Patents

Literature

67results about How to "Ensure proper temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

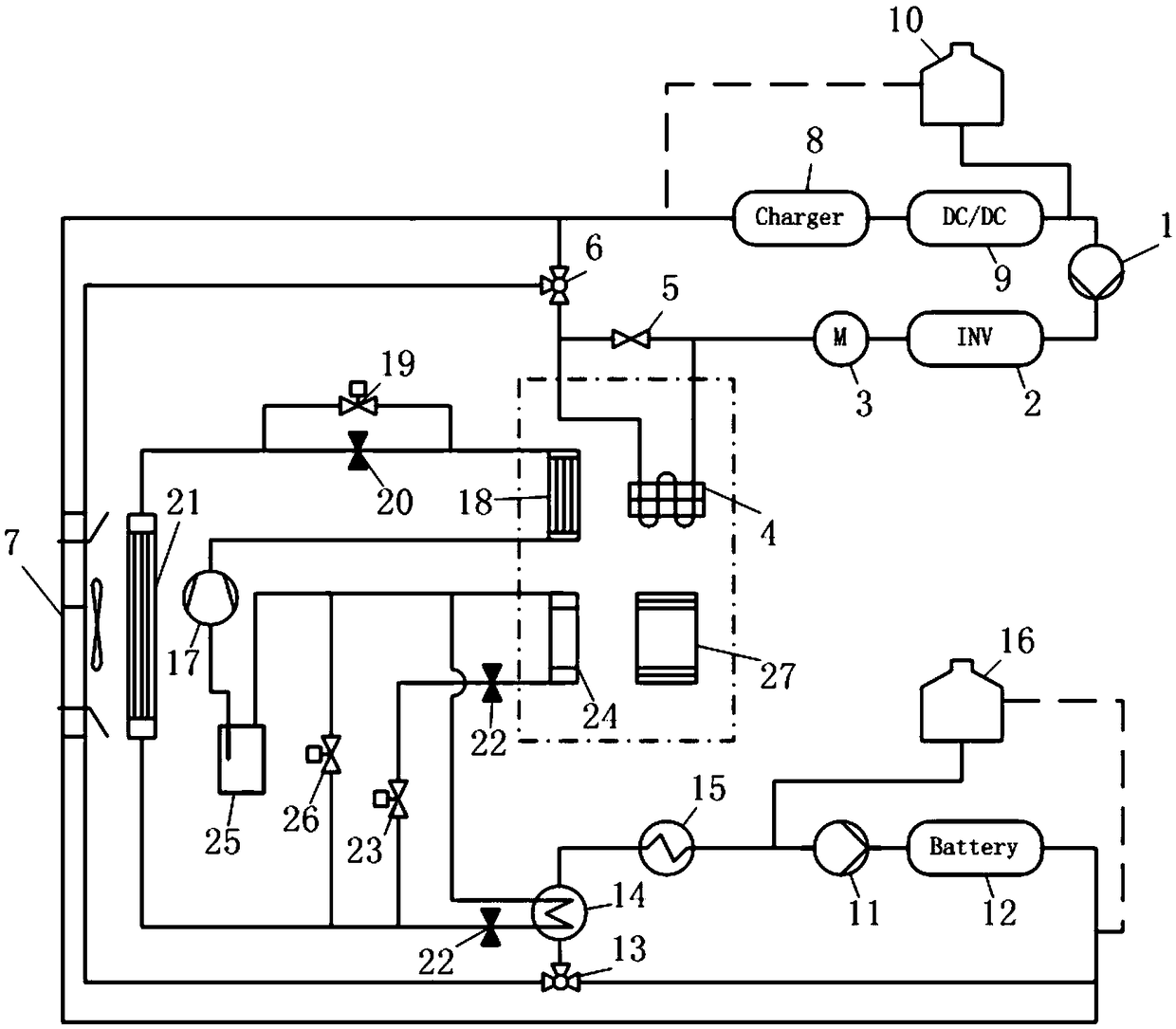

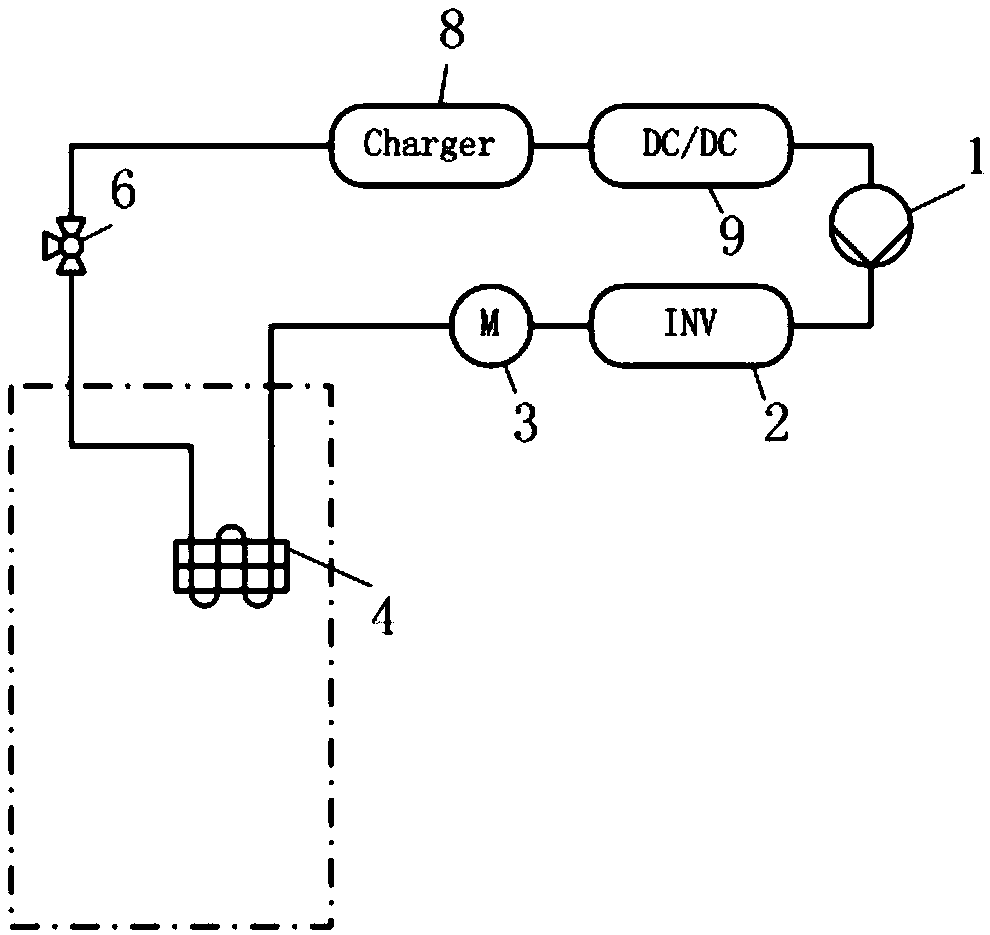

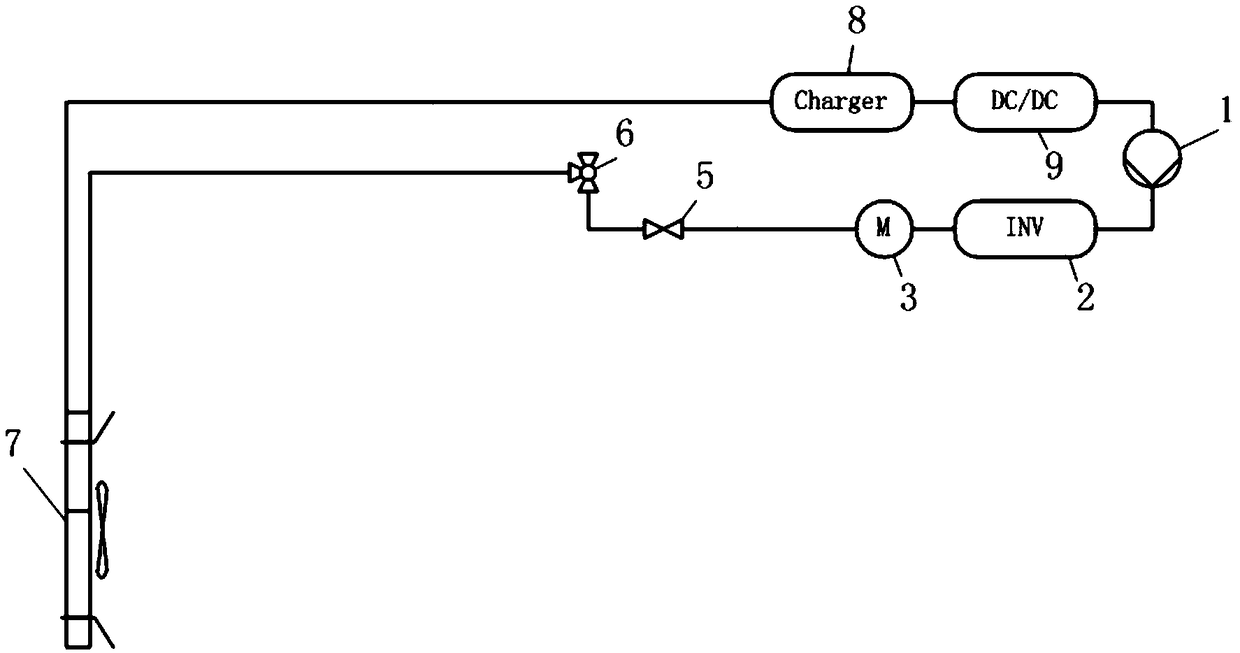

Finished vehicle thermal management system of pure electric automobile

PendingCN109466277AExtended service lifeAvoid wasting battery energyAir-treating devicesVehicle heating/cooling devicesElectric machineryExpansion tank

The invention discloses a finished vehicle thermal management system of a pure electric automobile, which comprises a motor water pump, a motor controller, a driving motor, an indoor radiator, a two-way electromagnetic valve, a first three-way electromagnetic valve, a double-cavity radiator, a charger, a DC / DC, a first expansion water tank and a battery water pump, a power battery, a second three-way electromagnetic valve, a heat exchange device, a water heating PTC, a second expansion water tank, an electric compressor, an indoor condenser, a first high-pressure electromagnetic valve, a heating throttling pipe, an outdoor condenser, a thermal expansion valve, a second high-pressure electromagnetic valve, an evaporator, a liquid storage drying tank, a third high-voltage solenoid valve anda high-voltage PTC. The system ensures the proper temperature of the driving motor, power battery and passenger cabin, particularly fully utilizes the residual heat of the driving motor to supply theheating of the passenger cabin and the cooling of the power battery under the condition of low temperature, and prolongs the service life of components such as the driving motor, the power battery andthe like, the waste of battery energy is avoided, the comfort of the passenger cabin is ensured, and the driving range of the finished vehicle is improved.

Owner:CHINA FIRST AUTOMOBILE

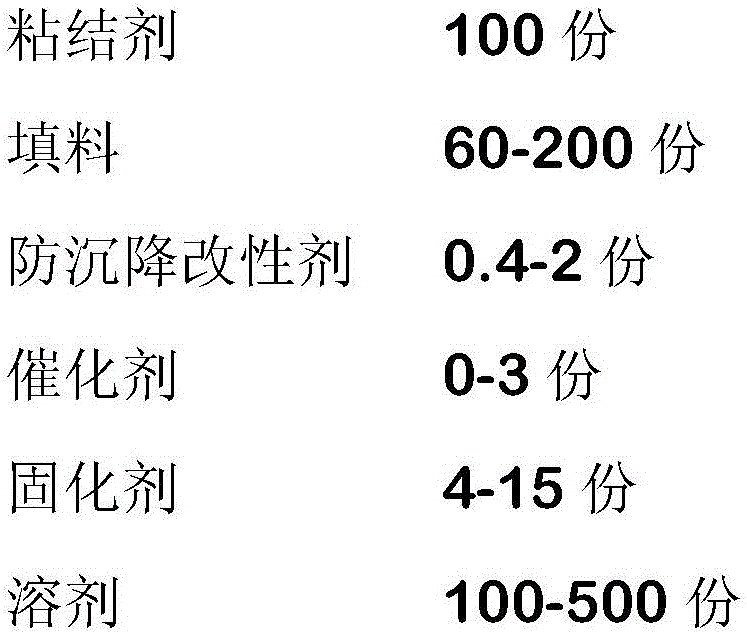

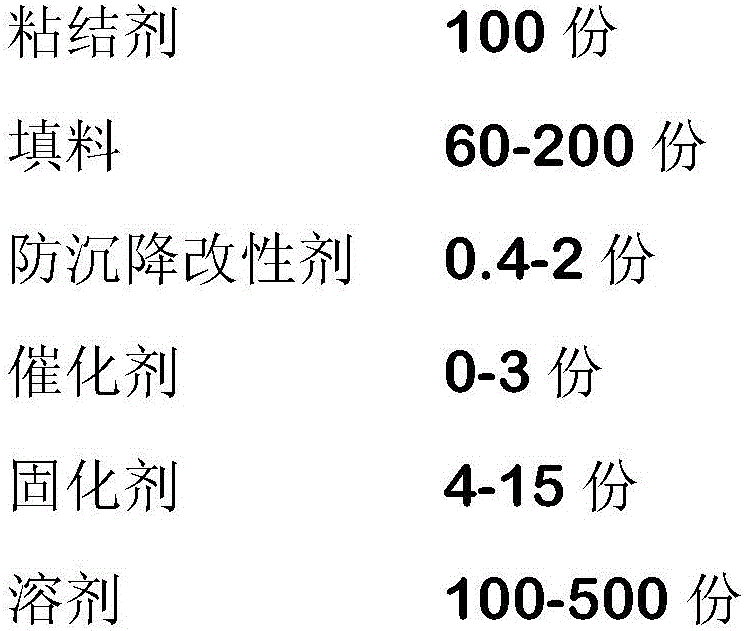

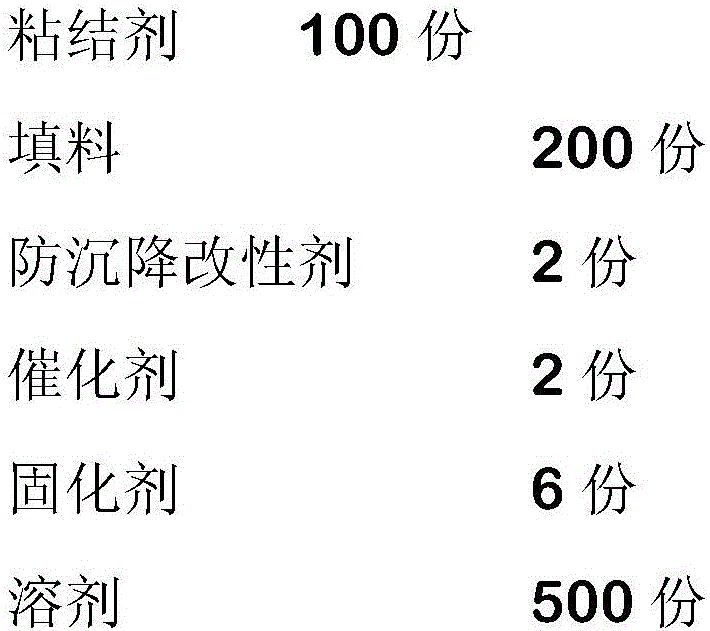

Spray coating type low-absorption and low-emission thermal control coating, preparation method thereof and application thereof

ActiveCN106566408AMeet coating requirementsEasy constructionPolyester coatingsSpace environmentSpray coating

The invention relates to a spray coating type low-absorption and low-emission thermal control coating, a preparation method thereof and an application thereof, and belongs to the technical field of spacecraft thermal control coatings. The invention also provides a preparation method for preparing the spray coating type thermal control coating low in absorption and low in emission. Based on the method, the coating is directly sprayed and coated onto the outer surface of a spacecraft in the spray coating manner, so that the performances of low absorption and low emission are realized. On one hand, the influence of the solar irradiation on the temperature inside the spacecraft is reduced. On the other hand, the radiation and the heat leakage of the spacecraft to the space environment are reduced. Therefore, the coating has an important effect in maintaining the proper temperature of the spacecraft during the long-periodic detection activity.

Owner:BEIJING SATELLITE MFG FACTORY

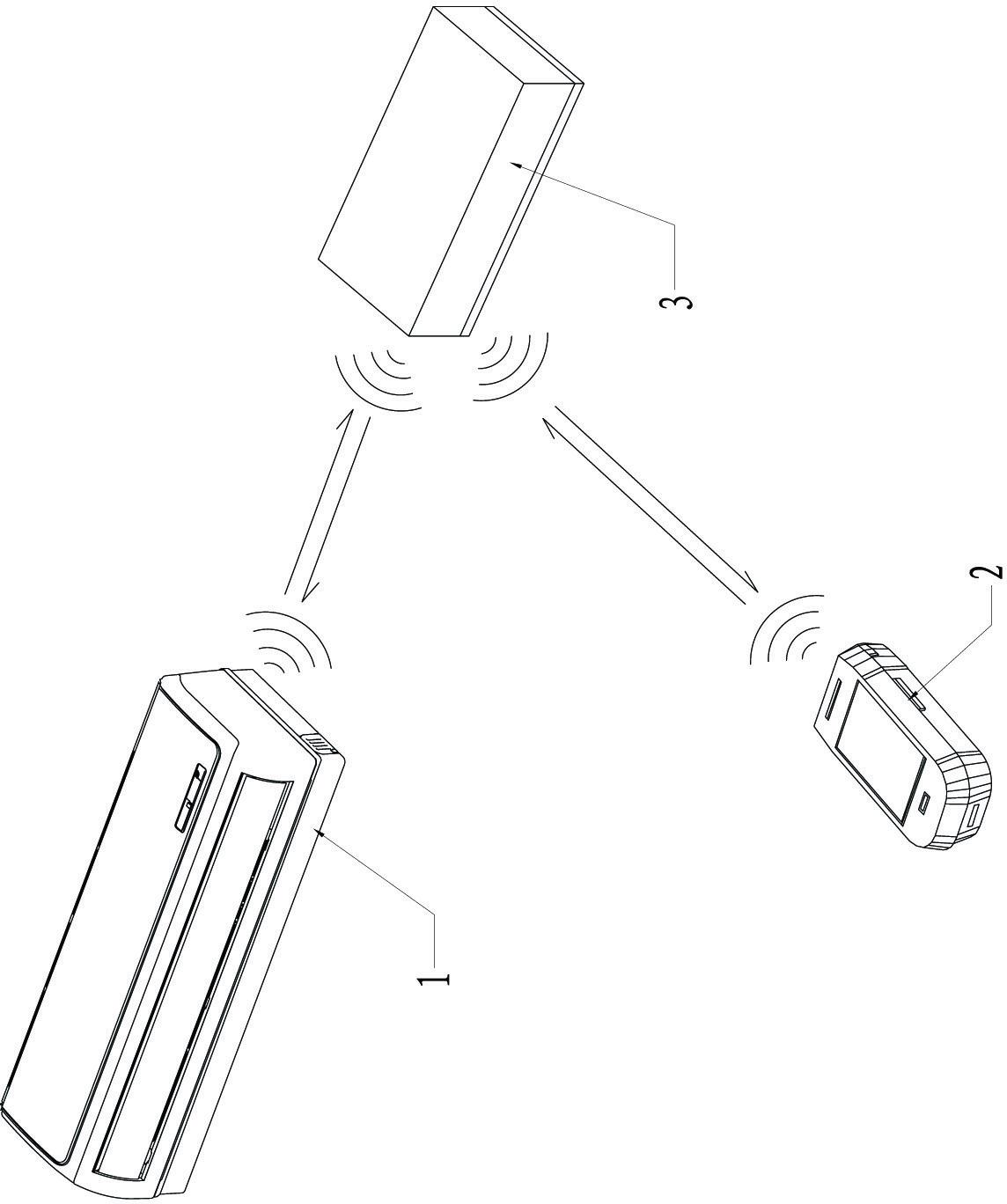

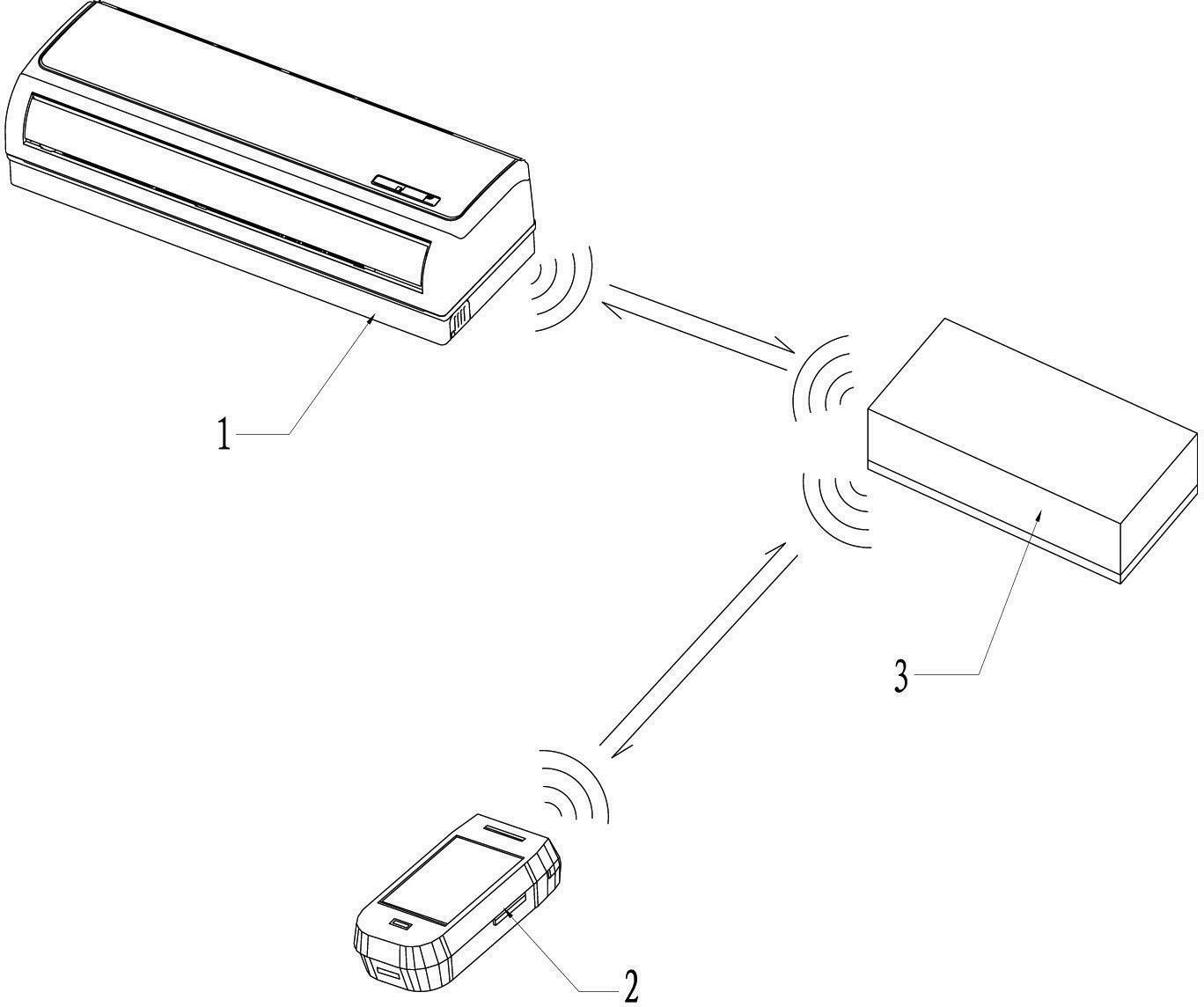

Air conditioner control module based on bluetooth wireless network

InactiveCN102589100AEnsure proper temperatureImprove comfortSpace heating and ventilation safety systemsLighting and heating apparatusWireless controlComputer terminal

