Patents

Literature

32results about How to "Easy maintenance of equipment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

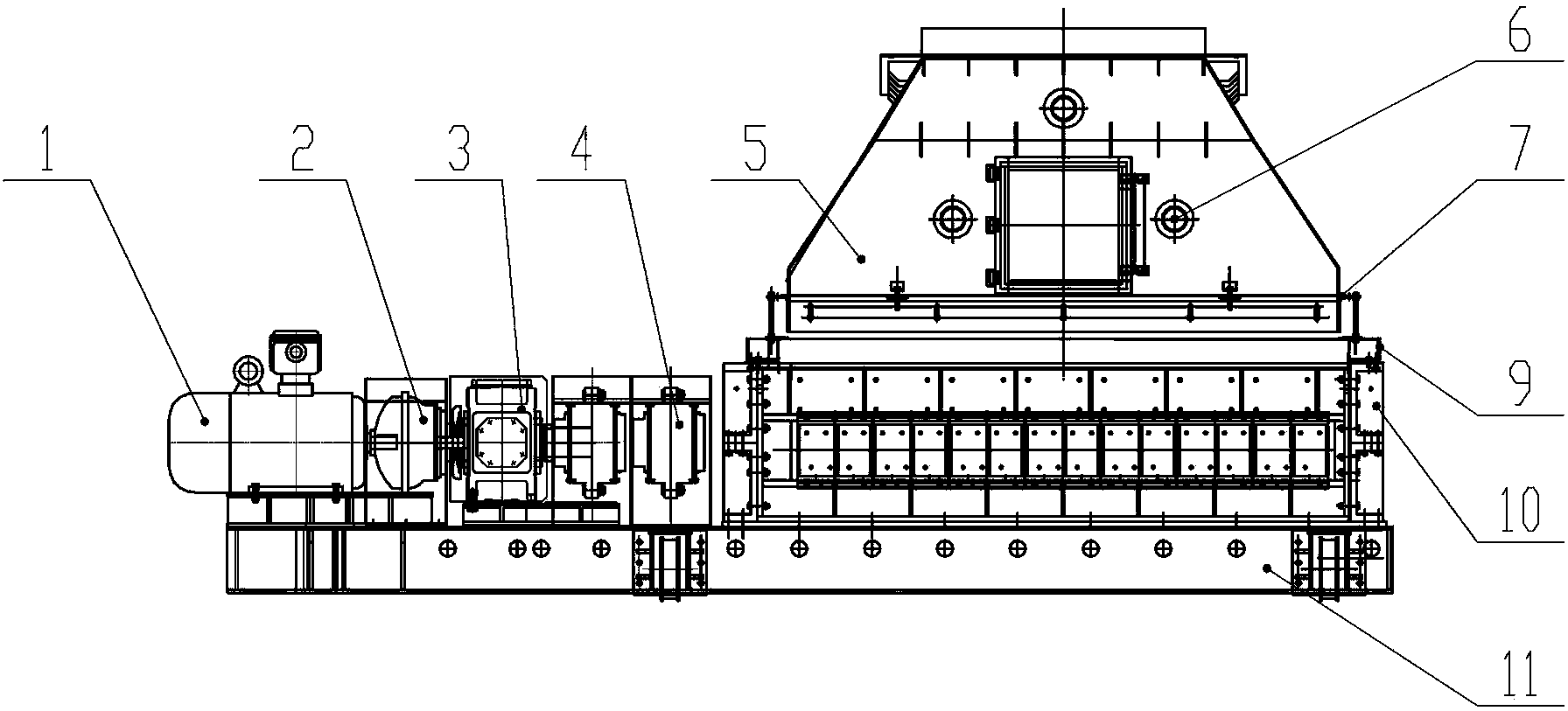

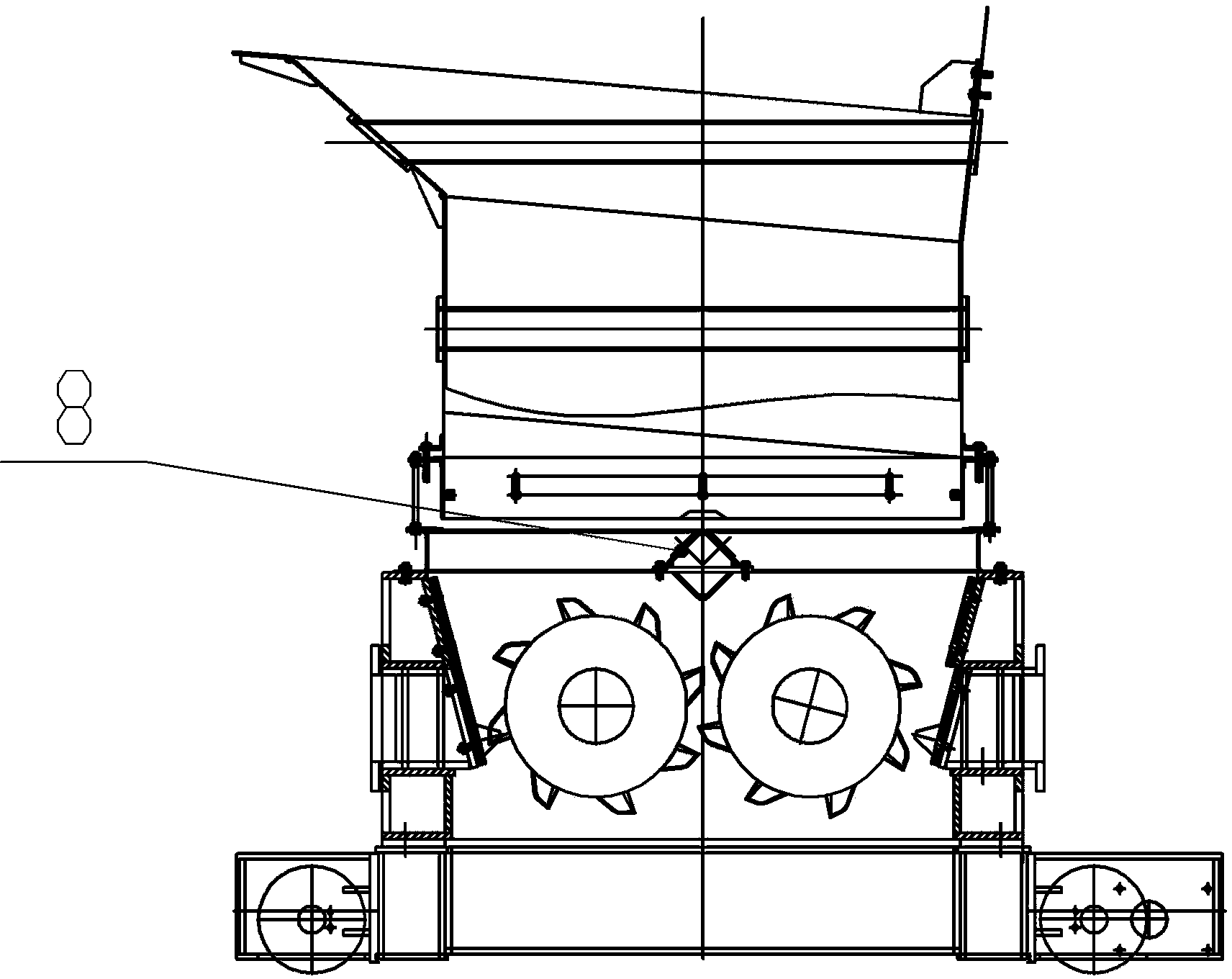

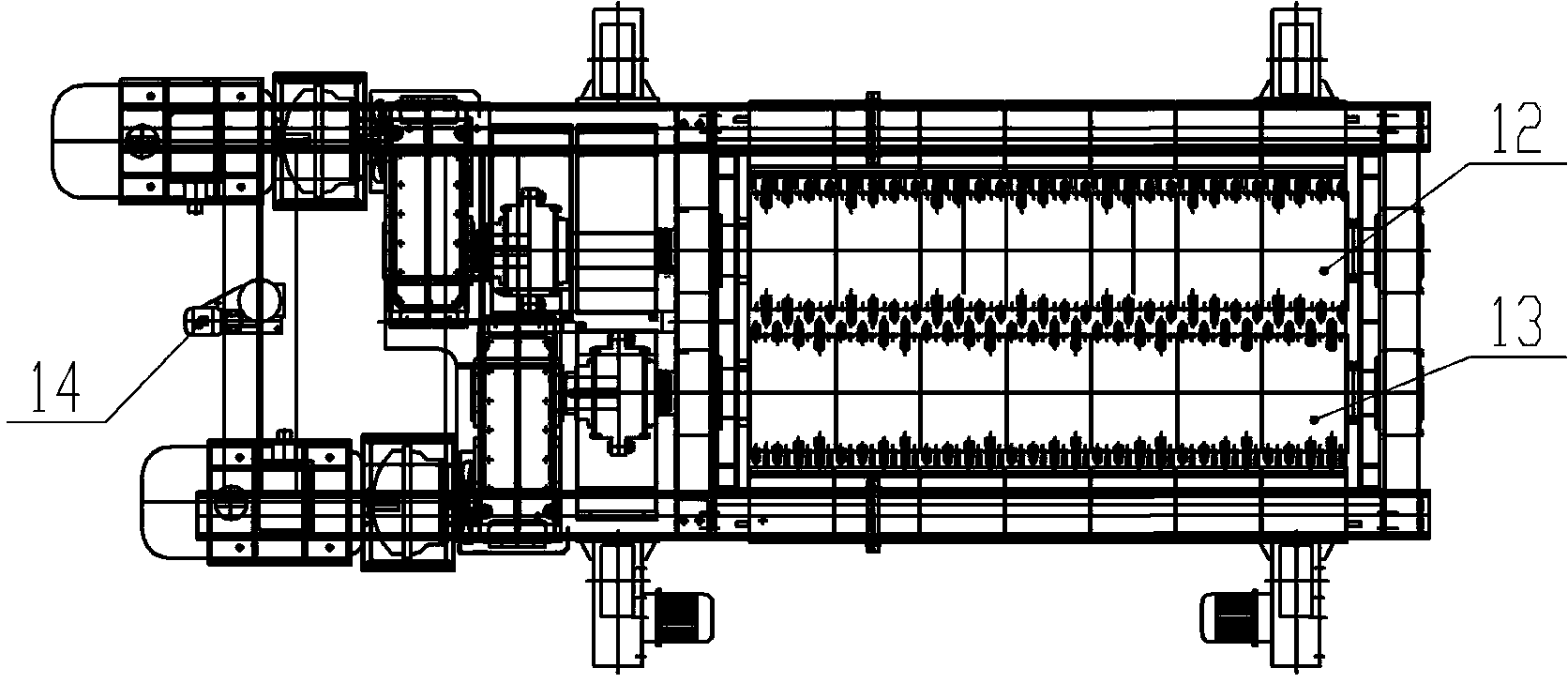

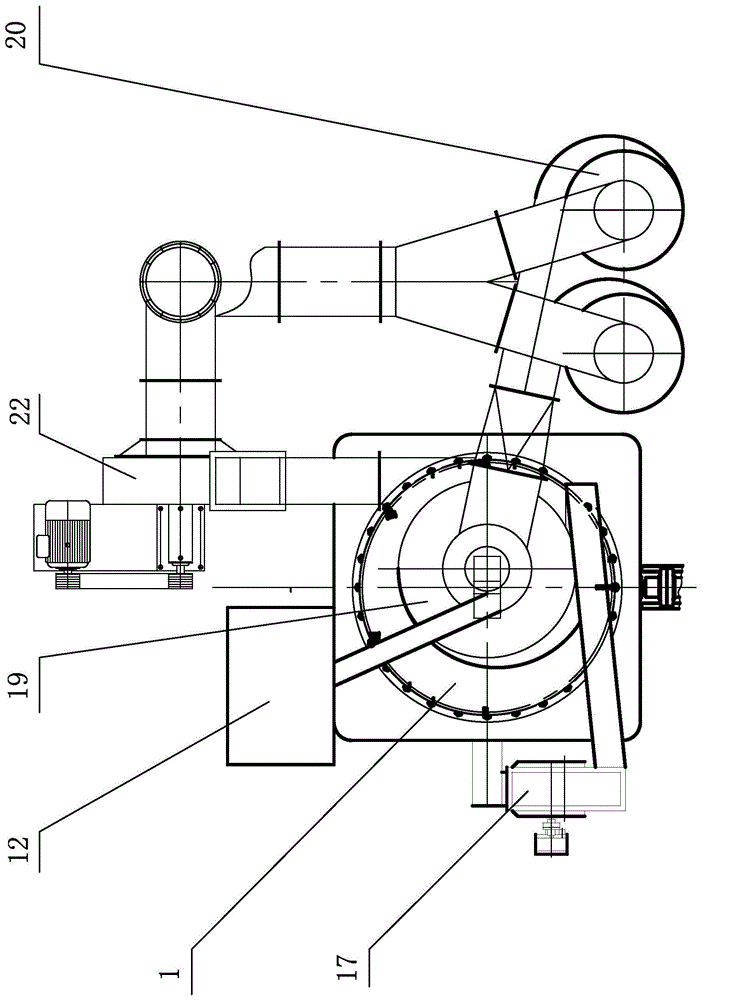

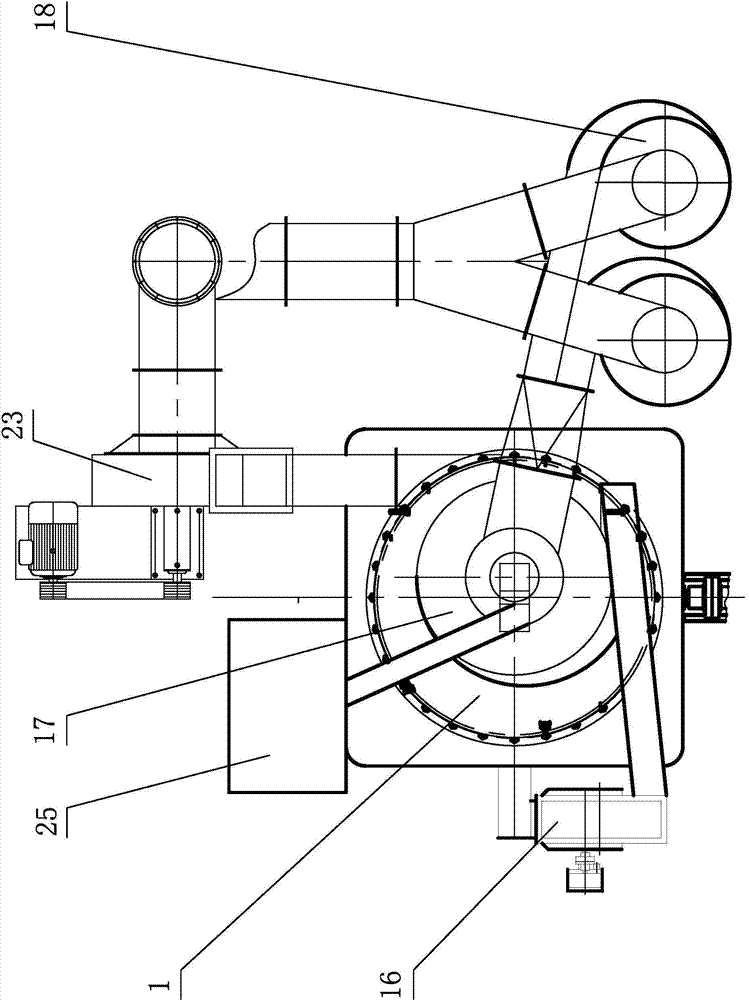

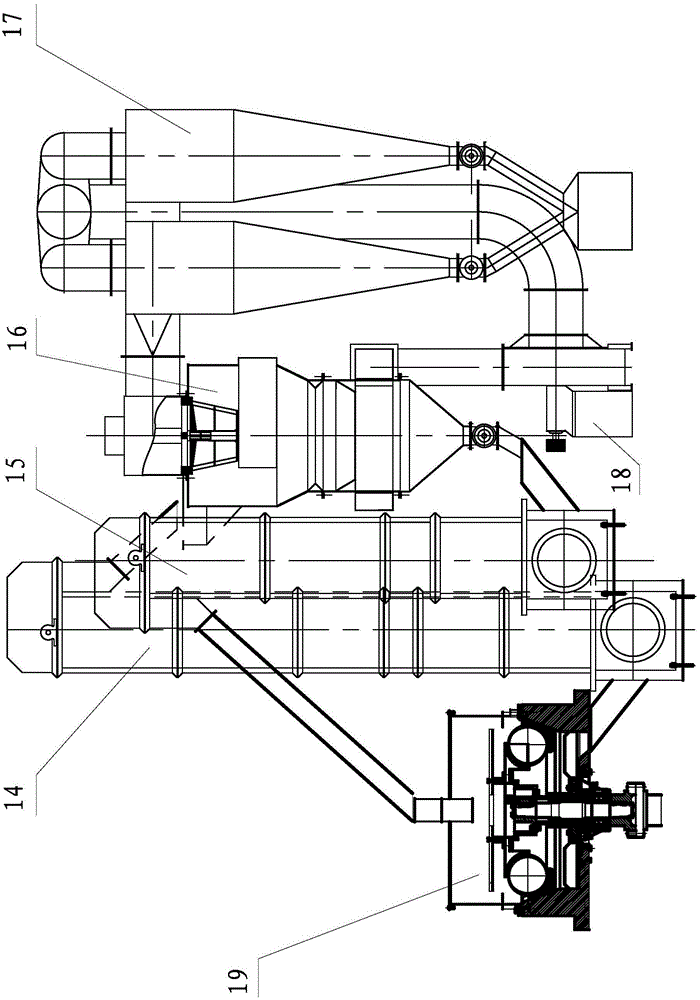

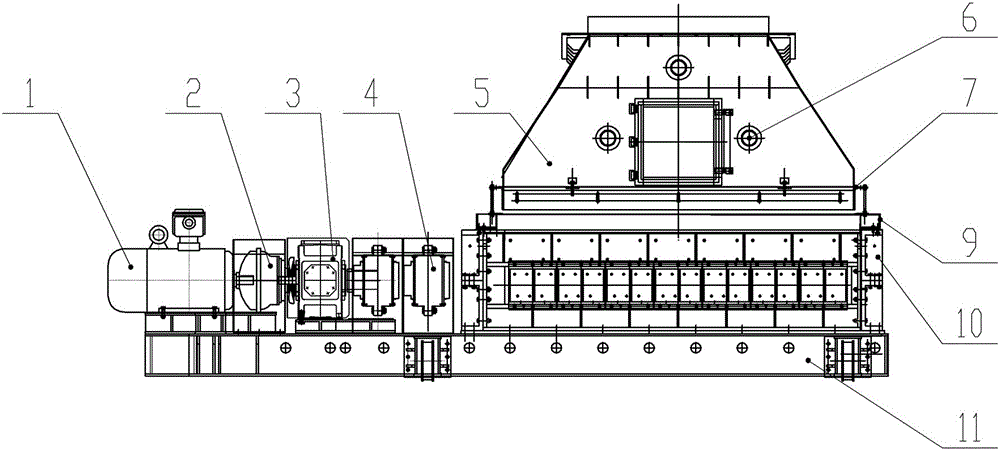

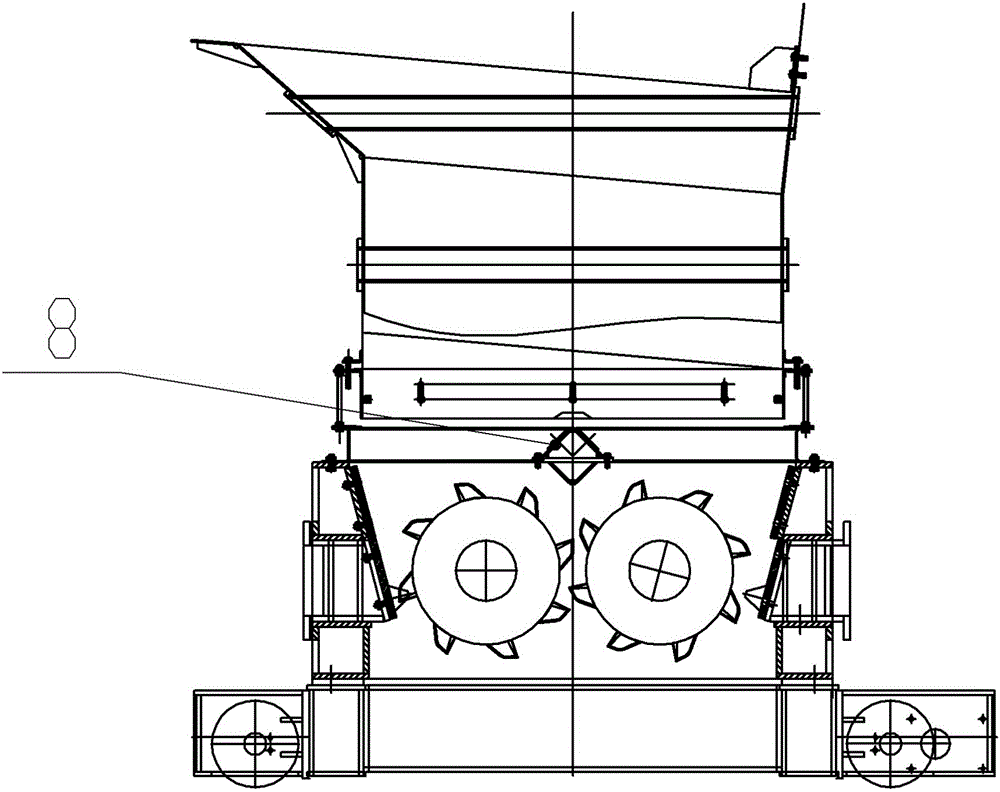

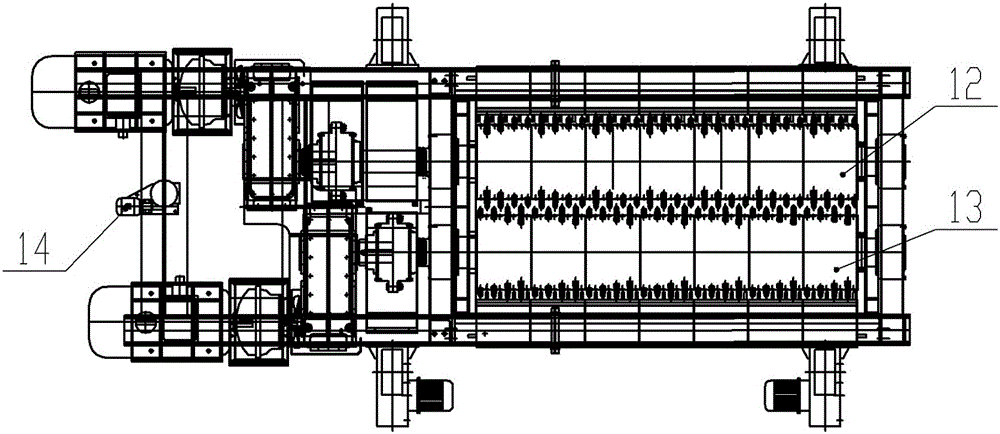

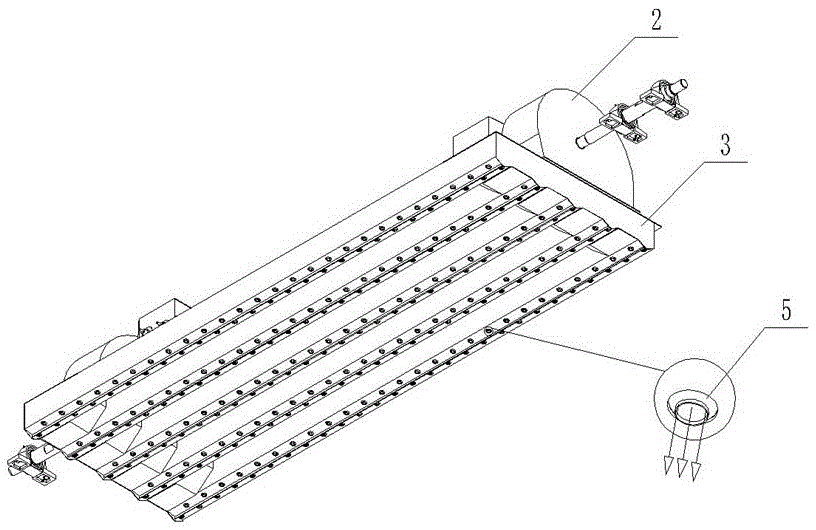

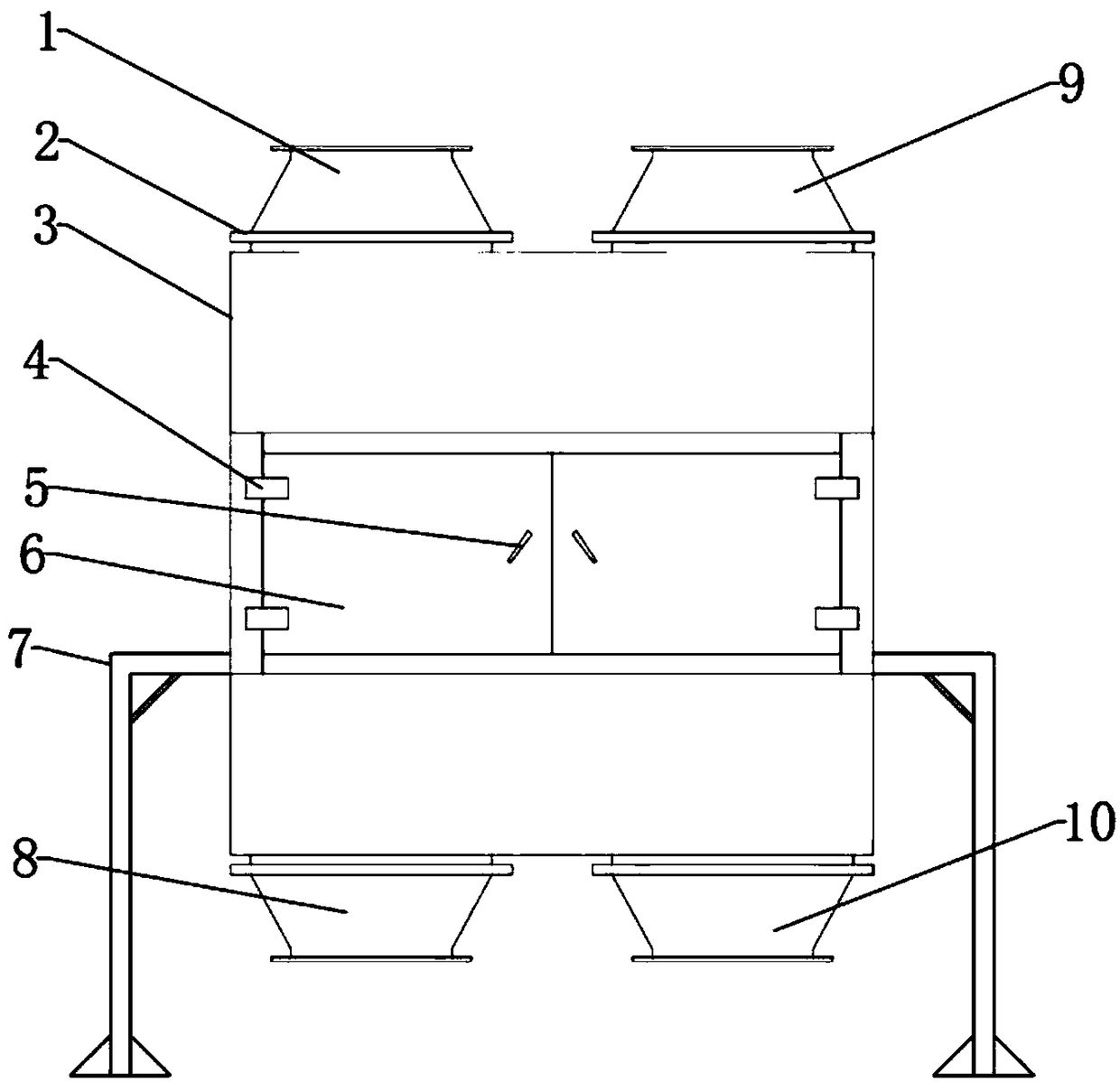

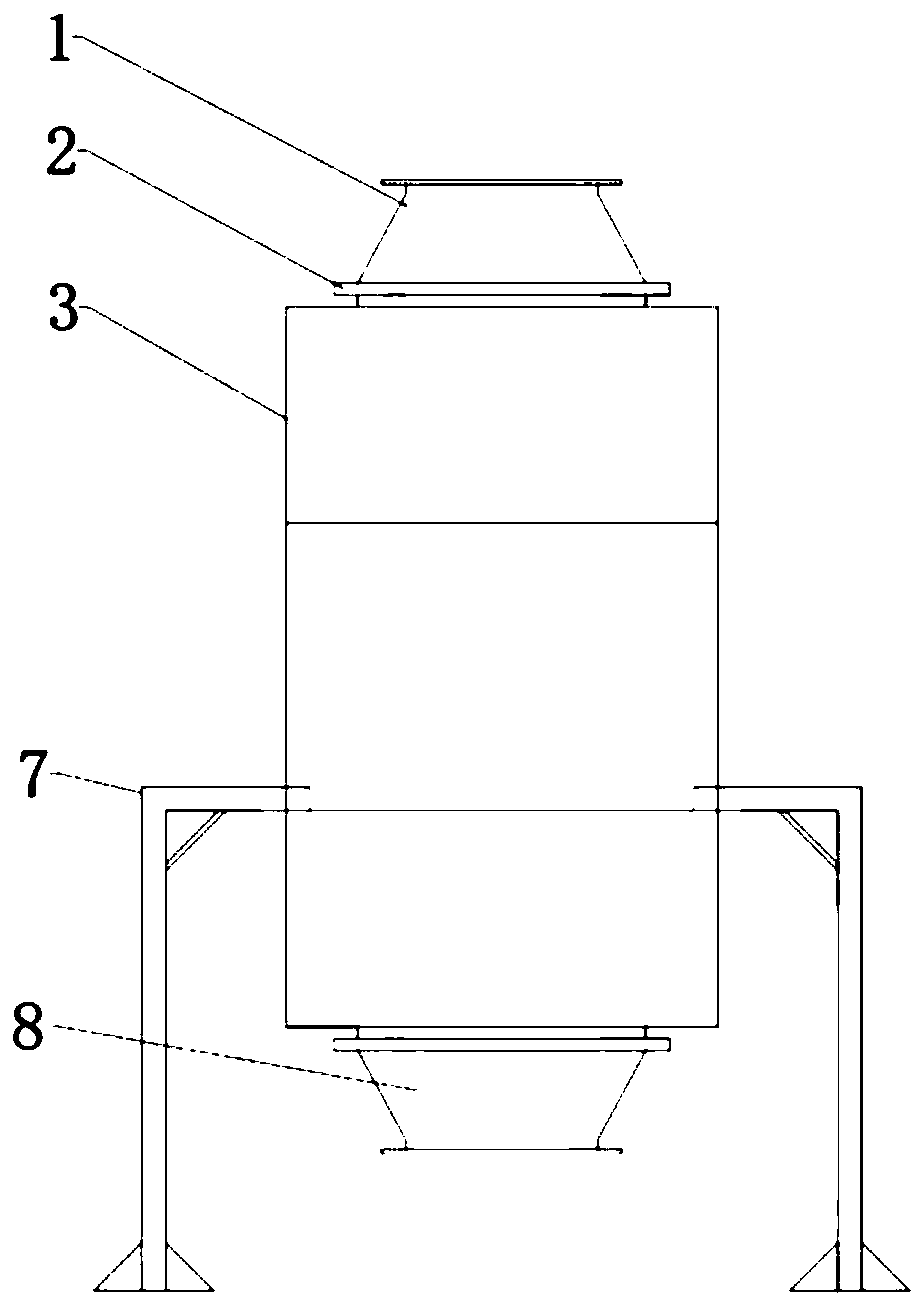

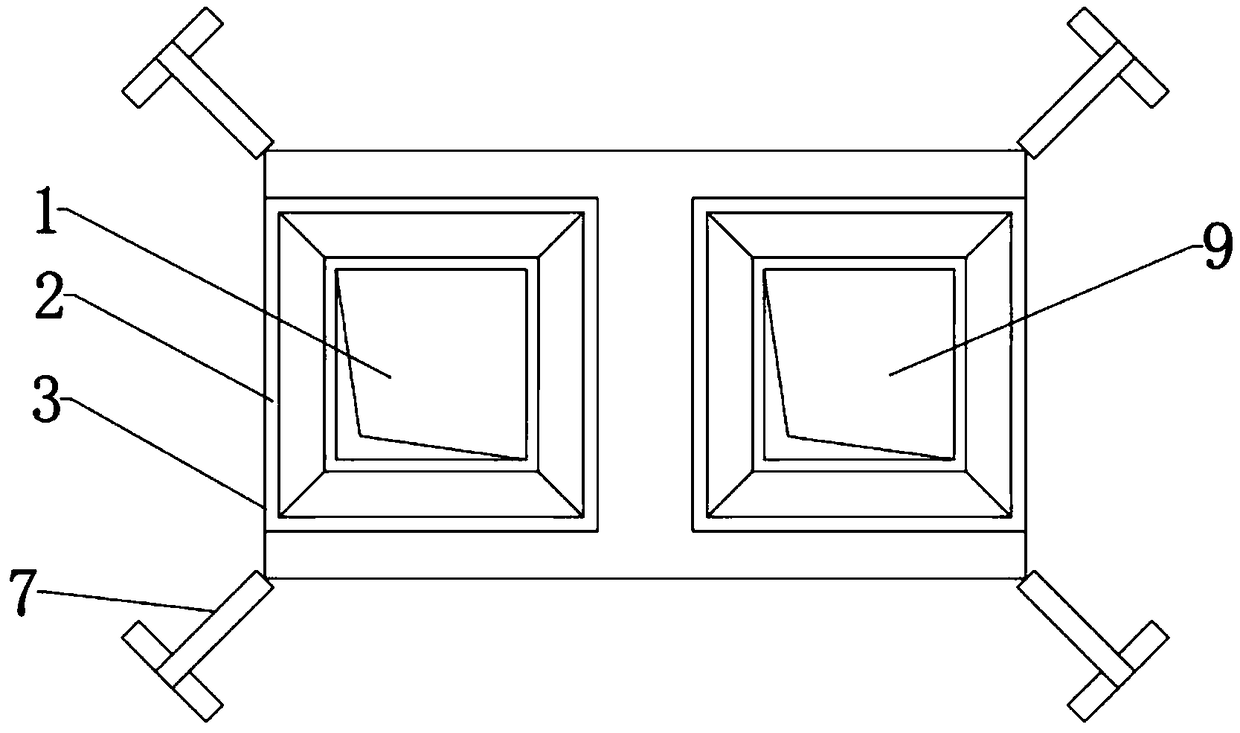

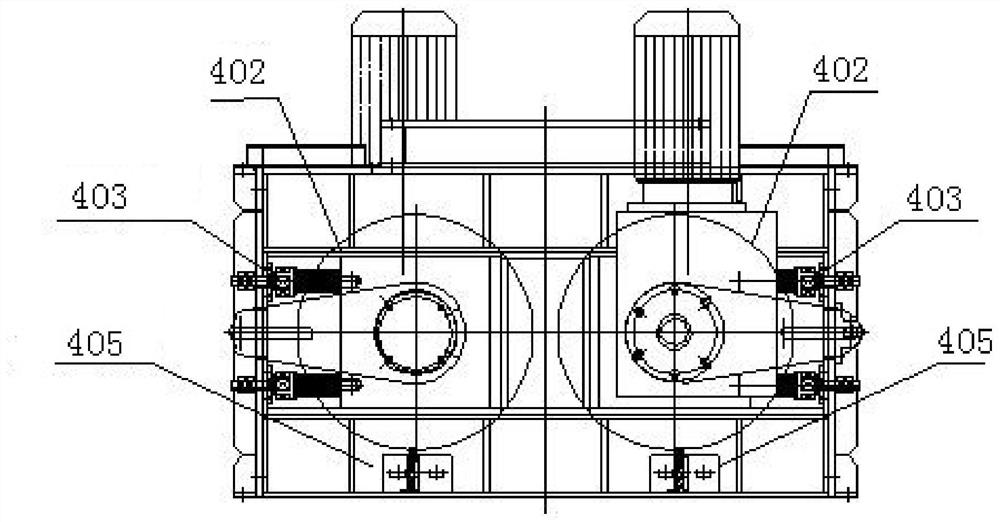

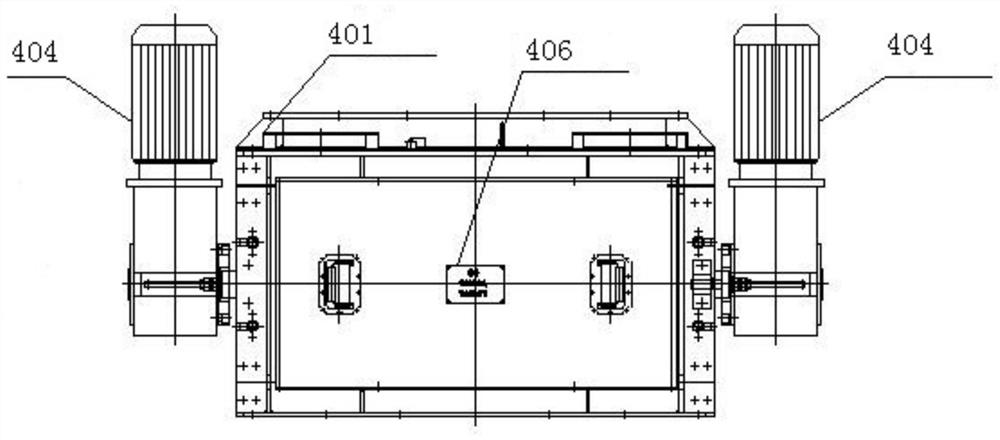

Large efficient screening-type double-toothed roll crusher provided with distribution device

The invention discloses a large efficient screening-type double-toothed roll crusher provided with a distribution device. The double-toothed roll crusher comprises a crushing device and the distribution device. The crushing device comprises a crushing drive motor, a fluid coupling, a reducer, a double-drum gear coupling, a crushing box, a base support, a left toothed roll, a right toothed roll and a lubricating grease pump, wherein the crushing drive motor, the fluid coupling, the reducer and the double-drum gear coupling form two sets of crushing drive units; and the two sets of crushing drive units are connected wit the left toothed roll and the right toothed roll inside the crushing box respectively. The distribution device comprises a distribution chute, an adjustable distribution stick, a movable connecting bracket, a distribution seat and a fixed connecting bracket, wherein the fixed connecting bracket and the distribution seat are fixed on the crushing box of the crushing device, the distribution chute is fixed at a discharge port of a material output belt machine head, and the distribution chute is connected with the crushing box through the movable and fixed connecting brackets. According to the large efficient screening-type double-toothed roll crusher, the problems of capital investment, equipment movement and the like of crushing equipment combined by a plurality of devices are solved fundamentally, the labor intensity of daily equipment maintenance is reduced, and the mining of surface mine materials is accelerated.

