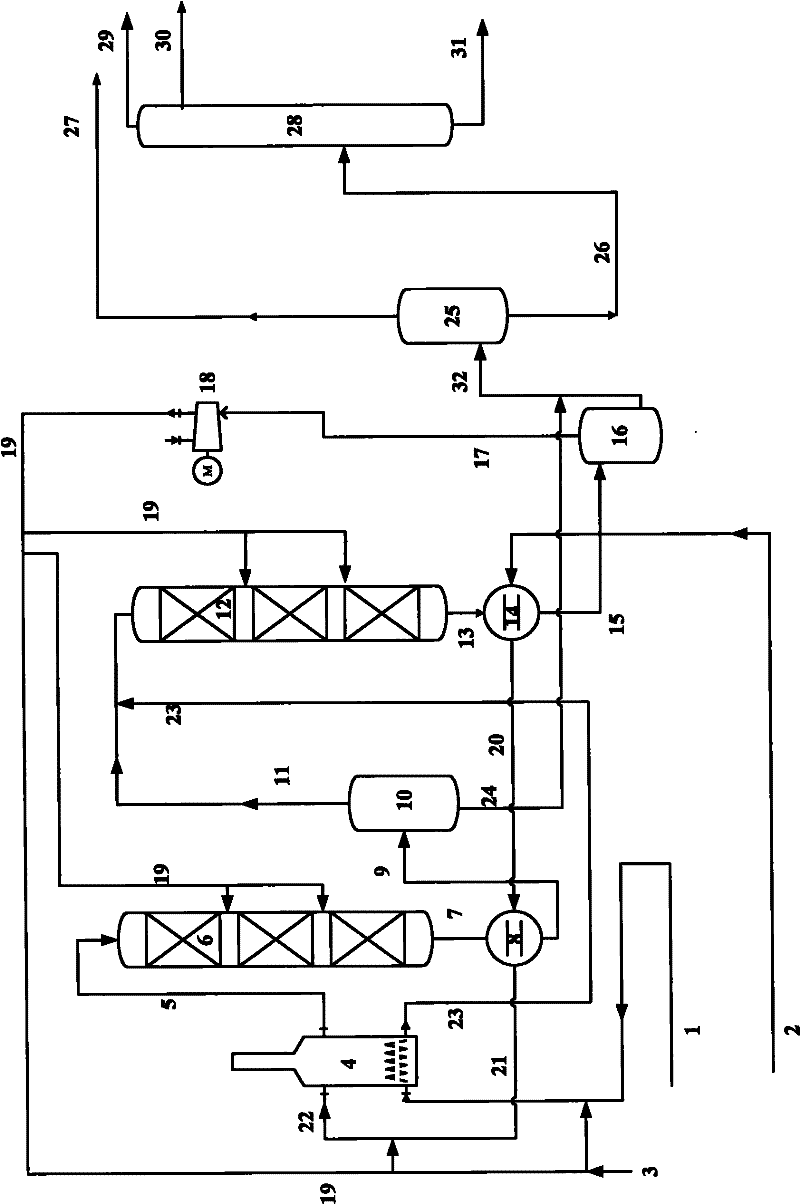

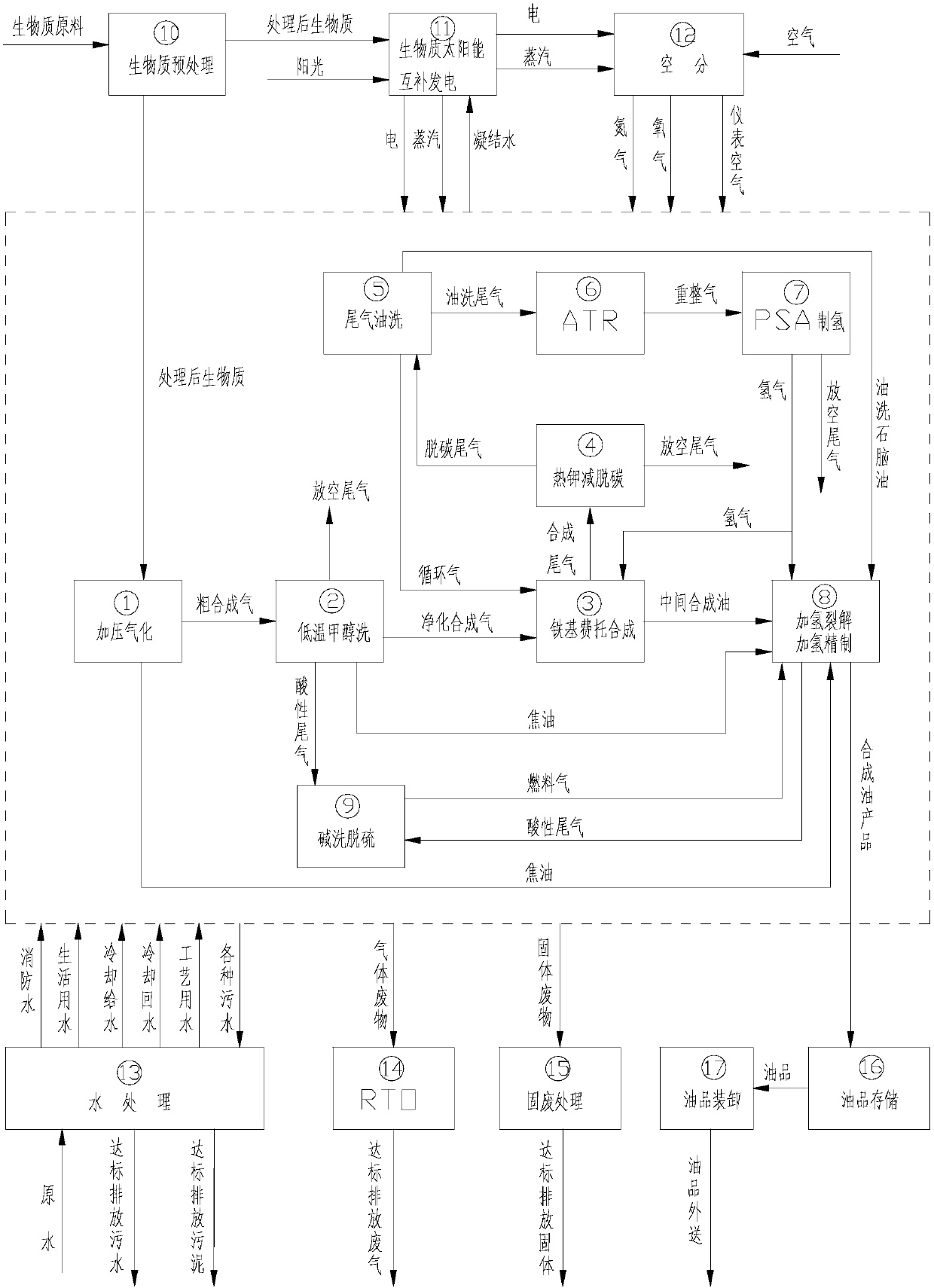

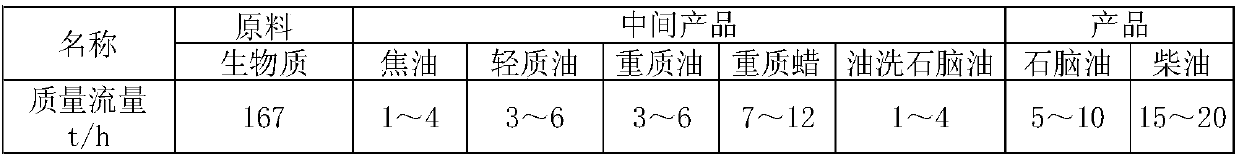

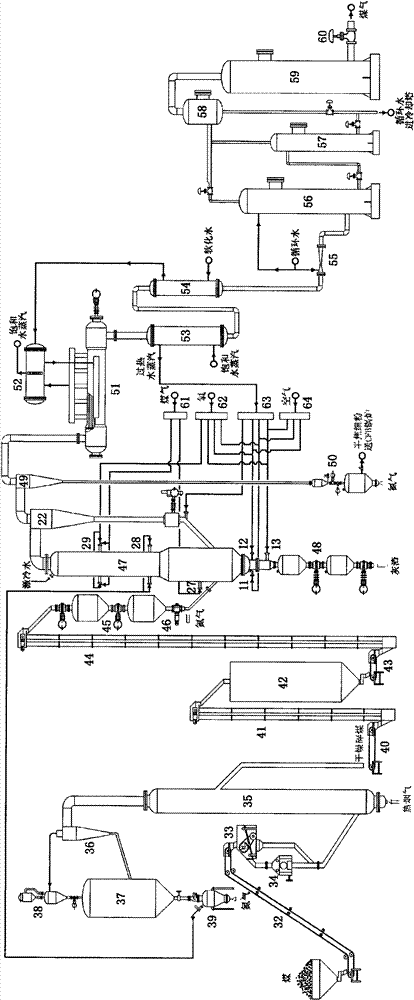

Technology and system for preparing synthetic oil by biomass indirect liquefaction

ActiveCN107557075ASave the conversion processShort processHydrogenCombustible gas catalytic treatmentTarBiomass

The invention discloses a technology and a system for preparing synthetic oil by biomass indirect liquefaction. The technology comprises the following steps of biomass pressure gasification, syntheticair purification, oil product synthesis, tail gas decarburization, tail gas oil washing, tail gas reforming, tail gas hydrogen production, oil product processing and tail gas desulfurization; in thebiomass pressure gasification step, the pressure of a gasifier is 3-5MPa (G), the temperature of a drying section in the gasifier is less than 500 DEG C, the temperature of a distillation section is 500-1000 DEG C, the temperature of a gasification section is 1000-1100 DEG C, the temperature of a burning section is 1100-2000 DEG C, and the temperature of a molten slag section is 1700-2000 DEG C; tar generated in the steps of biomass pressure gasification and synthetic air purification is taken as the raw material of an oil product processing step, and the tar is blended with intermediate synthetic oil obtained in the oil product synthesis step to obtain a synthetic oil product. According to the technology and the system thereof, each technology unit and a relevant matching technology are integrally considered, technology optimization is carried out from an integral angle, configuration is reasonable, and the efficient utilization of biomass new energy is realized.

