Method for adding rich oxygen in liquid waste treatment process

A technology for waste liquid treatment and oxygen enrichment, which is applied in the method of container discharge, oxidized water/sewage treatment, gas/liquid distribution and storage, etc. It can solve the problems of insufficient oxygen concentration and high energy consumption of compressors, and reduce energy consumption. , The effect of reducing the oxygen content of the compressed gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

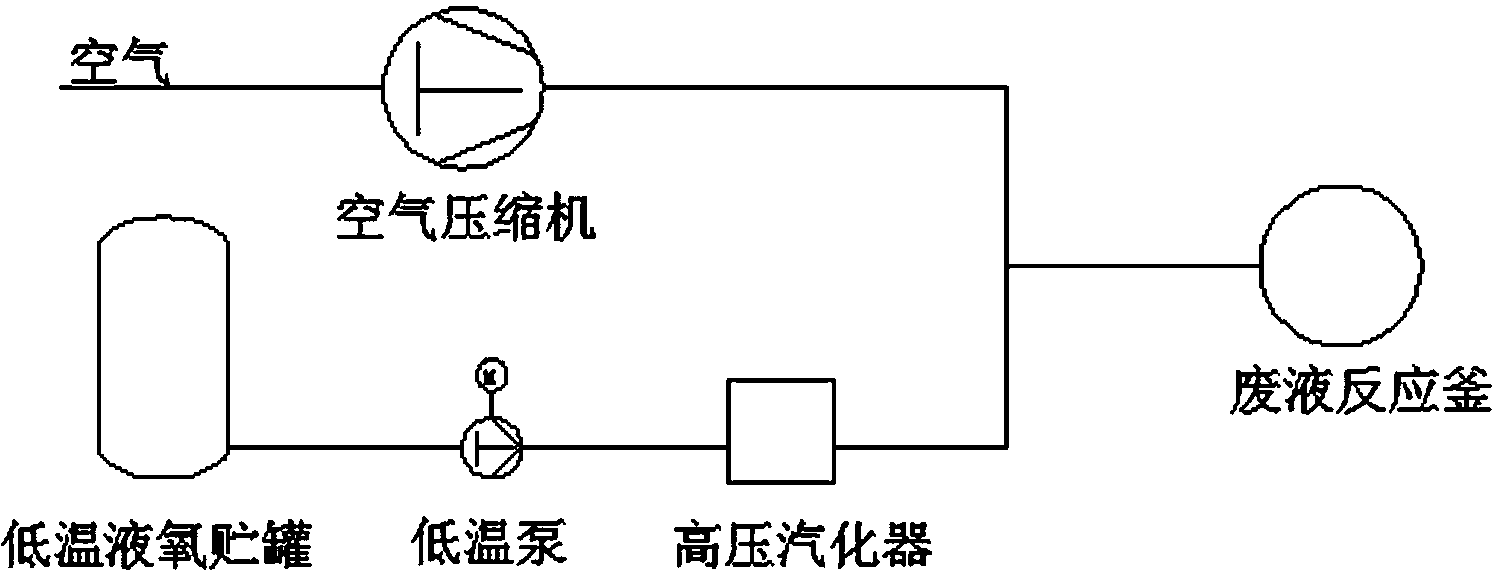

[0015] Such as figure 2 As shown, a method of adding oxygen enrichment in the waste liquid treatment process, the air is compressed by an air compressor to increase the pressure to 8~10MPa. The liquid oxygen stored in the cryogenic liquid storage tank is boosted by the cryogenic pump, and then vaporized into gas by the high-pressure vaporizer, and the pressure also reaches 8~10MPa. After the gasified oxygen and the compressed air are mixed in a certain proportion, the oxygen content reaches 30%~50%, and the mixed oxygen-enriched air enters the waste liquid reactor for use. The gasified oxygen is mixed with the compressed air in a certain ratio, and the mixing ratio is adjusted to meet the requirements by adjusting the rotation speed of the cryopump or adjusting the flow rate of the oxygen by a pneumatic valve.

[0016] For example: when the standard volume ratio of air and oxygen is 1:0.13, the oxygen content of the mixture is 30%, and when the standard volume ratio of air a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com