Hydrogen and natural gas combined liquefaction system and process

A natural gas and hydrogen technology, applied in the field of hydrogen and natural gas combined liquefaction system, can solve the problems of low liquefaction efficiency and high cost, and achieve the effects of improving the environment, compact structure and reducing carbon emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

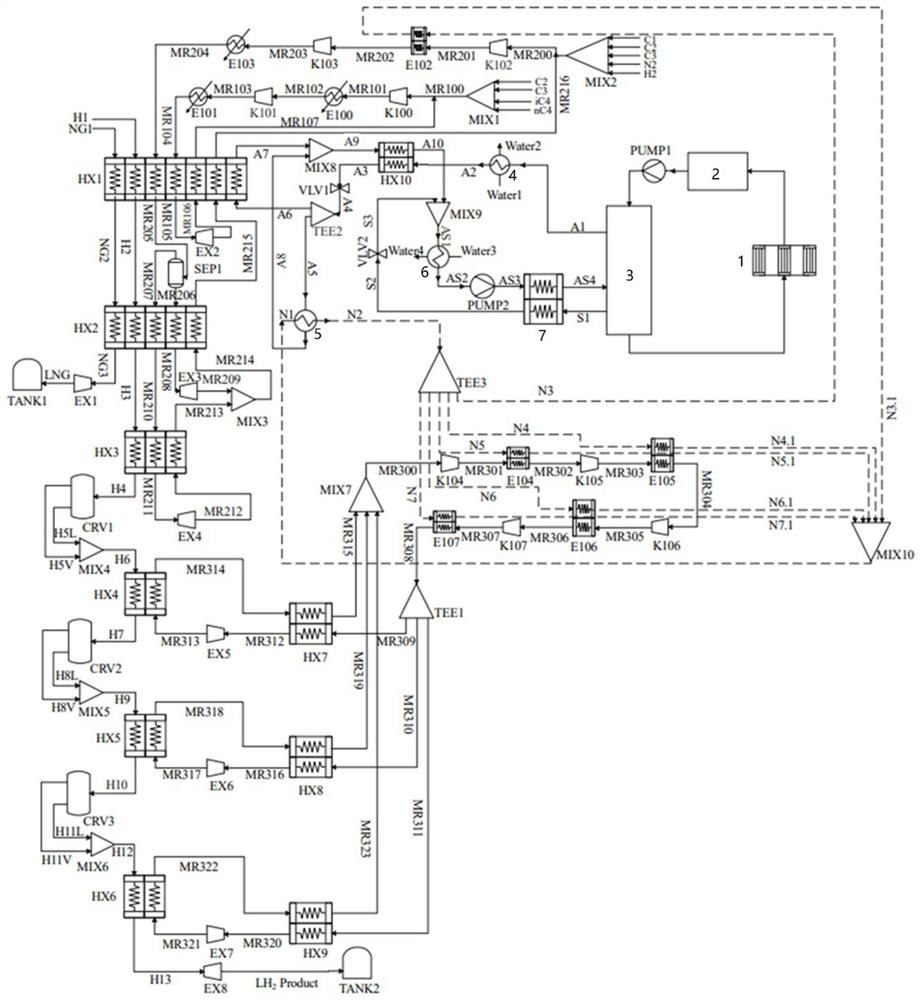

[0084] This embodiment provides a combined liquefaction system for hydrogen and natural gas, the structure of which is as follows figure 1 shown.

[0085] The system includes: DMR pre-cooling unit, solar absorption refrigeration unit, J-B cryogenic unit, expansion liquefaction unit, natural gas liquefaction pipeline, and hydrogen liquefaction pipeline; wherein,

[0086] The DMR pre-cooling unit includes a series-connected primary countercurrent heat exchanger HX1, secondary countercurrent heat exchanger HX2, tertiary countercurrent heat exchanger HX3, second expander EX2, gas-liquid separator SEP1, and third expander EX3 , the third mixer MIX3, the fourth expander EX4, the first Brayton cycle and the second Brayton cycle in series;

[0087] The first-stage countercurrent heat exchanger HX1 is provided with seven flow passages, the second-stage countercurrent heat exchanger HX2 is provided with five flow passages, and the third-stage countercurrent heat exchanger HX3 is provid...

