Integrated hydrogenation method for producing clean diesel

A diesel and clean technology, applied in hydrotreating process, petroleum industry, processing of hydrocarbon oil, etc., can solve the problems of high hydrogen consumption and high processing cost, and achieve the effect of reducing gas-liquid flow, good quality and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

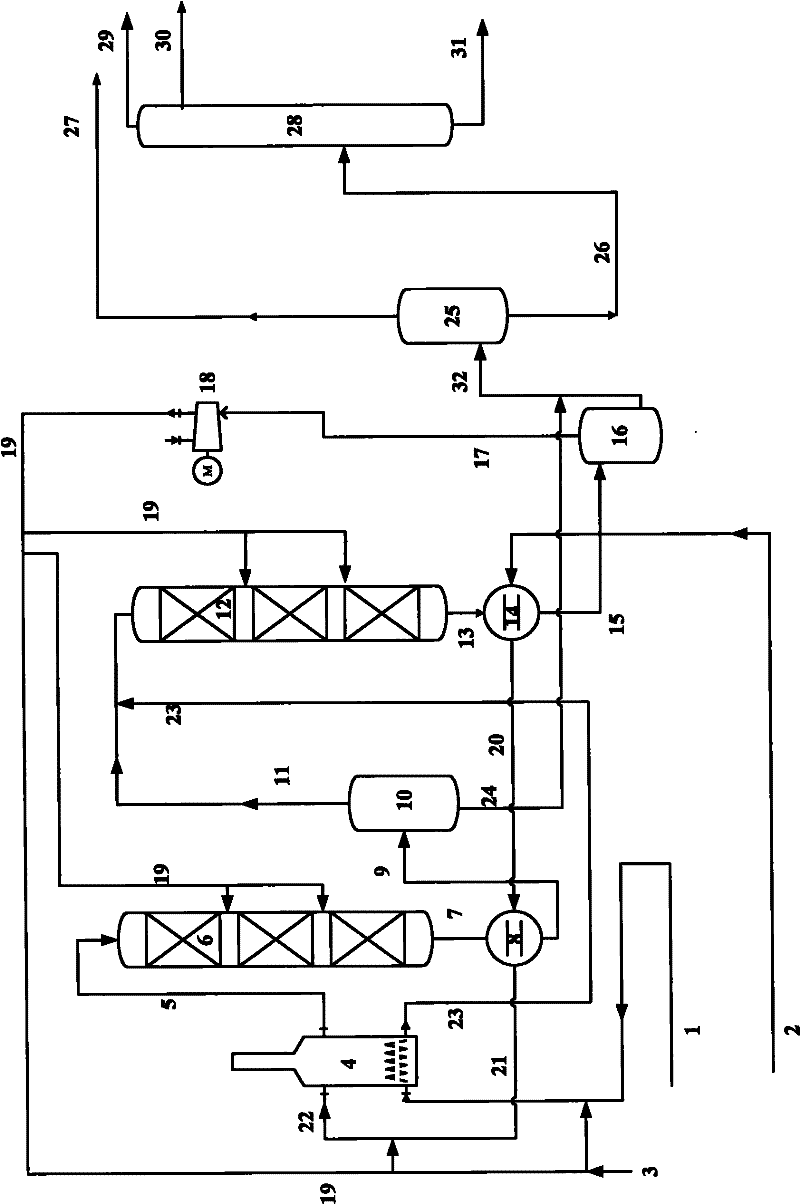

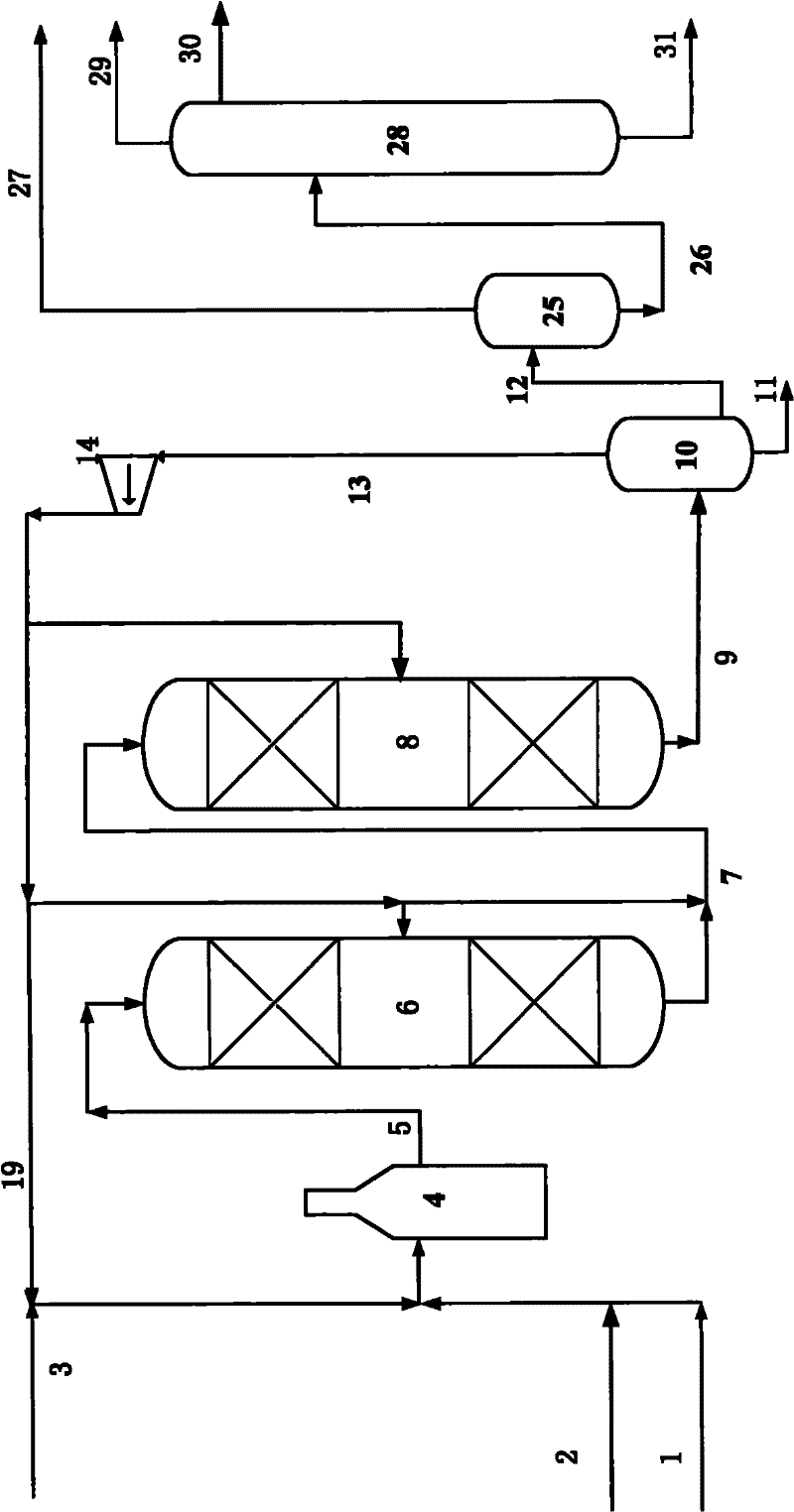

Method used

Image

Examples

Embodiment 1

[0042] The process method of the present invention is used to process high-sulfur and high cetane number straight-run diesel fuel A and low cetane number catalytic diesel raw material A on a medium-sized test device. The first reactor is filled with RG-1 / RS-1000 catalyst with a filling volume ratio of 15:140. The second reactor is filled with RG-1 / RS-1000 / RIC-2 catalyst, and the filling volume ratio is 20:125:65.

[0043] Table 1 Properties of raw materials for high-sulfur, high-cetane number direct firewood and low-cetane number fuelwood

[0044] Analysis Project

Zhichai raw material A

Density (20℃) / (g / cm 3 )

0.8356

0.9625

Sulfur content / (μg / g)

11000

6200

Nitrogen content / (μg / g)

97

252

Freezing point / ℃

-12

-34

Measured cetane number

54.8

19.3

Distillation range (ASTM D-86) / ℃

IBP / 5%

180 / 214

160 / 211

10% / 20%

228 / 246

222 / 235

30% / 50%

260 / 283

245 / 262

70% / 80%

311 / 326

290 / 304

90% / FBP

347 / 376

3...