The invention provides an air conditioner control module based on a bluetooth wireless network. The air conditioner control module comprises a controlled air conditioner, a control terminal and a controller, wherein the control terminal and the controller are connected through a wireless network, internally provided with bluetooth communication modules which are matched with each other, and realize the wireless control by the respective bluetooth communication modules; and the controller is used for receiving the inquiry information of the control terminal, receiving the control information of the control terminal and receiving the fault signals of the controlled air conditioner, wherein after being decoded, the inquiry information is generated into an inquiry instruction, the running state of the air conditioner is inquired, and the inquiry result returns to the control terminal; after being decoded, the control information is generated into a control instruction, the controlled air conditioner executes the corresponding operation according to the control instruction, and the control terminal feeds back the executing result; and after being decoded, the fault signals are generated into alarm information, and the alarm information is sent to the control terminal to be processed. After adopting the scheme, the air conditioner module based on the bluetooth wireless network can inquire and control the running state of the air conditioner in a real time manner, and alarms automatically when the air conditioner is in failure.

Owner:GUANGDONG CHIGO AIR CONDITIONING

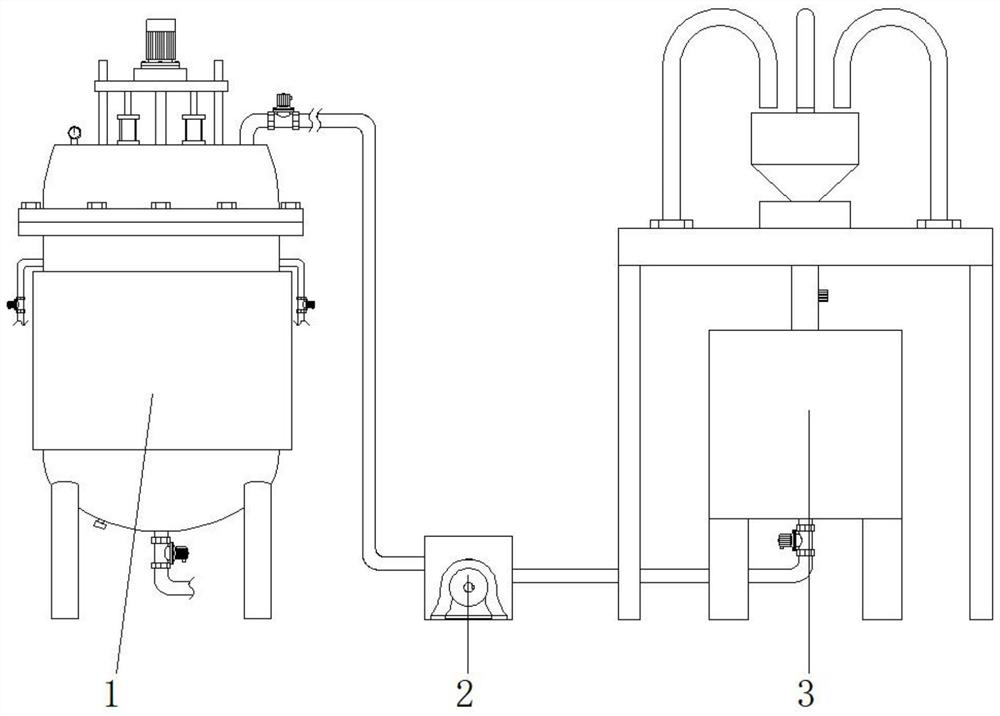

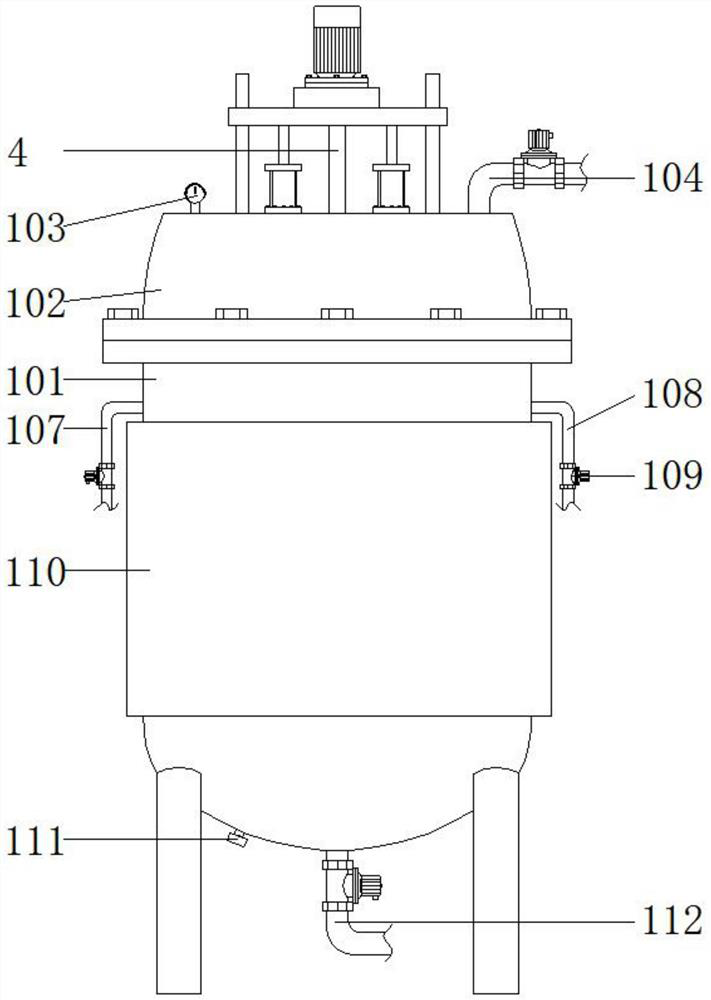

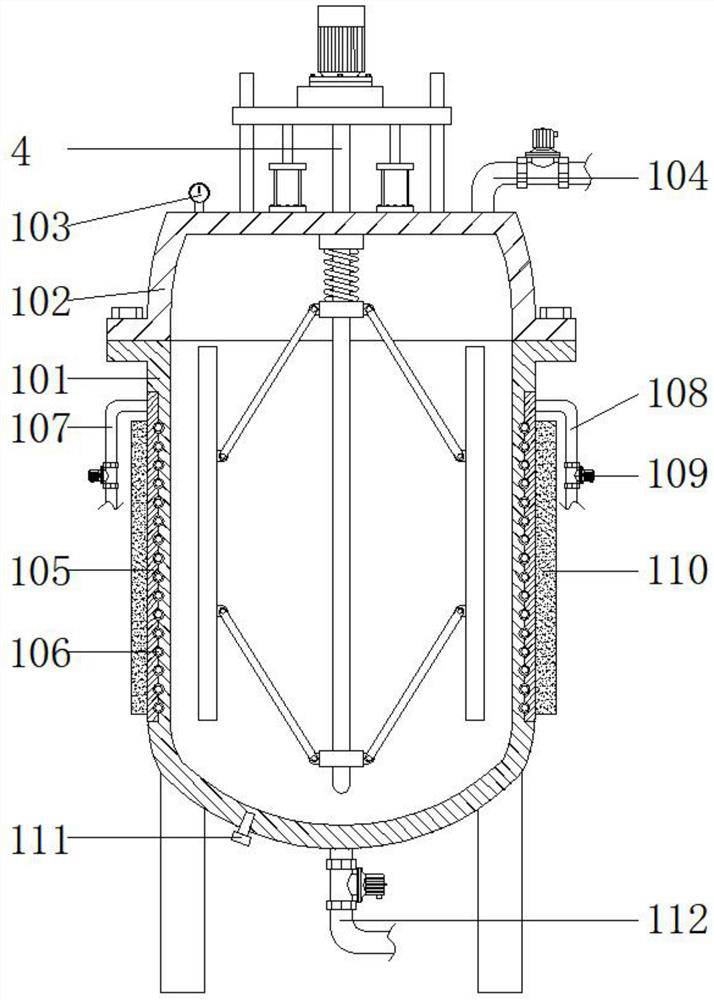

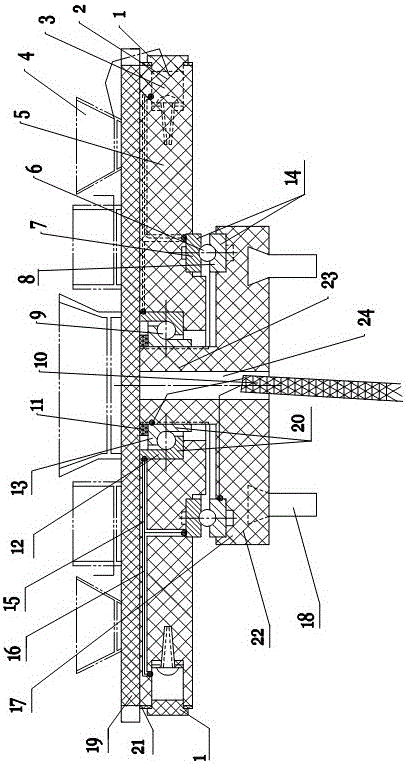

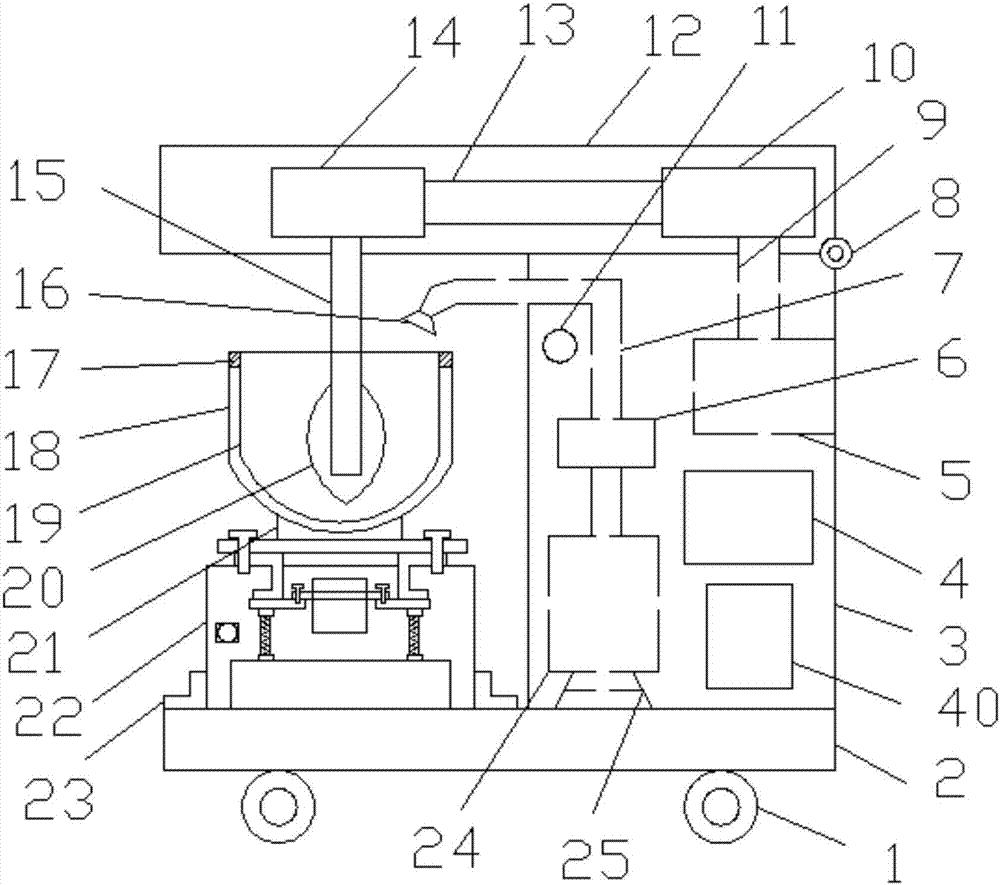

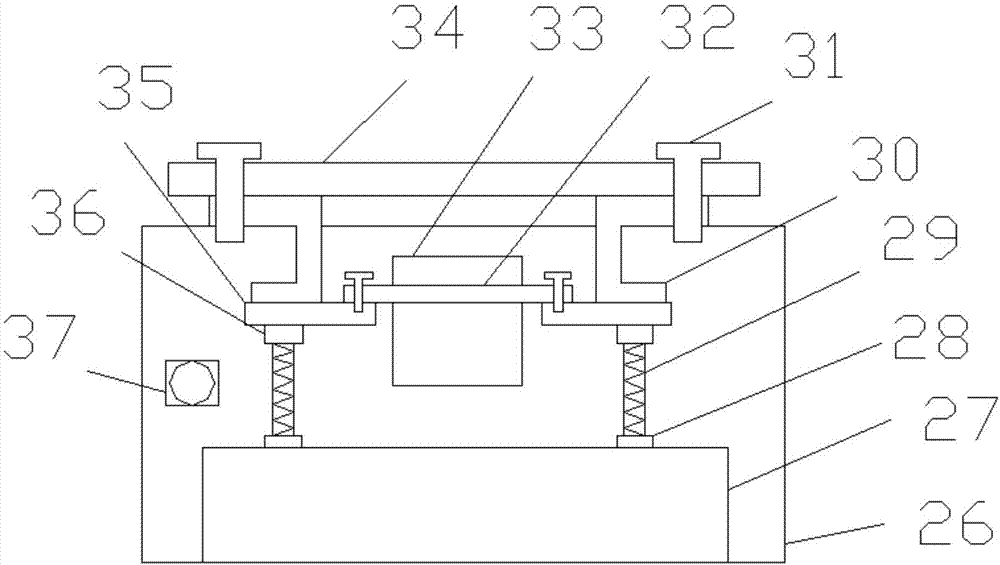

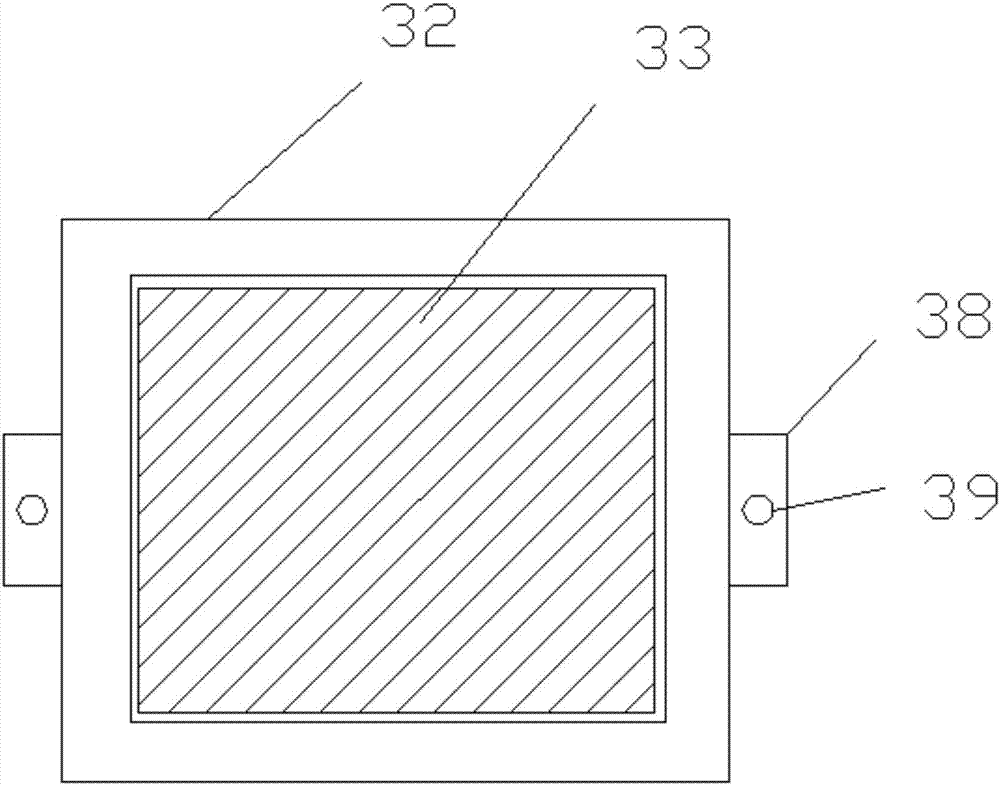

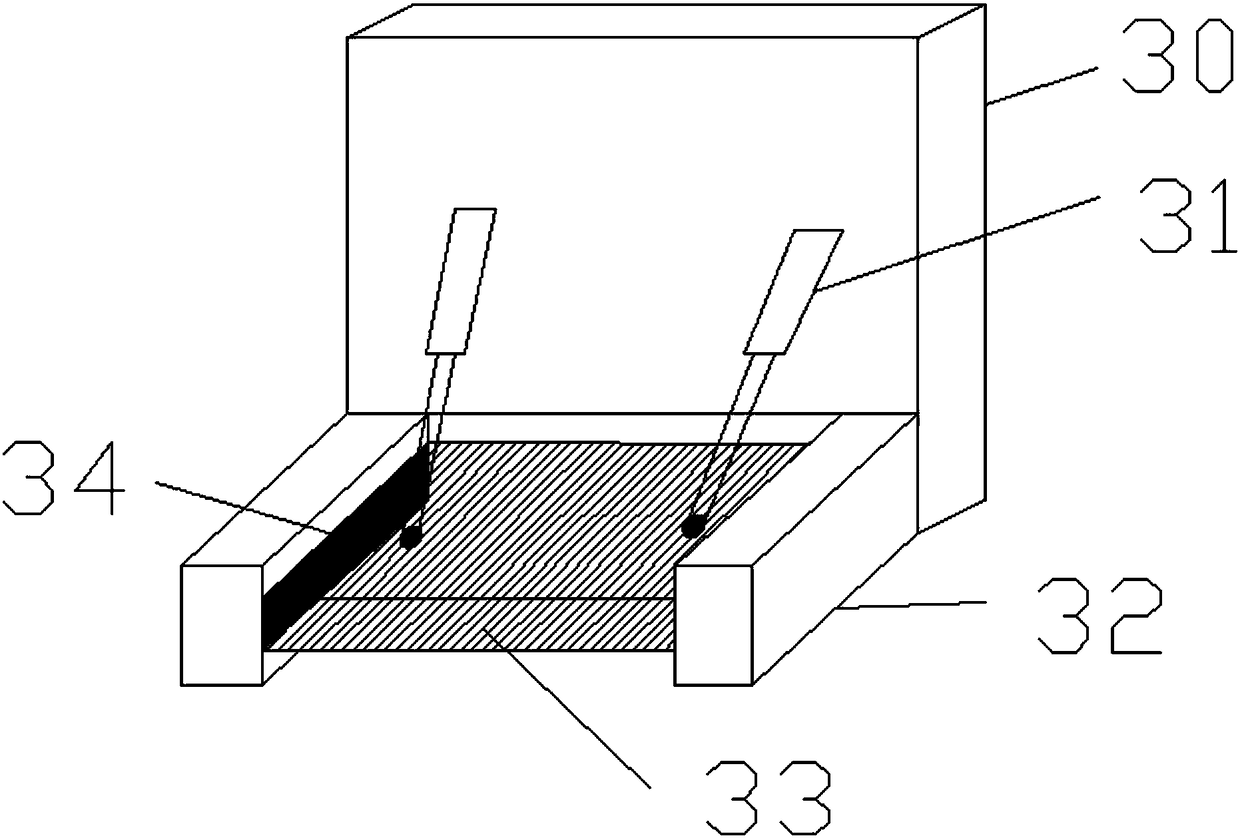

Lactic acid bacteria fermentation device

InactiveCN112481090AEasy to cleanEnsure proper temperatureBioreactor/fermenter combinationsBiological substance pretreatmentsBiotechnologyLactic acid bacterium

The invention discloses a lactic acid bacteria fermentation device, and relates to the technical field of food production. The lactic acid bacteria fermentation device comprises a fermentation mechanism and a batching mechanism, the fermentation mechanism and the batching mechanism are connected through an infusion pump, the batching mechanism can carry out automatic batching, the fermentation mechanism comprises a fermentation tank body, a stirring and cleaning part is fixedly installed at the top of the fermentation tank body, the stirring and cleaning part comprises a fermentation tank cover, fixed guide columns are fixedly connected with the four corners of the top of the fermentation tank cover correspondingly, a lifting plate is slidably connected between the fixed guide columns, anda telescopic air cylinder is further fixedly mounted at the top of the fermentation tank cover. Through the arrangement of the stirring and cleaning part, when the fermentation mechanism completes fermentation, the stirring and cleaning part can be used for stirring yoghourt during fermentation, and meanwhile, after fermentation is completed, the stirring and cleaning part can be used for cleaning the interior of the fermentation tank body, so that the fermentation mechanism is convenient to clean.