Embodiment 2

[0134] This embodiment provides a combined liquefaction process of hydrogen and natural gas, which is carried out by using the system provided in Embodiment 1, and specifically includes the following steps:

[0135] The refrigeration cycle of the DMR pre-cooling unit includes the following process steps:

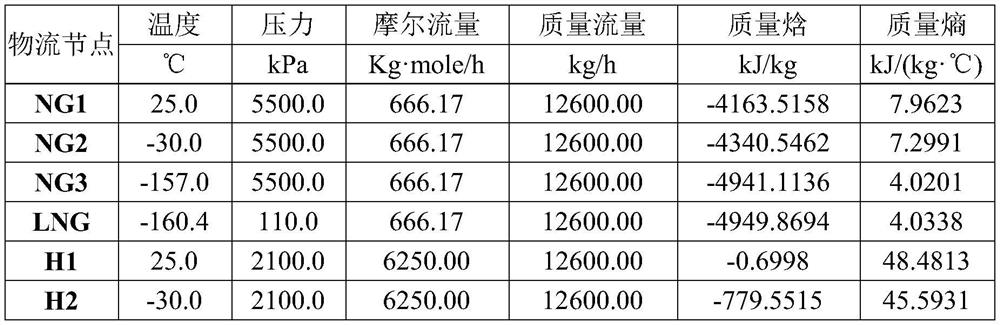

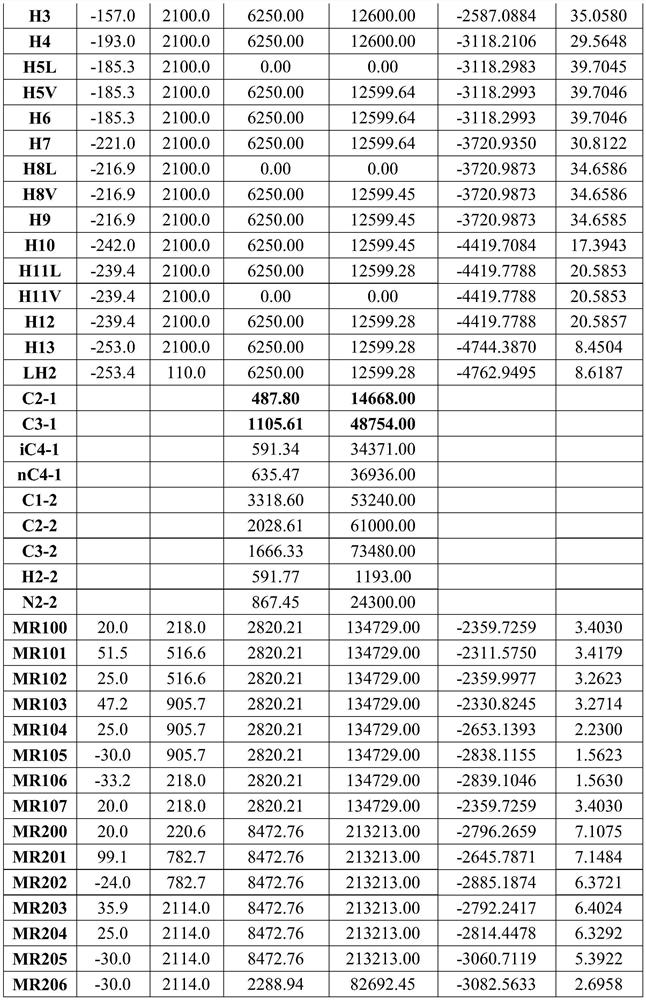

[0136] The DMR precooling unit consists of two independent mixed refrigerant (MR1 and MR2) Brayton cycles in series, which together provide cold energy for precooling and subcooling natural gas and precooling hydrogen. The inner cycle MR1 and the outer cycle MR2 use different mixed refrigerants respectively. The MR1 refrigerant (ie the first refrigerant) is composed of 17.3% C2 , 39.2%C 3 , 20.97% iC 4 and 22.53% nC 4 Composition (molar percent), MR2 refrigerant (ie, the second refrigerant) consists of 39.17% C 1 , 23.94%C 2 , 19.67%C 3 , 10.24%N 2 and 6.98%H 2 Composition (mol%);

[0137] The MR1 circulating refrigerant (MR100) is first pressurized to 9.057bar by th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com