Patents

Literature

84results about How to "Eliminate discharge" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Enhanced mercury control in coal-fired power plants

InactiveUS6808692B2Easy to captureEliminate dischargeChloride preparationUsing liquid separation agentPulverized fuel ashElemental mercury

A method of treating a coal combustion flue gas, which includes injecting a molecular halogen or thermolabile molecular halogen precursor, such as calcium hypochlorite, able to decompose to form molecular halogen at flue gas temperature. The molecular halogen converts elemental mercury to mercuric halide, which is adsorbable by alkaline solids such as subbituminous or lignite coal ash, alkali fused bituminous coal ash, and dry flue gas desulphurization solids, capturable in whole or part by electrostatic precipitators (ESPs), baghouses (BHs), and fabric filters (FFs), with or without subsequent adsorption by a liquid such as a flue gas desulphurization scrubbing liquor.

Owner:HAZELMERE RES

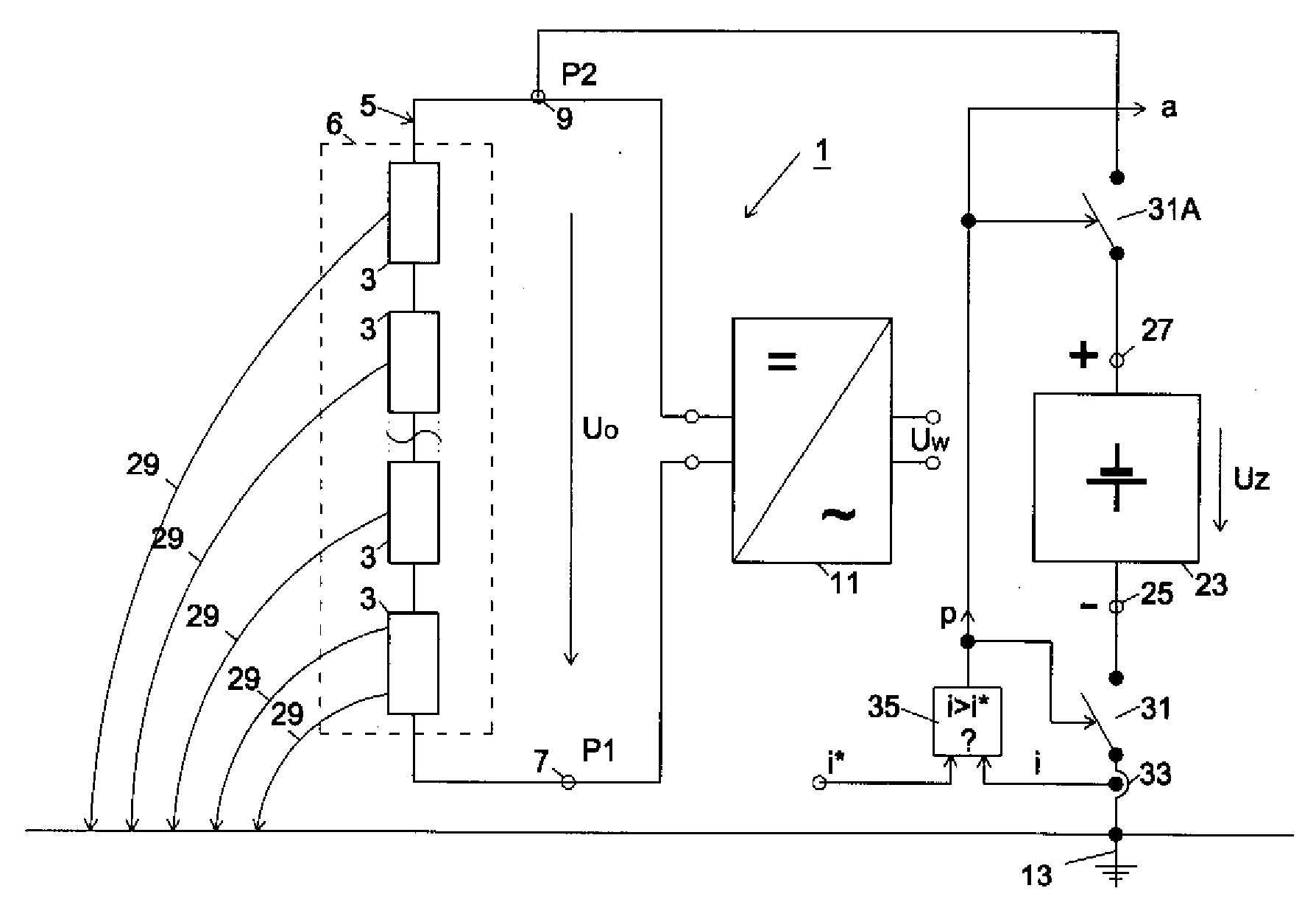

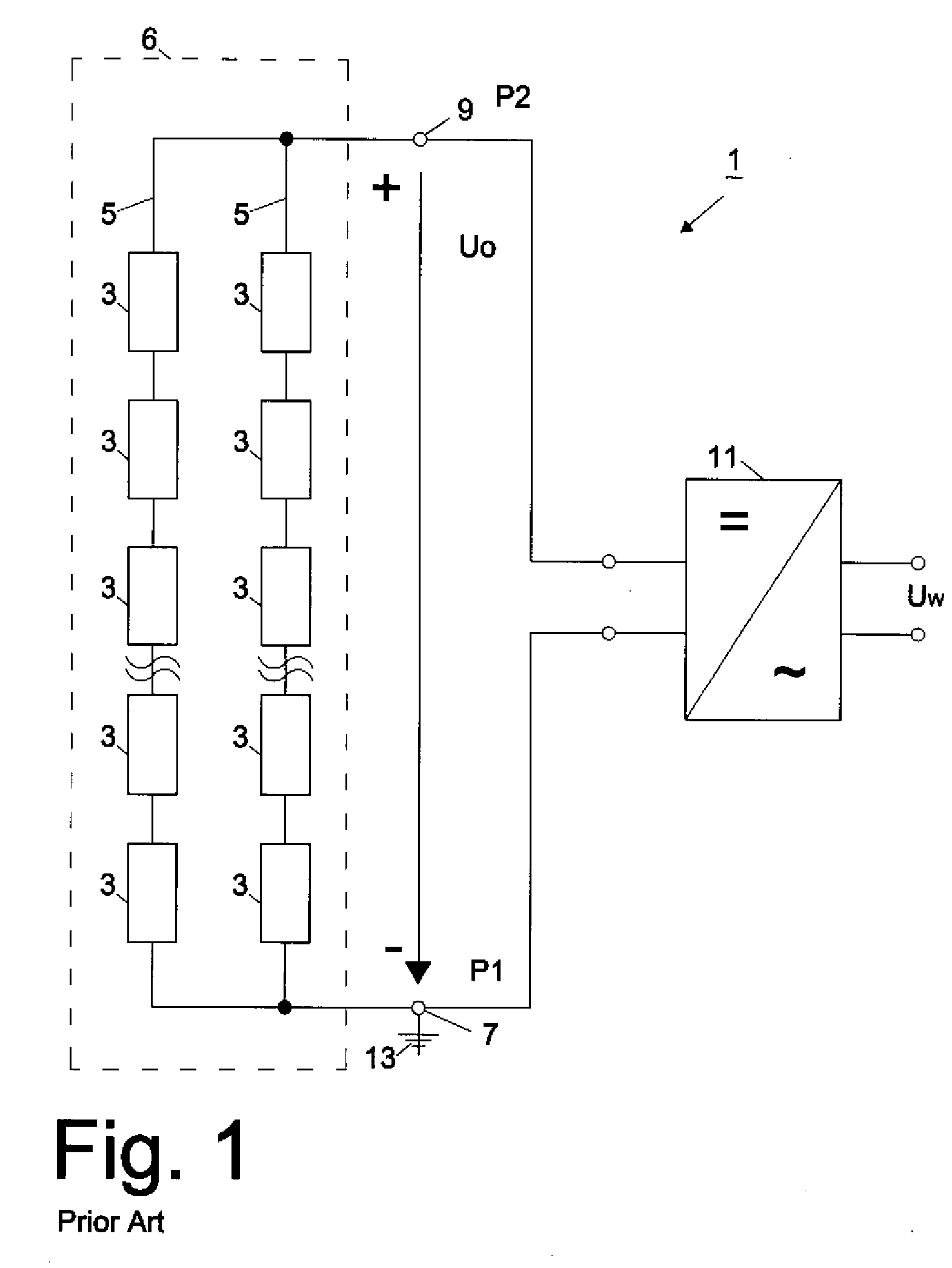

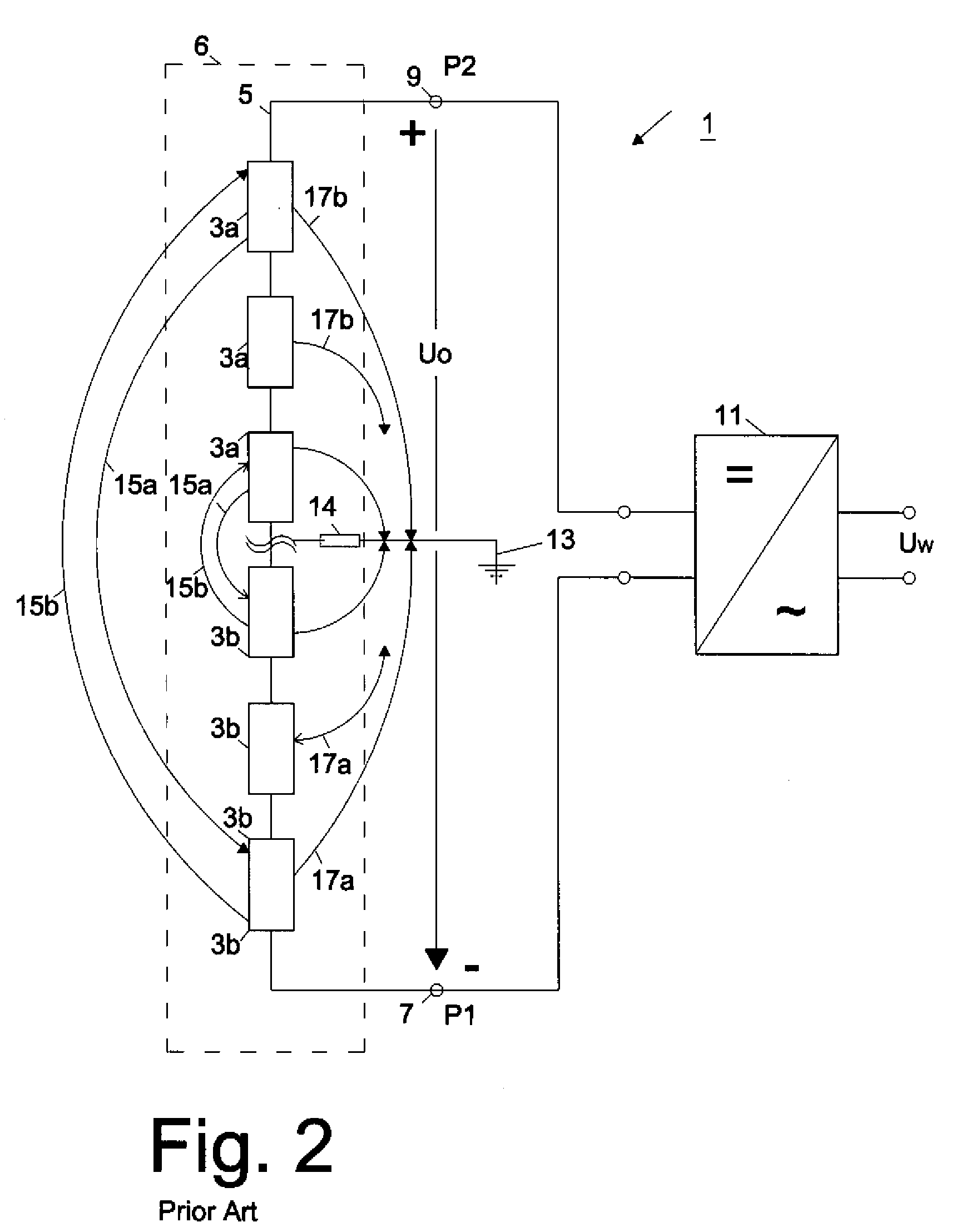

Photovoltaic system

ActiveUS20090101191A1Avoid damageEliminate dischargePV power plantsDiodePhotovoltaic generatorElectron

The photovoltaic system includes a plurality of photovoltaic modules which are connected to form a string or several strings connected in parallel, thereby forming a photovoltaic generator having a positive terminal and negative terminal. A DC constant voltage source connected to the photovoltaic generator to raise the potential of the positive terminal relative to ground potential. This reduces the flow of electrons out of the TCO layer of the modules, thereby reducing or completely eliminating cathode discharges which damage the modules.

