High-efficiency screening type large-scale double-toothed roller crusher with self-contained material distribution device

A material distribution device and double-toothed roller technology, applied in grain processing and other directions, can solve the problems of restricting the rapid development of open-pit mine materials, poor site applicability and equipment mobility, and long installation and commissioning cycle, achieving compact structure and floor space. Small, easy to remove for maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further explained and described below in conjunction with the accompanying drawings and specific embodiments:

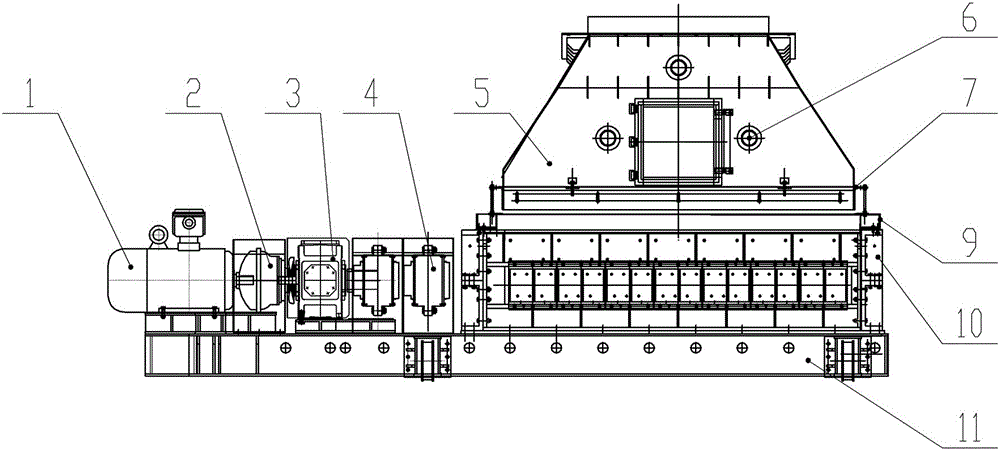

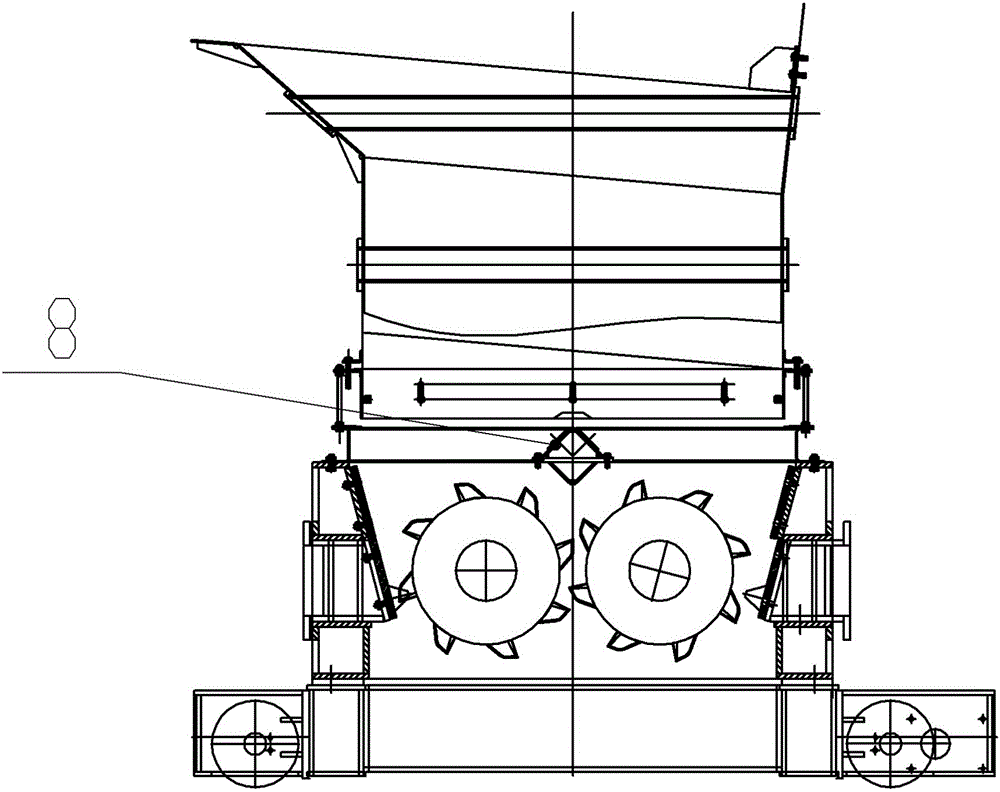

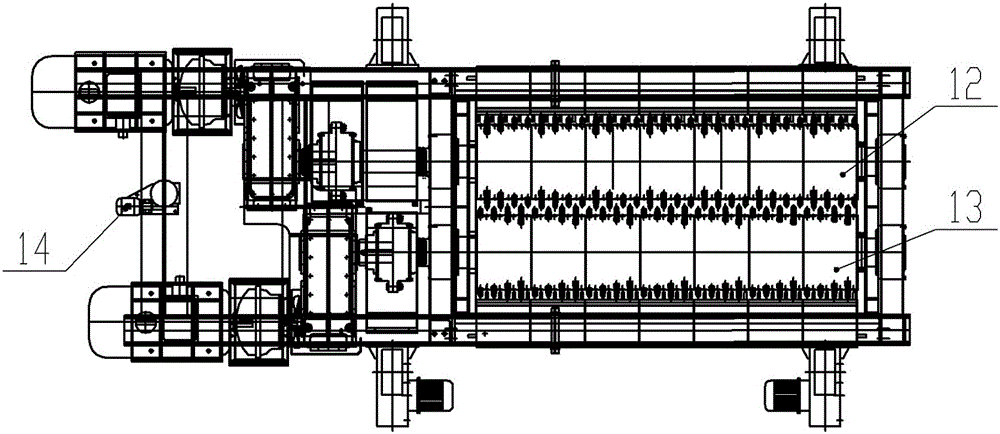

[0027] see Figure 1 to Figure 7 , a high-efficiency screening type large-scale double-toothed roller crusher with its own material distribution device, including a crushing device and a material distribution device. The crushing device includes a crushing drive motor 1, a hydraulic coupling 2, a reducer 3, a double drum type gear Type coupling 4, crushing box 10, bottom bracket 11, left toothed roller 12, right toothed roller 13 and grease pump 14, the crushing drive motor 1, hydraulic coupling 2, reducer 3 and double drum type The toothed coupling 4 constitutes a crushing drive unit, and the crushing drive unit consists of two sets, which are respectively connected with the left toothed roller 12 and the right toothed roller 13 inside the crushing box 10; The material bar 6, the movable connection bracket 7, the material distri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com