Sintered candy glaze with concave and convex texture and preparation method of porcelain tile

A technology of candy and texture, which is applied in the field of architectural ceramic decoration materials, can solve the problems that the uneven texture of candy glazed bricks is not strong enough, the three-dimensional effect of candy glazed bricks is not strong, the transparent frit is easy to melt and spread equally, and achieves a delicate touch on the brick surface , increase the performance of wear resistance and flexural strength, and increase the effect of decorative functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Embodiment 1-a kind of preparation method of the porcelain brick with concavo-convex texture on the surface, comprises the following steps:

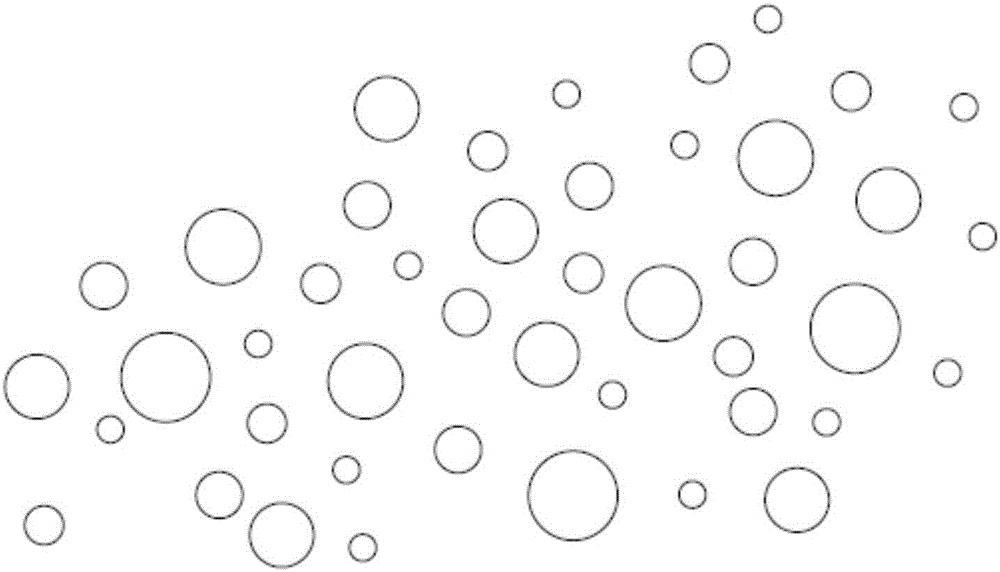

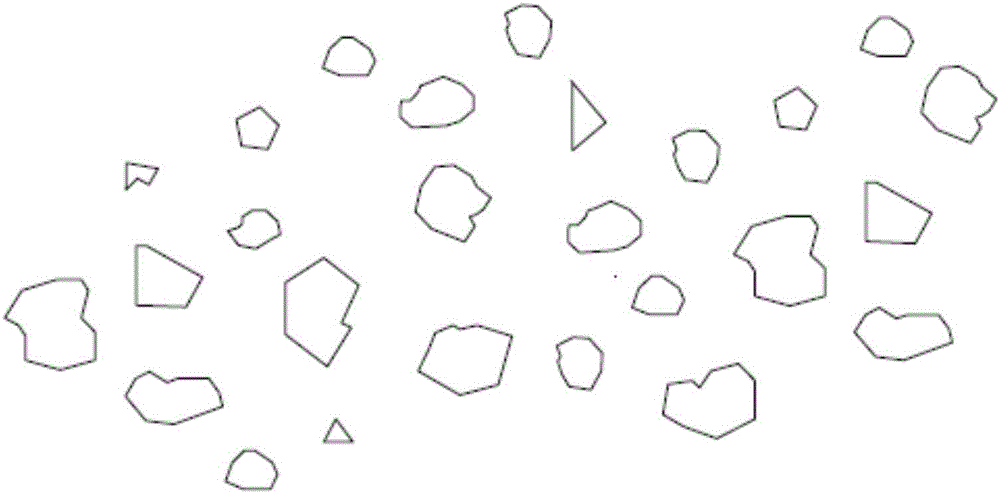

[0043] (1) Obtain large transparent frit by melting according to the existing process, and break the large transparent frit through water quenching mode to obtain transparent frit with irregular particles;

[0044] (2) Preparation of glaze: mixing the printing ink and the transparent frit of the irregular particles according to the mass ratio of 3:1 to prepare the glaze;

[0045] (3) Bottom glaze application: apply bottom glaze to the surface of the dried green body;

[0046] (4) Spray glaze: spray the glaze on the green body after applying the bottom glaze;

[0047] (5) Drying and high-temperature firing: After drying the adobe sprayed with the glaze, high-temperature firing and edge grinding quality inspection, a porcelain tile 1 with a concave-convex texture on the surface is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com