Owner:HENAN ZHENYUAN TECH

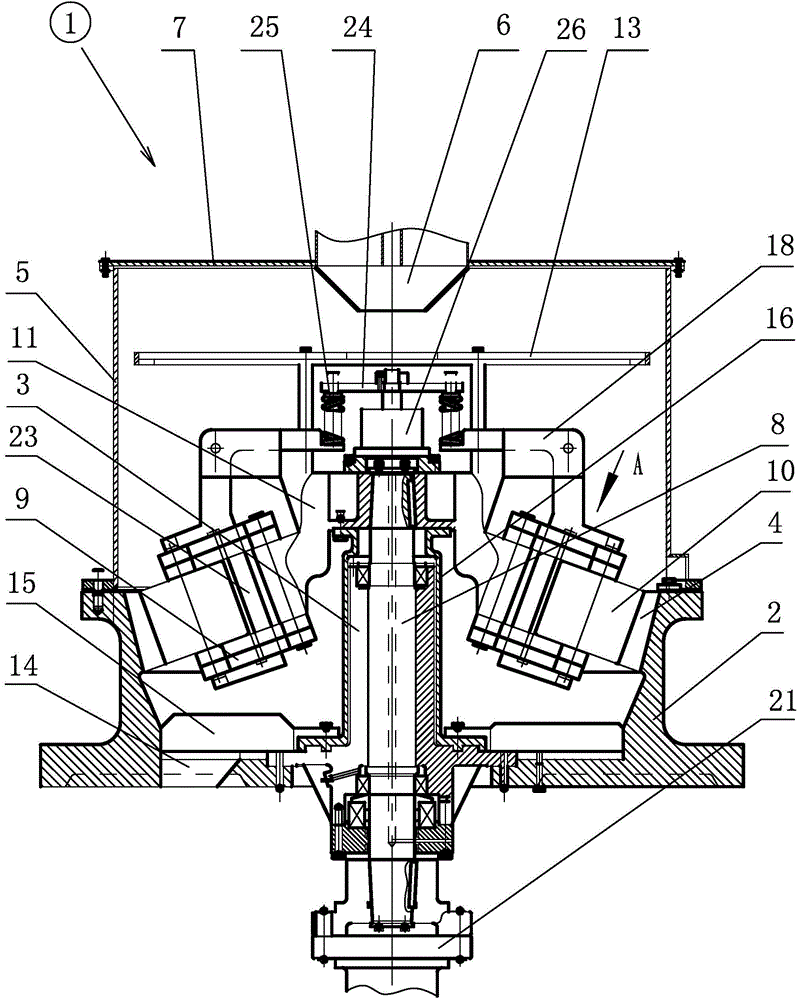

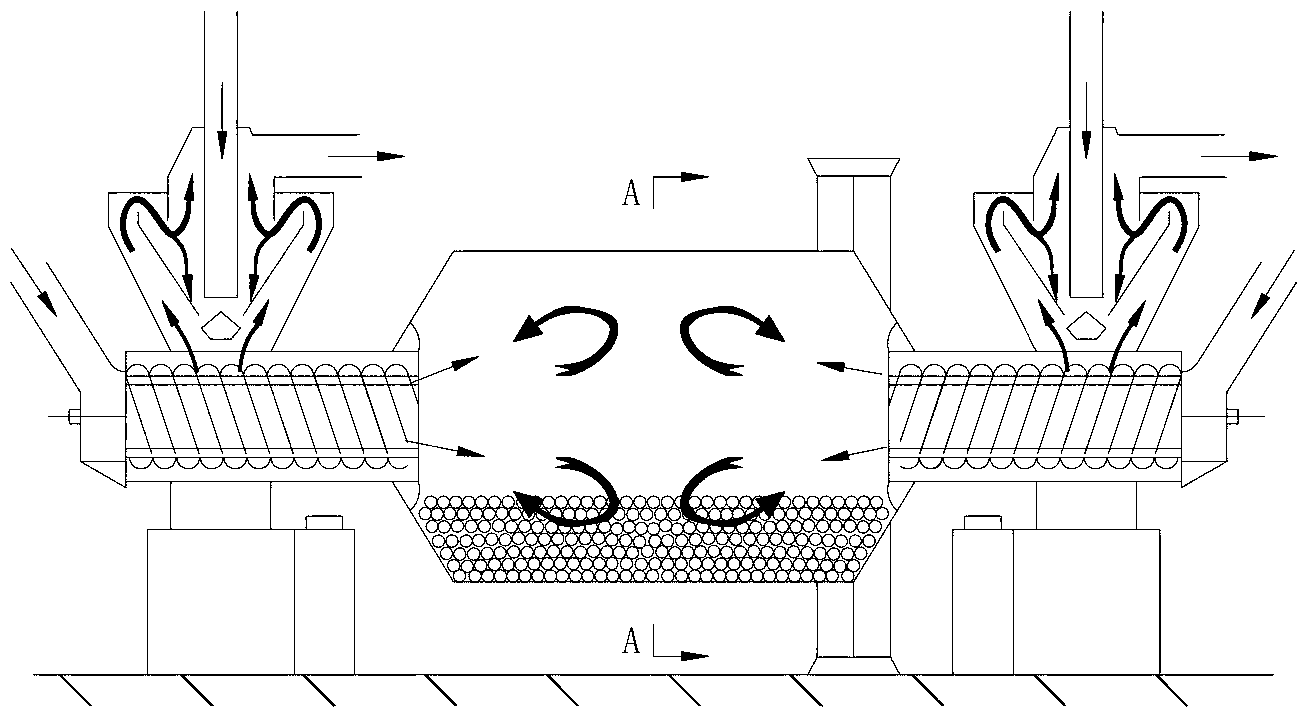

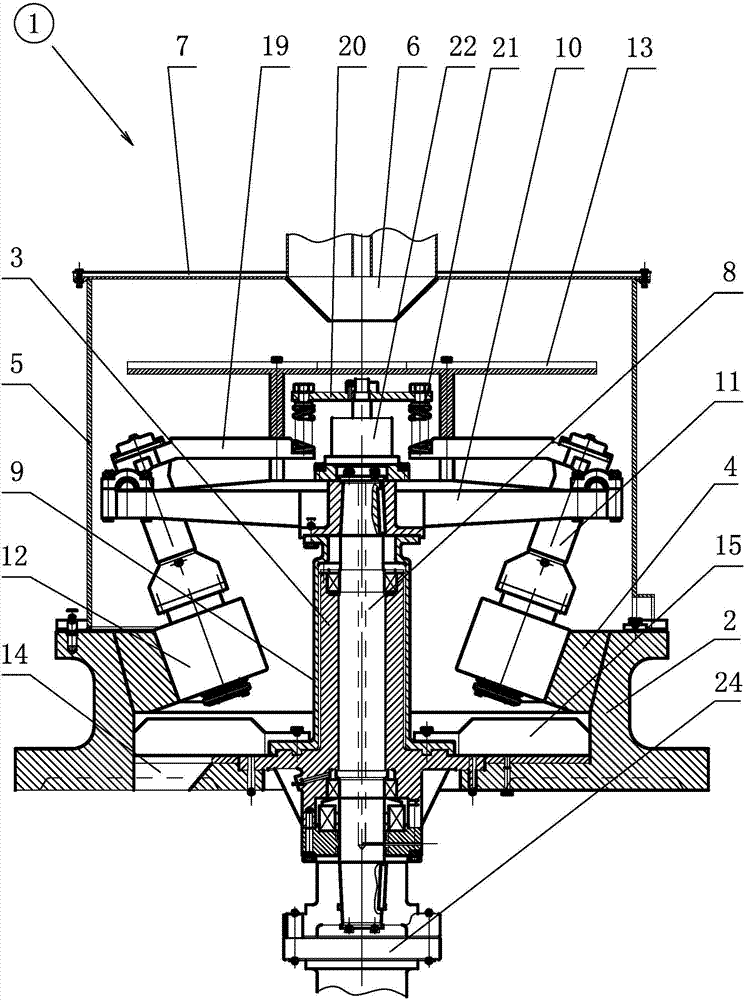

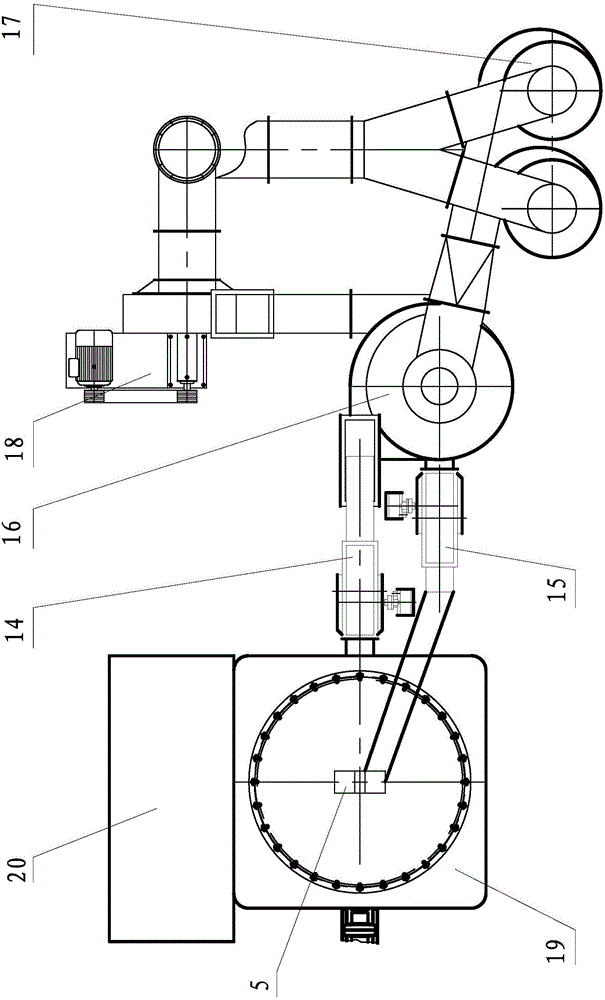

Inclined roll pressurized external circulating pulverizer

ActiveCN104668044AReduce energy lossEasy maintenance of equipmentGrain treatmentsPulverizerPulp and paper industry

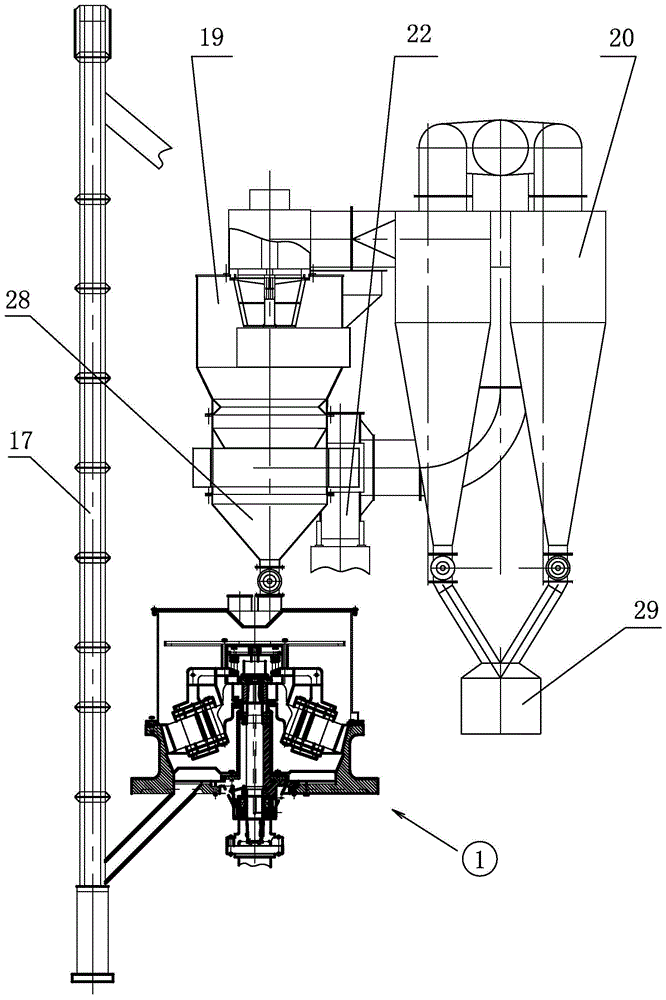

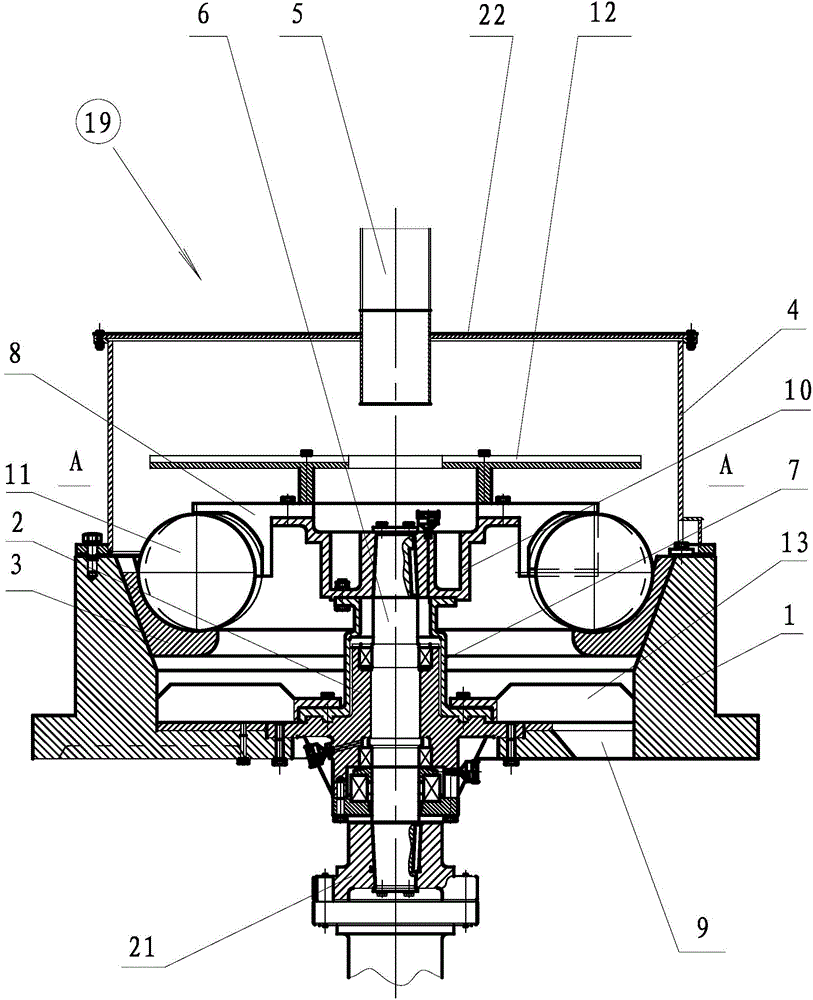

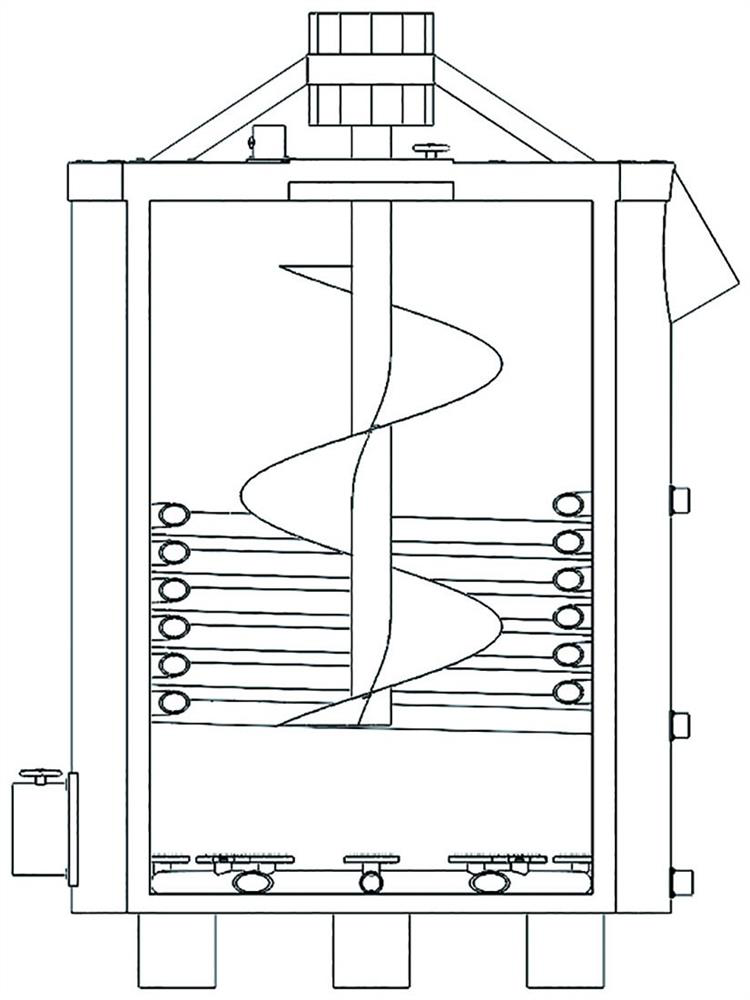

The invention discloses an inclined roll pressurized external circulating pulverizer. A central shaft bracket is mounted at the bottom of a pedestal of a main frame; grinding rings are mounted at the upper part of the pedestal; a hooding cylinder is mounted on the end face of the pedestal; the lower part of a spindle is mounted in the central shaft bracket; a grinding roller device is arranged at the upper part of the spindle; the grinding roller device comprises grinding roller racks and grinding rollers; the circumference of the grinding roller racks is uniformly and fixedly arranged on roller fixing racks and inclined downwards and outwards; the grinding rollers are mounted on the grinding roller racks and propped against the conical milling surfaces with larger upper parts and smaller lower parts of the grinding rings; the roller fixing rack is mounted at the upper end of the spindle; a material homogenizing disk is arranged at the upper part of the roller fixing rack and rotates coaxially with the roller fixing rack; a discharge hole of the main frame is formed in the bottom of the inner hole of the pedestal; scraping plates are arranged at the positions, corresponding to the discharge hole of the main frame, of the bottom of the pedestal; the circumference of the scraping plates is uniformly distributed and mounted on a material scraping frame; the material scraping frame and the roller fixing frame are coaxially and fixedly mounted; the discharge hole of the main frame is communicated with an outer-frame classification system. The inclined roll pressurized external circulating pulverizer disclosed by the invention is simple in structure, low in cost, prone to maintain, and short in replacement and maintenance time; as the pulverizer is free of material throwing motion of a scraper knife and the complicated and heavy grinding roller device, the loss of the total power can be greatly reduced.

