Patents

Literature

93results about How to "Controllable reaction speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for producing liquid calcium chloride by using industry waste acid

InactiveCN101254937AControllable reaction speedEliminate the pulping processCalcium/strontium/barium chloridesSpent acidAcid washing

The invention relates to a preparation method of liquid calcium chloride, in particular to a method for producing the liquid calcium chloride by using the waste industrial acid, which belongs to the technology field of chemical industry. The preparation method is characterized in allowing massive limestone and waste hydrochloric acid obtained by acid washing strip steel to react at a certain ratio and neutralizing with lime cream to obtain calcium chloride at a certain concentration. Proved by the production, the preparation method is capable of effectively reducing the production cost and achieving comprehensive utilization of the waste industrial acid and remarkable economic and social benefits.

Owner:KUNMING IRON & STEEL

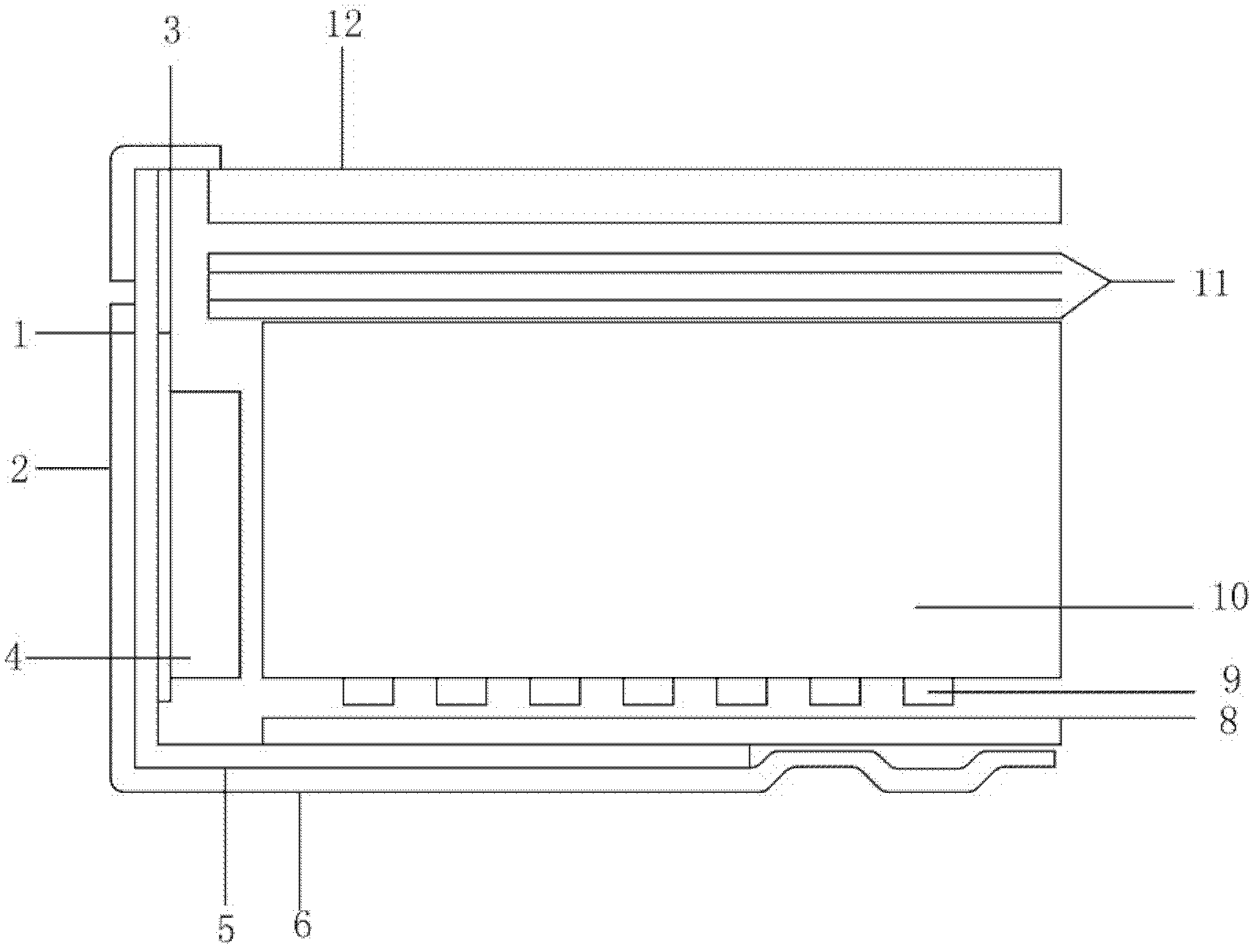

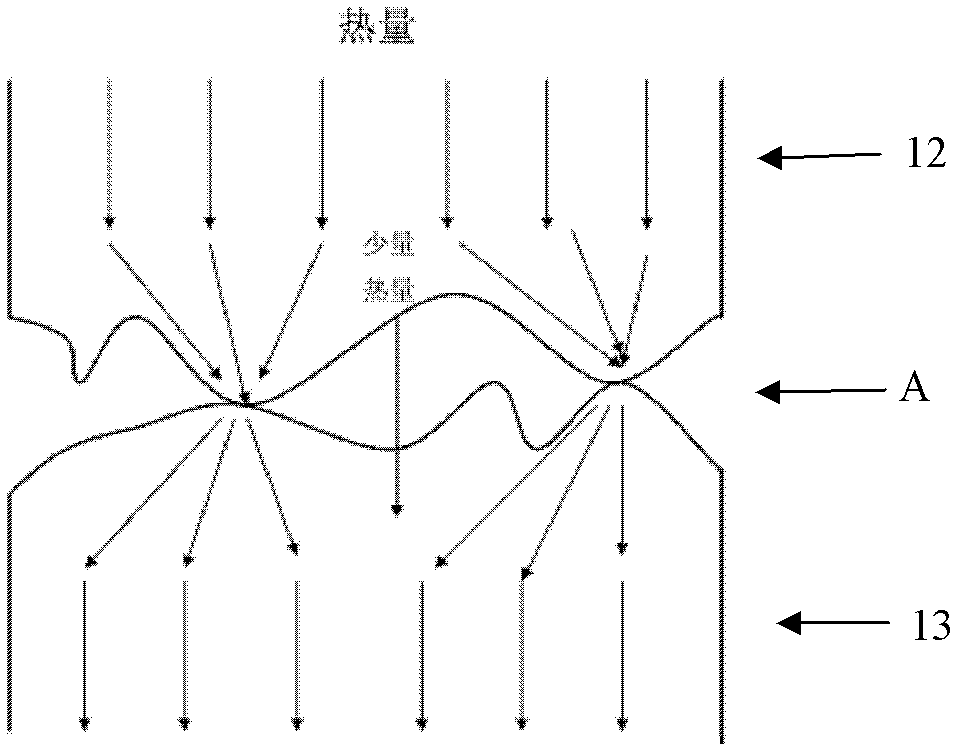

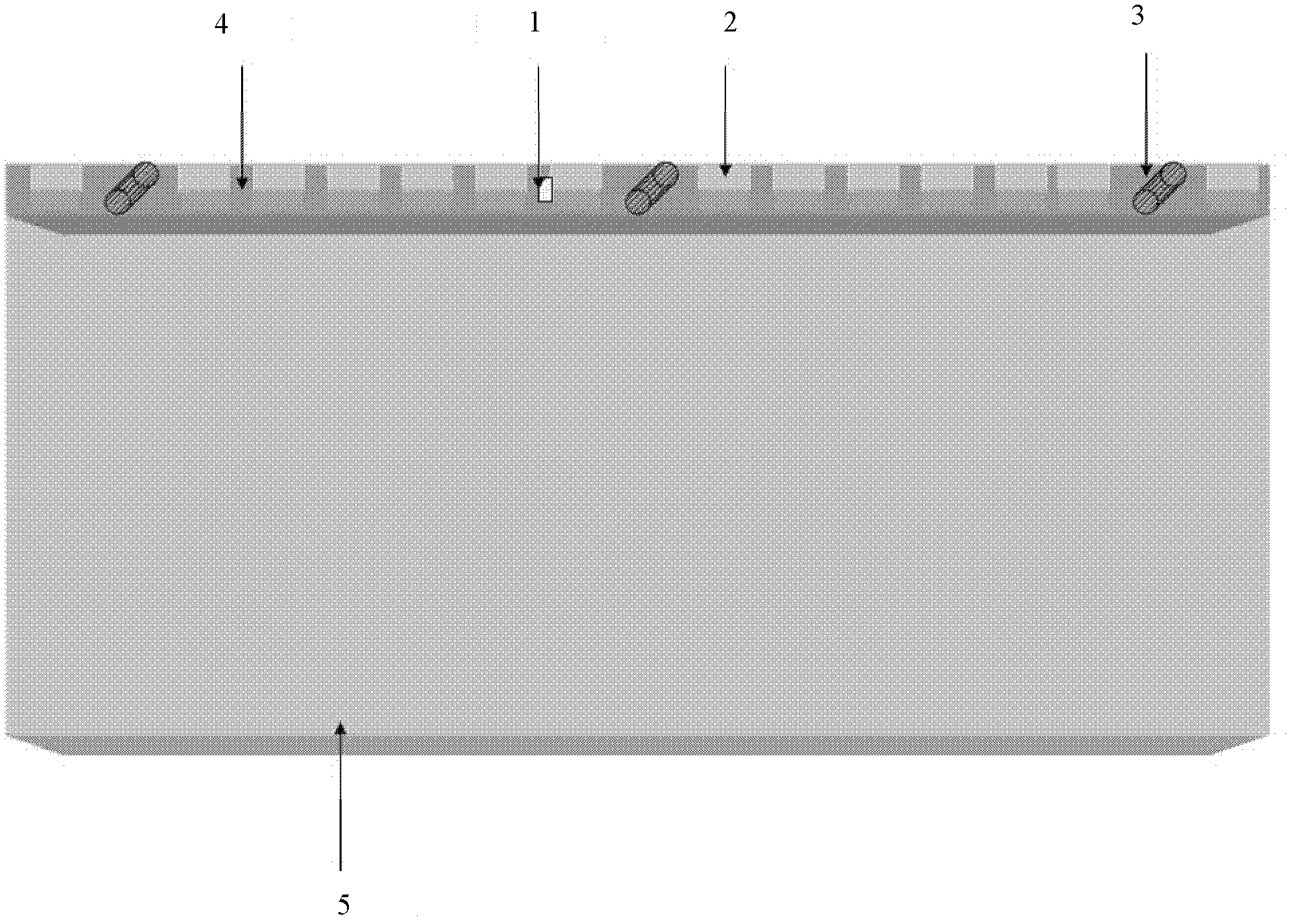

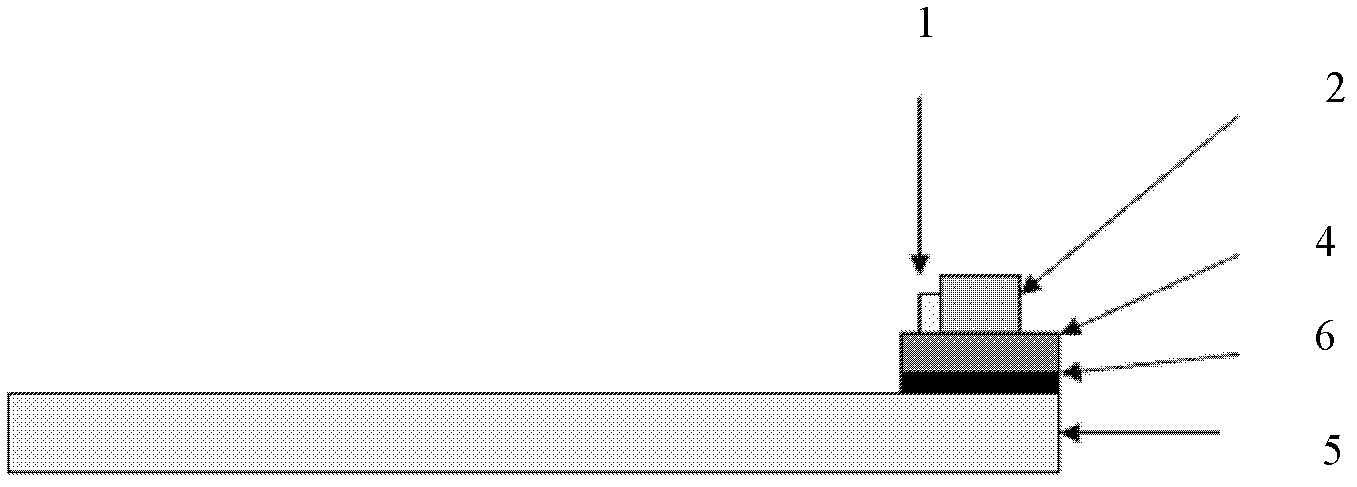

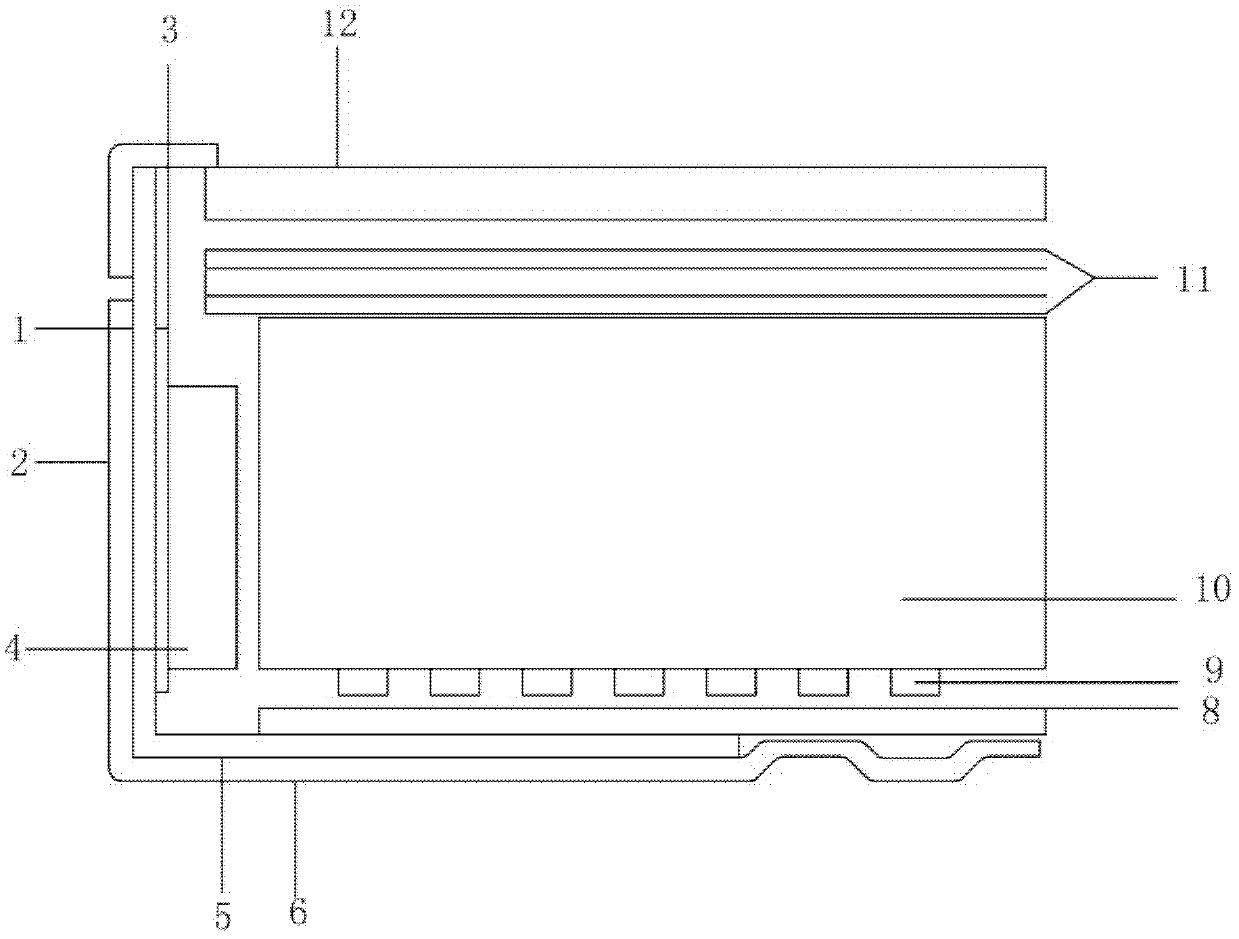

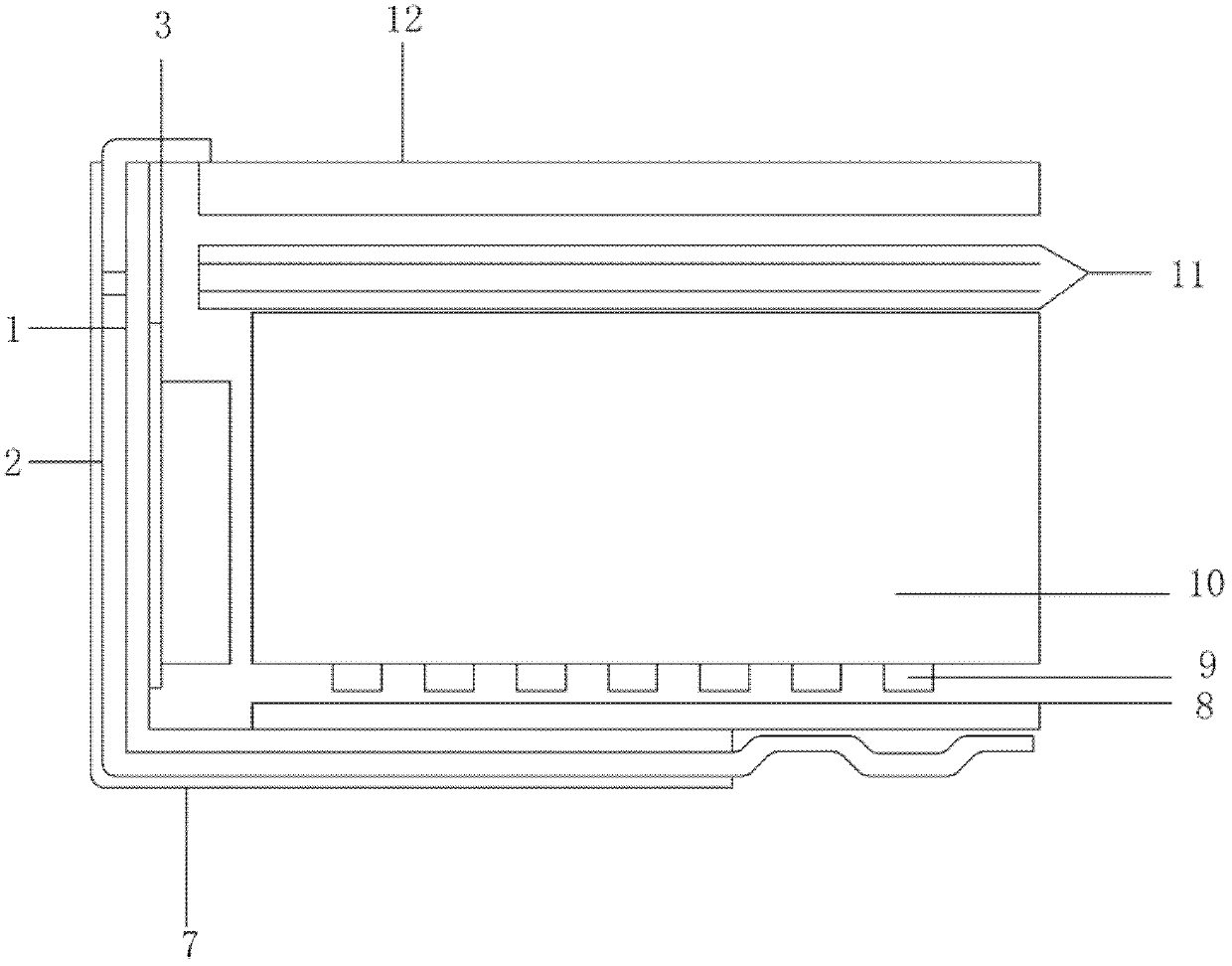

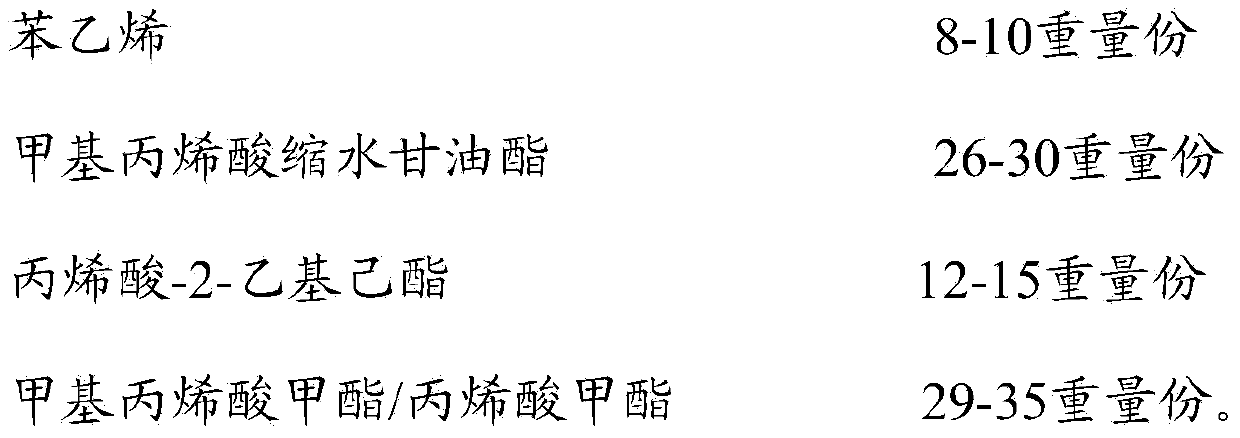

Modified acrylate heat-dissipation powder coating as well as preparation method and application thereof

ActiveCN102618141AExcellent heat transfer and cooling efficiencyReduced clusteringPoint-like light sourceLighting heating/cooling arrangementsSolventIn situ polymerization

The invention provides a modified acrylate heat-dissipation powder coating material which is prepared in a way that heat-dissipation agent is dispersed in a monomer solution, subjected to in-situ polymerization and then treated through desolventizing agent, wherein the weight ratio of the heat-dissipation agent to monomer is (1-25) to (7.5-9); the heat-dissipation agent comprises 82-90 percent of carbon fiber and 10-20 percent of nanometer material; and the monomer is one or more of styrene, methacrylic acid, glycidyl ester, acrylic acid-2-ethyl hexyl ester, methyl methacrylate and methyl acrylate. According to the invention, as the heat-dissipation coating material dispersed uniformly and added with the carbon fiber and nanometer material compound heat-dissipation particles is obtained by adopting solution in-situ polymerization, the heat transmission efficiency and the heat dissipation efficiency can be increased; and the heat-dissipation coating material can be coated as a heat-dissipation coating on the surface of a back plate of an LED LCM (liquid crystal model) to dissipate part of the heat generated by LEDs in a infrared radiation manner, so that the heat dissipation performance of the LED LCM is enhanced, and the heat dissipating capacity and the heat dissipation efficiency are improved in the same heat dissipation area.

Owner:HISENSE VISUAL TECH CO LTD

Method for polymerizing core-shell type aqueous polyurethane-polyacrylate (PUA) emulsion by in-situ radiation

The invention discloses a method for polymerizing core-shell type aqueous polyurethane-polyacrylate (PUA) emulsion by in-situ radiation, relating to the production method and process which are applied to textiles coating agent products. The method possesses the advantages of in-situ emulsion polymerization and radiation polymerization during product preparation process, solving the problems that the emulsifier and organic cosolvents existing in the current products pollute the environment, the products are poor in water resistance, the polymerization rate is hardly controlled, and the products are not stable among production batches, etc. The products have the following advantages of excellent water resistance, heat resistance, resistance to chemicals and wear resistance as well as low cost, availability for textile printing adhesion auxiliaries, emission without emulsifier and volatile organic solvents, and compliance with the requirements of environmental protection.

Owner:HEFEI JUHE RADIAL CHEM TECH

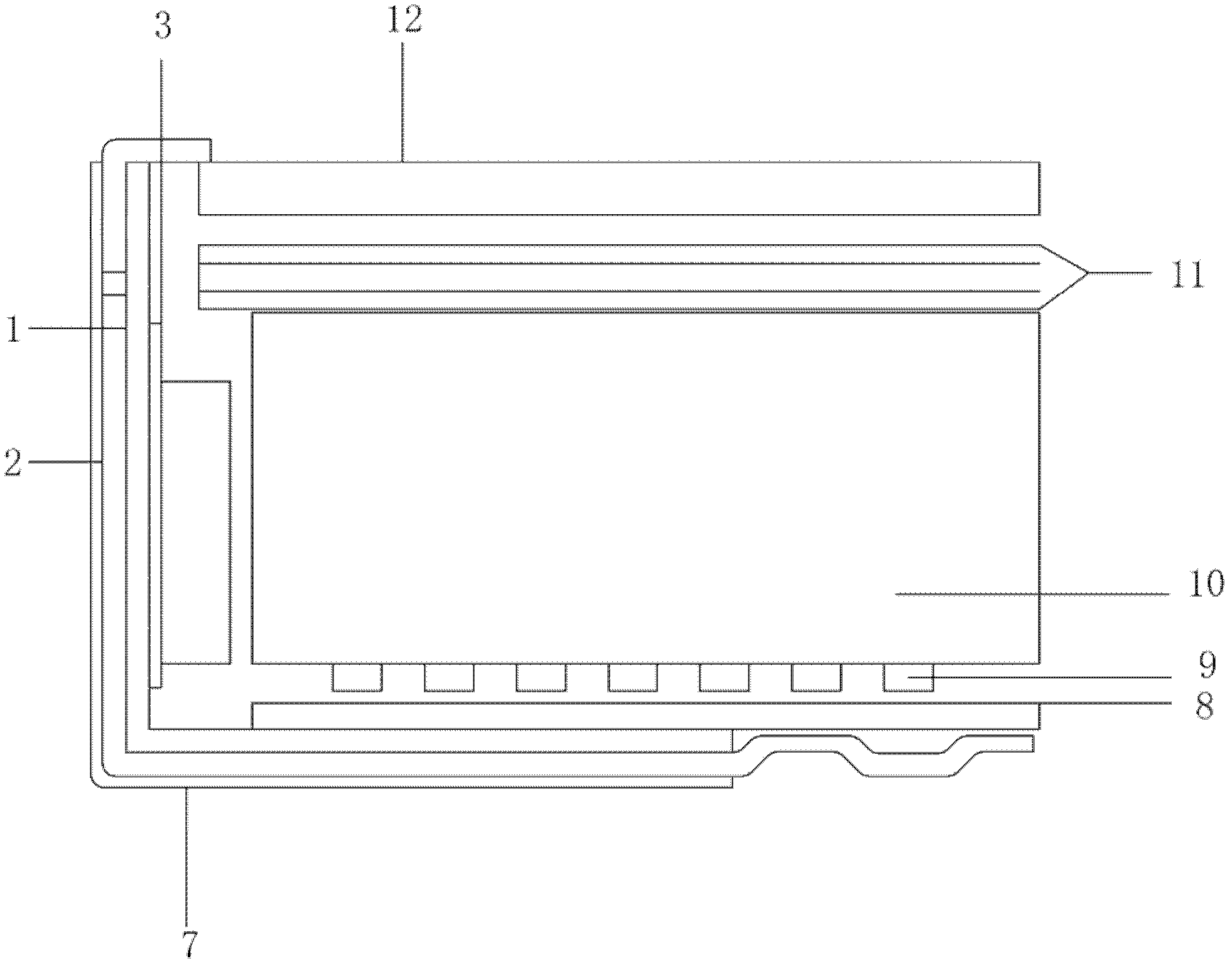

High-hardness epoxy modified polyurethane composite material and preparation method thereof

The invention relates to a high-hardness epoxy modified polyurethane composite material, which is prepared by adding a component A and a component B into a vacuumable sealed container and carrying out a mixed reaction by using a prepolymer method, wherein the component A is a mixture of a terminal isocyanate prepolymer and an epoxy resin, and the component B is a mixture of a chain extender and a catalyst. The preparation method comprises: weighing 130-140 parts of the component A and 2.4-15.2 parts of the component B, respectively pre-heating, adding the pre-heated components A and B to a vacuumable sealed container, mixing, carrying out vacuum deaeration while stirring, taking out after the gas bubbles are completely removed, pouring into a corresponding mold, carrying out low temperature curing, demolding, and carrying out heating vulcanization to prepare the high-hardness epoxy modified polyurethane composite material. According to the present invention, the product has advantages of high toughness, prolonged service life in the kettle, controllable reaction speed, low cost, and the like.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

