Preparation method of visible light responded WO3/{001}TiO2 composite photocatalyst

A composite light and catalyst technology, applied in the field of photocatalytic material research, to achieve the effect of promoting complete hydrolysis, simple preparation process, and inhibiting polymerization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] with WO 3 with TiO 2 The molar ratio is 1:1 as an example, the preparation of the WO 3 / {001}TiO 2 The method of composite photocatalyst is realized by the following steps:

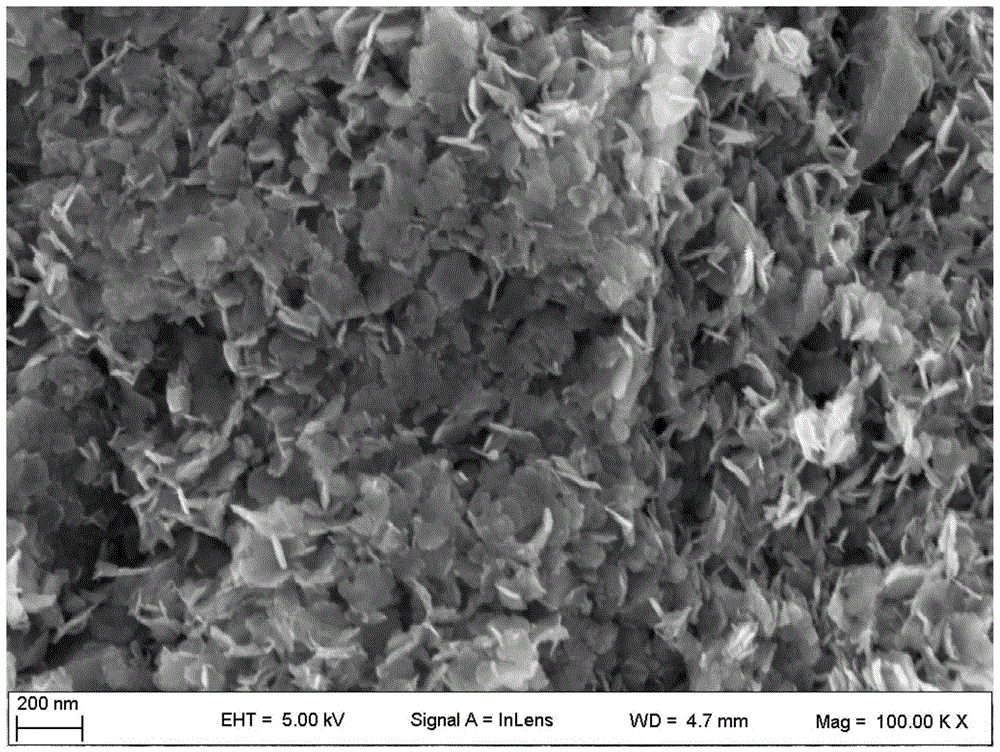

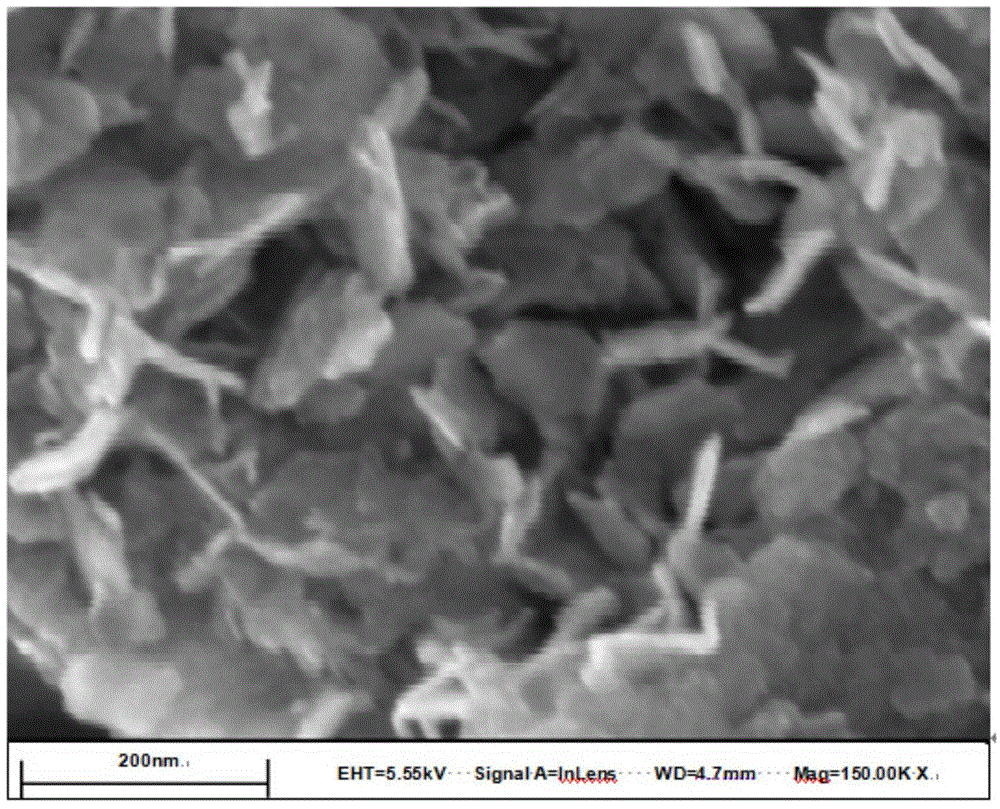

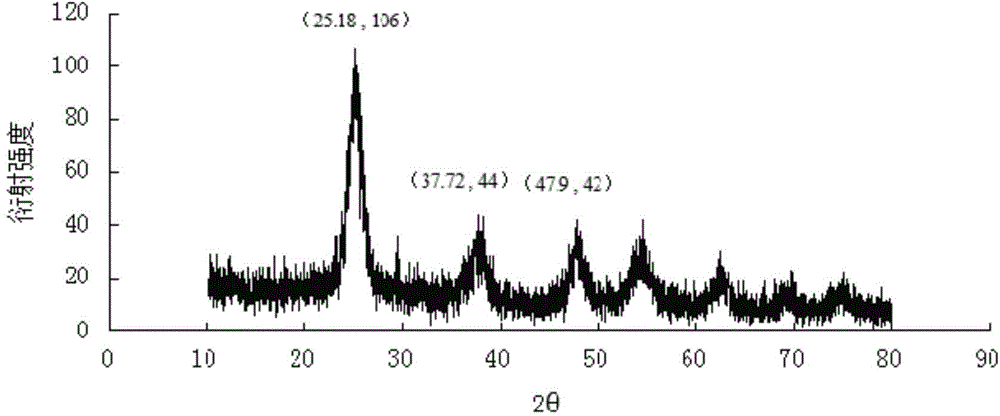

[0024] (1)﹛001﹜Anatase TiO with exposed facets 2 Single crystal preparation

[0025] ① Measure 30.4mL of absolute ethanol and add it to 35.2mL of butyl titanate, so that the molar ratio of butyl titanate and absolute ethanol is 1:5, mix well, and then prepare a mixed solution of A;

[0026] ② Measure 180mL of deionized water, add 20.2mL of HF, make the molar ratio of HF and deionized water is 1:22, and mix well to obtain the B mixture;

[0027] ③Add the mixed solution of A to the mixed solution of B dropwise, and the dropping speed is controlled at 3 drops per second, so that the molar ratio of butyl titanate in the mixed solution of A to the deionized water in the mixed solution of B is 1:100 , mixed at low speed for 2 hours to obtain TiO 2 Sol, aged at room temperature for 48 hours;

[00...

Embodiment 2

[0033] with WO 3 with TiO 2 The molar ratio is 1:10 as an example, the preparation of the WO 3 / {001}TiO 2 The method of composite photocatalyst is realized by the following steps:

[0034] (1)﹛001﹜Anatase TiO with exposed facets 2 Single crystal preparation