Owner:GUILIN SHENGXING MACHINERY MFG

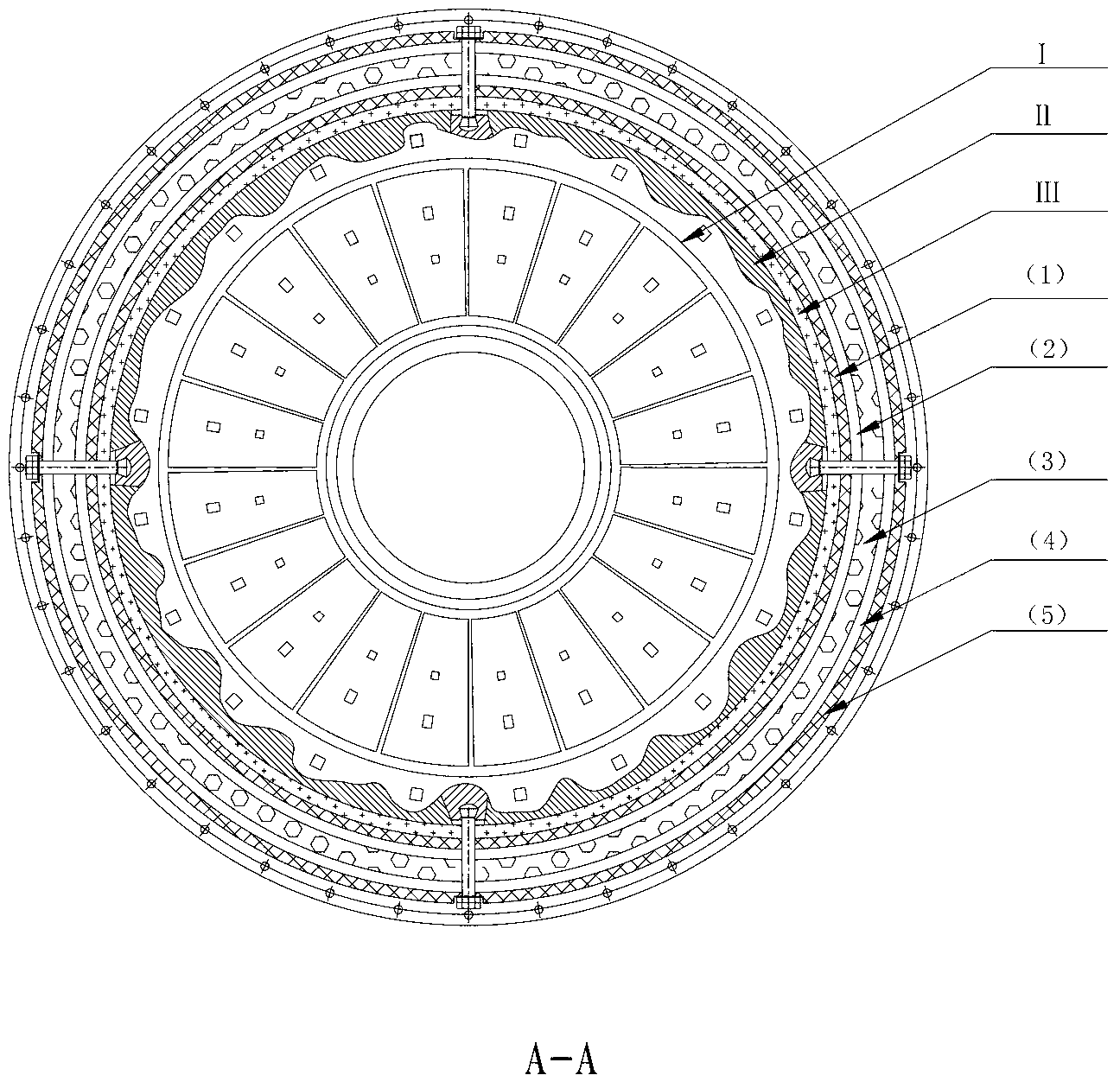

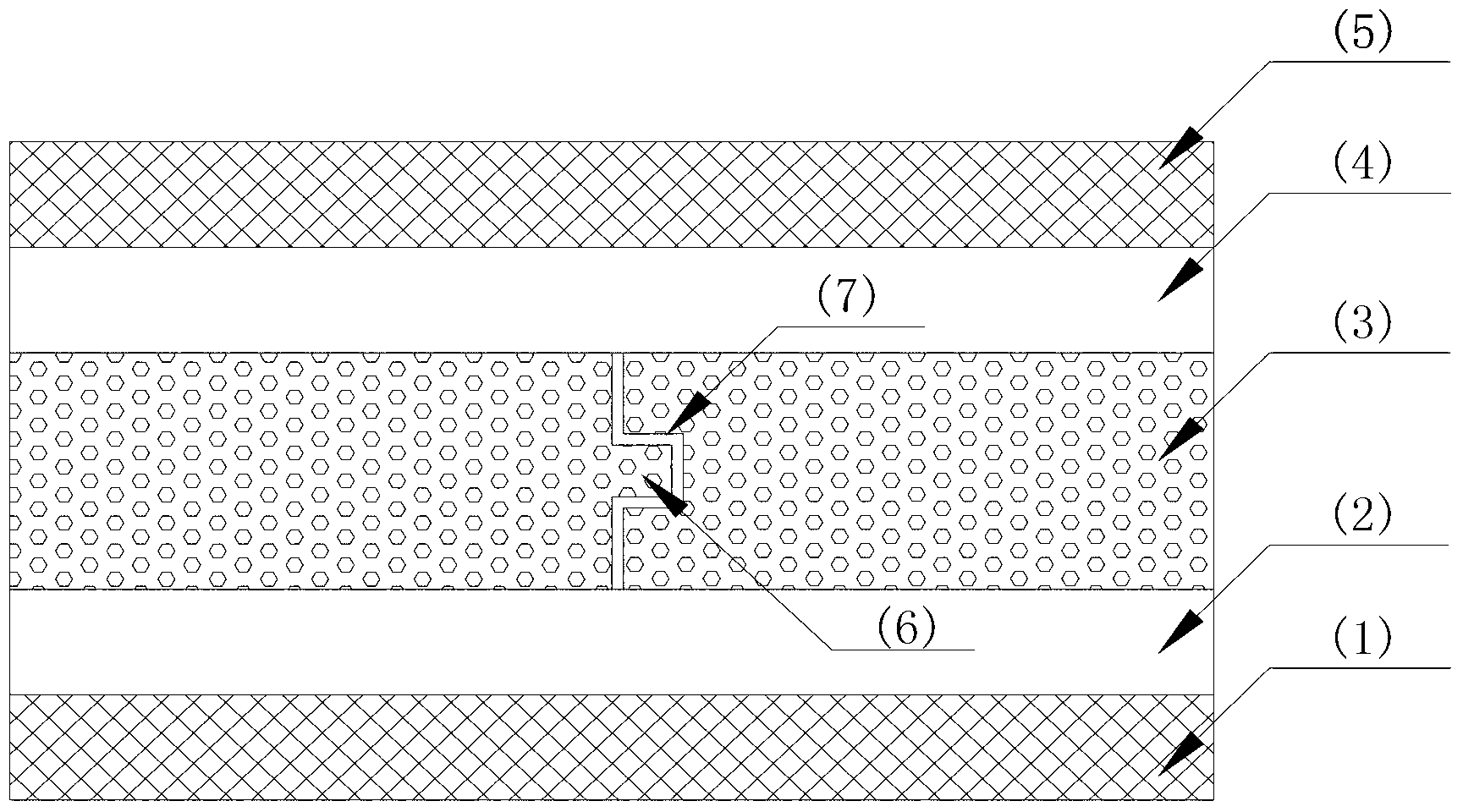

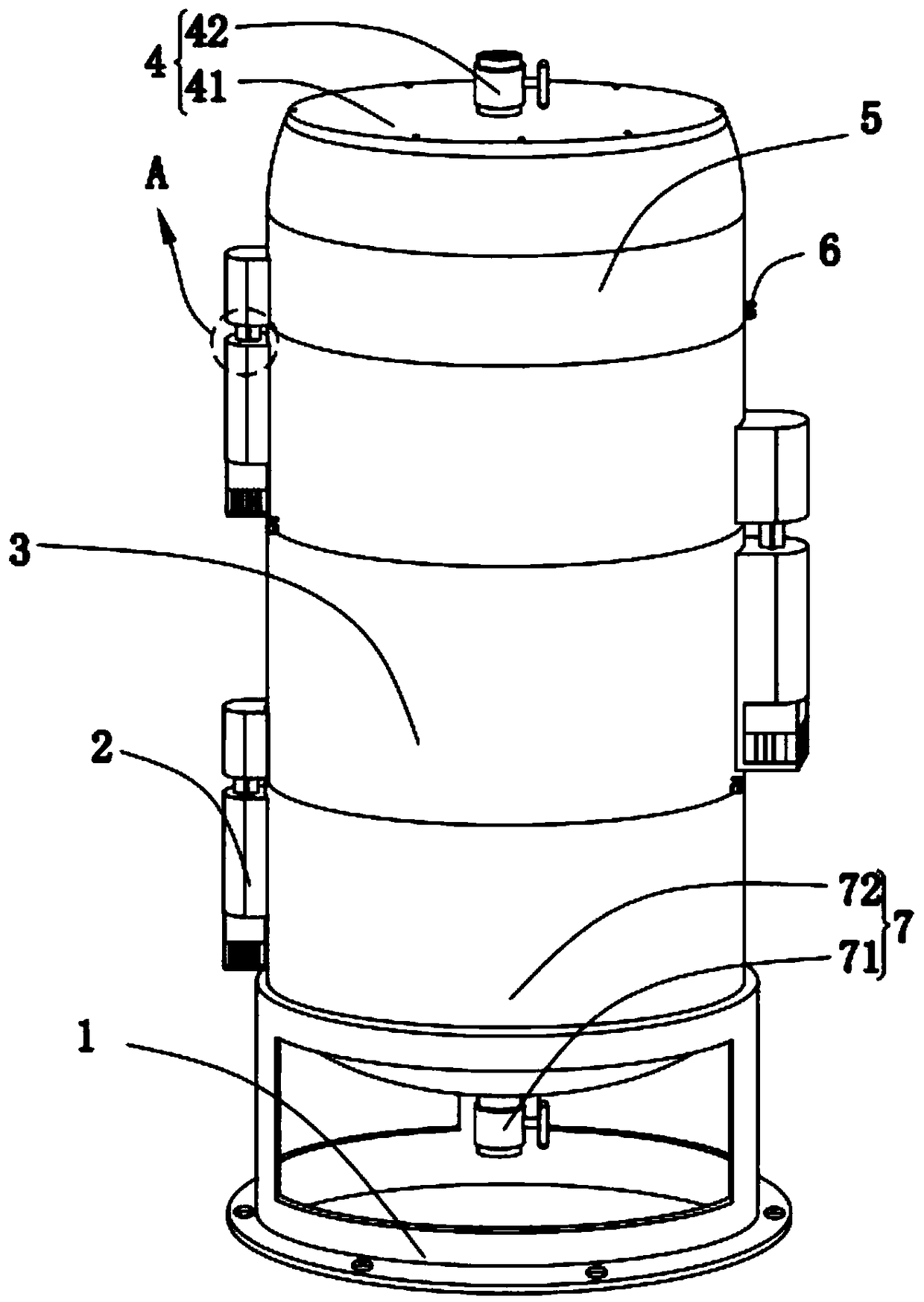

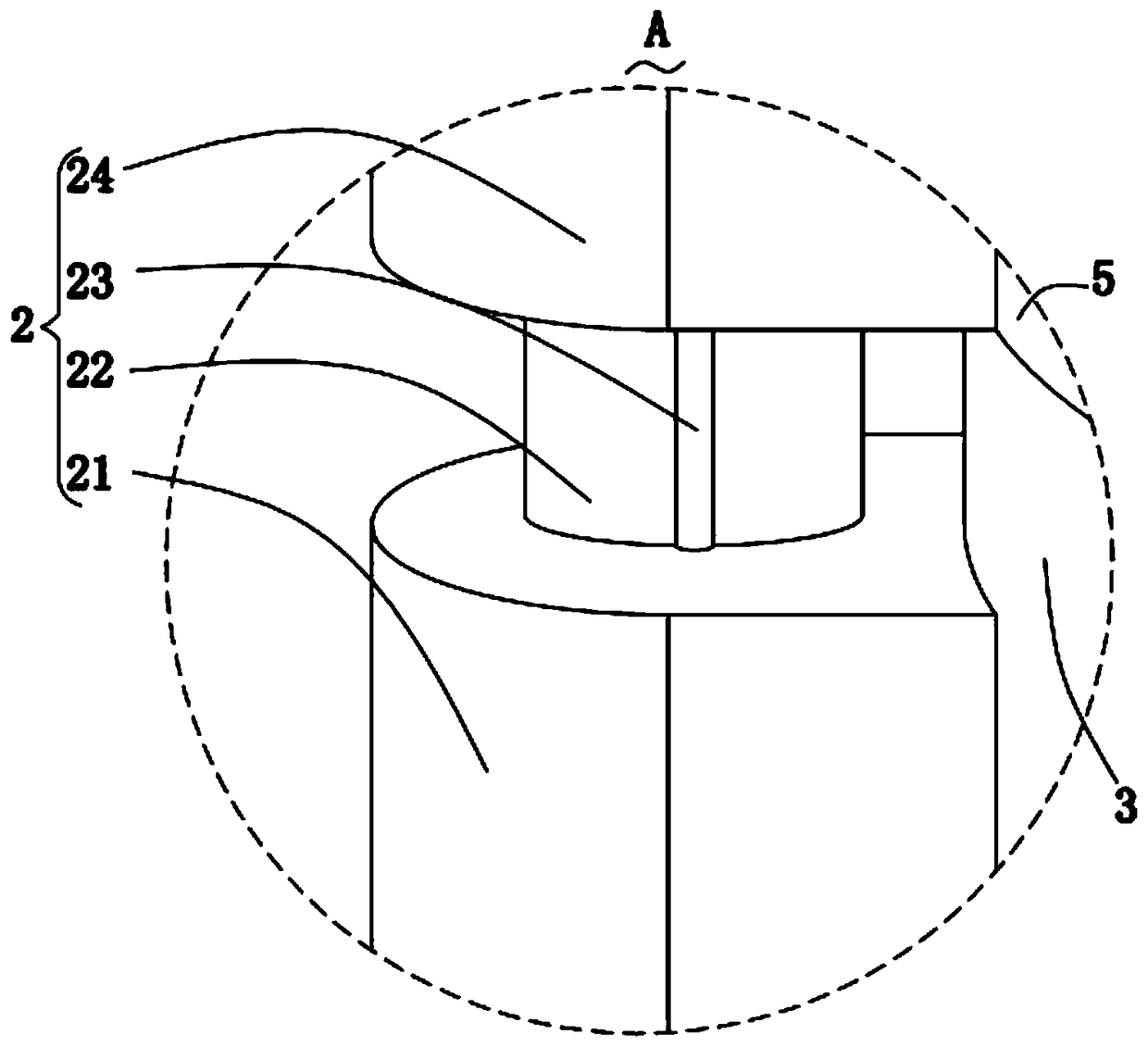

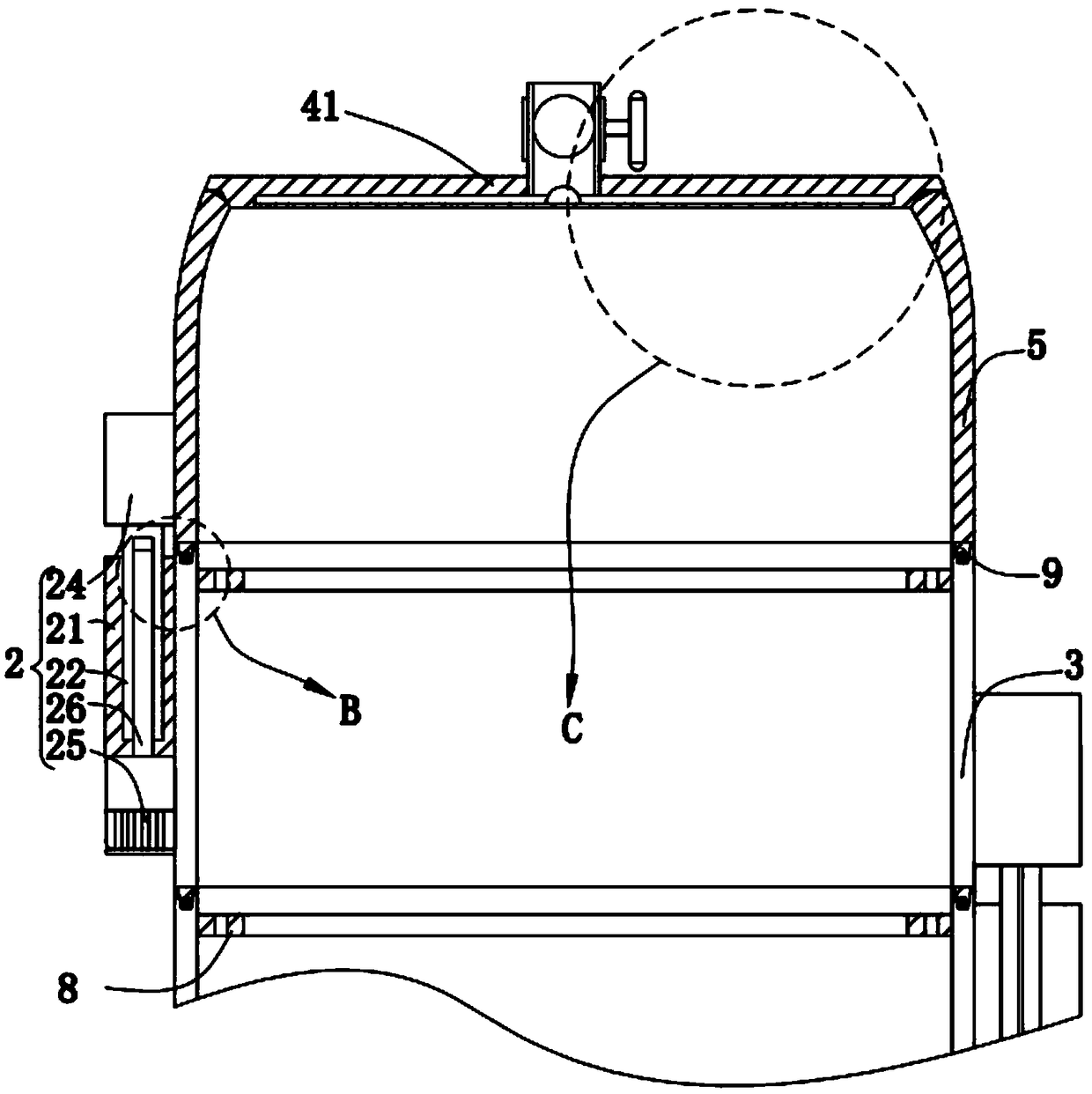

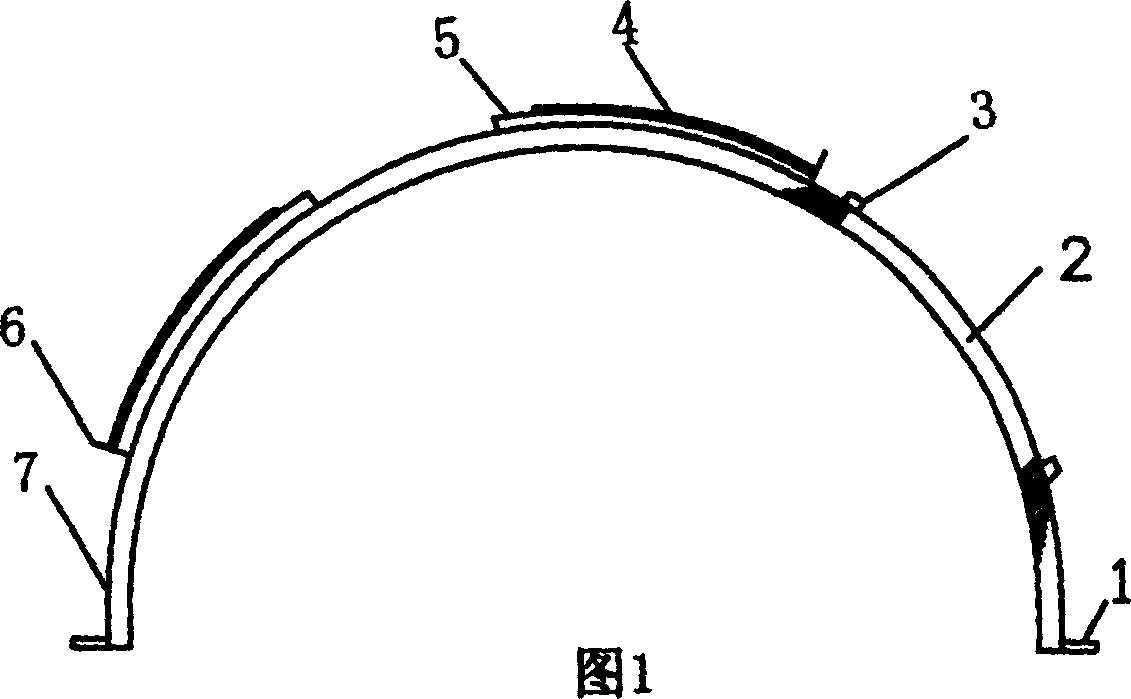

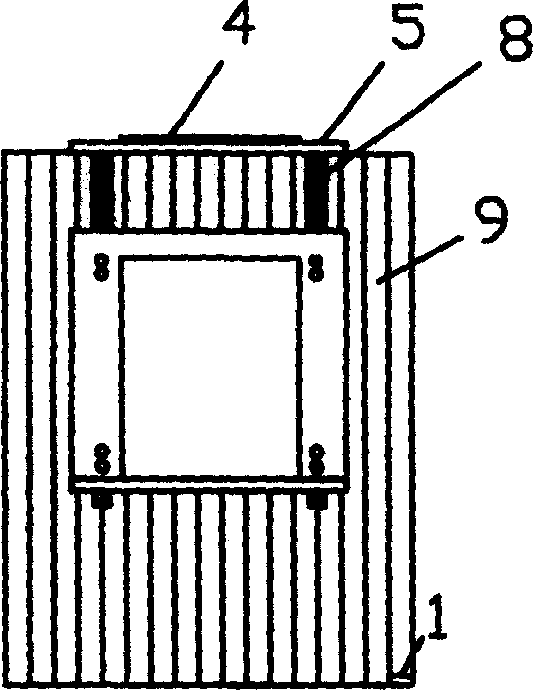

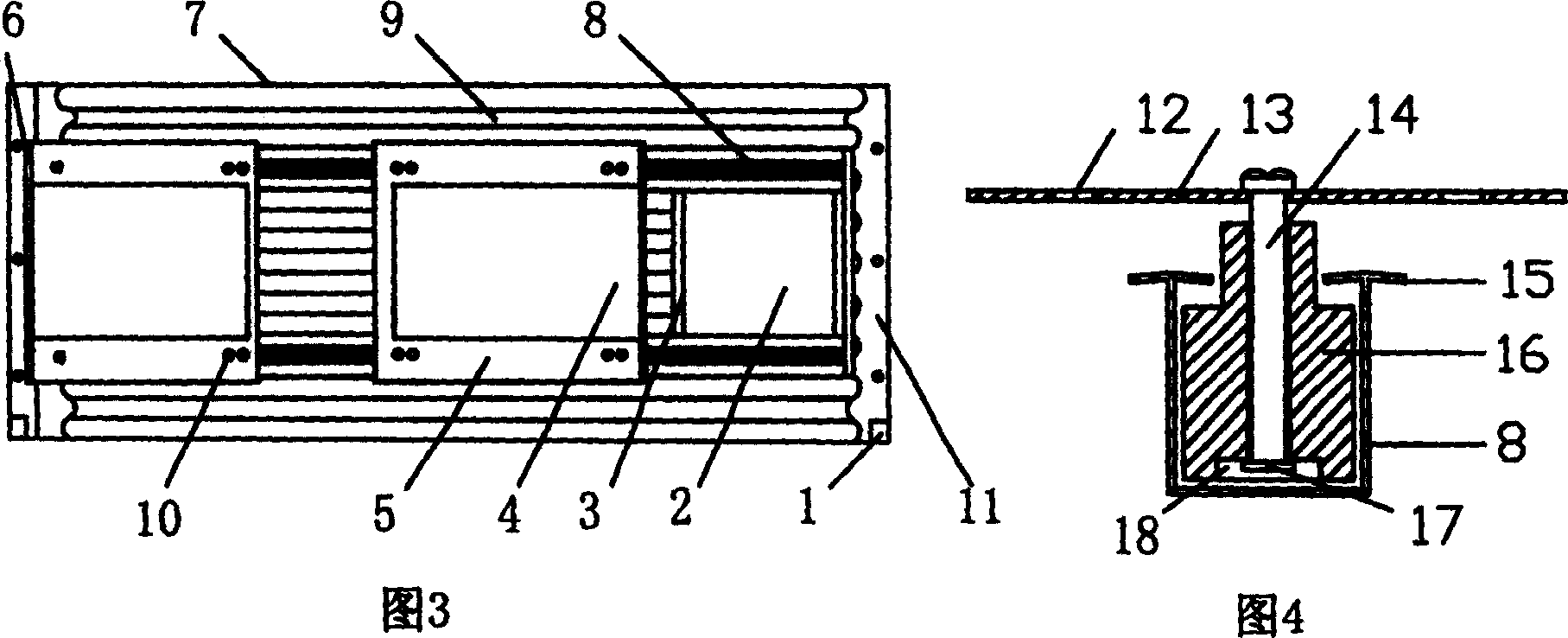

Low-noise sound insulation sleeve for double-ended ball mill

The invention relates to the technical field of mechanical noise reducing and particularly relates to a sound insulation sleeve. The sound insulation sleeve comprises a sound insulation sleeve inner layer (1), a metal foam aluminum plate layer (3), an outer layer sound-absorption fabric-smearing layer (4) and a sound insulation sleeve outer layer (5), wherein an inner layer sound-absorption fabric-smearing layer (2) is laid on the sound insulation sleeve inner layer (1); the metal foam aluminum plate layer (3) is laid on the inner layer sound-absorption fabric-smearing layer (2); the outer layer sound-absorption fabric-smearing layer (4) is laid on the metal foam aluminum plate layer (3); the sound insulation sleeve outer layer (5) is laid on the outer layer sound-absorption fabric-smearing layer (4). The sound insulation sleeve for reducing the noise of a double-ended ball mill is the low-noise sound insulation sleeve having the characteristics of compact structure, convenient implementation, relatively low cost and good sound reducing effect; by utilizing the metal foam aluminum plate layer which is light, can resist high temperature, reduce the cavity noise and can be recycled to form the filling material of the sound insulation sleeve of the ball mill, the noise of the ball mill can be reduced by 12dB-20dB (A), so that the safety protection of operators and the environmental protection are promoted.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