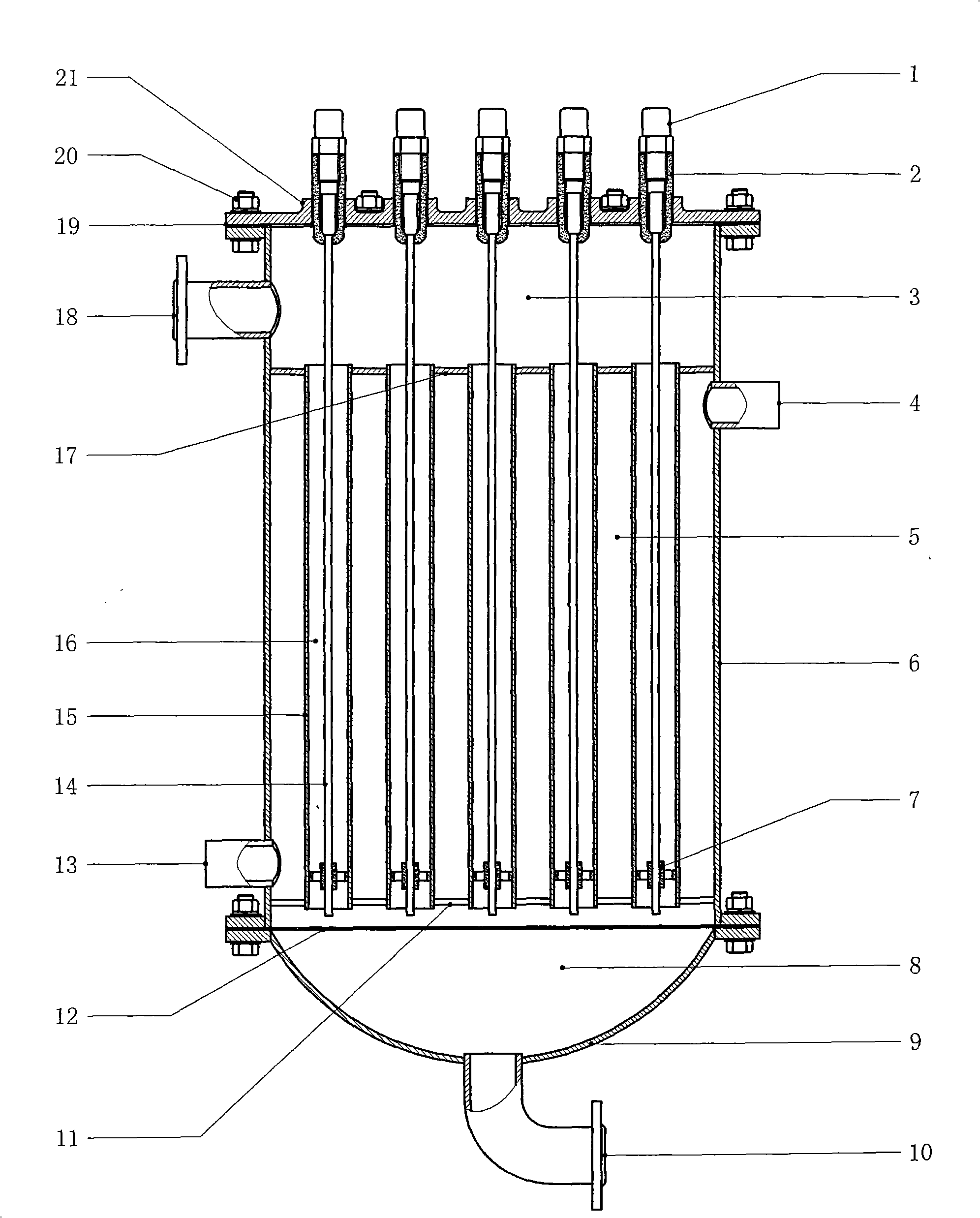

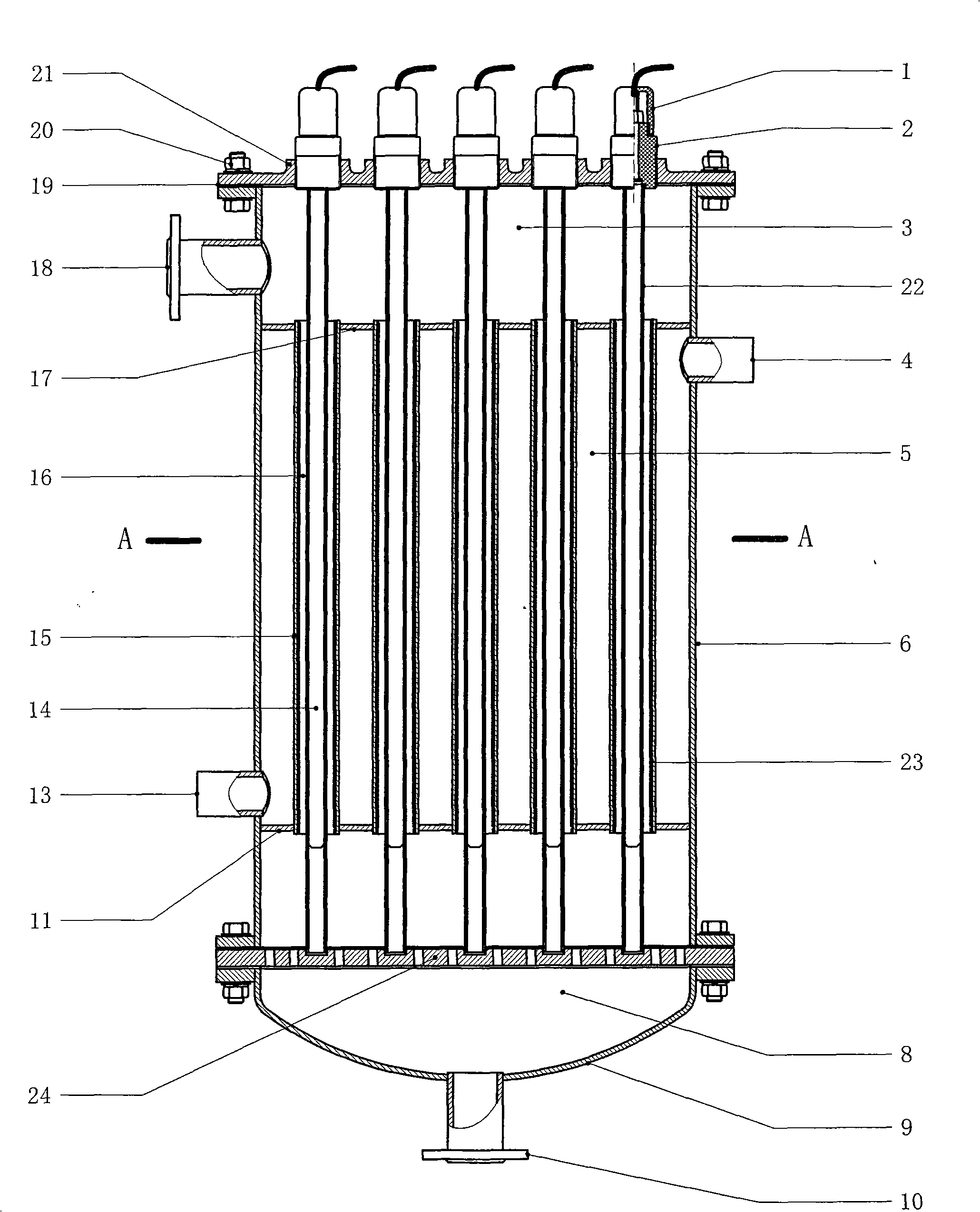

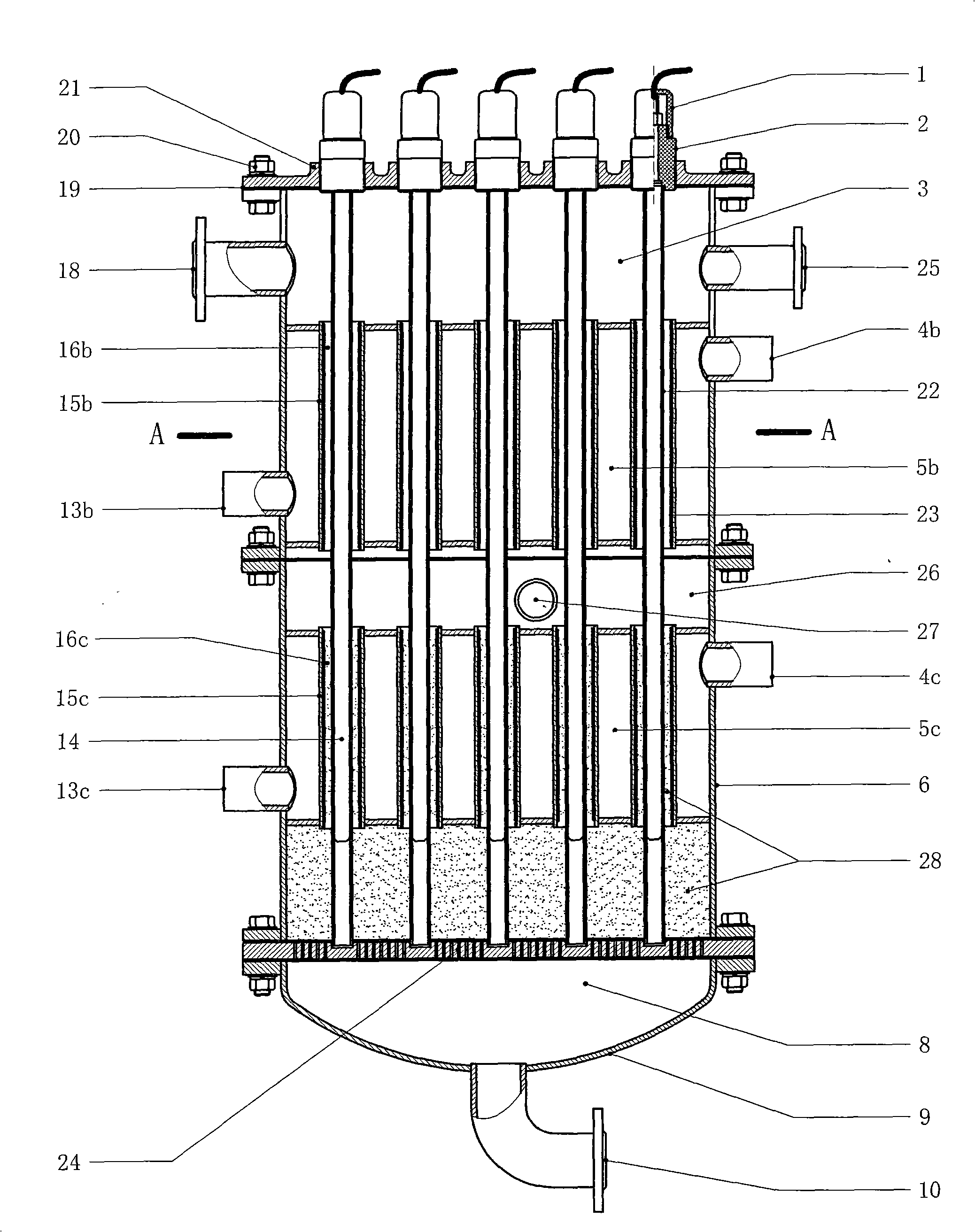

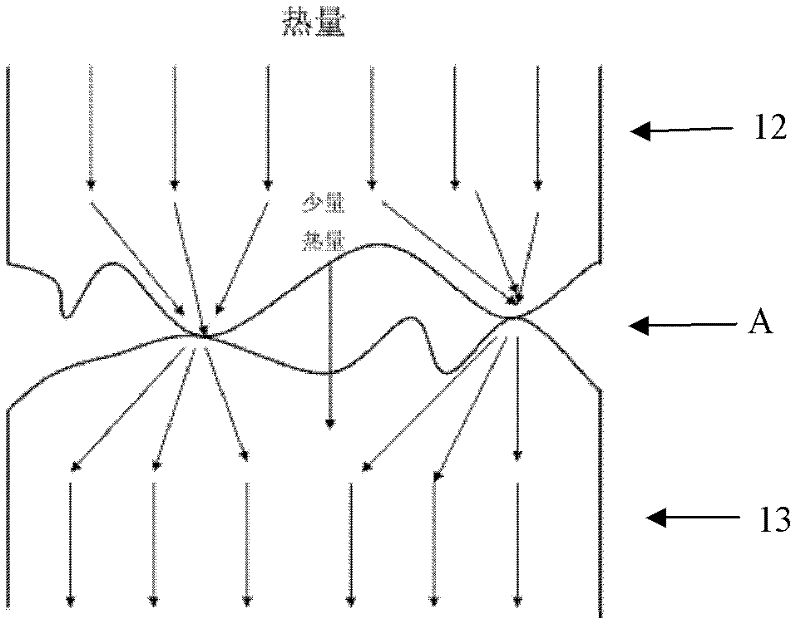

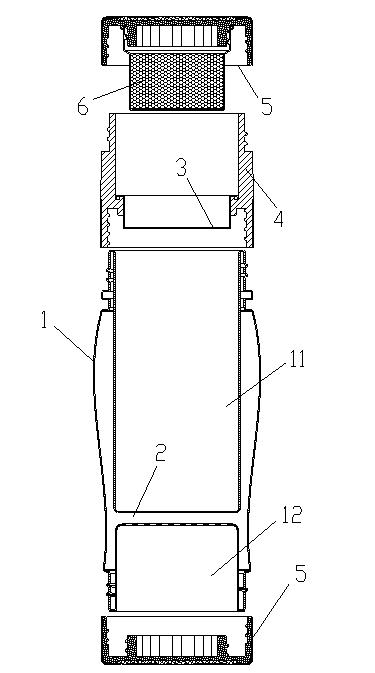

Electrocatalysis synthesis reactor

InactiveCN101254452AGood choiceControllable reaction speedEnergy based chemical/physical/physico-chemical processesLiquid-gas reaction processesChemical synthesisElectricity

An electrocatalytic synthesis reactor is provided, which relates to a reactor for chemical synthesis and mainly comprises a gas distribution chamber, a tubular electrocatalysis chamber, a collection chamber, a product discharge port, a cooling medium chamber and a housing, wherein a material gas inlet is provided on the side wall of the gas distribution chamber, the gas distribution chamber communicates with the collection chamber through the tubular electrocatalysis chamber, the product discharge port is provided at the bottom of the collection chamber, each unit of the tubular electrocatalysis chamber is defined by the inner space of an external electrode tube bundle and provided inside with a central electrode, and the periphery of the external electrode tube bundles is the cooling medium chamber. The synthesis reactor realizes synthetic reactions based on the synergetic catalysis of low-temperature plasmas and catalysts, allows the synthetic reactions to perform under approximately normal pressure, and allows the raw gases to enter the synthesis reactor without compression, thereby reducing energy consumption. Additionally, the synthesis reactor has the advantages of good selectivity, controllable reaction speed, and workability of producing methanol, dimethyl ether and synthetic ammonia by inputting raw gases related to the target product and selecting the relevant catalytic electrodes or catalysts.

Owner:衢州市广源生活垃圾液化技术研究所

Substrate-free pressure-sensitive acrylic thermal conductive adhesive, preparation method and application thereof

InactiveCN102391799AConnectivityPlay a thermal conductivityNon-macromolecular adhesive additivesFilm/foil adhesivesFiberCarbon fibers

The invention provides a substrate-free pressure-sensitive acrylic thermal conductive adhesive. A thermal conductive agent is dispersed in a monomer solution, and the thermal conductive adhesive is formed by curing and cross-linking after in situ polymerization; the consumption ratio of the thermal conductive agent to the monomer is (1-4): (6-9); the thermal conductive agent consists of 75 to 90 percent of carbon fibers and 10 to 25 percent of carbon nano tubes; and the monomer is acrylic acid and / or acrylate. Because the thermal conductive agent of specific components is uniformly dispersed in the acrylic polymerization monomer to form a stable three-dimensional netlike thermal conductive structure, so that the thermal conductive adhesive is good in thermal conductive performance and good in environment friendliness. The thermal conductive adhesive can be applied between a light emitting diode (LED) light bar and an aluminum alloy profile, between the aluminum alloy profile and a back plate, between the LED light bar and the back plate or between a chip and a radiator, is used as a double-sided adhesive tape, and is used under the condition of a big gap between two contact faces of liquid crystal modules.

Owner:HISENSE VISUAL TECH CO LTD

Method for synthesizing in-situ formed ceramic particle reinforced iron-aluminum-based composites by laser combustion

InactiveCN101906572AIncrease profitImprove performanceSelf-propagating high-temperature synthesisIron powder

The invention discloses a method for synthesizing in-situ formed ceramic particle reinforced iron-aluminum-based composites by laser combustion, belonging to the technical field of materials. The in-situ formed ceramic particle reinforced iron-aluminum-based composites are prepared by the following steps of: putting tungsten ore powder, iron powder, aluminum powder and carbon powder in a ball mill for milling to obtain a mixed powder material; and compressing the mixed powder material into a pressed compact, transmitting a high-energy laser beam by employing a CO2 laser processing machine to ignite the surface of the pressed compact and trigger self-propagating high temperature synthesis of the pressed compact. By the invention, two ceramic particle reinforced phases are simultaneously formed on one substrate, which shortens the preparation process of the composites, lowers material manufacture cost and facilitates large-scale production and application.