Owner:WUHAN KAIDI ENG TECH RES INST CO LTD

Method and device for gasifying multi-segment staged converted fluidized bed

ActiveCN101942344BLarge amount of processingReduced compression energy consumptionEnergy inputCombined combustion mitigationFluidized bedProcess engineering

The invention relates to method and device for gasifying a multi-segment staged converted fluidized bed. The method comprises the following steps of: supplying coal; supplying gas; gasifying; slagging; and conveying fine powder. The device for gasifying the multi-grade staged converted fluidized bed comprises an agglomerating ash separating unit, a pyrolyzing and gasifying reactor of the multi-segment staged fluidized bed and a semicoke fine powder cyclic feeding unit. The invention has the advantages of high volume utilization rate of a gasifying oven, great handling capacity and high utilization rate of total carbon, is suitable for a coal staging and converting system and can be singly used for producing gas for mass coal-based methane synthesis and coal chemical industry.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

Feed gas recovery method and device

PendingCN108057319AFlexible and controllable operationReduced compression energy consumptionGas treatmentDispersed particle separationChemistryDecarburization

The invention relates to a feed gas recovery method and device, and belongs to the technical field of gas separation engineering. The feed gas recovery method comprises the following steps: step one:lean liquid and feed gas conduct countercurrent contacting in an absorption module to absorb carbon dioxide, and an obtained solution is a rich liquid containing the feed gas; step two: the rich liquid and displacement gas conduct countercurrent contacting in a recovery module to replace the feed gas; Step three: the feed gas is recovered and returned to the absorption module for continuous recycling. The invention also discloses a feed gas recovery device. The feed gas recovery device comprises the absorption module and the recovery module communicating with each other. According to the feedgas recovery method and device, the feed gas in the rich liquid is replaced by the displacement gas under high pressure conditions, and the recovered high-pressure feed gas can be directly returned toan absorption decarburization device of the feed gas or enter subsequent process treatment.

Owner:上海朴力节能环保科技有限公司

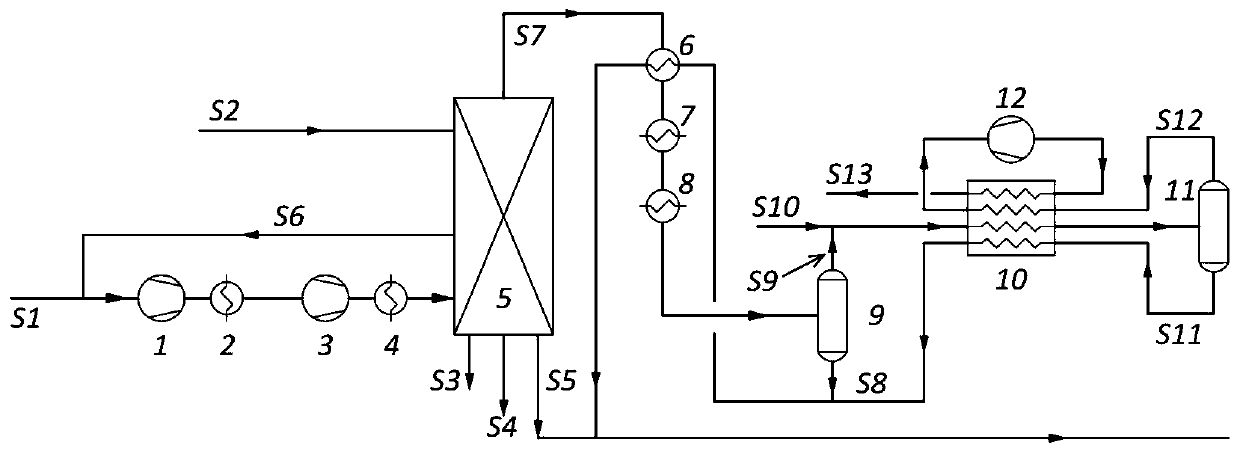

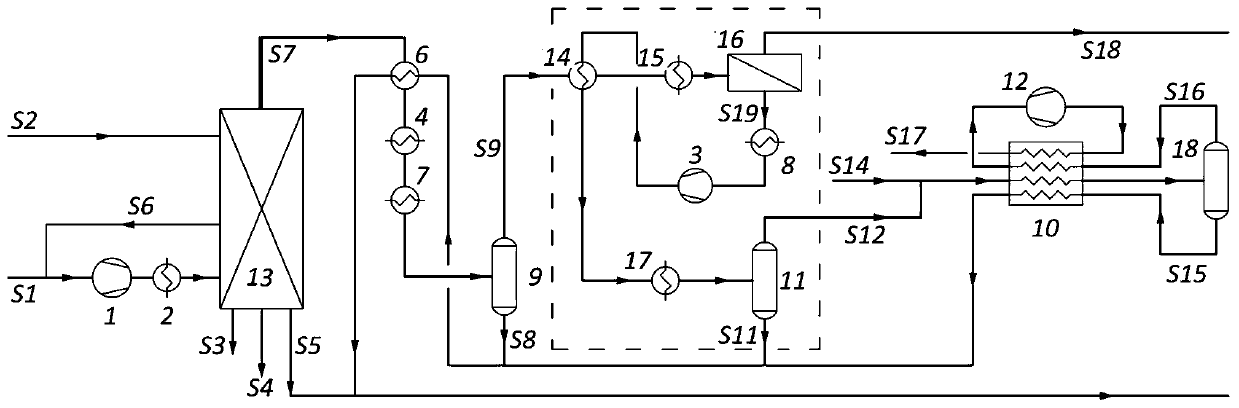

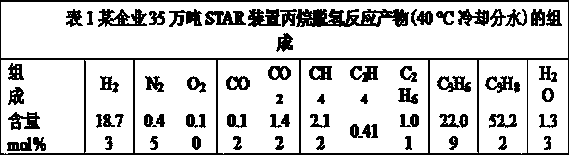

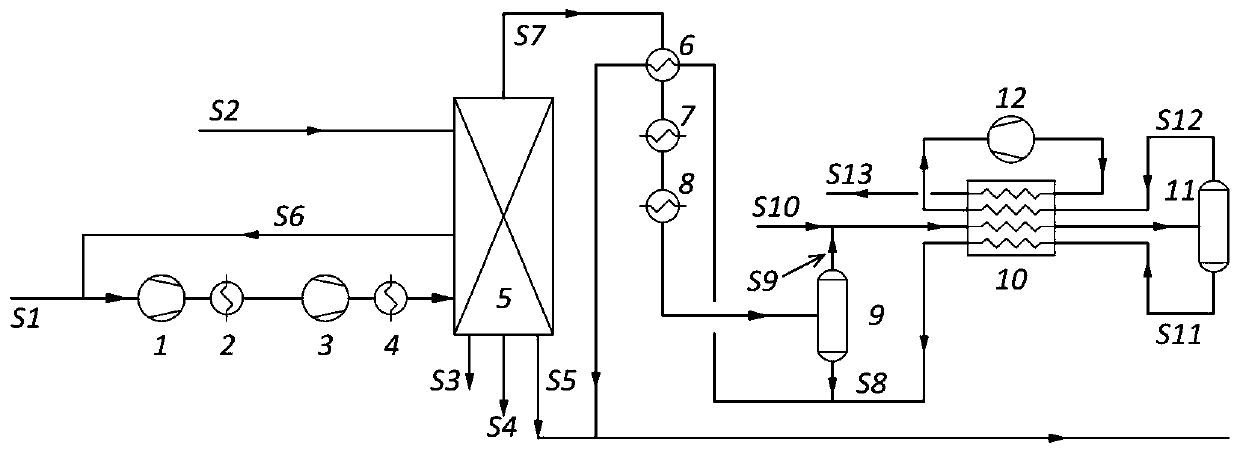

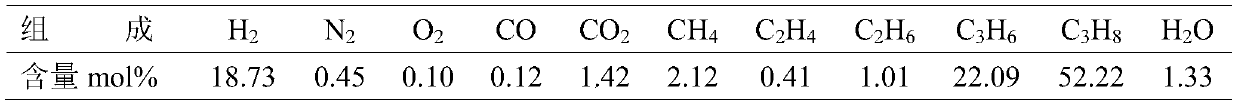

Hydrogen separation membrane embedded improved cryogenic liquefaction system for star propane dehydrogenation

ActiveCN110108091BReduce trafficReduced compression energy consumptionSemi-permeable membranesSolidificationDehydrogenationPhysical chemistry

The invention provides a hydrogen separation membrane embedded improved copious cooling liquefying system aiming at an STAR propane dehydrogenation process, and belongs to the technical field of petrochemical engineering. According to the system, starting from the composition characteristics of dehydrogenation reaction products, a hydrogen membrane separation unit is introduced behind a shallow cooling unit, most hydrogen is separated through selective permeation of a membrane, then pressurizing and copious cooling liquefying are further carried out, and propane and propylene are further separated from remaining non-condensable components. By means of the hydrogen membrane separation unit embedded improved copious cooling liquefying system, compression loads can be remarkably reduced whilehigh-concentration hydrogen is obtained, the total compression energy consumption can be reduced by 8-24%, the heat exchange load of a copious cooling unit can be reduced by 80-86%, the purity of thebyproduct hydrogen can be increased from 82 mol% to 99 mol%, and the requirements of hydrogen consumption devices such as hydrocracking devices in the refinery enterprise are met. Under the optimum working condition, by means of the 350,000-ton STAR process, 1020 kW of the compression energy consumption can be reduced, and 16,198 Nm<3> / h of qualified hydrogen is output.