[0035] ① Measure 30.4mL of absolute ethanol and add it to 35.2mL of butyl titanate, so that the molar ratio of butyl titanate and absolute ethanol is 1:5, mix well, and then prepare a mixed solution of A;

[0036] ② Measure 180mL of deionized water, add 20.2mL of HF, make the molar ratio of HF and deionized water is 1:22, and mix well to obtain the B mixture;

[0037] ③Add the mixed solution of A to the mixed solution of B dropwise, the dropping speed is controlled at 2 drops per second, so that the molar ratio of butyl titanate in the mixed solution of A to the deionized water in the mixed solution of B is 1:105 , mixed at low speed for 1 hour to obtain TiO 2 Sol, aging at room temperature for 24 hours;

[0038]...

Embodiment 3

[0043] with WO 3 with TiO 2 The molar ratio is 1:100 as an example, the preparation of the WO 3 / {001}TiO 2 The method of composite photocatalyst is realized by the following steps:

[0044] (1)﹛001﹜Anatase TiO with exposed facets 2 Single crystal preparation

[0045] ① Measure 30.4mL of absolute ethanol and add it to 35.2mL of butyl titanate, so that the molar ratio of butyl titanate and absolute ethanol is 1:10, mix well, and then prepare a mixed solution of A;

[0046] ② Measure 185mL of deionized water, add 20.2mL of HF, make the molar ratio of HF and deionized water is 1:20, and mix well to obtain the B mixture;

[0047] ③Add the mixed solution of A to the mixed solution of B dropwise, and the dropping speed is controlled at 2 drops per second, so that the molar ratio of butyl titanate in the mixed solution of A to the deionized water in the mixed solution of B is 1:150 , mixed at low speed for 1 hour to obtain TiO 2 The sol was aged for 36 hours at room temperatur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| surface energy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com