Owner:LIAONING TECHNICAL UNIVERSITY

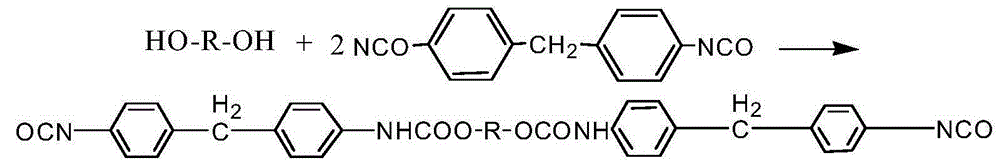

Preparation method of nano silicon dioxide/ hydroxyl silane coupling agent composite modified polyurethane super-hydrophobic membrane

PendingCN113248755AIncrease the degree of cross-linkingFavor molecular weightPolyurethane membraneCyanate ester

The invention discloses a preparation method of a nano-silica / hydroxysilane coupling agent composite modified polyurethane super-hydrophobic membrane. The nano-silica / hydroxysilane coupling agent composite modified polyurethane super-hydrophobic membrane is prepared from the following main raw materials: polyol, isocyanate, a catalyst, a hydrophilic chain extender, a neutralizer, a micromolecule chain extender, a silane coupling agent, nano-silica, deionized water and a post-chain extender. According to the invention, a synthesized polyurethane system is modified by introducing nano silicon dioxide particles modified by a hydroxyl silane coupling agent. A hydroxyl group of the hydroxyl silane coupling agent can chemically react with an isocyanate group of a waterborne polyurethane system, and silane is introduced to modify the hydrophobicity of the polyurethane membrane from the chemical aspect. The hydrophobicity of the polyurethane membrane is modified from the physical aspect by a micro-nano structure formed after the membrane is formed by the nano silicon dioxide particles treated by the hydroxyl silane coupling agent. The water contact angle of the prepared polyurethane super-hydrophobic membrane can reach 145-155 degrees, the rolling angle is 5-7 degrees, and the application field of the polyurethane membrane is widened.