Owner:DALIAN UNIV OF TECH

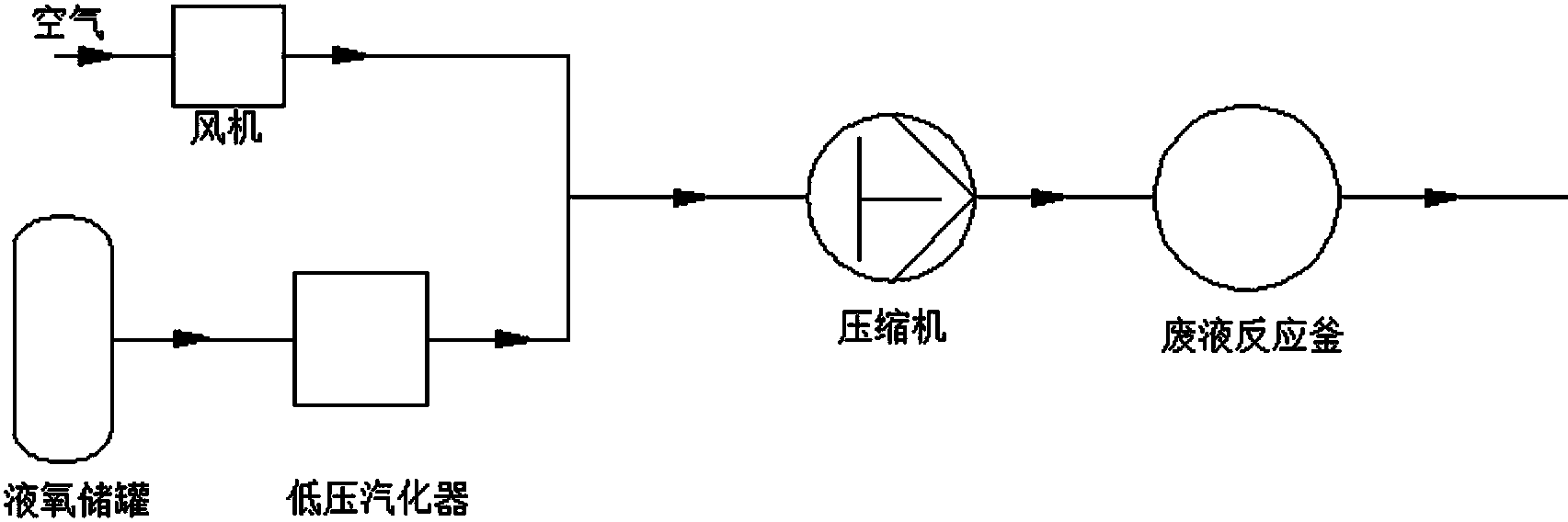

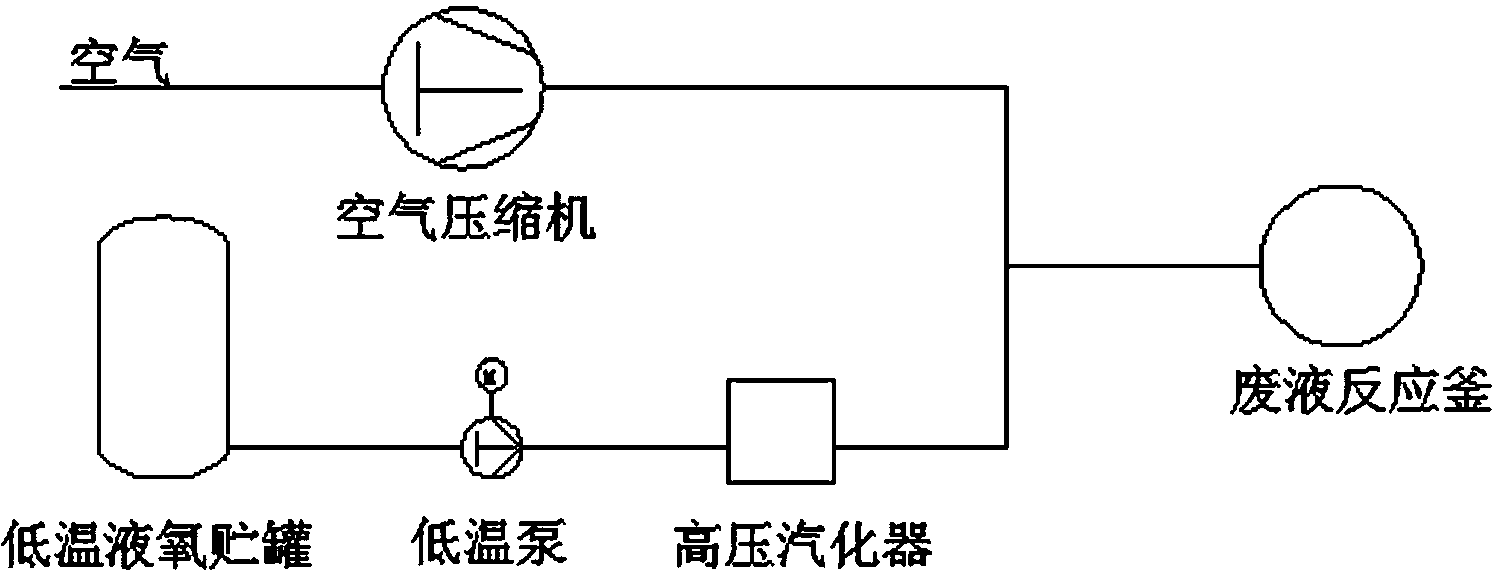

Method for adding rich oxygen in liquid waste treatment process

InactiveCN103453314AReduce energy consumptionReduced oxygen content in compressed gasPipeline systemsPressure vesselsLiquid oxygenEvaporator

The invention discloses a method for adding rich oxygen in a liquid waste treatment process. The method comprises the following steps of compressing air by an air compressor and improving the pressure to 8-10 MPa; gasifying liquid oxygen stored in a low-temperature liquid storage tank into a gas through a high-pressure evaporator by pressurizing through a low-temperature pump, wherein the pressure also achieves 8-10 MPa, and the oxygen content achieves 30-50% after the gasified oxygen and the compressed air are mixed according to a certain ratio; oxygen-enriched air enters a liquid waste reaction kettle to utilize after being mixed. By adopting the method for adding rich oxygen in the liquid waste treatment process disclosed by the invention, the position of adding oxygen is transformed; the safety of the compressor is improved; energy consumption of the compressor is reduced.

Owner:湖北和远气体股份有限公司

Hydrogen separation membrane embedded improved copious cooling liquefying system aiming at STAR propane dehydrogenation process

ActiveCN110108091AReduce trafficReduced compression energy consumptionSemi-permeable membranesSolidificationDehydrogenationPetrochemical

The invention provides a hydrogen separation membrane embedded improved copious cooling liquefying system aiming at an STAR propane dehydrogenation process, and belongs to the technical field of petrochemical engineering. According to the system, starting from the composition characteristics of dehydrogenation reaction products, a hydrogen membrane separation unit is introduced behind a shallow cooling unit, most hydrogen is separated through selective permeation of a membrane, then pressurizing and copious cooling liquefying are further carried out, and propane and propylene are further separated from remaining non-condensable components. By means of the hydrogen membrane separation unit embedded improved copious cooling liquefying system, compression loads can be remarkably reduced whilehigh-concentration hydrogen is obtained, the total compression energy consumption can be reduced by 8-24%, the heat exchange load of a copious cooling unit can be reduced by 80-86%, the purity of thebyproduct hydrogen can be increased from 82 mol% to 99 mol%, and the requirements of hydrogen consumption devices such as hydrocracking devices in the refinery enterprise are met. Under the optimum working condition, by means of the 350,000-ton STAR process, 1020 kW of the compression energy consumption can be reduced, and 16,198 Nm<3> / h of qualified hydrogen is output.

Owner:DALIAN UNIV OF TECH

MVR-heat pump coupled multi-effect evaporation water treatment system and working method thereof

ActiveCN113880171ASmall sizeOvercoming the need for additional live steam supplyWater treatment parameter controlEvaporator accessoriesWater treatment systemEngineering

The invention discloses an MVR-heat pump coupled multi-effect evaporation water treatment system and a working method thereof. The system comprises an MVR multi-effect evaporation cycle and a compression heat pump cycle. The method comprises the steps that a part of secondary steam in a first-effect evaporator serves as a heat source of a next-effect evaporator, a part of the secondary steam is mixed with last-effect secondary steam obtained after first-stage compression, the mixture enters a second steam compressor to be compressed and then enters the first-effect evaporator, a part of heat of first-effect condensate water is recycled through an evaporator of a compressor heat pump, and another air source evaporator absorbs heat from ambient air and is used for evaporating a part of the condensate water in the first-effect evaporator to generate steam, thereby maintaining stable operation of the system. The method for evaporating a part of the condensate water through the compression type heat pump completely meets the requirement for extra fresh steam supply during operation of an MVR multi-effect evaporation system; and by means of the method for directly compressing a part of high-pressure secondary steam, the purposes of reducing compression energy consumption, reducing the size of a compressor and reducing initial investment can be achieved.