Owner:PADCON

Enhanced mercury control in coal-fired power plants

InactiveUS20030161771A1Enhanced capture of mercuryEliminating undesirable dischargeUsing liquid separation agentHalide preparation methodsPulverized fuel ashElemental mercury

A method of treating a coal combustion flue gas, which includes injecting a molecular halogen or thermolabile molecular halogen precursor able to decompose to form molecular halogen at flue gas temperature. The molecular halogen coverts elemental mercury to mercuric halide adsorbable by alkaline solids such as subbituminous or lignite coal ash, alkali fused bituminous coal ash capturable in whole or part by electrostatic precipitators (ESPs), baghouses (BHs), fabric filters (FFs), dry flue gas desulphurization solids, with or without subsequent adsorption by a liquid such as a flue gas desulphurization scrubbing liquor.

Owner:HAZELMERE RES

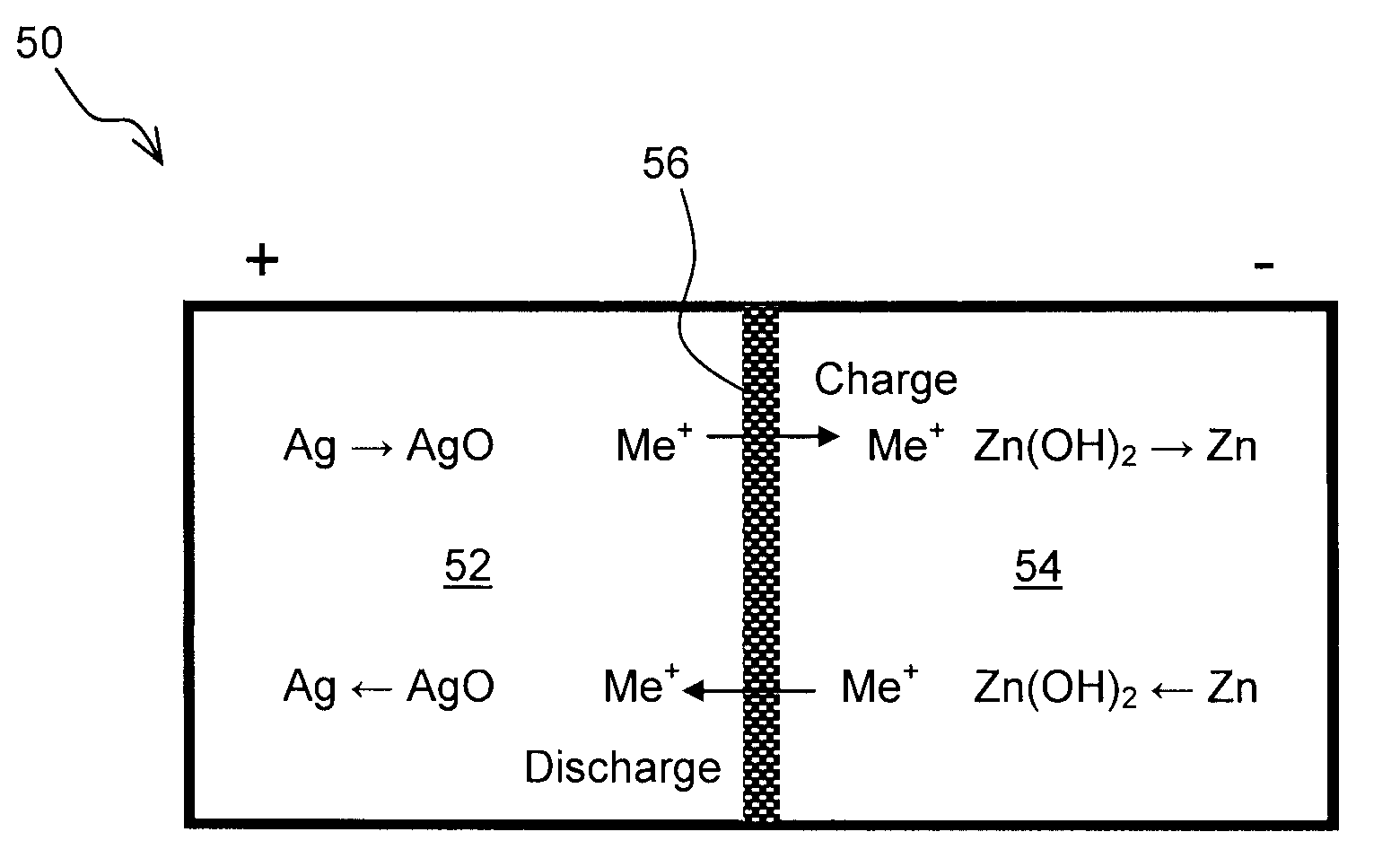

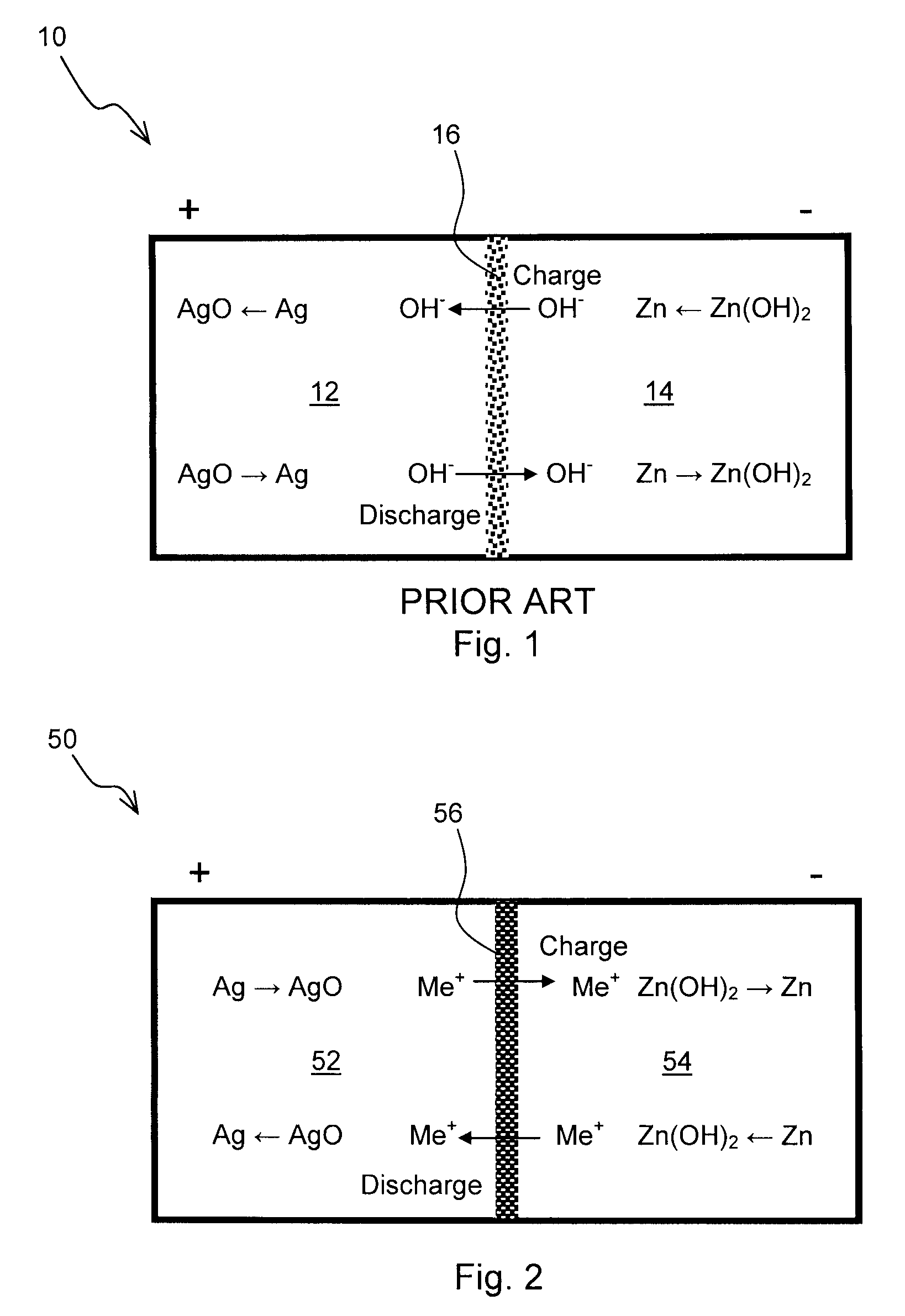

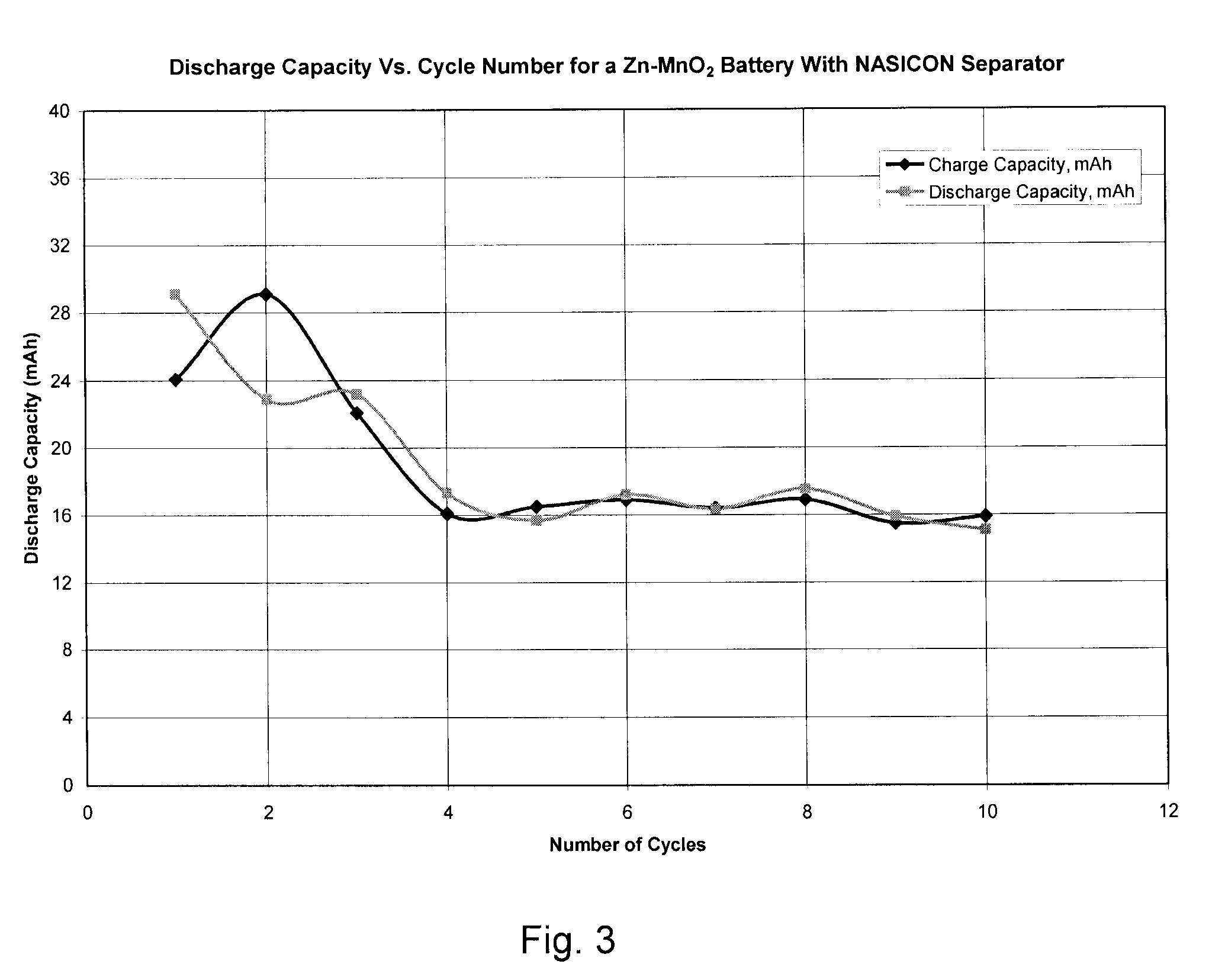

Zinc Anode Battery Using Alkali Ion Conducting Separator

InactiveUS20090189567A1Eliminates capacity lossEliminates self dischargeAlkaline accumulatorsBatteries circuit arrangementsAlkali ionsElectrolyte

