Oblique swing pressurization external circulation mill

A technology of external circulation and milling machine, which is applied in the direction of grain processing, etc., can solve the problems of low output per unit time, reactive power flying away of large materials, and insufficient feeding of Raymond mills, and achieve simple structure and fast falling time. The effect of elongation and increased grinding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

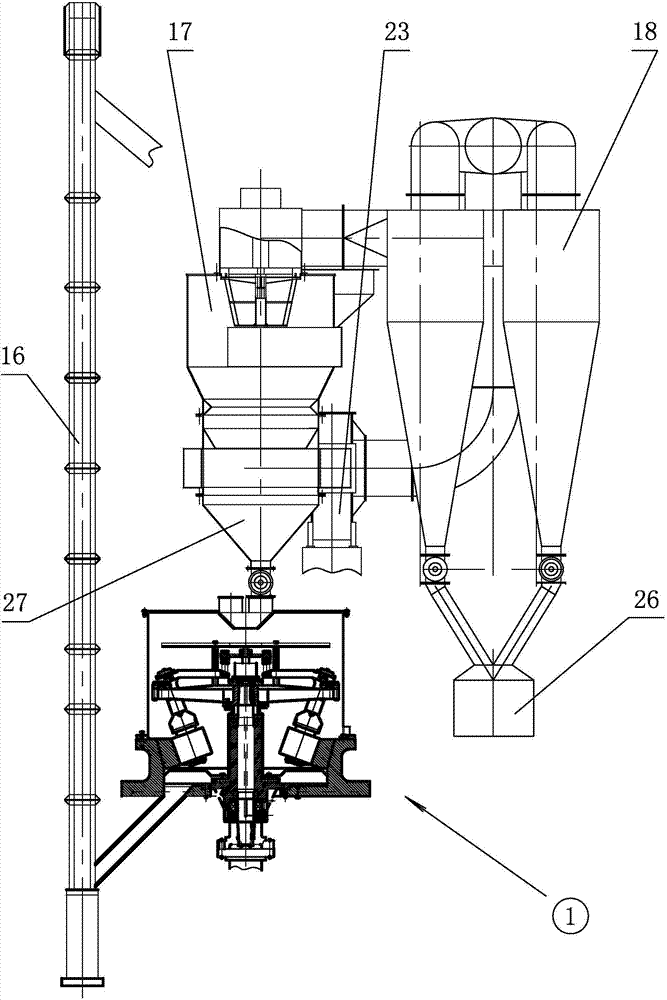

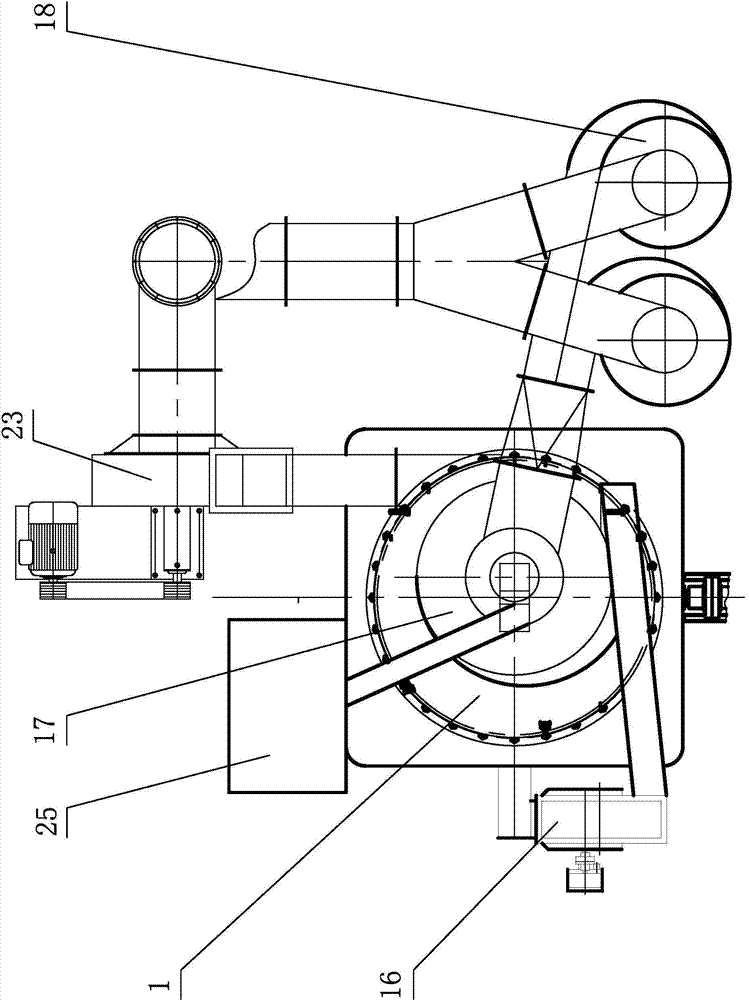

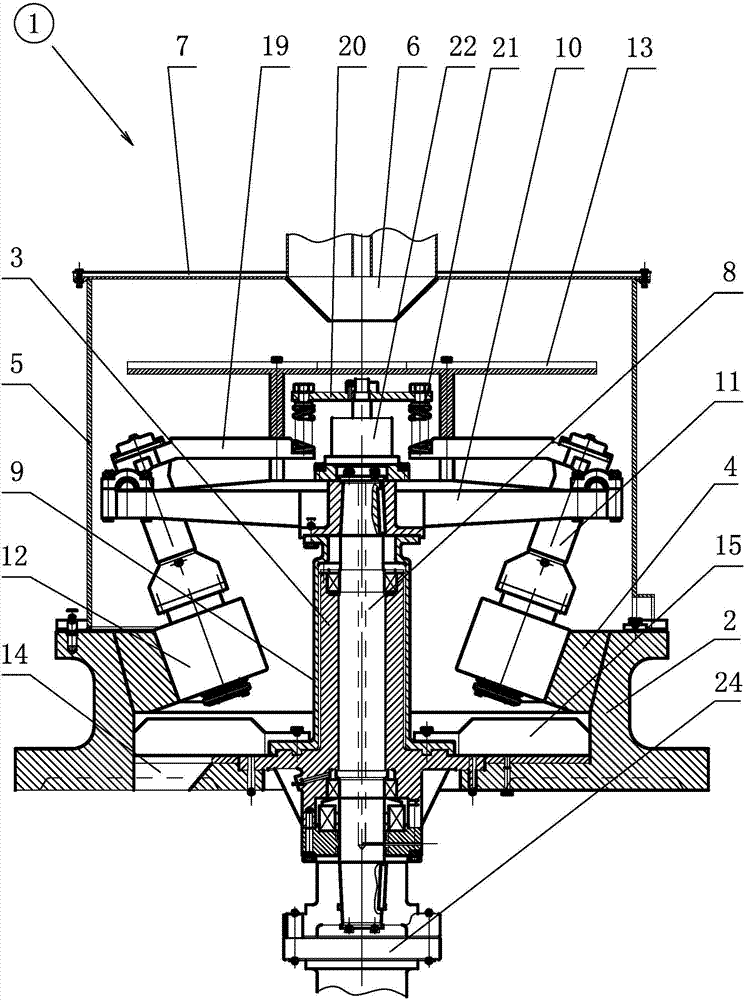

[0025] The technical solutions of the present invention will be further described below in conjunction with the embodiments shown in the accompanying drawings.

[0026] The base 2 of the mill host 1 of the oblique pendulum pressurized external circulation mill of the present invention is fixed on the concrete machine base, and the center of the lower part of the inner hole of the base 2 is installed with a hollow central shaft frame 3, a scraper frame 9 and a central shaft frame 3 Coaxial suit, the grinding ring 4 is coaxially installed on the upper part of the inner hole of the base 2, and the cover tube 5 is coaxially installed on the end surface of the base 2, and the upper cover 7 of the cover tube 5 is provided with a feed port 6 of the main engine in the center of the cover tube 5, and a discharge port 14 of the main machine It is opened at the bottom of the inner hole of the base 2 next to the central shaft frame 3, and the scraper plate 15 is evenly distributed on the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com