Owner:JIANGSU UNIV OF SCI & TECH

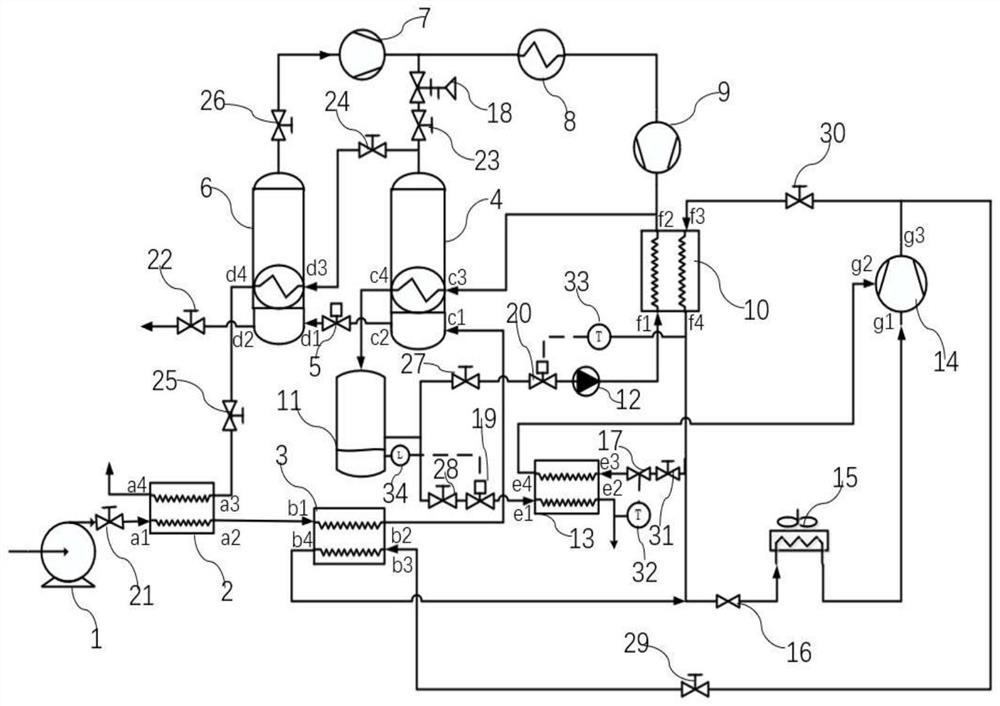

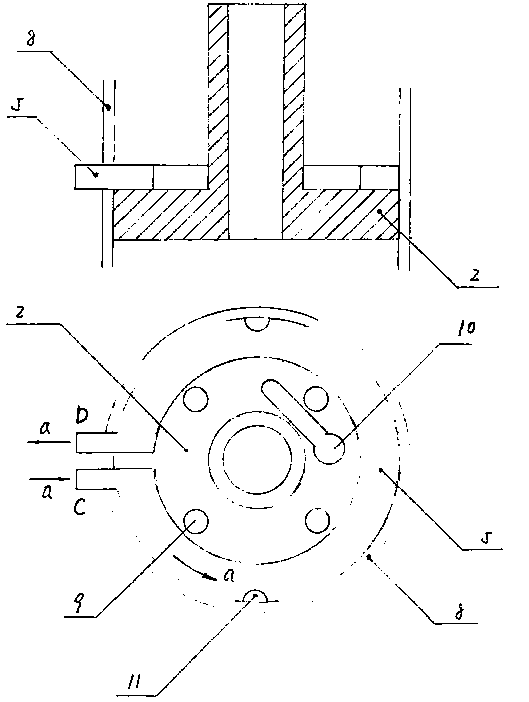

Reinforced desorption method of acidic gas

InactiveCN105749701AReduced compression energy consumptionAvoid thermal decompositionDispersed particle separationChemical/physical/physico-chemical processesMaterial consumptionProduct gas

The invention provides a reinforced desorption method of an acidic gas. The method is characterized in that inner groove-shaped micro-channels are introduced to a micro-channel reactor, and desorption process reinforcement of a carbon dioxide absorption liquid is carried out under 0.1-1MPa at 90-160DEG C for 0.01-100s. The micro-reactor comprises a plate heat exchange unit and a plate desorption unit, and the plate desorption unit is formed by the parallel inner groove-shaped micro-channels. The method can realize carbon dioxide desorption in an extremely short time, prevent absorbent overheating and reduce the volume of evaporated water, and has a small size in order to greatly reduce the energy and material consumption in the desorption process of the carbon dioxide absorption liquid and the occupied area. The energy consumption, the material consumption and the occupied area of the reinforced desorption method are respectively 20% or above lower than those of traditional tower desorption systems.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Energy-saving compressor

InactiveCN103470509AReduce work stressReduced compression energy consumptionRotary/oscillating piston pump componentsLiquid fuel engine componentsGas compressorInspired gas temperature

The invention discloses an energy-saving compressor. The energy-saving compressor belongs to a gas compressor and can be used for steam compression-type refrigeration and heating. The energy-saving compressor utilizes a cylinder with a thermostat. When a work temperature of the cylinder is higher than a gas suction temperature, a refrigeration working medium in the thermostat absorbs heat of the cylinder so that the work temperature of the cylinder is reduced and compression energy consumption of the energy-saving compressor is reduced.

Owner:黄小平

Blast furnace oxygen delivery system and working method

PendingCN110645475AReduced compression energy consumptionRealize energy saving and consumption reductionPipeline systemsPhysicsOxygen enrichment

The invention discloses a blast furnace oxygen delivery system and a working method. The system comprises a first oxygen delivery system, a second oxygen delivery system and a delivery main pipe; thefirst oxygen delivery system comprises a first delivery pipe, a first fire arrestor, a first stop valve, a first pressure gauge, a first pressure reduction regulating valve, a second pressure gauge, asecond stop valve and a third stop valve; and the second oxygen delivery system comprises a second delivery pipe, a second fire arrestor, a fourth stop valve, a third pressure gauge, a filter, a second pressure reduction regulating valve, a fourth pressure gauge, a third pressure reduction regulating valve, a fifth pressure gauge and a fifth stop valve. According to the system, middle-pressure oxygen and low-pressure oxygen can achieve hierarchical control, it is guaranteed that the low-pressure oxygen with low energy consumption is used firstly, the insufficient section is supplemented withthe middle-pressure oxygen, the problems that the low-pressure oxygen is diffused, and energy waste is generated when the middle-pressure oxygen is used a lot are effectively avoided, and oxygen-enriched energy conservation and consumption reduction of a blast furnace are achieved to the maximum limit.

Owner:NANJING IRON & STEEL CO LTD

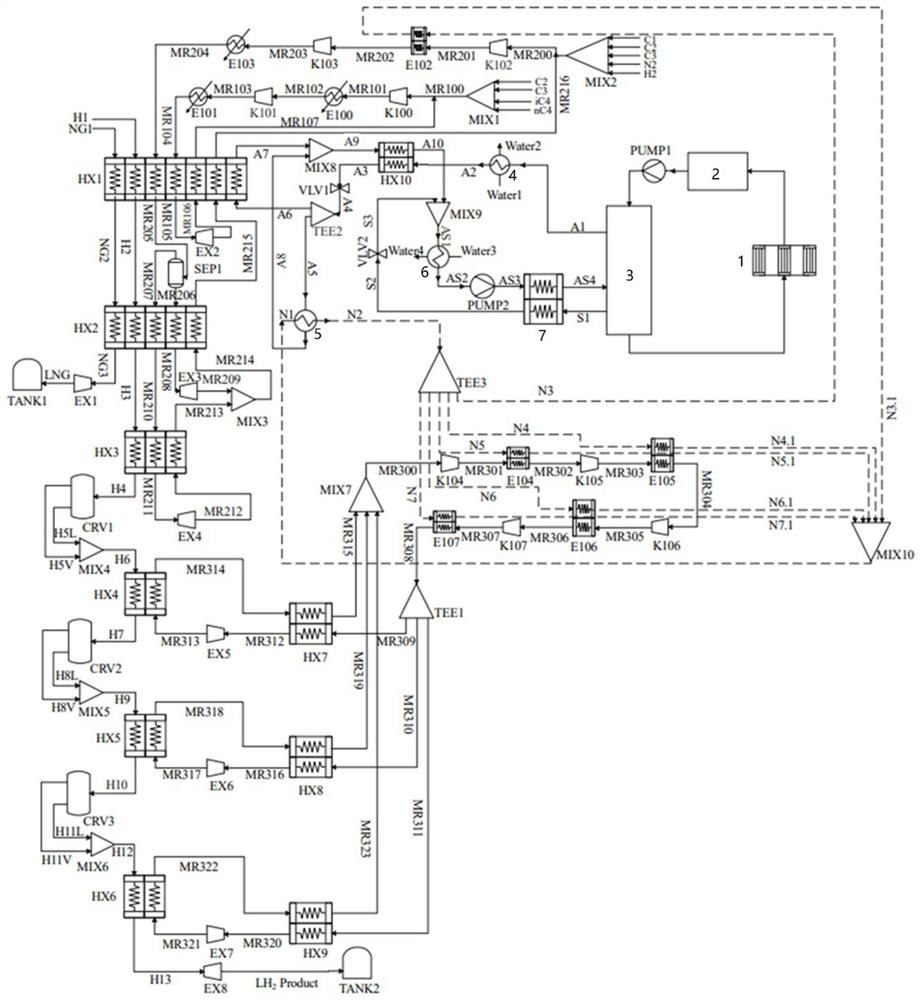

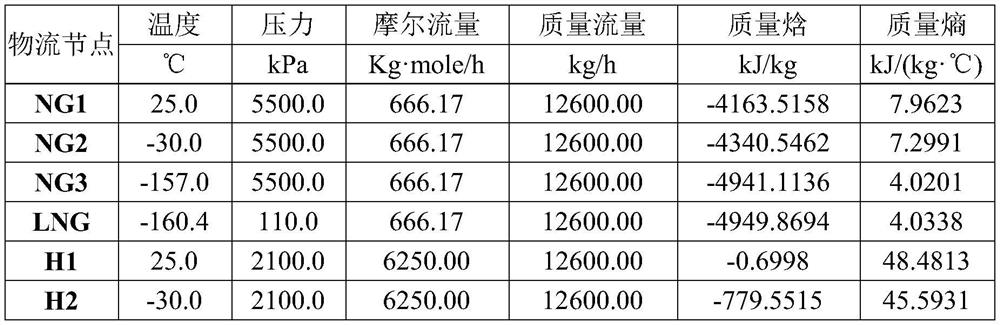

Hydrogen and natural gas combined liquefaction system and process

PendingCN114812096AEmission reductionReduce energy consumptionSolidificationLiquefactionRefrigerationPetroleum engineering

