Coal combustion apparatus capable of separating carbon dioxide and separation method thereof

A carbon dioxide and coal combustion technology, applied in chemical instruments and methods, heating devices, using non-combustion exothermic chemical reactions to generate heat, etc. time, improve the processing capacity, strengthen the coal gasification reaction and the effect of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

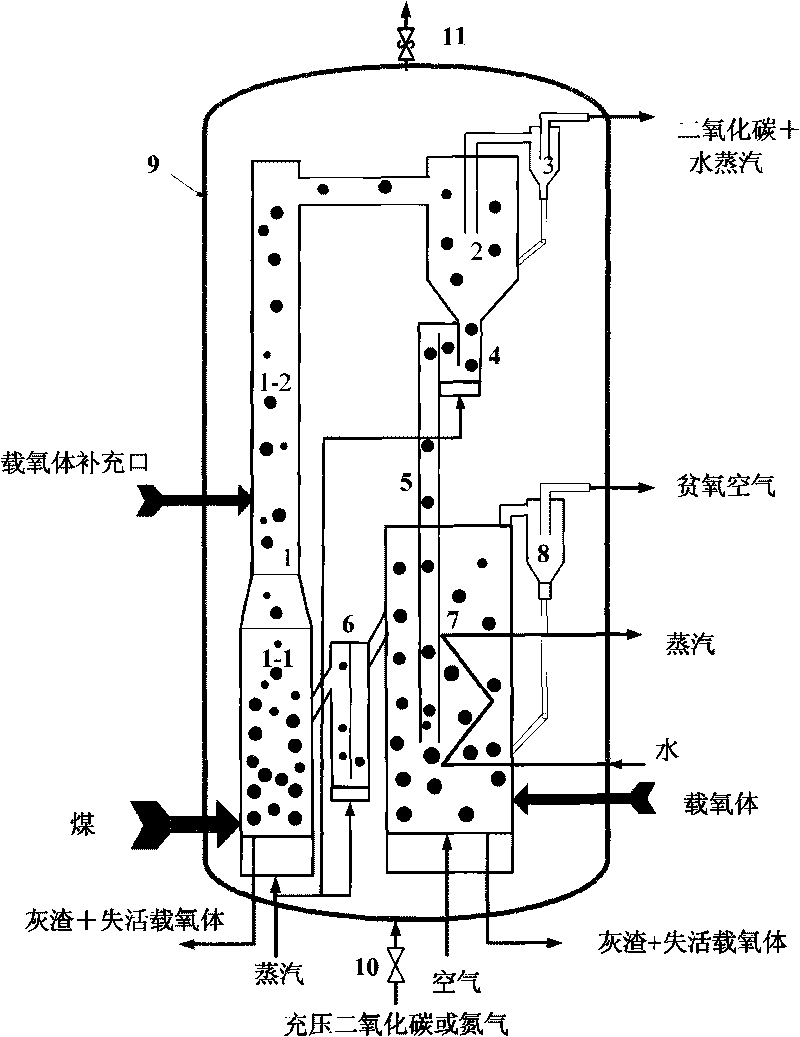

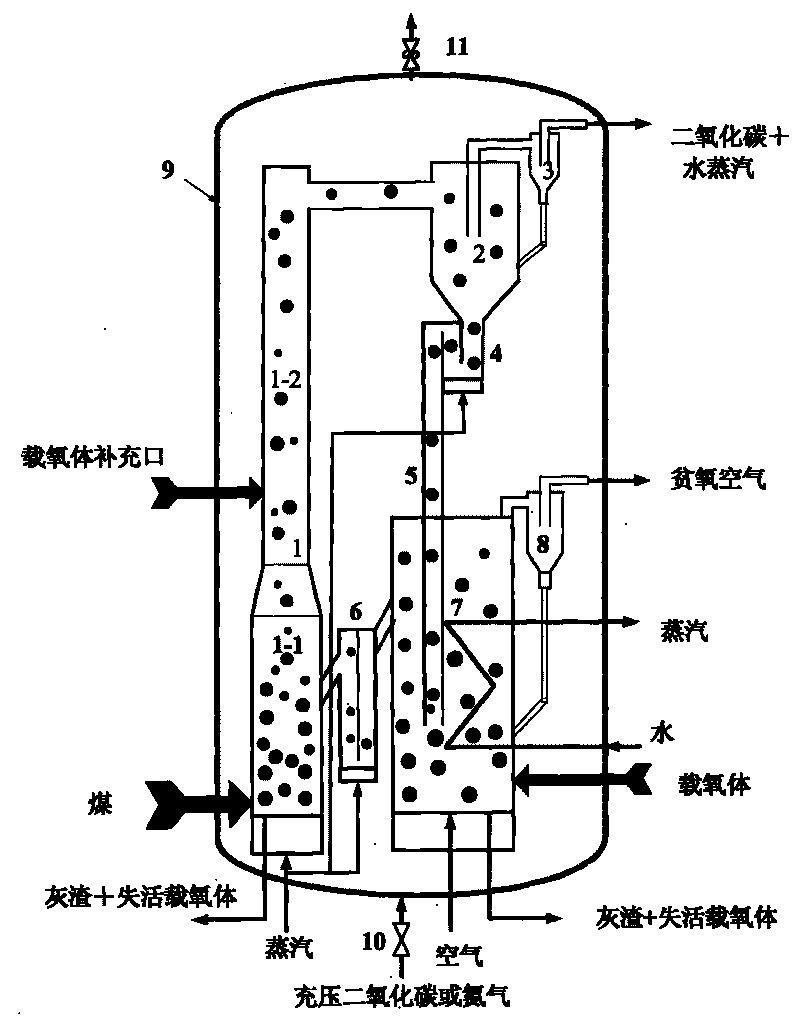

[0031] Such as figure 1 As shown, a coal combustion device capable of separating carbon dioxide is mainly composed of a fuel reactor 1, a primary cyclone separator 2, a dipleg 5 and an air reactor 7 connected in series, and it uses two independent reactors: the fuel reactor 1 and the air reactor 7, the lower part of the fuel reactor is a mixing chamber 1-1 with a large cross-section, and the upper part is a riser 1-2 with a small cross-section, and the height of the riser is more than three times that of the mixing chamber;

[0032] The whole system is arranged in a pressure shell 9 , and the pressure shell 9 is provided with a pressure charging valve 10 and a pressure relief valve 11 for adjusting the pressure in the pressure shell 9 .