Owner:清远一生自然生物研究院有限公司 +1

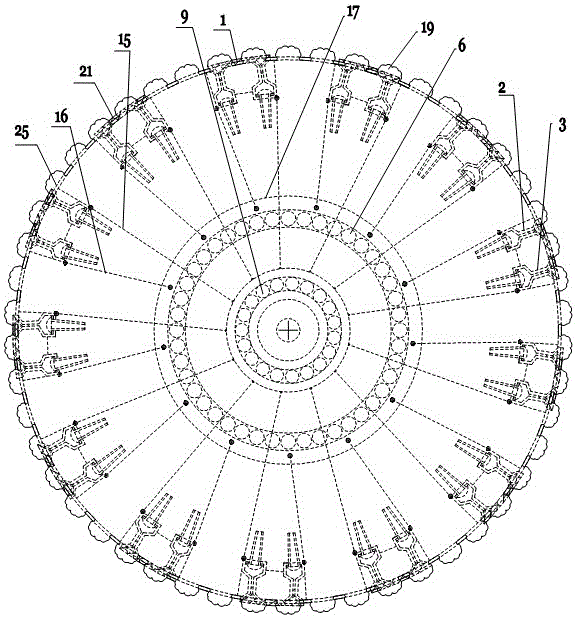

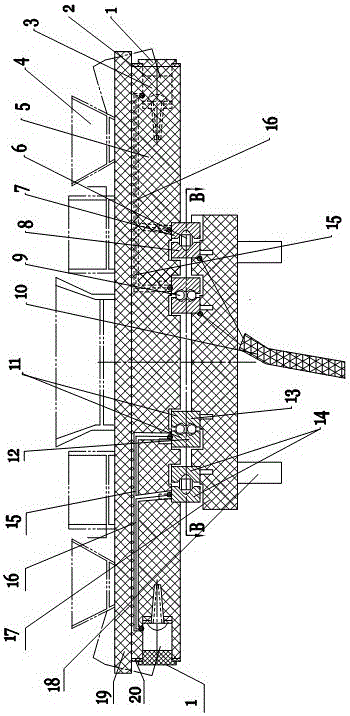

Rolling rotary isolated electricity conducting device for dining table

ActiveCN105852412ACompatible with useEnsure proper temperatureServing tablesRevolvable tablesElectricityMechanical engineering

The invention discloses a rolling rotary isolated electricity conducting device for a dining table. The rolling rotary isolated electricity conducting device comprises a fixed disc body and a rotary disc body, wherein a live line rotary electricity conducting bearing and a null line rotary electricity conducting bearing are arranged between the fixed disc body and the rotary disc body respectively; the rotary disc body can rotate around the fixed disc body; a plane plate which is used for storing a dinner plate and is made of an insulating material is arranged above the rotary disc body; and more than one power supply socket hole is uniformly formed in the side wall of the rotary plate body. Various types of dinner plates and a boiled water heat-insulating disc invented by an applicant can be put on the panel plate. The rolling rotary isolated electricity conducting device for the dining table has the advantages that the dining table can be pulled according to requirements, dishes can be rotated and supplied, the dining is convenient and the device is safe and reliable and is simple in structure; the boiled water heat-insulating disc can also be arranged to carry out proper-time heating and heat insulation of one or more meals, so that proper temperature of the meals is kept and the dining is relatively comfortable and easier; and the device is suitable for being used at homes, restaurants, hotels, guesthouses and the like and is suitable for technical requirements that the voltage is 220V or the voltage is 380V.

Owner:李良友

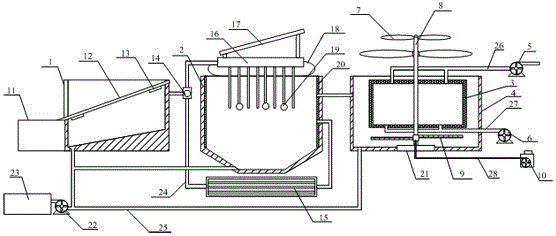

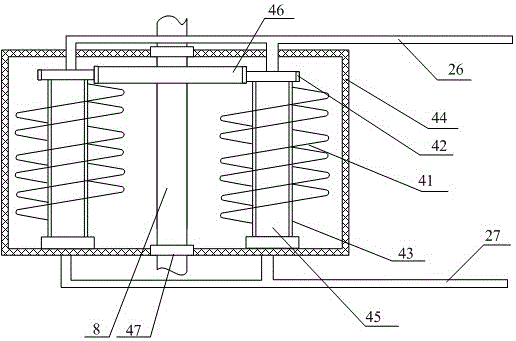

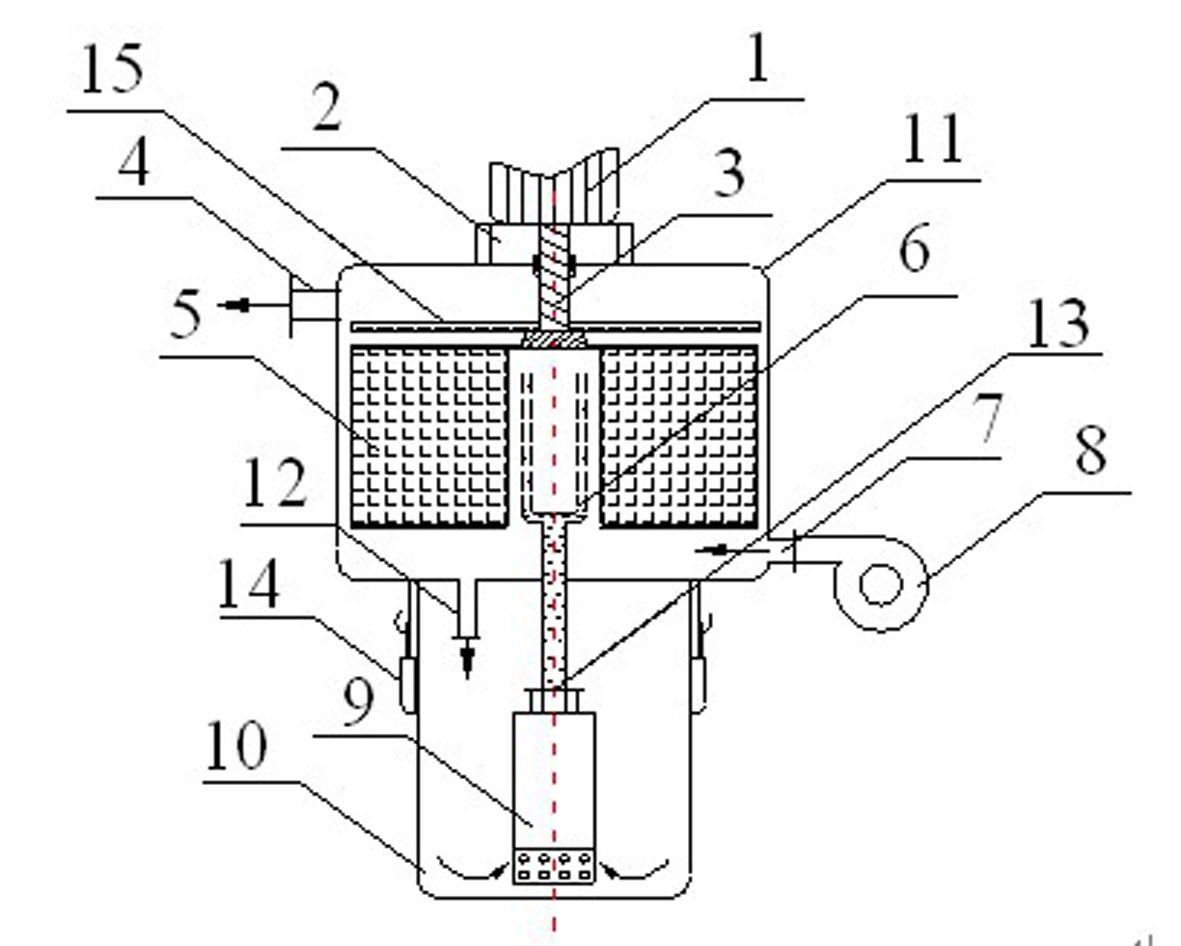

Efficient sewage treatment method based on MBR (Membrane Bioreactor) membrane

ActiveCN106630497AImprovement effectImprove equipment utilizationTreatment using aerobic processesTreatment involving filtrationImpellerPrecipitation

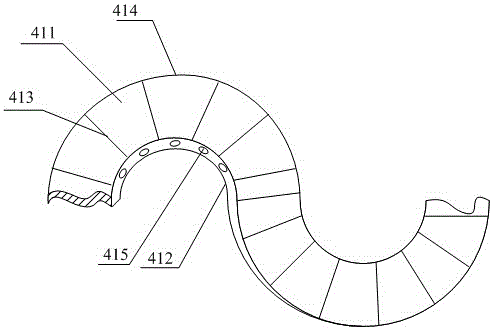

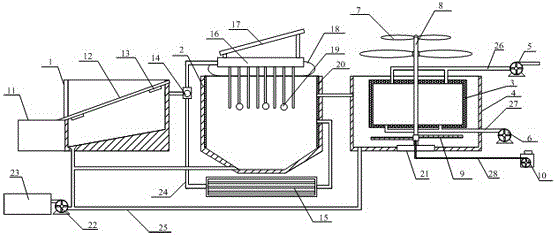

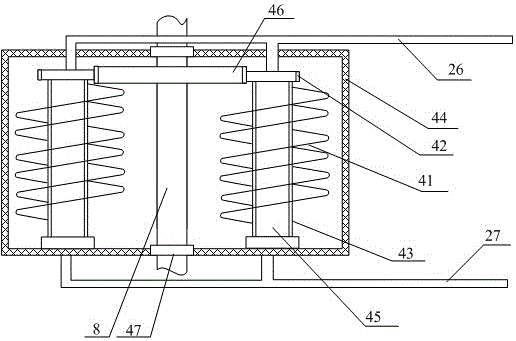

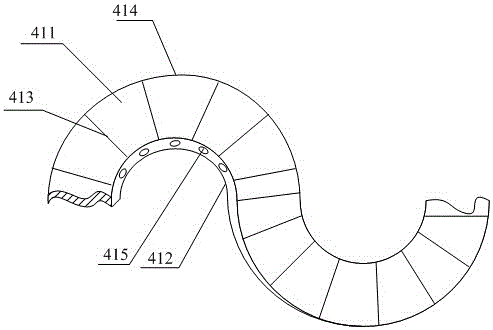

The invention discloses an efficient sewage treatment method based on an MBR (Membrane Bioreactor) membrane. The method comprises the following steps: carrying out sludge precipitation after sewage passes through a grid plate (12) in an adjusting tank (1); enabling the sewage to enter a facultative tank (2) through a three-way solenoid valve (14); when the temperature of the sewage in the facultative tank (2) is relatively high, enabling the sewage in the adjusting tank (1) to flow into the facultative tank (2) through an underground cooling pipe (15); when the temperature of the sewage in the facultative tank (2) is relatively low, controlling the three-way solenoid valve (14) to enable the sewage in the adjusting tank (1) to pass through a heating water tank (16) and flow into the facultative tank (2); driving a wind power driving rod (8) by a wind power impeller (7) to rotate, and driving two driven gears (42) through a driving gear (46); driving two MBR membrane bodies by the driven gears (42) to rotate and move; forming pressure difference by the sewage between an upper membrane layer (411) and a lower membrane layer (412), so as to improve the filtering efficiency; after purifying, discharging the sewage through a water drainage pipe (26); meanwhile, driving an aeration wheel (9) to rotate incessantly along with the wind power driving rod (8), so as to enlarge the aeration area and improve the utilization rate of equipment.