The invention provides a hydrogen and natural gas combined liquefaction system and process. The system comprises a DMR precooling unit, a refrigeration unit, a J-B cryogenic unit, an expansion liquefaction unit, a natural gas liquefaction pipeline and a hydrogen liquefaction pipeline. The DMR precooling unit is coupled with the refrigeration unit through a first-stage countercurrent heat exchanger; the DMR pre-cooling unit is connected with the J-B deep cooling unit through a first-stage ortho-parahydrogen converter; the natural gas liquefaction pipeline sequentially penetrates through the first-stage countercurrent heat exchanger and the second-stage countercurrent heat exchanger and is connected to the natural gas expansion machine. A hydrogen liquefaction pipeline sequentially penetrates through the first-stage countercurrent heat exchanger, the second-stage countercurrent heat exchanger, the third-stage countercurrent heat exchanger, the first-stage ortho-para hydrogen converter, the fourth-stage countercurrent heat exchanger, the second-stage ortho-para hydrogen converter, the fifth-stage countercurrent heat exchanger, the third-stage ortho-para hydrogen converter and the sixth-stage countercurrent heat exchanger and is connected to a hydrogen expansion machine. The invention further provides a hydrogen and natural gas combined liquefaction process adopting the system.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

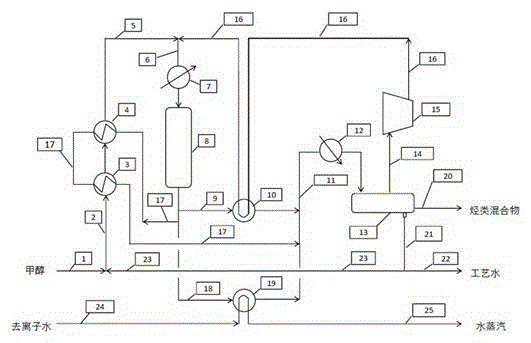

A method for producing hydrocarbon mixtures by one-step methanol conversion in a fixed-bed adiabatic reactor

ActiveCN104557371BEasy to controlThe purpose of jointly controlling the adiabatic temperature riseHydrocarbon from oxygen organic compoundsLiquid hydrocarbon mixture productionHydrocarbon mixturesOperating energy

The invention discloses a method for preparing a hydrocarbon mixture by using one-step methanol conversion in an adiabatic fixed bed reactor. The method comprises the following steps: mixing a raw material methanol with process water from a separator, performing heat exchange with one part of material at the reactor outlet for gasifying, mixing with dried circulating gas, carrying out a reaction for preparing the hydrocarbon mixture based on methanol conversion in the adiabatic fixed bed reactor filled with a ZSM-5 molecular sieve catalyst; dividing the material at the outlet of the adiabatic fixed bed reactor into three parts, collecting the three parts together after heat exchange; performing further cooling, and feeding into an oil-water-gas three-phase separator; and separating to obtain an oil-phase product, namely the hydrocarbon mixture. The method disclosed by the invention has the advantages of small gas cycle ratio and low operating energy consumption and is suitable for large-scale production.