Embodiment 2

[0050] The process method of the present invention is used to process coking diesel B with high sulfur content and higher cetane number and fuelwood B with low cetane number on a medium-sized hydrogenation test device. The first reactor is filled with RG-1 / RS-1000 catalyst with a filling volume ratio of 15:140. The second reactor is filled with RG-1 / RS-1000 / RIC-2 catalyst, and the filling volume ratio is 20:125:65.

[0051] Table 4 High cetane number coke firewood and low cetane number firewood raw materials properties

[0052] Analysis Project

Coke wood raw material B

Firewood raw material B

Density (20℃) / (g / cm 3 )

0.8394

0.8808

Sulfur content / (μg / g)

625

1100

Nitrogen content / (μg / g)

1358

512

Freezing point / ℃

-10

-16

Measured cetane number

44.1

33.0

Distillation range (ASTM D-86) / ℃

IBP / 5%

190 / 206

189 / 211

10% / 20%

215 / 226

225 / 242

30% / 50%

235 / 253

259 / 289

70% / 80%

288 / 306

321 / 337

90% / FBP

328 / 361

353 / 372

[0053] Ta...

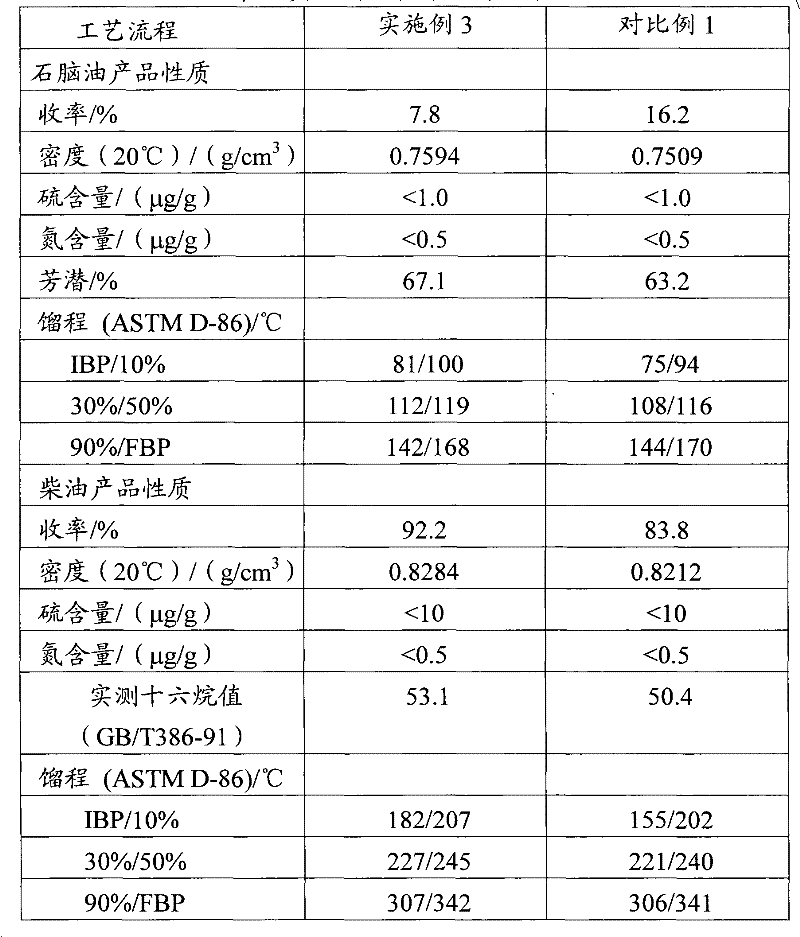

Embodiment 3

[0058] The process method of the present invention is used to process high-sulfur high-cetane number straight-run diesel oil C and low cetane number catalytic diesel raw material C on a medium-sized hydrogenation test device. The first reactor is filled with RG-1 / RS-1000 catalyst with a filling volume ratio of 15:140. The second reactor is filled with RG-1 / RS-1000 / RIC-2 catalyst, and the filling volume ratio is 20:125:65.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com