Patents

Literature

84 results about "Metals industry" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Transportable, self-contained, refrigeration system

InactiveUS6289684B1Easy to transportEasy to moveAir-treating devicesCompression machines with non-reversible cycleMetals industryMarine engineering

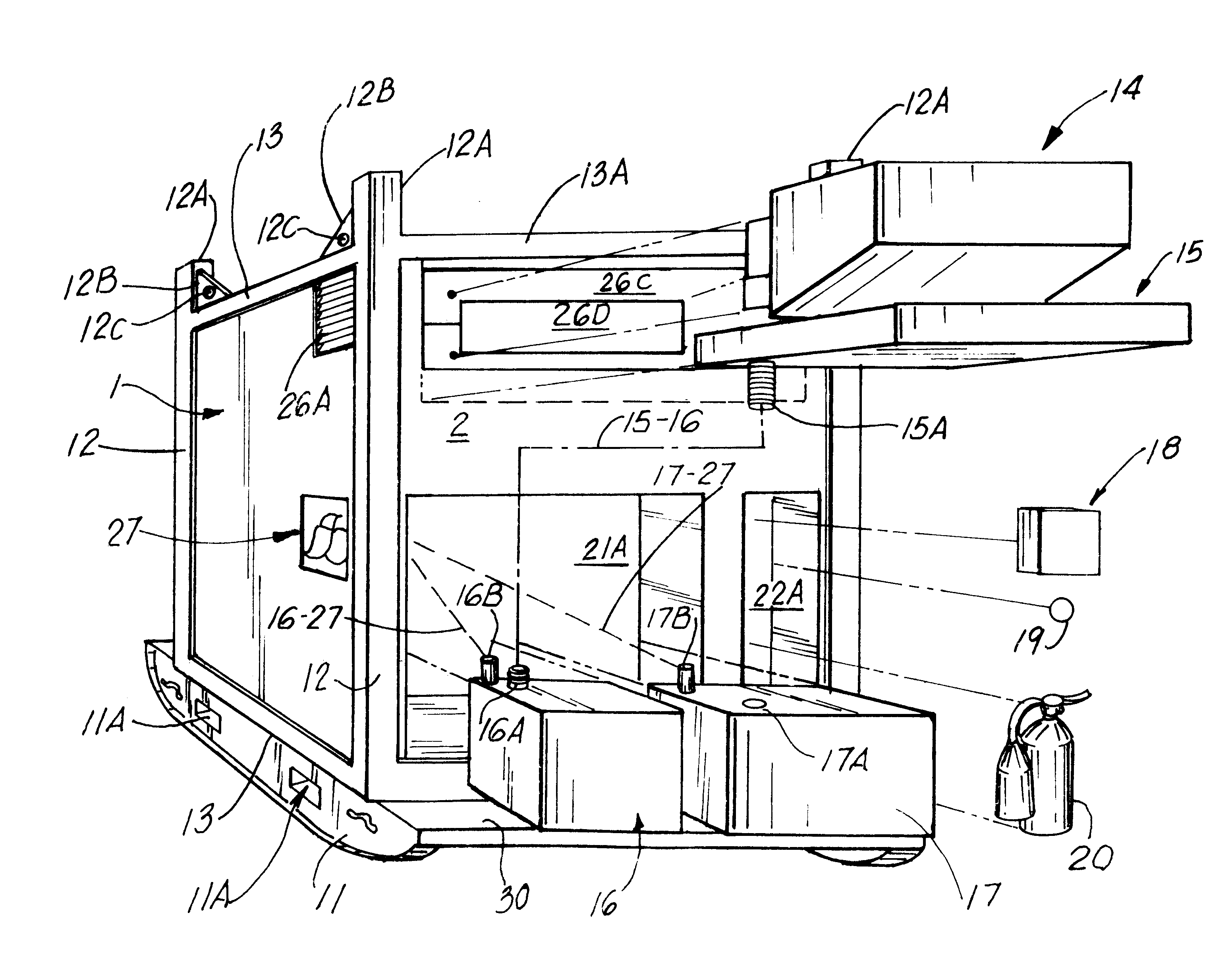

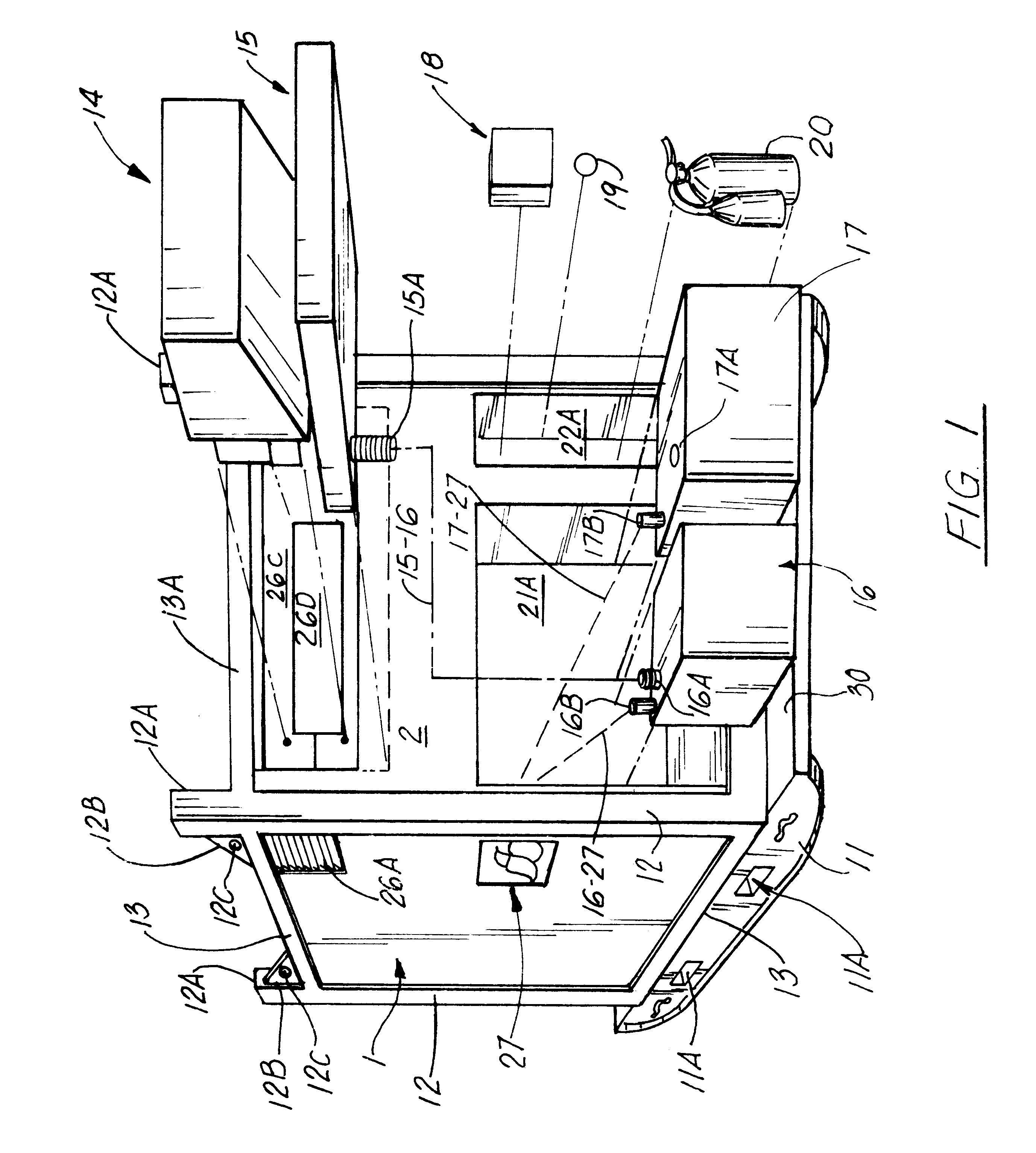

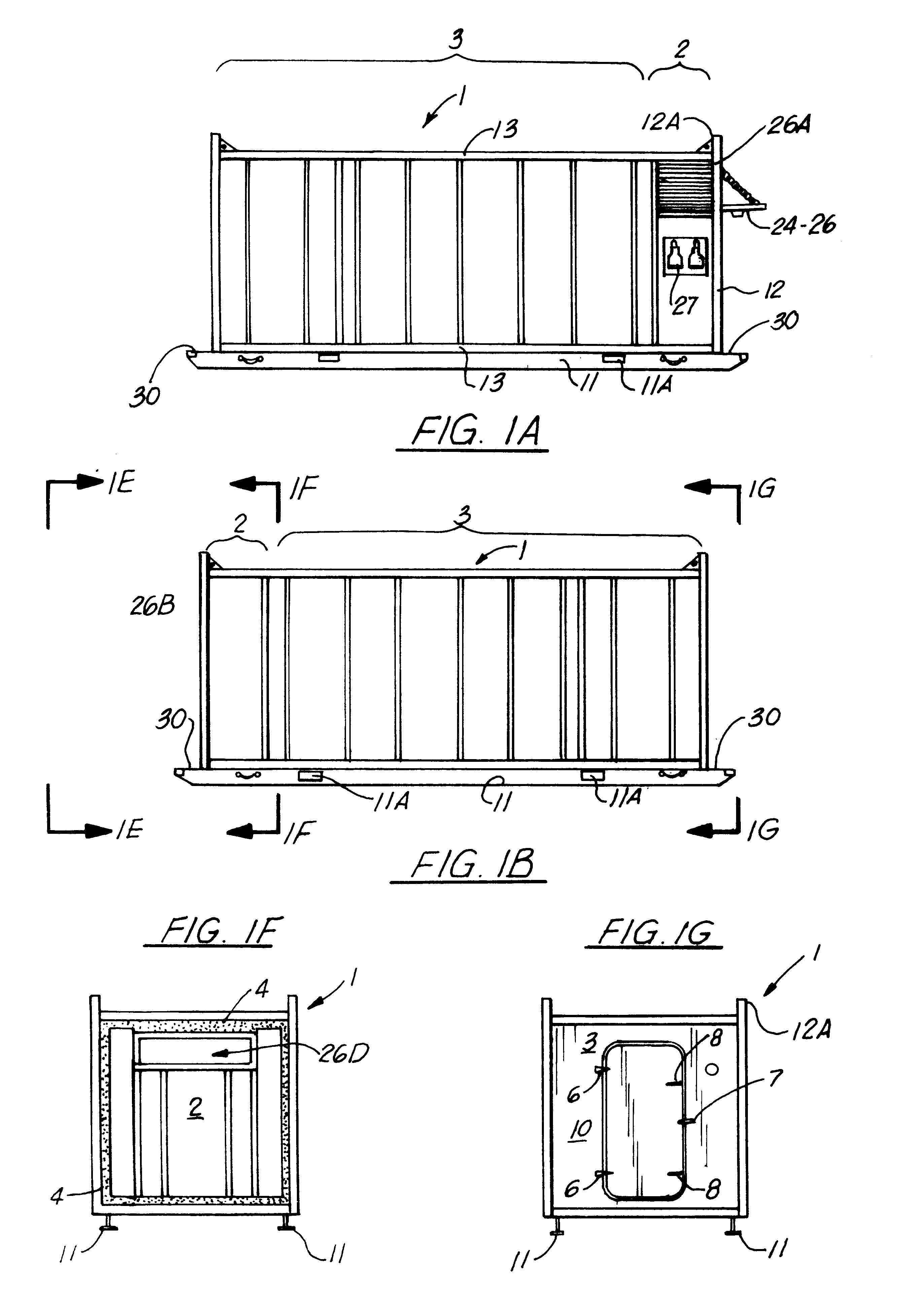

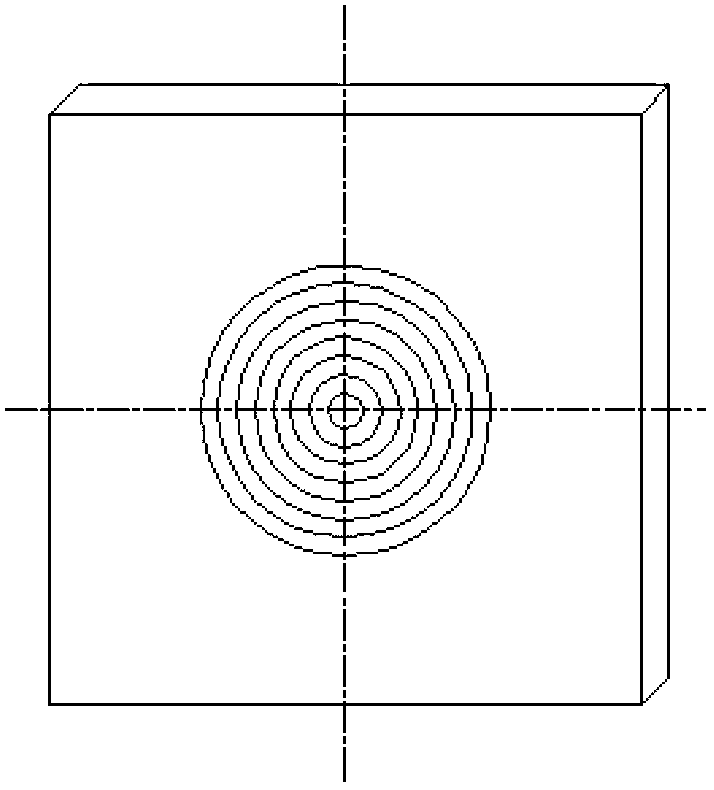

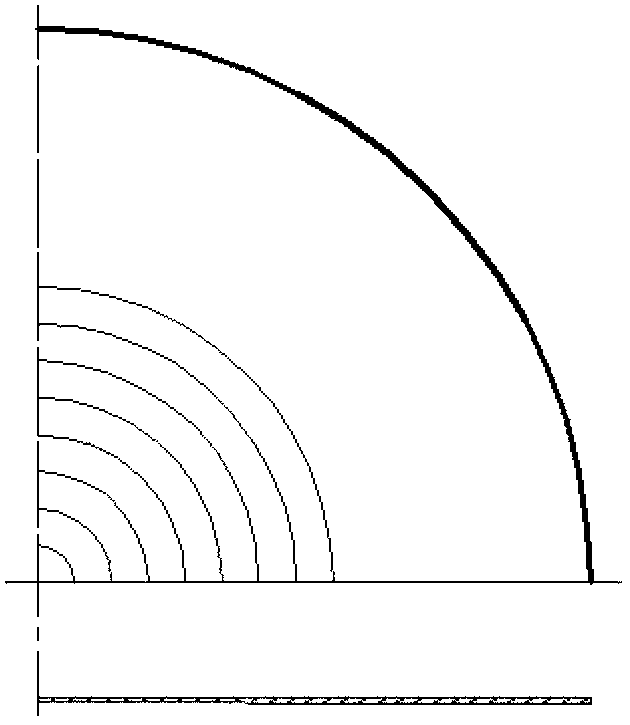

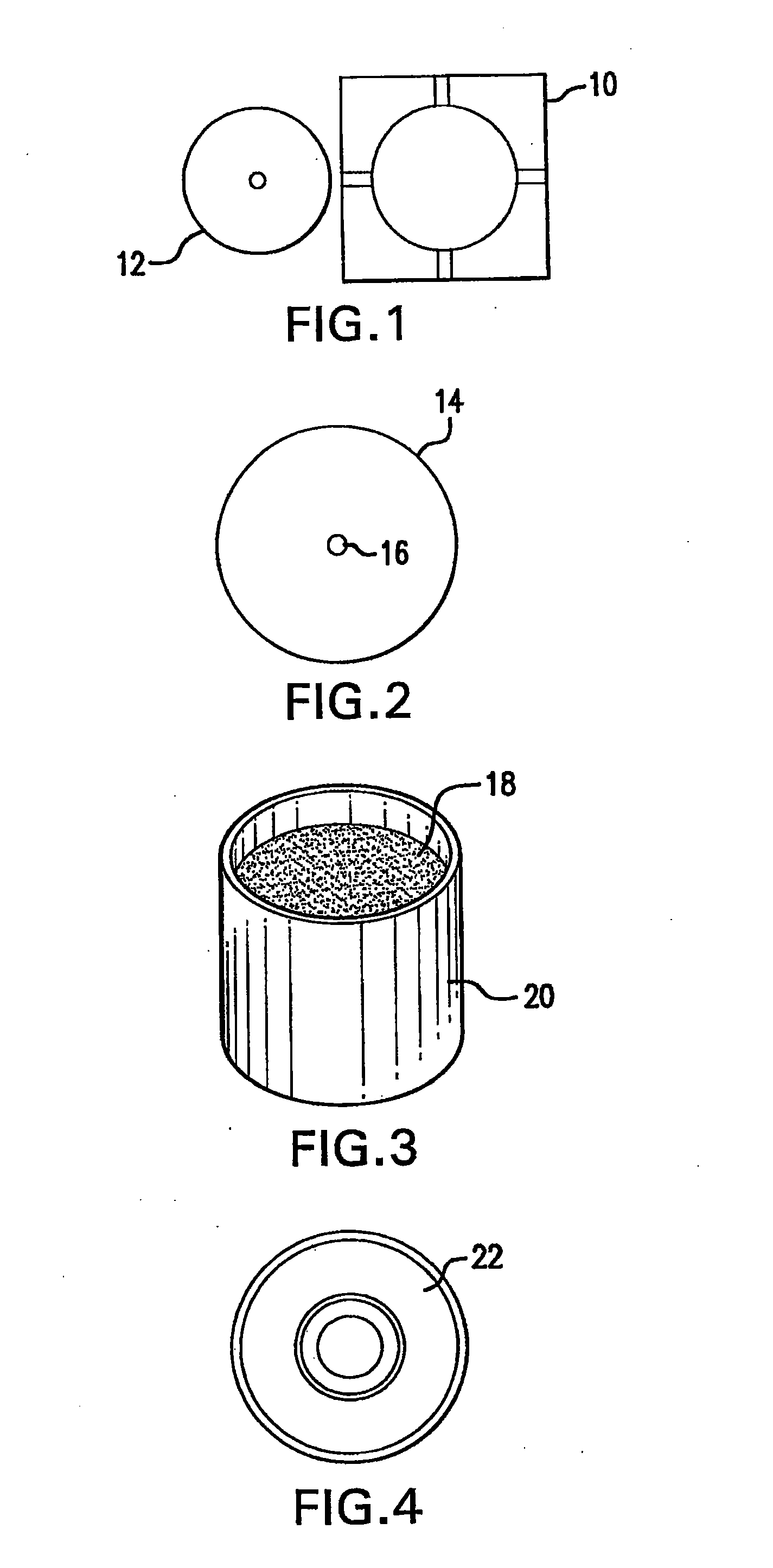

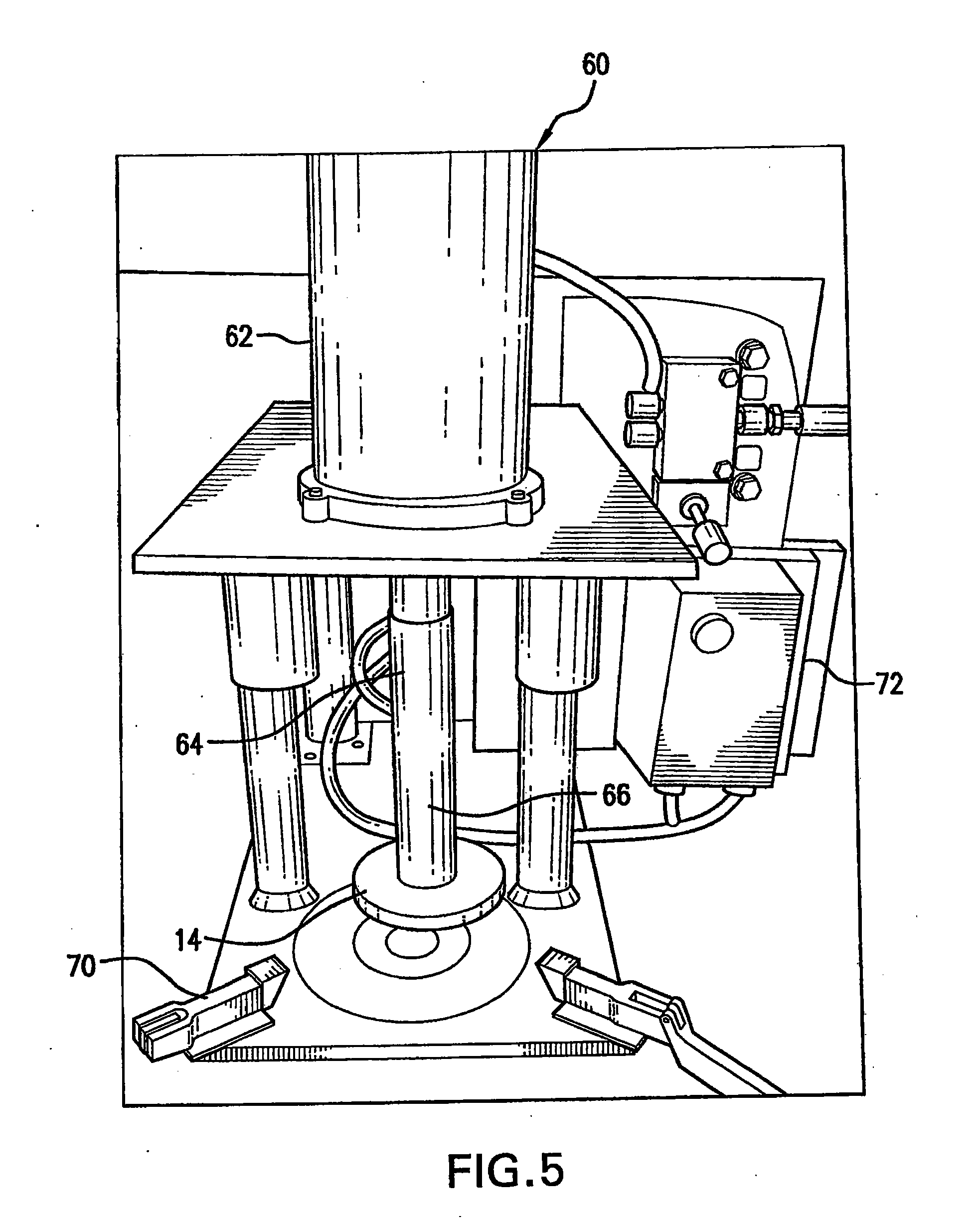

An extended, box-like, metal, industrial size, insulated container (1 / 101, two embodiments disclosed, FIGS. 1-1G & FIGS. 2A-2D) including a rigid, structural framework (12 / 13) for safely and reliably transporting and / or storing relatively large quantities of temperature sensitive items (food, medical supplies, ice, human corpses, etc.) over a long distance (e.g., from an on-shore food center to an offshore platform) and / or for a substantial period of time (7+days), useful for such delivery / storage and in emergencies, disasters, etc. The container includes at its ends a structurally protected, enclosed equipment section (2 / 102), which includes all operating machinery (e.g. compressor, motor, fuel tank, control mechanisms, etc., in isolated sub-compartments) and associated equipment, and a freezer / cooler section (3 / 103A-103B) for the temperature sensitive items. The second embodiment includes two, separate, freezer and cooler sections (103A / 103B) with separate, side doors (105A / 105B). An escape structure (FIGS. 3A & 3B) on the lock latch is included on the access door(s) for escape of an occupant who becomes locked in. Many other, innovative safety features are disclosed, along with innovative use methodologies (FIGS. 4 & 5).

Owner:GUIDRY & MORALES HLDG

Non-chrome washing agent for electrolytic metal manganese metal stainless steel pole plates

The invention relates to a non-chrome washing agent for electrolytic metal manganese metal stainless steel pole plates, which is characterized by being formed by preparing an organic sequestering agent, an inorganic corrosion inhibitor, a builder, a surface active agent, an antifoaming agent, an anti-sediment agent and other non-heavy-metal inorganic salt and organic compounds. The washing agent has the advantages of being friendly to environment, low in operating cost, good in using effect, small in damage on the pole plates, rapid in manganese electrolysis of the washed pole plates, easy to treat plate washing wastewater and the like. The washing agent can not only reduce heavy metal discharge of electrolytic manganese metal industries greatly, but also contributes to yield stabilization, and reduces cost.

Owner:XIANGXI AUTONOMOUS PREFECTURE JINGLIN NEW MATERIAL TECH

