Combination melting furnace for treatment of arsenicsoda slag and low-melting-pointheavy-metal containing waste residue

A technology with a low melting point and heavy metals, applied in the direction of incinerators, combustion methods, combustion types, etc., can solve the problem that waste gas and waste slag cannot be truly harmless, resource-based, and cannot be melted and sublimated to obtain different volatilized substances. Industrial waste cannot be fully burned, etc., to achieve the effect of simple and unique equipment structure, enhanced adaptability, and prevention of waste of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

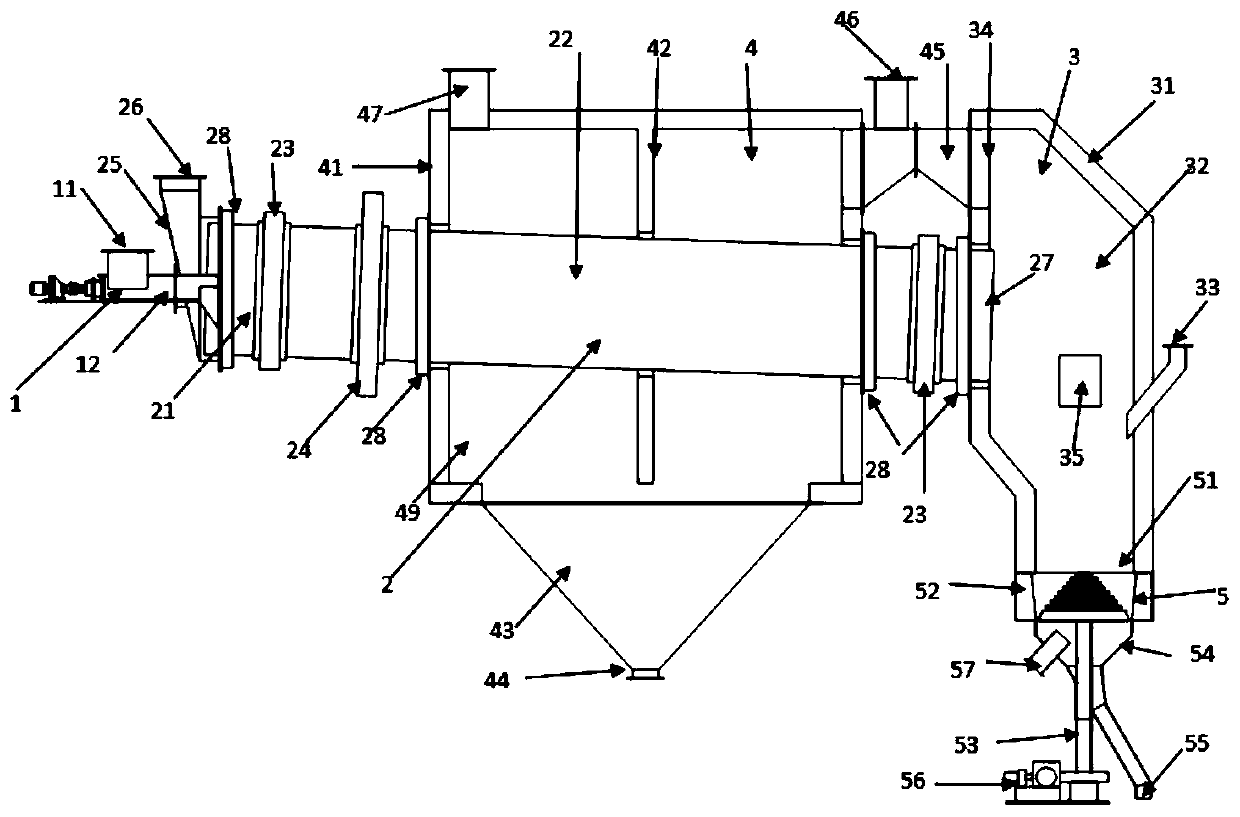

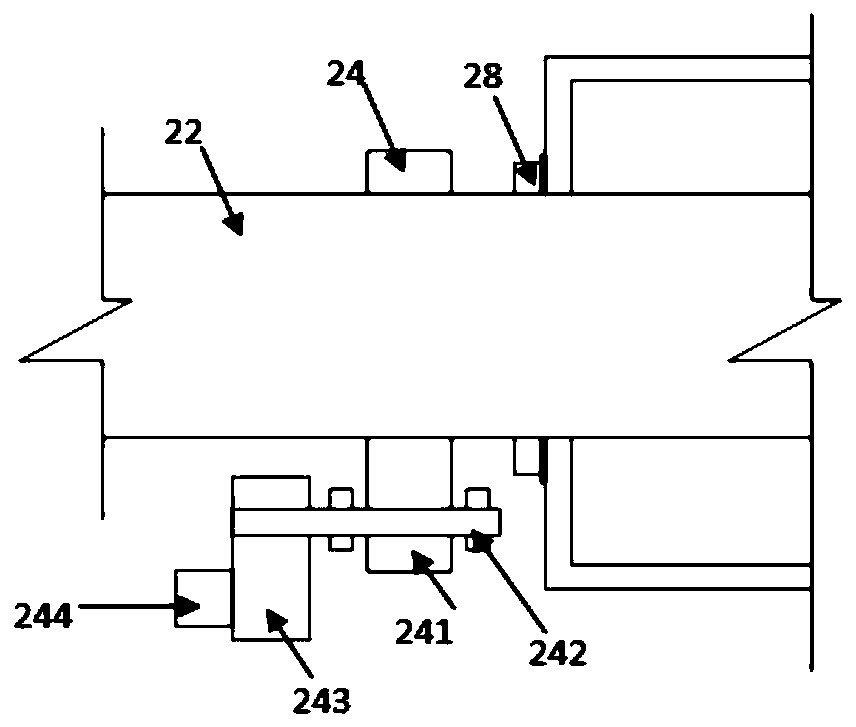

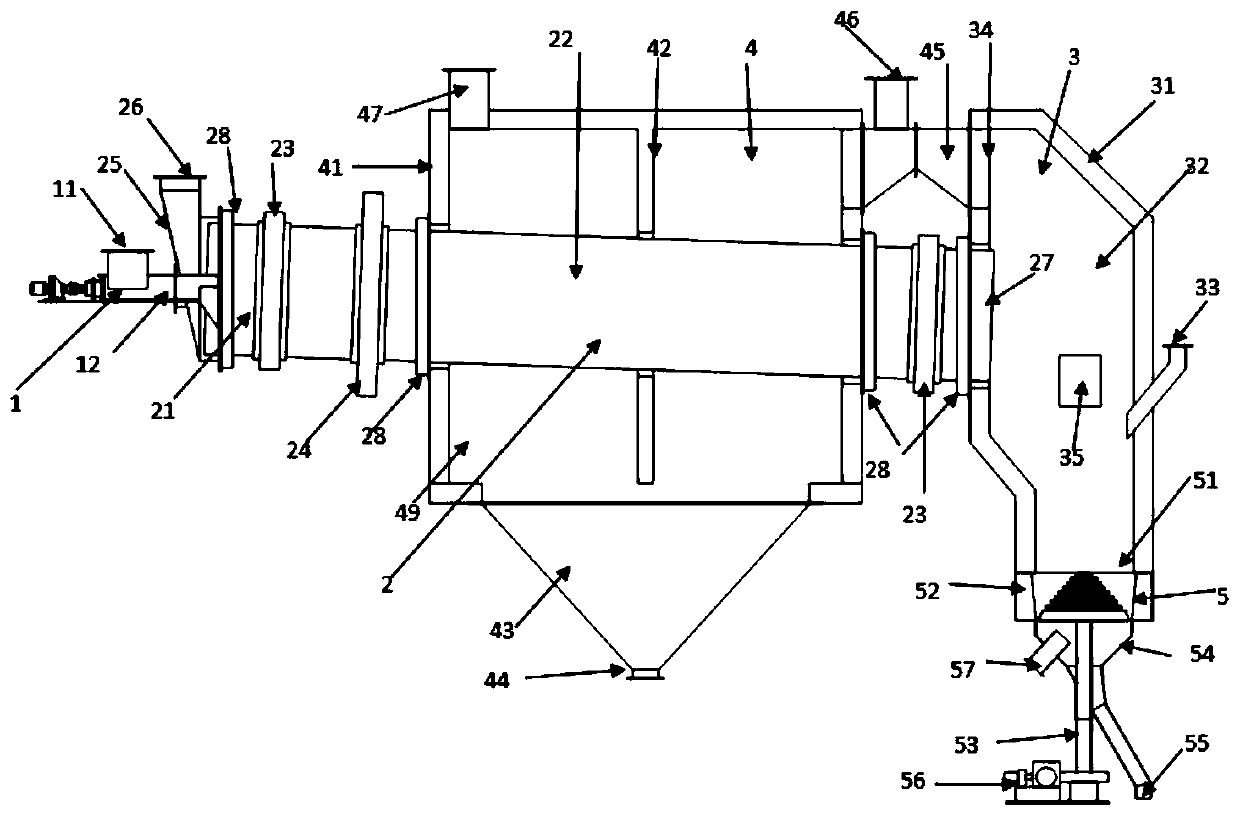

[0035] Such as Figure 1-2 As shown, the present invention provides a combined smelting furnace for processing arsenic-alkali slag and low melting point heavy metal waste slag, comprising an air lock feeder 1, a rotary kiln 2, a vertical incinerator 3, a high-temperature flue gas chamber 4 and crushing and discharging materials. Mechanism 5, the airlock feeder 1 is connected to the rotary kiln 2, the rotary kiln 2 is connected to the vertical incinerator 3, the vertical incinerator 3 is connected to the crushing and discharging mechanism 5, and the high-temperature flue gas The chamber 4 is wrapped outside the rotary kiln 2 , and the rotary kiln cylinder 22 is connected with both ends of the high-temperature flue gas chamber 4 and the vert...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com