Visible light response type nanosheet bismuth oxychloride catalyst and preparation method thereof

A bismuth oxychloride and nano-sheet technology, applied in the field of environmental chemical photocatalytic water treatment, can solve the problems of low photocatalytic activity and the like, and achieve the effects of high visible light catalytic activity, high yield and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The preparation steps of BiOCl visible light catalyst are:

[0023] Step 1: 0.01molBi(NO 3 ) 3 ·5H 2 O is added to 10ml of HCl and C7H17NO3 mixed solution, wherein the mass concentration of C7H17NO3 is 50%, the mass concentration of HCl is 37.5%, and stirred at room temperature until Bi(NO 3 ) 3 ·5H 2 O is completely dissolved;

[0024] Step 2: Use NH 3 ·H 2 O adjusts the pH=6 of the above solution, and stirs at room temperature for 30min;

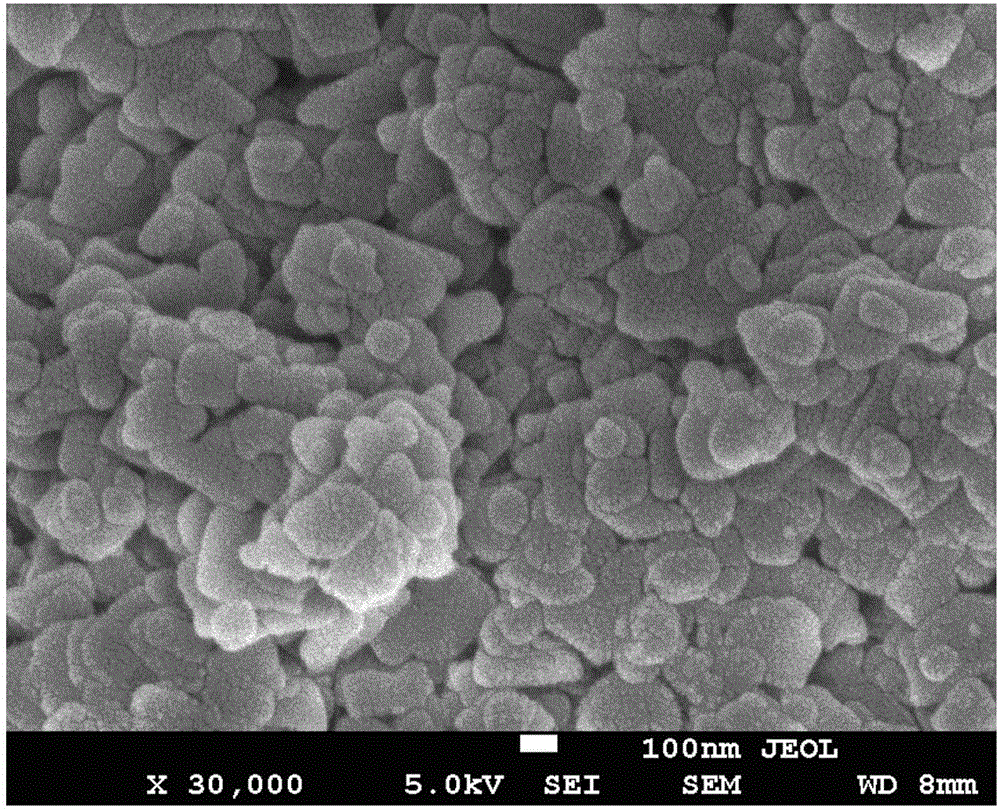

[0025] Step 3: After step 2, filter the obtained product, rinse with distilled water and absolute ethanol three times respectively, and then dry the product at 140°C for 8 hours to obtain off-white BiOCl photocatalyst material with a photocatalyst length of 100~ 200nm, nanosheets with a width of 50~150nm.

Embodiment 2

[0027] The preparation steps of BiOCl visible light catalyst are:

[0028] Step 1: 0.01molBi(NO 3 ) 3 ·5H 2 O is added in the HCl and C7H17NO3 mixed solution of 10ml, wherein the mass concentration of C7H17NO3 is 40%, the mass concentration of HCl is 38%, stirs at room temperature until Bi(NO 3 ) 3 ·5H 2 O is completely dissolved;

[0029] Step 2: Use NH 3 ·H 2 O adjust the pH=5 of the above solution, stir at room temperature for 30min;

[0030] Step 3: After step 2, filter the obtained product, rinse with distilled water and absolute ethanol three times respectively, and then dry the product at 140°C for 8 hours to obtain off-white BiOCl photocatalyst material with a photocatalyst length of 100~ 200nm, nanosheets with a width of 50~150nm.

Embodiment 3

[0032] The preparation steps of BiOCl visible light catalyst are:

[0033] Step 1: 0.01molBi(NO 3 ) 3 ·5H 2 O is added in the HCl and C7H17NO3 mixed solution of 10ml, wherein the mass concentration of C7H17NO3 is 30%, the mass concentration of HCl is 37.5%, stirs at room temperature until Bi(NO 3 ) 3 ·5H 2 O is completely dissolved;

[0034] Step 2: Use NH 3 ·H 2 O adjusts the pH=6 of the above solution, and stirs at room temperature for 30min;

[0035] Step 3: After step 2, filter the obtained product, rinse with distilled water and absolute ethanol three times respectively, and then dry the product at 120°C for 8 hours to obtain off-white BiOCl photocatalyst material with a photocatalyst length of 100~ 200nm, nanosheets with a width of 50~150nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com