Owner:SEDIN ENG +1

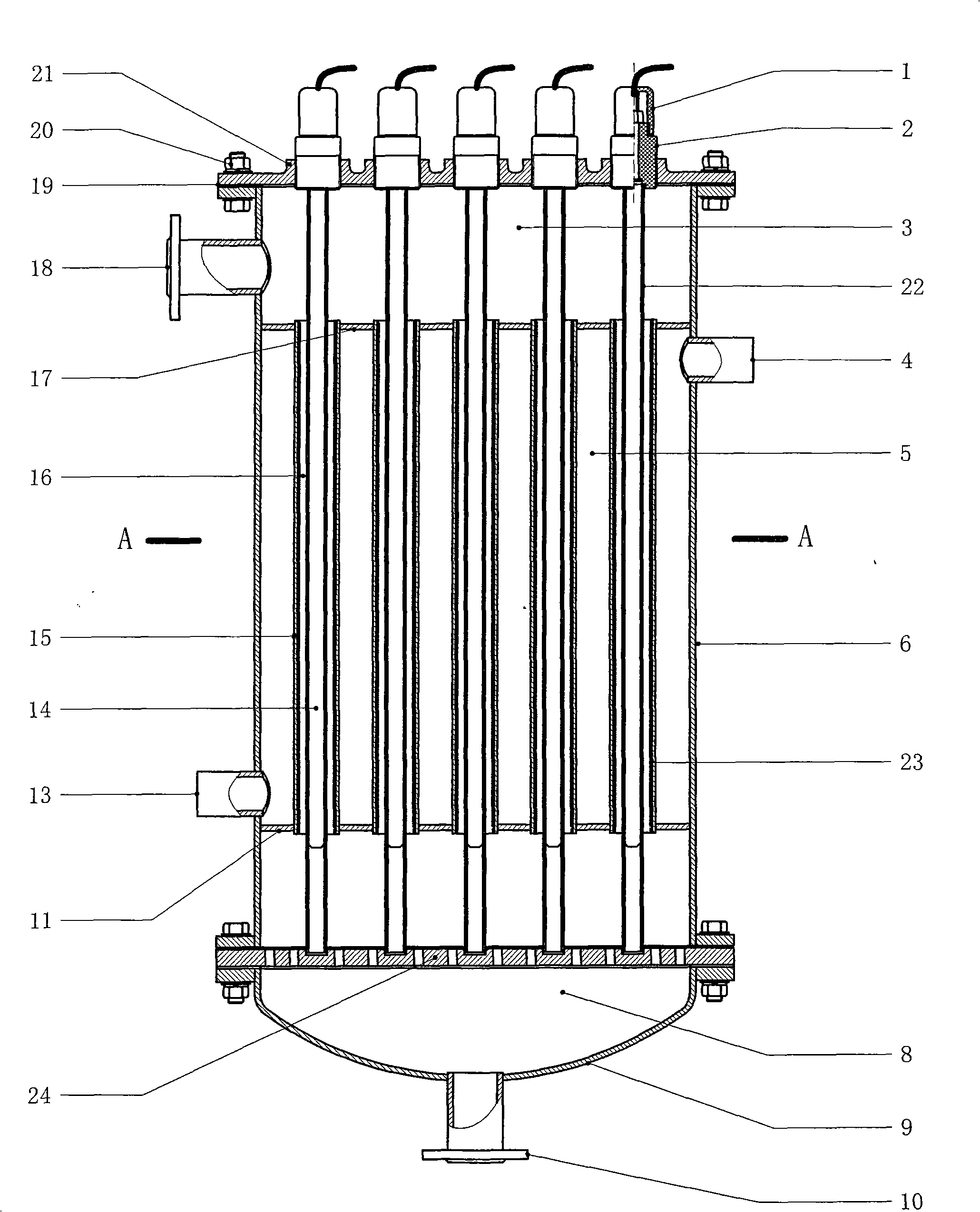

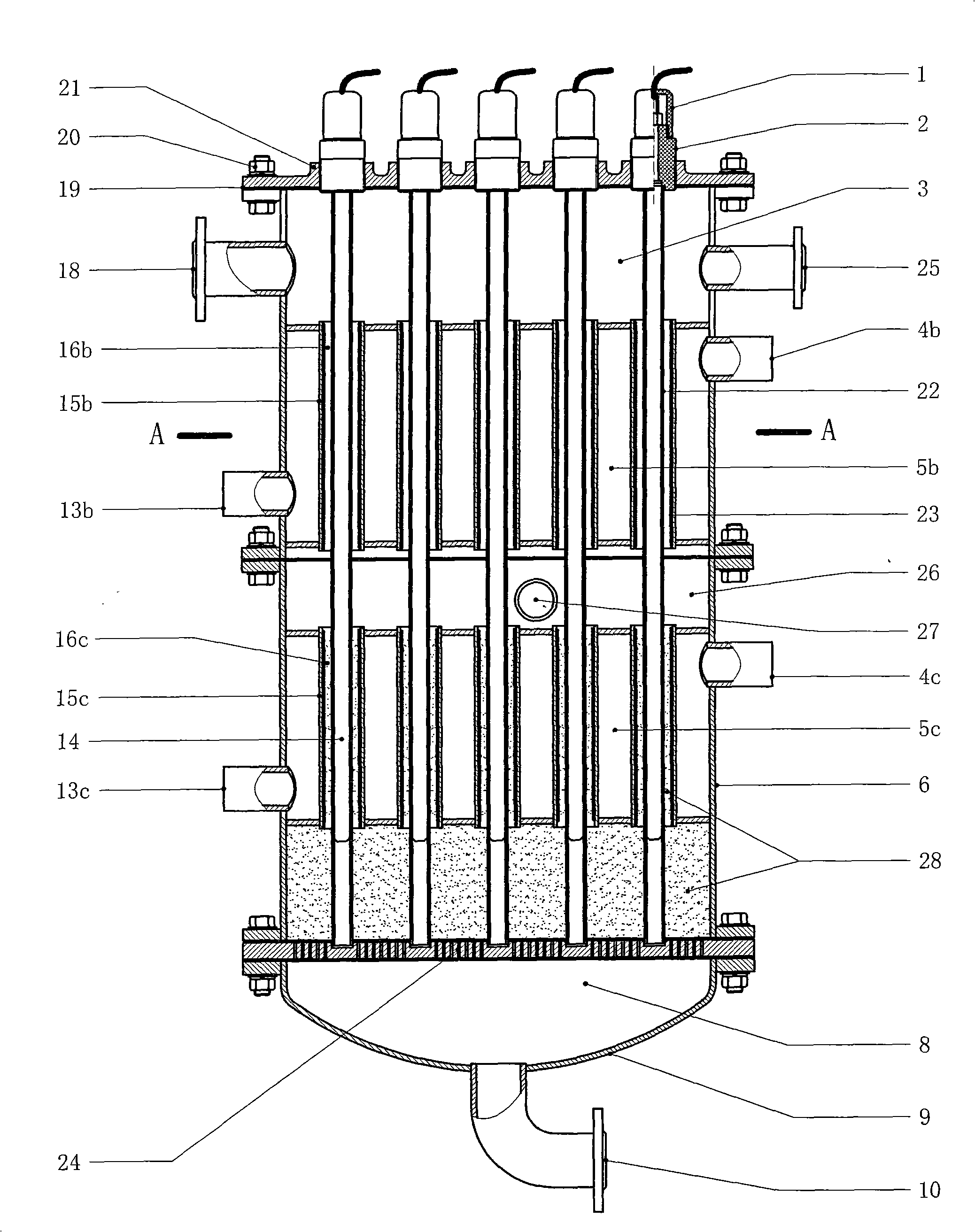

Electrocatalysis synthesis reactor

InactiveCN100531891CGood choiceControllable reaction speedEnergy based chemical/physical/physico-chemical processesLiquid-gas reaction processesChemical synthesisReaction rate

The electrocatalytic synthesis reactor relates to a chemical synthesis reactor, which is mainly composed of a gas distribution chamber, a tube-and-tube electrocatalysis chamber, a collection chamber, a product outlet, a coolant chamber, and a shell, wherein: the raw material gas inlet is from the gas distribution chamber The gas distribution chamber is connected to the collection chamber through the tubular electrocatalytic chamber, and the product outlet is connected from the bottom of the collection chamber. Each electrocatalytic chamber of the tubular electrocatalytic chamber is composed of the inner space of the outer electrode tube bundle, and each There is a central electrode in the electrocatalytic chamber, and the periphery of the outer electrode tube bundle is a coolant chamber. The synthesis reactor adopts low-temperature plasma and catalyst synergistic catalysis to carry out the synthesis reaction, so that the synthesis reaction can be carried out at close to normal pressure, and the raw material gas can enter the synthesis reactor without being compressed, so the required energy consumption is extremely low, and it also has selectivity Good and easy to control the reaction speed, input the raw material gas of the corresponding target product and select the corresponding catalytic electrode or catalyst to produce methanol, dimethyl ether, synthetic ammonia and other chemical products.

Owner:衢州市广源生活垃圾液化技术研究所

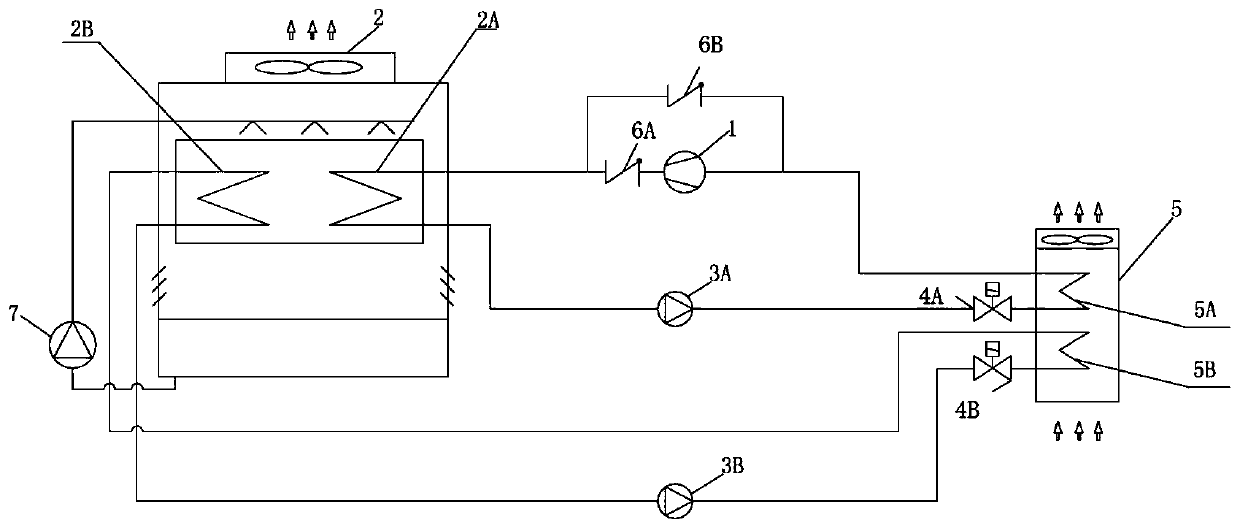

Double-circuit natural cooling type air conditioning system and control method thereof

PendingCN111426105AReduce cooling pressureTake advantage ofMechanical apparatusCompression machines with several evaporatorsFree coolingEngineering

The invention discloses a double-circuit natural cooling type air conditioning system and a control method of the double-circuit natural cooling type air conditioning system. The air conditioning system comprises a refrigeration / natural cooling circuit and a natural cooling circuit. The refrigeration / natural cooling circuit comprises a compressor, a first evaporative condenser, a first refrigerant pump, and a first evaporator. An inlet of the first evaporative condenser communicates with an outlet of a compressor. An inlet of the compressor communicates with an outlet of the first evaporator. An outlet of the first evaporative condenser communicates with an inlet of the first evaporator through a first refrigerant pump. The natural cooling circuit comprises a second evaporative condenser, a second refrigerant pump and a second evaporator. An inlet of the second evaporative condenser communicates with an outlet of the second evaporator. Evaporator proportions and the size of the compressor can be configured according to specific application environment, so that the system cost is reduced, and meanwhile, natural cold sources are fully utilized to improve energy efficiency.

Owner:CLIMAVENETA CHATUNION REFRIGERATION EQUIP SHANGHAI

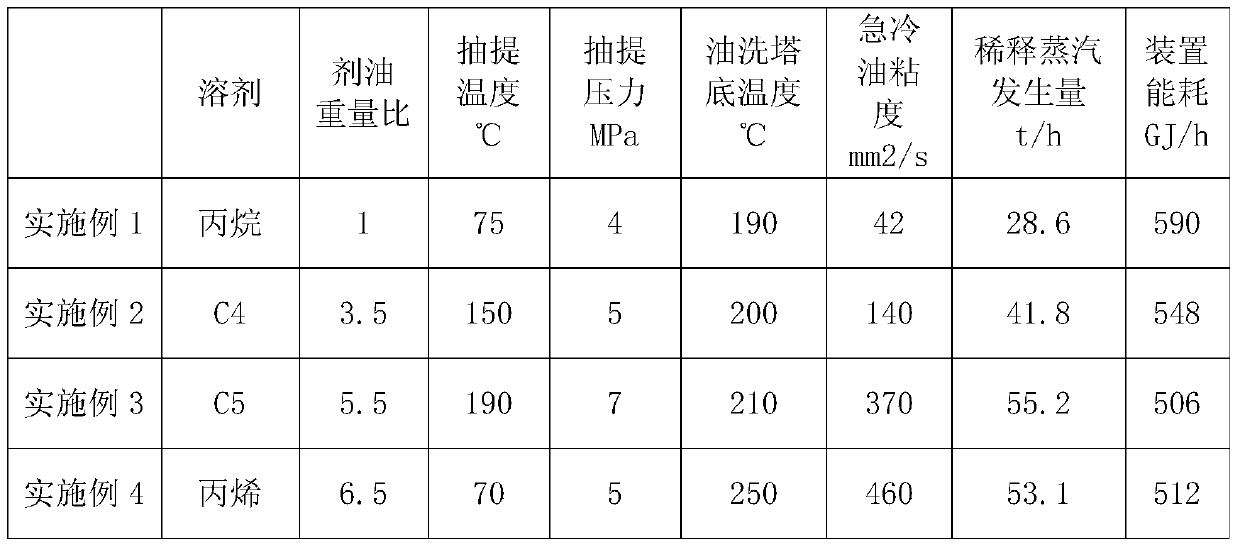

A method for reducing energy consumption of ethylene plant

ActiveCN105567295BReduce material consumptionLow viscosityThermal non-catalytic crackingHydrocarbon by hydrocarbon crackingComing outSolvent

The invention discloses a method for reducing energy consumption of an ethylene device; the method is characterized in that cracked gas coming out of a cracking furnace outlet is cooled by a quench cooler, then is sent into an oil washing tower and is subjected to substance separation, quench oil is led out from the tower bottom of the oil washing tower, and a part of the quench oil is sent to the quench cooler; a part of the quench oil returns to the oil washing tower; a part of the quench oil enters an extraction tower and is extracted by a solvent, a material at the tower top of the extraction tower returns to the oil washing tower, and an asphalt phase of a material at the tower bottom of the extraction tower is led out.

