Constant-temperature anaerobic/aerobic fermentation tank for treating rotten vegetable leaves

A technology for aerobic fermentation and fermenter, which is applied in specific-purpose bioreactor/fermenter, bioreactor/fermenter combination, biomass post-processing, etc. It is convenient for sampling observation and equipment maintenance, reducing initial investment and reducing equipment footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

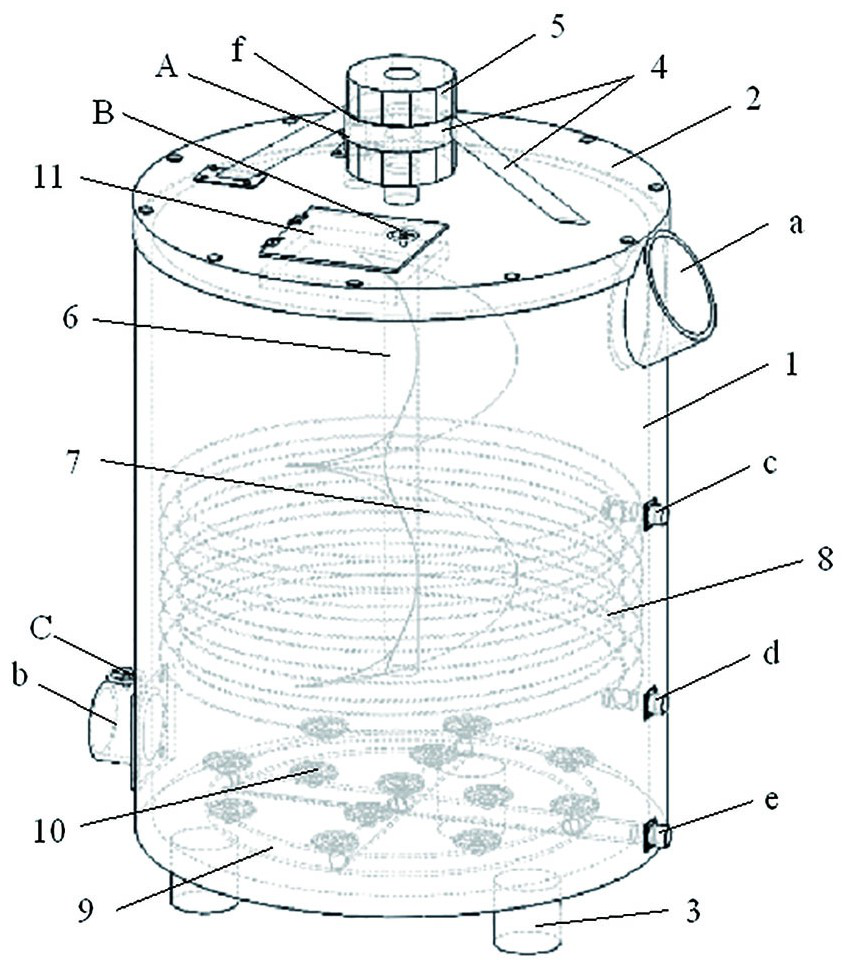

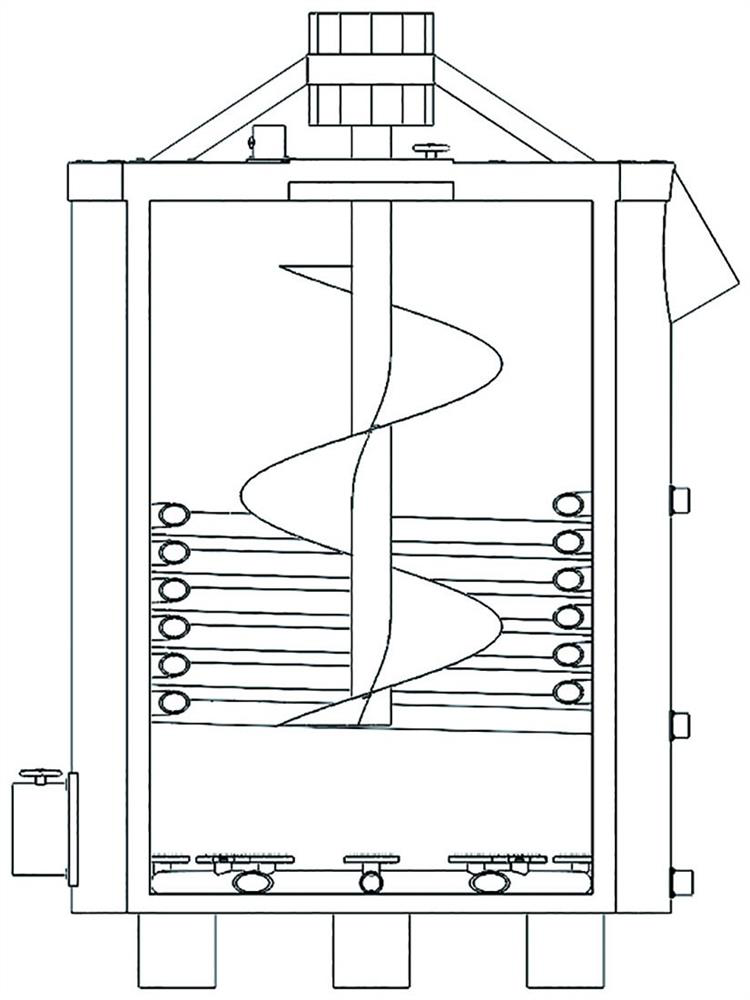

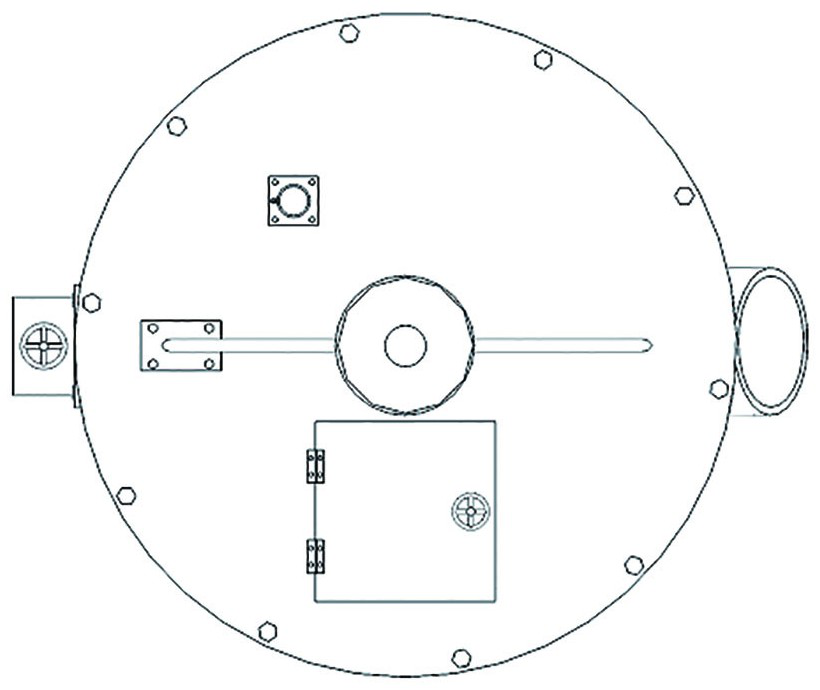

[0009] The present invention is a constant temperature anaerobic / aerobic fermentation tank for tail vegetable processing, comprising a fermentation tank body 1, the top of the fermentation tank body 1 is provided with a feeding port a, and the bottom is provided with a discharging port b. A gate valve C is installed at the port b; a thermal insulation coil 8 is installed on the inner wall of the fermentation tank body 1, and a water inlet c and a water outlet d are arranged on the outside of the fermentation tank body 1; an aeration pipe 9 is installed at the lower end of the fermentation tank body 1 , an aerator 10 is installed above the aeration pipe, and an air inlet e is arranged on the outside of the fermentation tank 1; the bottom end of the fermentation tank 1 is installed with a leg 3; the top of the fermentation tank 1 is installed with a tank cover 2 , the tank cover 2 reserves the maintenance inlet 11, the maintenance inlet 11 is installed with a sealing gate B, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com