Owner:浙江秀水环保有限公司

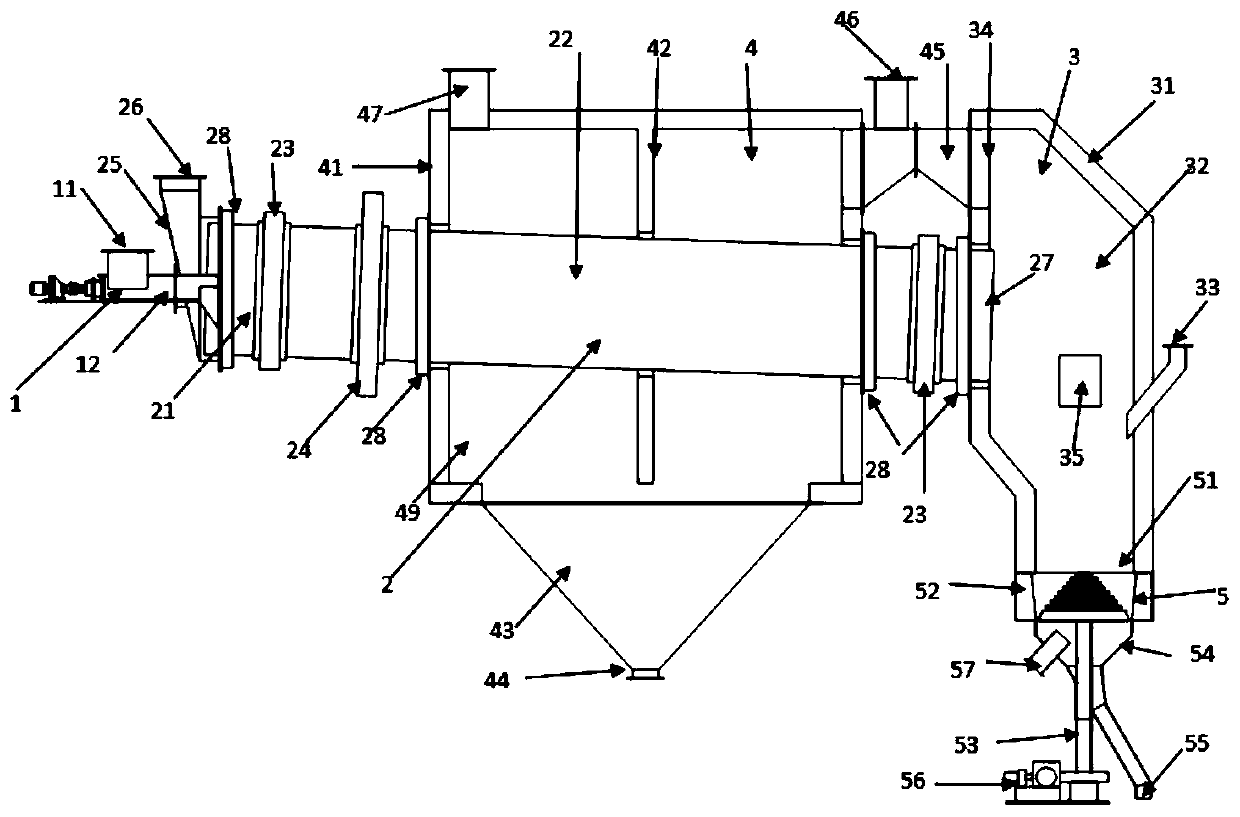

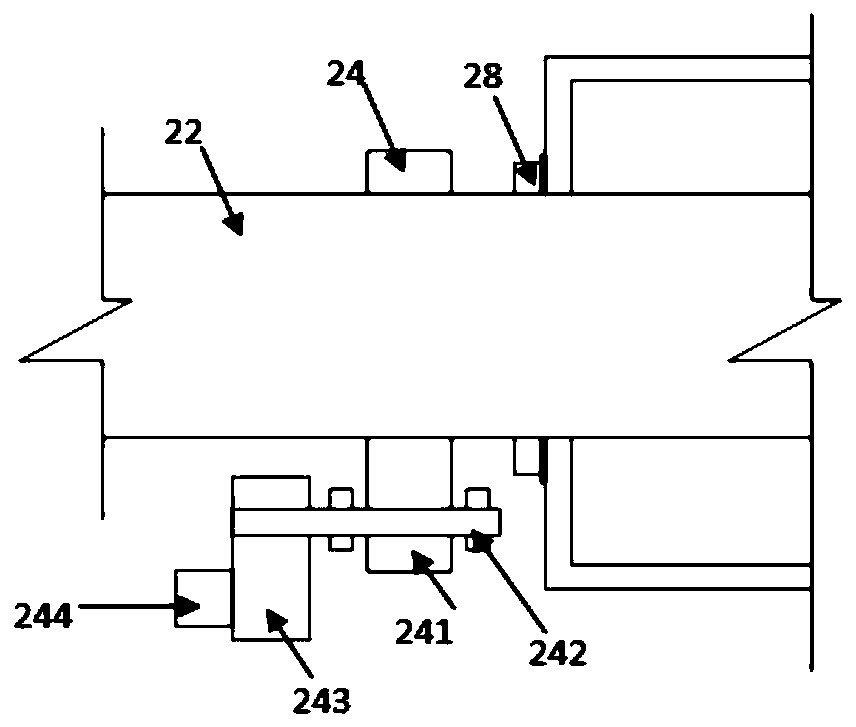

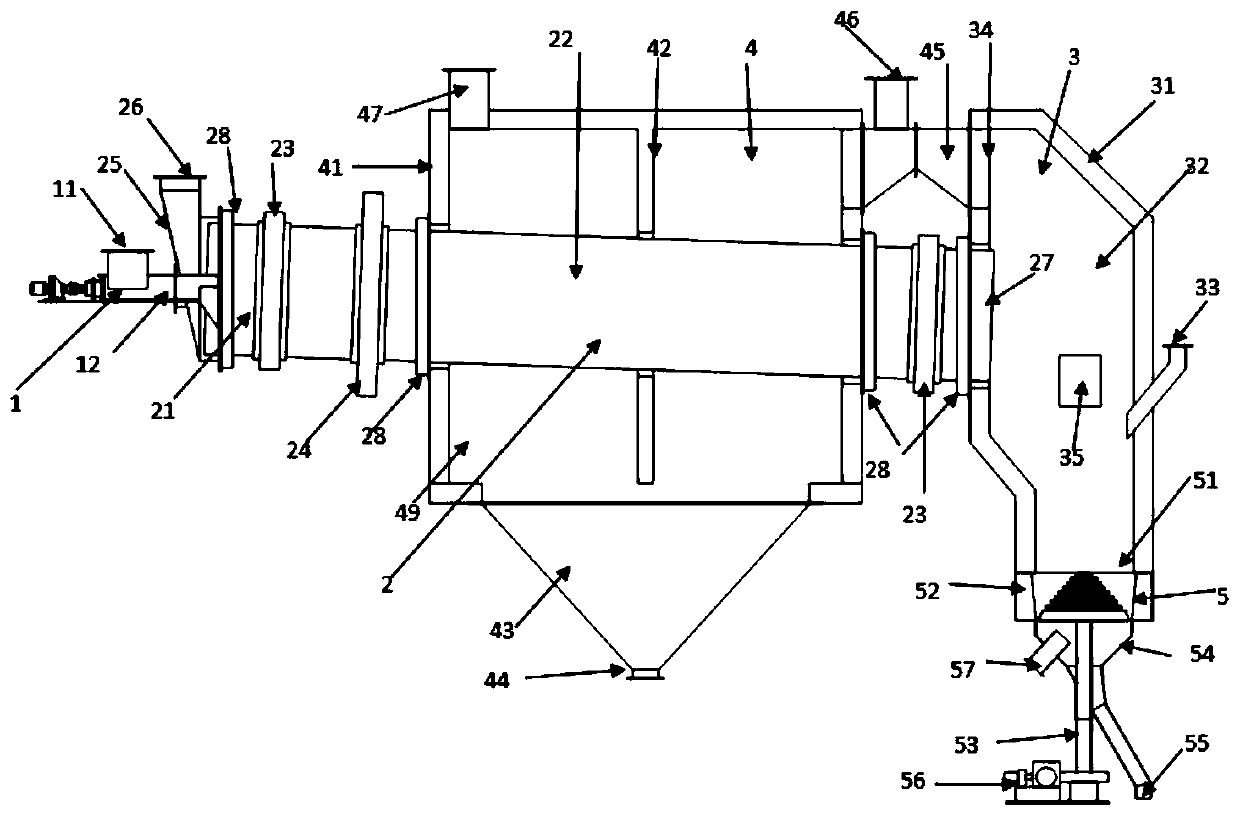

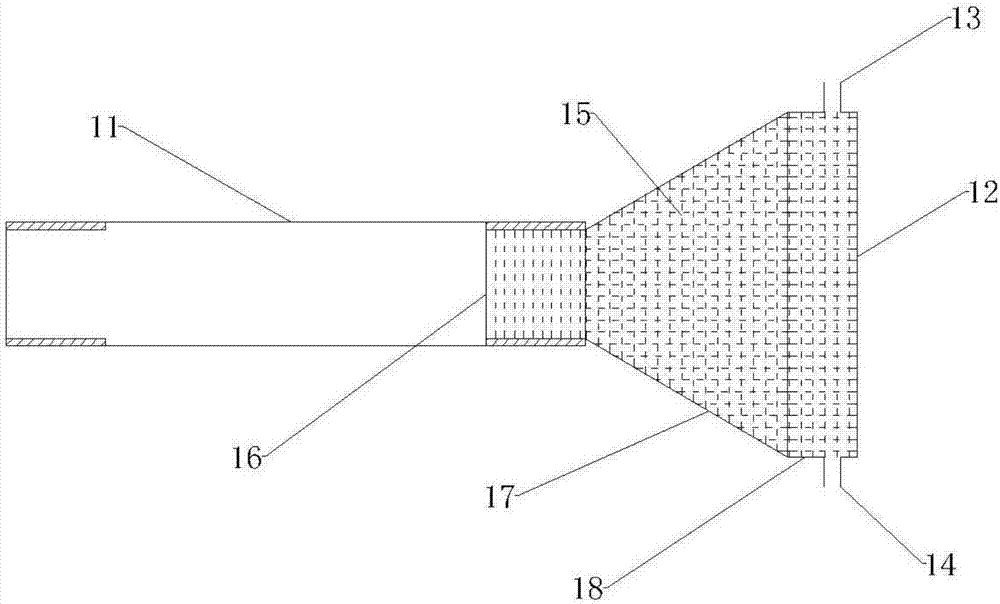

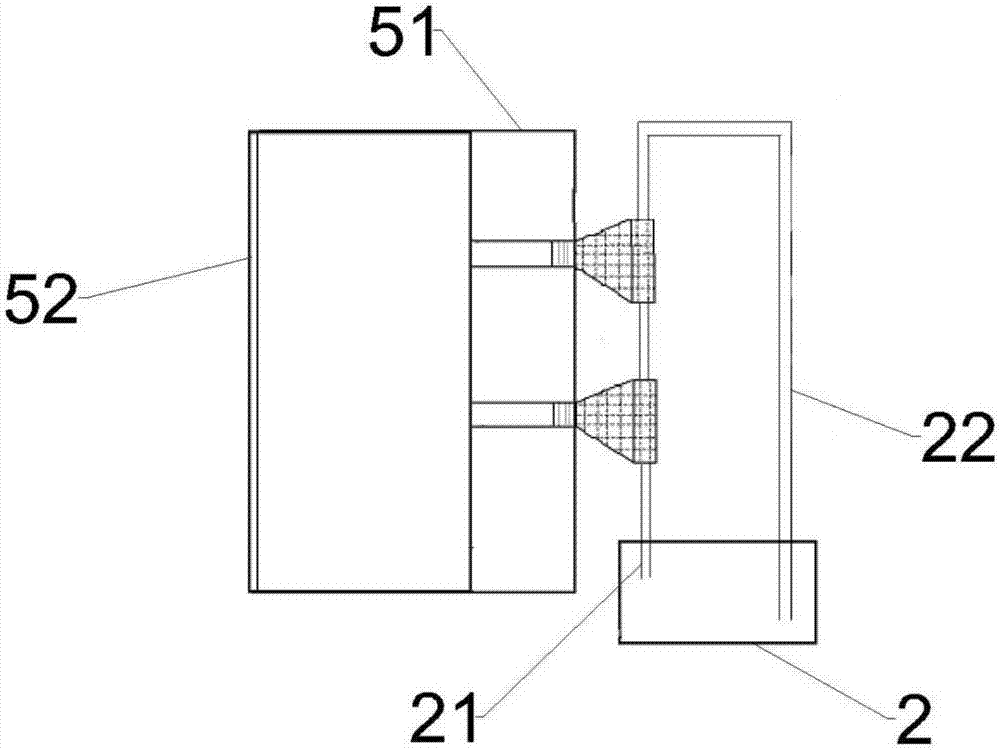

High-efficiency sewage treatment system based on MBR (Membrane Bioreactor) membrane

ActiveCN106630496AIncrease contact areaImprove the effect of permeation filtrationTreatment using aerobic processesTreatment involving filtrationSolenoid valveAir blower

The invention provides a high-efficiency sewage treatment system based on an MBR (Membrane Bioreactor) membrane. The high-efficiency sewage treatment system comprises a regulation tank, a facultative tank, an MBR tank, an MBR membrane component, a water yielding pump, an MBR membrane scavenging pump, pneumatic impeller, a pneumatic driving rod, an aeration wheel, an air blower, a filter residue tank, a grating panel, a vibrator, a three-way solenoid valve, an underground cooling pipe, a heating water channel, a photovoltaic panel, a supporting air bag, a temperature sensor, a heat absorption layer, a fixed seat, a blow-down pump, a sludge tank, a drainage pipe, a blow-down pipe, a washing pipe and an air pipe, wherein the regulation tank is connected with the facultative tank through the three-way solenoid valve; the MBR membrane component is mounted inside the MBR tank. Through the arrangements of the MBR membrane component, the pneumatic impeller, a dust-cap aeration wheel, the underground cooling pipe and the photovoltaic panel of the high-efficiency sewage treatment system, the utilization rate of the MBR membrane is promoted to be high; the sewage purification efficiency is improved; the energy consumption is low; the structure is simple; the sewage treatment cost is decreased; the practicability is high; the popularization and the use are convenient.

Owner:福建省融旗建设工程有限公司 +1

Domestic vibration dough kneading machine

InactiveCN107980832AHigh strengthGreat tasteMixing/kneading structural elementsMixing/kneading with vertically-mounted toolsSprayerWater storage tank

The invention discloses a domestic vibration dough kneading machine. The domestic vibration dough kneading machine comprises a base, a machine body is arranged on one side of the top part of the base,a water storage tank is arranged on one side of the bottom part in the machine body, a water supply pipe is arranged at the top part of the water storage tank, one side of the water supply pipe penetrates through one side of the top part of the machine body, extends to the outer side of the machine body, and is connected with a sprayer located on the outer side of the machine body, a water supplypump is arranged on the water supply pipe, a drive motor is arranged on one side of the top part in the machine body, a rotating shaft is arranged at the top part of the drive motor, a display is arranged on one side of the surface of the bottom part of the machine body, and a control panel is arranged below the display. The domestic vibration dough kneading machine has the beneficial effects that the domestic vibration dough kneading machine is reasonable in design and simple in structure, is convenient to use, and effectively improves the performance for sufficiently stirring the flour by astirrer, so that the chewiness and the taste of the dough are effectively improved; in addition, the manual operation is also effectively reduced, and the manpower resource is saved; and therefore, the working efficiency is effectively improved.

Owner:何永萍

Electricity larceny prevention ammeter box

InactiveCN106093498AAvoid destructionPrevent electricity theftTime integral measurementElectricityEngineering

The invention discloses an electricity larceny prevention ammeter box. The electricity larceny prevention ammeter box comprises a square-shaped main body which comprises a casing and an upper cover, wherein the upper cover can open and close the enclosed casing through a cipher lock. The cipher lock comprises a lock body; a controller which is arranged in a cavity and comprises a first control unit, a first unit and a second unit, wherein the first control unit is connected with an external power source and a battery, the first control unit is connected with the first unit and the second unit, the first unit is connected with the external power source, and the second unit is connected with the battery; a first alarm which is connected with the first control unit; a motor which is connected with the first unit; an emergency motor which is connected with the second unit; a lock bolt which is driven by the motor or the emergency motor; a lock catch; and a keyboard. The electricity larceny prevention ammeter box provided by the invention is quite high in safety, prevents ammeter damage or electricity larceny caused when non-workers open the ammeter box, and enables the electricity larceny prevention ammeter box to have wider applicability through arrangement of two power supply modes of the external power source and the battery.

Owner:NANNING SIFEI ELECTRONICS TECH

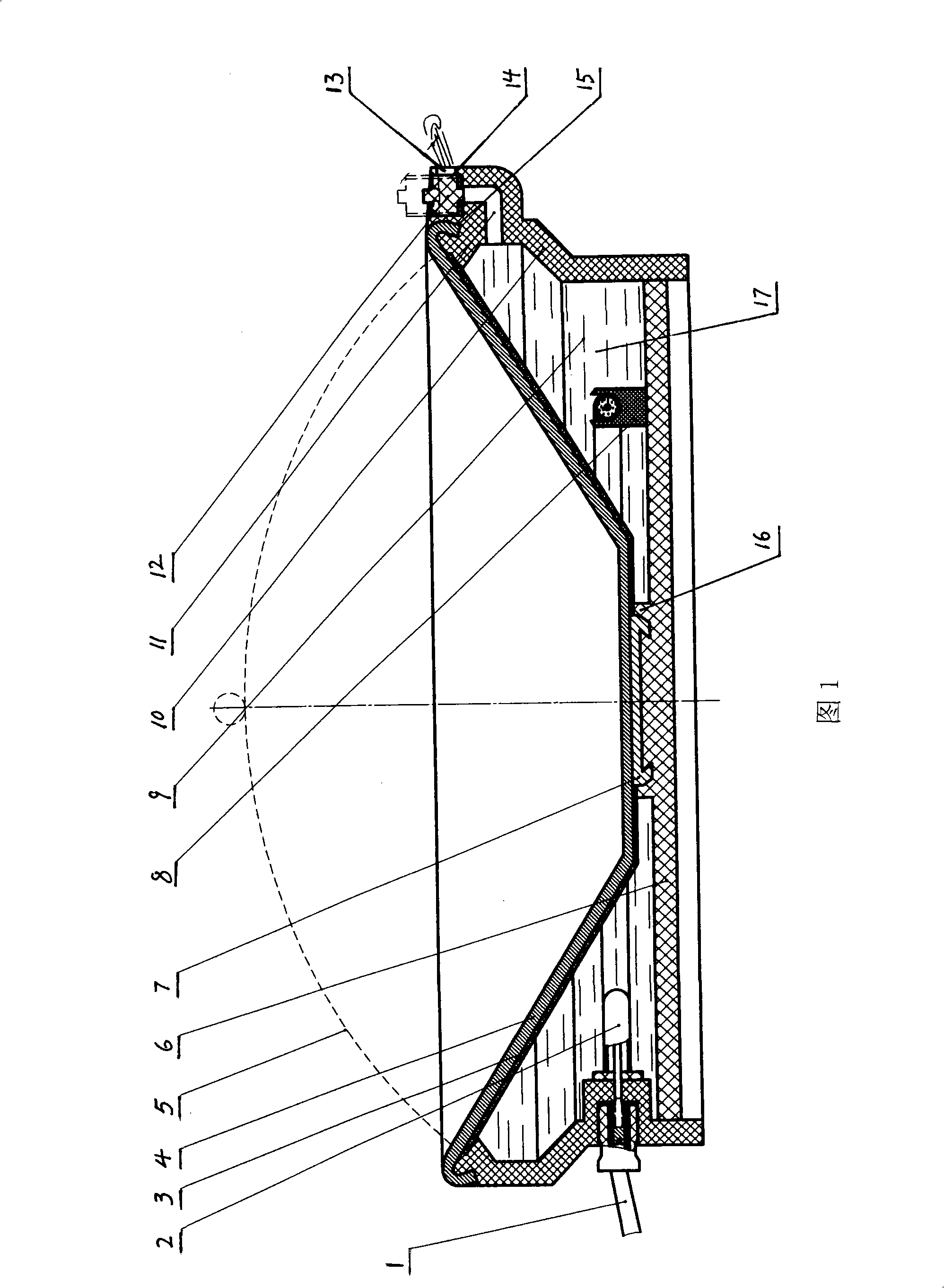

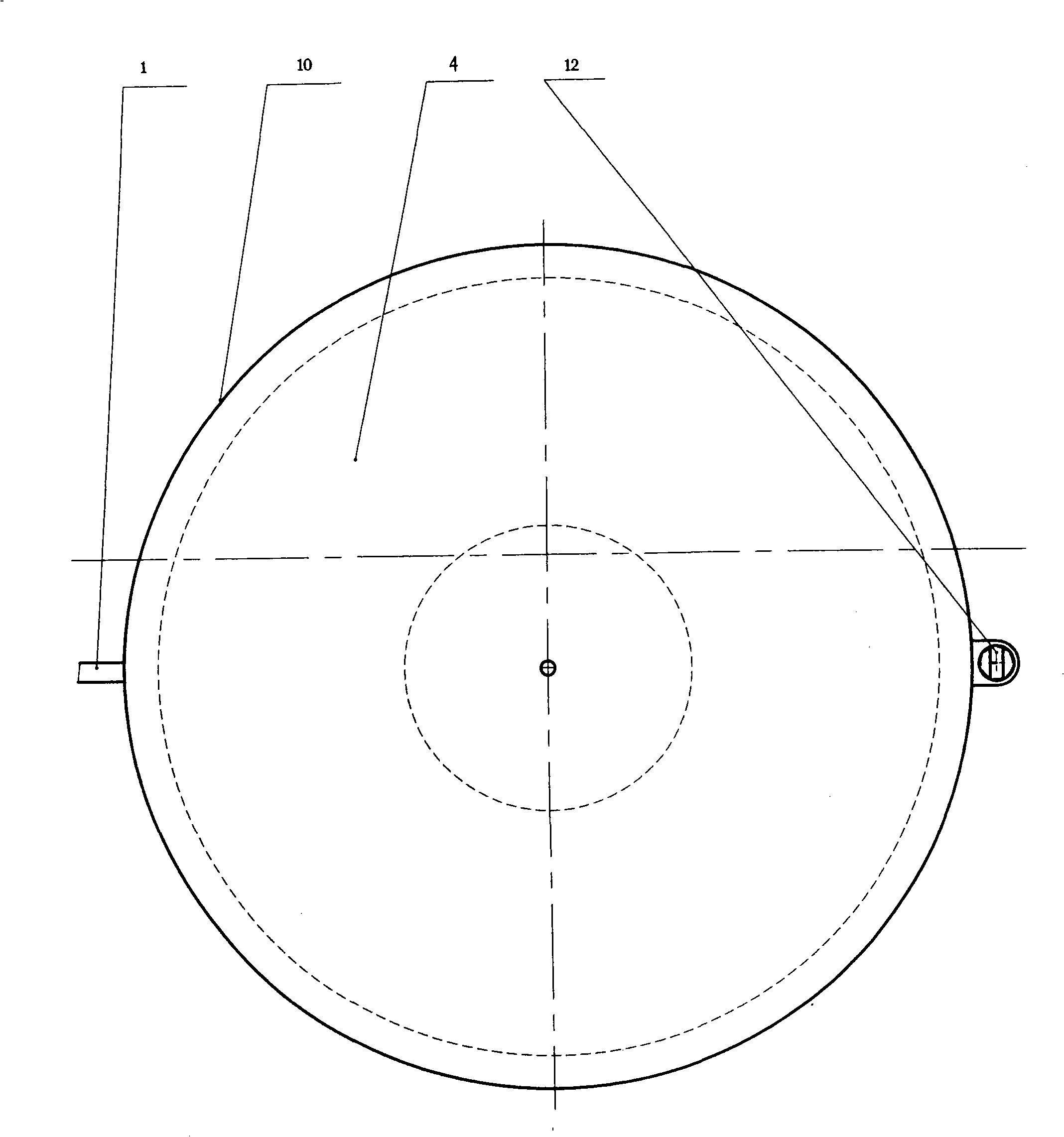

Combination melting furnace for treatment of arsenicsoda slag and low-melting-pointheavy-metal containing waste residue

PendingCN109708125ARealize thermal desorption methodImprove adaptabilityIncinerator apparatusMetals industrySlag

The invention discloses a combination melting furnace for treatment of arsenic soda slag and low-melting-point heavy-metal containing waste residue. The combination melting furnace for the treatment of the arsenic soda slag and the low-melting-point heavy-metal containing waste residue comprises an air-lock feeder, a rotary kiln, a vertical incinerator, a high-temperature flue gas chamber and a crushing discharging mechanism, the air-lock feeder is connected with the rotary kiln, the rotary kiln is connected with the vertical incinerator, the vertical incinerator is connected with the crushingdischarging mechanism, the high-temperature flue gas chamber covers the outer part of the rotary kiln, the cylindrical shell of the rotary kiln is connected with the two ends of the high-temperatureflue gas chamber and the machine shell of the vertical incinerator through sealing rings, after two stages of combustion process are conducted on materials through the rotary kiln and the vertical incinerator, high-temperature flue gas is discharged through the rotary kiln and an flue gas outlet of the high-temperature flue gas chamber, and complete combustion of the combusted slag is thoroughly achieved after through the action of the crushing discharging mechanism. The combination melting furnace for the treatment of the arsenic soda slag and the low-melting-point heavy-metal containing waste residue serves as combustion equipment, the equipment structure is simple and unique, the operation is convenient, the cost is low, waste residue smelting is conducted on industrial waste residue containing low-melting-point heavy-metal such as the arsenic soda slag and sludge containing arsenic, mercury, lead, zinc, cadmium through the unique technology of two stages combination combustion, andthe combination melting furnace for the treatment of the arsenic soda slag and the low-melting-point heavy-metal containing waste residue is also suitable for pyrolytic incineration of waste materialcontaining organics.