Owner:CHANGCHUN UNIV OF TECH

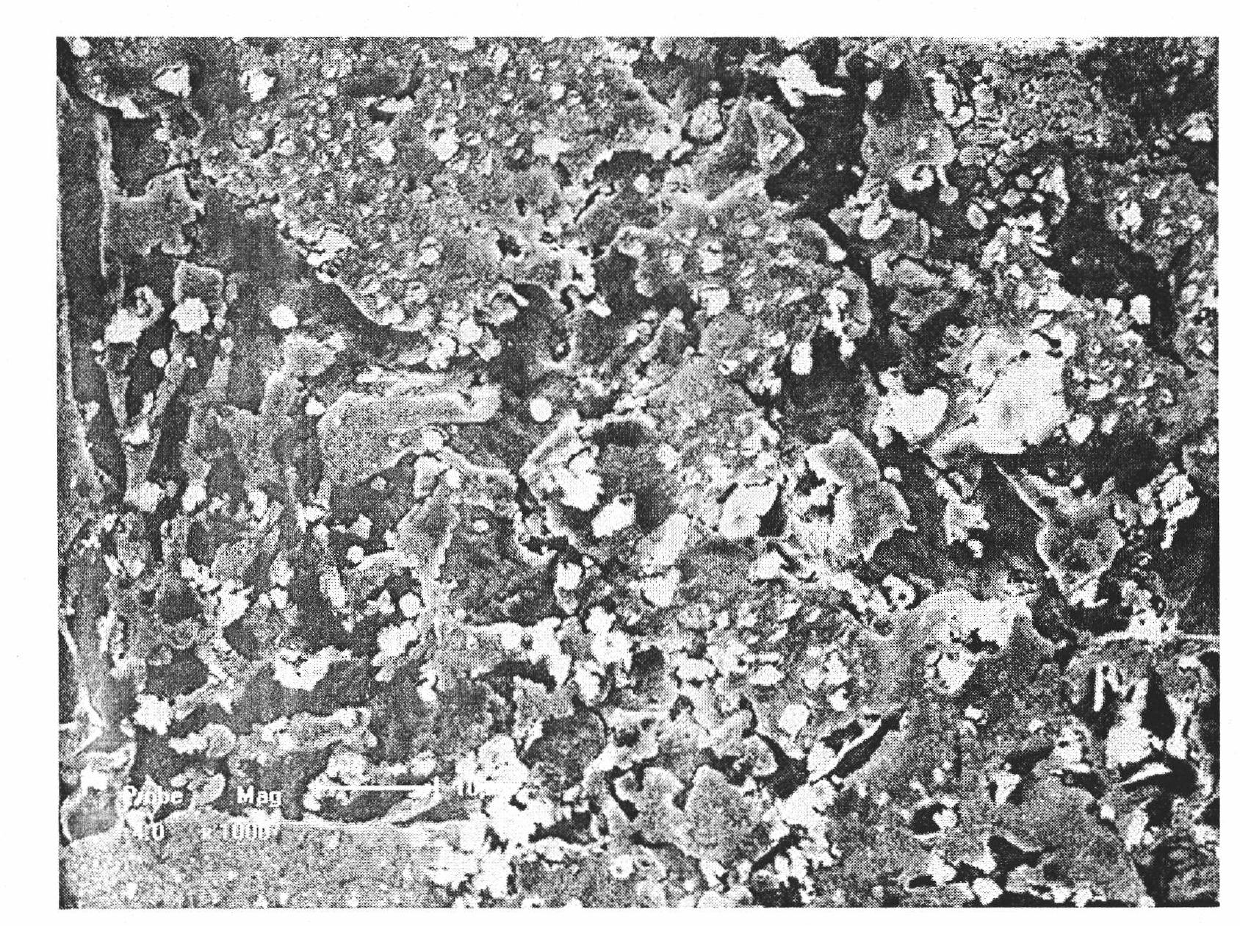

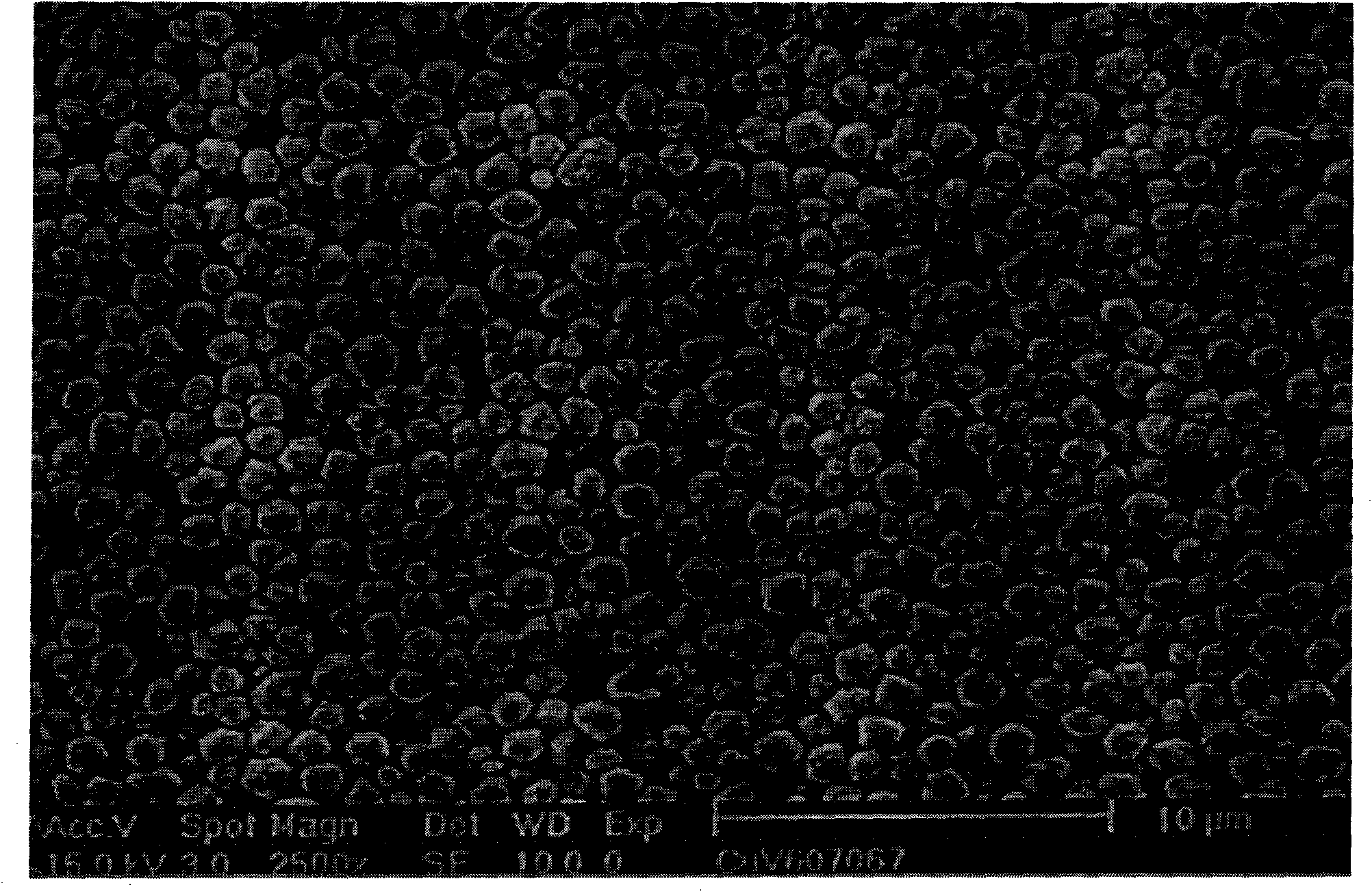

Method for preparing high-inoxidability sphere-like copper powder

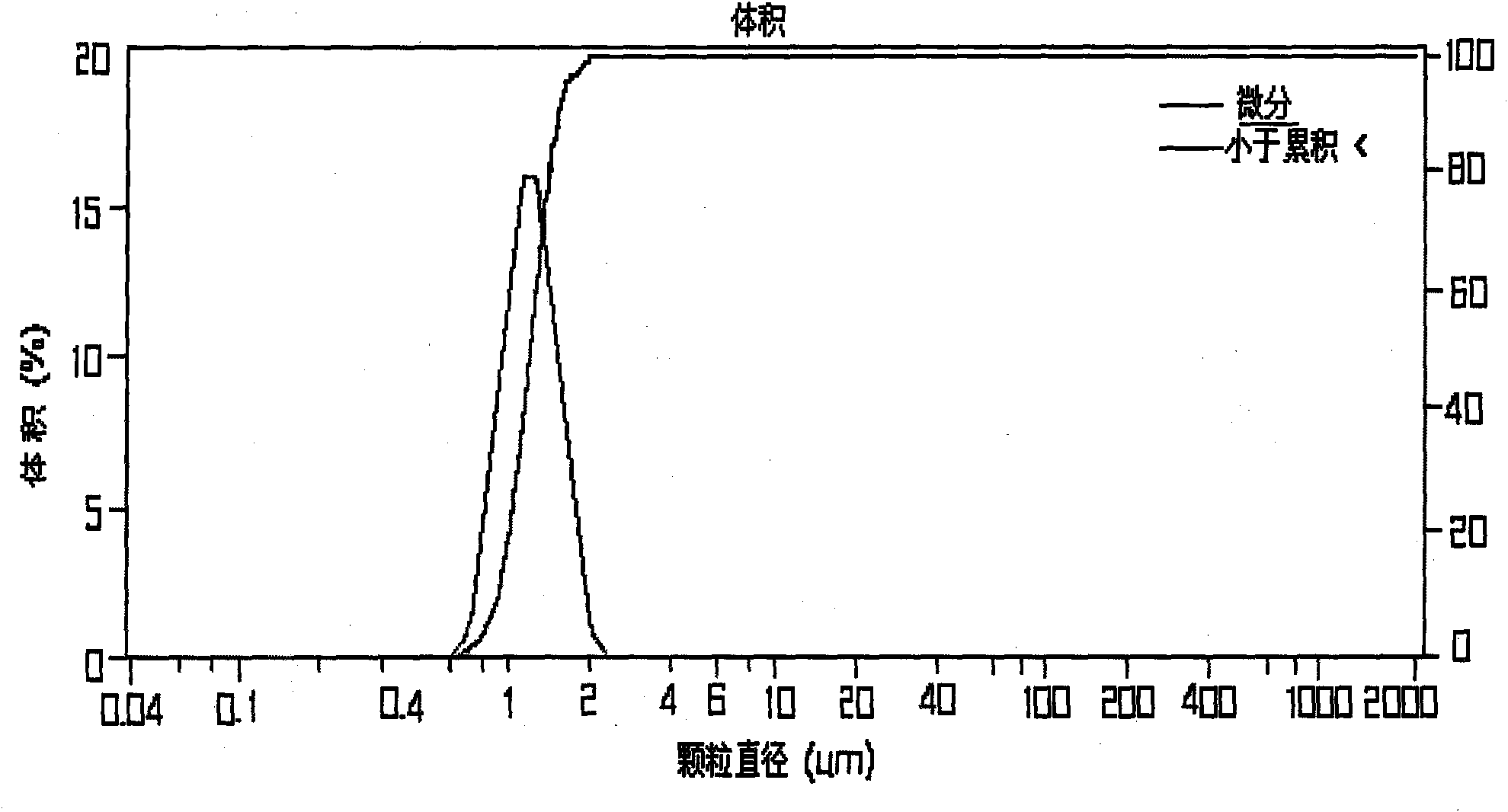

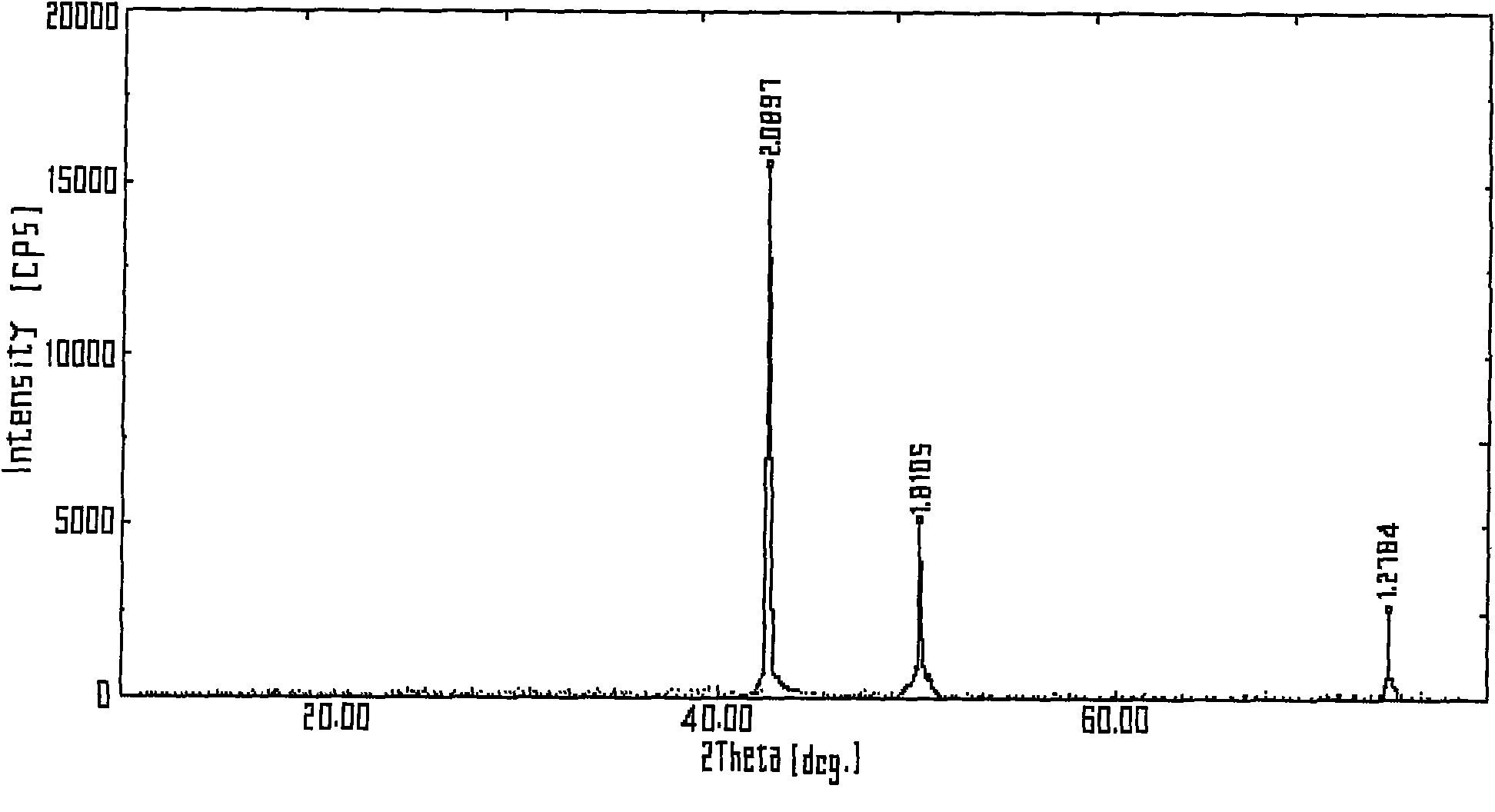

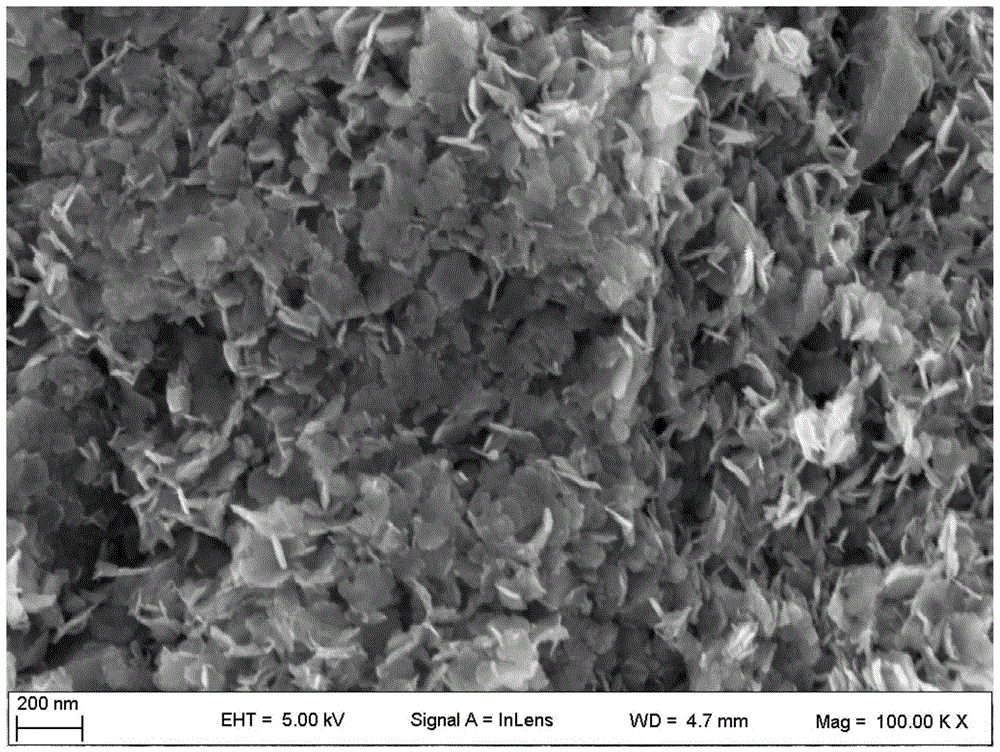

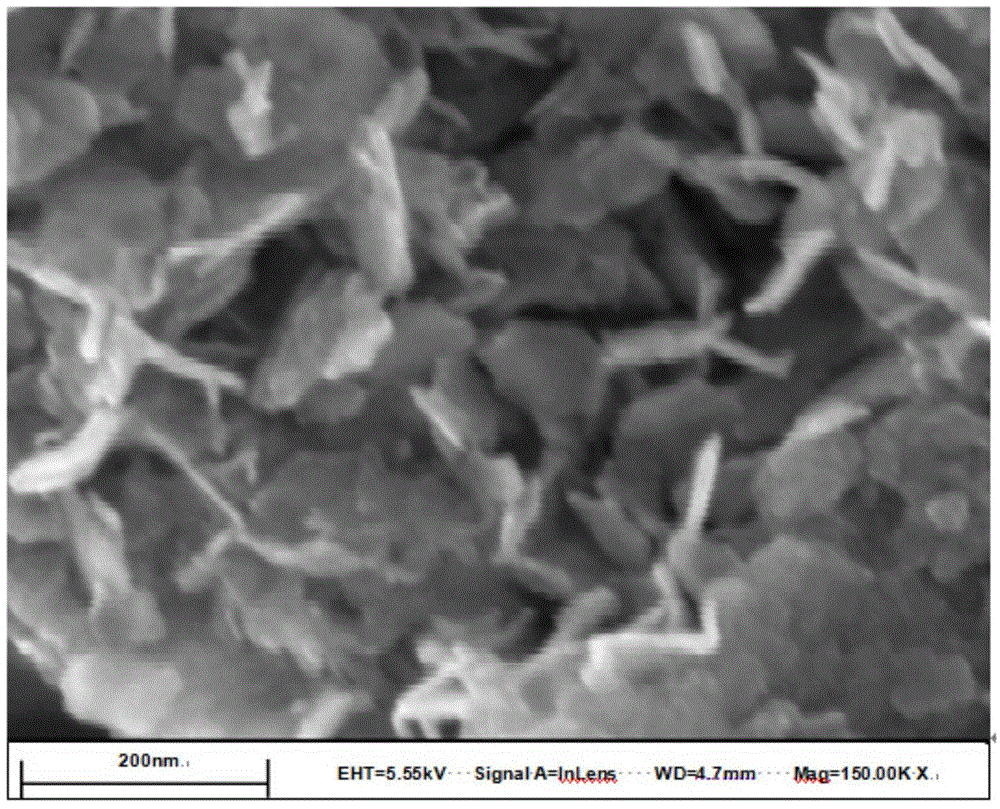

The invention discloses a method for preparing high-inoxidability sphere-like copper powder, which comprises the steps of reduction reaction, washing, surface chemical treatment and drying treatment, wherein the reduction reaction is to dissolve a reducing agent and a copperish initiator material into solvent and perform the reduction reaction under the action of an auxiliary agent, the reaction temperature is between 40 and 100 DEG C, and the reduction reaction time is between 2 and 5 hours. The reducing agent is vitamin C (C6H806, Vc,). The copperish initiator material is a substance which can be ionized into Cu2+ in aqueous solution and comprises one or several of hydrated copper sulfate, hydrated copper nitrate and hydrated copper chloride; the solvent is deionized water; and the auxiliary agent comprises an inorganic salt or an alkaline substance for adjusting the pH value and a water soluble polymer material for a surfactant. The obtained copper powder has the advantages of good dispersity, no agglomeration, small specific area, high tap density, controllable granule size, narrow grain size distribution range, and strong antioxygenic property.

Owner:GUANGDONG FENGHUA ADVANCED TECH HLDG

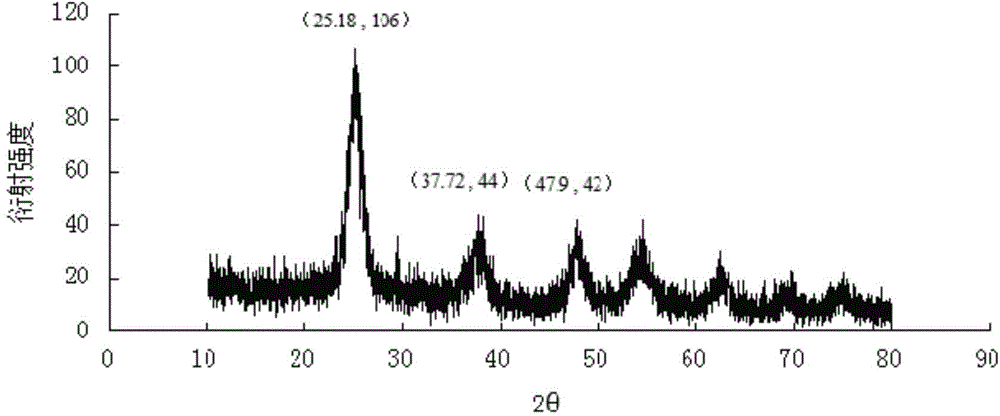

Preparation method of visible light responded WO3/{001}TiO2 composite photocatalyst

InactiveCN104475082AVisible light catalytic activity is highImprove visible light catalytic performanceWater/sewage treatment by irradiationEnergy based wastewater treatmentHydrolysisTitanic acid

The invention relates to a preparation method of visible light responded WO3 / {001}TiO2 composite photocatalyst. The preparation method comprises the following steps: by adopting an improved sol-gel method, firstly preparing {001} surface-exposed anatase TiO2 at room temperature, then depositing a certain amount of WO3 on the surface of the anatase TiO2 to construct a WO3 / {001}TiO2 composite system. according to the preparation method, the {001} surface-exposed anatase TiO2 is prepared by adopting the simple sol-gel method, so that the original preparation concept of inhibiting the hydrolysis of a titanium-containing precursor can be changed, the amount of water is increased to promote the complete hydrolysis of butyl titanate and inhibit the polymerization, the original feeding sequence is changed, butyl titanate is dropwise added into an HF water solution, uniform {001} surface-exposed anatase TiO2 can be formed at room temperature, the preparation technology is simple, the reaction conditions are mild, the reaction speed is easily controlled, the cost is low, and the preparation method is suitable for industrial popularization and application.

Owner:XIAN UNIV OF SCI & TECH

Pressure-sensitive acrylic acid thermally conductive adhesive, preparation method for same and application thereof

InactiveCN102433092AAnti-staticPlay a cohesiveNon-macromolecular adhesive additivesFilm/foil adhesivesCarbon fibersIn situ polymerization