Fluorine-containing amphoteric polymer for surface coating and preparation method thereof

InactiveUS20050096444A1Allows self-emulsificationExcellent soil releaseLiquid repellent fibresFiberMetals industry

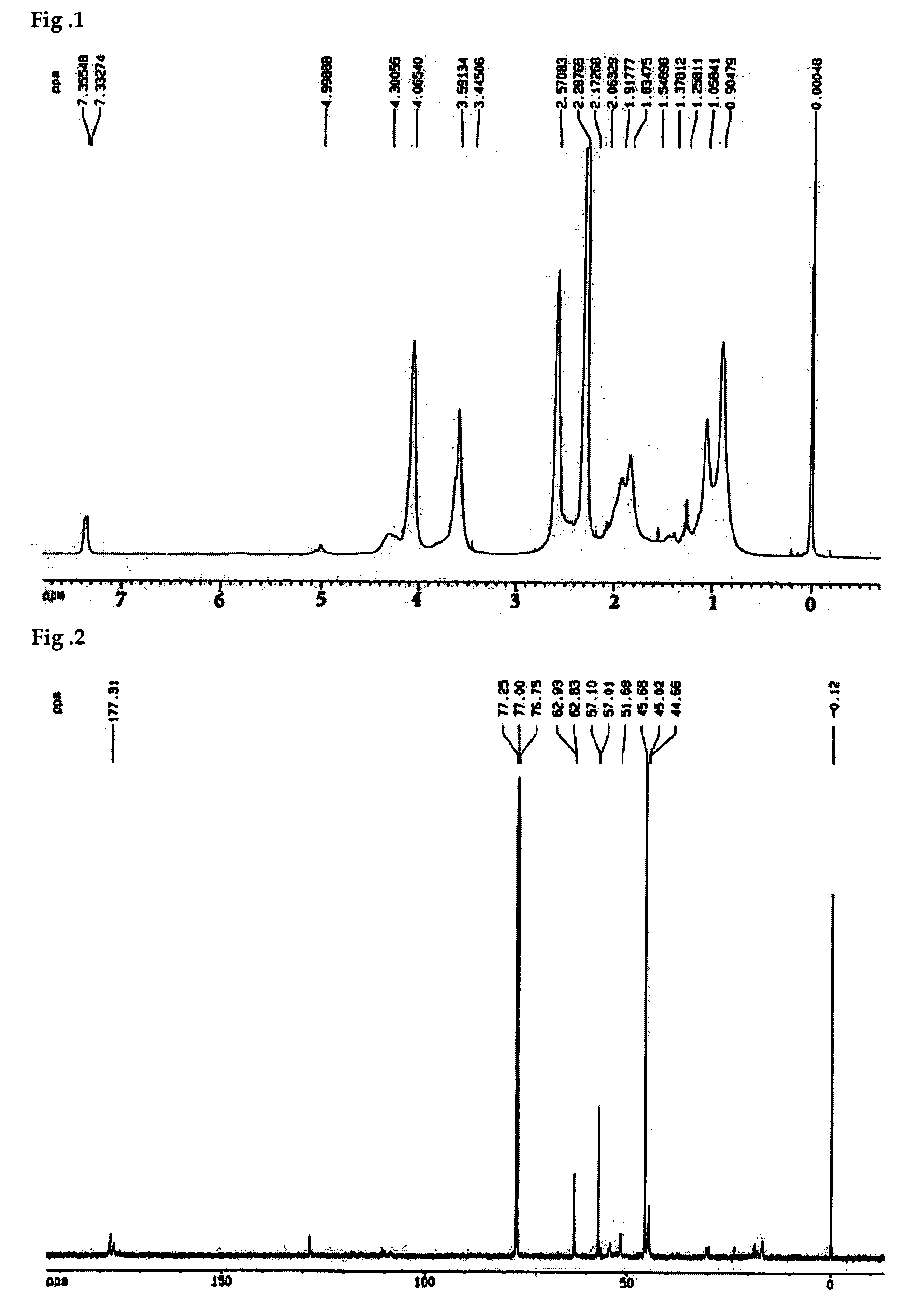

The present invention relates to a fluorine-containing amphoteric polymer for surface coating and preparation method thereof, in particular, to a fluorine-containing amphoteric polymer for surface coating and preparation method thereof in which a hydrocarbon compound with hydrophilic groups serves as a main chain and a macromonomer prepared by copolymerization of an unsaturated hydrocarbon compound and a perfluoro alkyl compound is incorporated into side chains, thereby imparting amphoteric property on the present polymer. Therefore, the present polymer allows self-emulsification and shows soil release, water-repellent and oil-repellent properties with no help of emulsifier, applicable to a variety of industrial fields such as coating, adhesive, fiber, precision chemistry, biological / biochemical industry, electric / electronic, automobile and metal industries.

Owner:KOREA RES INST OF CHEM TECH

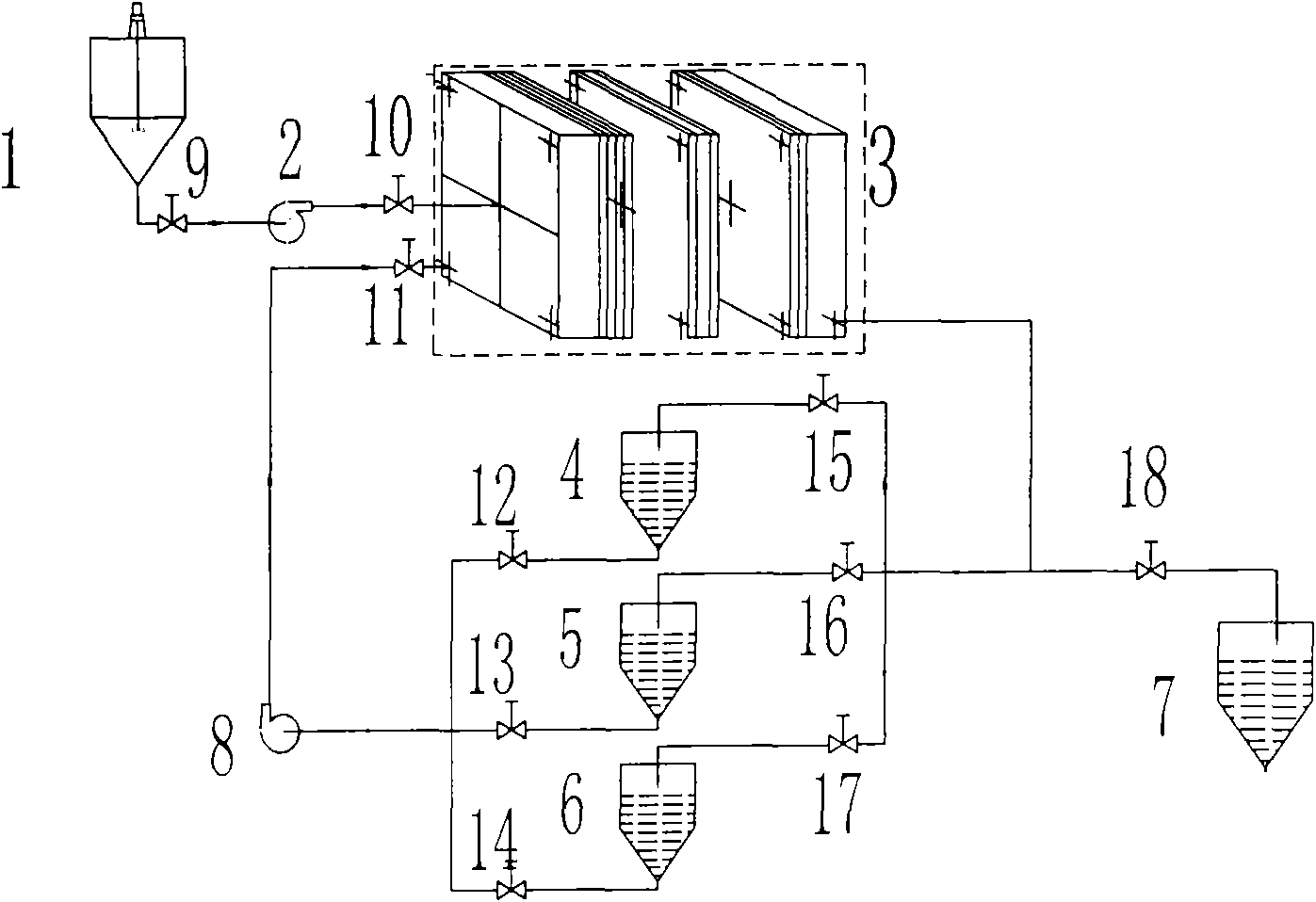

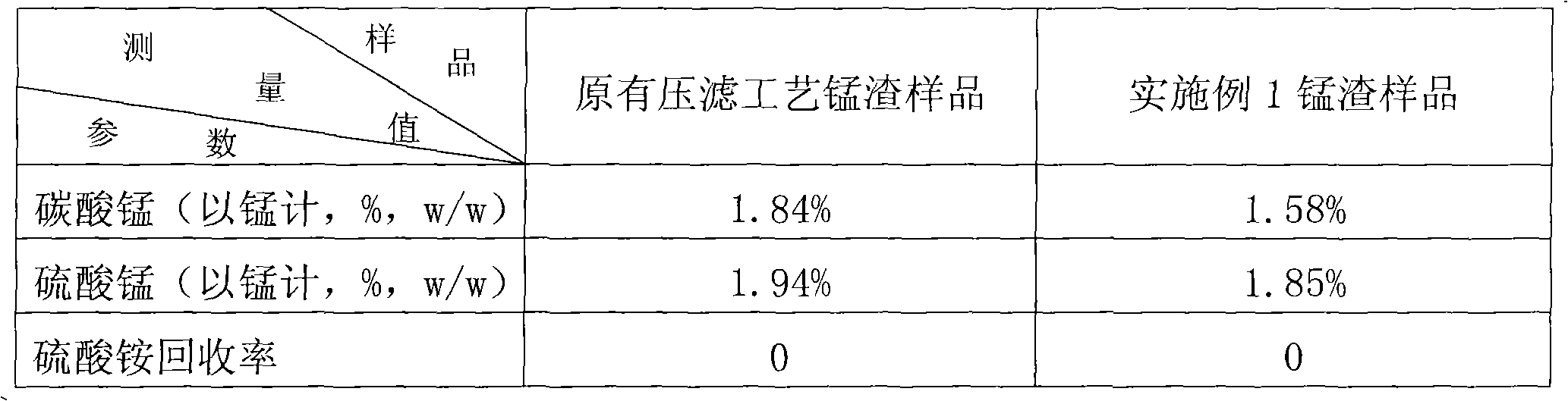

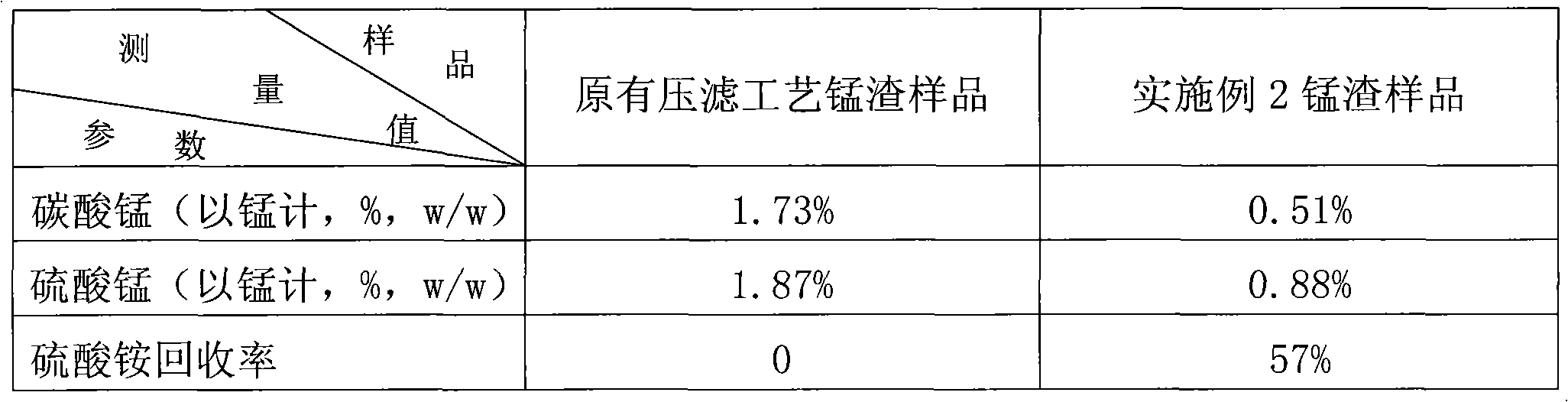

Integrative method of two-stage acid leaching, washing and filter pressing for manganese powder pickle liquor

ActiveCN101899583AManganese carbonate content decreasedReduce environmental risksProcess efficiency improvementMetals industryElectrolysis

The invention relates to an integrative method of two-stage acid pickling, washing and filter pressing for manganese powder pickle liquor in a membrane filter press, which is applied to the processing procedures of manganese powder leaching and filter pressing in an electrolytic manganese metal industry. The method comprises the following steps: (1) feeding materials; (2) carrying out acid leaching and washing for anolyte at twice; (3) washing by circulating water; (4) washing by a solution with lower manganese concentration or clear water; and (5) carrying out the filter pressing for a filter cake to finish operation. The invention can reduce manganese carbonate content (calculation by manganese) in an original filter pressing technology for manganese residues in the electrolytic manganese metal industry from 1.5%-2.0% to below 0.6%; manganese sulfate (calculation by manganese) can be reduced to below 0.8% from 1.5%-2.0% and the recovery rate of the ammonium sulfate can reach above 50%. Based on cleaner production idea of controlling a source, the invention recovers the ammonium sulfate by reducing residuals of manganese resource in manganese slag, thus environmental risk of manganese slag landfill is greatly reduced and the utilization ratio of the manganese resource is increased by about 8-14%.