[0033] The side outlet of the fuel reactor 1 is connected to the side inlet of the primary cyclone separator 2, and the upper part of the primary cyclone separator 2 is a flue gas outlet connected to the side of the secondary cyclone separato...

Embodiment 2

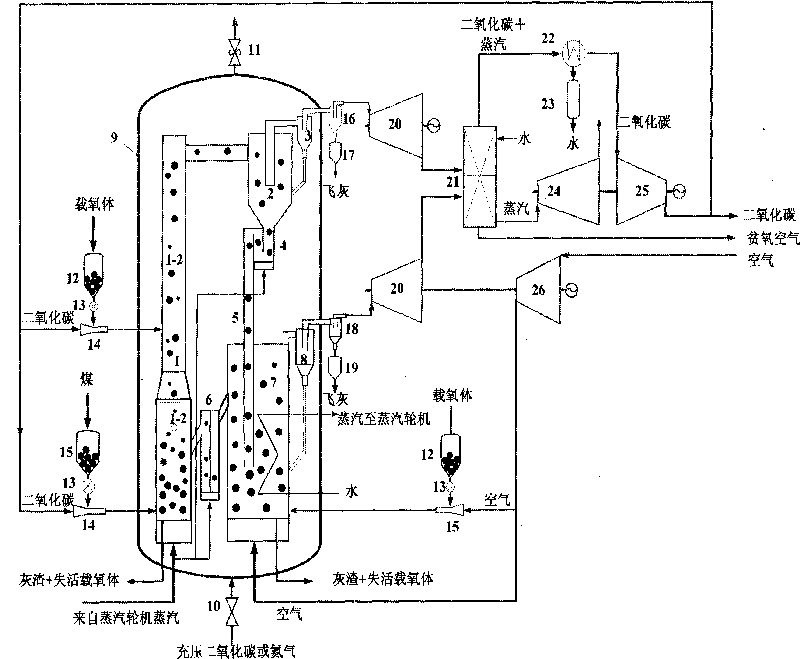

[0045] Such as figure 2 As shown, the power generation system using a coal combustion device that can separate carbon dioxide, the system consists of a coal combustion device that can separate carbon dioxide, an ash dust removal system, a coal and oxygen carrier feeding system, a flue gas turbine 20, a steam turbine 24, and an air compressor 26. Carbon dioxide compressor 25, waste heat boiler 21 and other components. The specific working method is as follows:

[0046] Coal is put into the coal tank 15, the feed valve 13 controls the amount of coal fed, and the recirculated carbon dioxide is sent to the mixing chamber 1-1 in the lower part of the fuel reactor by the conveying injector as conveying gas, and the coal particles are small particles in the range of 0-2mm , to facilitate pneumatic transportation and coal gasification reaction.

[0047] After the coal particles enter the mixing chamber 1-1, they are quickly mixed with the high-temperature bed material (mainly oxyge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com