The invention provides a pressure-sensitive acrylic acid thermally conductive adhesive, formed by dispersing a thermally conductive agent in monomer solution at first, then performing an in-situ polymerization, wherein the dosage ratio of the thermally conductive agent to the monomer is (1 to 4): (6 to 9); the thermally conductive agent is composed of 75-90% of carbon fibres and 10-25% of carbon nano-tubes; and the monomer is acrylic acid and / or acrylate. The pressure-sensitive acrylic acid thermally conductive adhesive provided by the invention is excellent in thermal conductivility and goodin environmental protection property because of uniformly dispersing a thermally conductive agent consisting of specific components in an acrylic acid polymerized monomer to form a stable three-dimensional meshy thermally conductive structure. The pressure-sensitive acrylic acid thermally conductive adhesive can be used between an LED (light-emitting diode) lamp bar and a back plate, between the LED lamp bar and an aluminium alloy section, between the back plate and the aluminium alloy section, between the gaps of chips such as CPU and GPU and a radiator, and in case that the gap of two contact surfaces is narrow in a liquid crystal module.

Owner:HISENSE VISUAL TECH CO LTD

Preparation method of crystalline silicon solar cell textured structure

ActiveCN106098810AReduce the depth of etchingReduce dosageSemiconductor/solid-state device manufacturingNanotechnologySurface etchingCitric acid

The invention discloses a method for preparing a textured surface structure of a crystalline silicon solar cell, which comprises the following steps: (1) forming a porous layer structure on the surface of a silicon chip; (2) etching the surface with a first chemical etching solution to form the textured surface surface structure; the first chemical etching solution is a mixed solution of hydrofluoric acid, an oxidizing agent and an additive; the additive is acetic acid or citric acid. The present invention designs a new chemical etching solution, and uses the chemical etching solution to etch the surface of the porous layer structure to form a suede structure. The experiment proves that the reaction speed of the chemical etching solution of the present invention is controllable, so that the suede surface can be guaranteed. The stability and uniformity of the structure, and the stability of the electrical performance of the solar cell.

Owner:CSI CELLS CO LTD

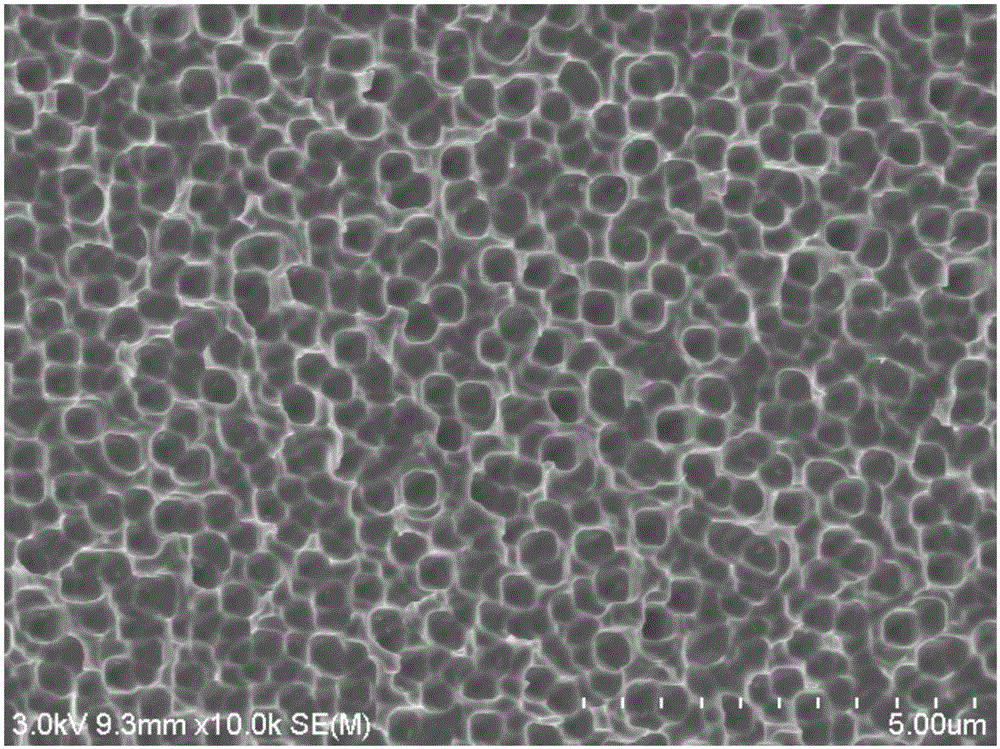

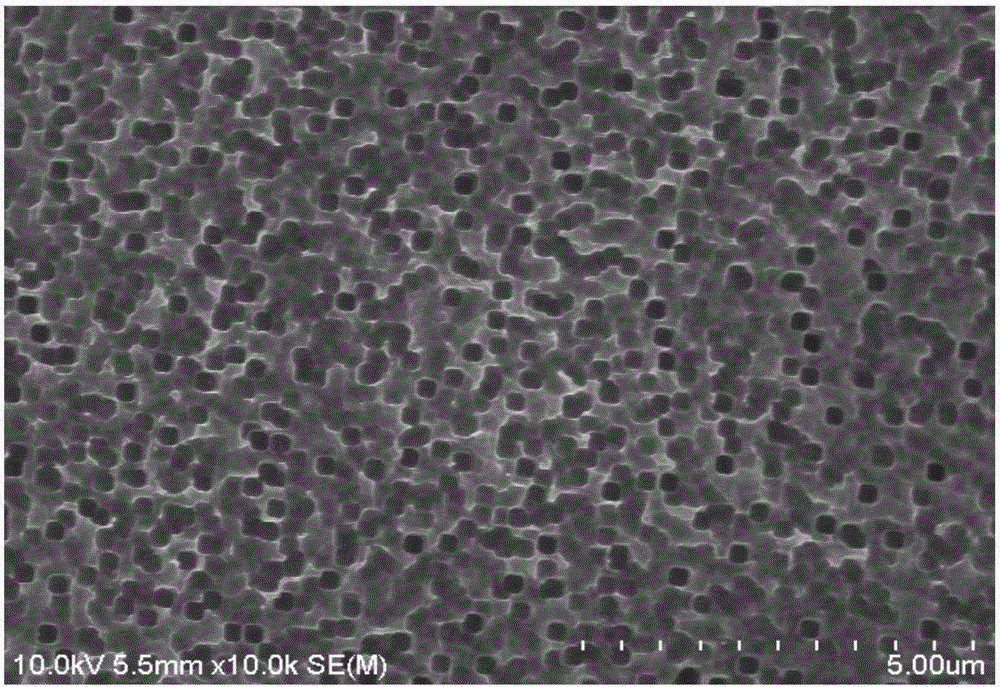

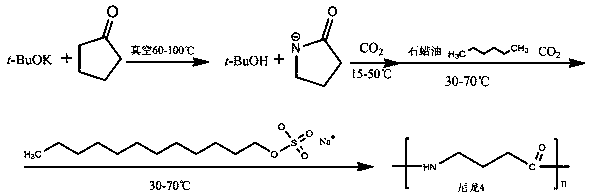

Preparation method of polybutyrolactam through anionic ring-opening polymerization

ActiveCN109851778AHigh molecular weightEasy to control polymerization ratePotassium tert-butoxideFiltration

The invention provides a preparation method of polybutyrolactam through anionic ring-opening polymerization. The preparation method comprises potassium tert-butoxide activation, carbon dioxide triggering, and addition of paraffin oil and sodium dodecyl sulfate. 2-pyrrolidone is taken as the primary raw material, after potassium tert-butoxide activation, carbon dioxide triggering, and addition of paraffin oil and sodium dodecyl sulfate, polymerization is performed, then n-hexane is added and stirred, and suction filtration is carried out to obtain polybutyrolactam. The preparation method has the advantages that the polymerization speed is slow and controllable, the polymer discharge is convenient, the molecular weight of polymers is high, and the requirements of massive production can be met.