Owner:CHINESE RES ACAD OF ENVIRONMENTAL SCI

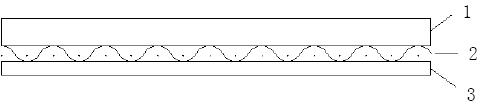

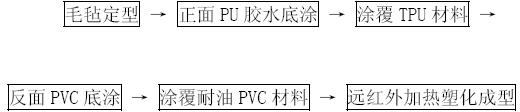

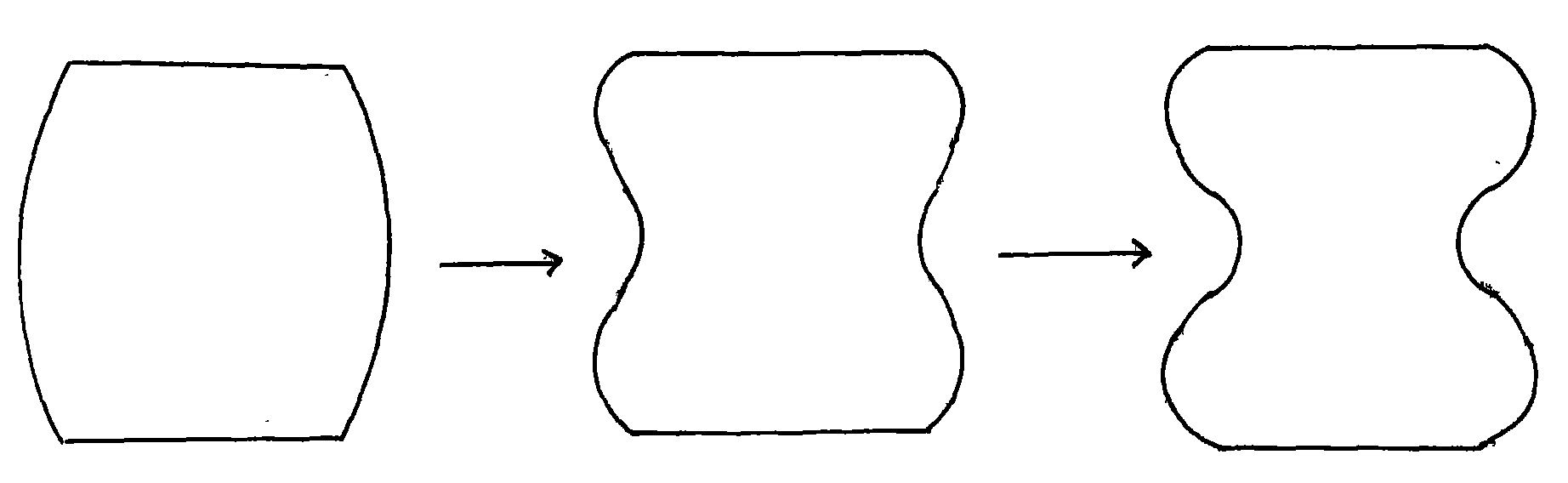

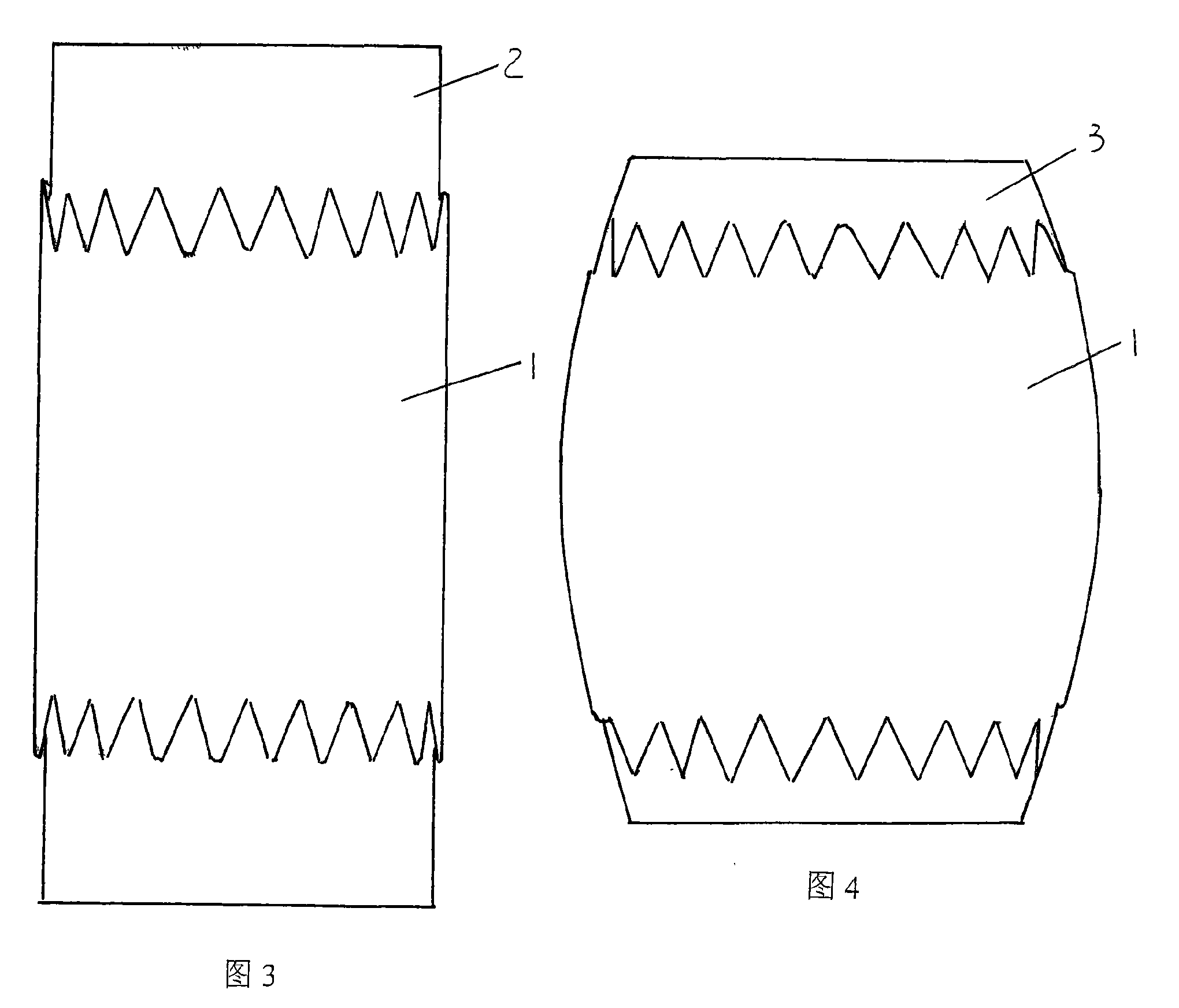

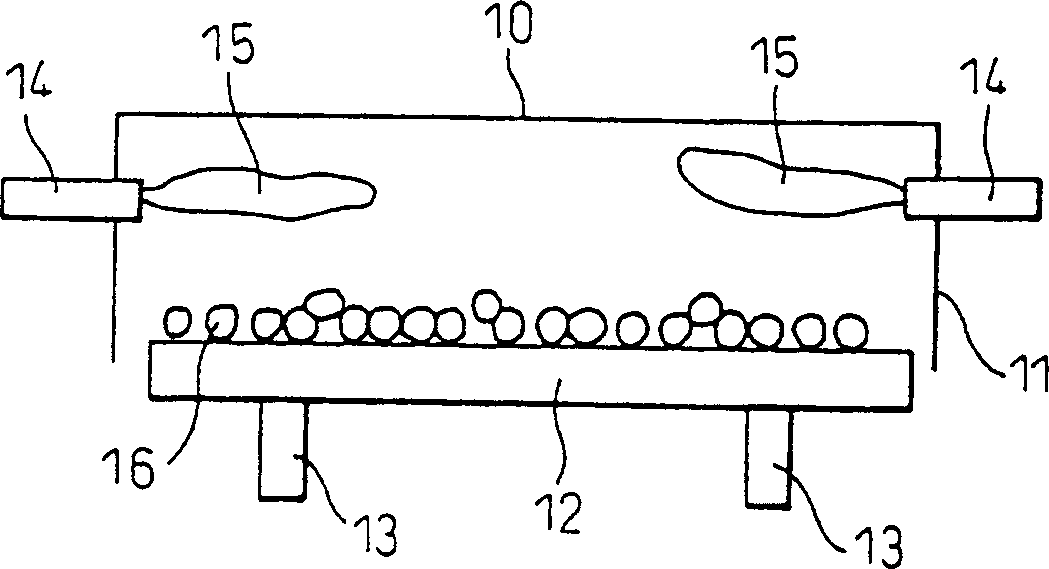

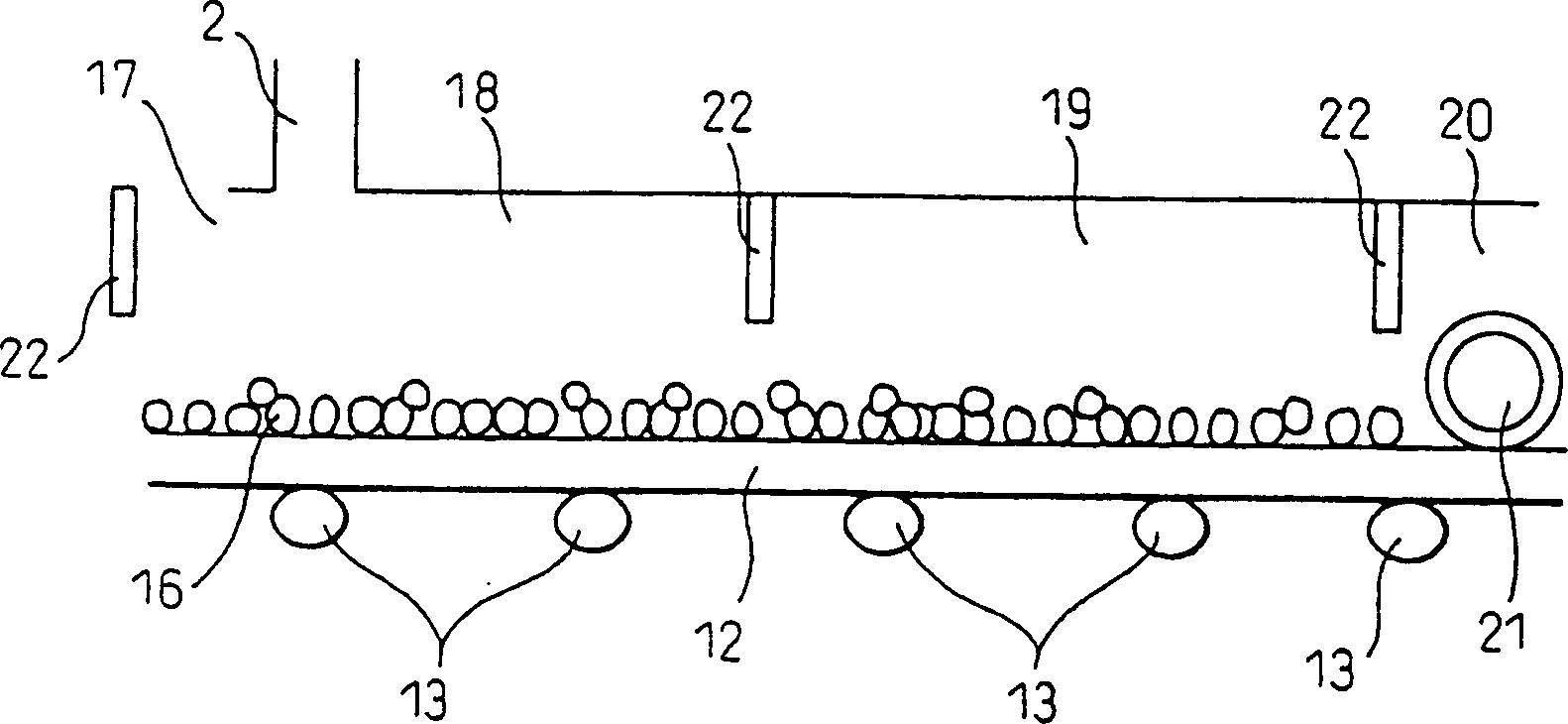

Seamless wrapper belt and manufacture method thereof

ActiveCN102424236AMeet the surface oil resistanceMeet the characteristicsConveyorsSynthetic resin layered productsPolyesterMetals industry

The invention relates to a seamless wrapper belt which is used for packing a cold rolled sheet metal. The wrapper belt takes an annular polyester fabric felt as a framework material, the front side of the framework material is a thermoplastic polyurethane elastomer material layer, and the back side of the framework material is an oil-resistant polrvinyl chloride material layer. A preparation method of the seamless wrapper belt comprises the following steps of: shaping the felt; firstly coating polyurethane (PU) glue at the front side of the framework material, thenand coating thermoplastic polyurethane elastomer (TPU) materials; firstly coating polyvinyl chloride (PVC) at the back side of the framework material, thenand coating oil-resistant PVC materials; and plastifying and shaping by means of far infrared heating, so that the seamless wrapper belt is manufactured. The invention has the advantages that an annular seamless conveyer belt is offered to a wrapper in a cold rolled sheet metal industry, so that not only can the characteristics of oil resistance and impact resistance of the surface be met, but also various problems caused by a seam can be basically avoided; and the seamless wrapper belt can be customized according to different perimeter sizes required by a customer, so that the personalized requirement of the customer can be met.

Owner:SHANGHAI YONGLI BELTING +1

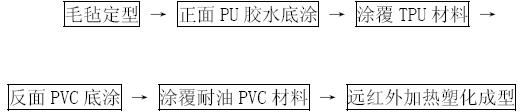

Method for upsetting high-temperature alloy round ingot

InactiveCN101633029AReduce deformation resistanceHigh yieldMetal-working apparatusMetals industryIngot

The invention provides a method for upsetting a high-temperature alloy round ingot, belonging to the technical field of hot processing forging of high-temperature alloy in the metal industry. The method comprises the following steps that an alloy round ingot blank is preprocessed, before the blank is heated in a furnace, the alloy round ingot is subjected to top crops and end crops, so that end faces of two ends of the alloy round ingot blank which is subjected to top crops and end crops are flat to a degree vertical to the axial line of the alloy round ingot, thereby obtaining an alloy round ingot to be heated in the furnace; a ceramic insulation blanket is coated, the ceramic insulation blanket is coated in the middle of the alloy round ingot to be heated in the furnace so as to obtain a ceramic insulation blanket coated alloy round ingot to be heated in the furnace; the ingot is heated in the furnace, the ceramic insulation blanket coated alloy round ingot to be heated in the furnace is fed into the furnace for heating; the ingot is discharged from the furnace; the time from discharging to upsetting is controlled to obtain the alloy round ingot to be upset; the ingot is upset, the alloy round ingot to be upset is upset to obtain an upset intermediate blank. The method has the advantages of improving the yield and forging efficiency of alloy forging, improving the quality of a forge piece, and reducing energy consumption.

Owner:江苏苏南特种金属保温锻造研发中心有限公司

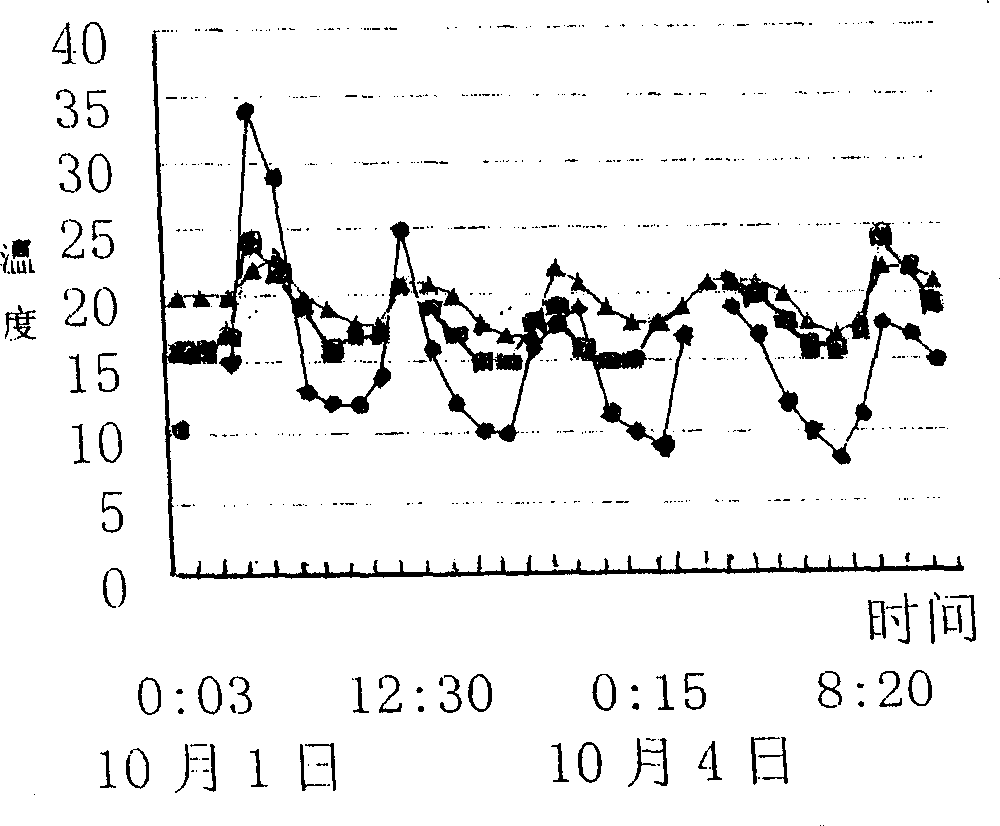

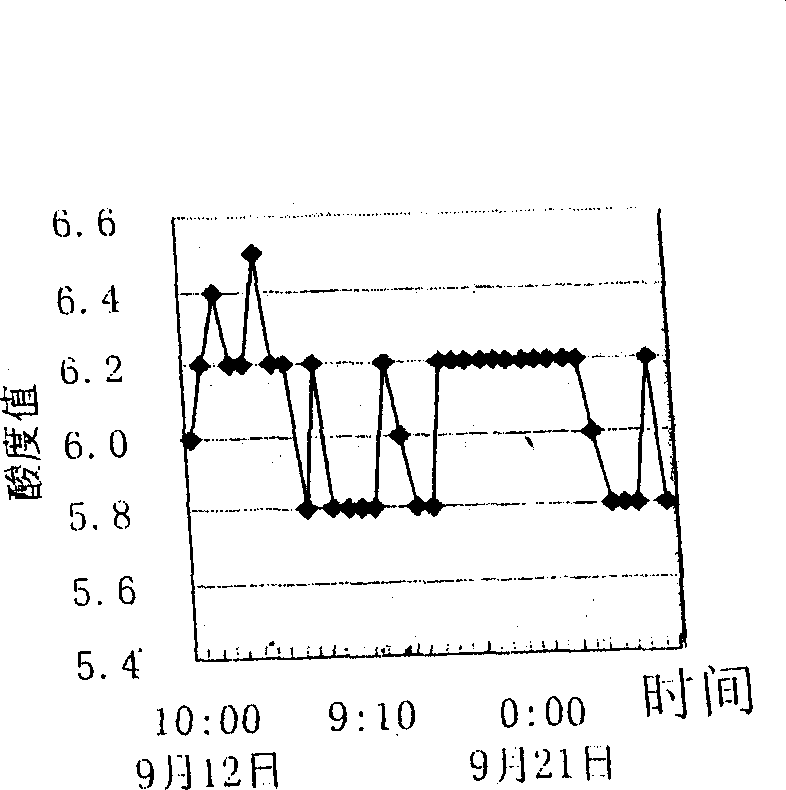

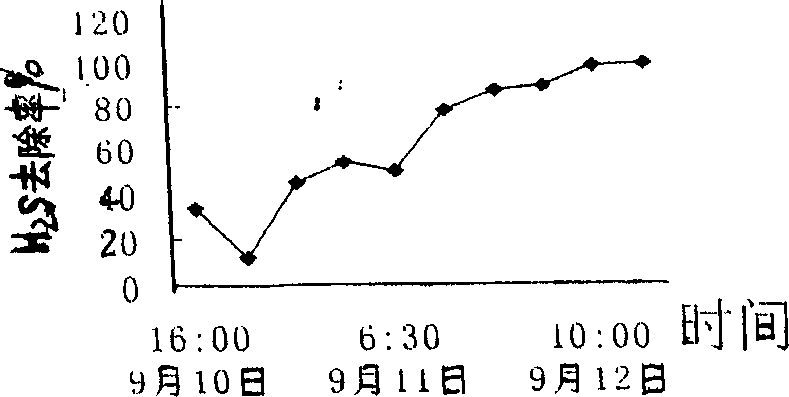

Method of deodour using biofiltration

InactiveCN1597067AExtend the life cycleWide variety of sourcesDispersed particle separationDeodrantsMetals industryChemical treatment

A biological filtering method for deodoring gas features that the odor gas flows through the particular biological filtering material for degradating the pollutent by microbes.

