Energy-saving compressor

A technology of compressors and throttle valves, which is applied in the field of new compressor cylinders, can solve the problems of large compression energy consumption, achieve the effects of reducing compression energy consumption, reducing production costs, and improving volumetric efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

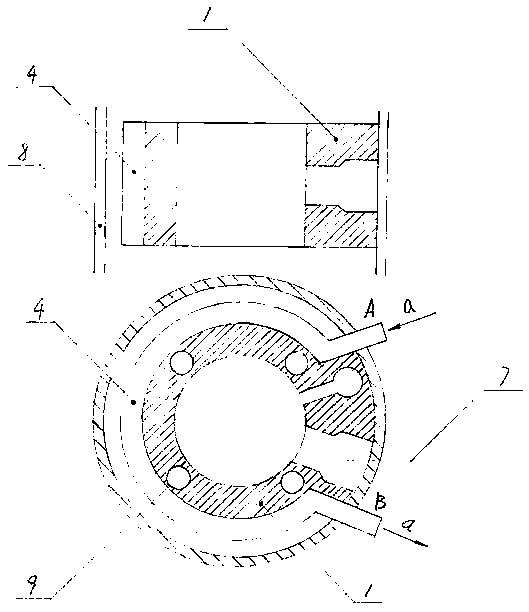

[0023] figure 1 What is shown is an embodiment in which an isothermal device is installed in the cylinder block of a rotor compressor: the isothermal device 4 is in the shape of a saddle, and is a flat hollow metal cavity, which is arranged on the outside of the cylinder block 1 . The refrigerant a enters the isothermal device 4 from port A. Since the temperature of the refrigerant a is equal to or lower than the suction temperature of the compressor, when the working temperature of the cylinder is higher than the suction temperature, the refrigerant a absorbs the heat of the cylinder body and reduces the working temperature of the cylinder, thereby making the compression The compression energy consumption of the machine is reduced. The refrigerant a carrying the heat of the cylinder flows out of the isothermal device 4 from port B.

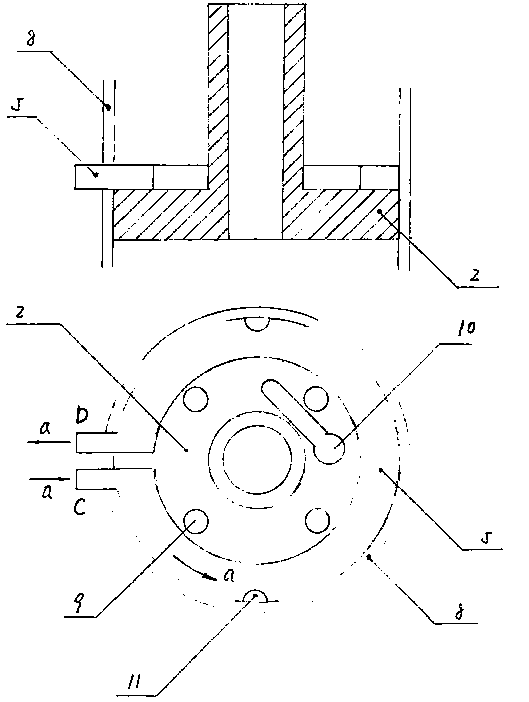

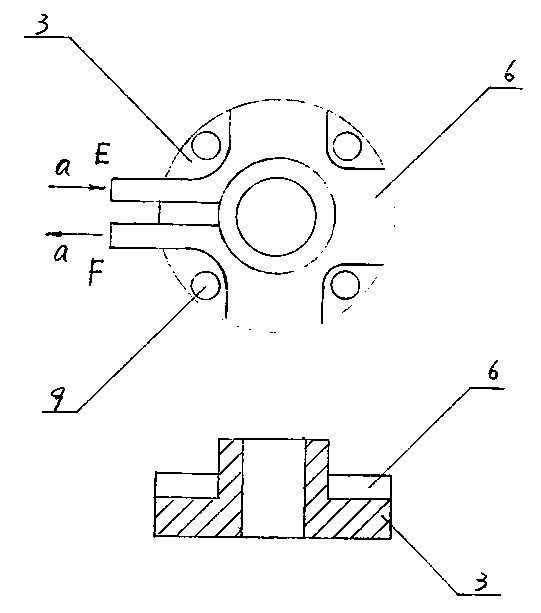

[0024] figure 2 What is shown is an embodiment in which an isothermal device is installed on the upper end cover of the cylinder of the ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com