Owner:TIANE CHEM FIBER GROUP CORP BAODING +1

Method for producing chitosan oligosaccharide with self-warming up oxidative degradation

InactiveCN101220061AUniform reaction speedControllable reaction speedOligosaccharidesVacuum dryingOligosaccharide

The invention relates to a preparation method of a chito-oligosaccharide, which is precisely a chito-oligosaccharide preparation method by means of self reaction heating and oxidation degradation. The invention firstly heats the water to a temperature of 25 to 60 DEG C, then puts high molecular weight chito-oligosaccharide raw material into the water and mixes well, whereafter adds hydrogen peroxide aqueous and acid and mixes well, and then the degradation reaction begins. The oxidation degradation reaction is exothermic, which needs no extra energy supply for the reaction system after the reaction begins. As the reaction carries on, the material gradually heats while the reaction speed gradually quickens. The even chito-oligosaccharide solution is gained after about two hours when the reaction completes, from which the chito-oligosaccharide powder with less than 2000 Dalton average molecular weight, narrow molecular weight distribution and high physiological activity effective polysaccharide with high content can be gained through direct spray drying, vacuum drying or lyophilization or drying after condensation. The preparation method of the invention can maintain the reaction system in higher temperature without heating for a long period, which needs very few production equipment investment and is characterized by simplicity, convenience, safety, economy, utility, high efficiency, low production cost and having no influence on the environment , etc.

Owner:杨志强

Preparation method of supported visible-light response WO3/{001}TiO2 compound photocatalyst

InactiveCN104689855AImprove separation efficiencyHigh utilization rate of visible lightOrganic-compounds/hydrides/coordination-complexes catalystsEnergy levelSingle crystal

The invention relates to a preparation method of a supported visible-light response WO3 / {001}TiO2 compound photocatalyst, which comprises three steps of (1) pretreatment of a supporter, (2) preparation of {001} crystal face exposure anatase TiO2 single crystals, and (3) preparation of the supported compound photocatalyst, the support supported catalyst with TiO2 as a center and coated with a WO3 core-shell structure is prepared, the characteristic that the tungsten trioxide (WO3) is taken as a narrow-gap (2.8eV) n-type semiconductor, and can be excited in a visible light range is fully utilized, the energy level difference between two semiconductor materials is utilized to effectively separate charges, the separating efficiency of a photon-generated carrier and the utilization rate of visible light are improved, the photocatalytic activity is high and unlikely to be lost, the catalytic activity is preserved for a long time, furthermore, the preparation process is simple, the reaction condition is mild, the reaction speed is easy to control, the cost is low, and the method is applicable to industrial promotion and application.

Owner:XIAN UNIV OF SCI & TECH

Synthesis method of glycal

Relating to the technical field of organic synthesis of glycal, the invention specifically relates to a synthesis method of glycal. The method comprises the steps of: dissolving 100 parts of triacetylribose halide in 150 parts of dichloromethane so as to obtain a halogenated sugar solution which is then cooled to a temperature below 10DEG C; mixing 150 parts of dichloromethane, 50 parts of zinc powder, and 100 parts of an ammonium chloride water solution well in a reaction vessel equipped with a condenser; heating the reaction vessel till generating backflow, then stopping heating, adding thehalogenated sugar solution for several times into the reaction vessel at a speed of 100r / min, with the halogenated sugar solution added of 1 / 20 of the halide solution by mass each time and the backflow generated each time after the adding of the halogenated sugar solution, and adding the halogenated sugar solution again after the end of the backflow, then waiting for the stop of the backflow, thus coming to the end of the reaction. The synthesis method provided in the invention has the advantages of simple operation, easily controllable reaction speed, fixed reaction time, strong repetitive operationality, and convenient product quality control. And the reaction method has high yield and can produce products of high purity.

Owner:JINAN SHENGQUAN GROUP SHARE HLDG

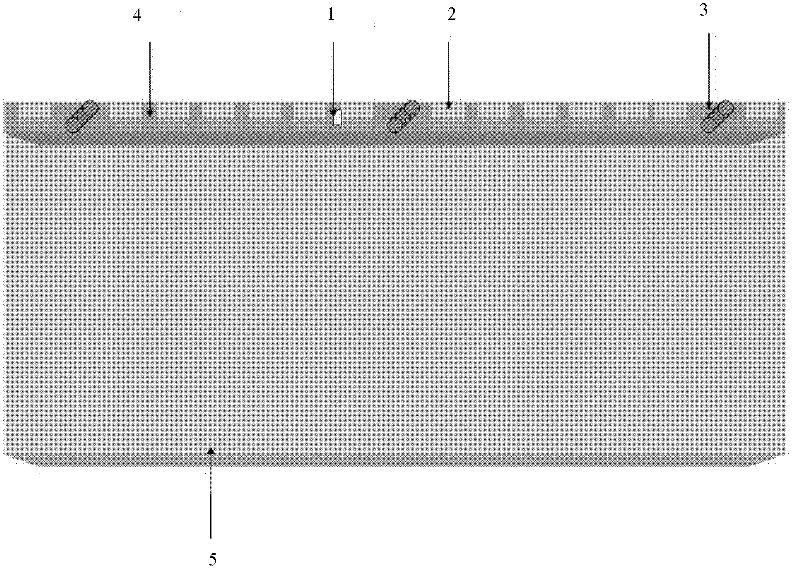

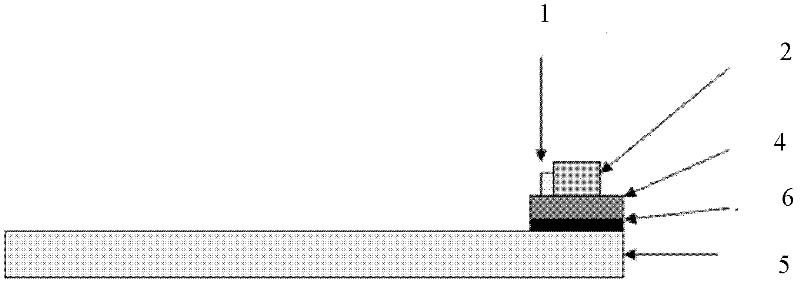

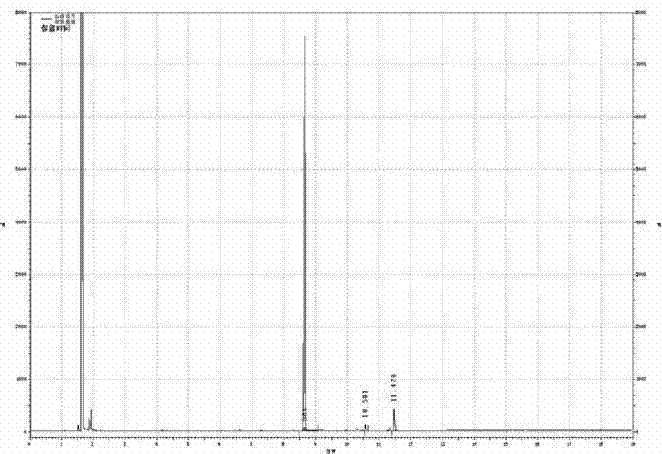

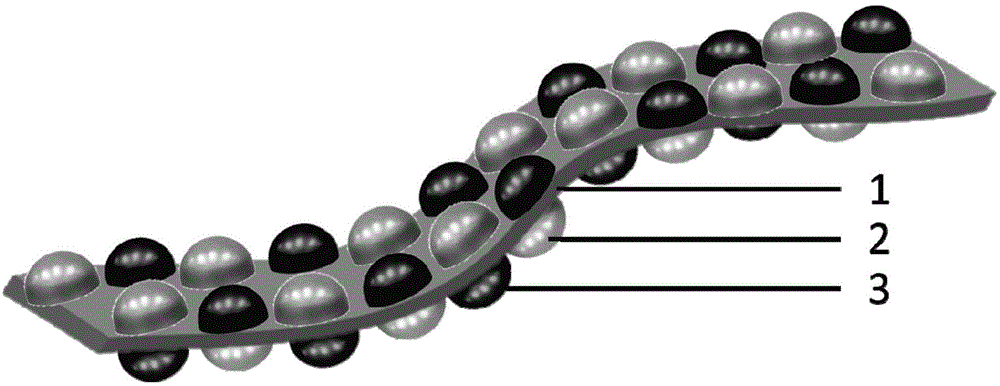

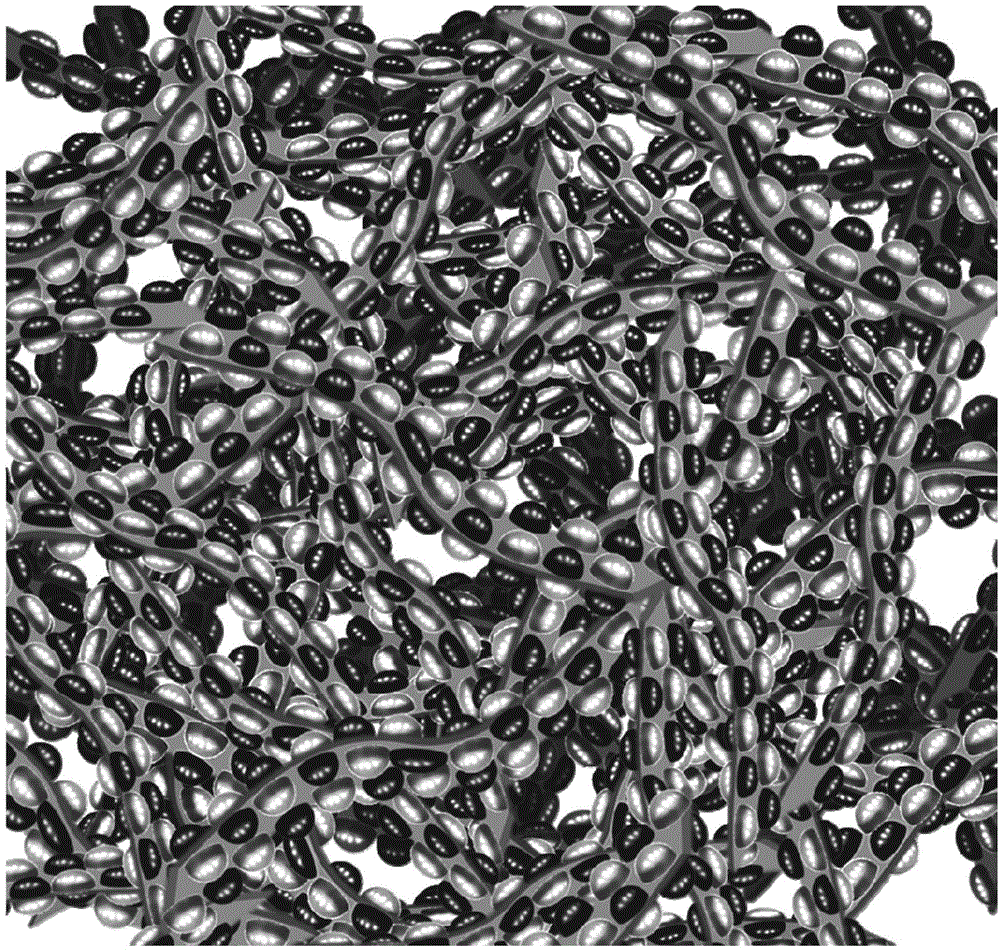

Reaction speed-controllable iron-titanium dioxide-carbon ternary micro-electrolysis composite nanometer catalyst and preparation method thereof

ActiveCN104607189AAchieve migrationInhibit sheddingMetal/metal-oxides/metal-hydroxide catalystsWater/sewage treatment by oxidationNano catalystElectrolysis

The invention discloses a reaction speed-controllable iron-titanium dioxide-carbon ternary micro-electrolysis composite nanometer catalyst. The catalyst adopts a cylindrical porous structure in shape and is formed by taking a titanium dioxide nano belt as a carrier and gathering a ribbon dispersed and embedded with carbon particles and metal iron particles on the surface, wherein the mass percentage of the titanium dioxide is 20-80 percent; the mass percentage of the carbon is 10-40 percent; the mass percentage of the iron is 10-40 percent; the ribbon has the length of 5-220 [mu]m, the width of 100-200 nm and the thickness of 20-40 nm; each of the carbon particles dispersed and embedded on the surface of the ribbon has the particle size of 30-50 nm, and each of metal iron particles has the particle size of 60-70 nm. The invention further discloses application of the catalyst. An experiment proves that the catalyst disclosed by the invention has high oxidation and catalysis ability and good mineralization effect and is widely applied to industrial water treatment.

Owner:浙江威尔森新材料有限公司

Production technique of guanidine nitrate

ActiveCN103951592ASimple processProcess condition control is simpleOrganic chemistryOrganic compound preparationChemistryLiquid ammonia

The invention relates to a production technique of a chemical product, particularly a production technique of guanidine nitrate, which comprises the following steps: mixing raw materials, and carrying out fusion reaction. The weight percent of the guanidine nitrate in the guanidine nitrate finished product is greater than 94%. By using ammonium carbonate instead of ammonia gas in the prior art as an assistant in the production process, the technique has the following advantages:1. the technique is simple and convenient for controlling technological conditions;2. the quality of the product is greatly improved: the maximum purity of the product obtained by the prior art is lower than 92%, but the purity of the product obtained by the technique is high than 94%, which is a qualitative improvement for large-scale production; and 3. the safety in the production process is enhanced: the technique does not need liquid ammonia storage tanks, transmission pipelines and other dangerous facilities in the existing production process, thereby greatly enhancing the safety in the production process.