Owner:李晓飞

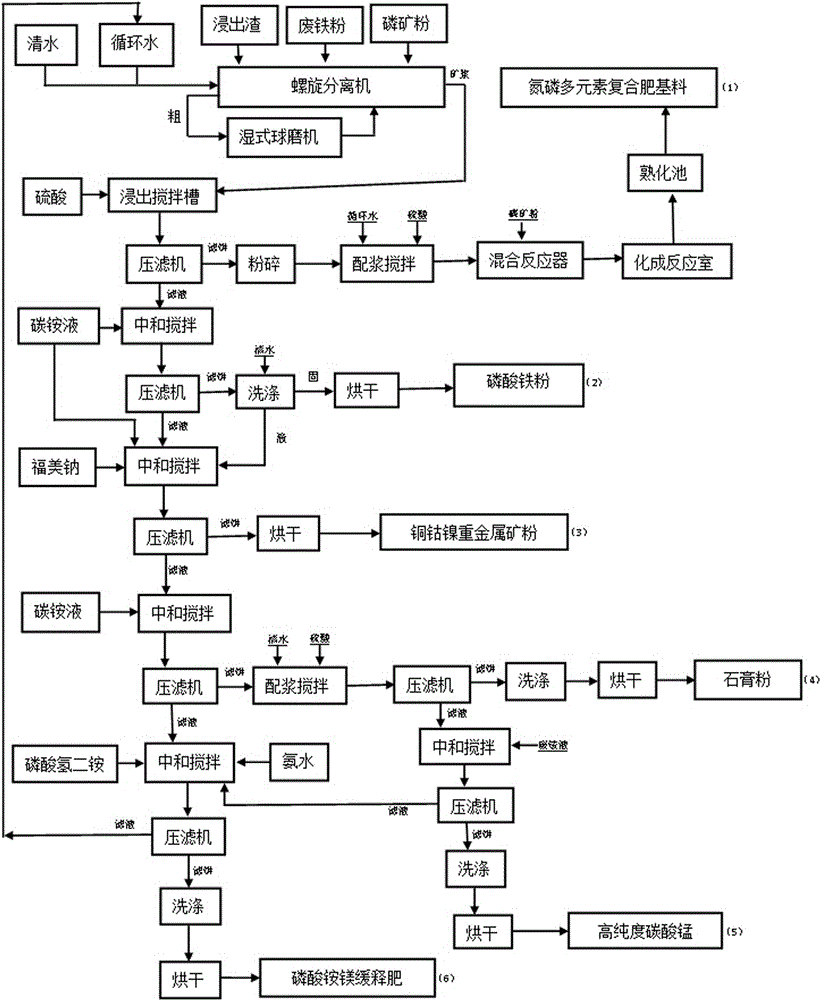

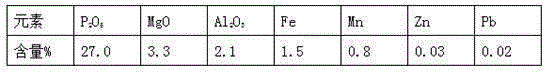

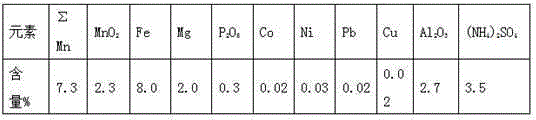

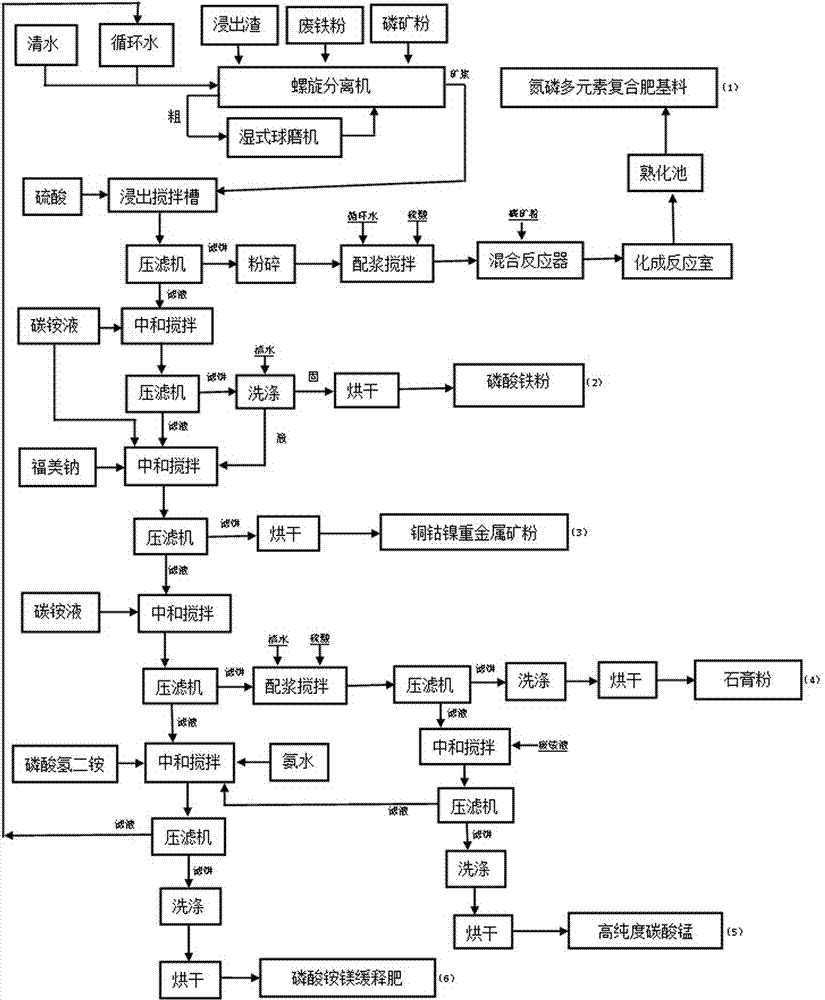

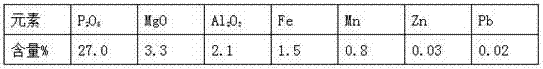

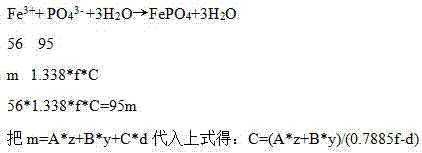

Comprehensive recycling method for leaching residues in electrolytic manganese metal production

InactiveCN105152153AThe preparation process steps are simpleEasy to operateCalcium/strontium/barium sulfatesProcess efficiency improvementFerric hydroxideMetals industry

A comprehensive recycling method for leaching residues in electrolytic manganese metal production concretely includes the steps that 1, a compound fertilizer substrate is prepared; 2, ferric phosphate powder is recycled; 3, copper-cobalt-nickel precious metal mineral powder is recycled; 4, gypsum powder is recycled; 5, high-purity manganese carbonate ore is prepared; 6, magnesium ammonium phosphate slow-release compound fertilizer is prepared. Iron, manganese and other resources in the leaching residues can be effectively recycled, and a certain amount of non-completely-dissolved manganese carbonate ore and manganese dioxide ore and precipitated ferric hydroxide and copper, cobalt and nickel precious metal sulfide ore contained in the leaching residues in electrolytic manganese metal production and Mn2+, NH4+ and other valuable substances can be recycled comprehensively and systematically, wherein the valuable substances are separated along with residue water; in this way, the effects of entire and comprehensive recycling and zero discharge are achieved, and the method has quite important meaning for energy conservation, emission reduction and environment pollution treatment in the electrolytic manganese metal industry.

Owner:赵阳臣

High-water-resistance fluorocarbon powder paint

InactiveCN106318057AImprove waterproof performanceStrong adhesionPowdery paintsPolyester coatingsMetals industryWater resistant

The invention relates to the technical field of compound design of water-resistant powder paints, particularly a high-water-resistance fluorocarbon powder paint which comprises a fluorocarbon resin, an epoxy modified alkyd resin, a carboxyl-terminated polyester resin, a bismaleimide resin, triethanolamine, dibutyltin dilaurate, 2-(2-aminoethoxy) ethanol, triallyl isocyanurate, aluminum tripolyphosphate, a silane coupling agent, graphene, nano silicon dioxide, nano titanium dioxide, polyethylene wax, precipitated barium sulfate and calcium fluoride. The powder paint has high water resistance; the coating has the advantages of high adhesion with the substrate, compact and smooth surface, favorable scratch resistance and favorable friction resistance, and is applicable to the fields of rail transit (high-speed rails, subways, light rails and the like), oil-gas water pipelines, ship industry, indoor / outdoor metal structural member engineering, electric appliance metal industry and other fields related to human domestic and industrial manufacturing.

Owner:JIANGSU HUAGUANG NEW MATERIAL TECH CO LTD

Propeller hub fairing skin machining method

The invention belongs to the field of aviation manufacturing and particularly relates to a propeller hub fairing skin machining method. The propeller hub fairing skin machining method comprises the steps of blanking, milling to flat plate woolen materials, the steps of forming variable thickness materials, the steps of forming variable thickness revolving body materials, powerspinning to the woolen materials and the steps of forming parts of revolving body shapes. The propeller hub fairing skin machining method overcomes the wrinkling problem caused by ordinary flow forming and further overcomes the problems of raw materials waste and low part fatigue strength brought by part appearance obtained by a method of mechanical machining. Due to the fact that a technology method of variable thickness powerspinning curve parts is adopted, the defect that uniform thickness plate materials are turned into different thickness curve parts in a powerspinning mode is overcome. In addition, in the process of attenuation flow forming, pressure stress on the surface of the parts is large, and the parts obtain large surface hardness. The mechanical performance of the parts is improved, and the fatigue strength and the surface hardness of the parts are improved. The overweight problem of powerspinning parts commonly existing in a sheet metal industry is solved.

Owner:SHAANXI AIRCRAFT CORPORATION

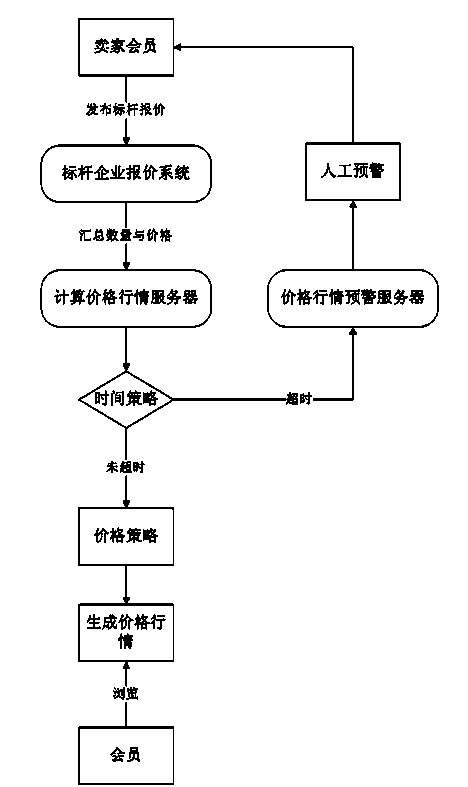

Automatic metal electronic commerce price information generation system and method

The invention provides an automatic metal electronic commerce price information generation system and method. The system is characterized in that the system is provided with a price information calculating server and a price information early warning server and meanwhile is provided with a time strategy calculating method, a price strategy calculating method and a system platform background operation server, wherein the price information calculating server and the price information early warning server depend on internet. The system supplies standardized service to merchants and end consumers of the metal internet industry and supplies guide service to industry price information. The system provides supply and demand information arranged according to areas, cities, varieties and the like. A system platform can perform statistic analysis on area price information tendency and prediction of metal varieties conveniently. The system can achieve supply and demand information complementation with the end consumers. The system can be used by users at two ends conveniently. Seller members and buyer members achieve metal industry chain connection electronic commerce through the automatic metal electronic commerce price information generation system and method.

Owner:LIAONING BOYU TECH

Toughened epoxy system for abrasion resistant coatings

ActiveUS20130052355A1Good physical propertiesOther chemical processesConjugated diene hydrocarbon coatingsCoating systemAcrylonitrile

An epoxy-based coating system for metal industrial equipment and parts provides superior abrasion resistance compared to known coating compositions. The coating system includes a resin component and a hardener component. The resin component includes one or more bisphenol epoxy resins and inorganic beads. The hardener component includes a butadiene acrylonitrile rubber, one or more curing agents, and inorganic beads. The resin component and hardener component are mixed together, applied to a metal surface, and cured to form the abrasion-resistant coating.

Owner:ILLINOIS TOOL WORKS INC

Fractional precipitation treatment method of wastewater containing nonferrous metal of nickel, lead and cadmium

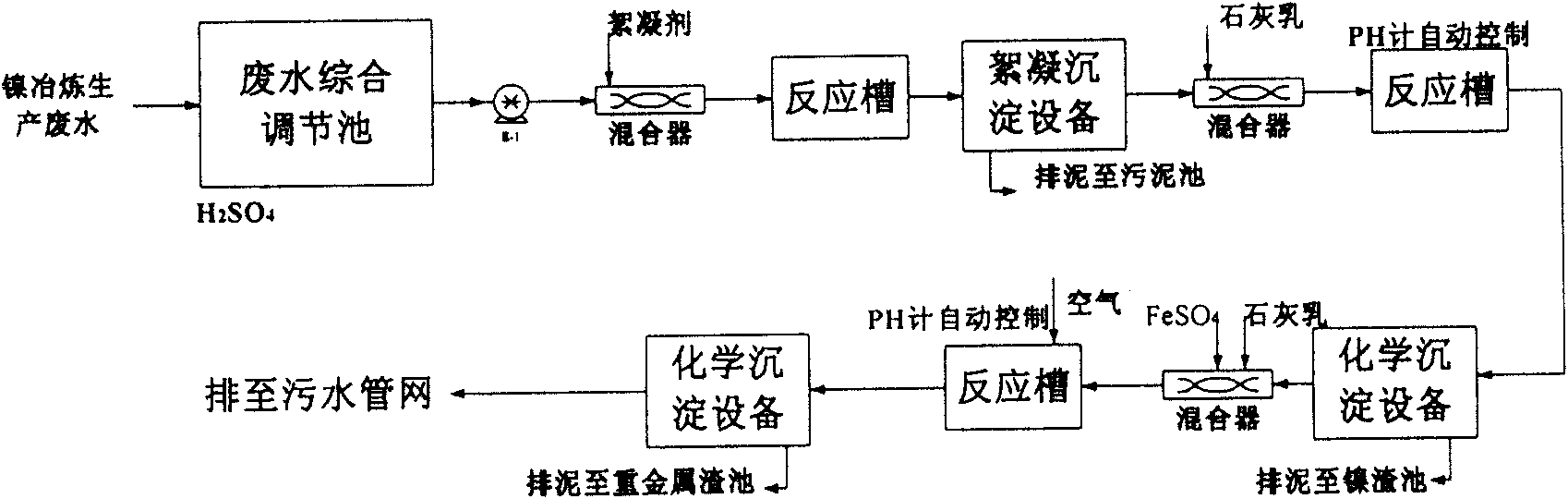

InactiveCN101665293AEfficient separationEasy to recycleWater contaminantsMultistage water/sewage treatmentMetals industryWater quality

The invention relates to a fractional precipitation treatment method of wastewater containing nonferrous metal of nickel, lead and cadmium, in particular to a method for treating industrial wastewatercontaining nonferrous metal, comprising the following steps: balancing water quality and water quantity after wastewater enters in a balance tank; raising the wastewater to a coagulation sedimentation tank for coagulation sedimentation; adding limemilk in the wastewater in a reactive tank, controlling the pH value to be 8.0, then settling hydroxide of the nickel in a primary sedimentation tank; adding limemilk into a settlement, controlling the pH value to be 11 and adding FeSO4 and polymeric ferric silicate sulfate, and then settling metal hydroxides in a secondary sedimentation tank. The invention can effectively separate almost all nickel metal from the wastewater to facilitate recycling, and then remove the residual metal ions in the wastewater by adopting a compulsory measure, thereby not only protecting the environment, but also realizing production saving.

Owner:CHANGCHUN INST OF TECH

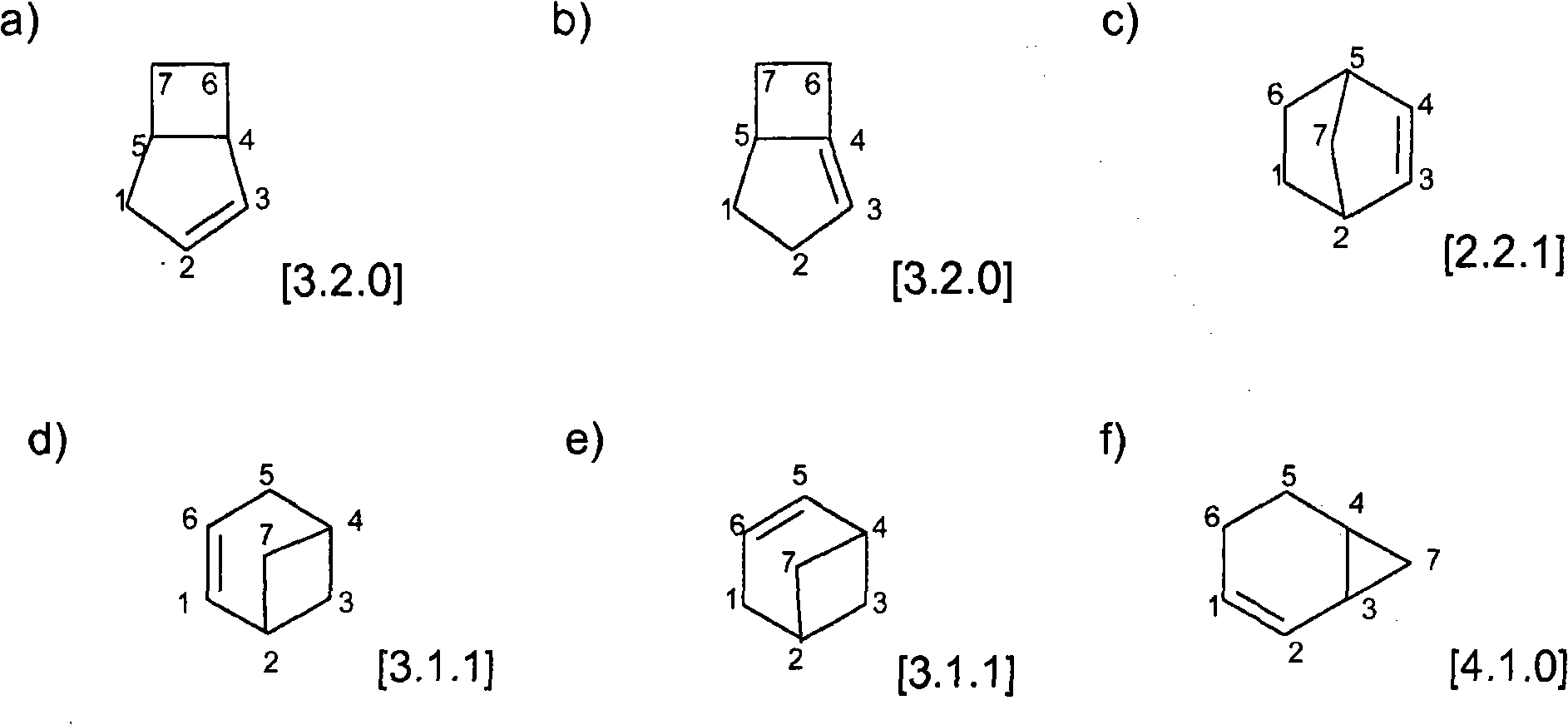

Centrifugal concentrator

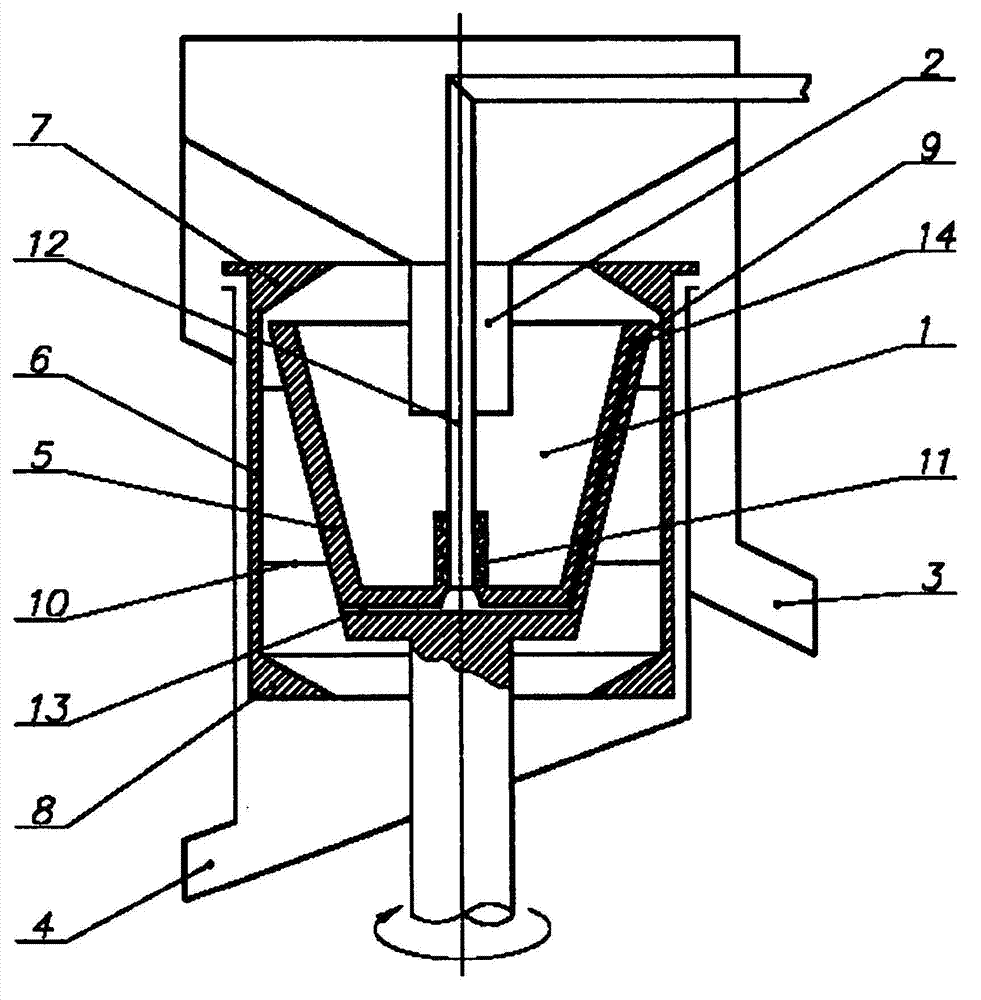

InactiveCN102971079AImprove stabilityQuality improvementRotary centrifugesWet separationFraction CollectorMetals industry