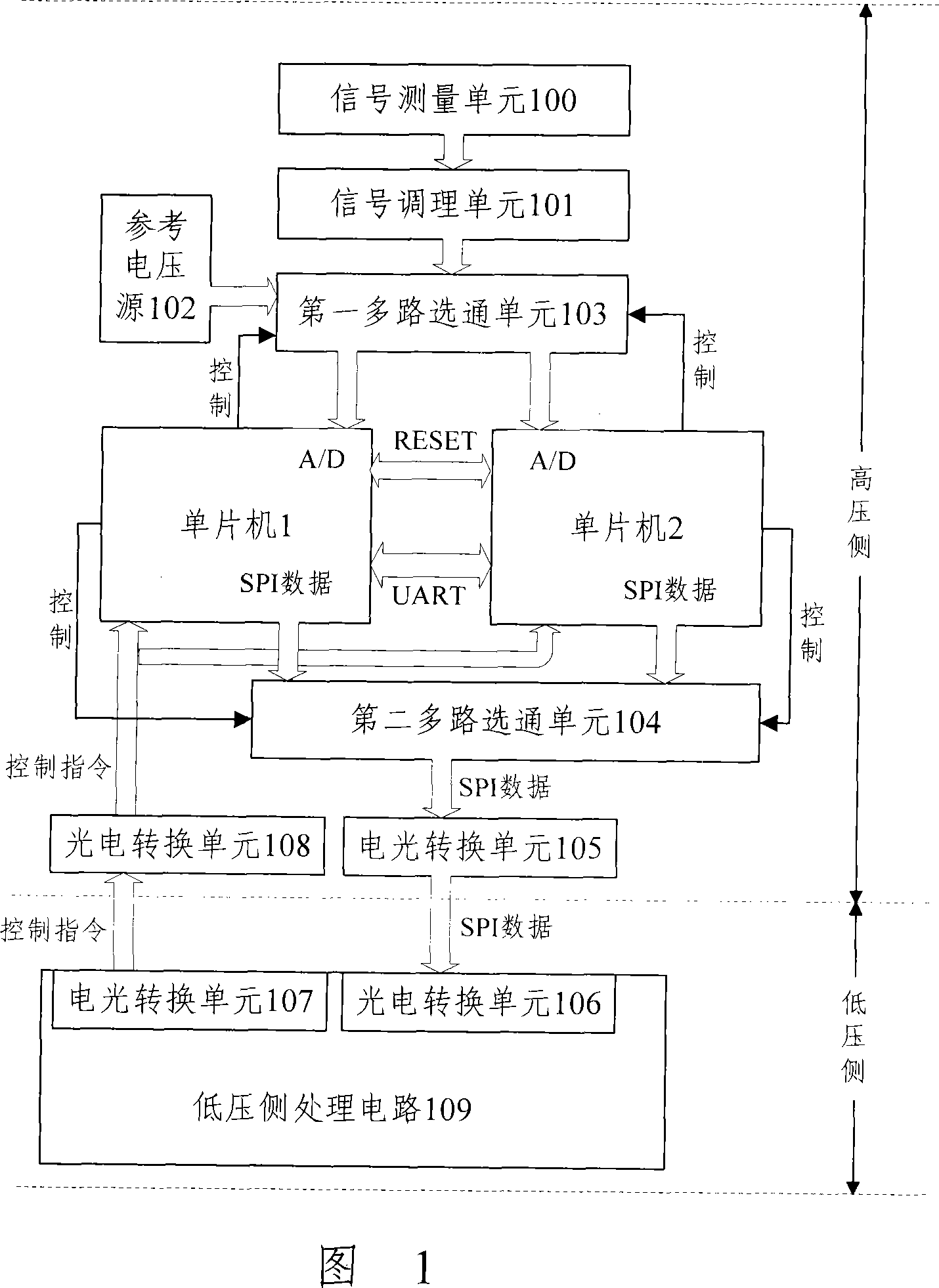

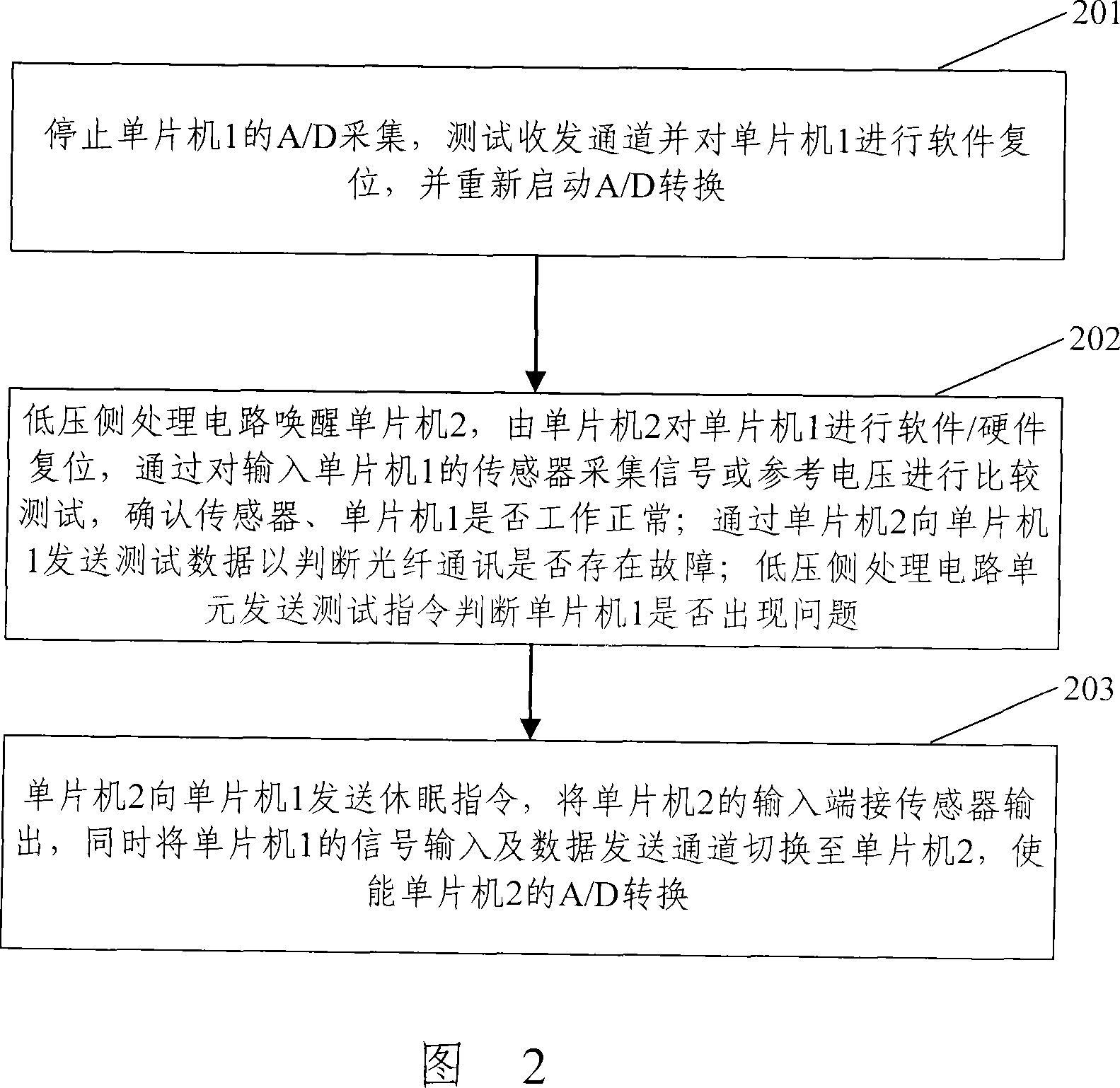

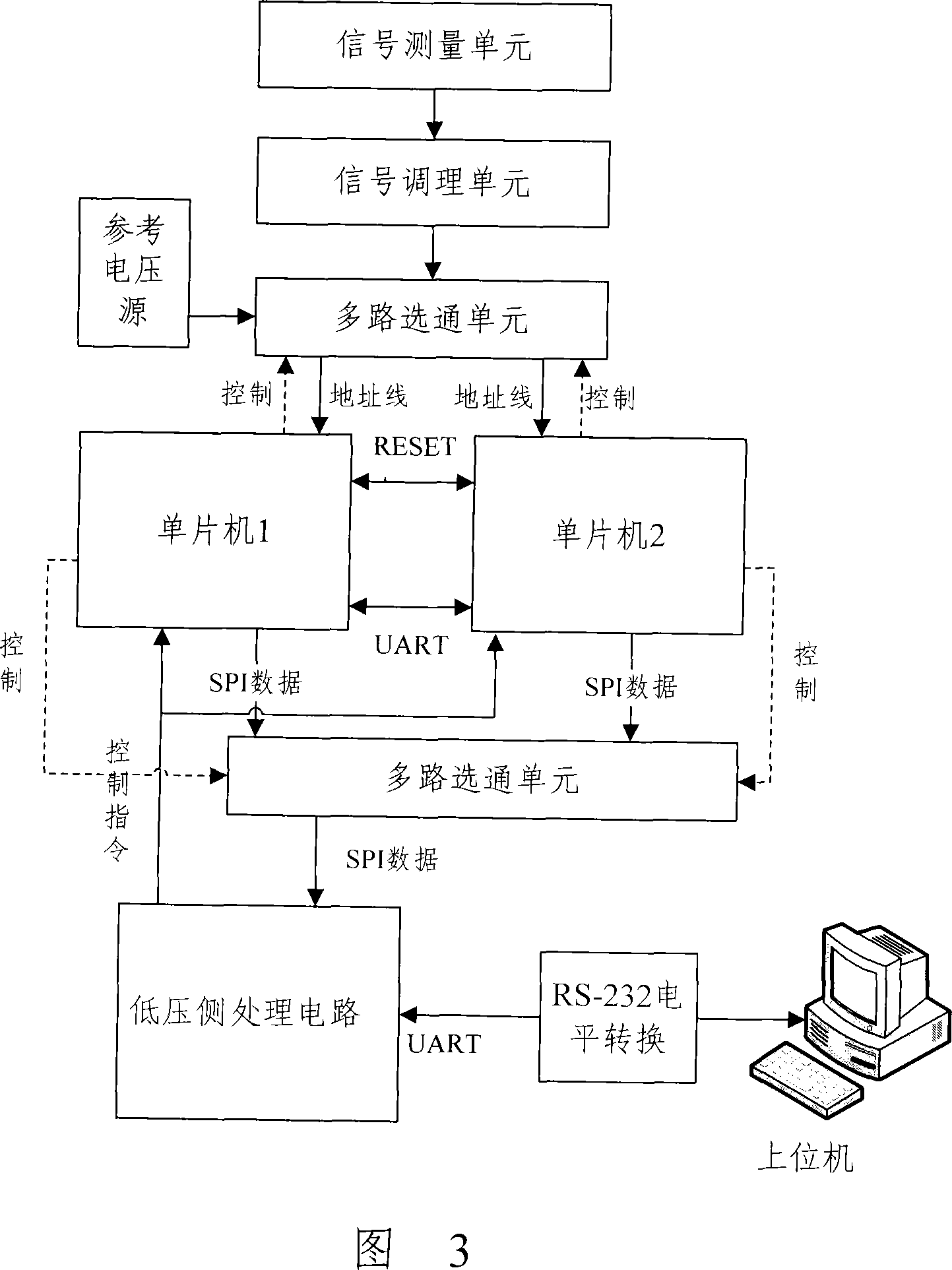

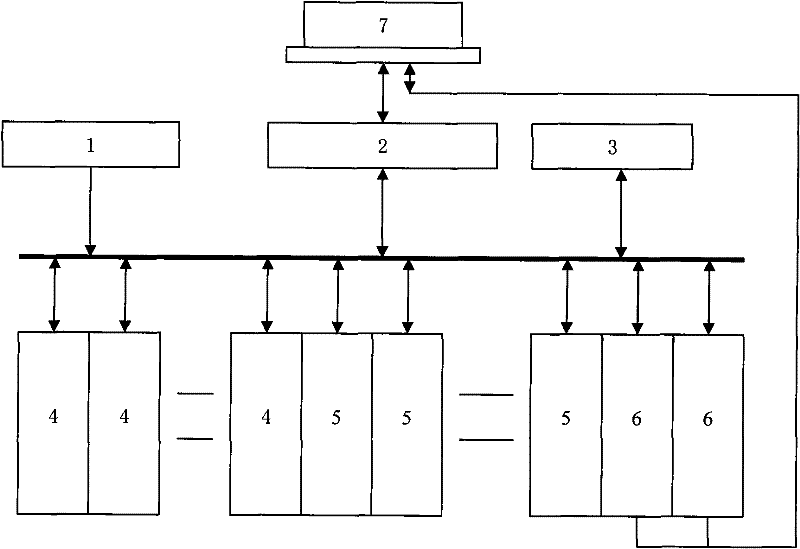

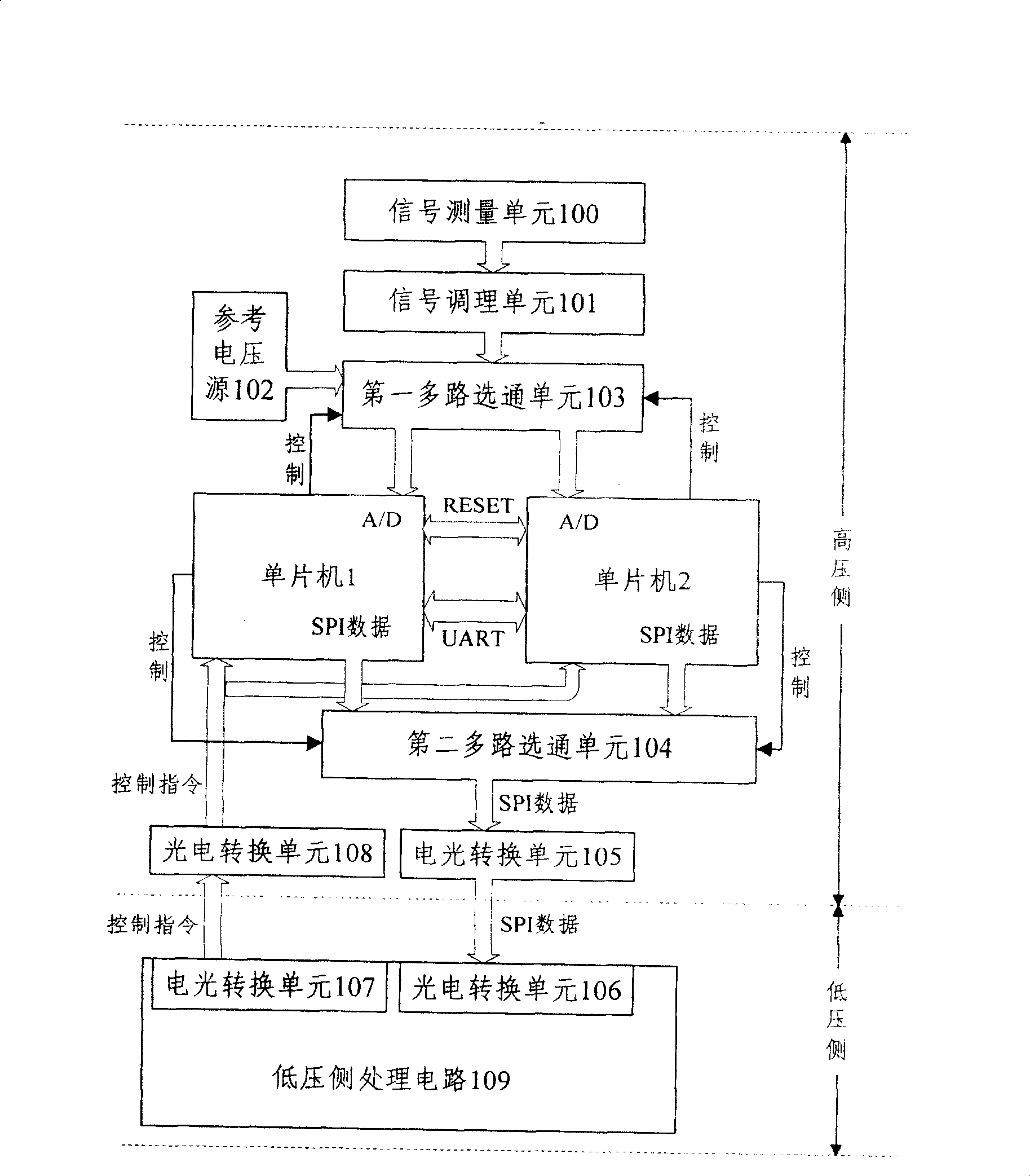

Electronic type transformer high voltage side redundant backup circuit and failure detection method

InactiveCN101126773AImprove reliabilityPrecise Fault Location InformationVoltage/current isolationFault locationTransformerLow voltage

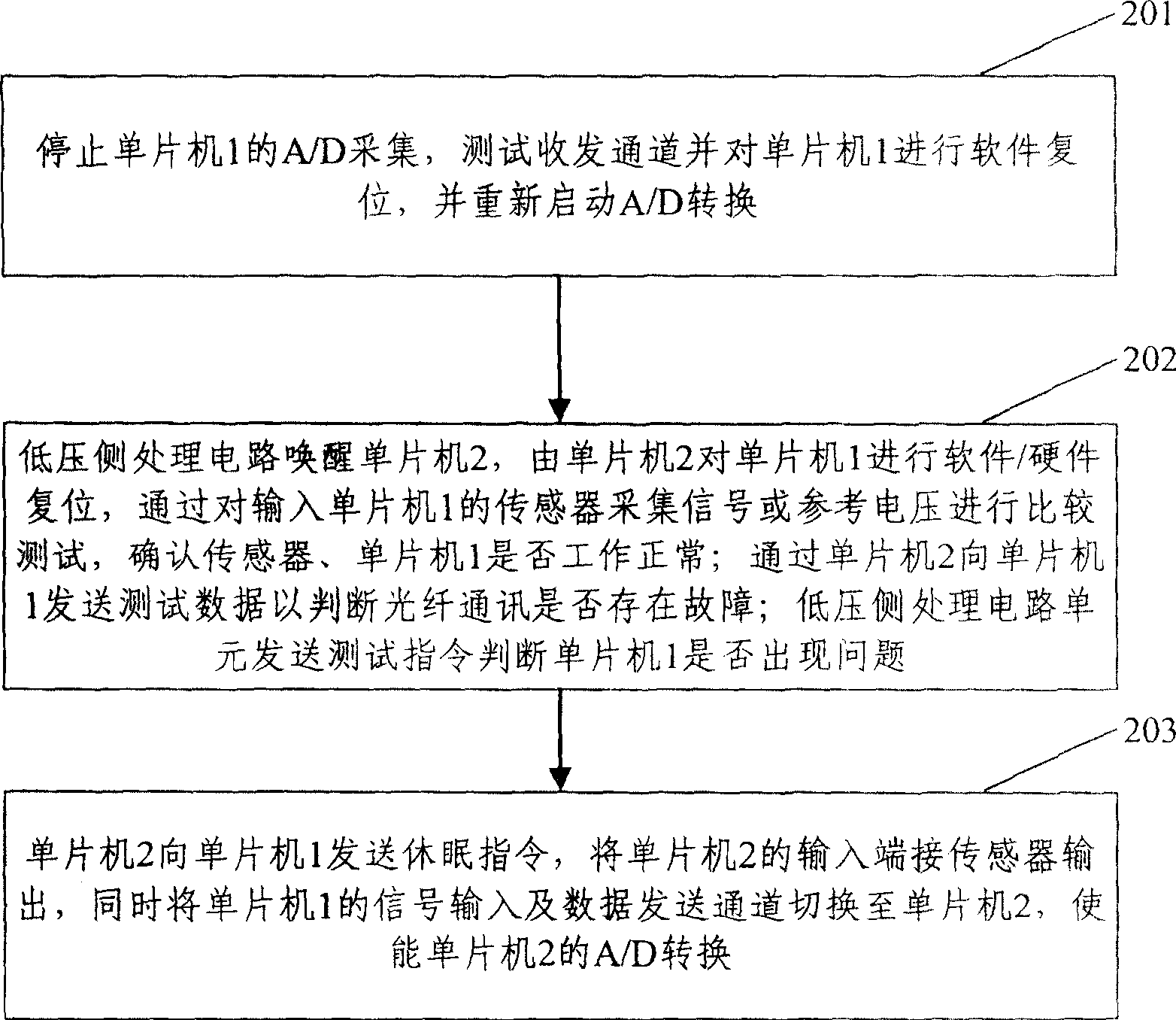

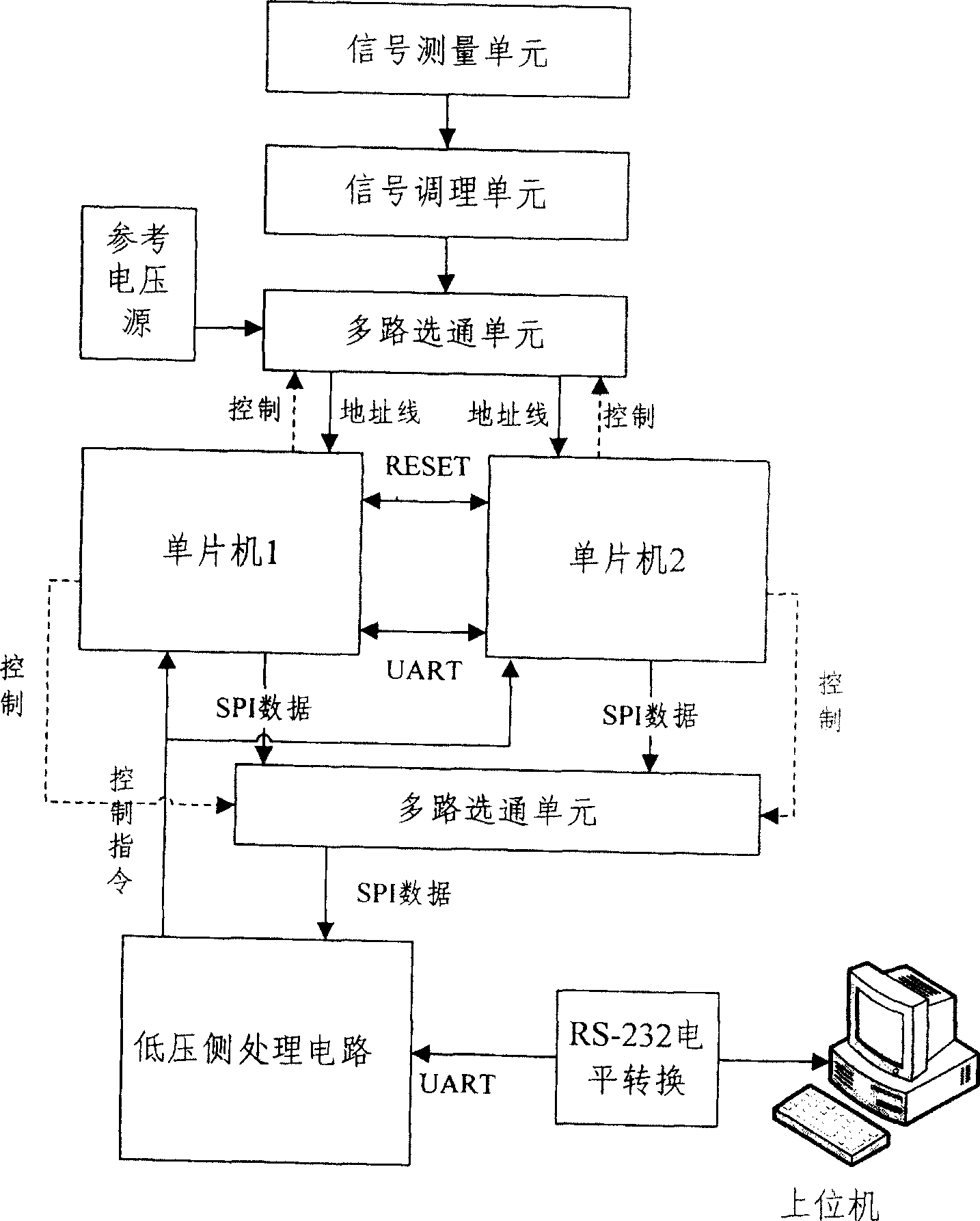

The utility model discloses a redundancy backup circuit at the high-voltage side of electronic transducer , which is characterized in that: the transducer high-voltage side circuit is added with a standby controller connected in parallel with a main controller and a corresponding multi-path gating circuit. When the transducer is in operation, the stand-by controller hibernates, and main controller completes all the functions of high-voltage side circuit. If the low-voltage side circuit judges that the high-voltage side circuit has failure possibility, the stand-by controller arranged on the high-voltage side is awakened. The stand-by controller sends a reset command to the main controller and conduct diagnostic tests over the high-voltage side circuits. If the main controller confirms the presence of faults, the current work of the main controller is switched to the stand-by controller to maintain the normal work of the transducer and overcome the transducer failure as a result of the main controller failure in high-voltage side circuit, thus improving the reliability of the transformer . The utility model also discloses a fault detection method based on the circuit for the provision of fault location information for the overhaul of transducer equipment, which facilitates the online maintenance of the equipment.

Owner:BEIHANG UNIV

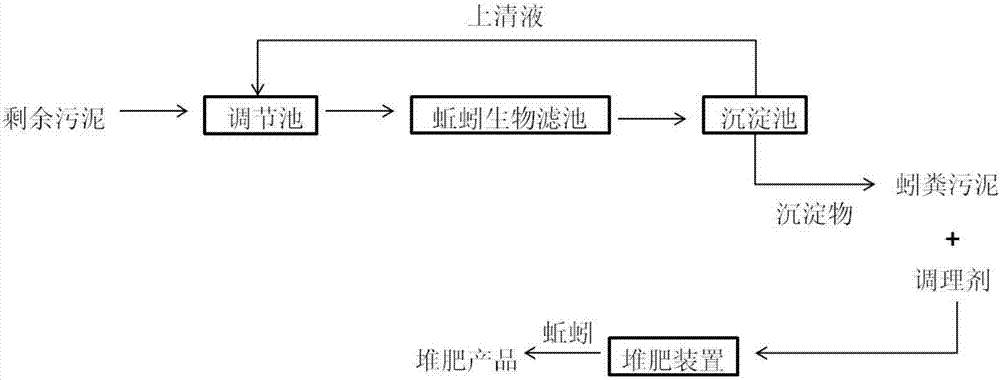

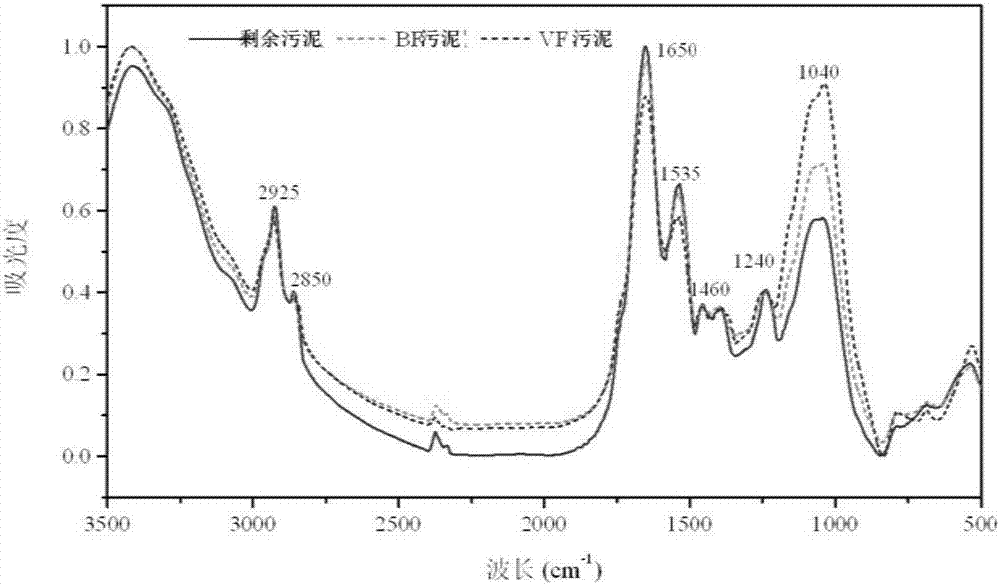

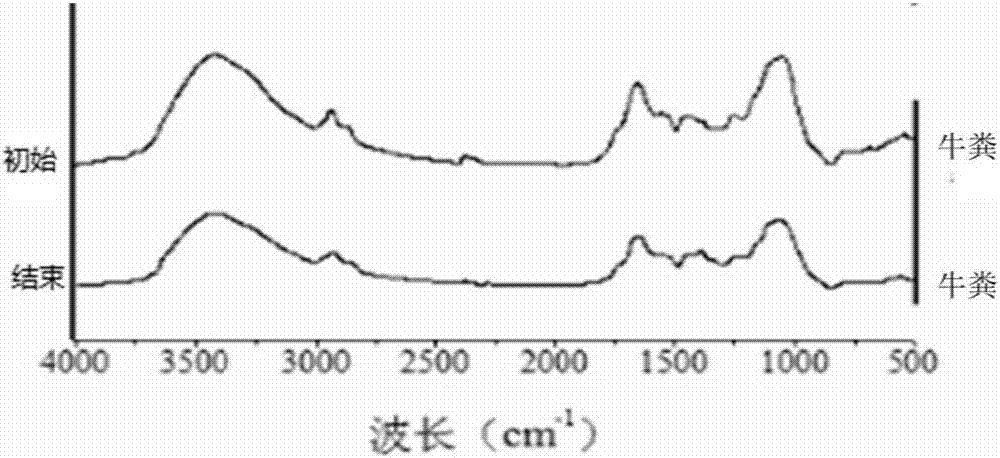

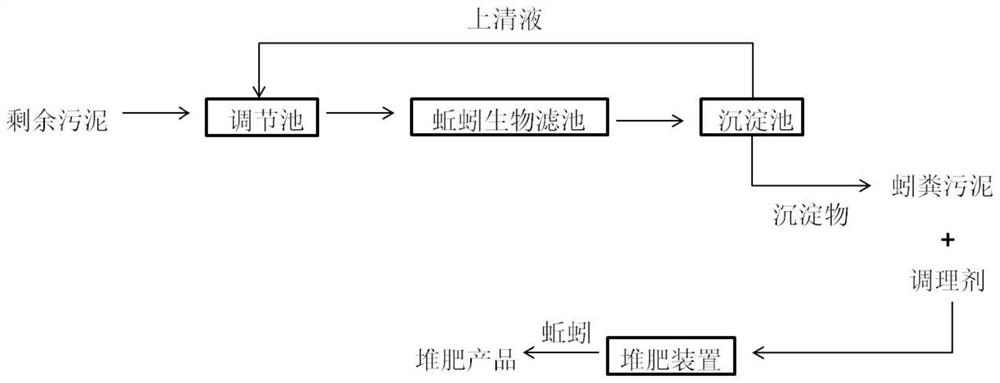

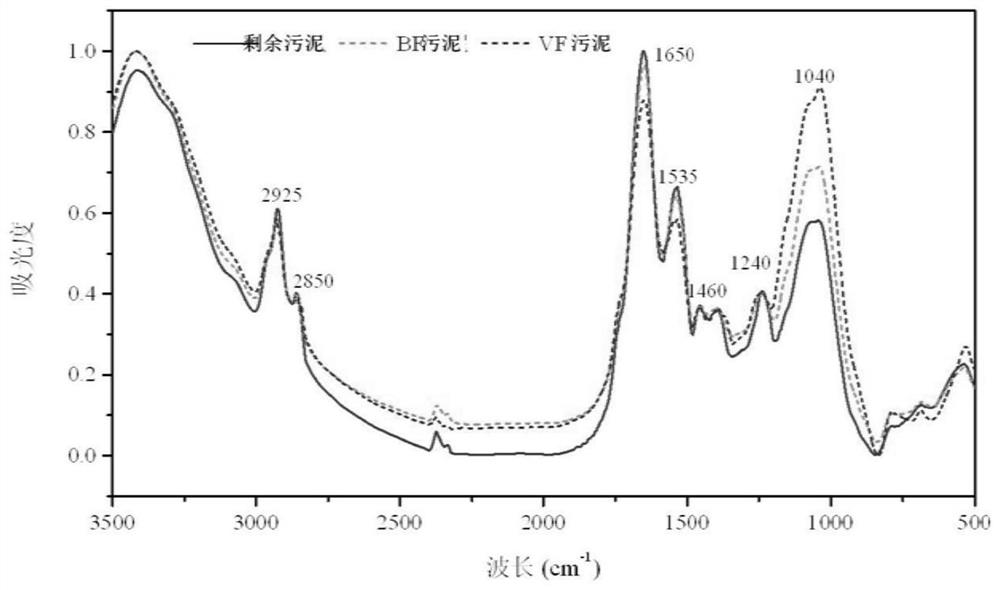

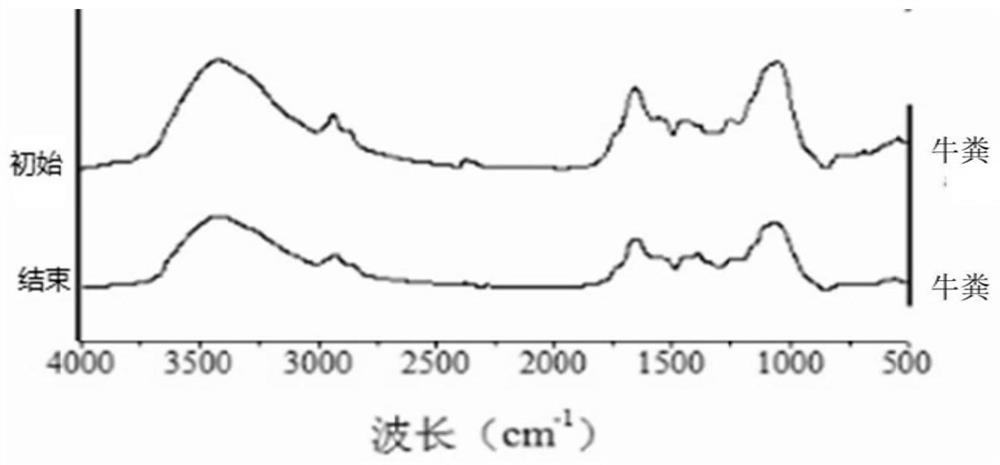

Method for treating surplus sludge, compost product and application

ActiveCN106866299AImprove the degree of humificationImprove agricultural valueSludge treatment by de-watering/drying/thickeningBio-organic fraction processingSludgeAromatization

The invention provides a method for treating surplus sludge, a compost product and application. The method for treating the surplus sludge comprises the steps that after the concentration of the surplus sludge is regulated, treatment is performed to obtain earthworm excrement sludge; the earthworm excrement sludge and a conditioner are mixed; earthworms are fed to form compost; after 56 to 63d, the compost product is obtained; the compost product is applied in an efficient agricultural fertilizer or a soil conditioner. The prepared compost product has the advantages that the humification degree of the sludge can be effectively improved; the molecular weight, the polycondensation degree and the aromatization degree of humic acid are improved, so that the sludge after earthworm composting is converted into an excellent agricultural fertilizer. In addition, the conditions required by the reaction process are simple; the reaction can be performed at normal temperature and normal pressure; the flow process is simple and convenient; the control is easy; the operation management and the equipment maintenance are convenient; the engineering cost and the operation cost are greatly reduced; natural advantages are realized on rural sludge with low treated sludge yield and wide distribution.