Owner:CHINA PETROLEUM & CHEM CORP +1

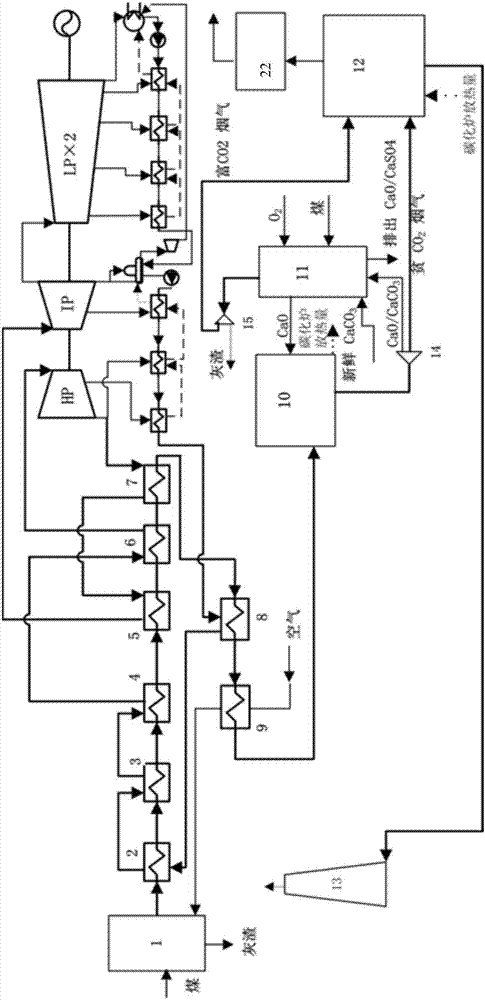

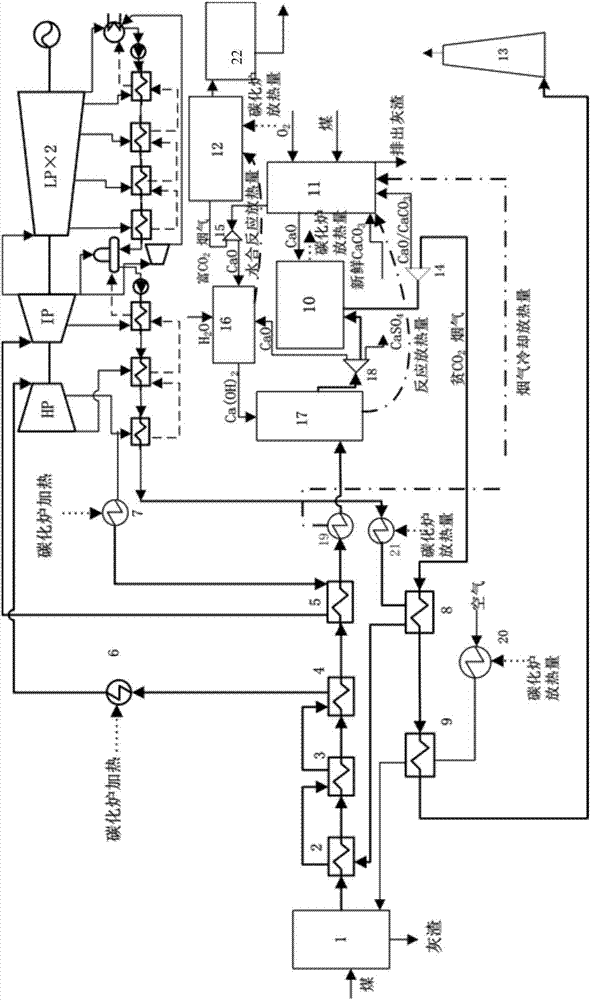

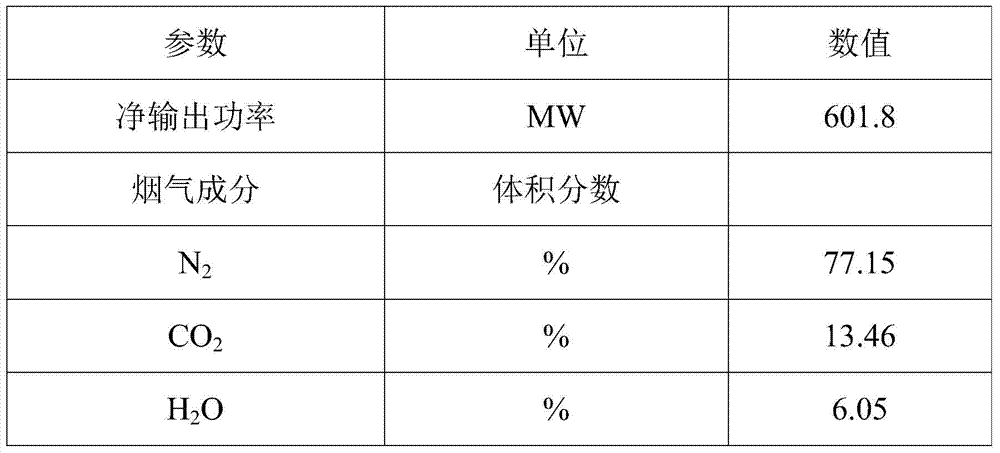

Coal-fired power generation system deeply integrated with calcium-based absorbent sequential desulfurization and decarbonization system

ActiveCN105485701BRealize energy complementarityReduce calcination energy consumptionFeed water supplyEnergy industryAir preheaterVulcanization

The invention relates to a coal-fired power generation system deeply and integrally provided with a system for desulfurizing and decarburizing a calcium-based sorbent in sequence. A heat source of a finishing superheater and a heat source of a low-temperature reheater are replaced with heat discharged from a carbide furnace, high-temperature smoke of an outlet of a high-temperature reheater outlet of an original standard system is cooled through a first heat exchanger and then directly enters a vulcanization reactor to be desulfurized, and CaSO4 is discharged; the heat discharged due to heat exchange of the first heat exchanger and heat discharged from a reaction in a sulfuration reactor are used for heating a calcinator; and remaining CaO after desulfurizing is conducted and inactivated CaO discharged from the calcinator are recovered and enter a hydration reactor to be subjected to hydrate activation and then enter a desulfurizing circulation, the desulfurized smoke enters the carbide furnace to be decarburized, waste heat of the smoke with lean CO2 of an outlet of the carbide furnace is recovered through an economizer and an air preheater, partial heat discharged from the carbide furnace is provided to heat the economizer and the air preheater to maintain the design parameters of an original power plant unchanged, the heat discharged from the hydration reactor and remaining heat after the heat load is replaced with the carbide furnace are recovered by a waste heat boiler module to be used for generating steam for acting.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