Owner:BEILITE CHEM CO LTD +2

Chemical polishing solution for titanium and titanium alloy

The invention relates to chemical polishing solution for titanium and titanium alloy, and belongs to a chemical formula. The chemical polishing solution consists of ammonium fluoride, lactic acid, nitric acid and water, wherein the content of the ammonium fluoride is 60 to 300g / L, the volume ratio of the lactic acid (the content is 85 to 90 percent) is 65 to 91 percent, and the volume ratio of the nitric acid (the content is 65 to 68 percent) is 9 to 35 percent. The solution has the characteristics that the reaction velocity is easy to control, the etching rate difference between different phases or between grains can be reduced, the titanium metal matrix is effectively protected, and the like. The chemical polishing solution for the titanium and the titanium alloy is simple and convenience and has the advantages of high efficiency, low cost, good surface quality and the like.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG

Stainless steel electrochemical polishing liquid and polishing process

The invention discloses stainless steel electrochemical polishing liquid and a polishing process, and relates to the technical field of surface electrochemical polishing of stainless steel equipment or products, in particular to the stainless steel electrochemical polishing liquid and the polishing process. The stainless steel electrochemical polishing liquid comprises compositions including, by weight, 15%-25% of sulfuric acid, 20%-35% of citric acid, 3%-10% of ethylene glycol, 1%-3% of ethylene diamine tetraacetic acid, 0.1%-0.5% of polyvinylpyrrolidone and the balance water. According to the stainless steel electrochemical polishing liquid and the polishing process, the sulfuric acid is a strong inorganic acid, has good dispersibility, can be completely ionized in the solution, helps toimprove the conductivity, dispersing ability and anode current efficiency of the polishing liquid and uniformly polishes the surface of the stainless steel; the citric acid has low acidity and high viscosity to prevent corrosion of the stainless steel; and the ethylene glycol is absorbed on the surface of the anode, formation of a diffusion layer is promoted, a film can be formed on the surface of the stainless steel together with citric acid to prevent over-corrosion of the stainless steel, and the polished stainless steel surface is bright and meticulous, and the reflectivity is greater than 98%.

Owner:SHANGHAI GUOSHUN IND EQUIP

Soaking cup with filter core

ActiveCN102358624ANovel structureEasy to carryWater/sewage treatment by substance additionDrinking vesselsEngineeringReaction speed

The present invention relates to a soaking cup with a filter core. The cup comprises a tubular cup. The cup is characterized in that: the lower part of the cavity of the tubular cup is provided with a separation plate to divide the cavity of the cup into a first cavity and a second cavity; the upper part of the tubular cup forms a screw connection with a tea storage tube, wherein the lower part of the tea storage tube is provided with a screen; the upper part of the tea storage tube and the lower part of the tubular cup respectively form screw connections with lids. With the soaking cup, the function of the ordinary soaking cup can be met; medicines, tea, emergency drugs or health products can be placed in the second cavity by the user, wherein the emergency drug soaking or the emergency drug taking requires water; the preparation process is simple, the product is easy to use, the reaction speed is rapid, the reaction degree is controllable, and significant economic and social benefits are provided.

Owner:FUZHOU PINXING TECH DEV

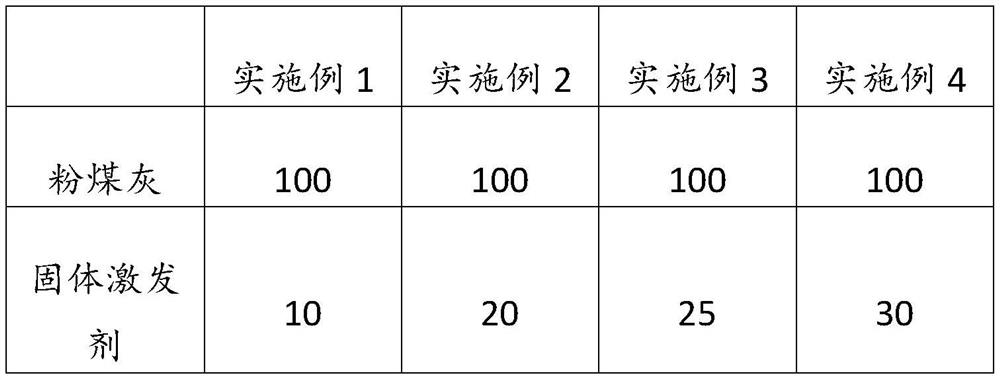

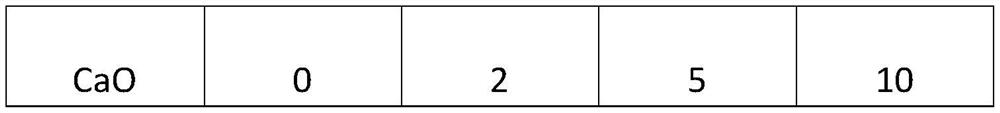

Fly ash cementing material as well as preparation method and application thereof

The invention discloses a fly ash cementing material as well as a preparation method and an application thereof, and relates to the technical field of concrete. The fly ash cementing material comprises the following components in parts by weight: 100 parts of fly ash, 10-30 parts of a solid activator and 0-10 parts of CaO. The invention provides a fly ash cementing material which gets rid of the constraints of mineral powder, steel slag, cement and clinker and can also be produced in places without the raw materials.

Owner:广东能源集团科学技术研究院有限公司 +1

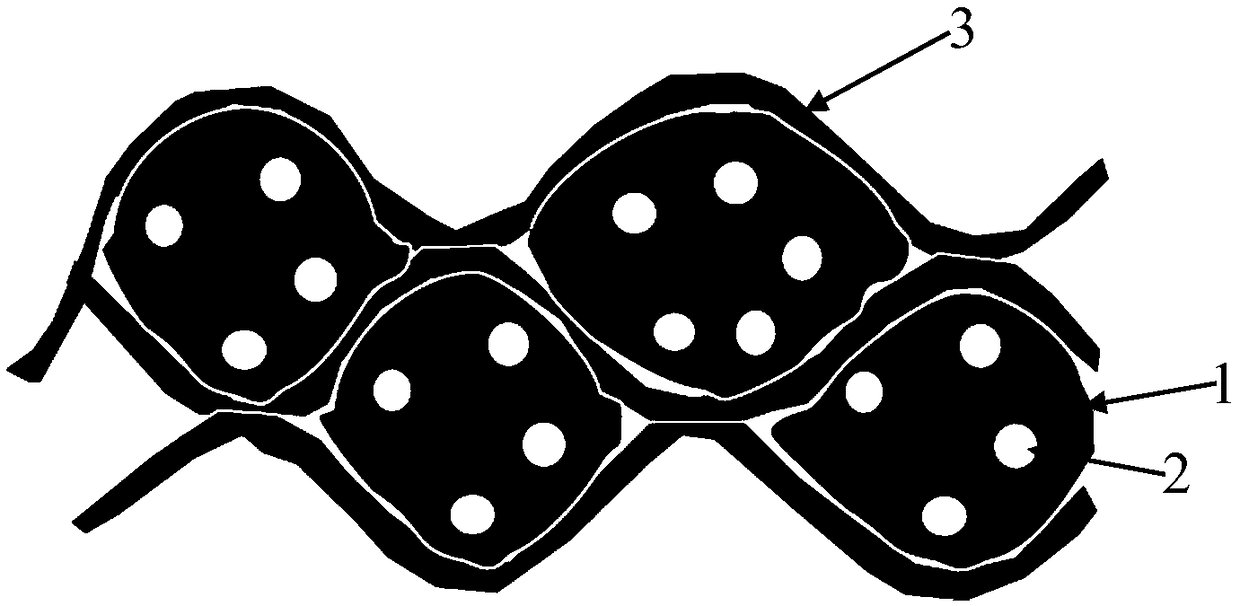

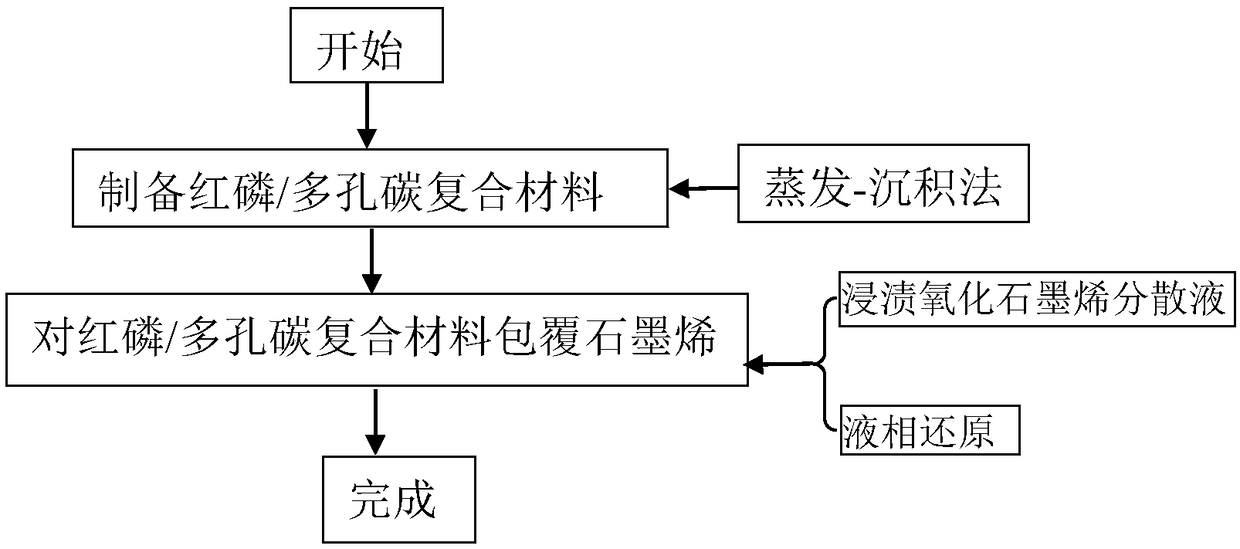

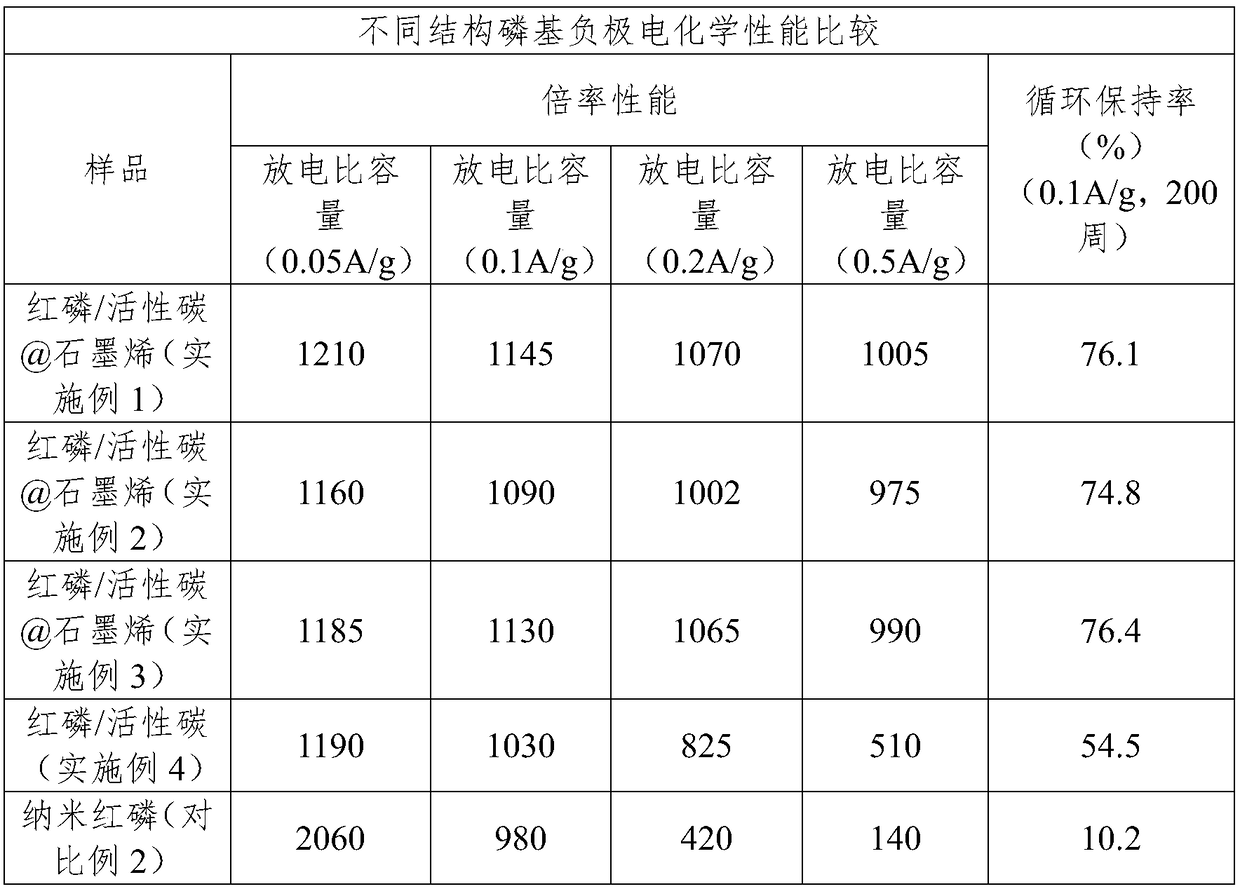

Phosphorus-based negative electrode material and preparation method thereof, negative electrode and lithium ion battery

InactiveCN109216682AStrong mechanical toughnessImprove conductivitySecondary cellsNegative electrodesPorous carbonEvaporation

The invention relates to a phosphorus-based negative electrode material, which comprises a core material and a coating material, wherein the core material is phosphorus / porous carbon composite material; The coating material is graphene, which is coated on the outside of the phosphorus / porous carbon composite material. The invention also relates to a preparation method of the phosphorus-based negative electrode material, preferably by evaporation. Phosphorus / porous carbon composites were prepared by deposition method, then dispersed in graphene oxide dispersion, and the graphene oxide was reduced to obtain graphene-coated phosphorus / porous carbon composites. The invention improves the electric conductivity and the anti-expansion stability of the phosphorus / porous carbon composite material by virtue of the high electric conductivity and the excellent mechanical toughness of the graphene and the like, thereby achieving the purpose of improving the electric conductivity of the phosphorus-based negative electrode and prolonging the cycle life of the phosphorus-based negative electrode battery.