Owner:TONGJI UNIV

Oblique swing pressurization external circulation mill

The invention discloses an oblique swing pressurization external circulation mill. A central shaft frame is mounted at the bottom of a base of a milling main engine; milling rings are mounted at an upper part of the base; a cover barrel is mounted on the end surface of the base; a main engine feeding hole is formed in an upper cover of the cover barrel; a main engine discharging hole is formed in the bottom of the base near the central shaft frame and communicated with an external grading system through a pipeline; a lower part of a main-engine main shaft is arranged on the central shaft frame; a fixed roller frame connected with a material scraping frame is mounted at an upper end of the main-engine main shaft; the central shaft frame is sleeved with the material scraping frame; material scraping plates are mounted on the material scraping frame; milling roller devices are uniformly distributed around the circumference of the main-engine main shaft; each milling roller device comprises a milling roller sleeve, a milling roller and a milling roller shaft; the milling roller sleeves are obliquely hung on the fixed roller frame; the milling rollers obliquely lean on the milling rings; a material equalizing plate synchronously rotating and provided with a baffle edge is arranged above the fixed roller frame; a pressurization mechanism acting on the milling roller devices is arranged on the fixed roller frame. According to the mill, a finished product is separated by adopting external circulation, so that equipment is convenient to repair; a shovel blade mechanism is not arranged, so that the power consumption is reduced and the total power loss of the milling main engine is reduced.

Owner:吴斌

External-circulating ball roller way-type mill

The invention discloses an external-circulating ball roller way-type mill. A central axis frame is mounted at the bottom of a base of a main machine; a milling ring is mounted at the upper part of the base; a hood cylinder is mounted on the end surface of the base; the lower part of a main shaft of the main machine is mounted inside the central axis frame; a milling roller device is arranged on the upper part of the main shaft of the main machine; the milling roller device comprises a roller dialing frame, and ball rollers which are uniformly distributed in the circumferential direction; the milling surface of the milling ring is a 1 / 4 circular surface; the roller dialing frame is coaxially and fixedly connected with the main shaft of the main machine; roller dialing blocks are uniformly mounted on the roller dialing frame in the circumferential direction; the roller dialing blocks clamp the back sides of the ball rollers; clamping surfaces of the roller dialing blocks are inwardly-concave spherical surfaces matched with the ball rollers; a discharge opening of the milling main machine is formed in the bottom of the base; scraping plates are arranged at the bottom of the base and are uniformly mounted on a scraping frame in the circumferential direction; the discharge opening is communicated with an external grading system through a pipeline. The external-circulating ball roller way-type mill adopts the ball rollers and the milling roller device, so that the external-circulating ball roller way-type mill is single in structure, low in cost, easy to repair and short in replacement and maintenance; a throwing operation of a shovel as well as the heavy milling roller device are avoided, so that the loss of total power is greatly reduced.

Owner:GUILIN SHENGXING MACHINERY MFG

High-efficiency screening type large-scale double-toothed roller crusher with self-contained material distribution device

Owner:HENAN ZHENYUAN TECH

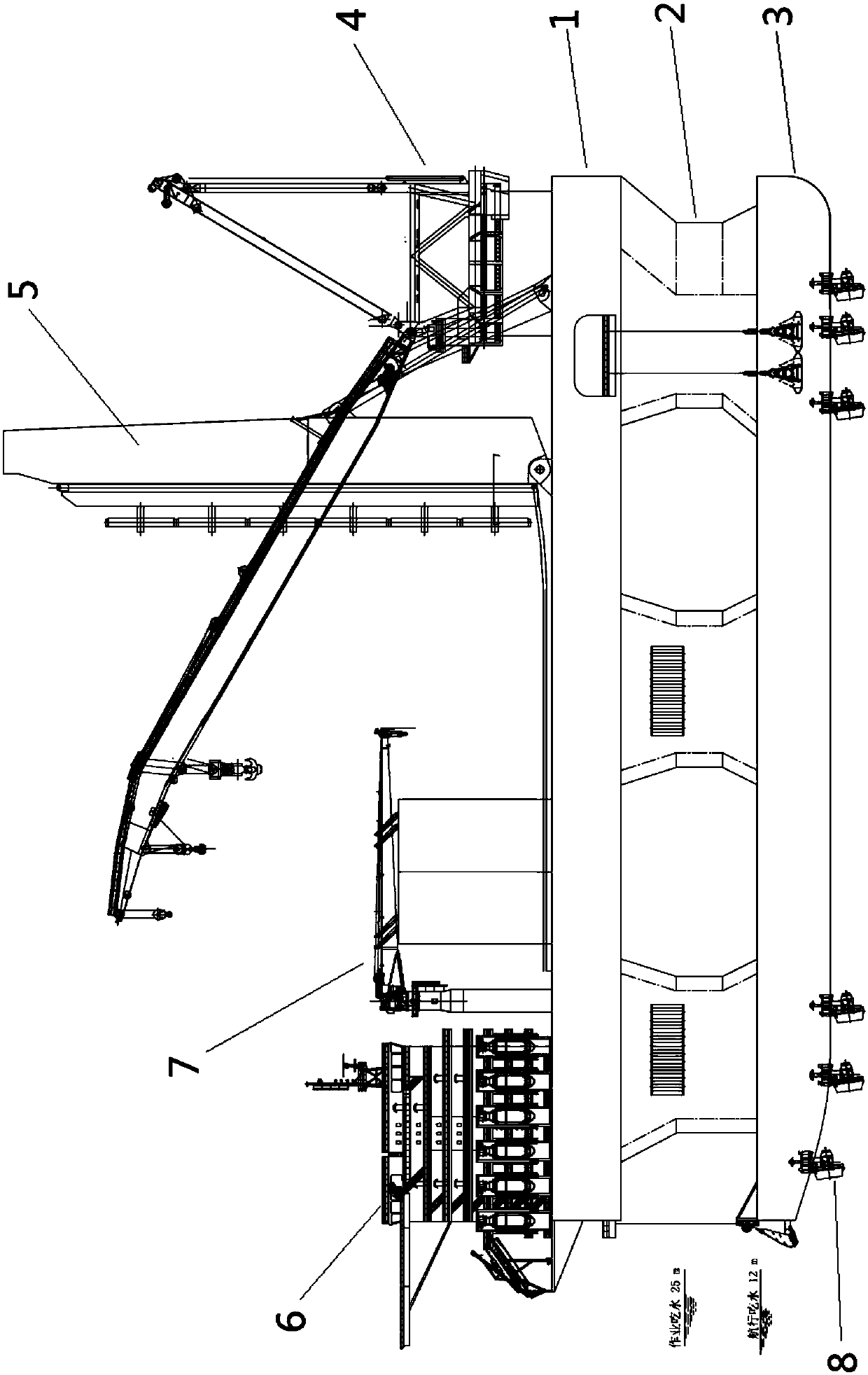

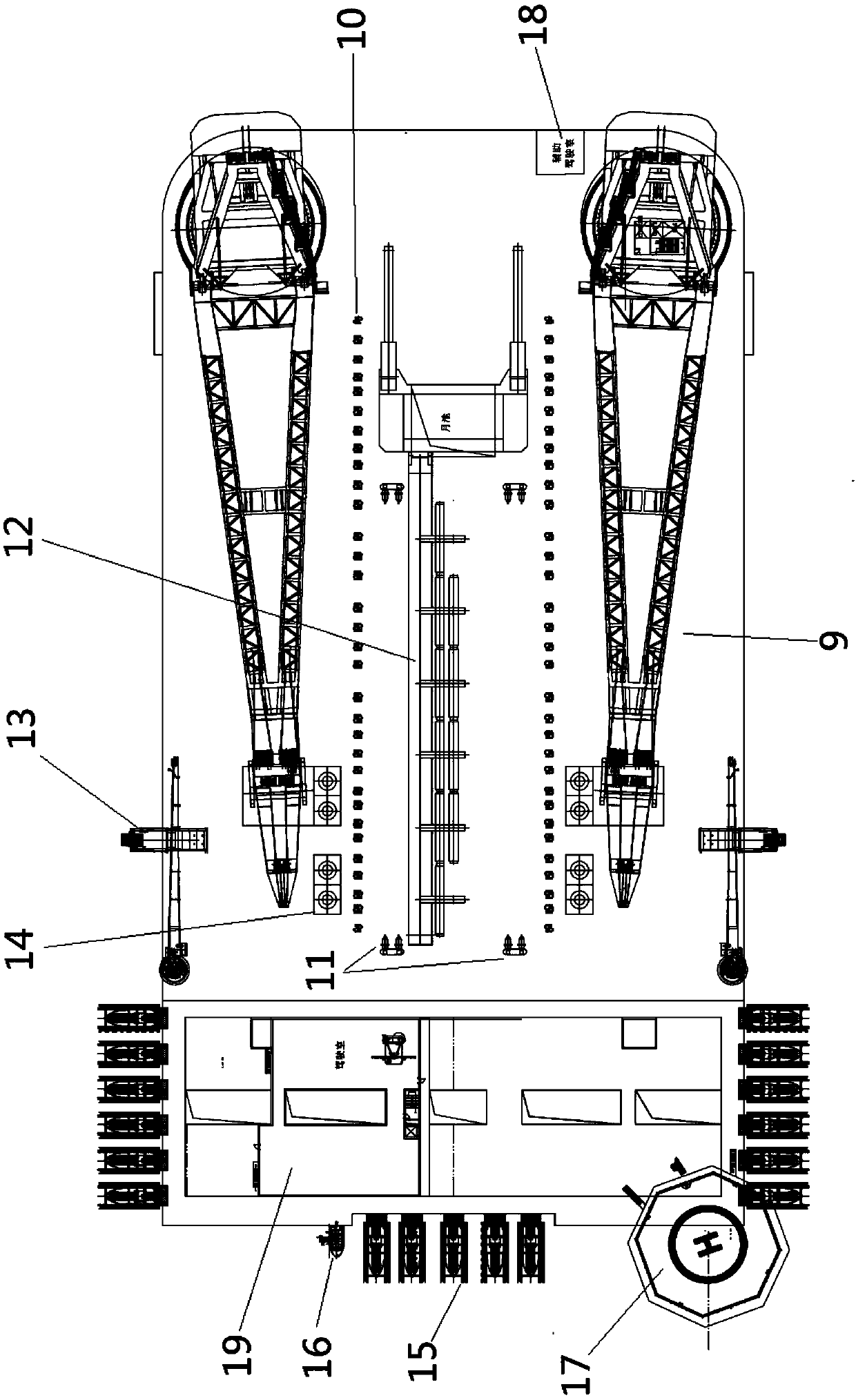

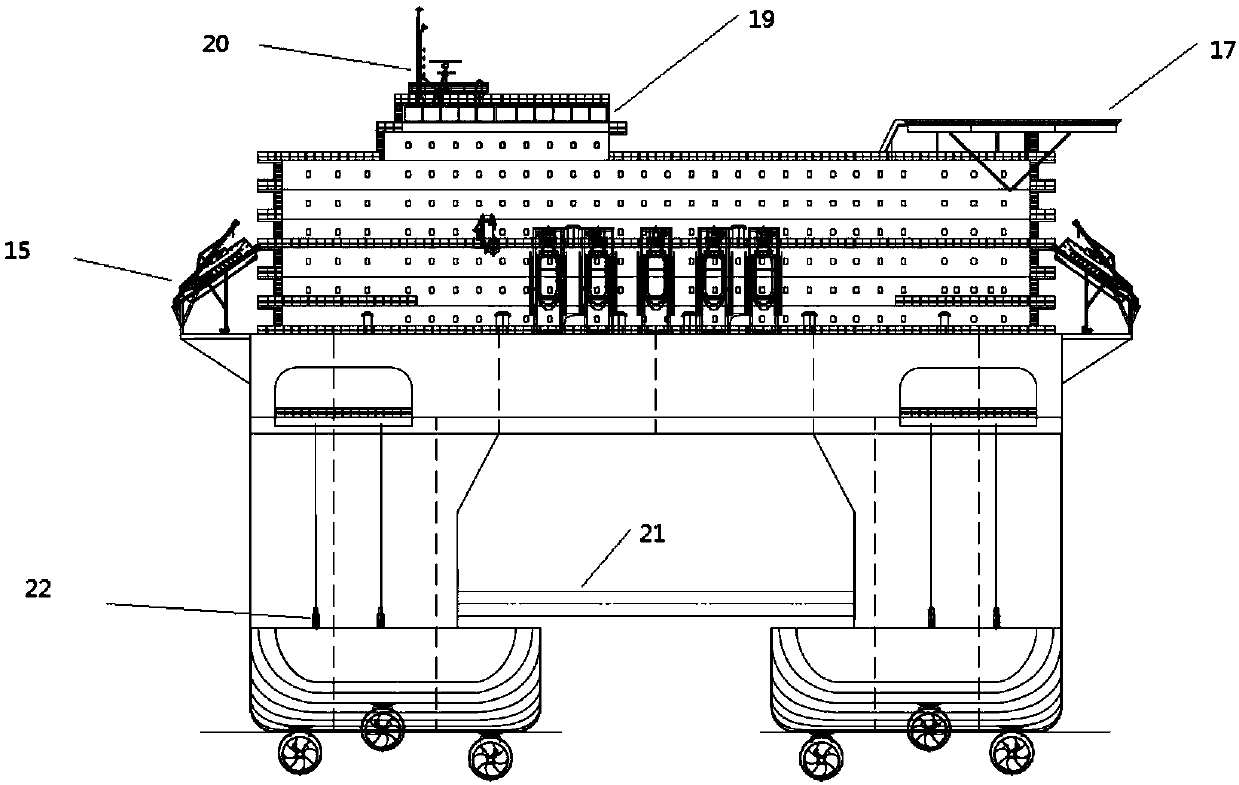

Improved deep-water semi-submersible laying pipe floating crane

InactiveCN107618626AAdd variable loadConvenient sourceHull decksPipe-laying vesselsMarine engineeringTower

The invention provides an improved deep-water semi-submersible laying pipe floating crane. A main floating ship body is composed of an upper floating body, a lower floating body and a plurality of stand columns which are arranged between the lower floating body and the upper floating body; the floating crane is characterized in that two main cranes are arranged on a main deck of the fore body of the upper floating body, a living building is arranged on the stern portion of the upper floating body, a J-shaped laying pipe tower is arranged in the middle of the portion, close to the fore body, ofthe upper floating body, and an auxiliary cab is arranged in the middle of the fore body of the upper floating body; the variable load of a deck of the sailing working condition can be effectively improved; the lifting operation and the pipe laying operation do not intervene manually; when the sailing working condition of a ship is converted into the operation working condition, the position change of the buoyant center is small, the adjustment requirement of ballast water is relatively reduced, and accordingly load adjustment is conducted more conveniently; a same type is adopted for all thrusters, so that the floating crane is easy and convenient to operate; spare parts are purchased more conveniently, and the device is maintained more conveniently.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Low-voltage motor restarting device

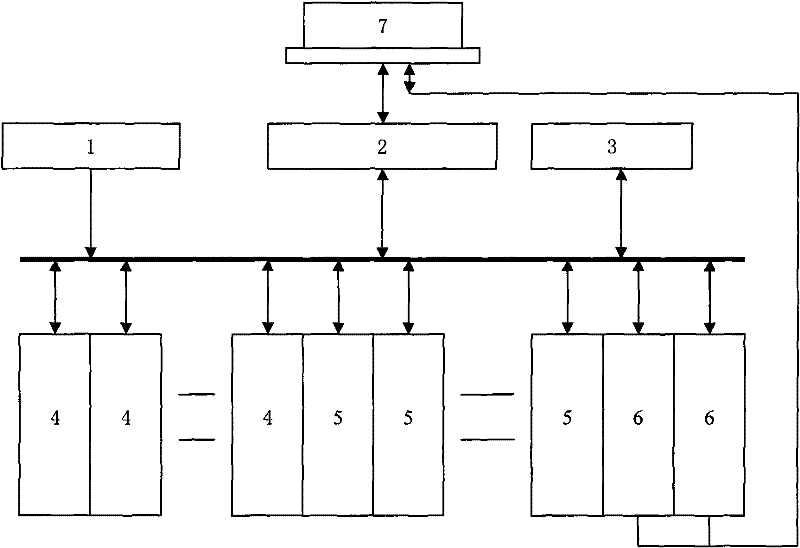

InactiveCN102237835APerfect electrical and safety isolationEasy maintenance of equipmentMultiple dynamo-motor startersModularityData transmission

The invention discloses a low-voltage motor restarting device, which comprises a master central processing unit (CPU) control unit, a power unit, analogue quantity units, input units, output units and a display unit. Each unit adopts a modular design and independent detection and control ways. The power unit is connected with the other units, and supplies working power to the other units. A low-voltage motor restarting function and data transmission among the master CPU control unit, the analogue quantity units, the input units, the output units and the display unit are realized by a controller area network (CAN) bus. The device has the characteristics of high reliability, high real-time performance, wide application range, low cost and flexibility and convenience of operation and maintenance.

Owner:SHANGHAI HUAJIAN ELECTRICAL EQUIP

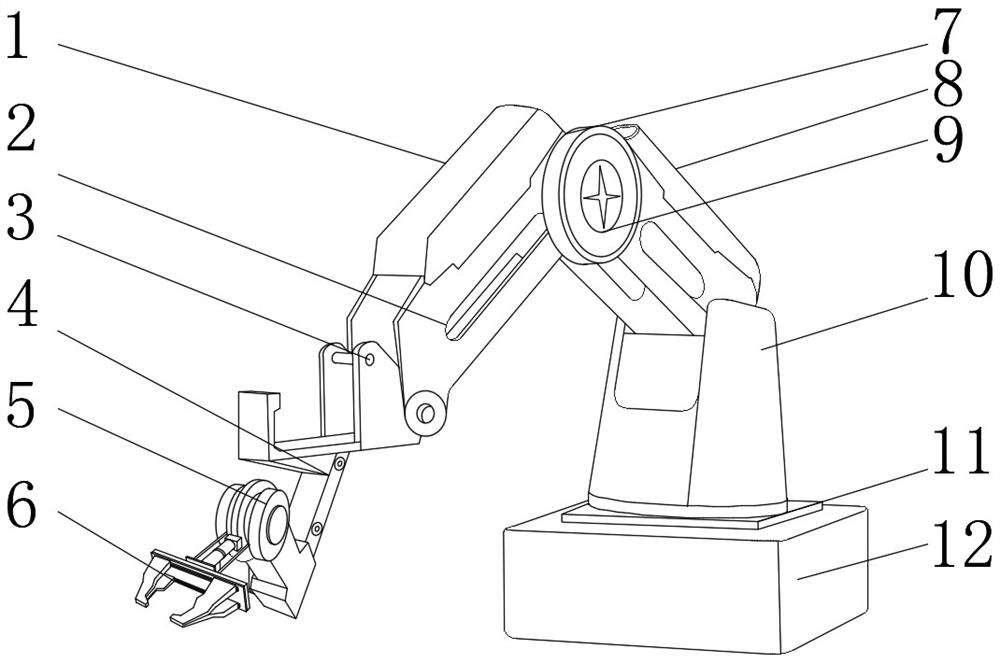

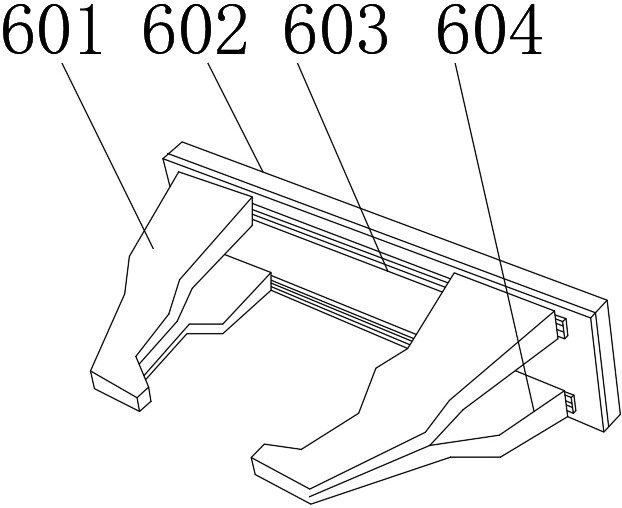

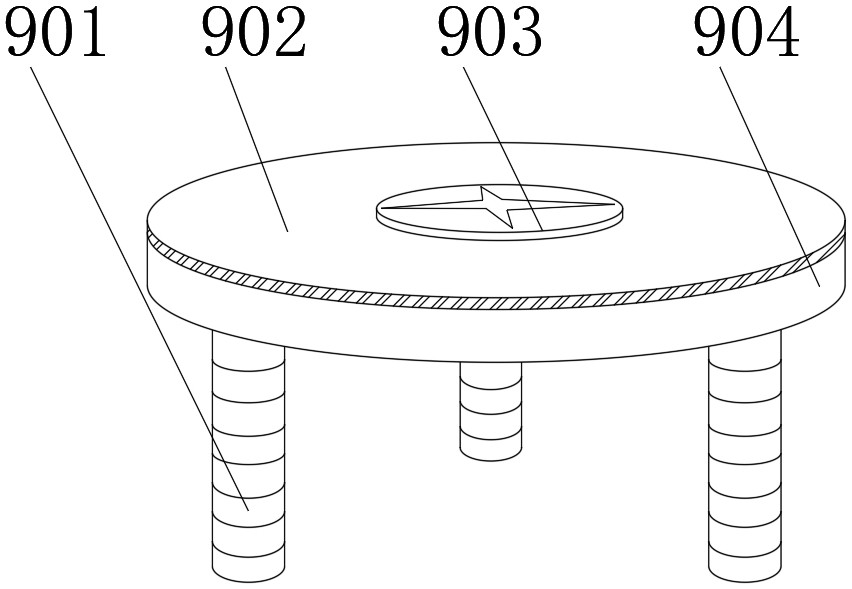

Industrial robot for positioning and mounting based on industrial production

PendingCN113043254AInstalled and disassembledEasy to disassembleProgramme-controlled manipulatorGripping headsEconomic benefitsIndustrial robotics

The invention discloses an industrial robot for positioning and mounting based on industrial production. The industrial robot comprises a protective shell, wherein an arm is arranged on the outer surface of one side of the protective shell, and a linkage shaft is arranged on the outer surface of one side of the arm. During positioning and mounting, equipment fixing base facilitates position fixing, a sliding rail dismounting device at the upper end can facilitate positioning and mounting, dismounting is convenient, dismounting and mounting are convenient, a fixed rotating device at the upper end can improve the positioning and mounting efficiency, operation is more convenient, the whole equipment device can be installed to the maximum extent only by controlling and mounting one part, the positioning and mounting time is shortened, certain economic benefits are achieved, the arm can be operated stably, the linkage shaft at the lower end is convenient to rotate, the position is controlled through the control rod, the rotating shaft on one side can rotate for operation, a gripper sliding buckle device at the front end can achieve the effect of convenient mounting during positioning and mounting, the mounting time is shortened, mounting and disassembly are convenient and fast, practicability is achieved, and operation is convenient.

Owner:宁波市健洋机器人有限公司

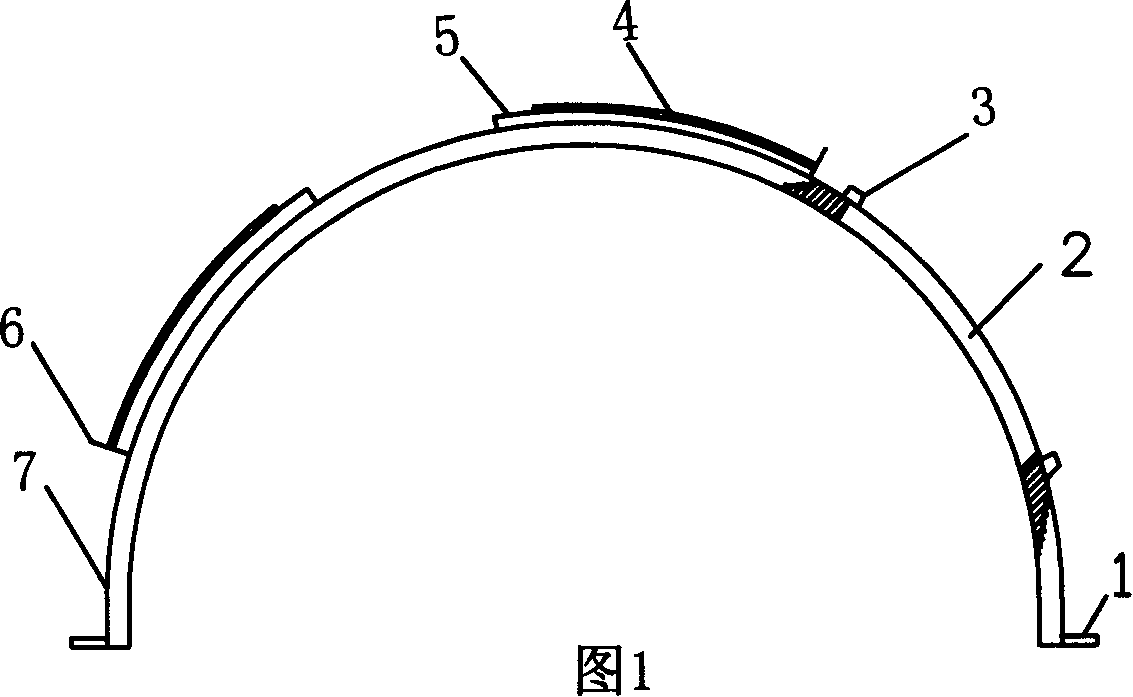

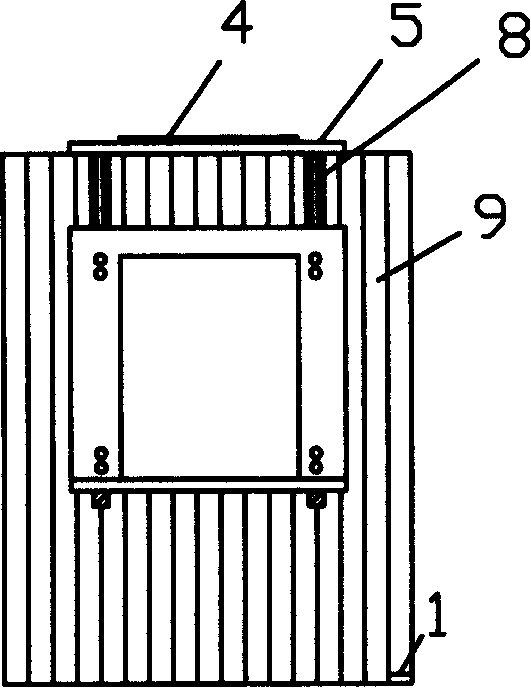

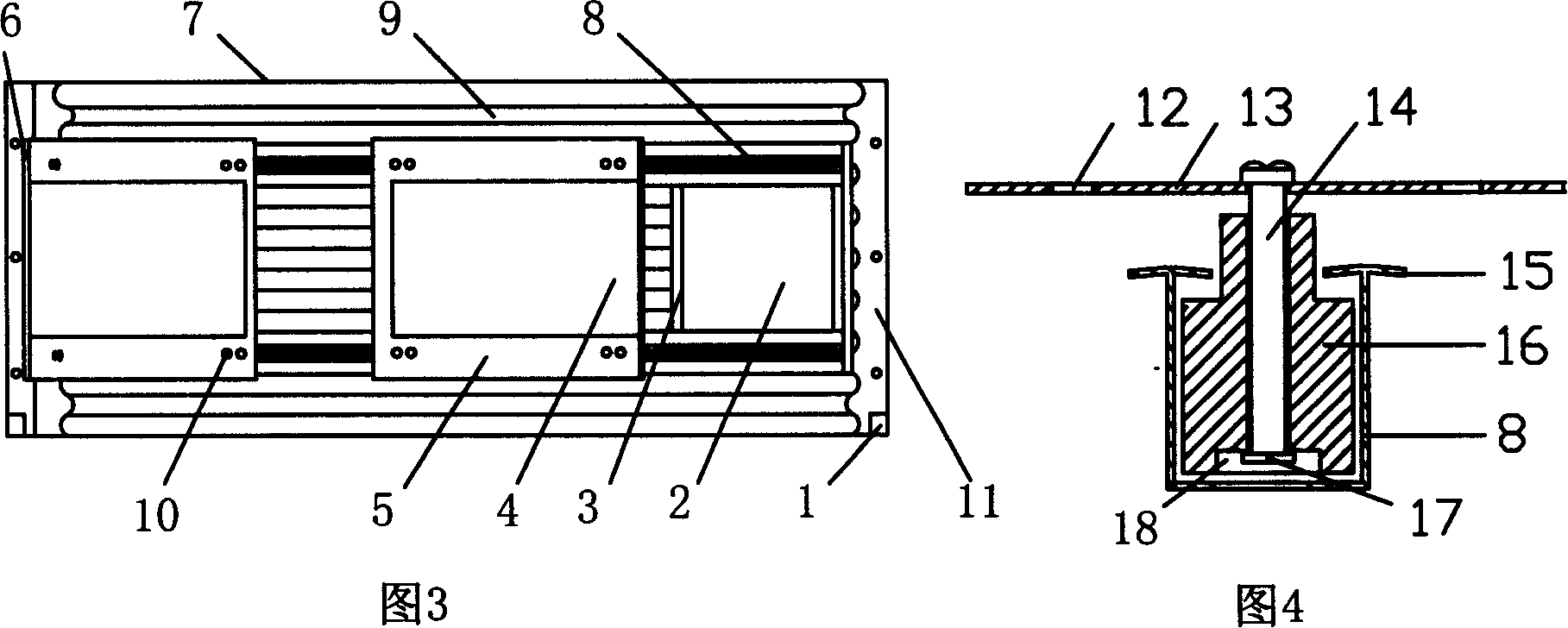

Flame-retardant arch transparent tile and its use

InactiveCN1474011AThere will be no observation flip phenomenonObserve flip phenomenonConveyorsRoof covering using tiles/slatesEngineeringPulley

The present invention includes arched flame-retardant transparent tile and arched flame-retardant nontransparent tile. The arched flame-retardant transparent tile has several sluices, two slideways,observing window and observing window cover connected via slide roller to the slideway and stoppers on two ends of the observing window and perpendicular to the sluice. Several pieces of arched flame-retardant transparent tile and arched flame-retardant nontransparent tile may be connected serially to form protecting hood for transporting conveyer belt or long corridor.

