Constant pressure testing machine and test method for ultra-high pressure and ultra-large vessels

A test method and ultra-high pressure technology, applied in the direction of applying stable tension/pressure to test the strength of materials, instruments, scientific instruments, etc., can solve the problem that the application range of the test equipment cannot meet the test requirements, and the test pressure can only reach more than 20 trillion. Pa, the test sample cannot be placed under this pressure, etc., to achieve the effect of easy operation and equipment maintenance, good sealing effect, and increased internal volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

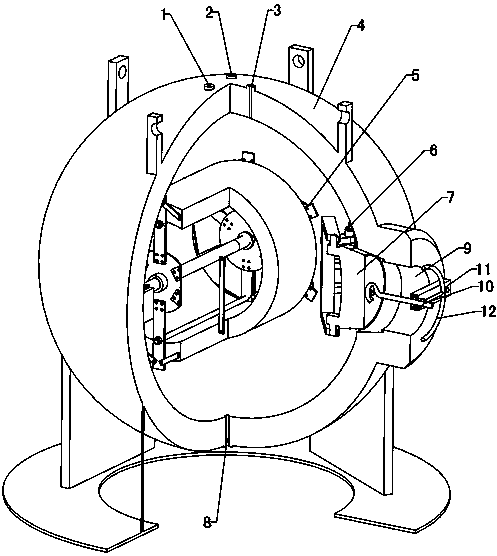

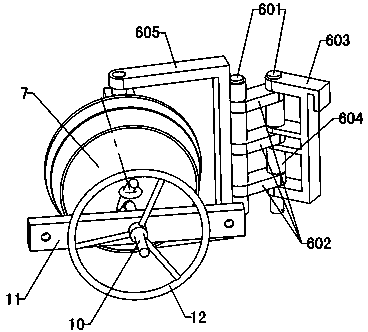

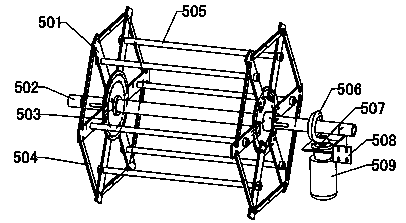

[0044] Figure 1~3 It is the best embodiment of the present invention, below in conjunction with attached Figure 1~3 The present invention will be further described.

[0045] Refer to attached Figure 1~3 : Ultra-high pressure super-large container constant pressure testing machine, including a pressure-resistant container body 4, the pressure-resistant container body 4 is a spherical shell, the spherical shell can be a structure formed by splicing two hemispheres, and the spherical shell is provided with a water injection port 1 , exhaust port 2, pressure source injection port 3 and medium discharge port 8, preferably, water injection port 1, exhaust port 2 and pressure source injection port 3 are arranged on the upper part of the spherical shell, and medium discharge port 8 is arranged on the spherical shell The bottom of the body; the optical cable winding mechanism 5 installed and rotated inside the spherical housing, one end of the optical cable winding mechanism 5 is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com