Owner:长沙中硅环保科技有限公司

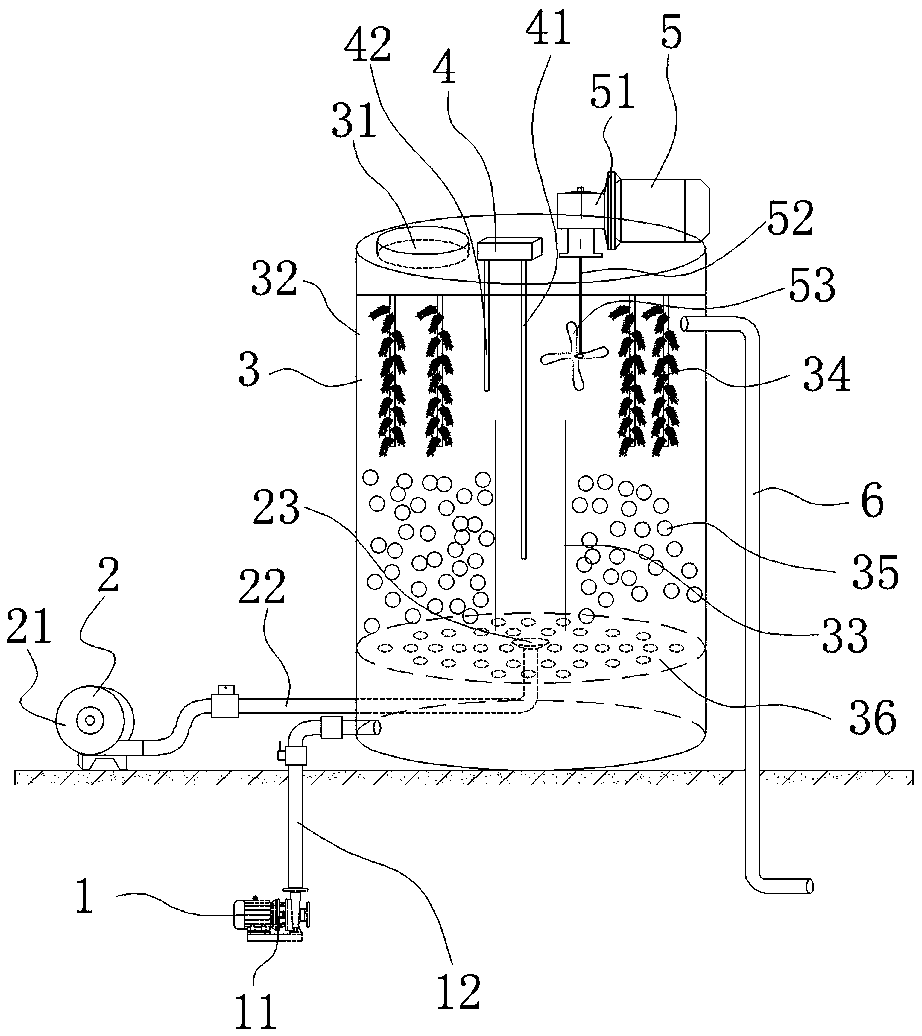

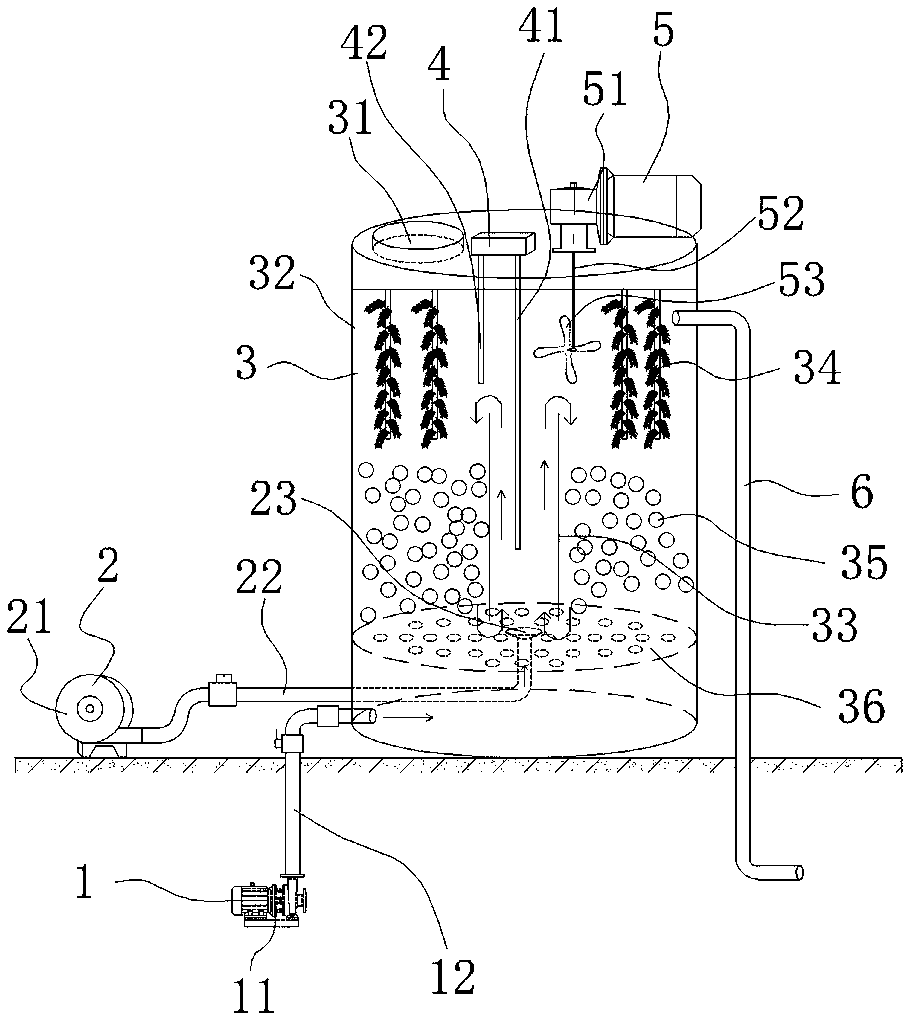

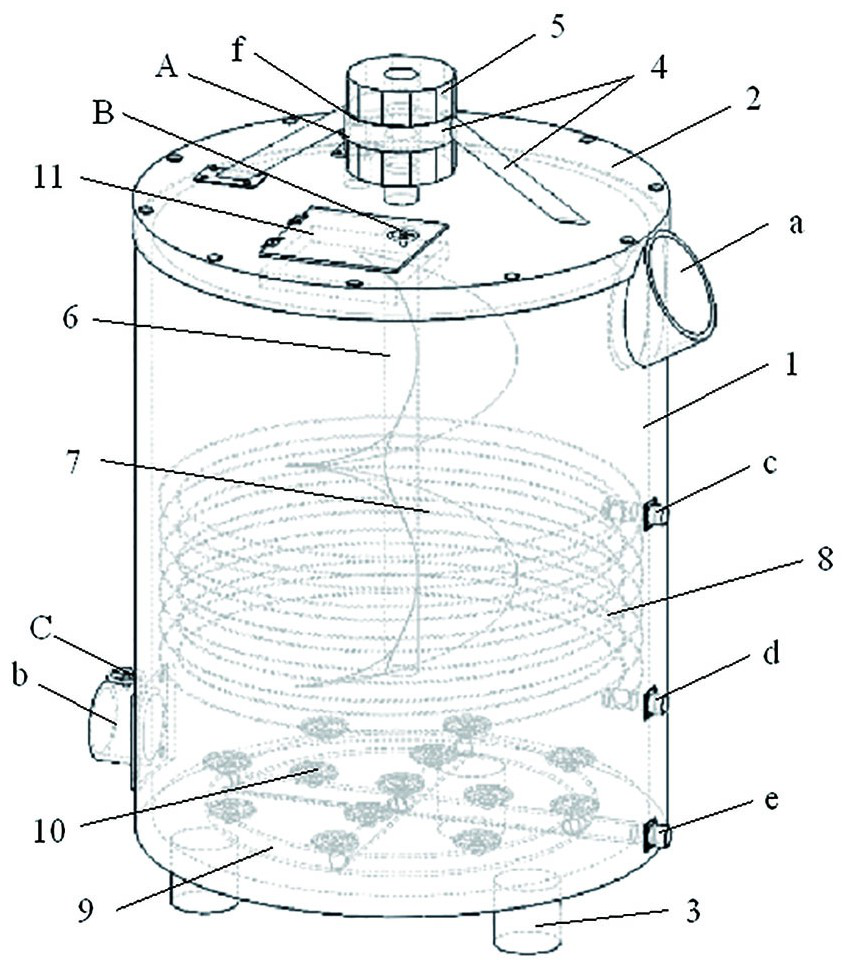

Device for promoting activation of indigenous microorganisms in water

InactiveCN109264873AAdaptableContinuous restoration of water environmentWater treatment parameter controlBiological treatment apparatusLaboratory culturePopulation

The invention discloses a device for promoting activation of indigenous microorganisms in water, and relates to the technical field of water repair. The device comprises a water inlet system, an aeration system, a microorganism culture tank, a temperature-control system, a stirring system and a water outlet tube. According to the device for promoting activation of indigenous microorganisms in water, a dominant population is formed by activating indigenous PGPR microorganisms in the water, alien microorganisms do not need to be thrown in the water, adaptability to the environment of the water is high, and effects of continuously repairing the environment of the water body and improving the water ecological system can be achieved.

Owner:安徽正一水务有限公司

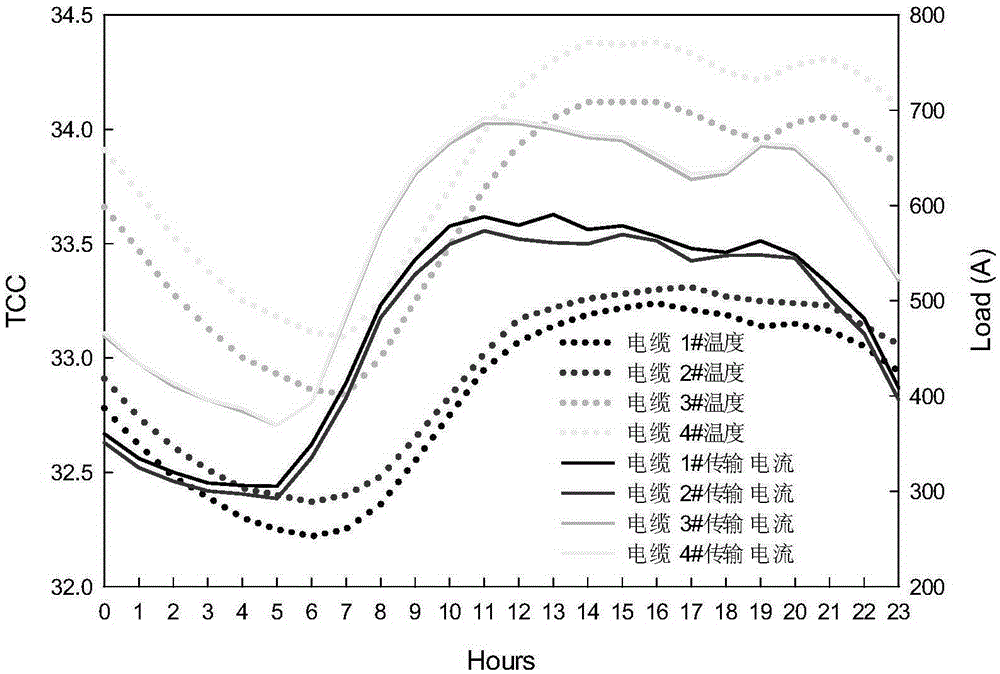

Electric power tunnel cable temperature control system and method

ActiveCN105302181AGuaranteed uptimeEnsure proper temperatureTemperatue controlTemperature controlControl system

The invention relates to an electric power tunnel cable temperature control system and method. The system includes current transformers, a control cabinet, a tunnel fan and temperature sensors, the plurality of current transformers and temperature sensors are hooped on an electric power tunnel cable through ferrules, the control cabinet is connected with the current transformers and the tunnel fan, the tunnel fan is arranged at a tunnel portal, and the inside of the electric power tunnel is ventilated through a ventilation duct. Compared with the prior art, the electric power tunnel cable temperature control system provided by the invention has the advantages of prejudgment, good effect and the like.

Owner:SHANGHAI MUNICIPAL ELECTRIC POWER CO +1

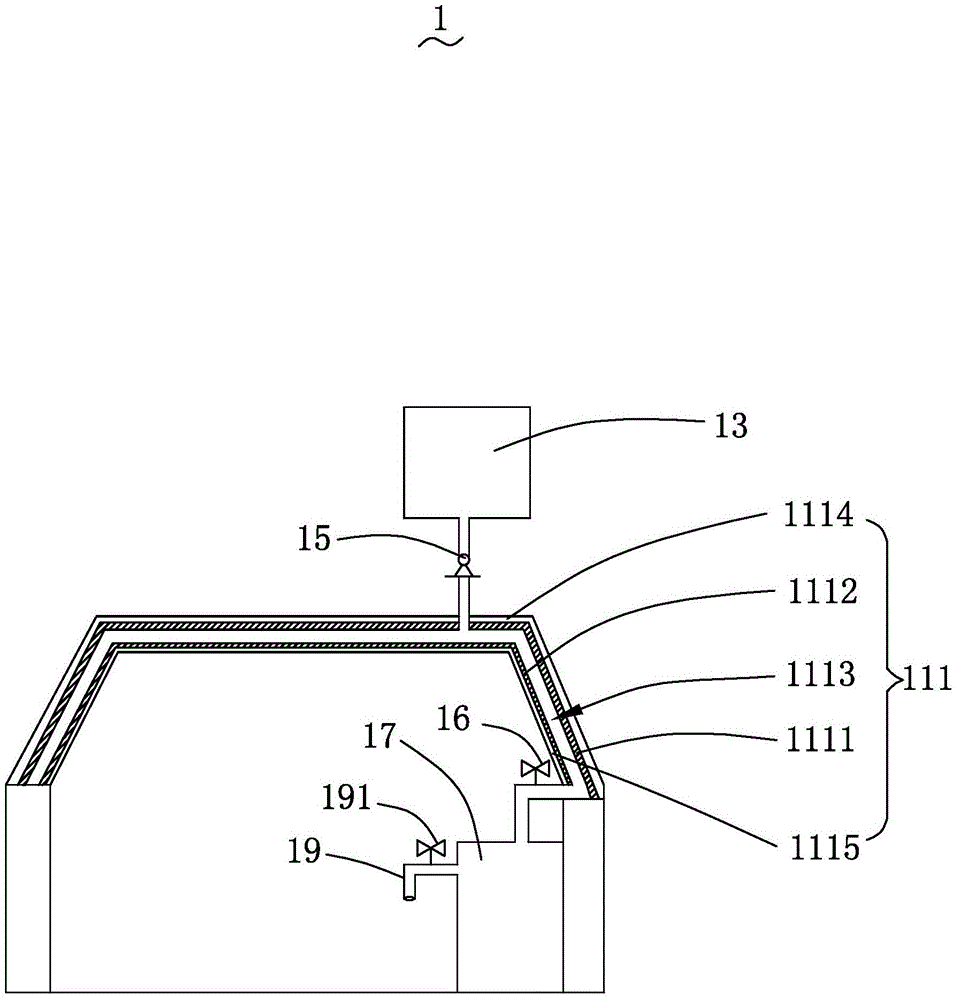

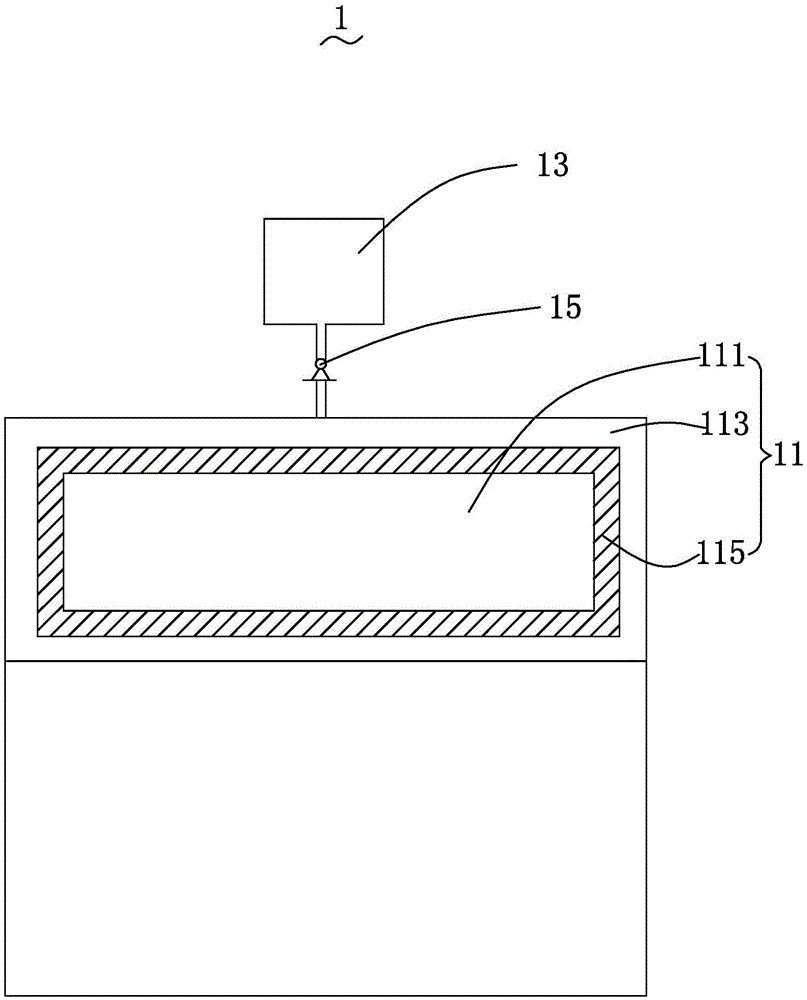

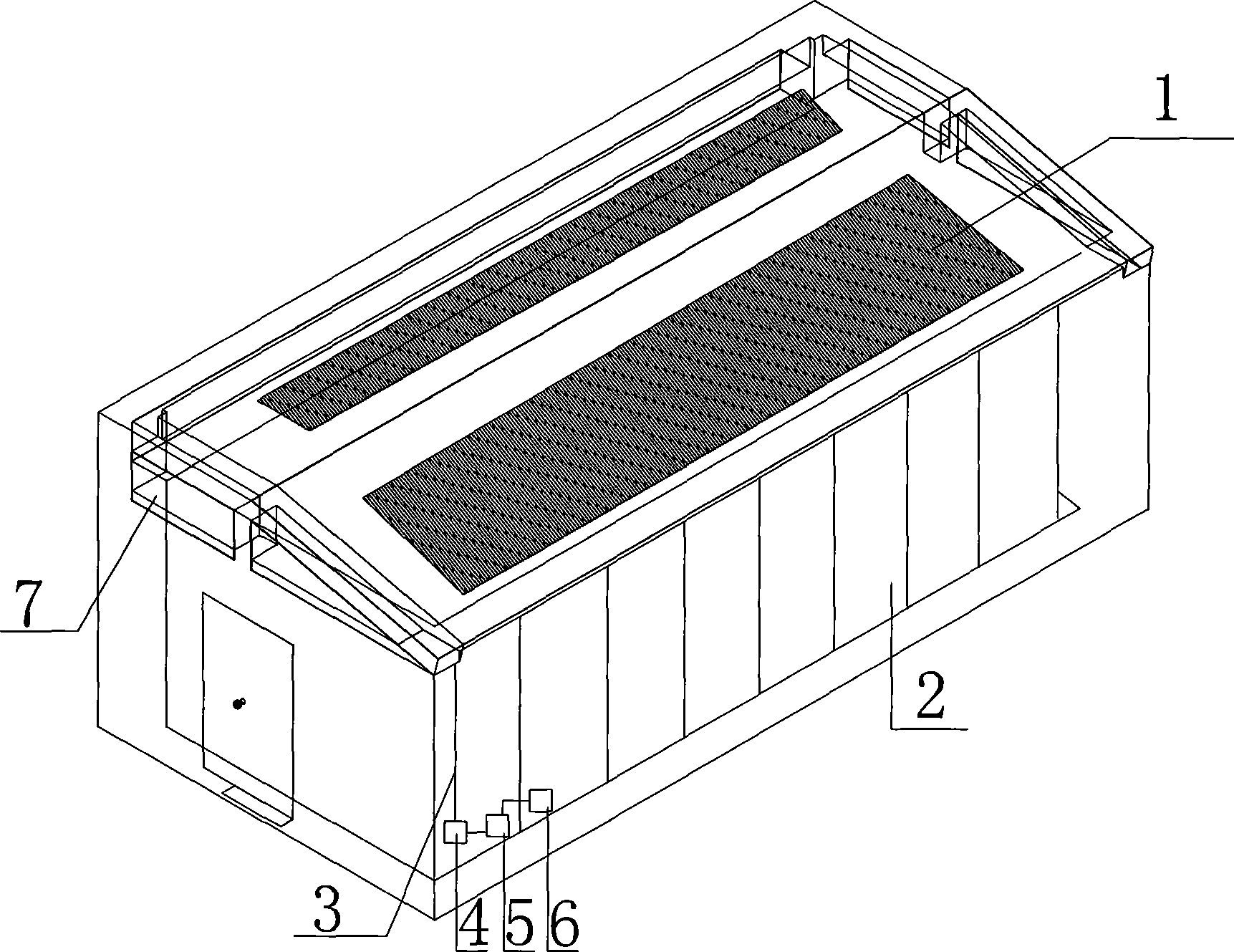

Energy-saving sunshine room

InactiveCN105421582AReduce deliveryReduce heat lossSolar heating energyRoof covering using slabs/sheetsWater storageEngineering

The invention provides an energy-saving sunshine room. The energy-saving sunshine room comprises a glass room, a water storage device, a power device and a hot water collecting device; the glass room comprises a glass panel and a supporting frame used for fixedly supporting the glass panel, the glass panel comprises a first glass panel body, a second glass panel body and a water storage layer, the first glass panel body and the second glass panel body are arranged in a spaced mode, the water storage layer is located between the first glass panel body and the second glass panel body, the water storage device, the water storage layer and the hot water collecting device are sequentially communicated, and the power device is arranged between the water storage device and the water storage layer. Compared with a related technology, the energy-saving sunshine room can utilize solar energy to heat water and supply hot water to the interior of the room and can be isolated from the outdoors to keep the suitable indoor temperature.

Owner:SHANGGAO BUILDING MATERIAL CHANGSHA CO LTD

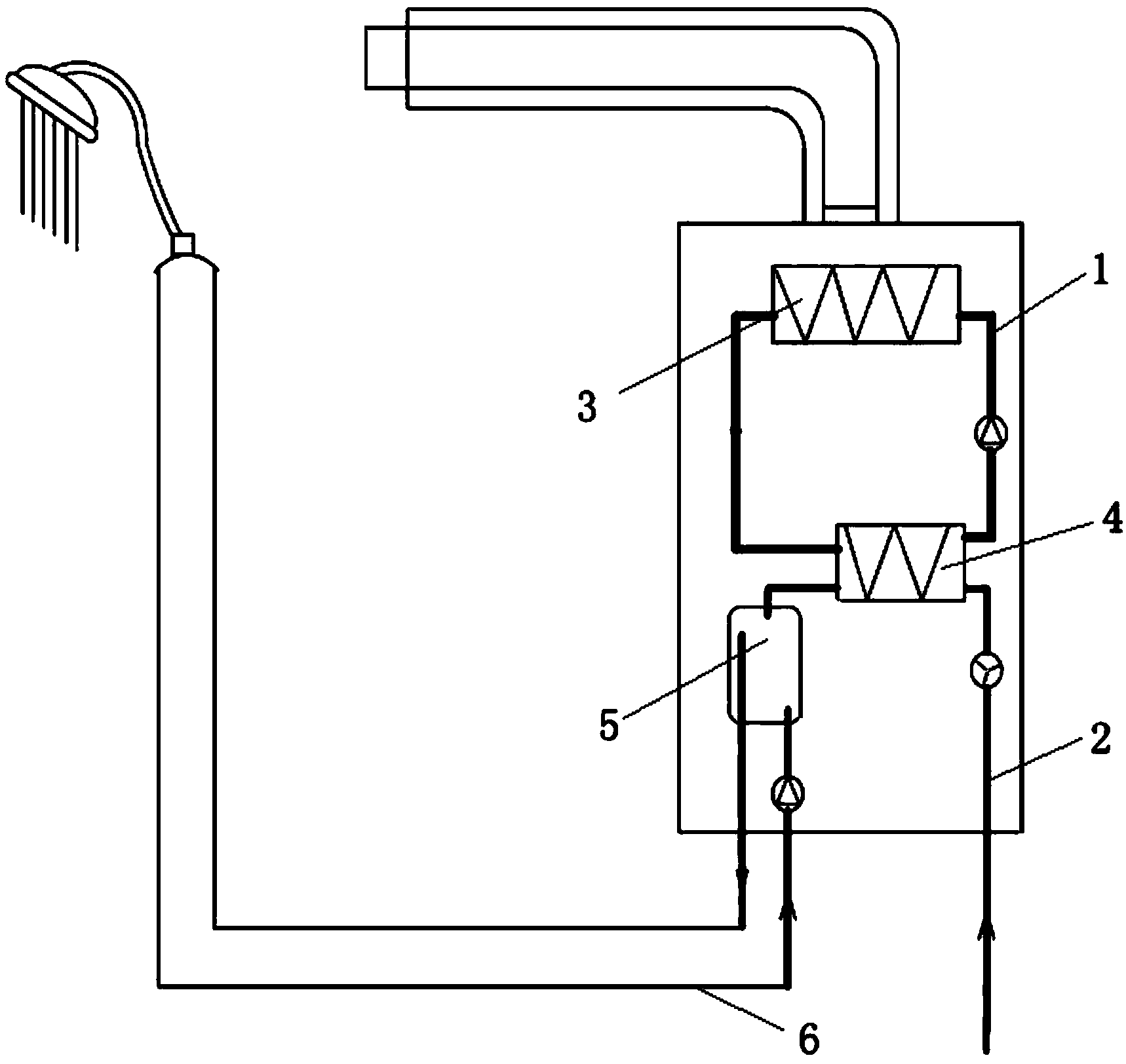

Gas water heater capable of outputting water at constant temperature

InactiveCN103776156AImprove comfortAvoid the problem of high temperature burnsWater heatersWater sourceWater flow

The invention discloses a gas water heater capable of outputting water at constant temperature. The gas water heater comprises a circulation loop and a water outlet pipeline; one end of the water outlet pipeline is connected with a water source, and the other end of the water outlet pipeline is connected with a water consumption point; the circulation loop is provided with a primary heat exchanger used for heating circulating water in the circulation loop; a secondary heat exchanger used for heating cold water in the water outlet pipeline is arranged between the circulation loop and the water outlet pipeline. The gas water heater capable of outputting water at constant temperature is provided with the primary and secondary heat exchangers to realize secondary heat exchange of the cold water in the water outlet pipeline, and avoids the problem that the cold water is excessively heated to cause high temperature scalding; moreover, residual cold water in the pipeline of the gas water heater can be recycled and heated, water waste is avoided, and the proper temperature of water in the water outlet pipeline is guaranteed, so that the comfort level of the gas water heater is improved.