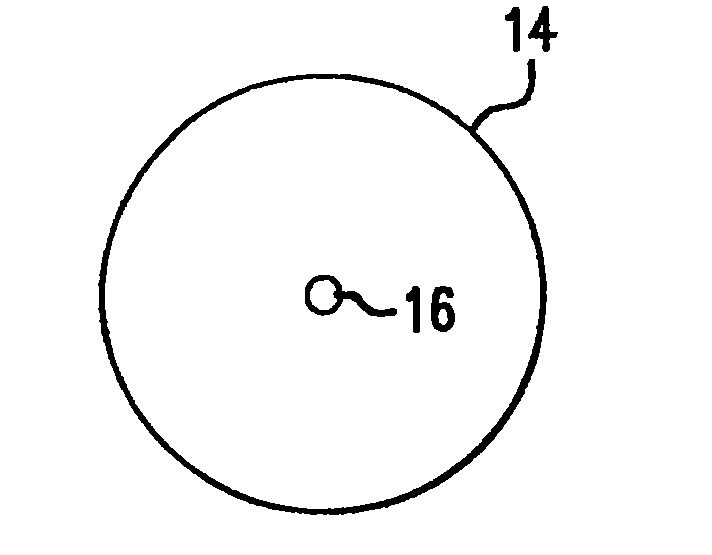

The invention relates to the field of mineral processing and can be used for separating solid particles according to density, for example in factories in the polymetal industry, in tin production plants and in gold mining plants, both at the initial enrichment stage and in the processing of industrial waste. The technical result consists in simplifying the design and increasing the operational reliability of the apparatus as well as enhancing the quality of the concentrate produced. The concentrator comprises a rotor (1), mounted on a rotational shaft, a feed pipe (2), a light fraction receiver (3) and a heavy fraction collector (4). The rotor (1) comprises a cone (5) with a base, and a cylindrical shell (6) with an annular runoff lip (7) on the light fraction receiver side and an annular lip for collecting the heavy fraction (8). An annular gap (9) is provided between the edge of the large base of the cone and the cylindrical shell (6). The inner cone of the rotor is rigidly connected to the cylindrical shell. A sleeve (11) with a seal having a stationary tube (12) inserted therein is disposed along the rotor axis on the base of the inner cone. The sleeve (11) is connected to channels oriented inside the shell (6) for supplying flushing water to the outer shell.

Owner:弗拉基米尔·米哈伊洛维奇·列皮奥欣 +1

Sheet metal part stamping process

The invention relates to the sheet metal industry, in particular to a sheet metal part stamping process. The sheet metal part stamping process comprises the following steps: a, punching and trimming; b, raising and deburring; c, cambering; d, removing offsets and bending; and e, side pushing and leveling. The sheet metal part stamping process is reasonable in structure, the quality problem in the cambered surface molding process is effectively relieved, the precision of a molded cambered surface is guaranteed, meanwhile, damage to a die in the molding process is effectively reduced, and the production cost is lowered.

Owner:SUZHOU KANGFU PRECISION MACHINERY CO LTD

Comprehensive recovery and utilization method of leaching slag in electrolytic manganese metal production

InactiveCN105152153BThe preparation process steps are simpleEasy to operateCalcium/strontium/barium sulfatesProcess efficiency improvementMetals industryElectrolysis

A comprehensive recycling method for leaching residues in electrolytic manganese metal production concretely includes the steps that 1, a compound fertilizer substrate is prepared; 2, ferric phosphate powder is recycled; 3, copper-cobalt-nickel precious metal mineral powder is recycled; 4, gypsum powder is recycled; 5, high-purity manganese carbonate ore is prepared; 6, magnesium ammonium phosphate slow-release compound fertilizer is prepared. Iron, manganese and other resources in the leaching residues can be effectively recycled, and a certain amount of non-completely-dissolved manganese carbonate ore and manganese dioxide ore and precipitated ferric hydroxide and copper, cobalt and nickel precious metal sulfide ore contained in the leaching residues in electrolytic manganese metal production and Mn2+, NH4+ and other valuable substances can be recycled comprehensively and systematically, wherein the valuable substances are separated along with residue water; in this way, the effects of entire and comprehensive recycling and zero discharge are achieved, and the method has quite important meaning for energy conservation, emission reduction and environment pollution treatment in the electrolytic manganese metal industry.

Owner:赵阳臣

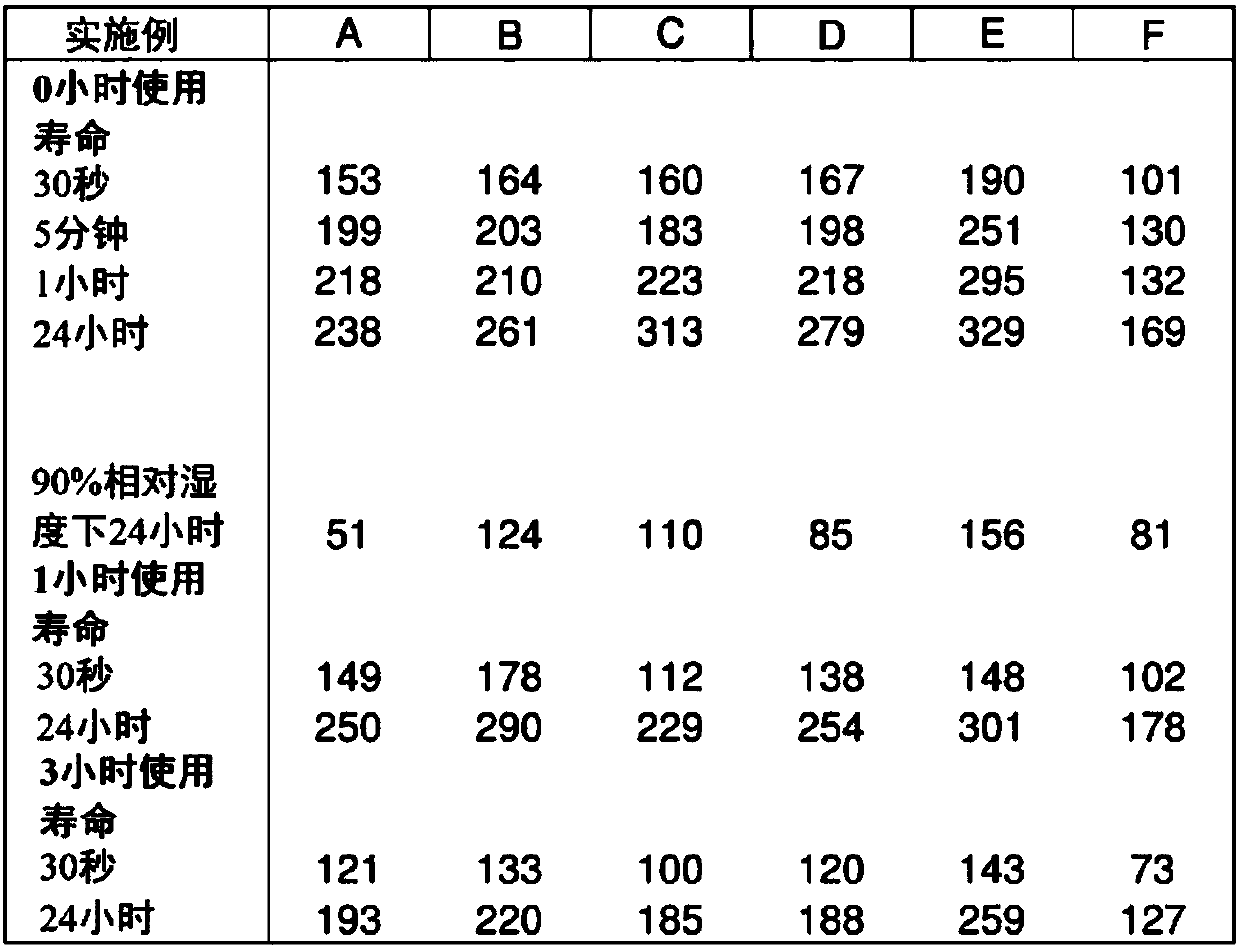

Three component polyurethane binder system

InactiveCN107624124ANon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesMetals industryHydrofluoric acid

An organic binder system is mixed with molding material for sand casting in the metals industry. The organic binder system has three parts, the first two of which are conventional and are used in thecold box or no bake process. The third part, which is combined with the first two parts at the time of use, contains at least an alkyl silicate and, optionally, a bipodal aminosilane. In some embodiments, an amount of hydrofluoric acid is included in one or both of the first two parts. Use of the organic binder system provides improved tensile strength in the mold, especially in high relative humidity.

Owner:ASK CHEM LLC

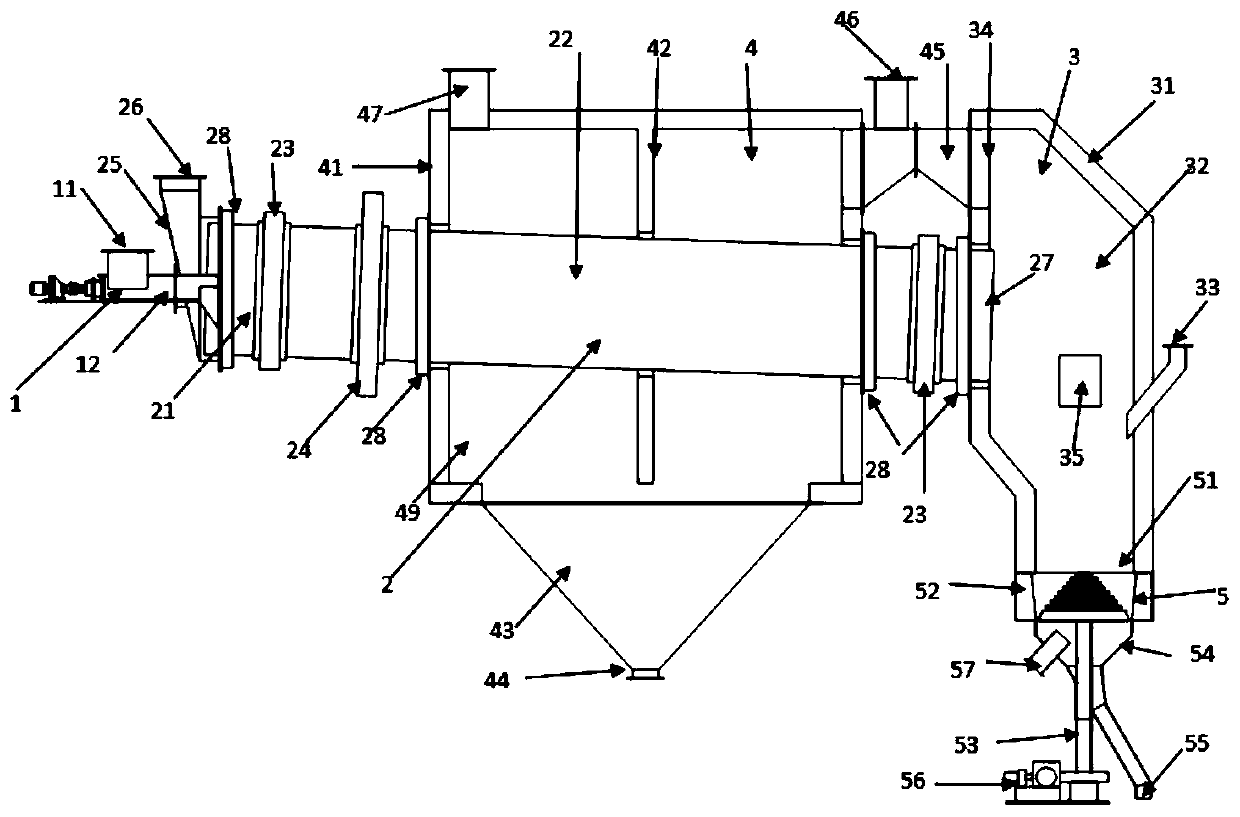

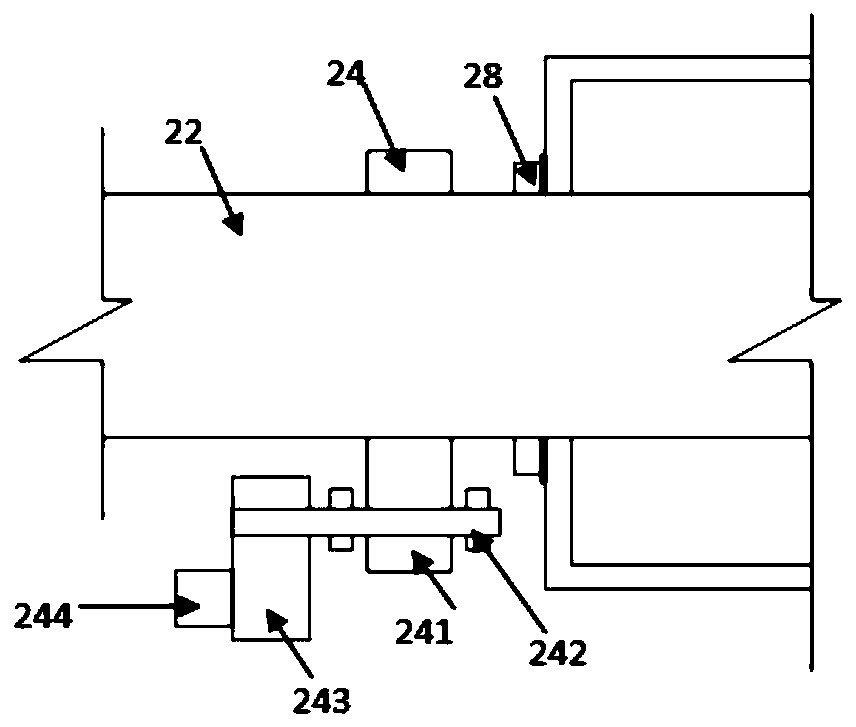

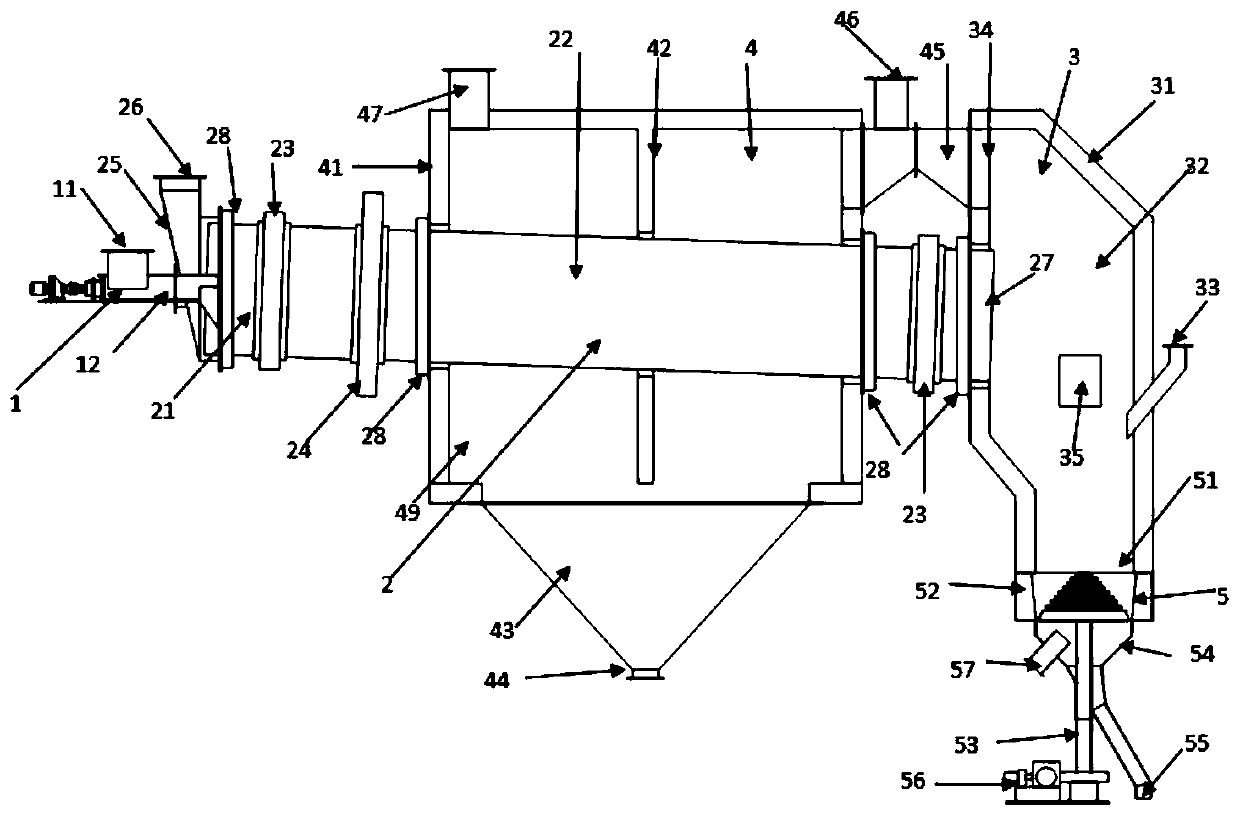

Combination melting furnace for treatment of arsenicsoda slag and low-melting-pointheavy-metal containing waste residue

PendingCN109708125ARealize thermal desorption methodImprove adaptabilityIncinerator apparatusMetals industrySlag

The invention discloses a combination melting furnace for treatment of arsenic soda slag and low-melting-point heavy-metal containing waste residue. The combination melting furnace for the treatment of the arsenic soda slag and the low-melting-point heavy-metal containing waste residue comprises an air-lock feeder, a rotary kiln, a vertical incinerator, a high-temperature flue gas chamber and a crushing discharging mechanism, the air-lock feeder is connected with the rotary kiln, the rotary kiln is connected with the vertical incinerator, the vertical incinerator is connected with the crushingdischarging mechanism, the high-temperature flue gas chamber covers the outer part of the rotary kiln, the cylindrical shell of the rotary kiln is connected with the two ends of the high-temperatureflue gas chamber and the machine shell of the vertical incinerator through sealing rings, after two stages of combustion process are conducted on materials through the rotary kiln and the vertical incinerator, high-temperature flue gas is discharged through the rotary kiln and an flue gas outlet of the high-temperature flue gas chamber, and complete combustion of the combusted slag is thoroughly achieved after through the action of the crushing discharging mechanism. The combination melting furnace for the treatment of the arsenic soda slag and the low-melting-point heavy-metal containing waste residue serves as combustion equipment, the equipment structure is simple and unique, the operation is convenient, the cost is low, waste residue smelting is conducted on industrial waste residue containing low-melting-point heavy-metal such as the arsenic soda slag and sludge containing arsenic, mercury, lead, zinc, cadmium through the unique technology of two stages combination combustion, andthe combination melting furnace for the treatment of the arsenic soda slag and the low-melting-point heavy-metal containing waste residue is also suitable for pyrolytic incineration of waste materialcontaining organics.