Owner:武钢北湖福利加工厂

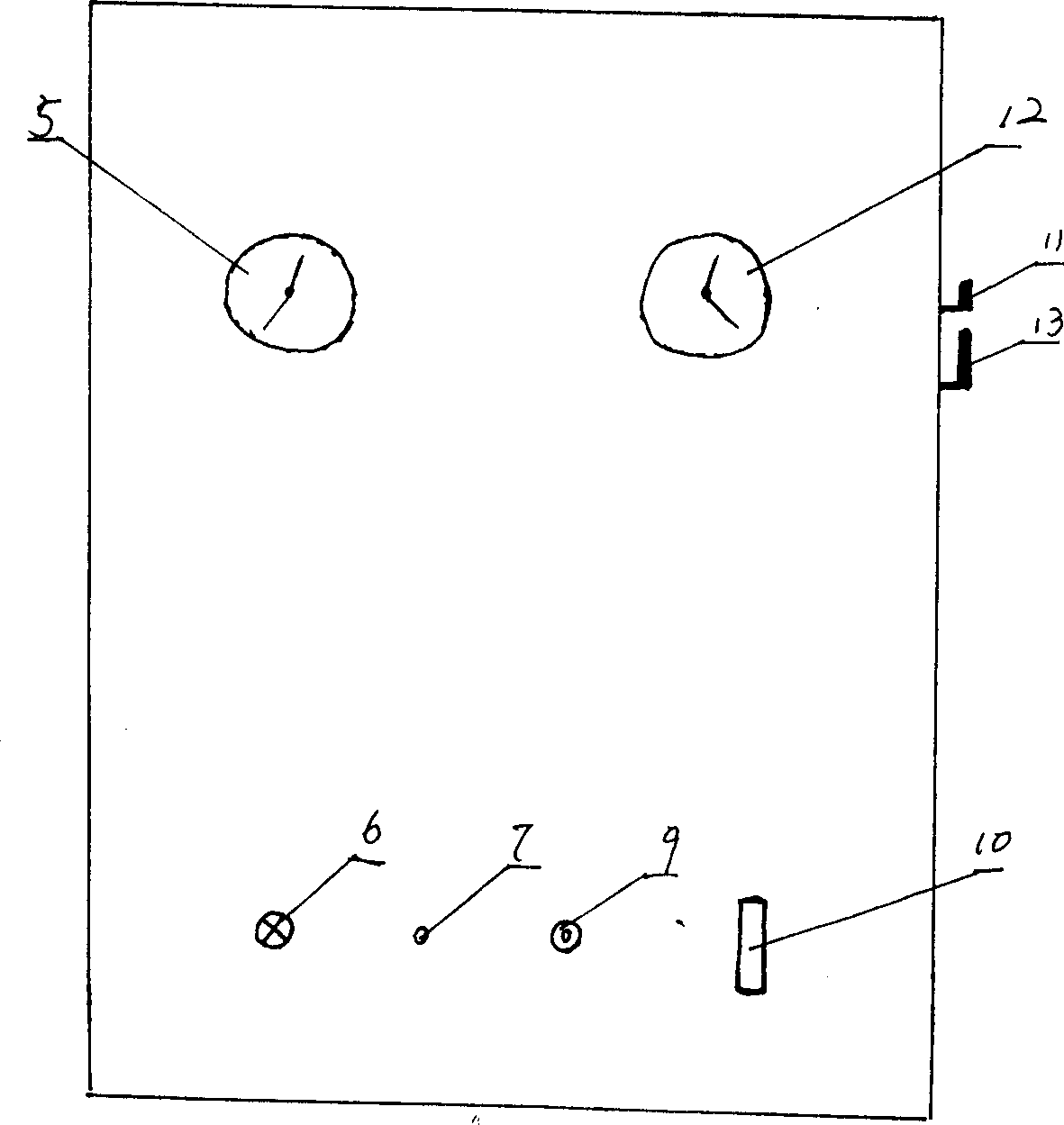

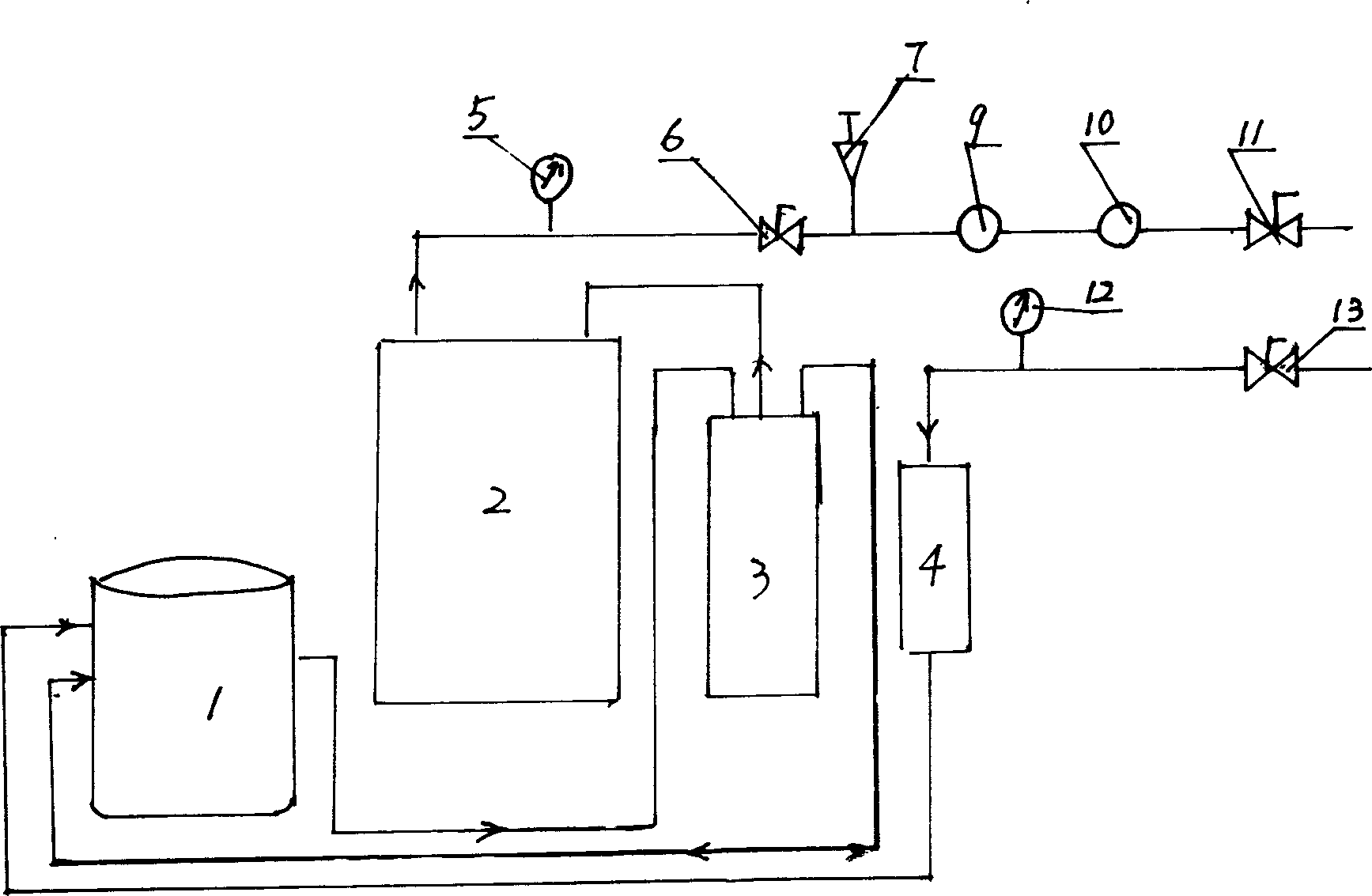

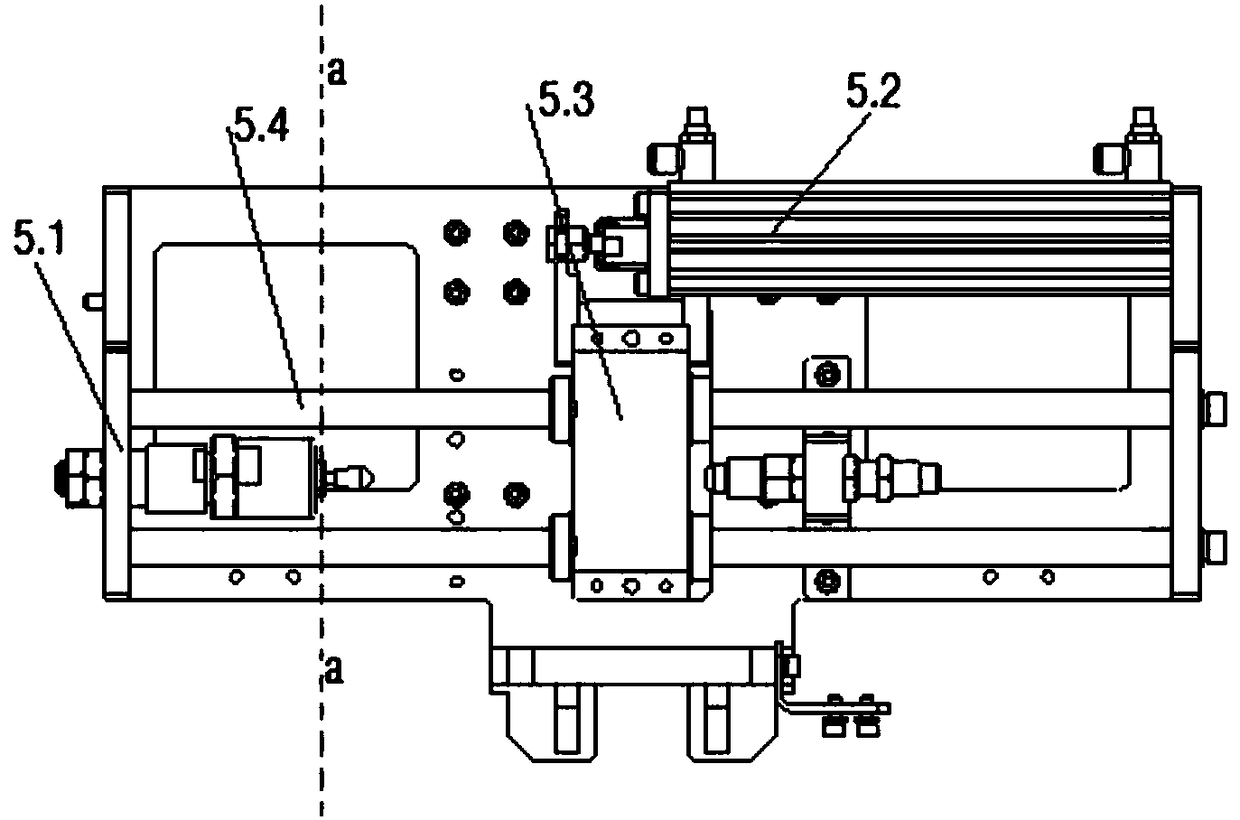

Digital type refrigerant quantitative charging-discharging machine

InactiveCN1479062AQuick debuggingEasy maintenance of equipmentRefrigeration componentsRefrigerantRefrigerated temperature

A digital quantitative refrigerant pumping-out and filling-in machine for manufacturing and repouring the refrigerator is composed of casing, air pumping-out and filling-in unit, and quantitative liquid pumping-out and filling-in unit. Its advantages is high precision, small size and light weight.

Owner:刘志刚

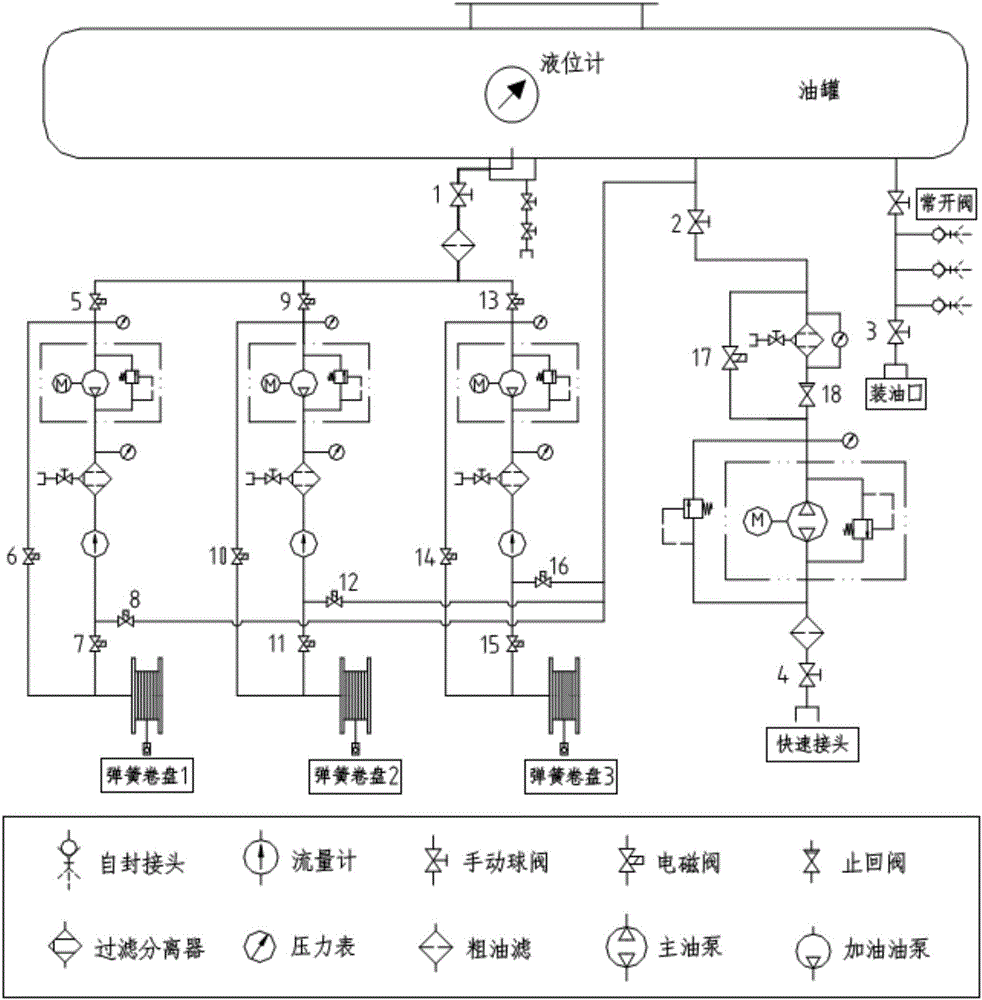

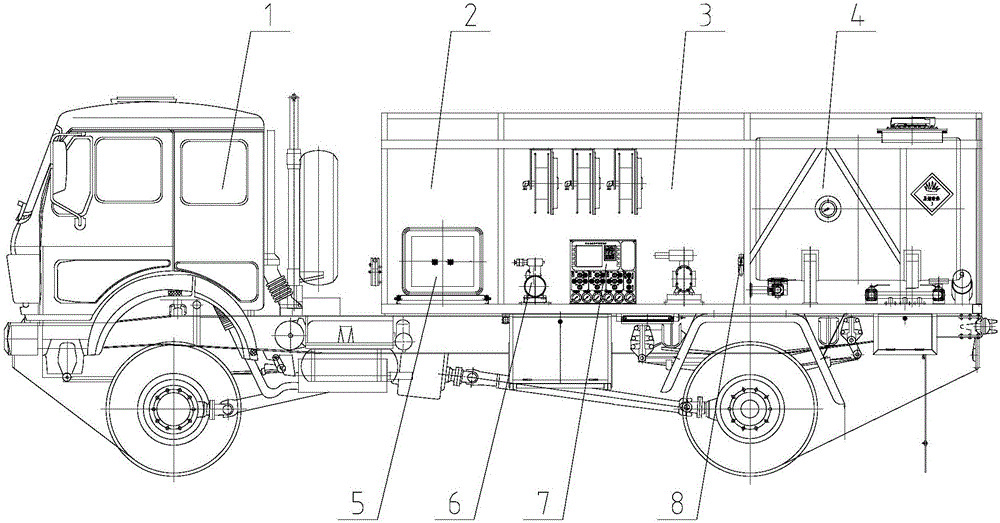

Unmanned plane fueling vehicle and working method thereof

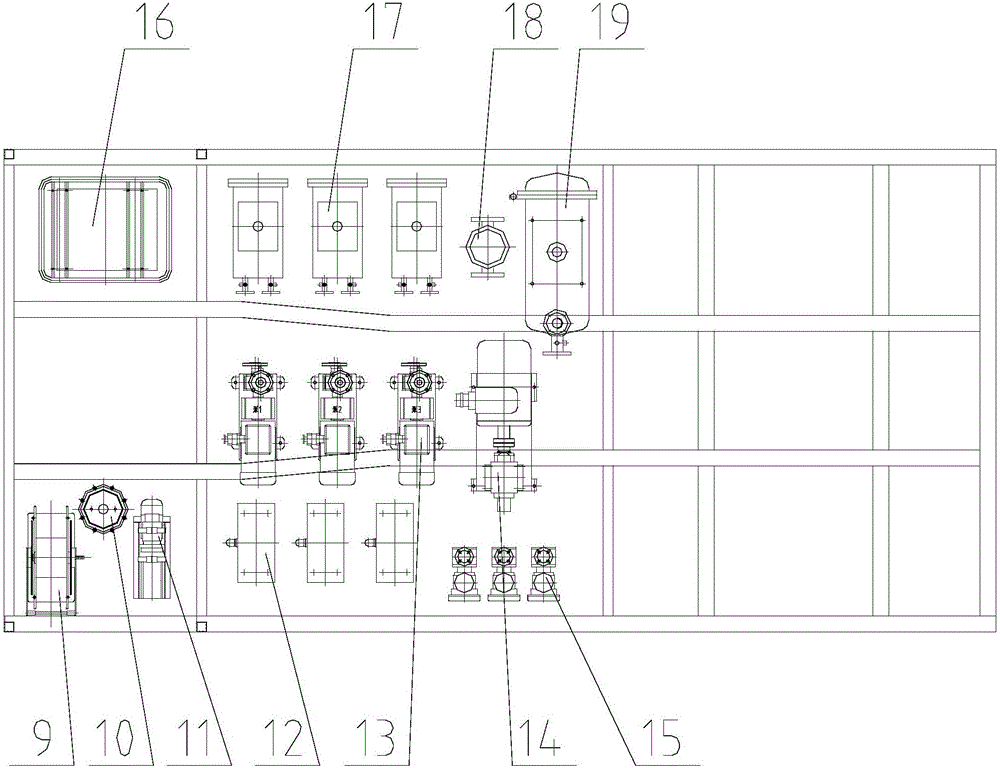

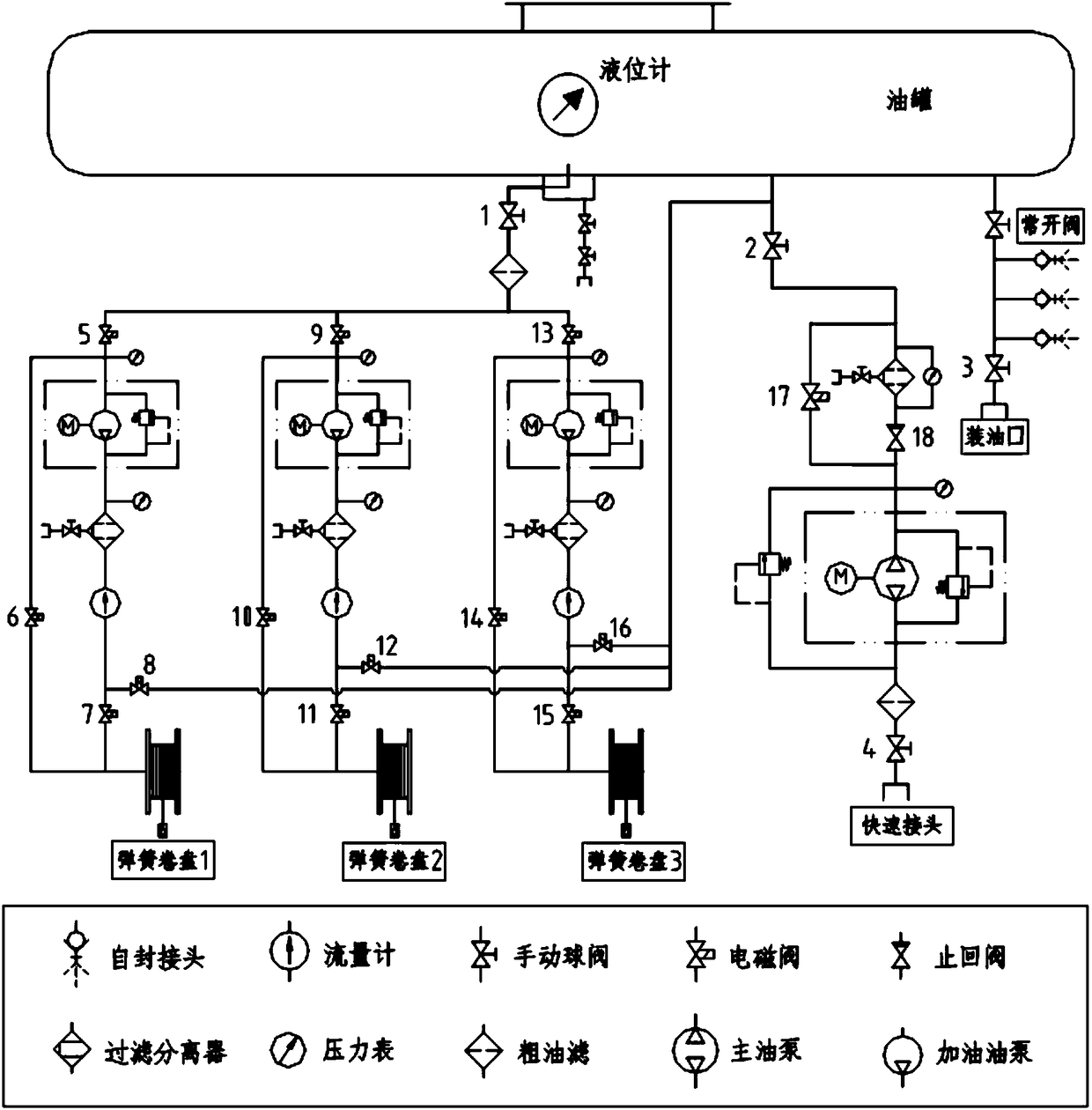

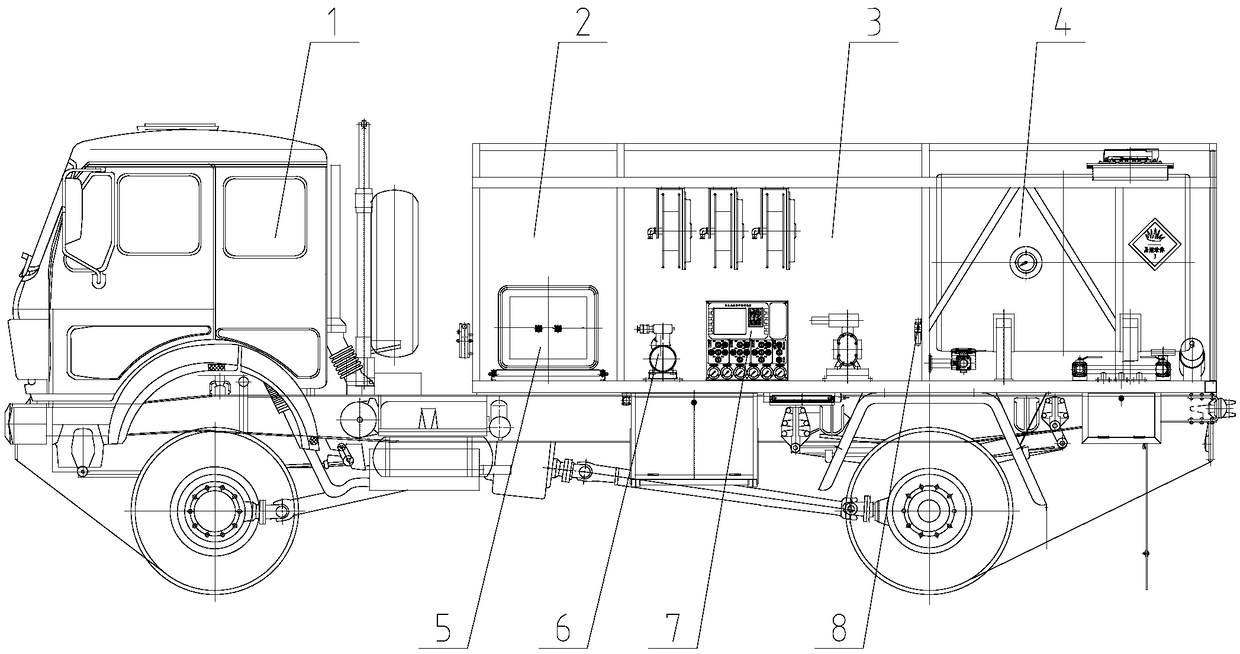

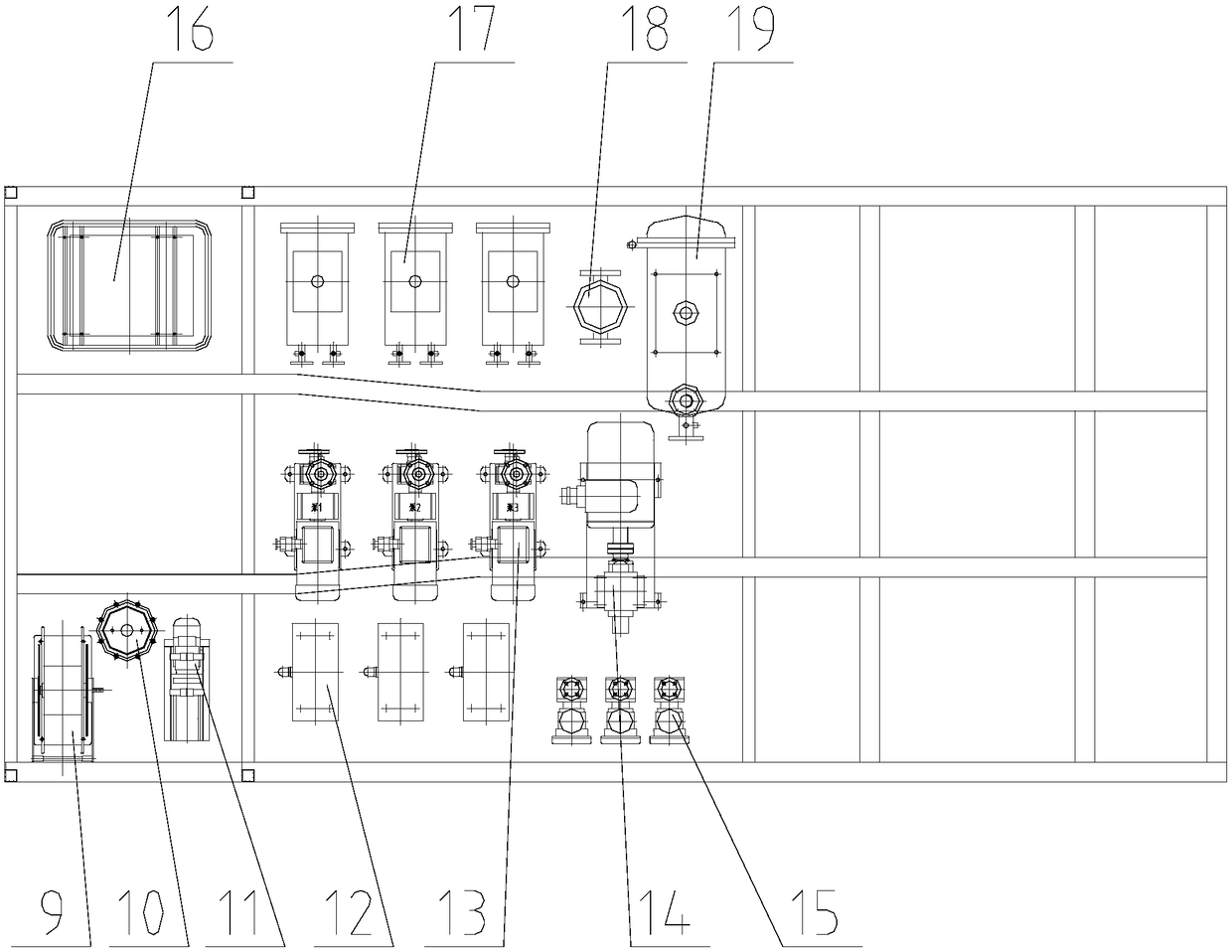

ActiveCN106364692AReduce volatilitySolve the problem that the oil pumping is difficult and cannot reach the vacuum stateLiquid handling installationsTank vehiclesPowertrainElectromagnetic valve

The invention discloses an unmanned plane fueling vehicle and a working method thereof. The unmanned plane fueling vehicle comprises a vehicle body. An accessory bin, an operation bin and an oil tank assembly are arranged on a chassis of the vehicle body. A power assembly is arranged in the accessory bin. An oil circuit system, an electric system and a gas circuit system are arranged in the operation bin. The oil circuit system comprises three sets of fueling circuits and a main oil circuit. Each fueling circuit comprises a first manual ball valve connected with an oil tank. Each first manual ball valve is connected with a coarse filter. The coarse filter is connected with a first electromagnetic valve, a fifth electromagnetic valve and a ninth electromagnetic valve. According to the unmanned plane fueling vehicle and the working method thereof, functions and technologies are advanced, operation is easy, performance is reliable, a soft oil bag can be effectively protected in oil fueling and pumping processes, and the situations that the oil bag is damaged during fueling, or oil in the oil bag cannot be pumped completely during oil pumping, and consequently the service life of the oil bag is shortened are avoided. The unmanned plane fueling vehicle can also be applied to other fields that fuel is stored in soft oil bags and safety requirements are extremely high.