Owner:VAILLANT BEIJING HEATING EQUIP

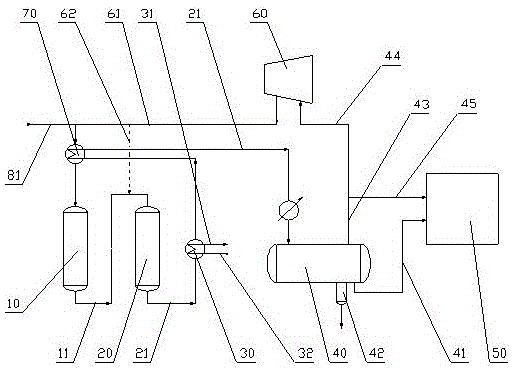

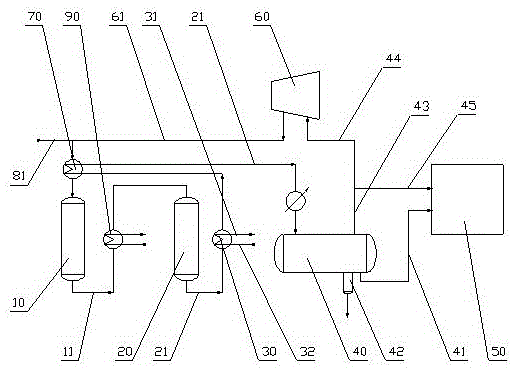

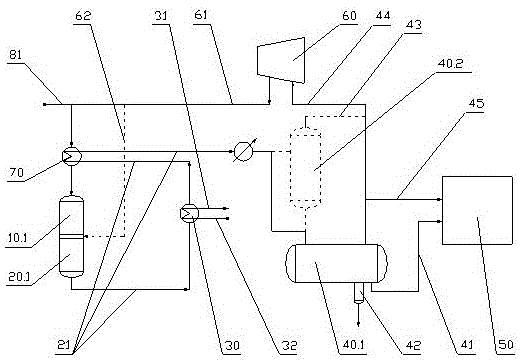

Light dydrocarbon preparation method and light dydrocarbon preparation system with methyl alcohol as raw materials

ActiveCN105038839AControl reaction temperatureRaise the reaction temperatureLiquid hydrocarbon mixture productionBio-feedstockGas phaseGas compressor

The invention relates to a light dydrocarbon preparation method with methyl alcohol as raw materials, and further relates to a light dydrocarbon preparation system in which the method is adopted. The method comprises the steps that heat exchange and heating are carried out on the raw materials, methyl alcohol, and discharged materials of a synthesis reactor through an inlet and outlet heat exchanger, and then methyl alcohol and the discharged materials are conveyed into a methyltertiarvbutyl ether reactor; meanwhile, circulating gas is conveyed into the methyltertiarvbutyl ether reactor, the reaction temperature of the methyltertiarvbutyl ether reactor is controlled through the circulating gas conveyed into the methyltertiarvbutyl ether reactor, after heat recycling and cooling, the discharged materials of the synthesis reactor enter a three-phase separation system, and most of a gaseous phase separated out by the three-phase separation system is used as the circulating gas after being boosted by a gas compressor. The preparation system comprises a feed conveying pipeline, the methyltertiarvbutyl ether reactor, the synthesis reactor, the three-phase separation system and an after-separation system capable of separating fuel gas, liquefied gas, light dydrocarbon and heavy oil out of corresponding oil phases. The technological process is simple, control difficulty is low, energy consumption is low, and product quality is high and stable.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Damp-proof electric meter box

InactiveCN105866494AKeep dryEnsure proper temperatureHumidity controlTime integral measurementEngineeringMoisture sensor

The invention discloses a moisture-proof electric meter box, which comprises a square main body, which includes a box body and an upper cover; a controller, which includes: a first priority unit, which is respectively connected to the first unit, the second unit, the third unit, The fourth unit, the fifth unit and the sixth unit, the second priority unit, which are respectively connected to the seventh unit, the eighth unit, the ninth unit and the tenth unit; the temperature sensor, which are respectively connected to the first unit and the second unit unit; a pair of fans, respectively connected to the third unit and the fourth unit; an alarm, respectively connected to the fifth unit and the sixth unit; a humidity sensor, respectively connected to the seventh unit and the eighth unit; and a quartz Heating pipes, which are respectively connected to the ninth unit and the tenth unit. The moisture-proof electric meter box of the present invention uses a humidity sensor and a quartz heating tube to cooperate with dehumidification to ensure drying in the box and has a good moisture-proof effect.

Owner:NANNING SIFEI ELECTRONICS TECH

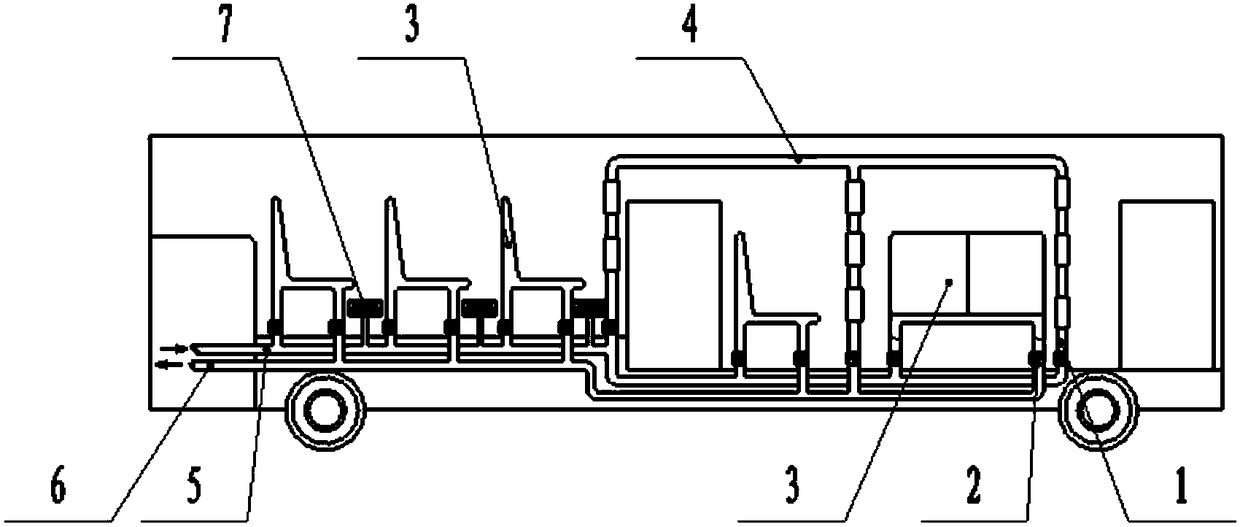

Temperature adjusting method and device for passenger car

InactiveCN108394253AEnsure proper temperatureImprove efficiencyAir-treating devicesVehicle heating/cooling devicesEngineeringMechanical engineering

The invention discloses a temperature adjusting method and device for a passenger car, and belongs to the field of car structures. Seats in the passenger car are manufactured as plastic-based hollow seal seats, vent holes are reserved in two opposite seat legs, air valves are arranged on the two opposite seat legs, the two opposite seat legs reserving the vent holes are respectively connected to an air inlet pipe and an air outlet pipe which are located under a passenger floor; in addition, a transverse handle tube and a vertical handle tube in the passenger car are manufactured as hollow structures and are communicated with each other, the whole transverse and vertical handle tubes are connected with the air inlet pipe and the air outlet pipe which are located under the passenger floor toform a loop, an air valve is connected between the vertical handle tube and the air inlet pipe, an air valve is also connected between the vertical handle tube and the air outlet pipe, and air outlets are formed in the inner walls of two sides of the passenger car and a ceiling. According to the method and device, the temperature adjustment in the passenger car is more efficient and quicker.

Owner:宋佳睿

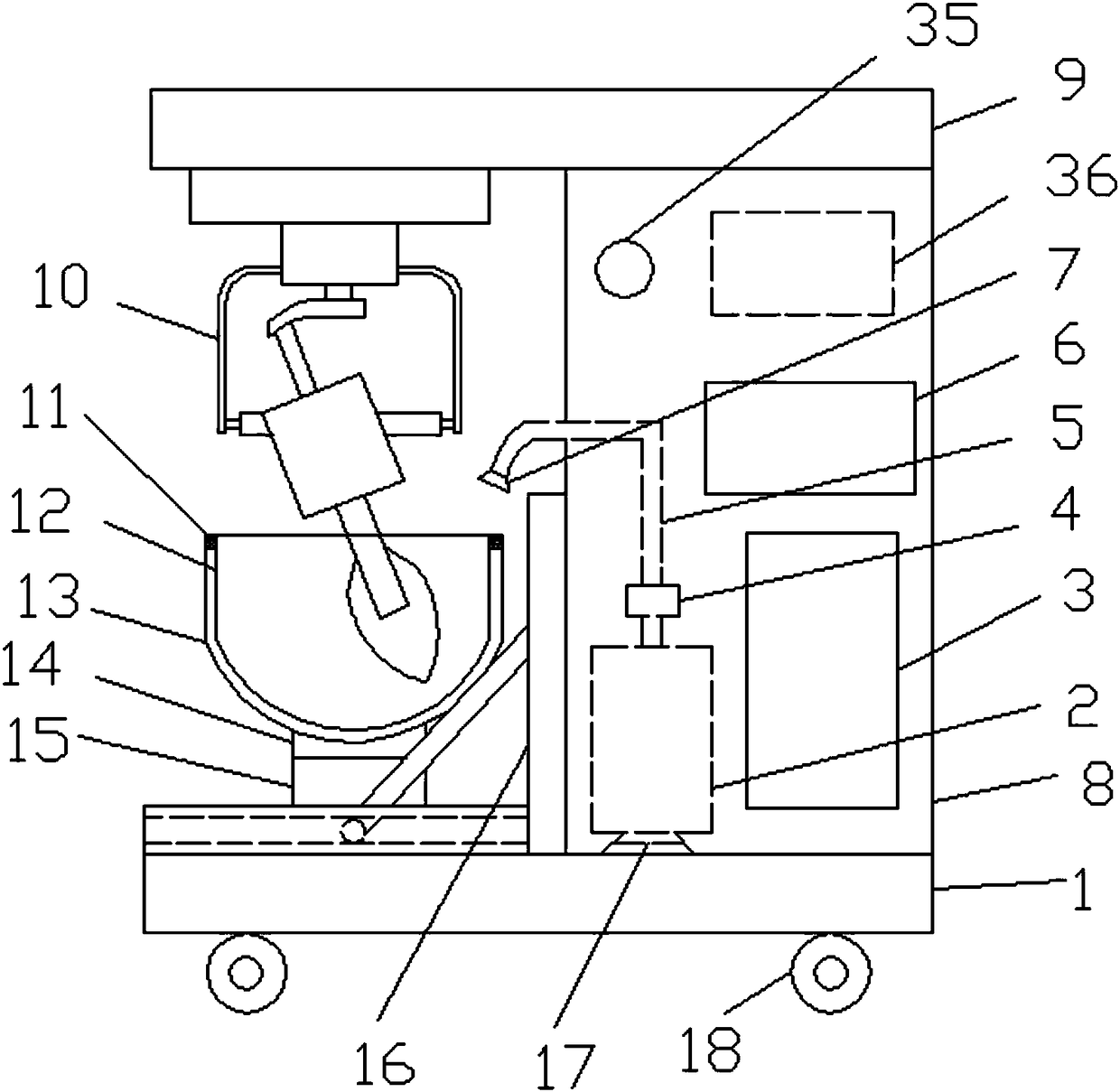

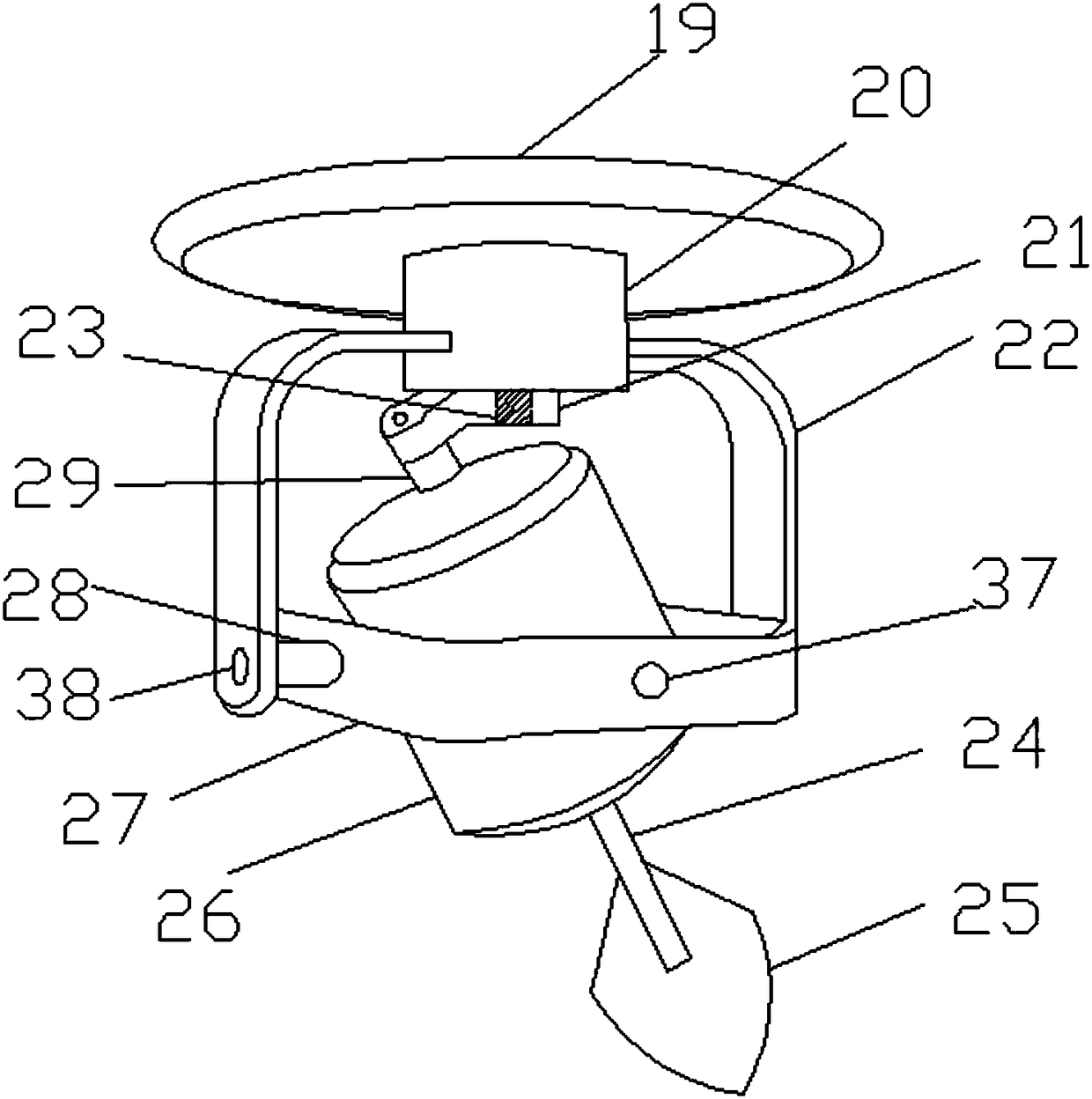

Automatic dough mixer

ActiveCN108077347AEvenly mixedSolve the problem of dead cornersMixing/kneading structural elementsWater storage tankDisplay device

The invention discloses an automatic dough mixer, comprising a base, wherein a machine body is arranged at one side of the top of the base, and a water storage tank is arranged at the bottom of the inside of the machine body; a water supply pipe is arranged at the top of the water storage tank, and one side of the water supply pipe penetrates through one side of the top of the machine body and extends to the outside of the machine body and is connected with a spray head outside the machine body; a water supply pump is arranged on the water supply pipe, and storage batteries are arranged at oneside of the top of the inside of the machine body, and a control panel is arranged on the surface of the bottom of the machine body; a display is arranged above the control panel, and a top cover isarranged at the top of the machine body; a rotary stirring device is arranged at one side of the bottom of the top cover. The automatic dough mixer provided by the invention has the beneficial effectsof reasonable design, simple structure and convenience in use, and effectively solves the problems of the traditional dough mixer that stirring is insufficient, dead angles easily occur, and the like. In addition, the manual operation is effectively reduced, and human resources are saved, thereby effectively improving the work efficiency.

Owner:GANZHOU LIANGHUA FEIER SNOW FOOD CO LTD

Thermal insulation plate with boiling water

The invention discloses a boiled water heat preservation plate which comprises a plate cover, and a plate bottom and a plate body which are made from insulant. The boiled water heat preservation plate is characterized in that a bowl-shaped metal plate which is fixed with an insulating layer at the back is arranged in the plate body; the top of the bow-shaped metal plate and an annular groove at the top of the plate body are connected by a screw thread and are movably installed together; the bowl-shaped metal plate, the plate body and the plate bottom form a water containing cavity which is filled with water; one end of an electric heating tube which is installed in the water containing cavity is fixed at the plate body and is connected with a power supply wire which is equipped with a temperature control regulator; the edge at the top of the plate body is processed with an exhaust port and is processed with a bottle cork slot with inner screw threads; the lateral wall at the top of the plate body is processed with a water channel which is communicated the water containing cavity with the bottle cork slot; a bottle cork with the lateral wall processed with external screw threads can be screwed into the bottle cork slot to open and close the water channel. The boiled water heating preservation plate has the advantages of being capable of heating and warming meal in due time, keeping the proper temperature of the meal, being convenient for moving and carrying, high efficiency, being safe and reliable, simple structure, and the boiled water heat preservation plate is suitable for being used at home, restaurant, hotel, guesthouse, etc.