Owner:长沙中硅环保科技有限公司

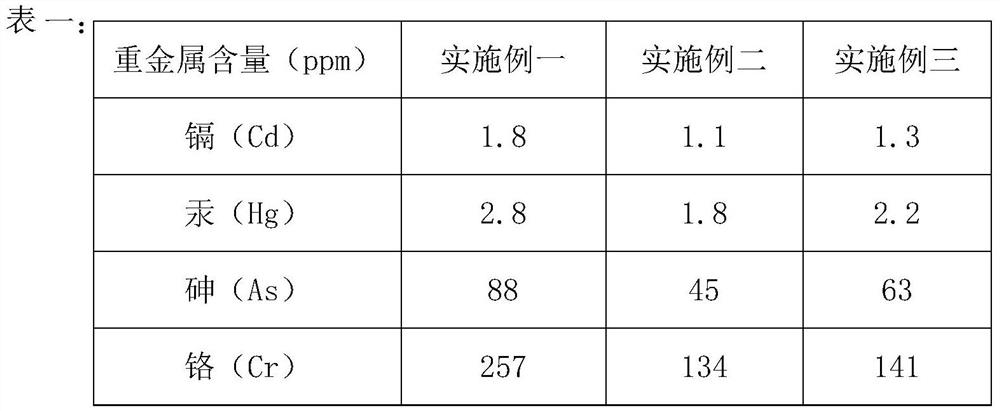

Remediation agent for heavy metal industrial contaminated site and remediation method thereof

InactiveCN112588811AImprove repair effectNo secondary pollutionContaminated soil reclamationEarth material testingMetals industryEnvironmental engineering

The invention relates to the technical field of heavy metal pollution remediation, in particular to a remediation agent for a heavy metal industrial contaminated site and a remediation method thereof.The remediation agent comprises 60%-80% of an agent a, 10%-20% of an agent b and 10%-20% of an agent c. The agent a is prepared from the following components by mass: 30-40 parts of inorganic alkaline matter and 40-50 parts of coal ash. The method comprises the following steps: A, separation; B, drilling; C, repairing; and D, inspection. According to the method, the application range is expanded,targeted adjustment can be conducted according to the actual pollution situation, secondary pollution is avoided, and therefore the remediation effect on the heavy metal industrial pollution site iseffectively improved; and by ditching and arranging separation walls, remediation agents of different proportions are injected into pile holes drilled at equal intervals, omnibearing permeation and restoration are carried out on a soil layer of the contaminated site, and finally an optimal formula is obtained through inspection and trial and error, so that the restoration efficiency of the heavy metal industrial contaminated site is further improved.

Owner:江西省三汇科技有限公司

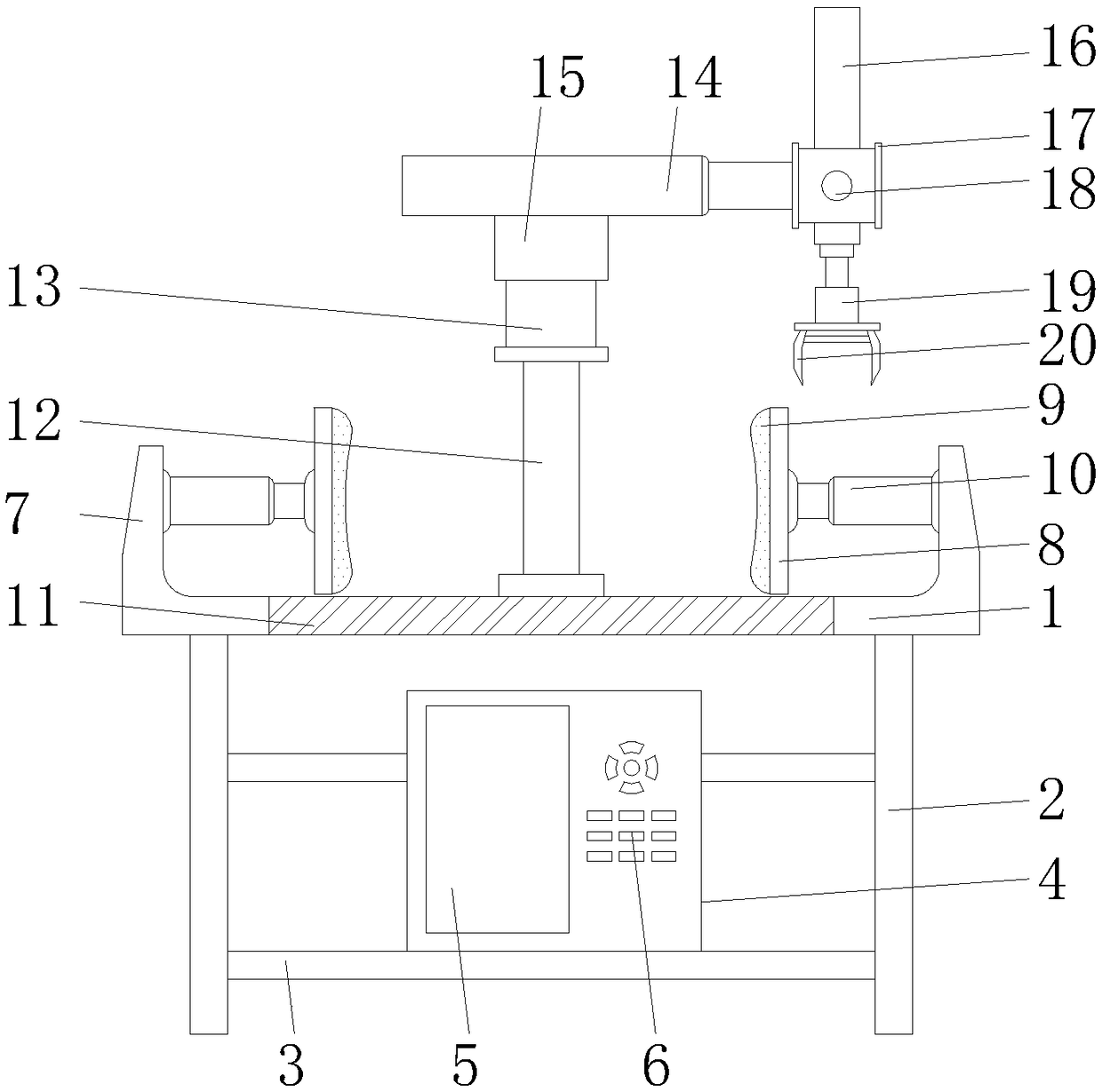

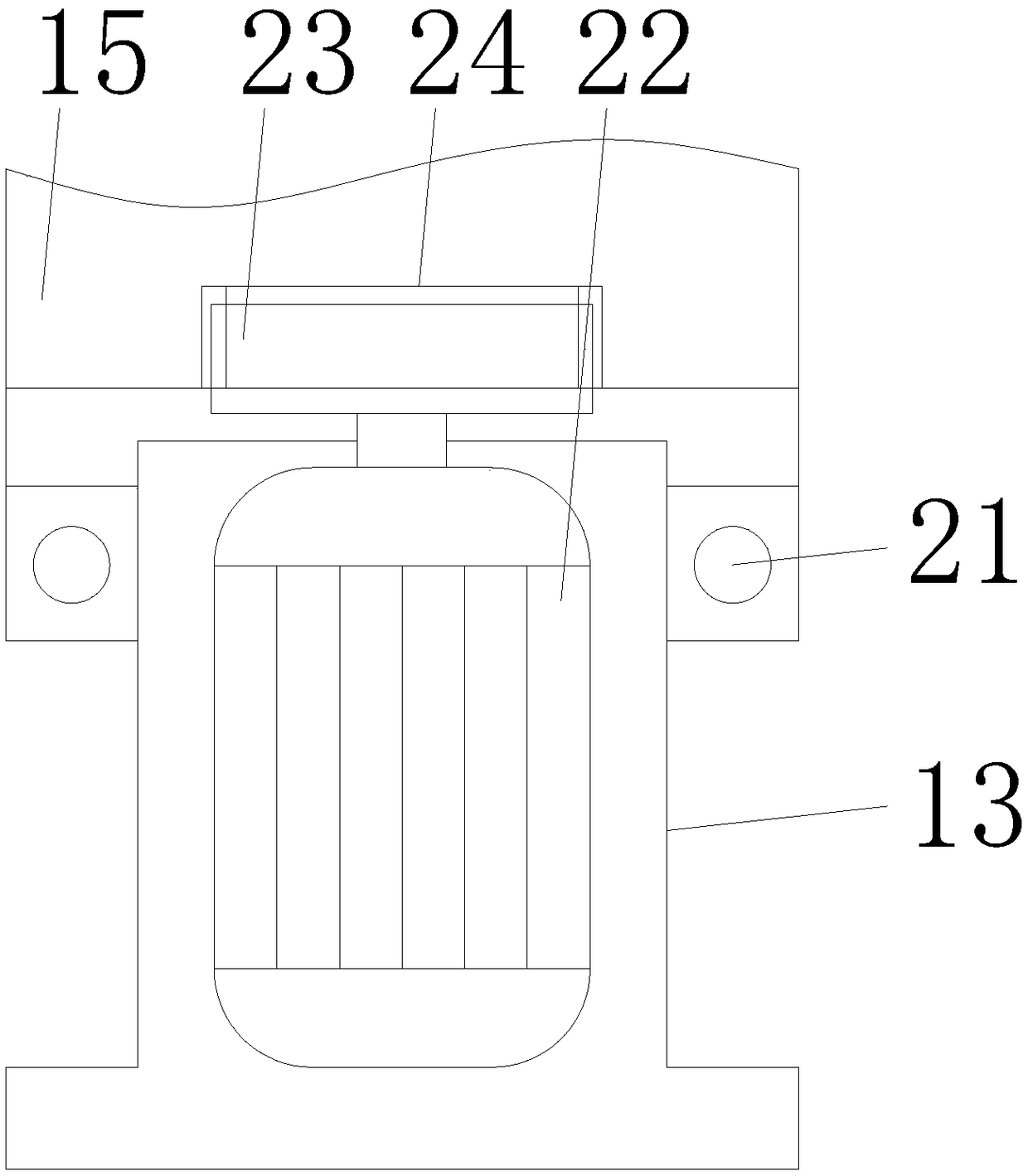

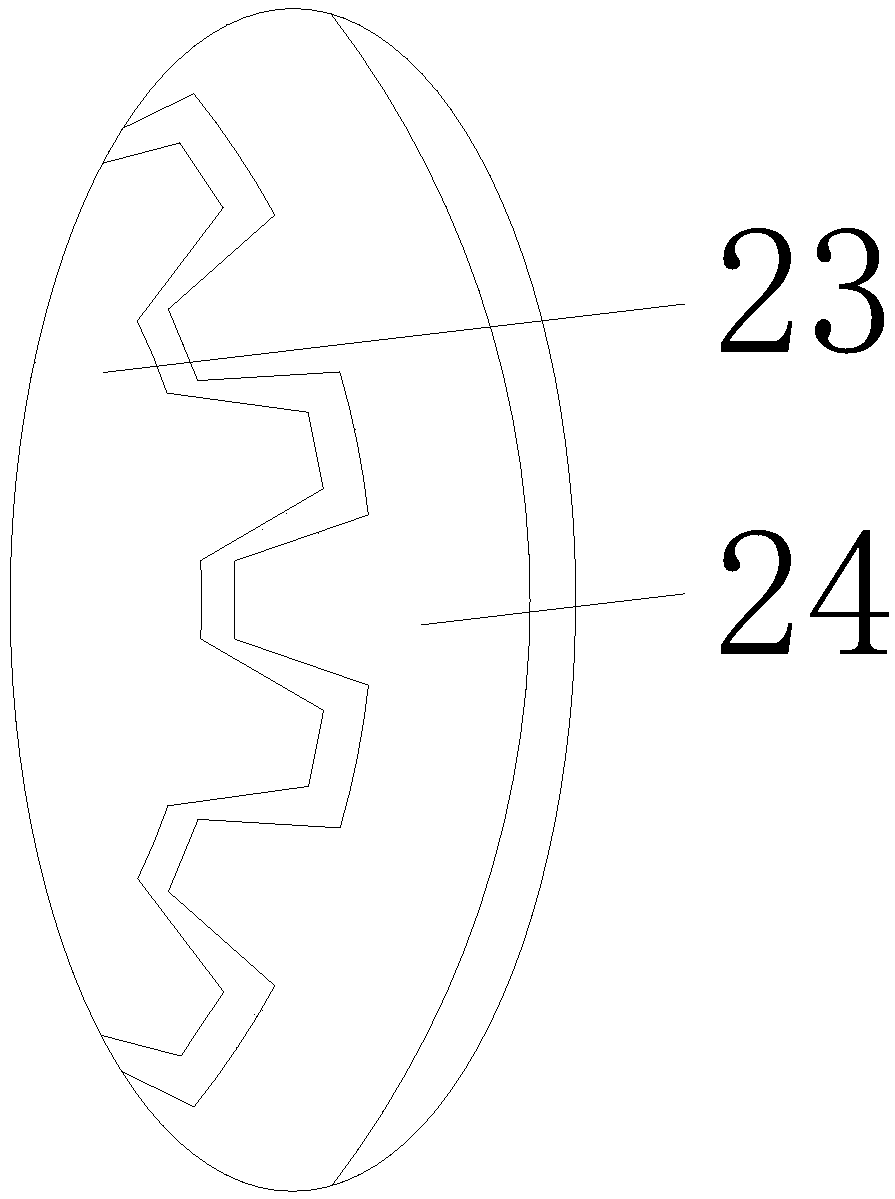

Numerical control equipment for automatic welding in sheet metal industry

InactiveCN108994517ASolve the problem that the fixation is more complicated and inconvenient to useSimple structureWelding/cutting auxillary devicesAuxillary welding devicesNumerical controlMetals industry

The invention discloses numerical control equipment for automatic welding in the sheet metal industry. The numerical control equipment comprises a bottom plate, a numerical control controller, a fixedclamping plate, an electric push rod, a first telescopic rod, a second telescopic rod and an electric gripper. Supports are installed on lower part of the bottom plate, a transverse rod is installedbetween the supports, and the numerical control controller is installed on the transverse rod. A side mounting plate is arranged on the upper part of the bottom plate, the fixed clamping plate is installed on the inner side of the side mounting plate, the fixed clamping plate is fixed to the side mounting plate through the electric push rod, and a leakage plate is arranged at the middle position of the bottom plate. Through the bottom plate, the numerical control controller, the fixed clamping plate, the electric push rod, the first telescopic rod, the second telescopic rod and the electric gripper, the numerical control equipment for automatic welding in the sheet metal industry solves the problem that welding equipment is complicated in fixation and inconvenient to use, so that the positions between welding parts are difficult to adjust after the welding parts are fixed.