Owner:桑德新能源技术开发有限公司 +1

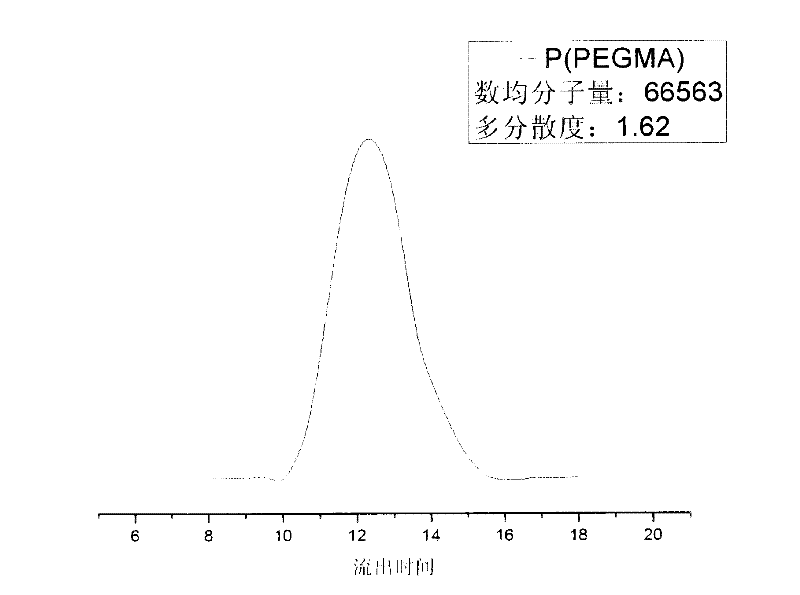

Ligand-free Transition Metal Catalytic Activity/Controlled Radical Polymerization Method in Aqueous Phase

The invention discloses a novel environmentally-friendly polymerization method. In the method, low-oxidation-state copper catalytic polymerization is used as a basis; and polymerization reaction is initiated in a water-phase system at normal temperature without a ligand. In the reaction, alkyl bromide or various kinds of substances containing the alkyl bromide are used as an initiator; bivalent copper and a reducer are used for producing low-valence copper to serve as a catalyst; and the polymerization of olefin monomer is initiated in aqueous solution at normal temperature. The method has the advantages of high reaction efficiency, environmental friendliness, low cost, low energy consumption and capability of effectively synthesizing an oligomer, a block polymer, a graft polymer, a star polymer and the like.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Graphene nanoribbons and preparation method thereof

InactiveCN103924257ATo achieve the purpose of strippingAvoid reunionElectrolysis componentsChemical vapor deposition coatingGraphene nanoribbonsReaction speed

The invention relates to graphene nanoribbons and a preparation method thereof. The preparation method comprises the following steps: taking a strip-shaped carbon nano wall sheet as a working electrode, a lead plate as a counter electrode, Hg / Hg2SO4 as a reference electrode, and an ionic liquid as an electrolyte solution; completely immersing the working electrode, the counter electrode and the reference electrode in the electrolyte solution of an electrolytic bath, applying a voltage of 0.1 to 20 V to the working electrode, keeping for 0.1 to 10 hours, then applying a reverse voltage of -20 to -0.1 V, keeping for 0.1 to 10 hours, and thus obtaining a mixture of the graphene nanoribbons and the ionic liquid; filtering the mixture, washing and filtering the obtained filter residue, carrying out vacuum drying to constant weight, and thus obtaining the graphene nanoribbons. The graphene nanoribbons are simple in preparation process, the reaction speed and the product quality can be controlled by controlling voltage values, the graphene nanoribbons can effectively be prevented from being agglomerated again after stripping by utilizing the ionic liquid as the electrolyte solution, and the production efficiency is improved.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +2

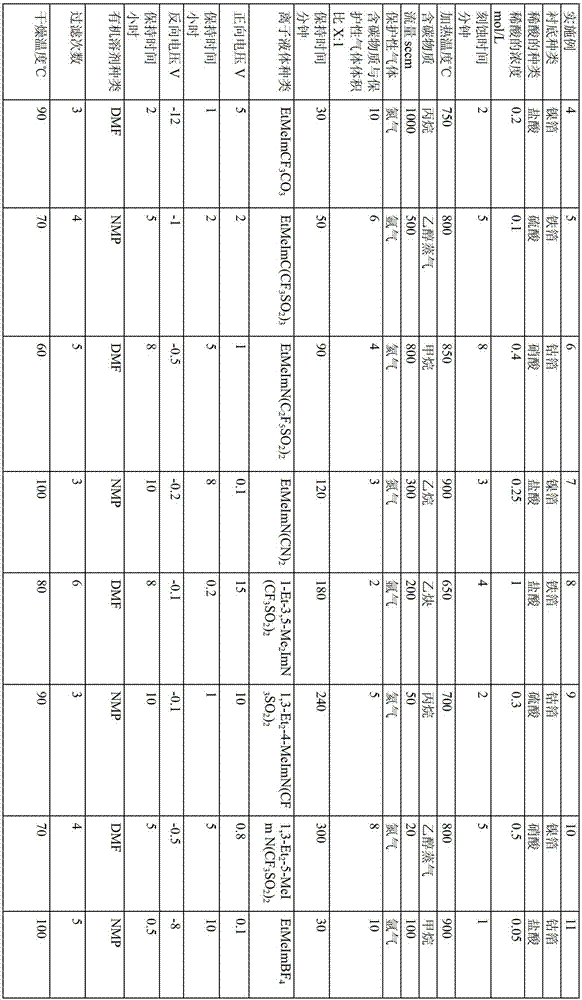

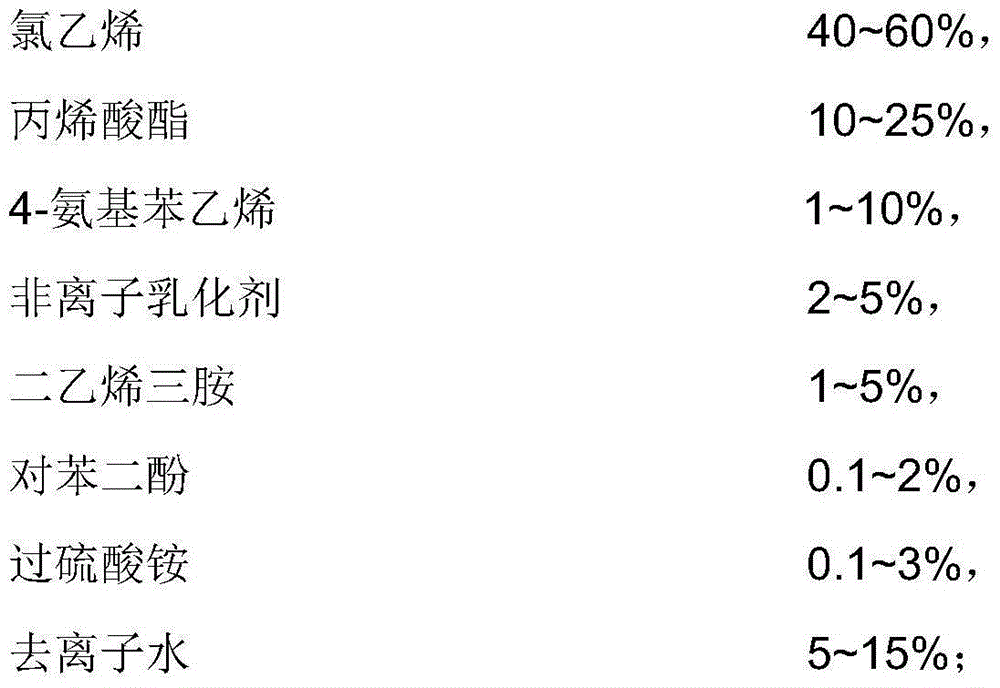

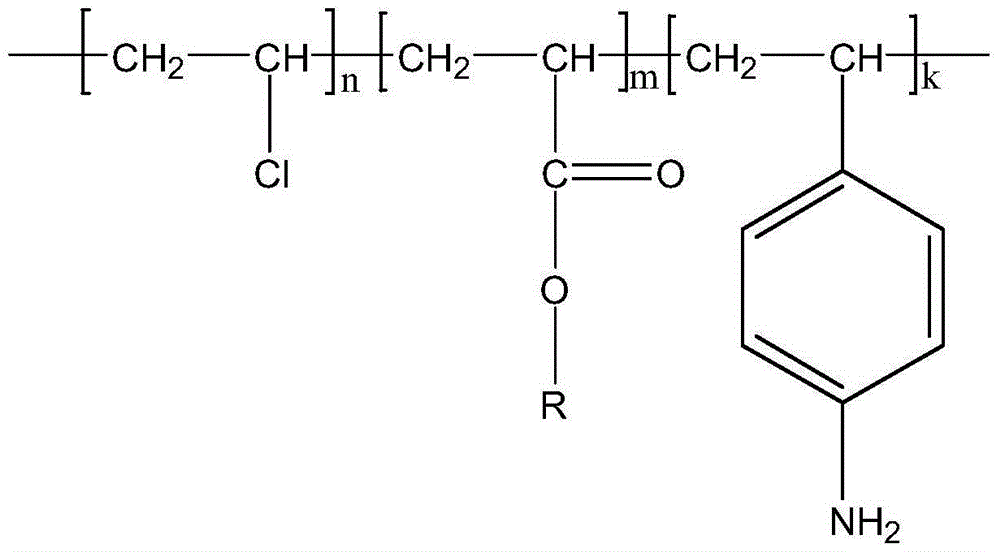

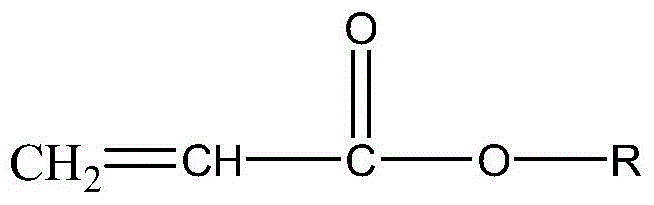

Terpolymer emulsion containing non-ionic emulsifier and preparation method therefor

The invention discloses a terpolymer emulsion containing a non-ionic emulsifier. The emulsion comprises the components in percentage by weight: 40-60% of chloroethylene, 10-25% of acrylate, 1-10% of 4-amino styrene, 2-5% of the non-ionic emulsifier, 1-5% of diethylenetriamine, 0.1-2% of hydroquinone, 0.1-3% of ammonium persulfate and 5-15% of deionized water. The terpolymer emulsion containing the non-ionic emulsifier disclosed by the invention is excellent in stability, high in film compactness, relatively small in emulsion particle size and good in water resistance and acid and alkali resistance; by adopting a monomer copolymerization process of chloroethylene, acrylate and 4-amino styrene, the emulsion not only is simple and easy to operate, but also is easy to control the reaction speed and low in cost, and meets the environmental-friendly principle. The invention further discloses a preparation method for the terpolymer emulsion containing the non-ionic emulsifier.

Owner:RUNTAI CHEM TAIXING CO LTD

Modified acrylate heat-dissipation powder coating as well as preparation method and application thereof

ActiveCN102618141BImprove heat transfer efficiencyImprove cooling efficiencyPoint-like light sourceLighting heating/cooling arrangementsFiberGlycidyl methacrylate

The invention provides a modified acrylate heat-dissipation powder coating material which is prepared in a way that heat-dissipation agent is dispersed in a monomer solution, subjected to in-situ polymerization and then treated through desolventizing agent, wherein the weight ratio of the heat-dissipation agent to monomer is (1-25) to (7.5-9); the heat-dissipation agent comprises 82-90 percent of carbon fiber and 10-20 percent of nanometer material; and the monomer is one or more of styrene, methacrylic acid, glycidyl ester, acrylic acid-2-ethyl hexyl ester, methyl methacrylate and methyl acrylate. According to the invention, as the heat-dissipation coating material dispersed uniformly and added with the carbon fiber and nanometer material compound heat-dissipation particles is obtained by adopting solution in-situ polymerization, the heat transmission efficiency and the heat dissipation efficiency can be increased; and the heat-dissipation coating material can be coated as a heat-dissipation coating on the surface of a back plate of an LED LCM (liquid crystal model) to dissipate part of the heat generated by LEDs in a infrared radiation manner, so that the heat dissipation performance of the LED LCM is enhanced, and the heat dissipating capacity and the heat dissipation efficiency are improved in the same heat dissipation area.

Owner:HISENSE VISUAL TECH CO LTD

Method for preparing conducting-state polyaniline by sanding

The invention relates to a method for preparing conducting-state polyaniline by sanding, which comprises the following steps: dissolving aniline in an HCl solution, slowly adding the solution into a reactor filled with sodium dodecyl benzene sulfonate and glass beads, and evenly mixing by sanding at 200-1000 r / min; adding an oxidant, and sanding at room temperature to react for 1-5 hours; and after the reaction finishes, carrying out vacuum filtration, washing, drying and grinding to obtain the conducting-state polyaniline. The method obviously shortens the reaction time and reduces the water consumption, thereby effectively lowering the production cost and relieving the pressure of sewage treatment. The electric conductivity of the conducting-state polyaniline prepared according to the invention is up to 5.3 S / cm.

Owner:CHONGQING UNIV

Reduction method of copper zinc catalyst for hydrogen production by methanol steam reforming

ActiveCN102416327BSimple and safe operationLow costHydrogenCatalyst activation/preparationSteam reformingCopper

The invention discloses a reduction method of a copper zinc catalyst for hydrogen production by methanol steam reforming, which is simple and safe in operation, and low in cost. The method comprises the following steps of: A) a copper zinc catalyst dehydration stage, that is, increasing the temperature of a cracking reactor, introducing dry air or inert gas with a space velocity of 10-30 h-1 into the reactor loaded with the copper zinc catalyst, increasing the temperature from 80 DEG C to 170 DEG C till no physical water is discharged; B) a copper zinc catalyst reduction stage, that is, continuing heating the reactor, introducing deionized water with a gas space velocity of the deionized water of 250-450 h-1 so as to establish a steam balanced system; introducing hydrogen with a space velocity of the hydrogen of 4-10 h-1 and a hydrogen volume percent of 0.5-4%, controlling the temperature at 180-240 DEG C; C) a copper zinc catalyst reduction strengthening stage, that is, maintaining the temperature of the catalyst bed layer, introducing a methanol aqueous solution with a mass concentration of 10-20% and a liquid space velocity of 0.1-0.3 h-1.

Owner:JIANGSU NUOMENG CHEM

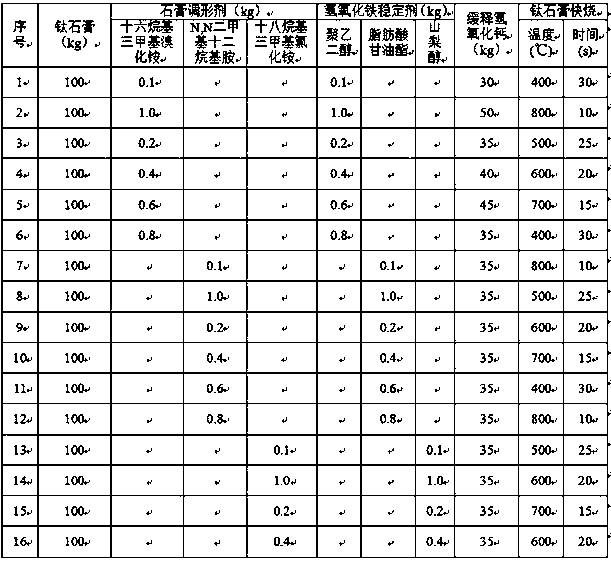

Method for separating iron and sulfur from titanium dioxide wastewater

ActiveCN110128039APromotes crystal growthGood for liquid-solid separationMaterial nanotechnologyFerric oxidesFerric hydroxideCyclonic separation

The invention discloses a method for separating iron and sulfur from titanium dioxide wastewater, and the method comprises the following steps: adding gypsum seed crystals, a gypsum shape adjusting agent and a ferric hydroxide stabilizer into the titanium dioxide wastewater, uniformly mixing, adding slow-release calcium hydroxide, and performing cyclonic separation to obtain titanium gypsum and asolution containing nano ferric hydroxide; filtering the titanium gypsum by pressing, and quickly burning the titanium gypsum to obtain a gypsum cementing material; and adding a coagulant into the solution containing the nano ferric hydroxide to obtain a ferric hydroxide precipitate, performing liquid-solid separating, adding a shaping agent into the ferric hydroxide precipitate, mixing uniformly,adding into an autoclave to crystallize to obtain ferric oxide red. The method has low production cost and high efficiency, and realizes high-quality recycling of resources.

Owner:SOUTHWEAT UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com