Owner:李洲

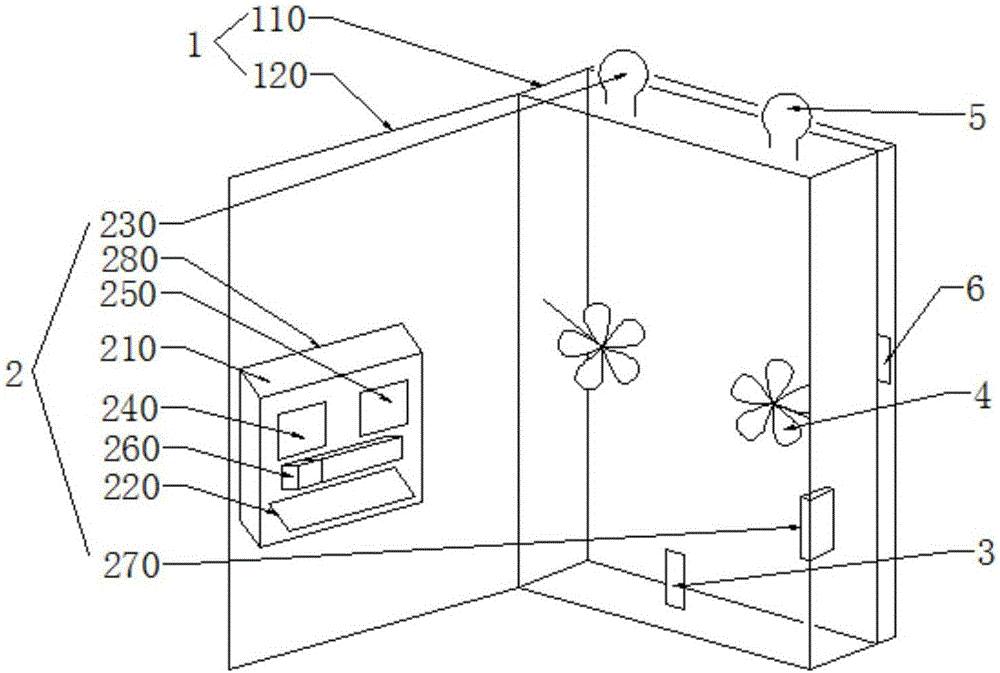

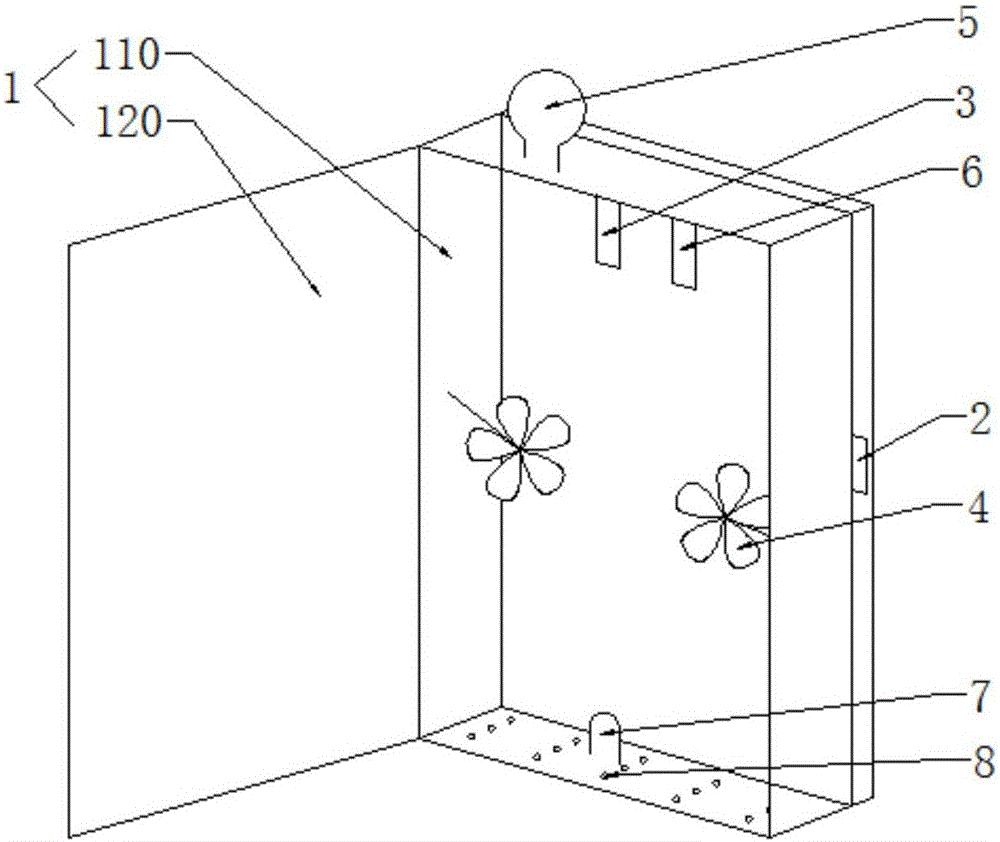

Indoor air purification integrated device

InactiveCN102078746AEasy to operateEnsure proper temperatureUsing liquid separation agentPublic placeIndoor air quality

The invention belongs to the technical field of indoor air quality control, in particular relates to an indoor air purification integrated device, and substantially solves the problem of quality of indoor polluted air in public places. The indoor air purification integrated device comprises a shell, wherein an annular filler is arranged inside the shell; an air outlet, an air inlet, a liquid outlet and a liquid inlet pipe are welded on the shell; the liquid inlet pipe is connected with a liquid outlet of a submersible pump; and the bottom of the shell is connected with a detachable liquid storage tank. The invention has the advantages that: the device is easily and fast operated, has a small size and a small occupied space, and can be arranged in any region, and harmful gas and dust can be simultaneously treated.

Owner:ZHONGBEI UNIV

Biomass heating fire wall and fresh air conditioner integrated system

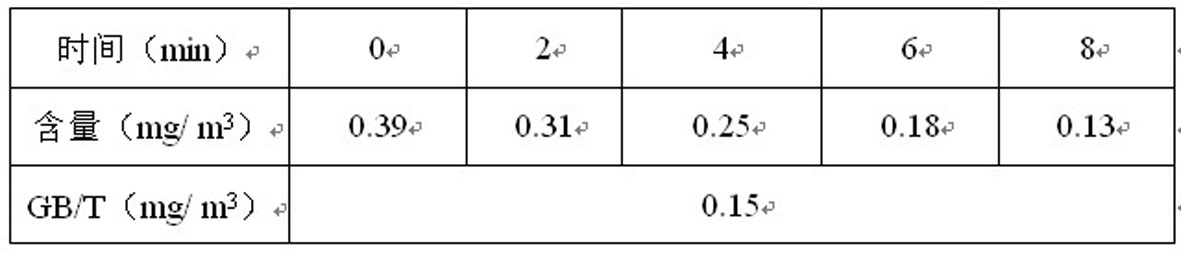

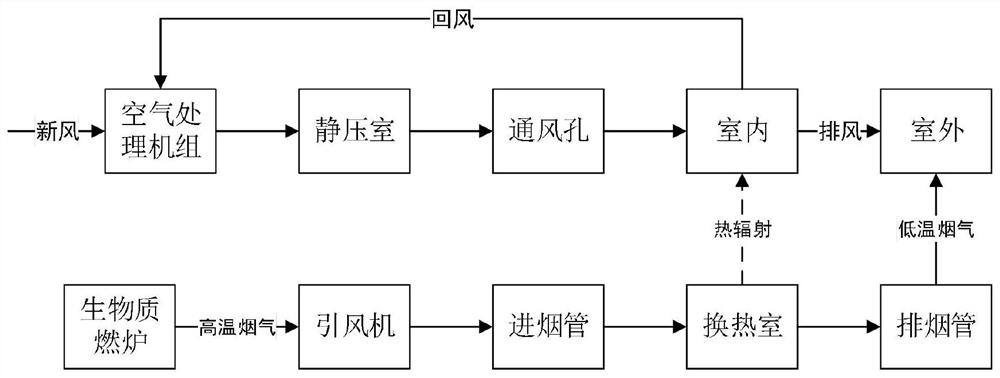

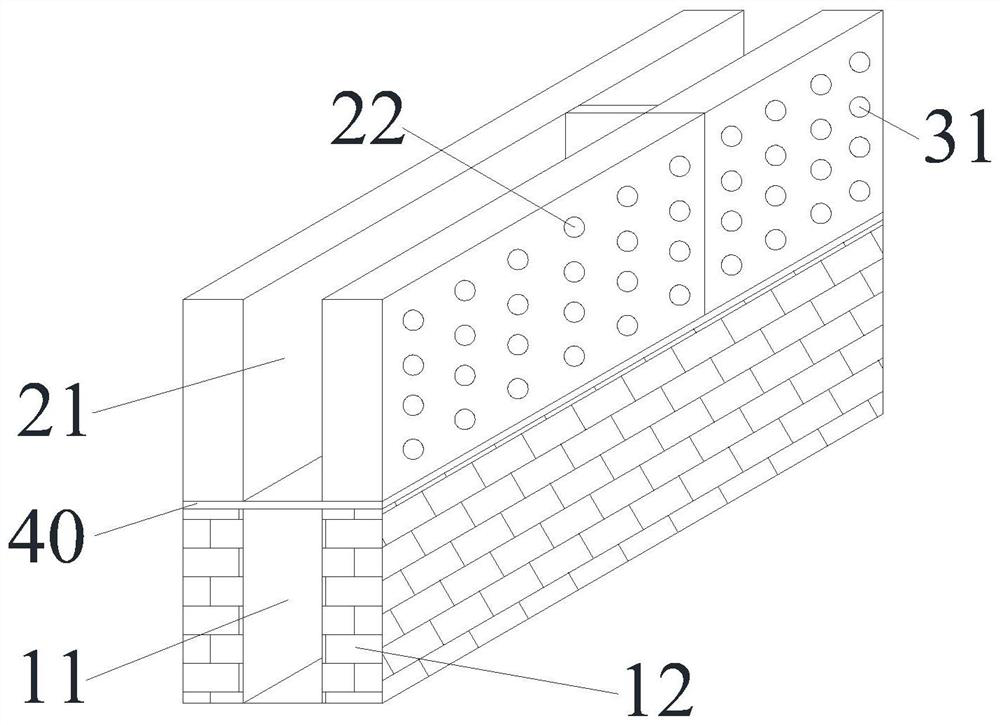

ActiveCN113028484AImprove applicabilitySmall footprintDucting arrangementsMechanical apparatusFresh airBiomass combustion

The invention provides a biomass heating fire wall and fresh air conditioner integrated system. The biomass heating fire wall and fresh air conditioner integrated system comprises a fire wall subsystem and a fresh air conditioner subsystem; the fire wall subsystem comprises a biomass combustion furnace, a smoke inlet pipe, a heat exchange chamber and a smoke exhaust pipe which are sequentially connected; the heat exchange chamber comprises an outdoor wall, an indoor heating wall and a plurality of water capsules; the water capsules are arranged in a hollow interlayer formed between the indoor heating wall and the outdoor wall; the fresh air conditioner subsystem comprises a static pressure chamber which is arranged on the heat exchange chamber in an overlapped manner; and a plurality of ventilation holes are formed in the wall face, making contact with the interior of a room, of the static pressure chamber and connected with the static pressure chamber and the interior of the room. The fire wall subsystem and the fresh air conditioner subsystem are combined, and better practicability is achieved; the side wall space of a building is fully utilized, and the occupied area of the system is effectively reduced; and the fire wall subsystem stores heat through the water capsules while storing heat through the indoor heating wall, heat in smoke is absorbed more fully, the energy utilization rate is high, and energy waste is reduced to the maximum degree.

Owner:HUNAN UNIV OF SCI & TECH

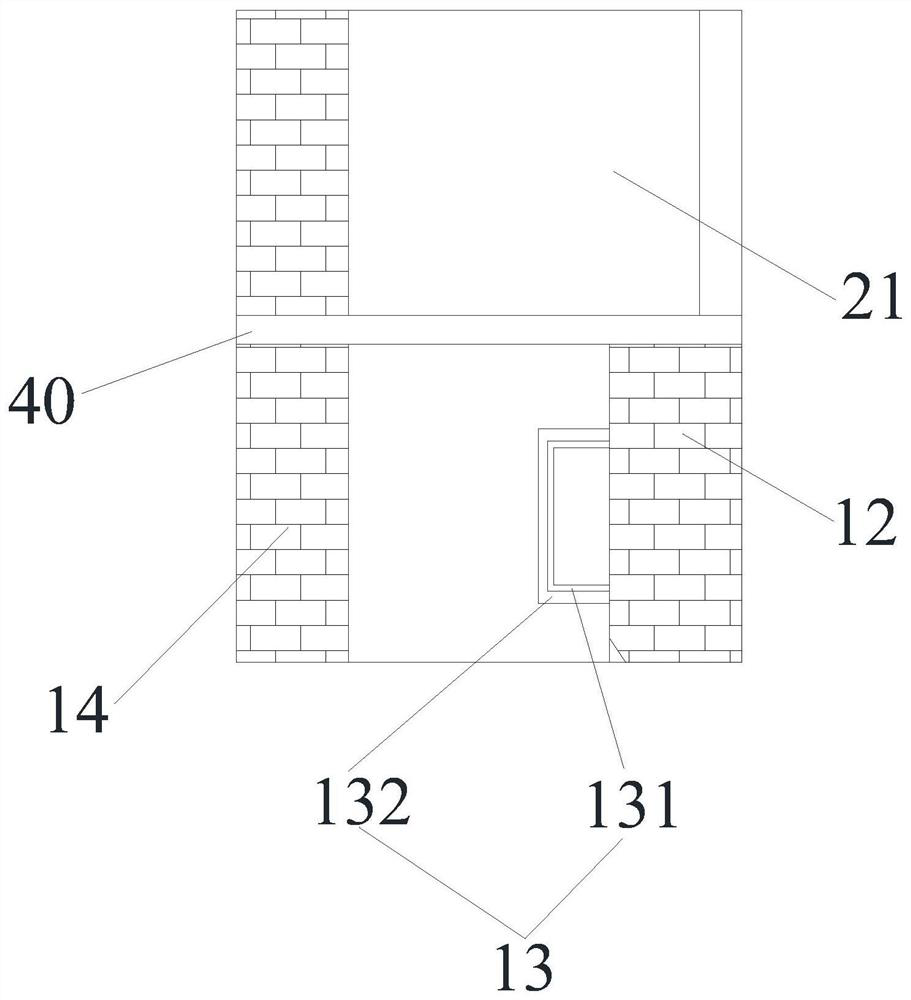

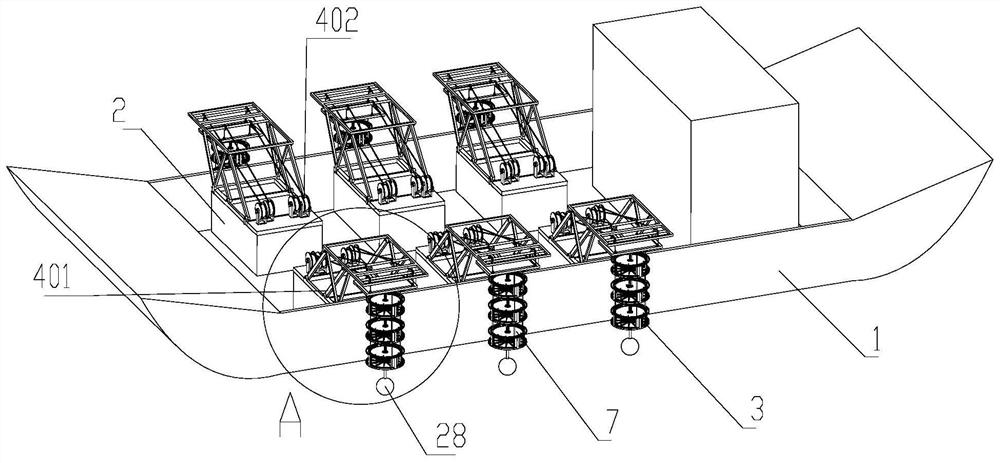

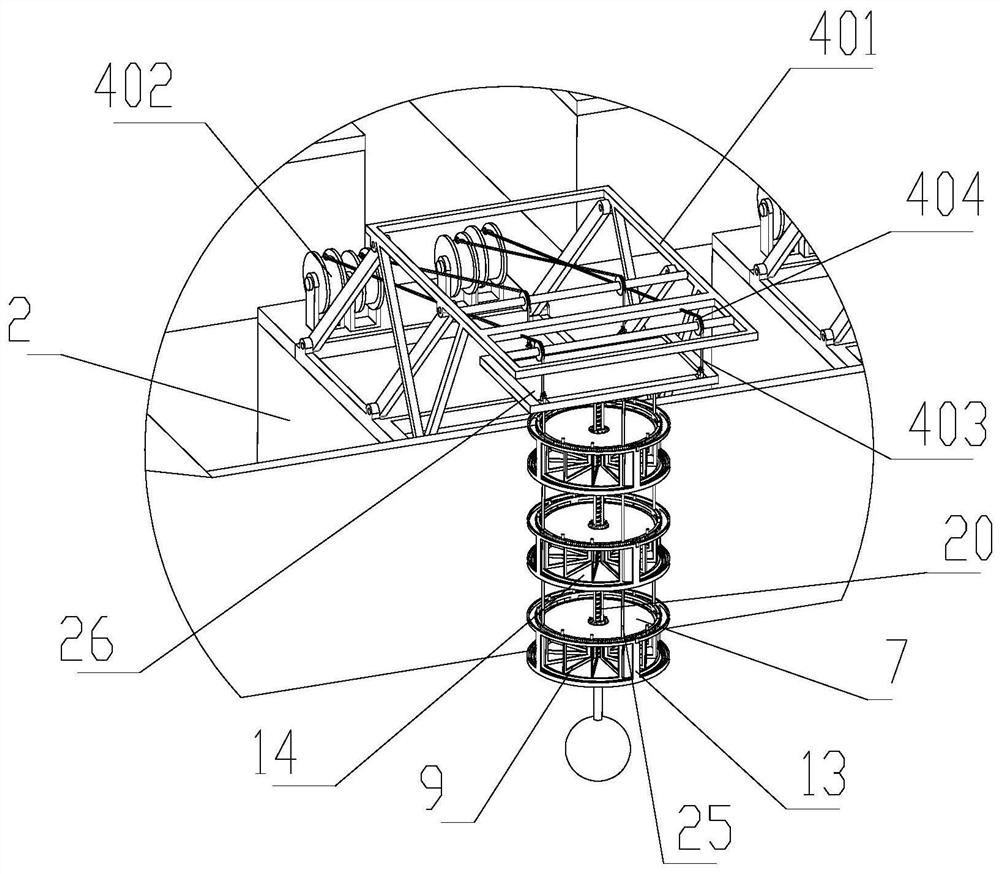

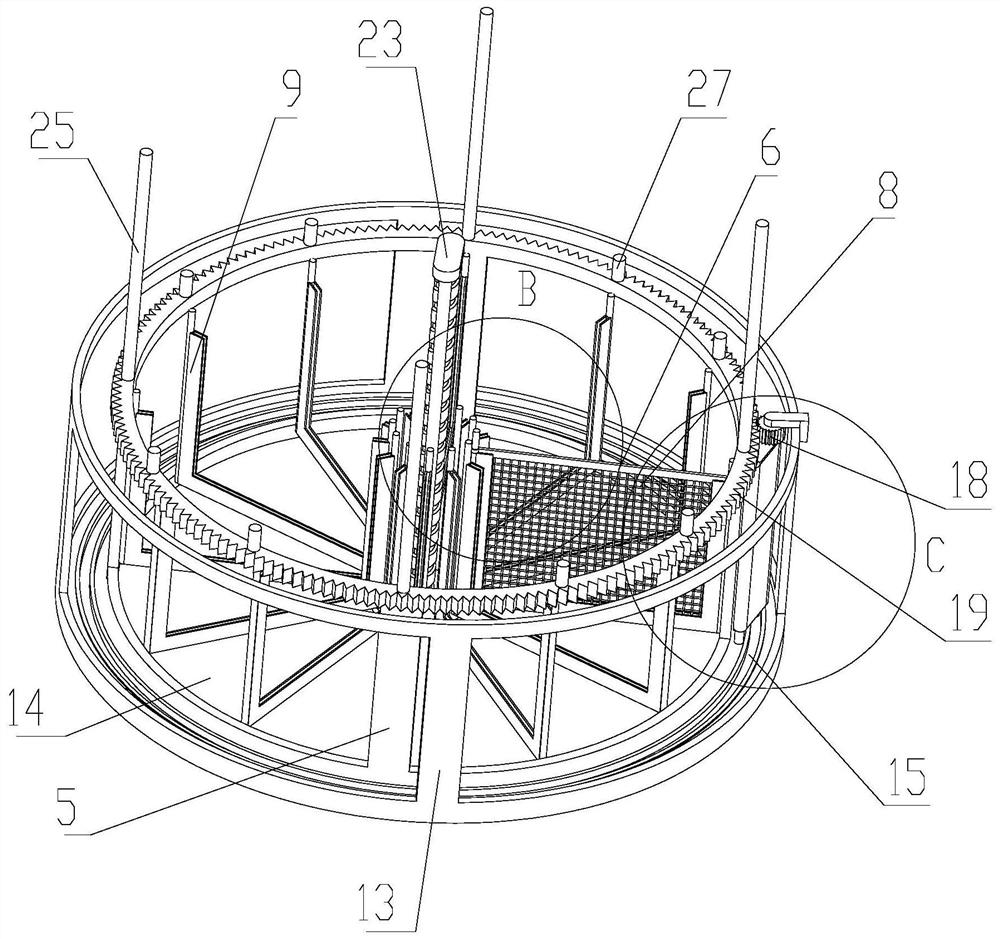

Holothurian culture ship

ActiveCN113557993AEnsure proper temperatureEasy to fixWaterborne vesselsClimate change adaptationMarine engineeringStructural engineering

The invention discloses a holothurian culture ship and relates to the technical field of holothurian culture ship equipment. According to the technical scheme, the holothurian culture ship comprises a ship body and a plurality of bases arranged on the ship body, traction mechanisms are arranged on the bases, and the traction mechanisms are connected with a plurality of culture net cages in a hanging mode; each culture net cage comprises an annular frame and a plurality of concave mesh fixing frames arranged in the annular frame, and meshes are inserted into the mesh fixing frames. The holothurian culture ship has the advantages that the culture net cages are combined with the ship body, lifting of the culture net cages is controlled through the traction mechanisms, and the culture net cages sink by a certain depth through the traction mechanisms when the ship encounters heavy storm waves; a plurality of mesh fixing frames are arranged in the annular frames, the number of meshes and the intervals between the meshes can be adjusted according to needs, the space in the cages is fully utilized, breeding benefits are improved, mesh cloth can be regularly replaced by a mesh cloth repairing mechanism or the mesh cloth can be repaired when the mesh cloth is damaged, and use safety is guaranteed.

Owner:SHANDONG NEW HOPE LIUHE GROUP +3

Refrigeration and heating decorative plate

ActiveCN108661276ANo generationDoes not destroy humidityCovering/liningsSpace heating and ventilation safety systemsHeat conductingEngineering

The invention discloses a refrigeration and heating decorative plate. The refrigeration and heating decorative plate comprises a decorative plate body, semiconductor modules, refrigeration and heatingwater tanks, a circulating water pump, a water outlet tee module, a backwater tee module and a control module. The decorative plate body is connected with the circulating water pump through a feed pipe and connected with the refrigeration and heating water tanks through a backwater pipe and the backwater tee module. The circulating water pump is connected with the refrigeration and heating watertanks through the water outlet tee module. The semiconductor electronic modules are sealed by insulation metal heat-conducting slices and arranged in the refrigeration water tank and the heating watertank. The semiconductor modules, the refrigeration and heating water tanks, the circulating water pump, the water outlet tee module and the backwater tee module are connected with the control moduleby means of a wired circuit, and the control module is located on upper cover plates of the refrigeration and heating water tanks. In different seasons, different instructions are activated, and functions are automaticlly switched, health and comfort are brought to household life, and the purpose of energy saving and emission reduction can be achieved.