Owner:安徽尘缘节能环保科技有限公司

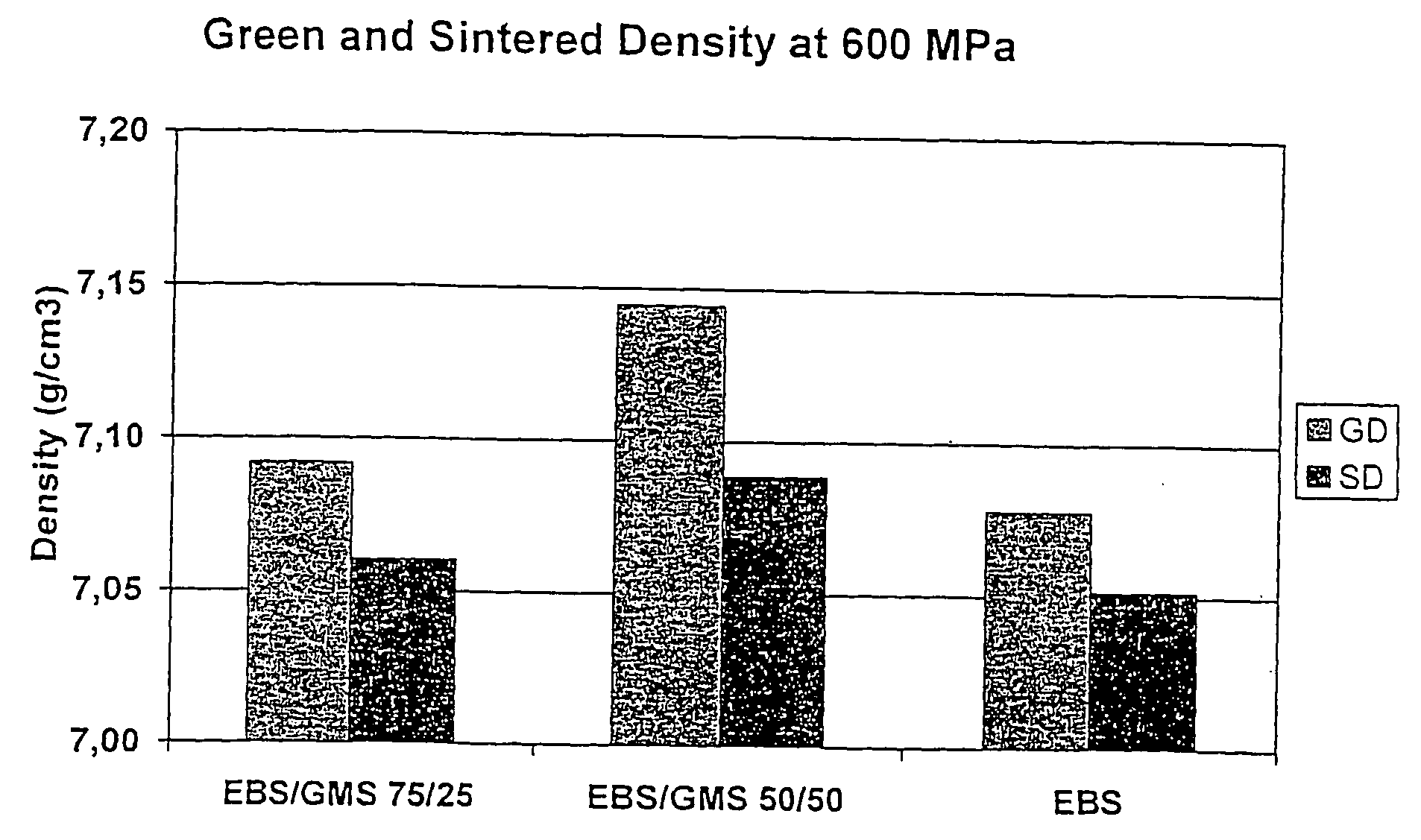

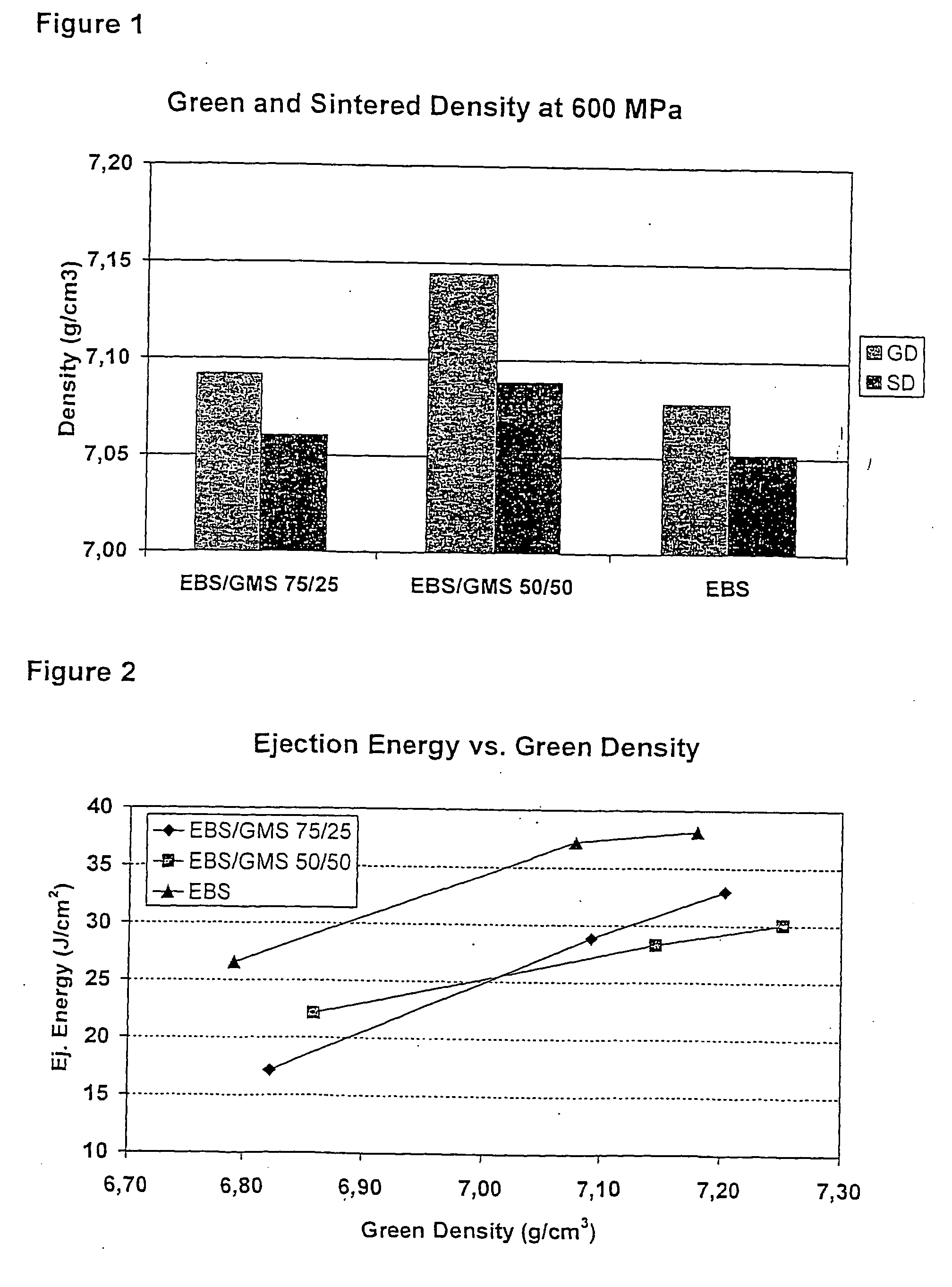

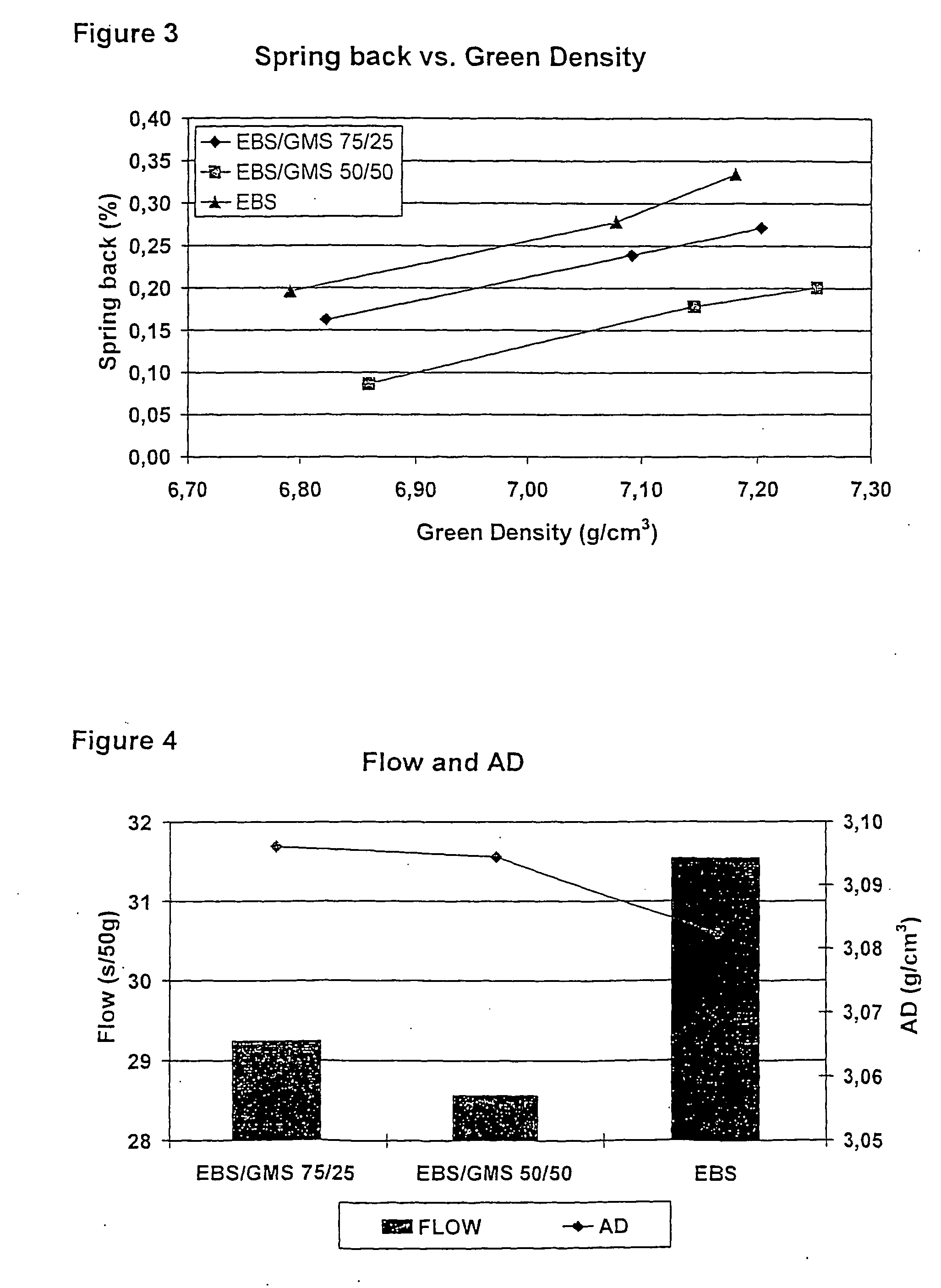

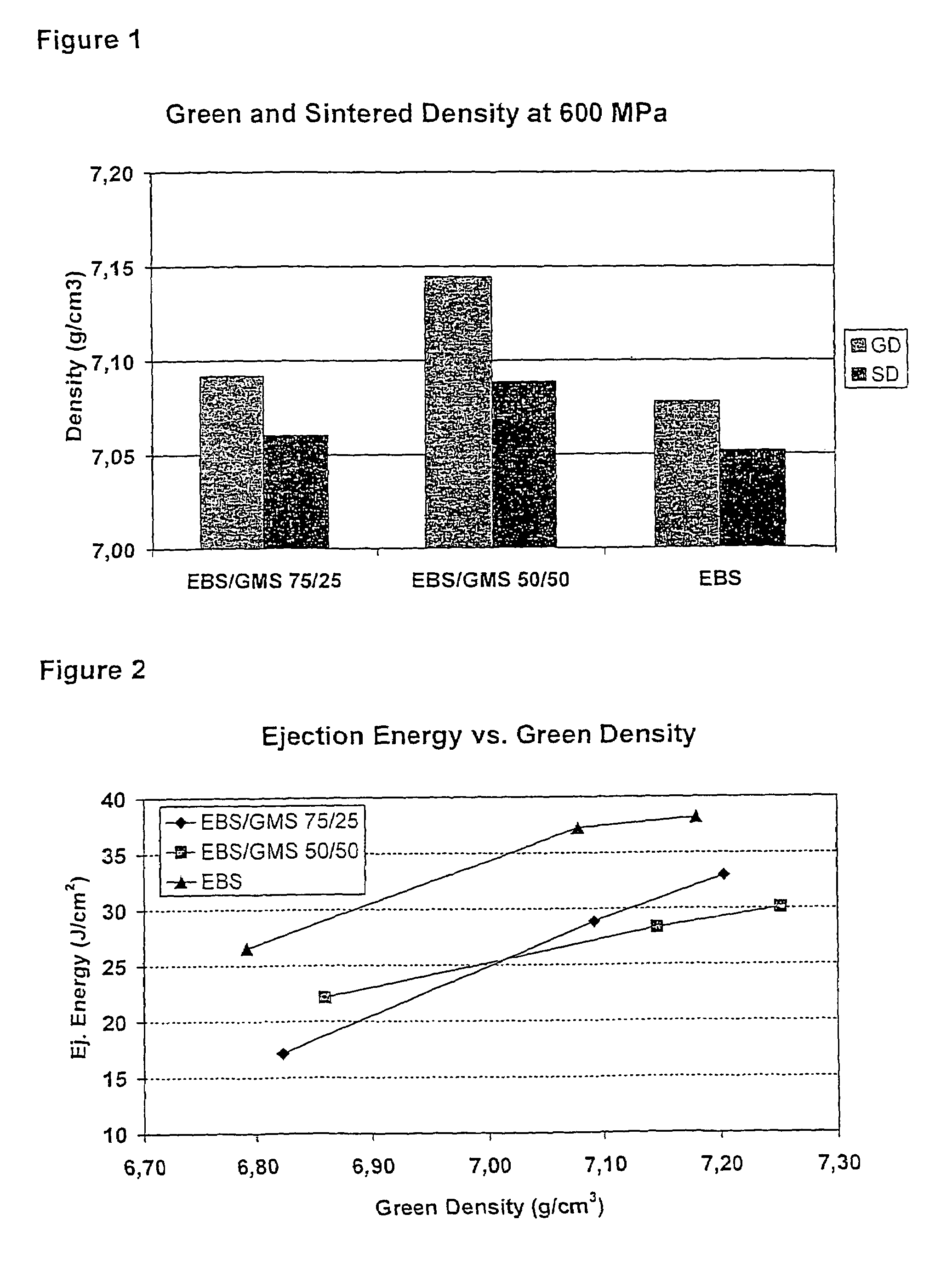

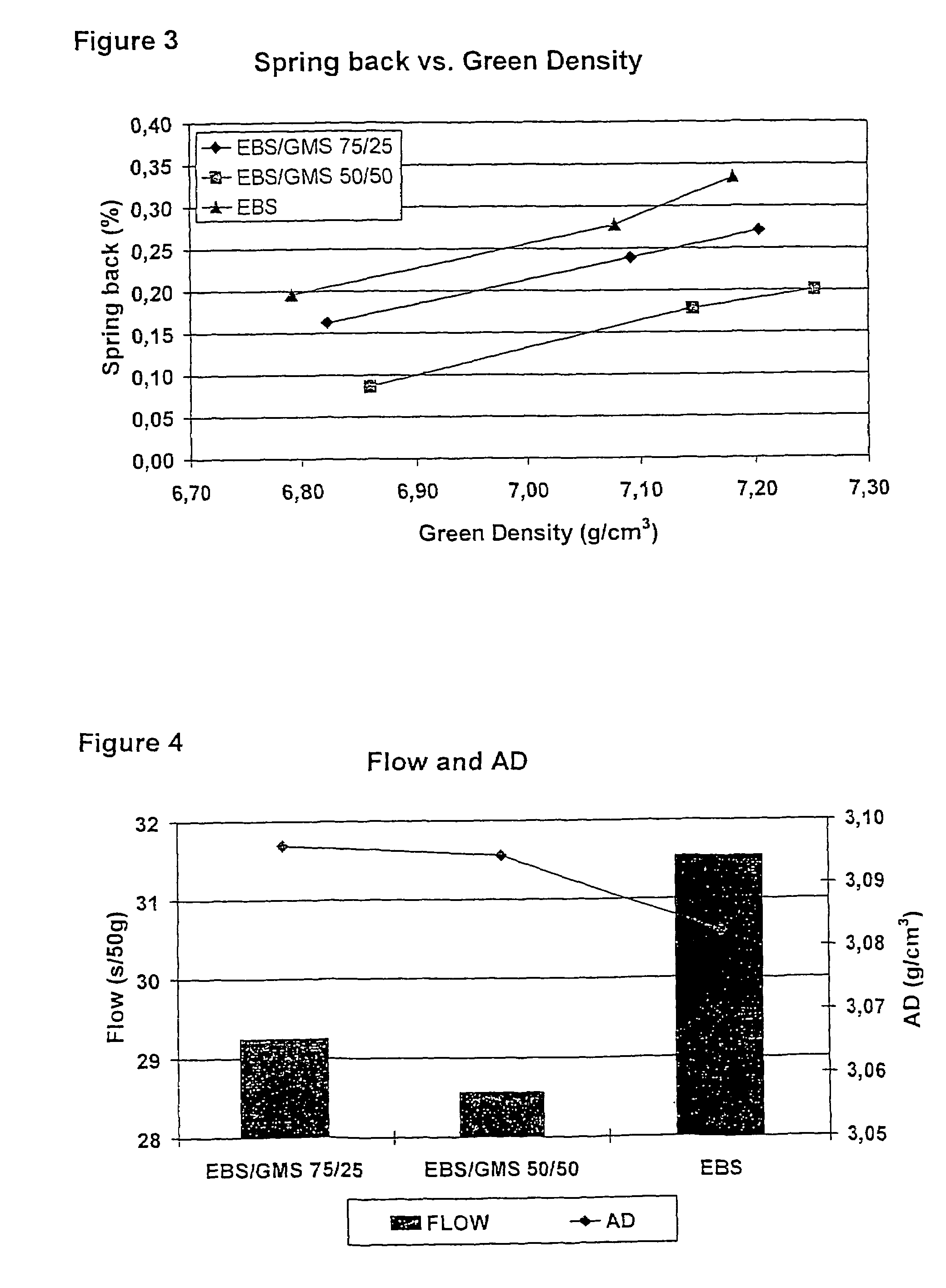

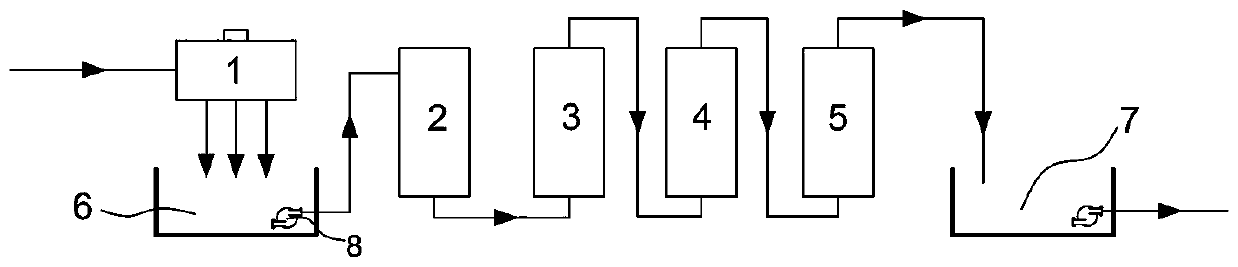

Metal powder composition including a bonding lubricant and a bonding lubricant comprising glyceryl stearate

InactiveUS20050247163A1High and consistent densityLower average energyTransportation and packagingMetal-working apparatusMetals industryIron powder

Owner:HOGANAS AB

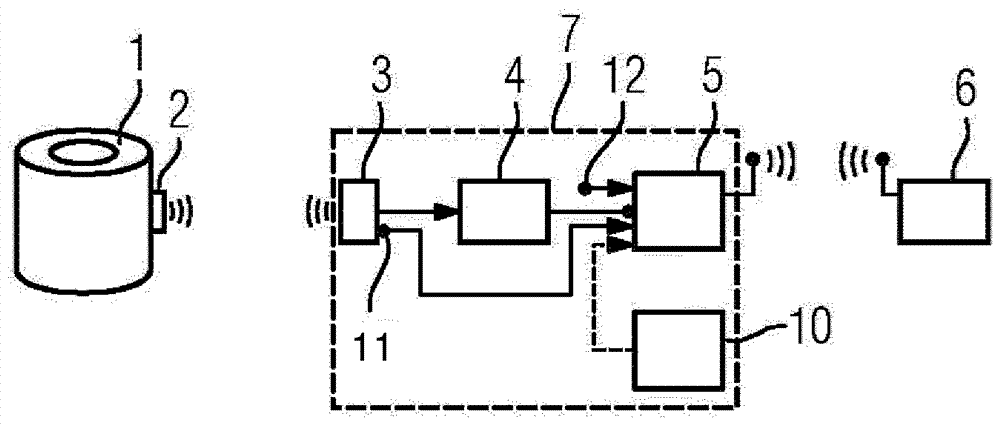

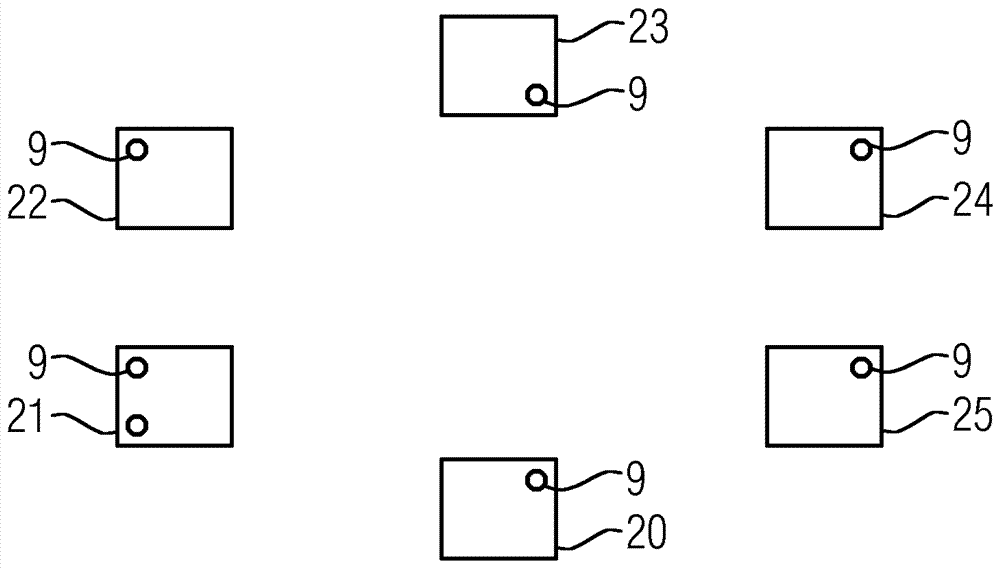

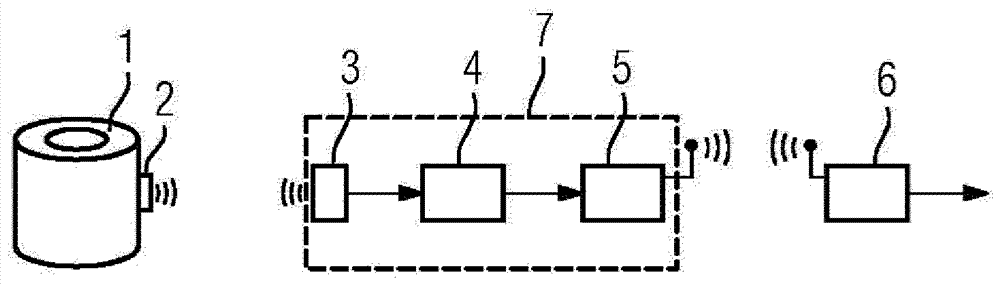

Metal industry installation and method for tracking a vessel, in particular a metallurgical vessel

InactiveCN107075595ASimplify Condition MonitoringEasy to installElectric furnaceProcess efficiency improvementMetals industryEngineering

The invention discloses a metal industry installation comprising a plurality of processing stations, through which a vessel (1), in particular a metallurgical vessel (1) passes at least partially, wherein the vessel (1) is equipped with a transponder (2) comprising transponder data, wherein at least one first tracking position (9) is provided in the metal industry installation, the tracking position comprises at least one first read station (7), for the vessel (1) passing the first tracking position (9) to communicate by means of the transponder (2), in particular for identifying the passing vessel (1) using the transponder data, and wherein at least one gateway (6) is provided in the metal industry installation, and wherein at least the first read station (7) for communication, in particular for transmitting the transponder data, is wirelessly connected to the gateway (6). In addition, the invention discloses a corresponding method.

