Method for separating iron and sulfur from titanium dioxide wastewater

A technology for the separation of titanium dioxide wastewater and iron-sulfur, which is applied in the fields of iron oxide, iron oxide/iron hydroxide, nanotechnology for materials and surface science, etc. , high water content, to achieve the effect of being conducive to liquid-solid separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with specific examples.

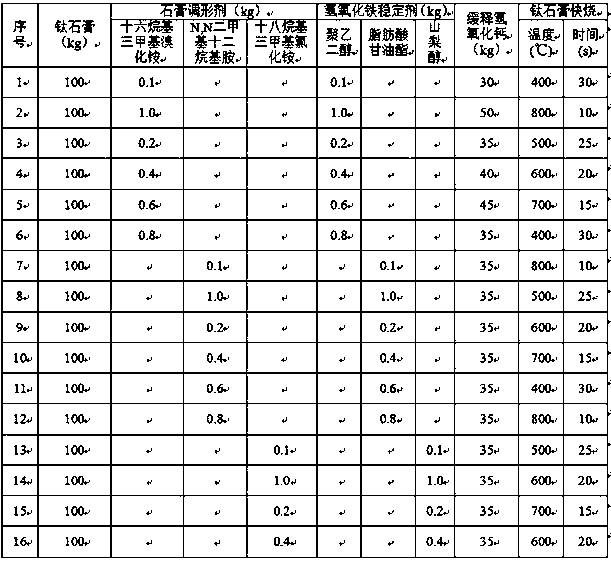

[0027] Add gypsum seed crystals (0.5% of the mass of titanium gypsum), gypsum modifier, and ferric hydroxide stabilizer to titanium dioxide wastewater and mix evenly, then add slow-release calcium hydroxide, and obtain titanium gypsum and nano-hydrogen by cyclone separation. Iron oxide solution; titanium gypsum is obtained by pressure filtration and fast burning to obtain gypsum cementitious material. See Table 1 for the gypsum modifier, ferric hydroxide stabilizer, and titanium gypsum flash-burning temperature and time.

[0028] Table 1

[0029]

[0030] In Example 1-Example 16, the crystal grains of titanium gypsum are all greater than 30 μm, and the particle size of nanometer iron hydroxide is less than 100 nm; the dry compressive strength of the cementitious materials after fast burning is all greater than 10 MPa.

[0031] A coagulant is added to the solutio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com