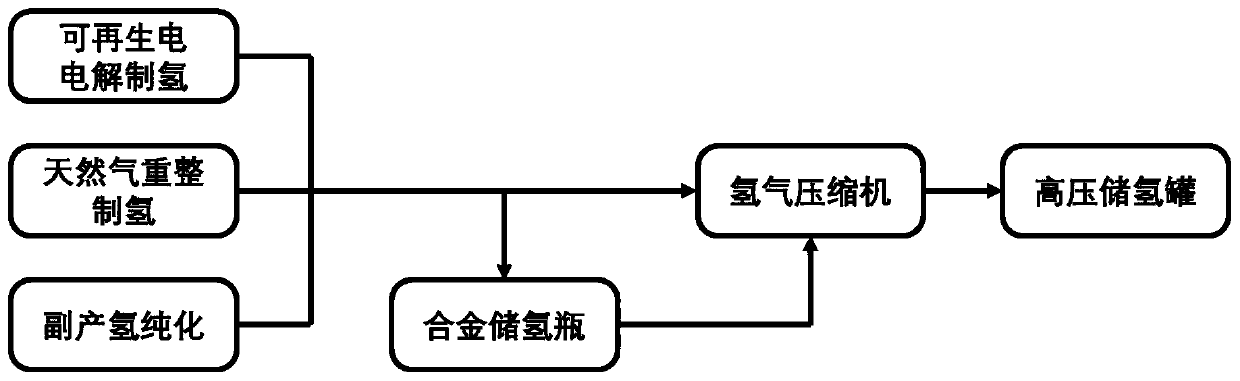

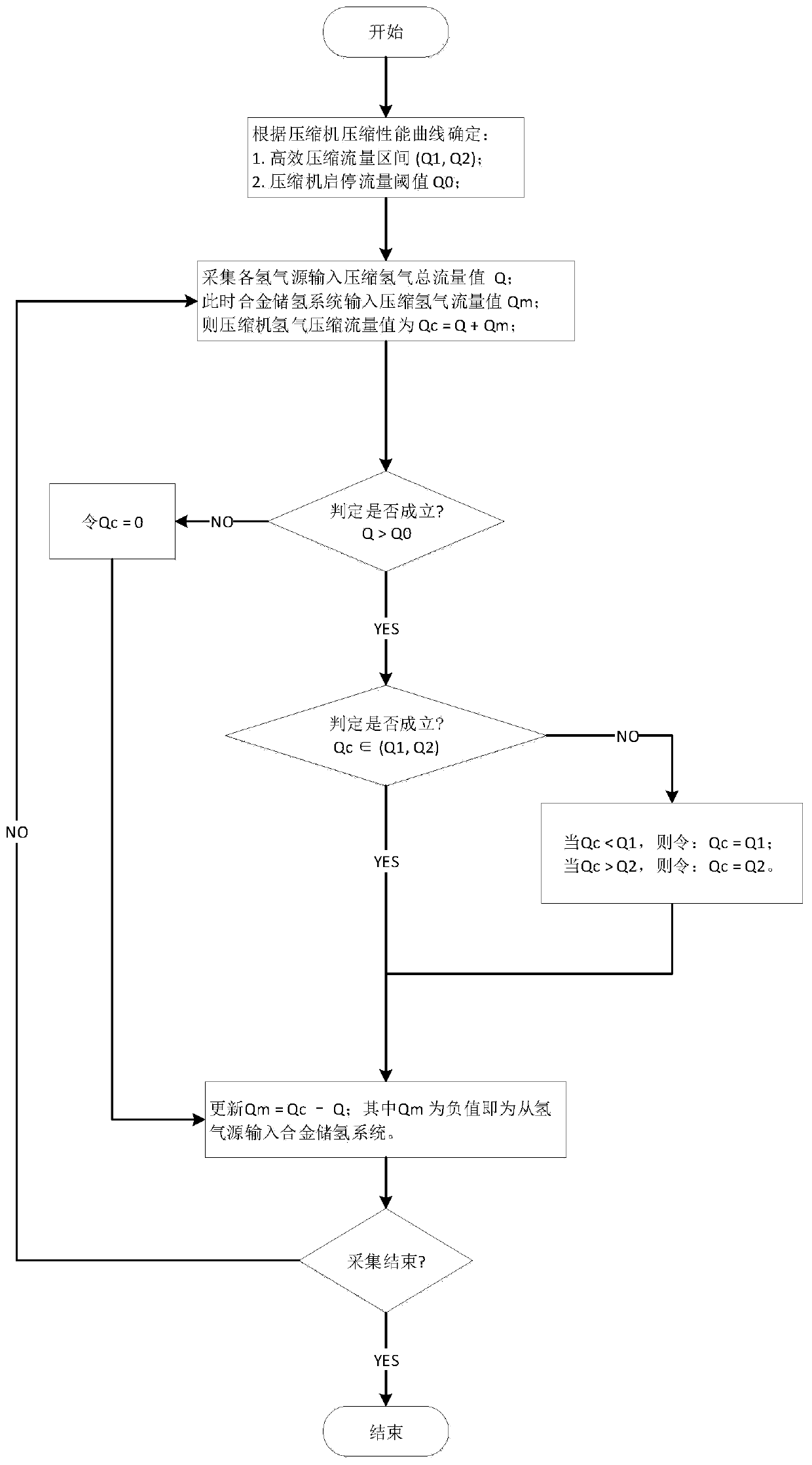

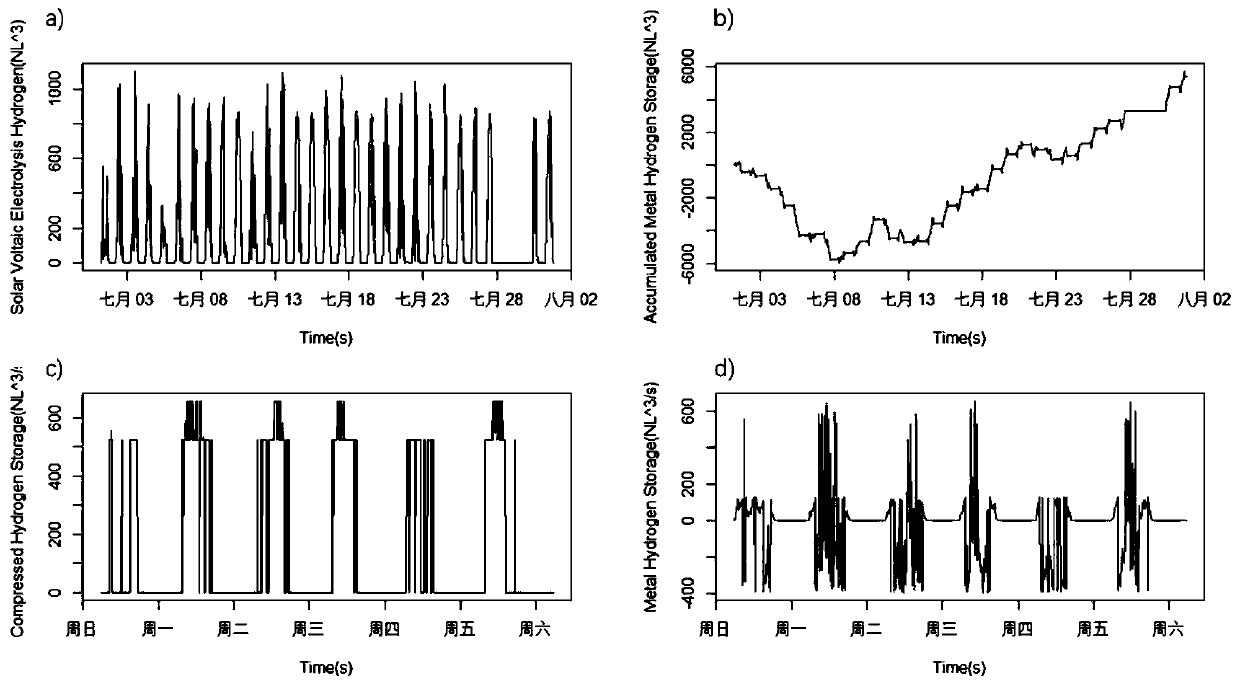

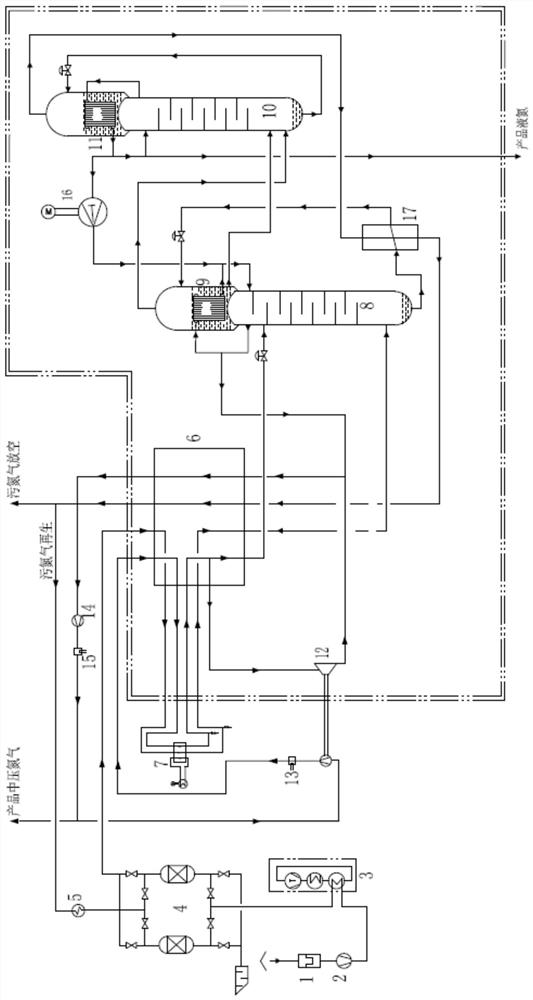

Small-scale low-energy-consumption stepped hydrogen storage system and method

ActiveCN110425416AEfficient storageStable storageFluid transferredFluid handledSystems designHydrogen compression

The invention relates to a small-scale low-energy-consumption stepped hydrogen storage system. A hydrogen source, an alloy hydrogen storage system and a high-pressure hydrogen storage system are included. The hydrogen source is arranged at the input end of a hydrogen pipeline. The hydrogen pipeline is connected with the high-pressure hydrogen storage system. The high-pressure hydrogen storage system comprises a classified hydrogen compressor and a classified high-pressure hydrogen storage tank. The hydrogen pipeline is provided with a branch, the branch is provided with the alloy hydrogen storage system, and the output end of the alloy hydrogen storage system is connected to the hydrogen compressor of the high-pressure hydrogen storage system. The small-scale low-energy-consumption steppedhydrogen storage system has the beneficial effects that through the small-scale low-energy-consumption stepped hydrogen storage system, for the hydrogen source large in flow fluctuation, the method that the hydrogen storage energy consumption is reduced through the stepped hydrogen storage system is utilized, through alloy hydrogen storage, high-pressure hydrogen storage and other hydrogen storage technologies, the stepped hydrogen storage strategy is implemented, hydrogen compression energy consumption is reduced, system design redundancy is reduced, and small-scale efficient and stable hydrogen storage is achieved. The method and the strategy are safe, reliable, efficient, stable, economical and practical.

Owner:ZHEJIANG ZHENENG TECHN RES INST

A Low Energy Consumption Medium Pressure Nitrogen Production Process

ActiveCN111141110BEasy to separateHigh extraction rateSolidificationLiquefactionMolecular sieveProcess engineering

The invention discloses a process for producing medium-pressure nitrogen with low energy consumption. The devices required for the production include filters, turbine air compressors, air pre-cooling units, molecular sieve adsorbers used alternately, electric heaters, and main heat exchangers. Refrigerator, cryogenic refrigerator, rectification column I, main condensing evaporator I, rectifying column II, main condensing evaporator II, booster turboexpander, booster turboexpander booster aftercooler, circulating nitrogen pressure machine, circulating nitrogen compressor aftercooler, liquid nitrogen pump, subcooler. Using the process of the invention to produce medium-pressure nitrogen has high extraction rate and low device energy consumption.

Owner:HANGZHOU TURNING ENERGY TECH DEV CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com