Owner:AEROSUN CORP

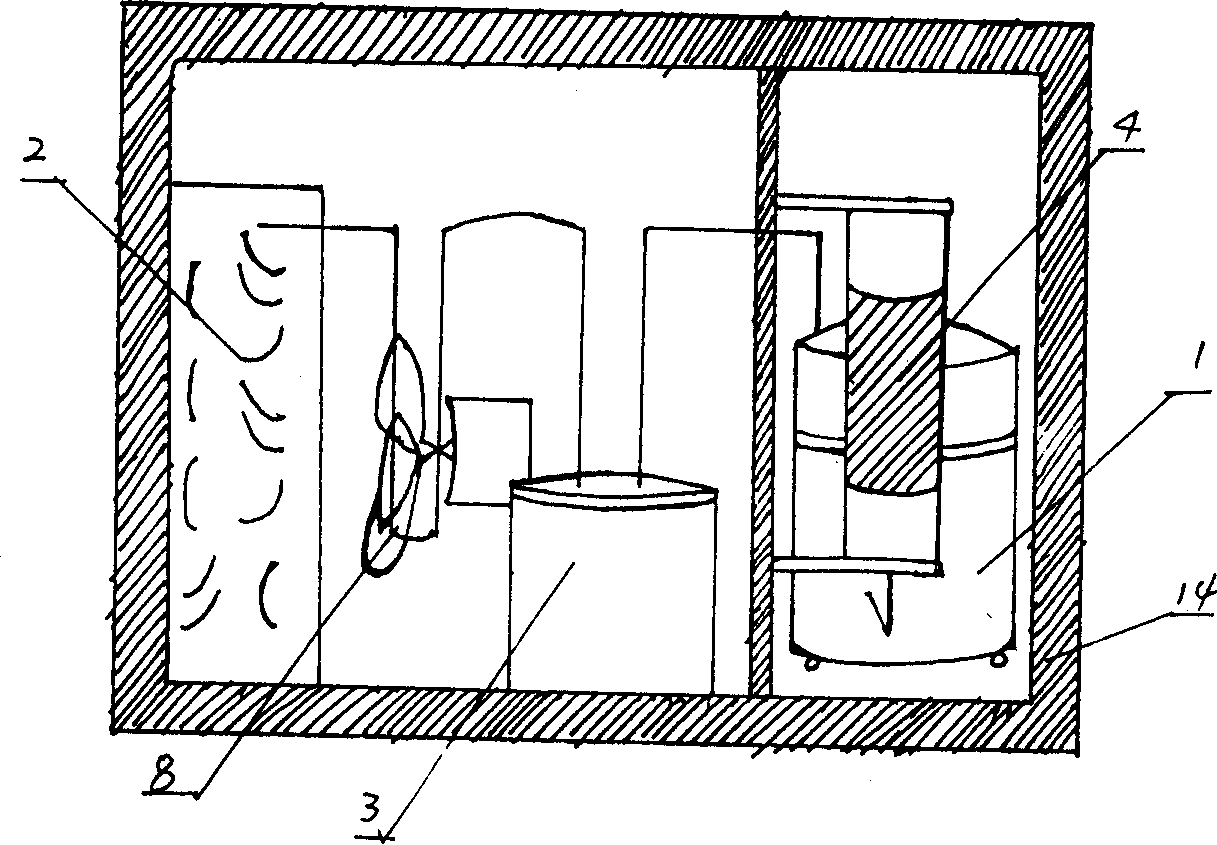

Constant-temperature anaerobic/aerobic fermentation tank for treating rotten vegetable leaves

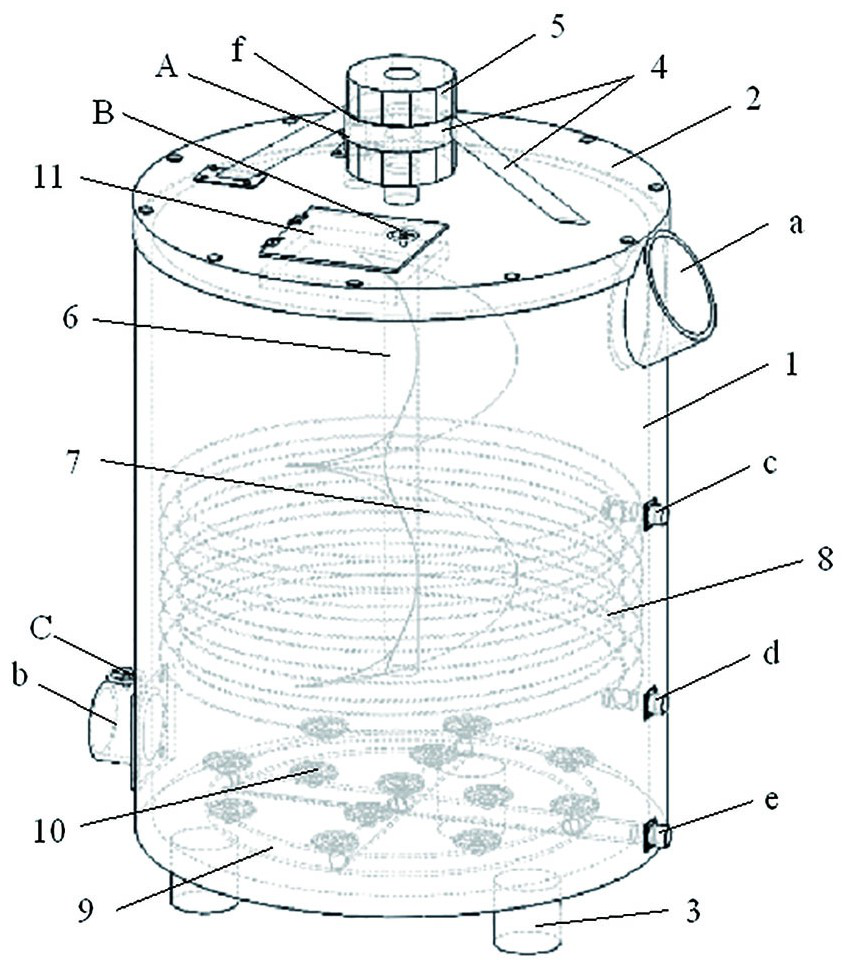

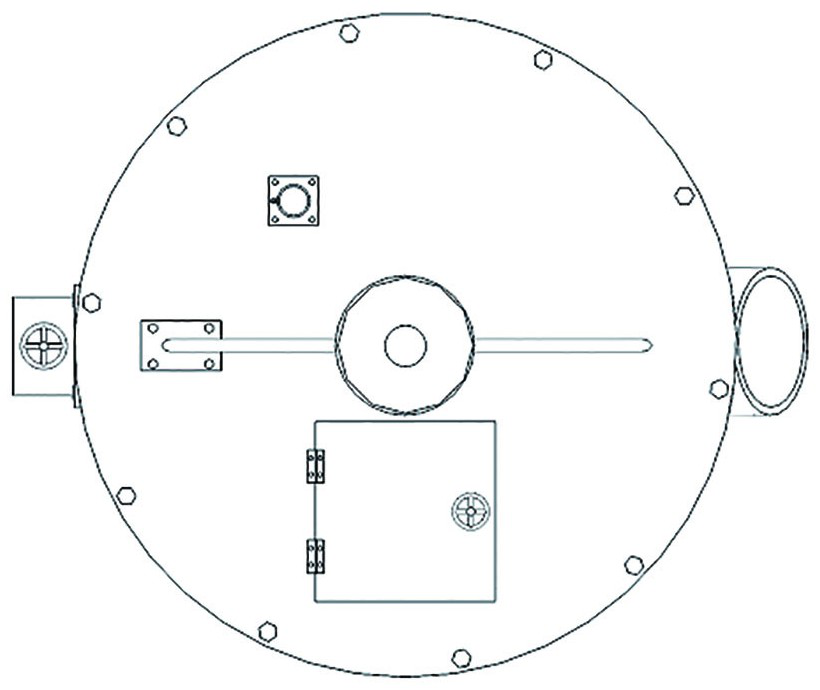

PendingCN114672401ATank structure is simpleCompact distributionBioreactor/fermenter combinationsBiological substance pretreatmentsBiogasBiology

A constant-temperature anaerobic / aerobic fermentation tank for treating rotten vegetable leaves aims to effectively maintain the optimal fermentation temperature and realize switching of anaerobic / aerobic environments, a feed port is formed in the top of the fermentation tank body, a discharge port is formed in the bottom of the fermentation tank body, and a gate valve is mounted at the discharge port; a heat-insulating coil is mounted on the inner wall surface of the tank body; a water inlet and a water outlet are formed in the outer side of the fermentation tank body; an aeration pipeline is mounted at the lower end in the tank body, an aerator is mounted above the aeration pipeline, and an air inlet is formed in the outer side of the tank body; supporting legs are mounted at the bottom end of the tank body; a tank cover is mounted at the top end of the tank body, a sampling port is reserved in the tank cover, and a sealing gate is mounted at the sampling port; the tank cover is provided with a biogas outlet which is provided with a stop valve; a support is installed on the tank cover, a motor is fixed in the support and connected with a paddle column entering the tank body, and rotating paddles are installed on the surface of the paddle column. The device is compact in structure and simple to use, anaerobic and aerobic reactions can be carried out on the rotten vegetable leaves in a single tank, the occupied area of equipment can be effectively reduced, and the initial investment is reduced.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

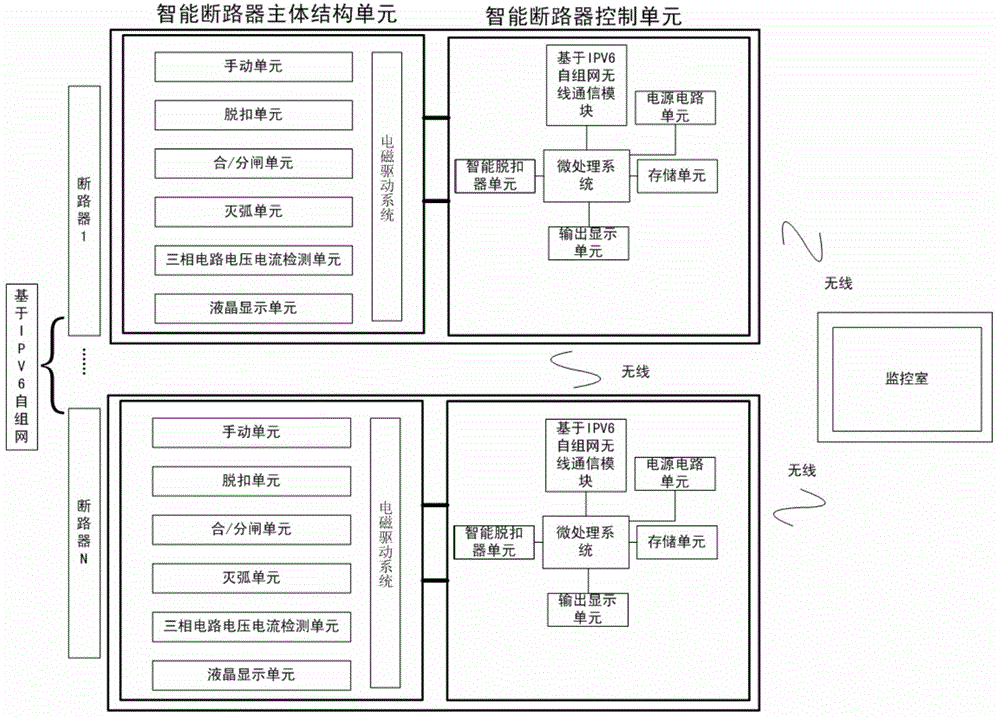

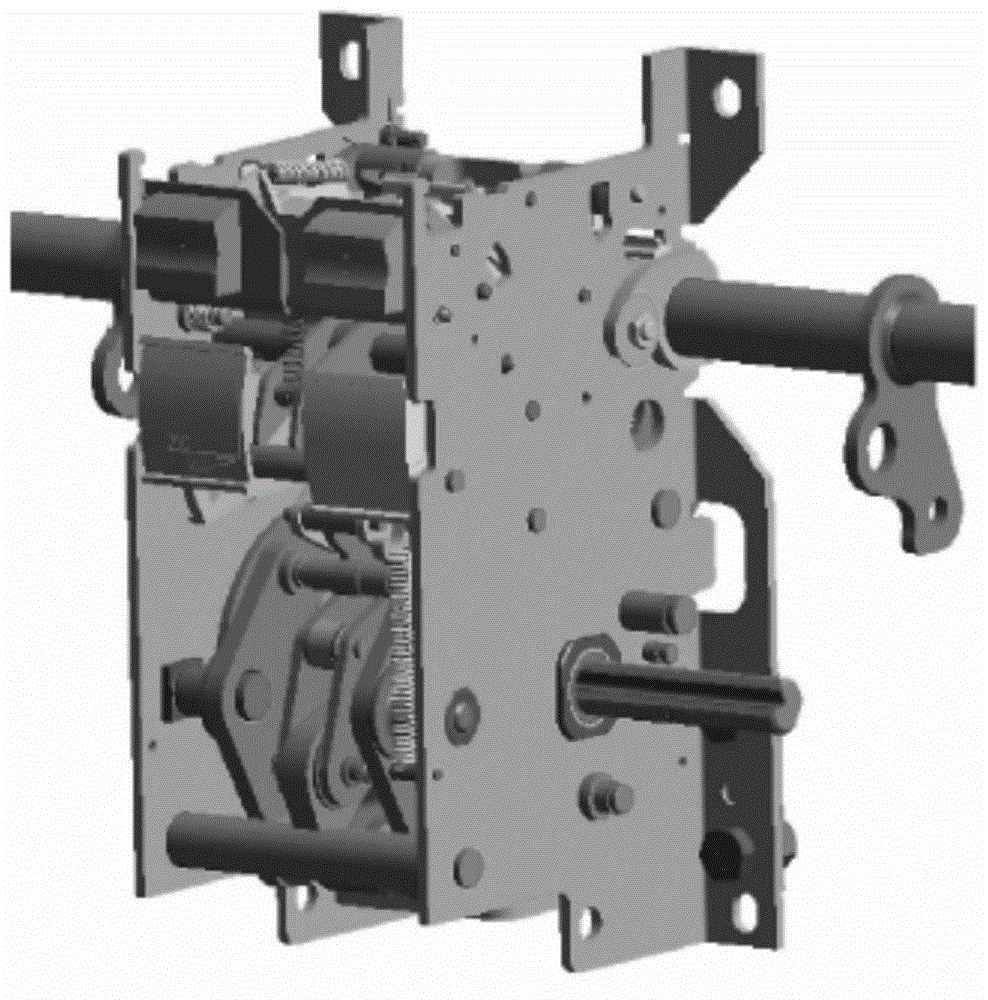

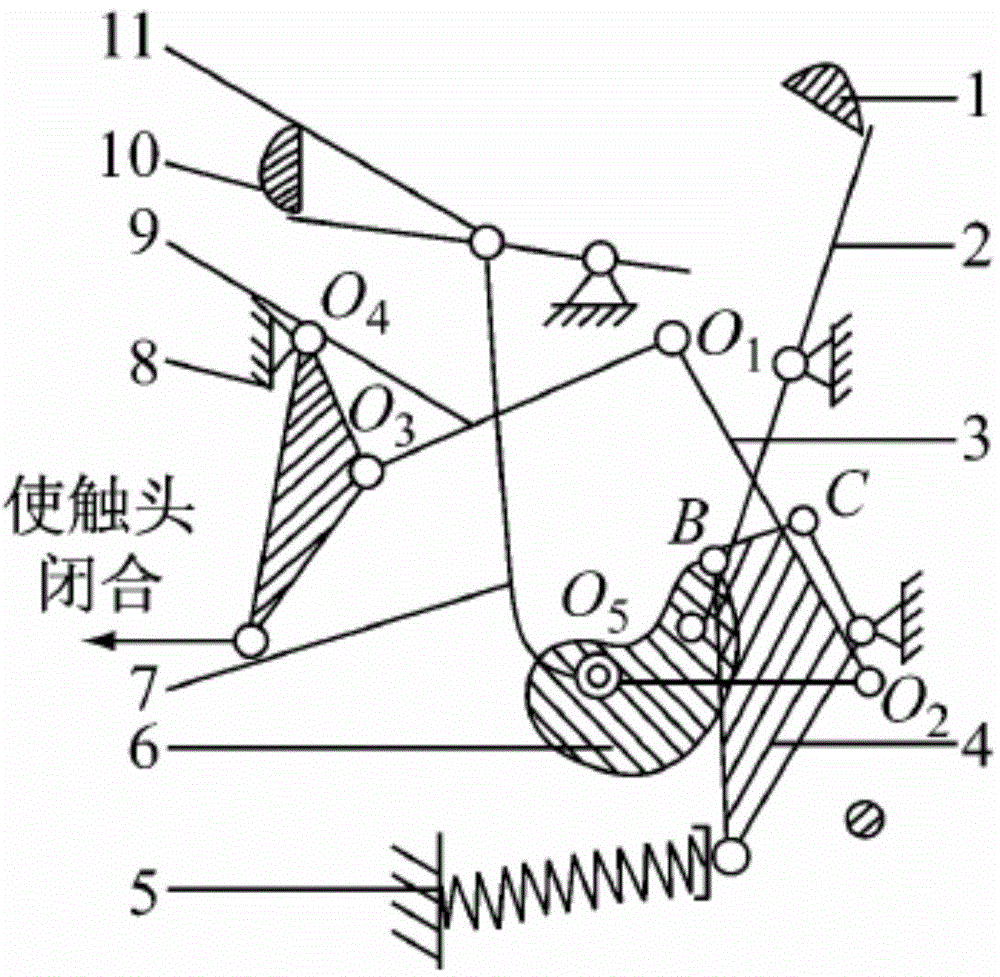

Frame-type breaker based on IPV6 intelligent ad hoc network wireless communication

InactiveCN104935074ASolve the problem of mutual interference and interruptionEasy to find on siteCircuit arrangementsSustainable buildingsWireless ad hoc networkNetwork communication

The present invention relates to a frame-type breaker based on IPV6 intelligent ad hoc network wireless communication which realizes the wireless ad hoc network communication among a plurality of breakers based on an IPV6 ad hoc network communication technology. An intelligent frame breaker comprises a drawer seat, a breaker main body structure unit and a breaker control unit, the breaker main body structure unit comprises an operation mechanism, a contact system, an arc extinguishing system and an accessory device, and the breaker control unit comprises a microprocessor system, an output display unit, a power supply circuit unit, a storage unit, an intelligent release unit and a wireless communication module based on IPV6 communication. The operation personnel realize the communication among a plurality of breakers and between the breakers and a monitoring room based on an IPV6 intelligent ad hoc network communication technology, thereby improving the system reliability, and guaranteeing the safety of the operation personnel.

Owner:ANHUI BORUI ELECTRIC

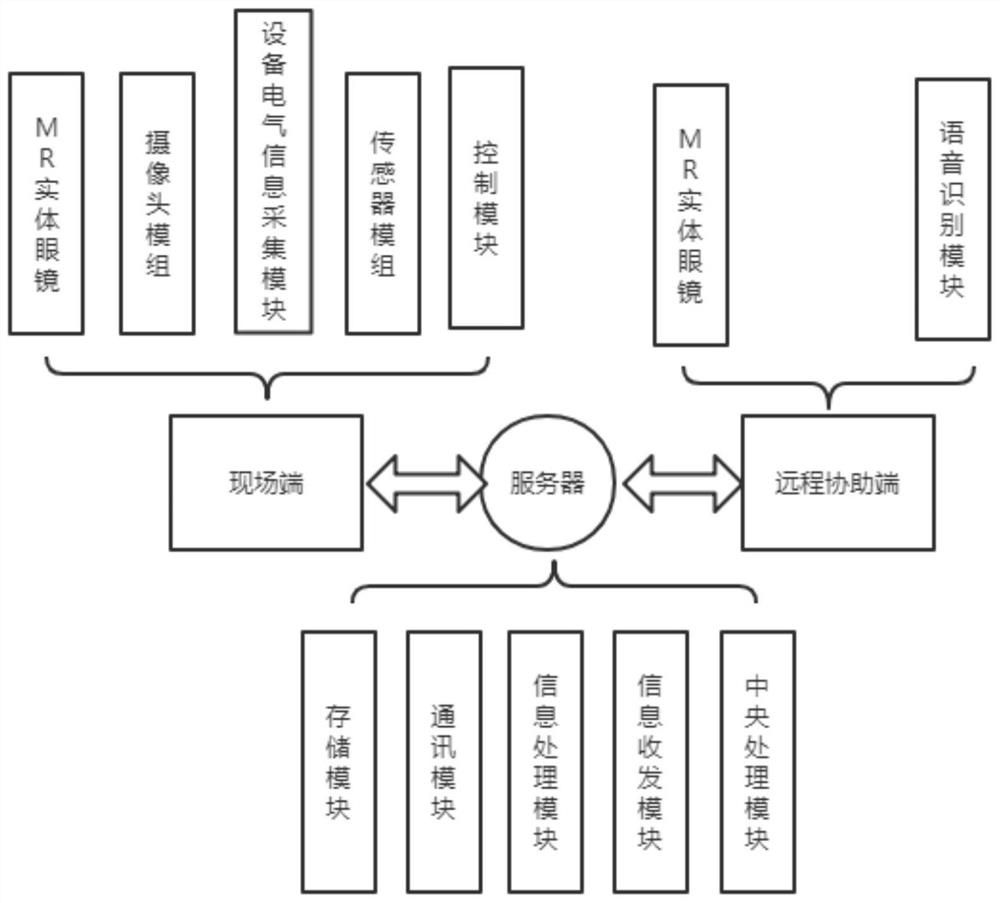

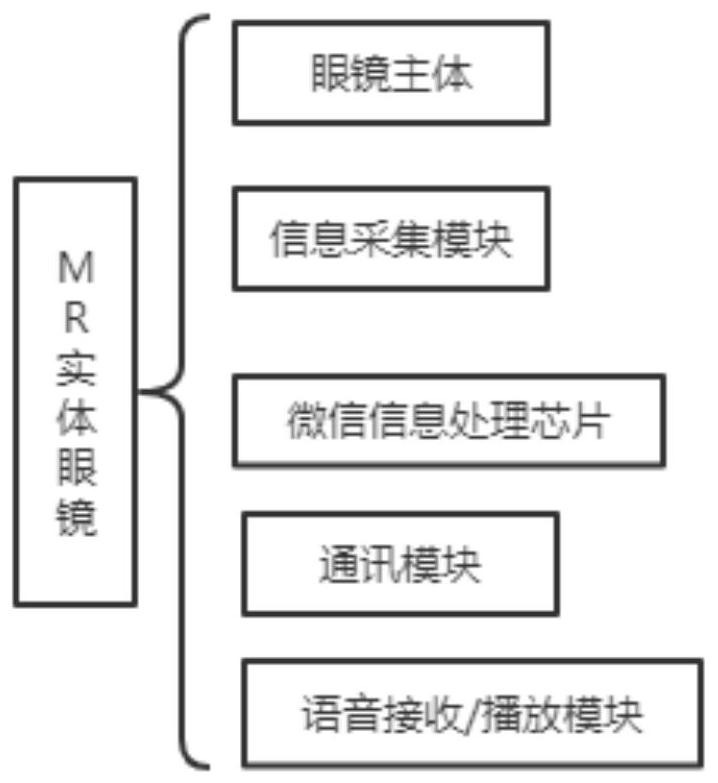

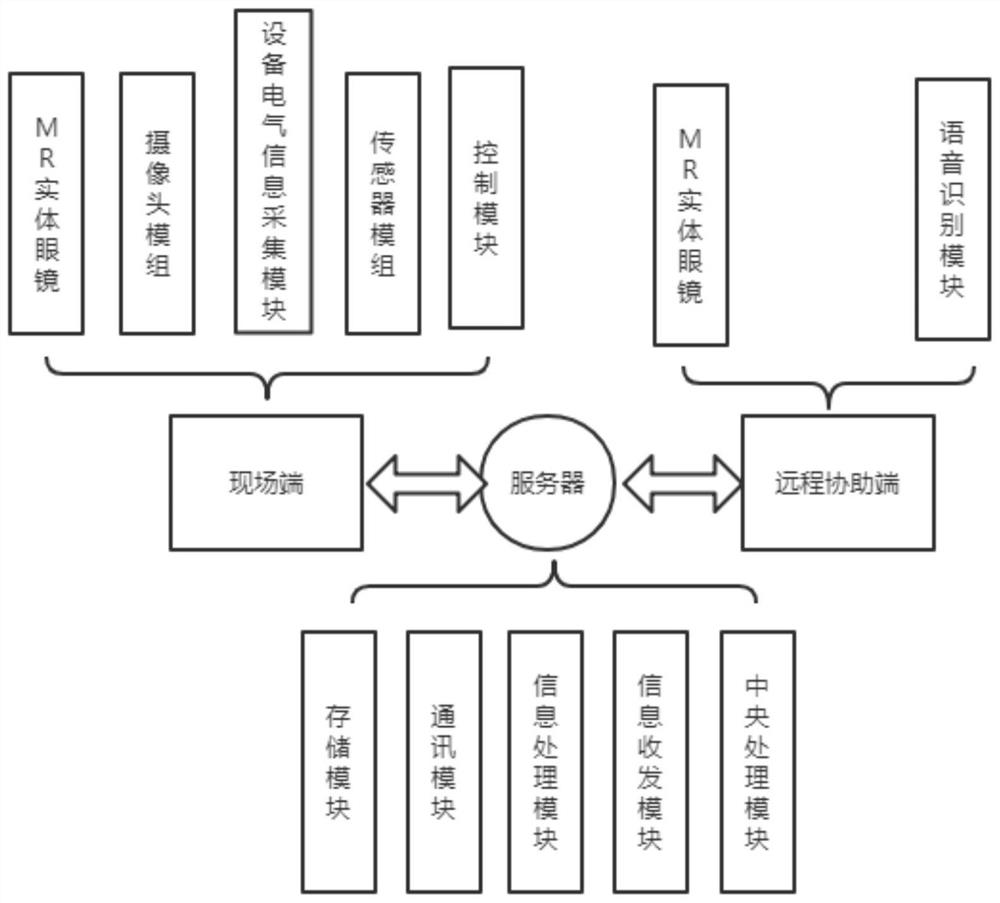

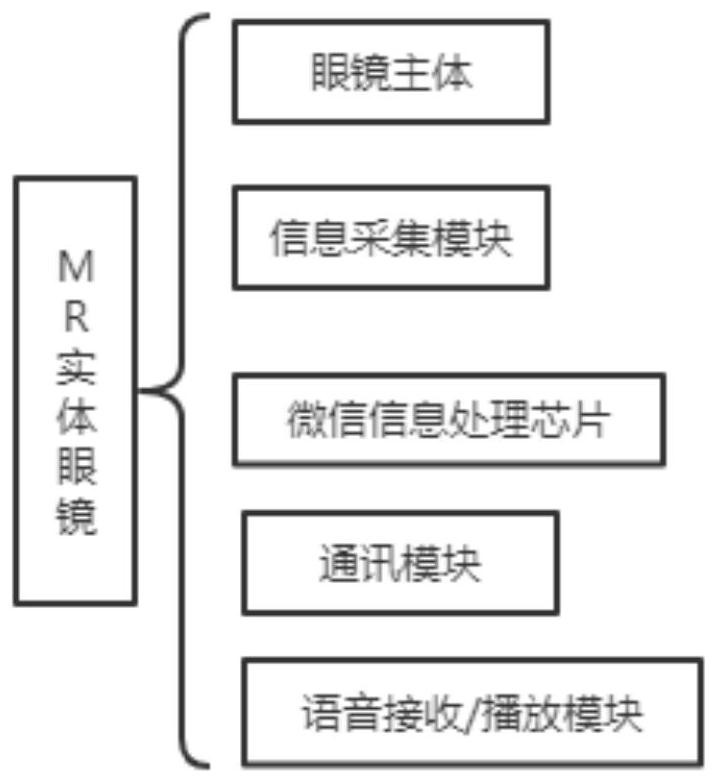

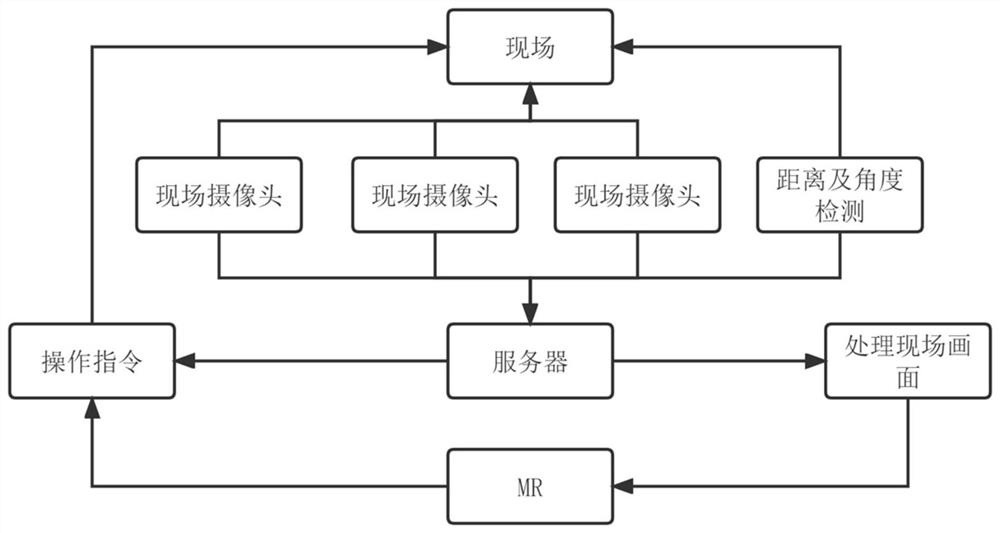

Remote assistance system for MR glasses equipment

InactiveCN113721760AImprove efficiencyImprove ease of useInput/output for user-computer interactionCharacter and pattern recognitionInformation processingEngineering

The invention discloses a remote assistance system for MR glasses equipment, and relates to the technical field of remote assistance equipment maintenance. In order to solve the problem that remote auxiliary maintenance is inconvenient, the system specifically comprises a field end, a server and a remote assistance end, wherein the field end and the remote assistance end are in bidirectional connection through the server, and the field end comprises at least one MR entity glasses, a camera module, a sensor module and an equipment electrical information acquisition module. The server comprises a storage module, a communication module, an information processing module, an information transceiving module and a central processing module, and the remote assistance end comprises at least one MR entity glasses and a voice recognition module. The MR entity glasses comprise a glasses body, and an information acquisition module, a micro information processing chip, a communication module, a display module and a voice receiving / playing module which are fixedly carried on the glasses body. According to the invention, a function of remotely assisting equipment maintenance by professionals is realized, and the efficiency and the use convenience are greatly improved.