Owner:深圳东盟建材实业有限公司

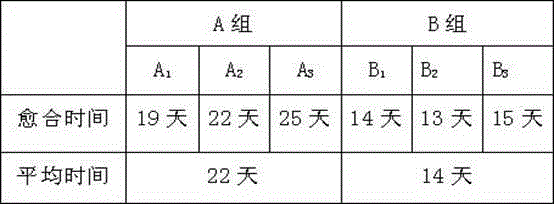

Treatment method of medical cotton fabric

InactiveCN104645404AImprove antibacterial propertiesSpeed up healingAbsorbent padsBandagesWound healingWound surface

The invention discloses a treatment method of medical cotton fabric. The method comprises the following steps: (1) pretreating a base material; (2) preparing silver ion mixed liquid; (3) dispersing a silver-ion antibacterial layer in the matrix; and (4) sequentially laying far-infrared coated fabric and bamboo charcoal fiber cloth. The treated medical cotton fabric can be prevented from being adhered to a wound surface by use of Vaseline in the medical cotton fabric. The bamboo charcoal fiber cloth is capable of well keeping the wound surface at certain humidity and in a microenvironment, which is beneficial to healing of the wound; and the far-infrared coated fabric has the functions of improving blood circulation, promoting metabolism and improving healing speed of the wound.

Owner:江西亚丰医材有限公司

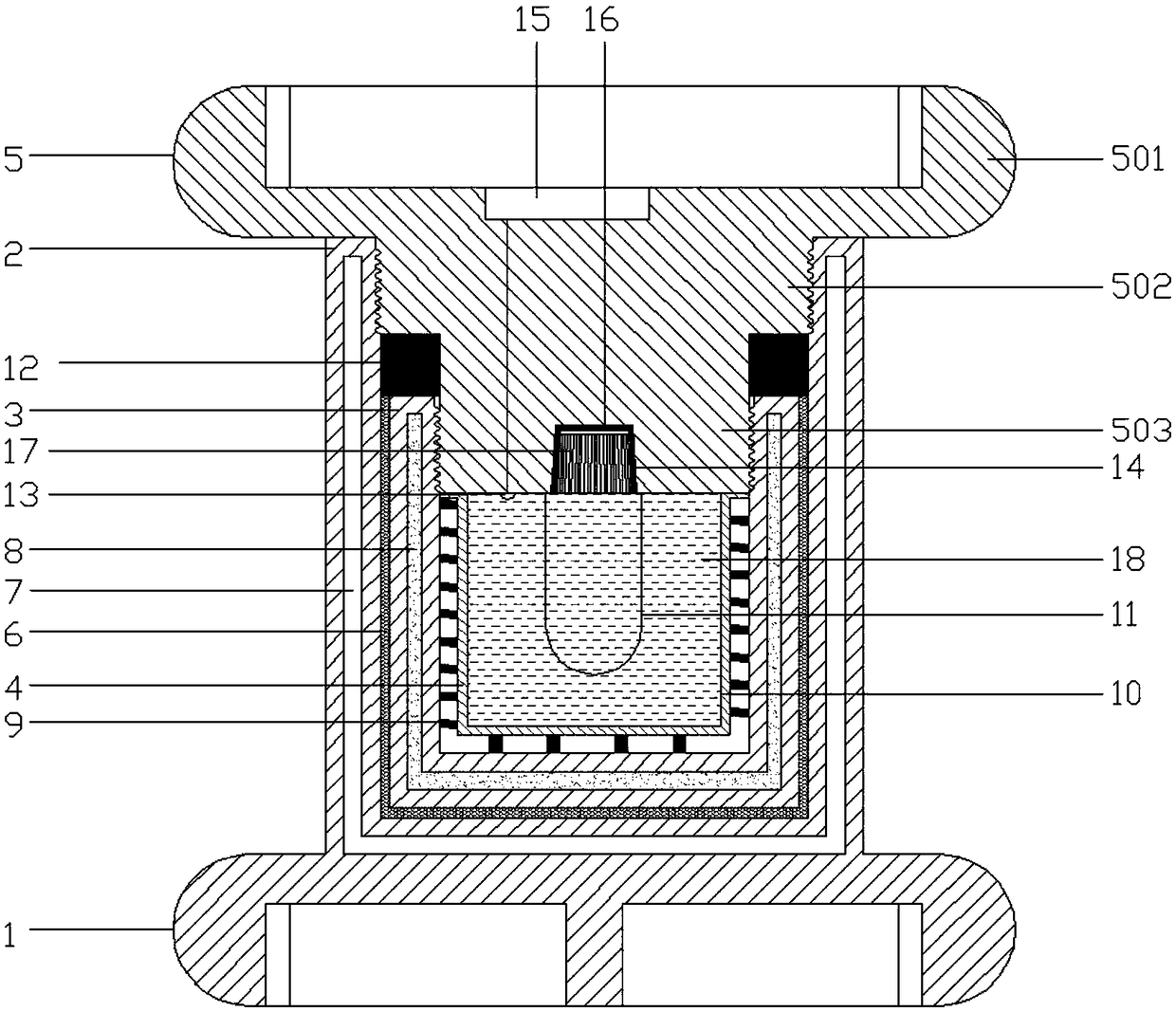

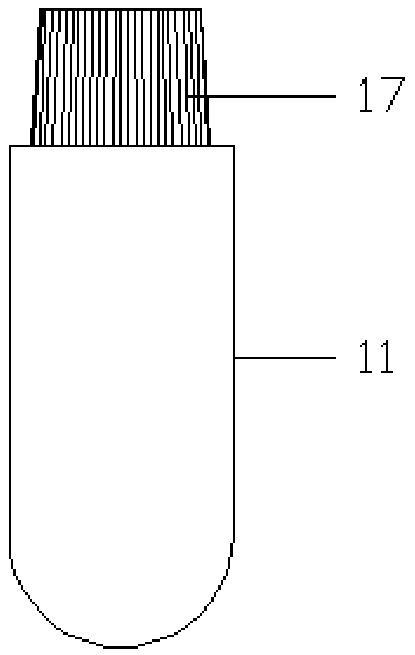

Cold-storage and breakage-proof conveying and packaging device for drugs

InactiveCN109250309AAvoid collisionAvoid shockContainer decorationsLevel indicationsDisplay deviceDrug Storage

The invention discloses a cold-storage and breakage-proof conveying and packaging device for drugs. The device comprises a base, an outer cylinder, an inner cylinder, an inner container and a cylinderlid; the outer cylinder is provided with a vacuum sandwich layer, and the vacuum sandwich layer is provided with a liquid nitrogen storage bin; the inner container is arranged in the inner cylinder,the sandwich layer is arranged between the inner cylinder and the inner container, spiral heat conduction sheets are arranged in the sandwich layer, the inner container is provided with an accommodating bin, and the accommodating bin is internally provided with a drug storage bottle connected with the cylinder lid; the cylinder lid comprises an outer lid body, a first inner lid body and a second inner lid body, and the second inner lid body is provided with a temperature sensor connected with the accommodating bin and a groove connected with a bottle lid of the drug storage bottle; the temperature sensor is connected with a temperature display arranged on the outer lid body. Through the arrangement of the liquid nitrogen storage bin, it is guaranteed that the drugs are subjected to cold storage for a long term in a standing state, the proper temperature of the drugs is guaranteed, the liquid nitrogen storage bin is connected with the inner cylinder and the inner container through the spiral heat conduction sheets, and cold or heat is conveniently transferred to the accommodating bin in the inner container.

Owner:QUANZHOU HUANGZHANG INTELLIGENT TECH CO LTD

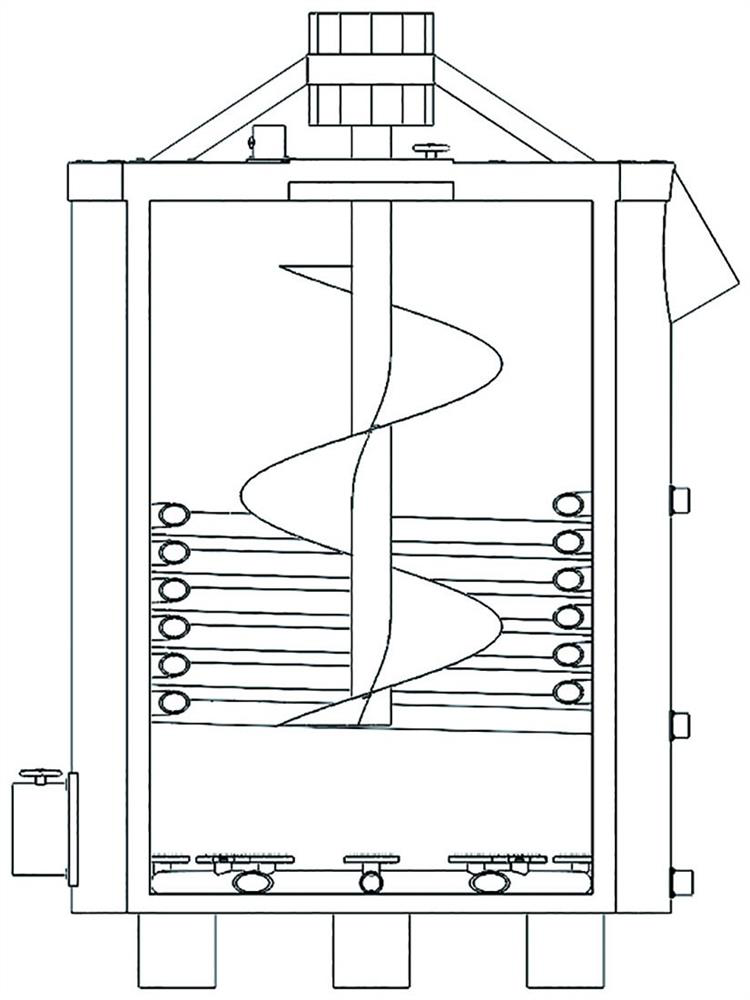

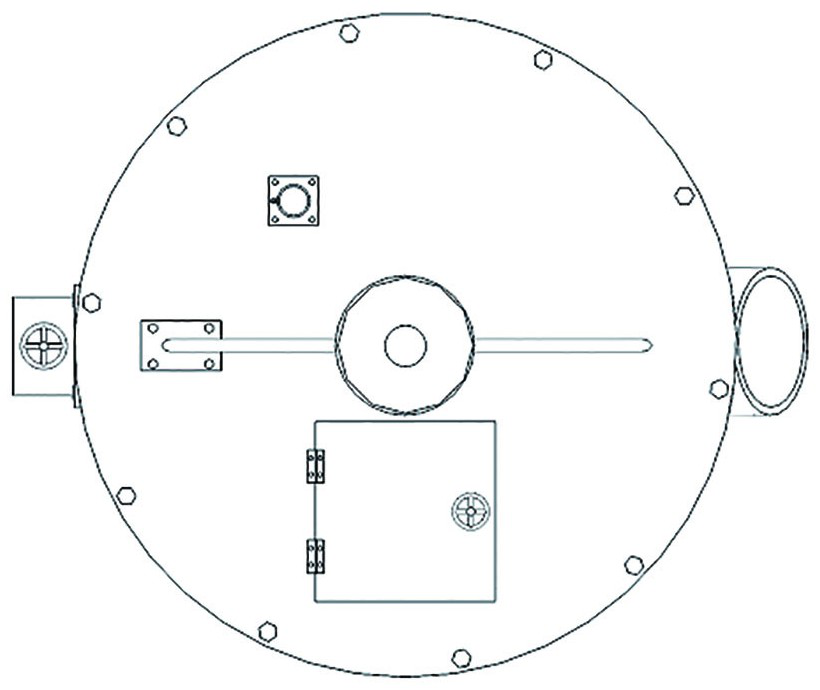

Constant-temperature anaerobic/aerobic fermentation tank for treating rotten vegetable leaves

PendingCN114672401ATank structure is simpleCompact distributionBioreactor/fermenter combinationsBiological substance pretreatmentsBiogasBiology

A constant-temperature anaerobic / aerobic fermentation tank for treating rotten vegetable leaves aims to effectively maintain the optimal fermentation temperature and realize switching of anaerobic / aerobic environments, a feed port is formed in the top of the fermentation tank body, a discharge port is formed in the bottom of the fermentation tank body, and a gate valve is mounted at the discharge port; a heat-insulating coil is mounted on the inner wall surface of the tank body; a water inlet and a water outlet are formed in the outer side of the fermentation tank body; an aeration pipeline is mounted at the lower end in the tank body, an aerator is mounted above the aeration pipeline, and an air inlet is formed in the outer side of the tank body; supporting legs are mounted at the bottom end of the tank body; a tank cover is mounted at the top end of the tank body, a sampling port is reserved in the tank cover, and a sealing gate is mounted at the sampling port; the tank cover is provided with a biogas outlet which is provided with a stop valve; a support is installed on the tank cover, a motor is fixed in the support and connected with a paddle column entering the tank body, and rotating paddles are installed on the surface of the paddle column. The device is compact in structure and simple to use, anaerobic and aerobic reactions can be carried out on the rotten vegetable leaves in a single tank, the occupied area of equipment can be effectively reduced, and the initial investment is reduced.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

Ventilation system capable of regulating temperature of chicken house

ActiveCN107466898AIncrease temperatureIncrease kinetic energyAnimal housingBird housingsEngineeringHoneycomb like

The invention discloses a ventilation system capable of regulating the temperature of a chicken house. The chicken house includes a first wall body and a second wall body. The ventilation system includes several ventilation devices and several exhaust fans; each ventilation device includes a ventilation pipe and a ventilation body, wherein the ventilation pipe penetrates through the first wall body and the ventilation body is arranged at any end of the ventilation pipe and is communicated with the ventilation pipe; one end of each ventilation body is a small hole end, the other end of each ventilation body is a big hole end, each small hole end is detachably connected with the corresponding ventilation pipe, each big hole end is provided with a water inlet and a water outlet, and each ventilation body is internally provided with a wet curtain of a honeycomb structure; exhaust fans can pump air in the chicken house out from the chicken house; when the temperature in the chicken house is more than 27 DEG C, the big hole end of each ventilation body faces toward the outside of the chicken house, and when the temperature in the chicken house is less than 21 DEG C, the big hole end of each ventilation body faces toward the inside of the chicken house. The system can effectively regulate the temperature of the chicken house, improve the ventilation effect, meanwhile save energy and improve the feeding efficiency of chickens.

Owner:广西富鹏农牧有限公司

Method for culturing green beef cattle

InactiveCN106614346APromote digestionPromote absorptionFood processingAnimal feeding stuffWeight gainingDisease

The invention provides a method for culturing green beef cattle. The method comprises the following steps: (1) selection of breeds, wherein tall and big cattle with strong bones, plump muscles and strong physique are selected; (2) selection of feed, wherein the feed mainly includes Chinese herbal medicine ingredients, concentrate, coarse fodder and green fodder; (3) precision feed processing, wherein the granulation processing technology is used, anti-nutritional factors, toxic and harmful substances and micro-organisms in the feed are destroyed and suppressed; (4) disease preventing and insect expelling, and comprehensive examination of newly bought cattle; (5) cowshed temperature control, wherein the temperature has great impact on cattle feed consumption and weight gain. The method for culturing the green beef cattle has the advantages that selecting good breeding species is the foundation of farmers survival, Chinese herbal medicine is chosen as feed, digestion and nutrient absorption of the beef cattle are promoted, the quality of beef is improved, temperature has great impact on cattle feed consumption and weight gain, appropriate temperature is guaranteed, cattle physique is enhanced, diseases are reduced and economic benefits are increased.

Owner:柳州市香柳苗木种植专业合作社

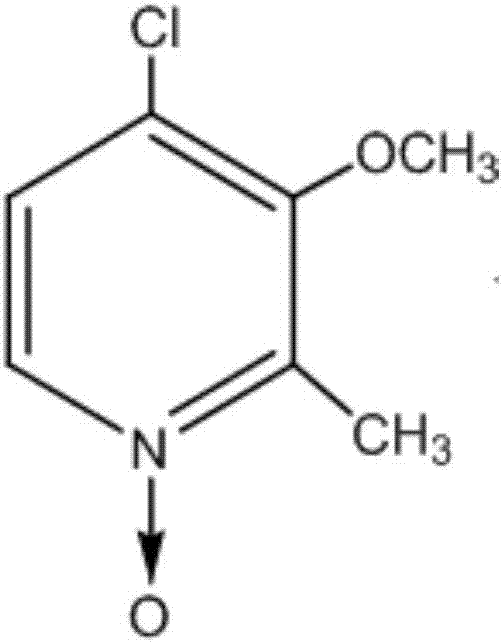

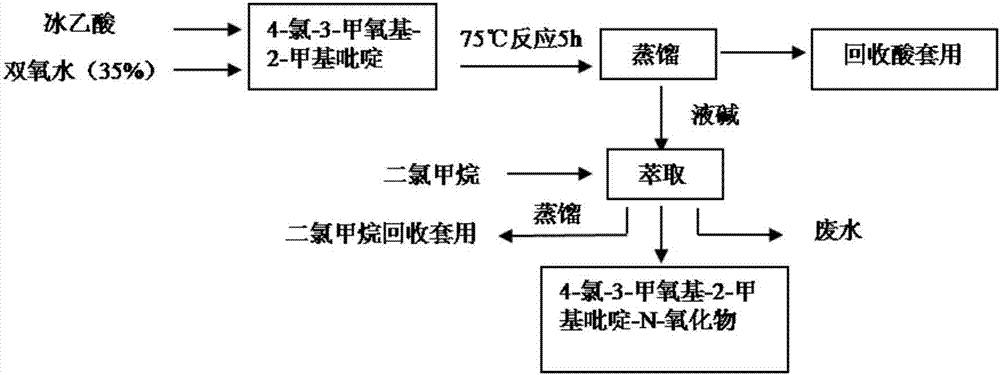

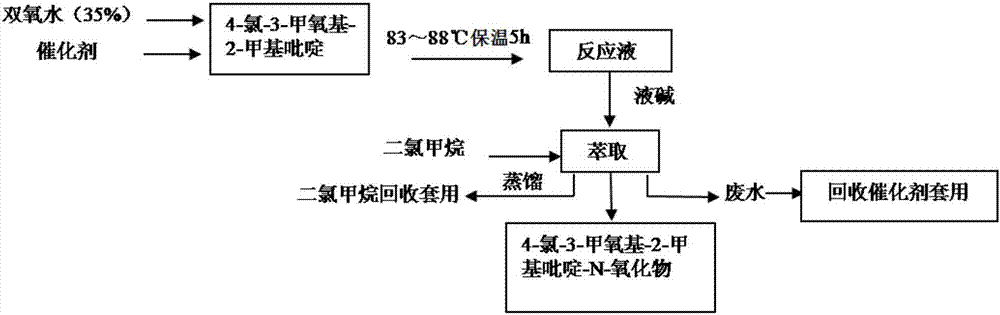

Synthesis method of 4-chloro-3-methoxy-2-methylpyridine-N-oxide

ActiveCN107129466AReduce usageInhibition of hydrolysis reactionOrganic chemistrySynthesis methodsSodium hydroxide

The invention discloses a synthesis method of a pantoprazole intermediate compound 4-chloro-3-methoxy-2-methylpyridine-N-oxide. The synthesis method comprises the following steps: by taking 4-chloro-3-methoxy-2-methylpyridine as a raw material and a phosphotungstic acid solution as a catalyst, performing an oxidation reaction with oxydol; and after the oxidation reaction, regulating the pH value to 7-9 with sodium hydroxide to decompose the excessive oxydol, extracting 4-chloro-3-methoxy-2-methylpyridine-N-oxide with dichloromethane, washing the extract liquid with water to a neutral state, adding anhydrous Na2SO4, drying, and evaporating under reduced pressure to remove the dichloromethane so as to obtain the 4-chloro-3-methoxy-2-methylpyridine-N-oxide. The synthesis method has the advantages of mild reaction conditions, high safety, high yield, high operation convenience, no waste acid discharge, greenness, environment friendliness and low cost, thereby being more suitable for industrial production.

Owner:CHUZHOU UNIV +1

Solar sunlight house

InactiveCN101440654AEnsure proper temperatureRealize building energy savingRoof covering using slabs/sheetsRoof covering using tiles/slatesElectricityElectrical battery

The invention discloses a solar sun house, which comprises solar batteries, double-layer glass with the solar batteries, connecting wires, a storage battery, a controller, an inverter and a load, wherein the roofing of the sun house is formed by two large-sized solar batteries which are embedded in front-layer glass of the double-layer glass to be used as walls around the sun house; and by the connecting wires, the electricity outputted by the solar batteries on the roofing and around the house is mediated and controlled to be stored in the storage battery by the controller, and makes the load work by inversion of the inverter. The whole house utilizes the solar energy, and the roof of the house adopts the large-sized solar batteries to fully absorb sunlight; the double-layer glass around can absorb solar energy by the solar batteries embedded in the glass, and the solar energy is converted into electrical energy to be supplied to the load; and the double-layer glass is filled with inert gases or vacuum-pumped, thereby effectively stopping heat and cold conduction, having partial sun-shading effect, keeping the proper temperature indoors and finally realizing the building energy conservation.

Owner:SHANGHAI JIUNENG ENERGY SCI & TECH DEV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com