Owner:PRIMETALS TECH AUSTRIA GMBH

Casting-molded large-scale nitride-combined silicon carbide product

Owner:SINOSTEEL LUOYANG INST OF REFRACTORIES RES

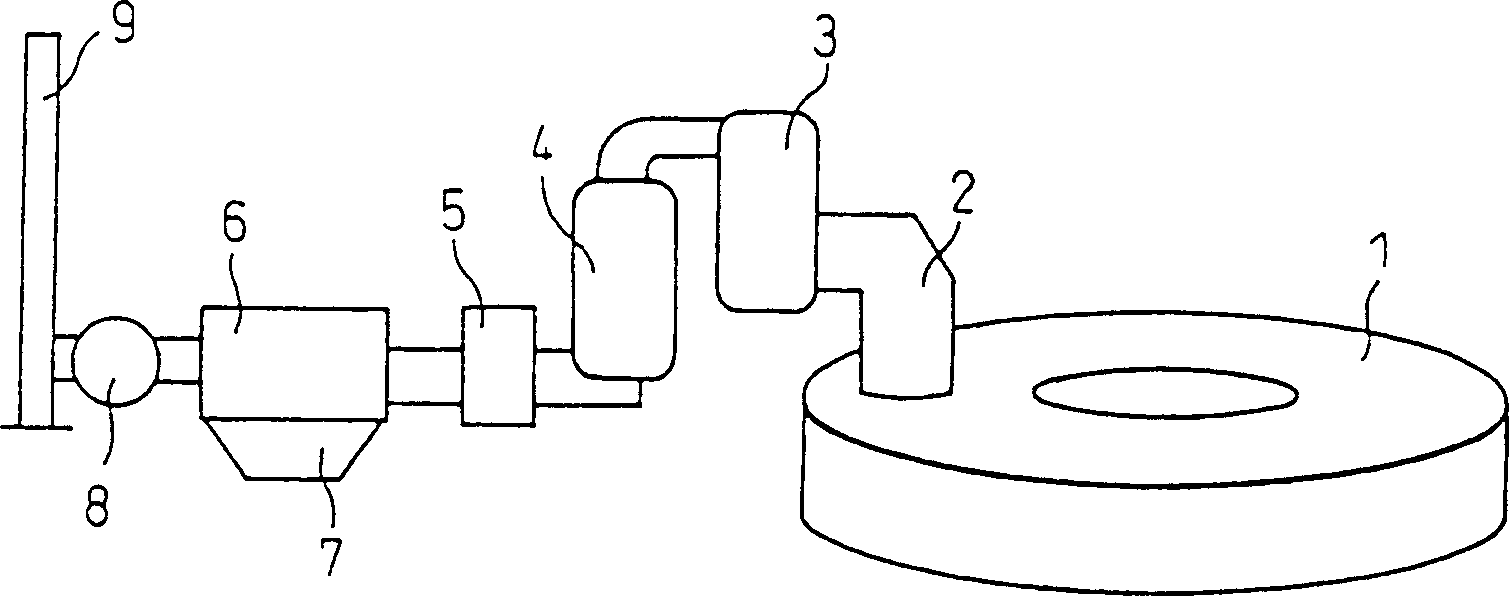

Method for operating rotary heartn type reducing furnace and rotary hearth type reducing furnace facilities

InactiveCN1474877AHigh thermal efficiencyAvoid cloggingExhaust gas handlingIncreasing energy efficiencyMetals industrySludge

The present invention provides a method of operation and a facility for the same suppressing the generation of dioxins in the combustion exhaust gas and efficiently reclaiming heat from high temperature combustion exhaust gas when firing and reducing fines of chromium ore, iron ore, or other ore or pellets formed from dust sludge, etc. containing iron oxide or other metal oxides generated in the metal industry in a reducing rotary hearth furnace. This treats the combustion gas generated in the reducing rotary hearth furnace to make the temperature of the gas 800 DEG C. or higher for at least a certain time, to make the concentration of the carbon monoxide not more than 200 ppm in terms of volume ratio and to achieve a sufficiently well developed turbulent state at least at one of the inside of the exhaust gas outlet duct and the vicinity of the exhaust gas outlet duct for at least a certain time, then rapidly cooling the gas. Further, it controls the total number of moles of zinc and lead, the total number of moles of alkali metals, and the total number of moles of halogen elements contained in the combustion exhaust gas to a predetermined ratio.

Owner:NIPPON STEEL CORP

Metal powder composition including a bonding binder/lubricant

InactiveUS7247187B2High and consistent densityLower average energyTransportation and packagingMetal-working apparatusMetals industryIron powder

The present invention concerns a metal powder composition for the powder metal industry, wherein the metal powder is selected from the group consisting of an atomized iron-based powder or a sponge iron powder, and a lubricant composition comprising glyceryl stearate.

Owner:HOGANAS AB

Reclaimed water recycling technology used for metal industrial cooling system

InactiveCN107555654AQuality improvementAvoid damageWater contaminantsWaste water treatment from metallurgical processMetals industryParticulates

The invention relates to a reclaimed water recycling technology used for a metal industrial cooling system. Raw water of the technology is cooling water containing various metal ions and impurities; the raw water passes through a cooling tower, a bag type filter, a manganese sand filter, a mixing bed and a chelating resin bed in sequence, and iron ions, calcium ions and magnesium ions in the cooling water are removed step by step; meanwhile, suspended matters and particulate matters in the cooling water also can be filtered, so that the cooling water reaching recycling standards is obtained; after a lot of metal ions in the cooling water are removed, the cooling water cannot react with a metal generation raw battery in a utilization process, so that damages to equipment and metal productsare reduced, the service life of the equipment is prolonged, and the quality of the metal products is improved; meanwhile, the effects of recycling water resources and reducing the cost are also realized, and certain guarantees are also provided for environment protection.

Owner:ZHEJIANG JUNE5 ENVIRONMENT TECH CO LTD

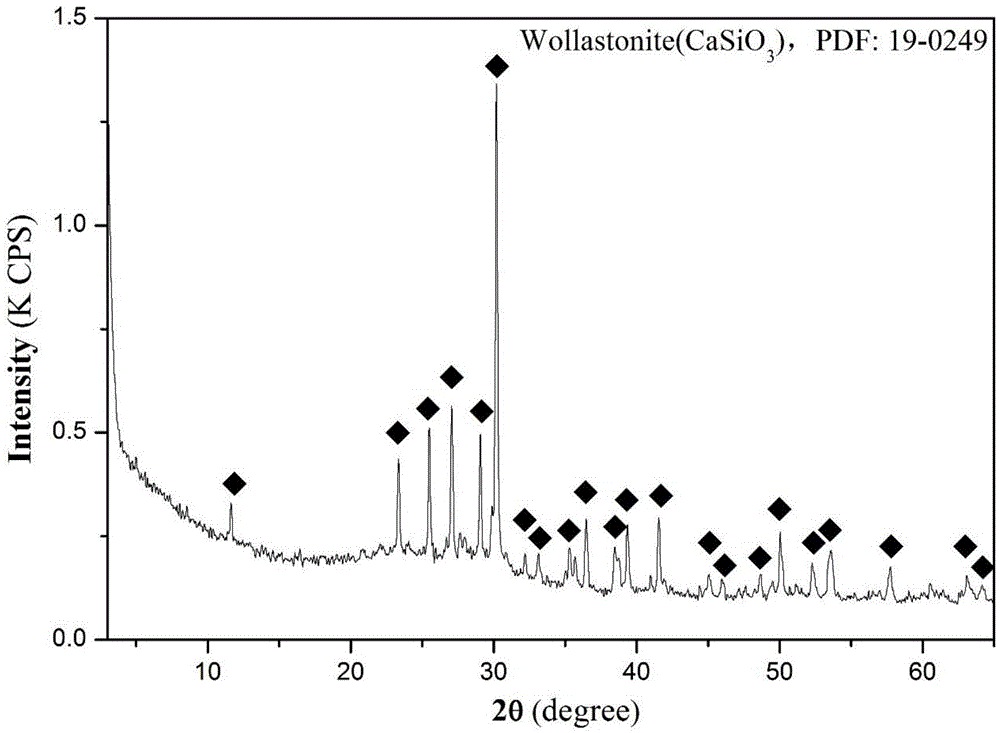

Compound tailing slag microcrystal glass and preparation method thereof

The invention belongs to the field of industrial solid waste resource utilization, and particularly relates to compound tailing slag microcrystal glass and a preparation method thereof. The compound tailing slag microcrystal glass comprises the following raw material ingredients in parts by weight: 30 to 90 parts of electrolytic manganese residues, 5 to 20 parts of lead-zinc flotation tailings, 5 to 30 parts of quartz sand and 0 to 20 parts of feldspar. Compound tailing slag of the electrolytic manganese residues and the lead-zinc flotation tailings are used as major raw materials for preparing the microcrystal glass; the harm of the electrolytic manganese residues and the lead-zinc flotation tailings on environment can be eliminated; the resource utilization of the electrolytic manganese residues and the lead-zinc flotation tailings is realized; microcrystal glass products with high additional values can also be produced; the sustainable development of electrolytic manganese metal industry, lead zinc ore selection and purchasing and processing industry is promoted. The prepared microcrystal glass has excellent characteristics of high mechanical strength, high abrasion resistance, good heat stability and the like; meanwhile, the characteristics of glass and ceramics are realized; the compound tailing slag microcrystal glass can be used a high-grade building decoration material.

Owner:SAFECLEEN TECH +1

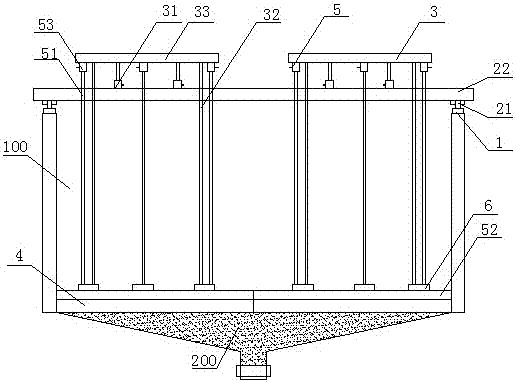

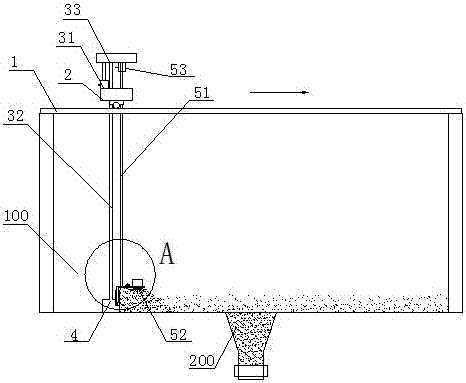

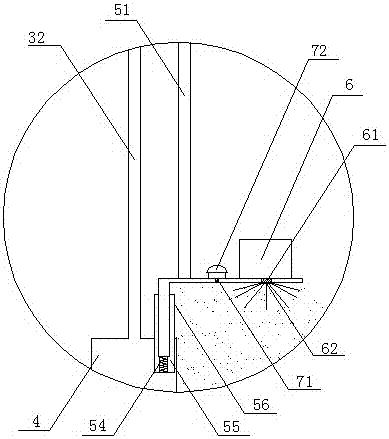

Settling basin for treating high-concentration heavy metal industrial wastewater

ActiveCN107344746AWalk to achieveGrowth inhibitionSpecific water treatment objectivesWater contaminantsMetals industryWastewater

The invention discloses a settling basin for treating high-concentration heavy metal industrial wastewater that comprises the settling basin and a mud scraper arranged on the settling basin, wherein the mud scraper comprises a rail, a walking device, a lifting mechanism and a mud scraping plate; the walking device comprises walking wheels and a connecting bridge; the mud scraping plate comprises a front mud scraping plate and a rear mud scraping plate; the front mud scraping plate and the rear mud scraping plate are in up-and-down movable connection with each other; the lifting mechanism comprises a first lifting cylinder, a second lifting cylinder, a front fixing rod, a rear fixing rod and a lifting bridge; one end of the first lifting cylinder is connected with connecting bridge while the other end is connected with the lifting bridge; one end of the front fixing rod is connected with the lifting bridge while the other end is connected with the front mud scraping plate; the second lifting cylinder is arranged between the rear fixing rod and the lifting bridge; the rear mud scraping plate is connected with the lower end of the rear fixing rod. The invention has the advantages of excellent mud scraping effect, high speed and capability of thoroughly removing the sludge at the bottom of the settling basin; sludge is difficult to raise and the secondary floating diffusion phenomenon of the sludge is avoided; the heavy metal is effectively flocculated; the secondary pollution of the heavy metal to soil is avoided; the service life is long.

Owner:南京圆点环境清洁技术有限公司

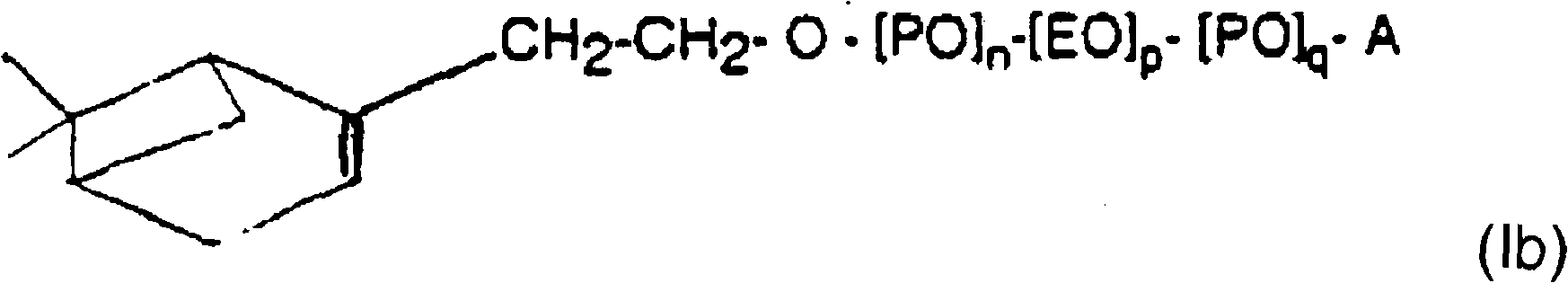

Aqueous treatment composition for inhibiting corrosion and acid attack on metallic surfaces

InactiveCN102046848ASurface-active detergent compositionsSpecific water treatment objectivesMetals industryThiourea

The present invention relates to an aqueous treatment composition for inhibiting corrosion and acid attack on metallic surfaces that comprises a thiourea organic derivative, a polyalkoxylated terpene nonionic surfactant and an acid. The invention also relates to a process for cleaning industrial metallic equipment, in particular heat exchangers in which a heat transfer fluid, generally based on air or on water, flows, with a view to cleaning them and removing scale and other soiling.

Owner:RHODIA OPERATIONS SAS

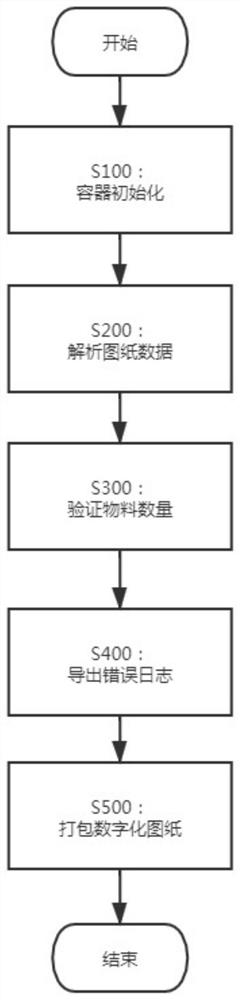

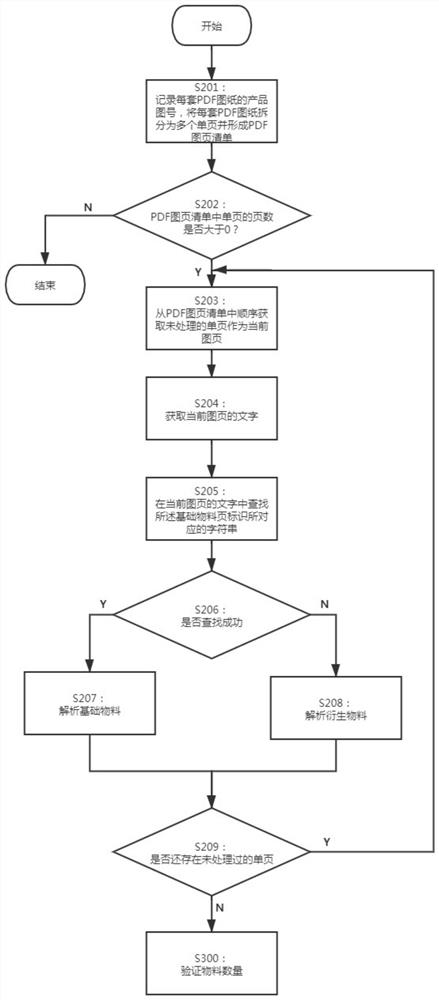

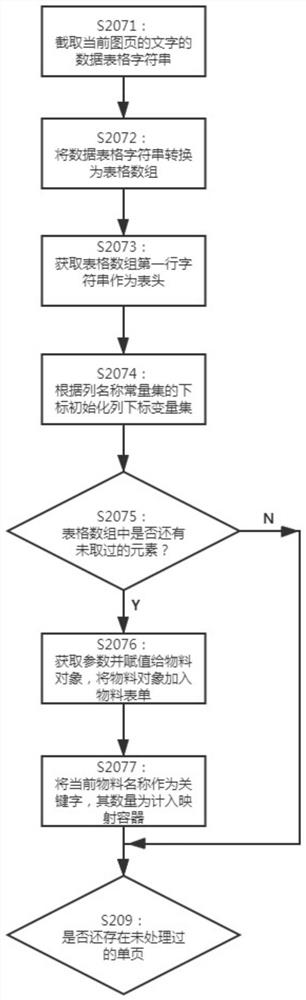

Digital conversion method for PDF drawing in sheet metal industry

PendingCN112183029AReduce the impactClear structureNatural language data processingManufacturing computing systemsMetals industryDigital transformation

The invention discloses a digital conversion method for a PDF drawing in the sheet metal industry. The digital conversion method is characterized by comprising the following steps: S100, initializinga container; S200, analyzing the drawing data, including: S201, splitting each set of PDF drawing into a plurality of single pages and forming a PDF drawing page list; S202, judging whether the page number of a single page in the PDF picture page list is greater than 0 or not; if so, executing the step S203; otherwise, ending the process; S203, sequentially obtaining current graph pages from the PDF graph page list; S204, acquiring characters of the current picture page; S205, searching a character string corresponding to the basic material page identifier in the characters of the current picture page; S206, judging whether the search is successful or not; if so, executing the step S207; otherwise, executing the step S208; S207, analyzing the basic material, and executing the step S209; S208, analyzing the derivative material; S209, judging whether an unprocessed single page still exists or not; if so, executing the step S203; otherwise, executing the step S300; S300, verifying the quantity of the materials; S400, exporting an error log; S500, packaging the digital drawing.

Owner:SICHUAN QIAODUOTIANGONG PRECISION EQUIP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com