Hydrogen separation membrane embedded improved copious cooling liquefying system aiming at STAR propane dehydrogenation process

A technology of propane dehydrogenation and separation membrane, applied in the field of petrochemical industry, can solve the problems of waste, high energy consumption of compression, etc., achieve the effect of reducing energy consumption of compression, reducing energy consumption of compression, and significant economic advantages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

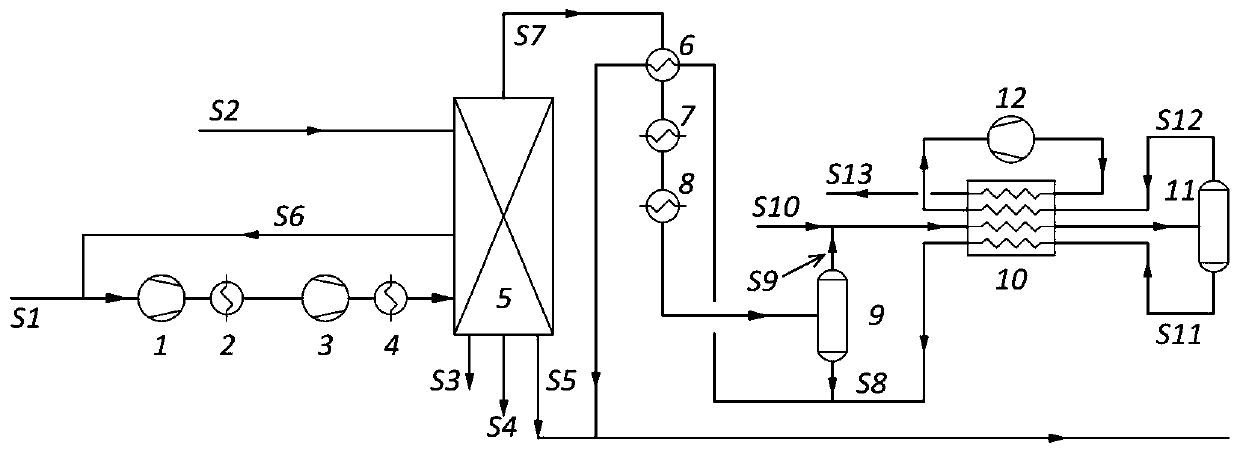

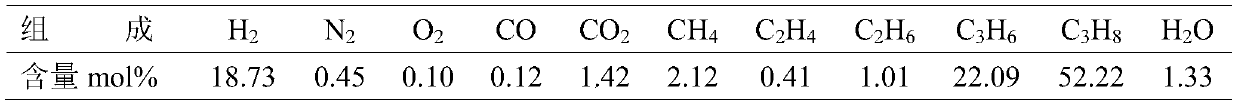

[0021] Example 1 For the propane dehydrogenation reaction product of a typical 350,000-ton STAR process of an enterprise, the traditional cryogenic liquefaction system is used for processing, and the corresponding technical scheme is described as follows:

[0022] Table 2 is a list of the composition and operating parameters of key materials in Example 1.

[0023]

[0024] The propane dehydrogenation reaction product S1 cooled to normal temperature enters the first cooler 2 after being pressurized to 1.40MPaG by the first compressor 1, then enters the second cooler 4 after being further pressurized to 3.20MPaG by the second compressor 3, Lower the temperature of the material to normal temperature, and then enter the decarburization / dehydration system 5. At the same time, the decarbonization absorbent S2 also enters the decarburization / dehydration system 5; in the decarburization / dehydration system 5, five streams of material output are generated, and the decarburization Abs...

Embodiment 2

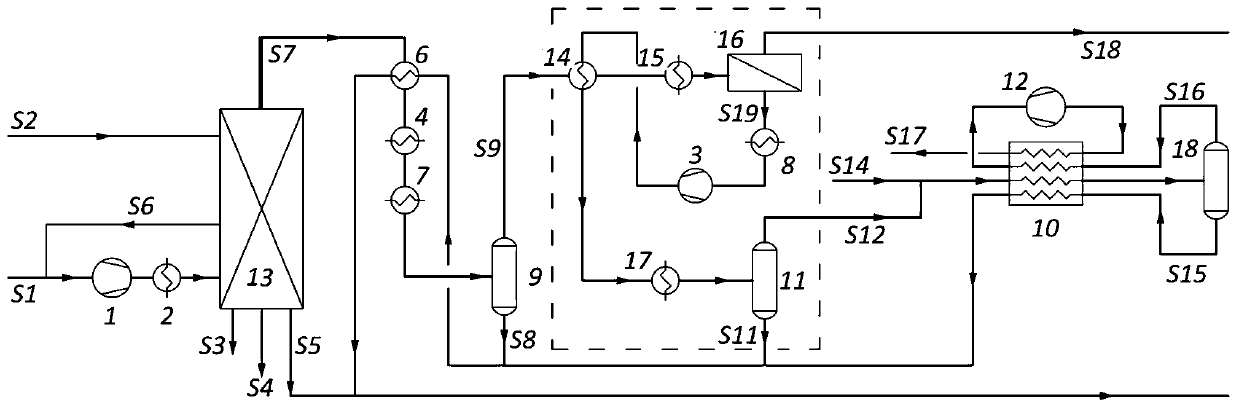

[0029] Embodiment 2 For the propane dehydrogenation reaction product of a typical 350,000-ton STAR process of a certain enterprise, the improved cryogenic liquefaction system embedded in the hydrogen separation membrane provided by the present invention is used for processing. The specific technical scheme is as follows:

[0030] Table 3 is a list of composition and operating parameters of key materials in Example 2.

[0031]

[0032] Such as figure 2 As shown, the propane dehydrogenation reaction product S1 cooled to normal temperature is pressurized to 1.90MPaG by the first compressor 1 and then enters the first cooler 2, the temperature is lowered to normal temperature, and then enters the decarburization / dehydration system 13, at the same time , the decarburization absorbent S2 also enters the decarburization / dehydration system 13; in the decarbonization / dehydration system 13, five streams of material output are produced, the decarbonization absorbent rich liquid S3 an...

Embodiment 3

[0040] Example 3 For the propane dehydrogenation reaction product of a typical 350,000-ton STAR process of an enterprise, the hydrogen separation membrane provided by the present invention is used to process the improved cryogenic liquefaction system. The specific technical scheme is as follows:

[0041] Table 5 is a list of composition and operating parameters of key materials in Example 3.

[0042]

[0043]

[0044] Such as figure 2 As shown, the propane dehydrogenation reaction product S1 cooled to normal temperature is pressurized to 2.30MPaG by the first compressor 1 and then enters the first cooler 2, the temperature is lowered to normal temperature, and then enters the decarburization / dehydration system 13, and at the same time , the decarburization absorbent S2 also enters the decarburization / dehydration system 13; in the decarbonization / dehydration system 13, five streams of material output are produced, the decarbonization absorbent rich liquid S3 and condense...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com