Method of deodour using biofiltration

A technology of biological filtration and biological filter material, which is used in various industrial enterprises, municipal sewage sludge and garbage treatment, and purification of odorous gases produced by agricultural and animal husbandry enterprises. Secondary pollution and other problems, to achieve the effect of low construction cost investment, obvious removal effect and long service cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] The main components of the filter material configuration include wood chips, tree root materials, and bark main materials account for about 65%, and humus soil, pine needle soil, and ceramsite account for 35%.

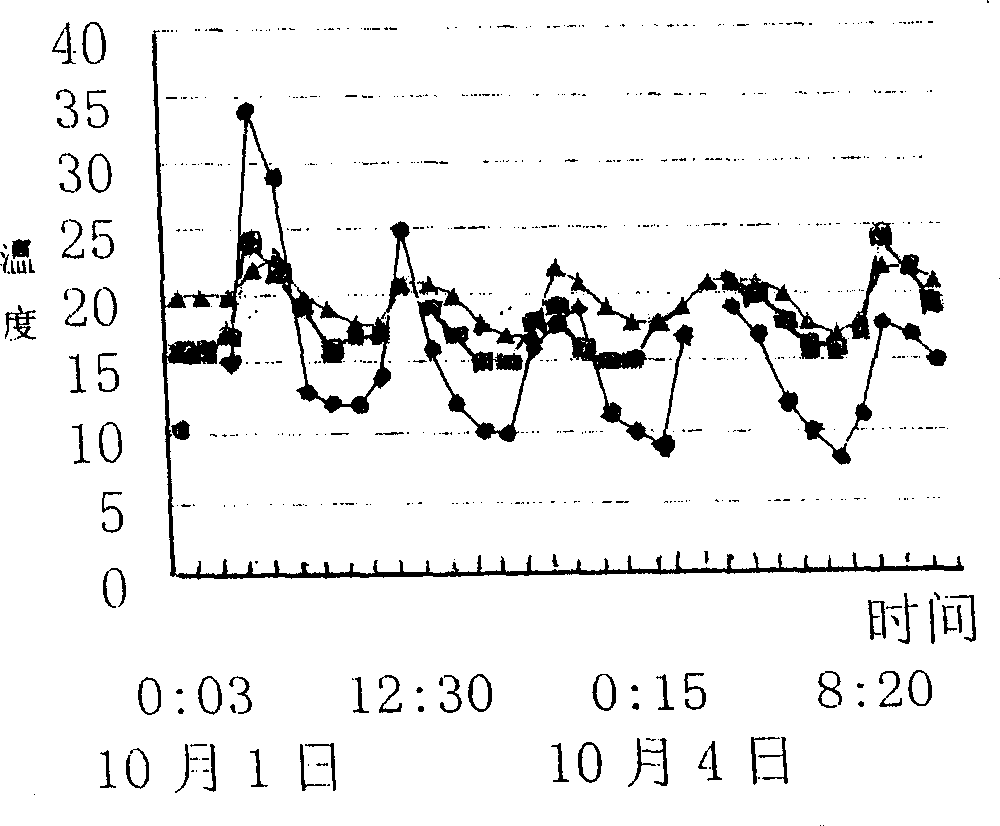

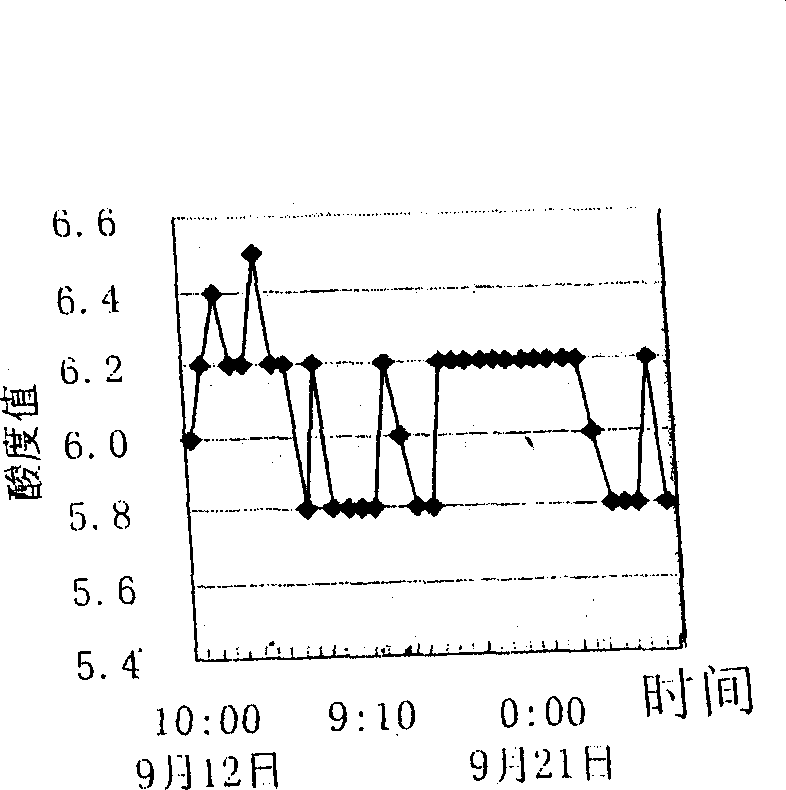

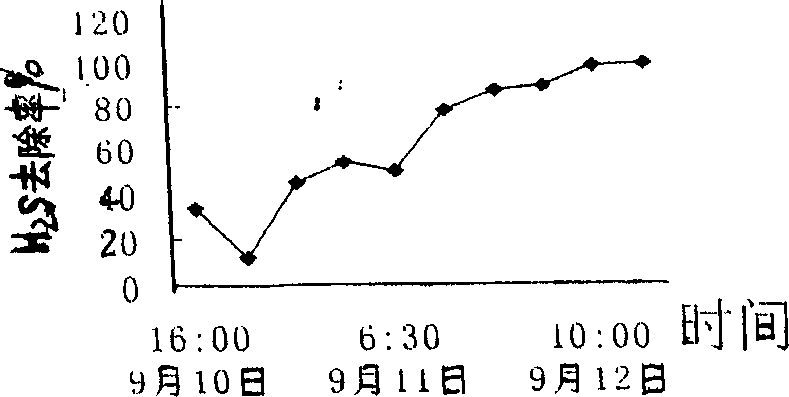

[0021] In August 2003, it was actually installed and applied at the water inlet grille of Tianjin Jizhuangzi Wastewater Treatment Plant. The actual treatment gas volume was 300 cubic meters per hour, the pollutant gas concentration range was between 30-200ppm, and the online test time was about 60 days. Two testers measure the inlet and outlet of the system at the same time, and continuously measure and record the temperature, humidity, pressure and other parameter data in detail. After entering the stable period of the system, the hydrogen sulfide treatment efficiency is stable above 98%, and the gas concentration treatment effect is relatively obvious. After the gas sampling analysis and identification by the Institute of Atmospheric Physics of the Chinese Aca...

Embodiment 2

[0023] The main components of the filter material configuration include wood chips, tree root materials, bark and other main materials accounting for about 70%, and humus soil, hemp palm and shells accounting for 30%.

[0024] In February 2004, it was actually installed and applied in the cyclone sedimentation tank of Guangzhou Datansha Wastewater Treatment Plant. The actual treatment gas volume was 500 cubic meters per hour, and the concentration range of pollutant gas was between 20-80ppm. The test time was nearly 3 days Monthly, measure and record the temperature, humidity, pressure, concentration and other parameter data in detail. The continuous test data shows that the hydrogen sulfide treatment efficiency is stable above 96%, the treatment effect reaches and exceeds the limit value stipulated in the "Odor Pollutant Emission Standard", the gas concentration treatment effect is very good, and the filter bed surface filter material also adopts a separate The structure of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com