Owner:江苏嘉恒智能科技有限公司

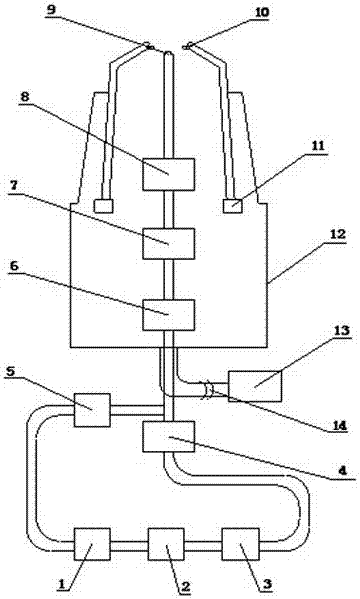

Slim-waist fire fountain device

PendingCN107080962ASave fuelEasy maintenance of equipmentStage arrangementsTraffic volumeAutomotive engineering

The invention discloses a slim-waist fire fountain device which comprises a digital flaming device, a flaming device outside bracket, a novel ignition controller system, a fuel recycling system and a digital main engine, wherein the digital flaming device comprises a fire retardance valve, a high pressure gasification device, a flow control solenoid valve and an anti-scaling self-cleaning flaming nozzle that are mounted sequentially from bottom to top; the novel ignition controller system comprises an igniter as well as an electronic positive ignition head and an electronic negative ignition head that are mounted at the top end of the igniter; and the fuel recycling system comprises an oil tank, a high pressure pump main engine, a high pressure internal storage package, a fuel control solenoid valve and a high pressure return valve that are connected with one another in sequence by fuel tubes. The slim-waist fire fountain device has the advantages that equipment maintenance is convenient and fast, the ignition is quick and efficient, the energy is saved, the environment is protected, the flaming effect shows a swing effect with random variations of three-dimensional patterns, the fire type is attractive, and flaming actions perfectly coincide with beats.

Owner:江苏欧亚水秀景观工程有限公司

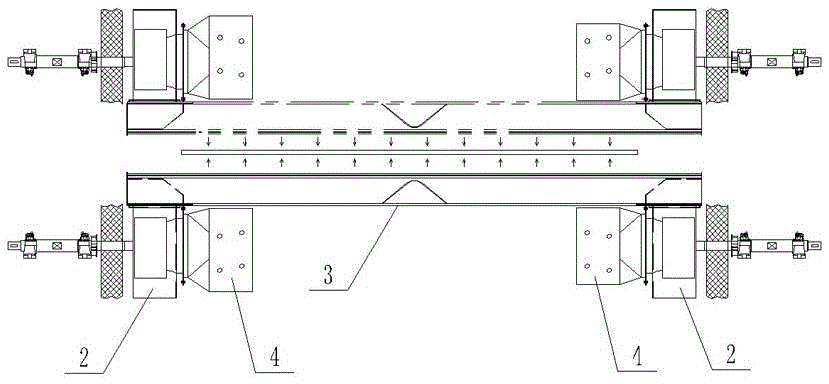

Forced convection laminated glass pre-pressing machine

ActiveCN104446013BAvoid lostReduce processing costsLaminationLamination apparatusFrequency changerAir volume

The invention relates to a forced convection sandwich glass pre-presser. The forced convection sandwich glass pre-presser comprises an operation table, a preheating zone, an initial pressing zone, a convection zone, a final pressing zone, a sheet discharging zone, a pneumatic system, a forced convection system, a heat insulation system and a lifting device, wherein a plurality of groups of convection fans and a plurality of groups of high-temperature-resistant stainless steel air grids are arranged at the top and the bottom of a furnace body; each group of fans is mounted in a two-to-two correspondence manner; heating boxes are arranged at air inlets of the fans; the air grids are arranged at the lower parts of two heating boxes; air outlets are formed in the lower parts of the air grids and are aligned to to-be-processed glass; a plurality of thermocouples are mounted inside the furnace body; an upper furnace body is provided with an H-shaped linkage mechanism and a lifting mechanism; a motor on the side of the furnace body is used for driving the fans to generate forced convection for circularly transferring heat; motors of the fans adopt variable-frequency and variable-speed motors; a PLC processing system is used for controlling a frequency changer to automatically adjust the air volume in the furnace body; the strength of the upper convection is adjusted to be consistent with the heating of the lower surface, so that the to-be-processed glass is symmetrically and uniformly heated so as to be adaptive to requirements of different-radiation-rate LOW-E coated glass.

Owner:SHENZHEN HANDONG GLASS EQUIP MFG CO LTD

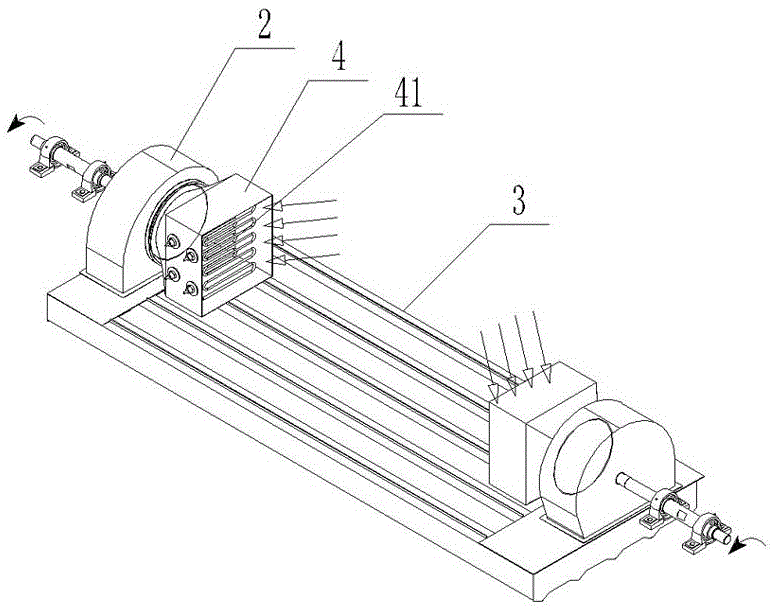

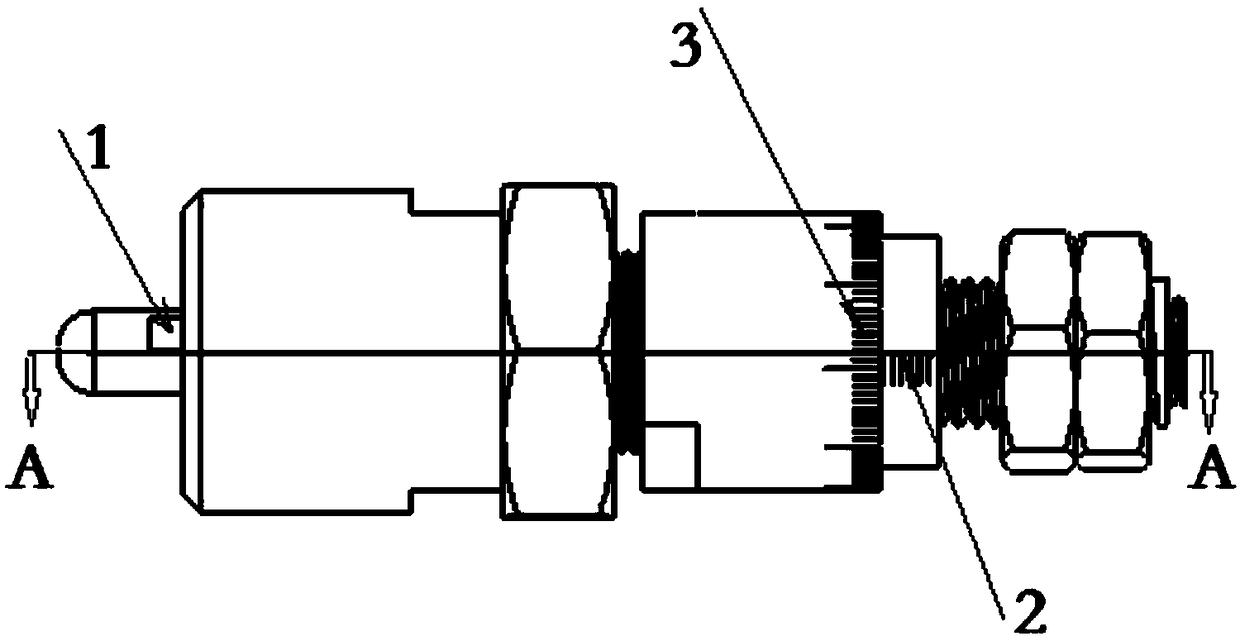

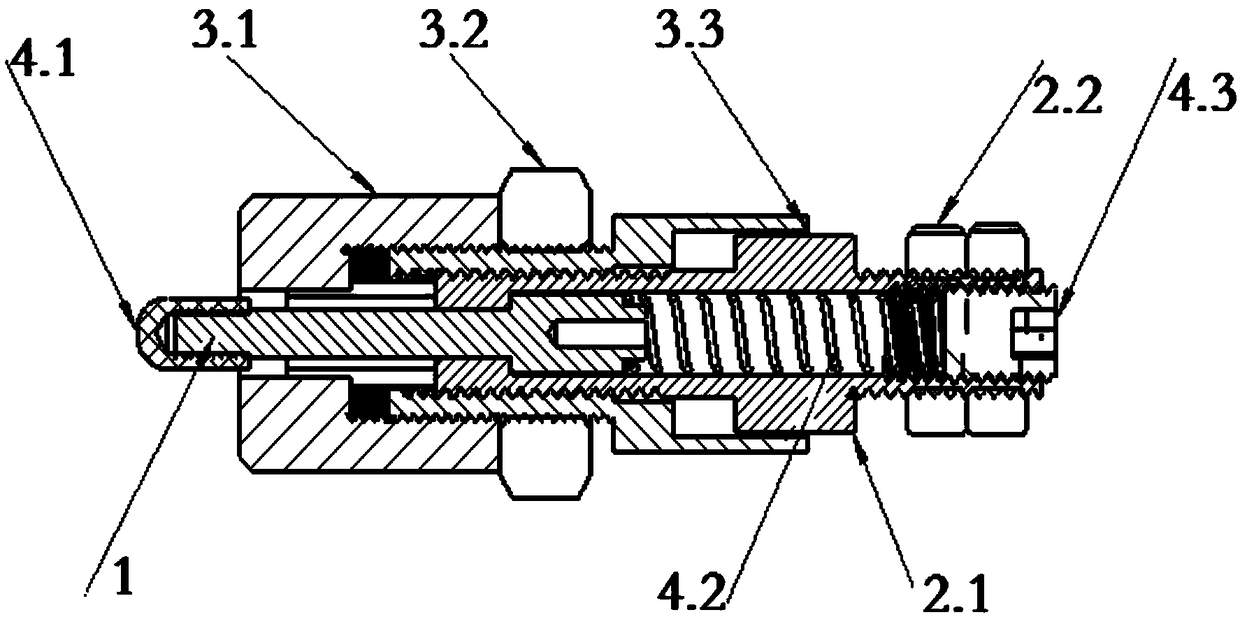

Positioning adjustment mechanism

PendingCN108942412ASimple structureEasy to operateAutomatic control devicesMeasurement/indication equipmentsEngineeringMachining

The invention provides a positioning adjustment mechanism and relates to the field of machining. The positioning adjustment mechanism comprises a mandrel, a coarse positioning mechanism and a precisepositioning mechanism, wherein the coarse positioning mechanism is provided with an axial through hole, and the mandrel and a buffer force adjusting mechanism are arranged in the through hole; the precise positioning mechanism is installed on the coarse positioning mechanism in a sleeving mode and forms a micrometer-like structure together with the coarse positioning mechanism; the buffer force adjusting mechanism is connected with the mandrel and used for buffering pressure impact caused by stop of a target tool; and the coarse positioning mechanism roughly presets the forwarding or stop position of the target tool, and the precise positioning mechanism further adjusts the position of the target tool precisely by precisely positioning and adjusting differential motion of a thread on a dial according to the position of the coarse positioning mechanism. The positioning adjustment mechanism is simple in structure and convenient to operate, impact pressure of loads is effectively buffered, and in the process that the target tool is stopped and positioned, precise positioning and accurate reading are achieved.

Owner:孙臣慧

Coal chemical industry separation tower

ActiveCN109022021AEasy maintenance of equipmentGuaranteed tightnessHydrocarbon oils refiningChemical industryCoal chemical industry

The invention relates to the field of chemical industry devices, and concretely relates to a coal chemical industry separation tower. The coal chemical industry separation tower comprises a fixed frame, three driving structures, two first sleeves, a flow dividing structure, a second sleeve, a water valve, a flow guiding structure, fixed rings and three sealing structures; the top end of the firstsleeve, away from the flow guiding structure, at the end; the second sleeve is connected with the adjacent first sleeve through one of the driving structures, and the flow guiding structure is connected with the adjacent first sleeve through one of the remaining driving structures; the two first sleeves are connected by the remaining driving structure; and the sealing structures are used to seal the adjacent two first sleeves, seal the corresponding first sleeve and the second sleeve and seal the corresponding first sleeve and the flow guiding structure. The cooperation of the driving structures with the circular first sleeves makes packing layers on trays on the fixed rings in the first sleeves and the flow guiding structure easily replaced, so the packing layers on the trays at differentpositions can be dismounted and replaced, thereby the coal chemical industry separation tower is convenient and quick to overhaul and maintain.

Owner:淮北雷德机电科技有限公司

Electronic type transformer high voltage side redundant backup circuit and failure detection method

InactiveCN100507580CImprove reliabilityPrecise Fault Location InformationVoltage/current isolationFault locationTransformerHemt circuits

The invention discloses a redundant backup circuit on the high-voltage side of an electronic transformer. A standby controller connected in parallel with the main controller and a corresponding multi-channel gating circuit are added to the high-voltage side circuit of the transformer. During the operation of the transformer, the The standby controller sleeps, and the main controller completes all the functions of the high-voltage side circuit. If the low-voltage side circuit judges that the high-voltage side circuit may have a fault, it wakes up the high-voltage side standby controller, and the standby controller sends a reset command to the main controller. , and test and diagnose the high-voltage side circuit. If it is confirmed that the main controller is faulty, the current work of the main controller will be switched to the standby controller to keep the transformer working normally, which overcomes the failure of the high-voltage side circuit due to the main controller. The defect that causes the transformer to fail to work, thus improving the reliability of the transformer; the present invention also discloses a fault detection method based on the aforementioned circuit, which provides fault location information for the inspection and maintenance of the transformer equipment, and facilitates the online detection of the equipment. maintain.

Owner:BEIHANG UNIV

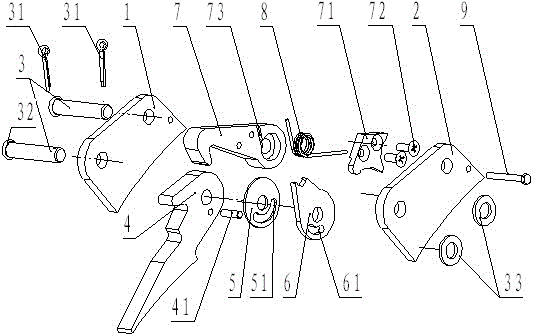

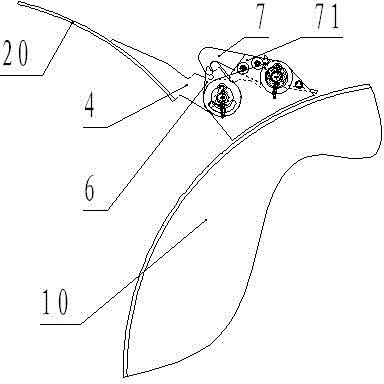

A multi-station hinge support mechanism

The invention discloses a multi-station hinge support mechanism. The multi-station hinge support mechanism includes a support, on which a rotating bracket and a hook are respectively hinged, and the ends of the rotating bracket and the hook are provided with a mutual engagement structure, and the described hook is provided with a twist for reset. When the rotating bracket is opened, it is engaged with the hook and supported. The support is also provided with a hinged cam. The rotating bracket is provided with a dial pin for toggling the cam. Used to support the driven body to separate the hook from the rotating bracket. The multi-station hinge support mechanism adopting this technical scheme can make the doors of conditioner and other equipment in any state of closing, opening, holding, and unlocking, and can be switched freely. The structure is simple and easy to operate, which brings convenience to maintenance equipment.

Owner:牧羊有限公司

Equipment remote assistance platform based on MR glasses

PendingCN114723076AImprove efficiencyImprove ease of useImage data processingOptical elementsInformation processingCamera module

The invention discloses an equipment remote assistance platform based on MR glasses, and relates to the technical field of remote assistance equipment maintenance. The problem that remote auxiliary maintenance is inconvenient is solved. The system specifically comprises a field end, a server and a remote assistance end, the field end is bidirectionally connected with the remote assistance end through the server, and the field end comprises at least one MR entity glasses, a camera module, a sensor module and an equipment electrical information acquisition module. The server comprises a storage module, a communication module, an information processing module, an information transceiving module and a central processing module, and the remote assistance end comprises at least one MR entity glasses and a voice recognition module. The MR entity glasses comprise a glasses main body, and an information acquisition module, a micro information processing chip, a communication module, a display module and a voice receiving / playing module which are fixedly carried on the glasses main body. According to the invention, a function of remotely assisting equipment maintenance by professionals is realized, and the efficiency and the use convenience are greatly improved.

Owner:江苏嘉恒智能科技有限公司

Method for treating excess sludge and composting products and applications

ActiveCN106866299BImprove the degree of humificationImprove agricultural valueSludge treatment by de-watering/drying/thickeningBio-organic fraction processingSoil scienceSludge

The invention provides a method for treating surplus sludge, a compost product and application. The method for treating the surplus sludge comprises the steps that after the concentration of the surplus sludge is regulated, treatment is performed to obtain earthworm excrement sludge; the earthworm excrement sludge and a conditioner are mixed; earthworms are fed to form compost; after 56 to 63d, the compost product is obtained; the compost product is applied in an efficient agricultural fertilizer or a soil conditioner. The prepared compost product has the advantages that the humification degree of the sludge can be effectively improved; the molecular weight, the polycondensation degree and the aromatization degree of humic acid are improved, so that the sludge after earthworm composting is converted into an excellent agricultural fertilizer. In addition, the conditions required by the reaction process are simple; the reaction can be performed at normal temperature and normal pressure; the flow process is simple and convenient; the control is easy; the operation management and the equipment maintenance are convenient; the engineering cost and the operation cost are greatly reduced; natural advantages are realized on rural sludge with low treated sludge yield and wide distribution.

Owner:TONGJI UNIV

Flame-retardant arch transparent tile and its use

InactiveCN1186240CEasy to useLabor-saving operationConveyorsRoof covering using tiles/slatesPolymer scienceEngineering

The present invention includes arched flame-retardant transparent tile and arched flame-retardant nontransparent tile. The arched flame-retardant transparent tile has several sluices, two slideways, observing window and observing window cover connected via slide roller to the slideway and stoppers on two ends of the observing window and perpendicular to the sluice. Several pieces of arched flame-retardant transparent tile and arched flame-retardant nontransparent tile may be connected serially to form protecting hood for transporting conveyer belt or long corridor.

Owner:武钢北湖福利加工厂

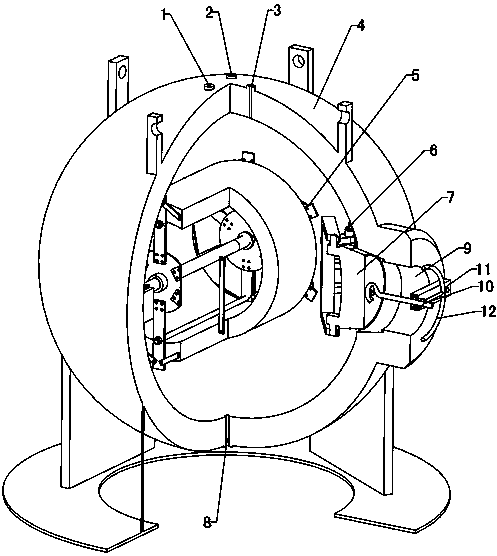

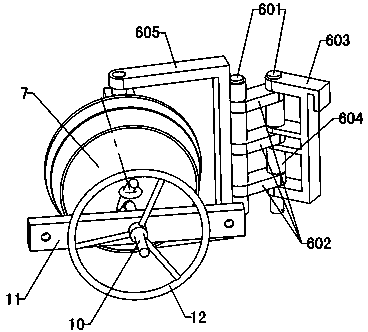

Constant pressure testing machine and test method for ultra-high pressure and ultra-large vessels

ActiveCN105865931BIncrease the internal volumeExpand the scope of testingTesting dielectric strengthMaterial strength using tensile/compressive forcesUltra high pressureEngineering

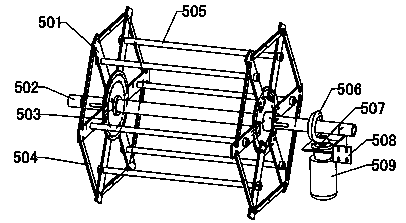

The invention discloses an ultrahigh-pressure extralarge vessel constant-pressure test machine and a detection method, and belongs to the field of deep-sea optical cable water tightness inspection equipment. The ultrahigh-pressure extralarge vessel constant-pressure test machine is characterized in that a pressure vessel body (4) is a spherical shell, an optical cable winding mechanism (5) of a rotating device is installed inside the spherical shell, a sealed channel (9) is formed outside the spherical shell and communicated with the interior of the spherical shell, and the sealed channel (9) is provided with a self-sealing door (7) installed in an embedded mode; an optical cable sample placed in the pressure vessel body (4) is pressurized at a constant speed, the pressure is maintained, whether the optical cable sample is broken or not is monitored, then the test is automatically ended with the test result automatically saved, the optical cable sample is subjected to a water penetration test or a hydrostatic pressure resistance test, the test is ended if the optical cable sample is broken, and a new sample is installed. According to the ultrahigh-pressure extralarge vessel constant-pressure test machine and the detection method, the internal capacity of the pressure vessel is increased, the test length of a deep-sea optical cable is increased, the test range of the optical cable is widened, and the test requirement that the optical fiber bears the ultrahigh pressure of 85 MPa or below in the deep sea at 8500 m or below can be met.

Owner:CHENGDE DESHENG DETECTION EQUIP CO LTD

An unmanned aerial vehicle and its working method

ActiveCN106364692BReduce volatilitySolve the problem that the oil pumping is difficult and cannot reach the vacuum stateLiquid handling installationsTank vehiclesUncrewed vehicleTruck

The invention discloses an unmanned plane fueling vehicle and a working method thereof. The unmanned plane fueling vehicle comprises a vehicle body. An accessory bin, an operation bin and an oil tank assembly are arranged on a chassis of the vehicle body. A power assembly is arranged in the accessory bin. An oil circuit system, an electric system and a gas circuit system are arranged in the operation bin. The oil circuit system comprises three sets of fueling circuits and a main oil circuit. Each fueling circuit comprises a first manual ball valve connected with an oil tank. Each first manual ball valve is connected with a coarse filter. The coarse filter is connected with a first electromagnetic valve, a fifth electromagnetic valve and a ninth electromagnetic valve. According to the unmanned plane fueling vehicle and the working method thereof, functions and technologies are advanced, operation is easy, performance is reliable, a soft oil bag can be effectively protected in oil fueling and pumping processes, and the situations that the oil bag is damaged during fueling, or oil in the oil bag cannot be pumped completely during oil pumping, and consequently the service life of the oil bag is shortened are avoided. The unmanned plane fueling vehicle can also be applied to other fields that fuel is stored in soft oil bags and safety requirements are extremely high.

Owner:AEROSUN CORP

Gas pollutant porous medium adsorbing device with uniform air supply

InactiveCN109482037AHigh adsorption rateEasy maintenance of equipmentGas treatmentDispersed particle separationSteel platesPollutant

Owner:DONGHUA UNIV +1

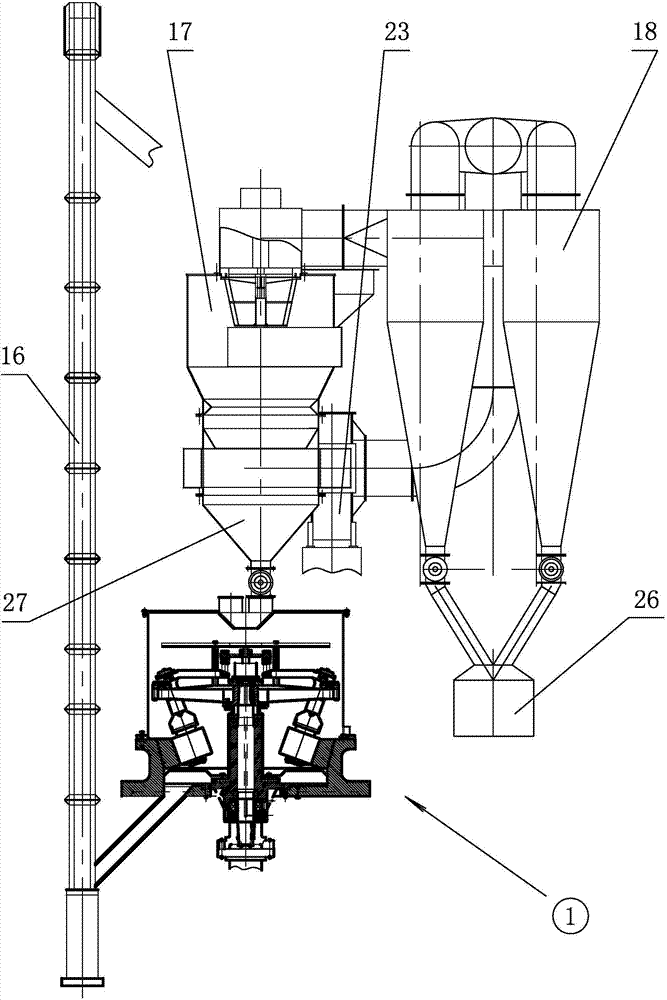

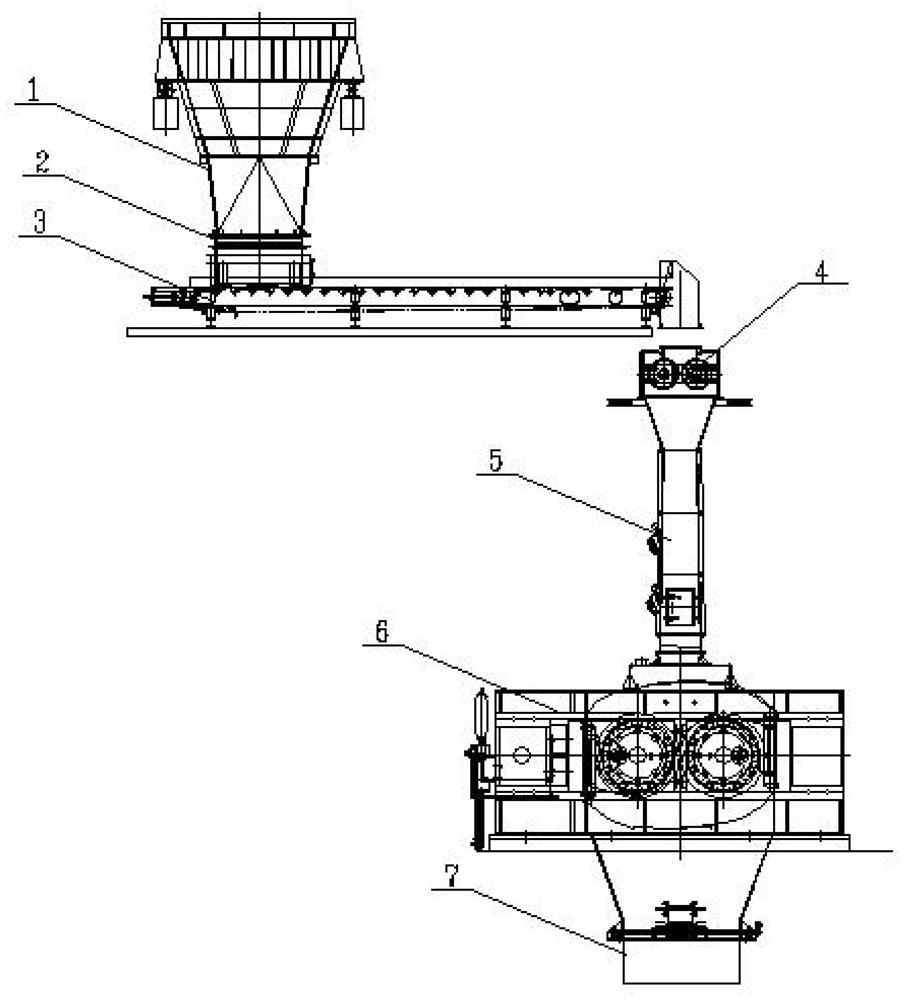

Fine iron powder pre-pressing-roller grinding system and method

PendingCN112210660AReduced material level requirementsReduced impact of rolling effectStock levelIron powder

The invention discloses a fine iron powder pre-pressing-roller grinding system and method, and relates to the field of pretreatment of fine iron powder pellet raw materials. The fine iron powder pre-pressing-roller grinding system comprises a feeding system, a pre-pressing machine and a high-pressure roller grinding machine, wherein the high-pressure roller grinding machine is connected with the pre-pressing machine for pre-pressing materials, a feeding port of the pre-pressing machine is connected with the feeding system, and material supply between the feeding system and the pre-pressing machine is in linkage. According to the fine iron powder pre-pressing-roller grinding system and method, fine iron powder becomes compact from a loose state through pre-pressing of the pre-pressing machine, and the requirements of operation of the high-pressure roller grinding machine for a stock column and a stock level are effectively reduced; the influence of supplied material fluctuation on the rolling effect is effectively reduced; air among the materials is exhausted in advance under the pre-pressing action, so that the product rolling index of the high-pressure roller grinding machine is effectively increased; the materials are effectively prevented from being accumulated to block a feeding channel; and the equipment operation is easy, the technological process is short, the system operation is stable, and the application prospect is wide.

Owner:CHENGDU LEEJUN IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com