A zinc anode storage battery comprising a first electrode containing zinc or a zinc alloy, a second electrode containing an oxidizing material capable of electrochemical reduction by zinc, an alkaline electrolyte, and a substantially non-porous, alkali-ion conducting separator provided between the first electrode and the second electrode. The alkali conducting separator may be a solid alkali metal ion super ion conducting material, wherein the alkali metal is Na, K, or Li.

Owner:CERAMTEC

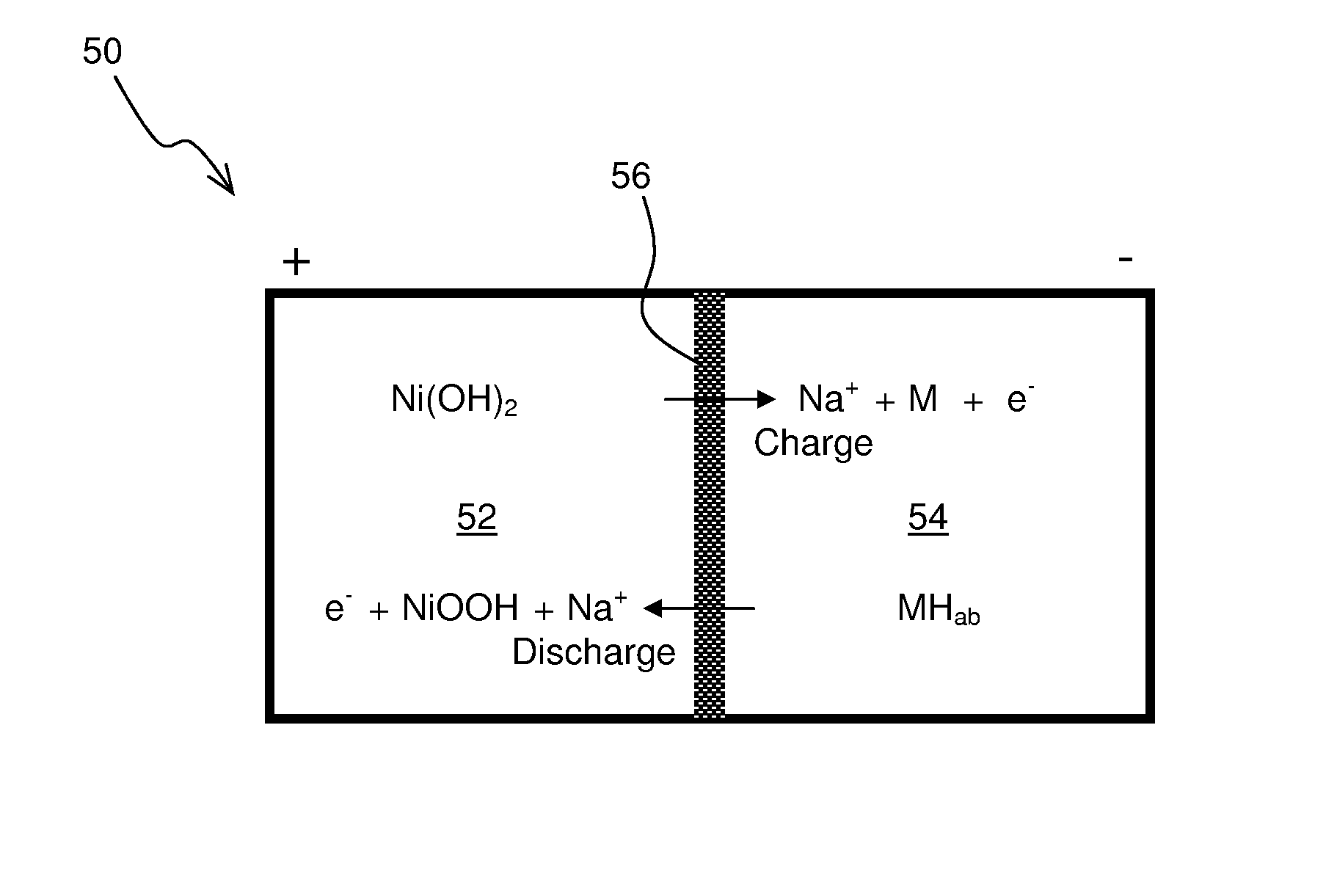

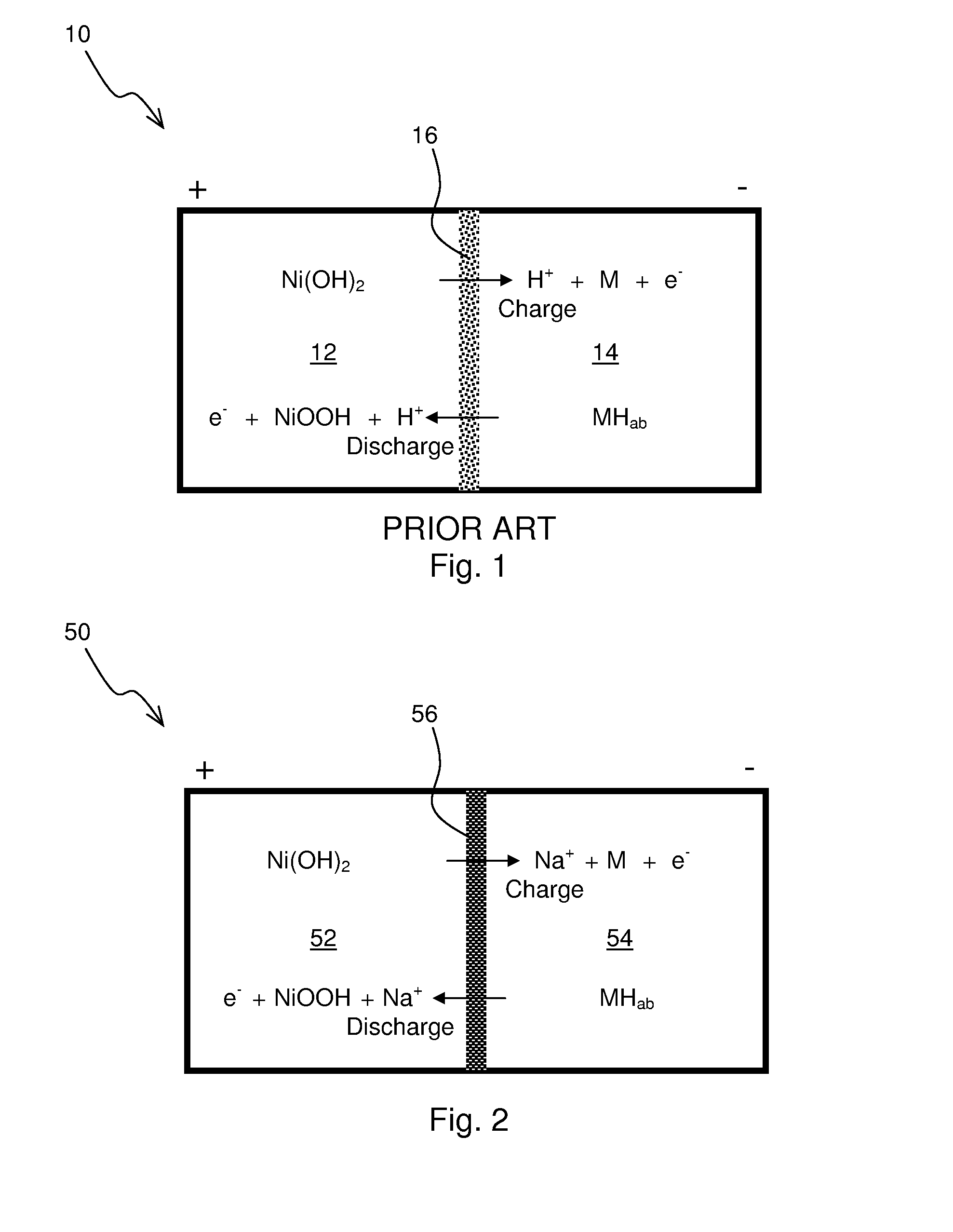

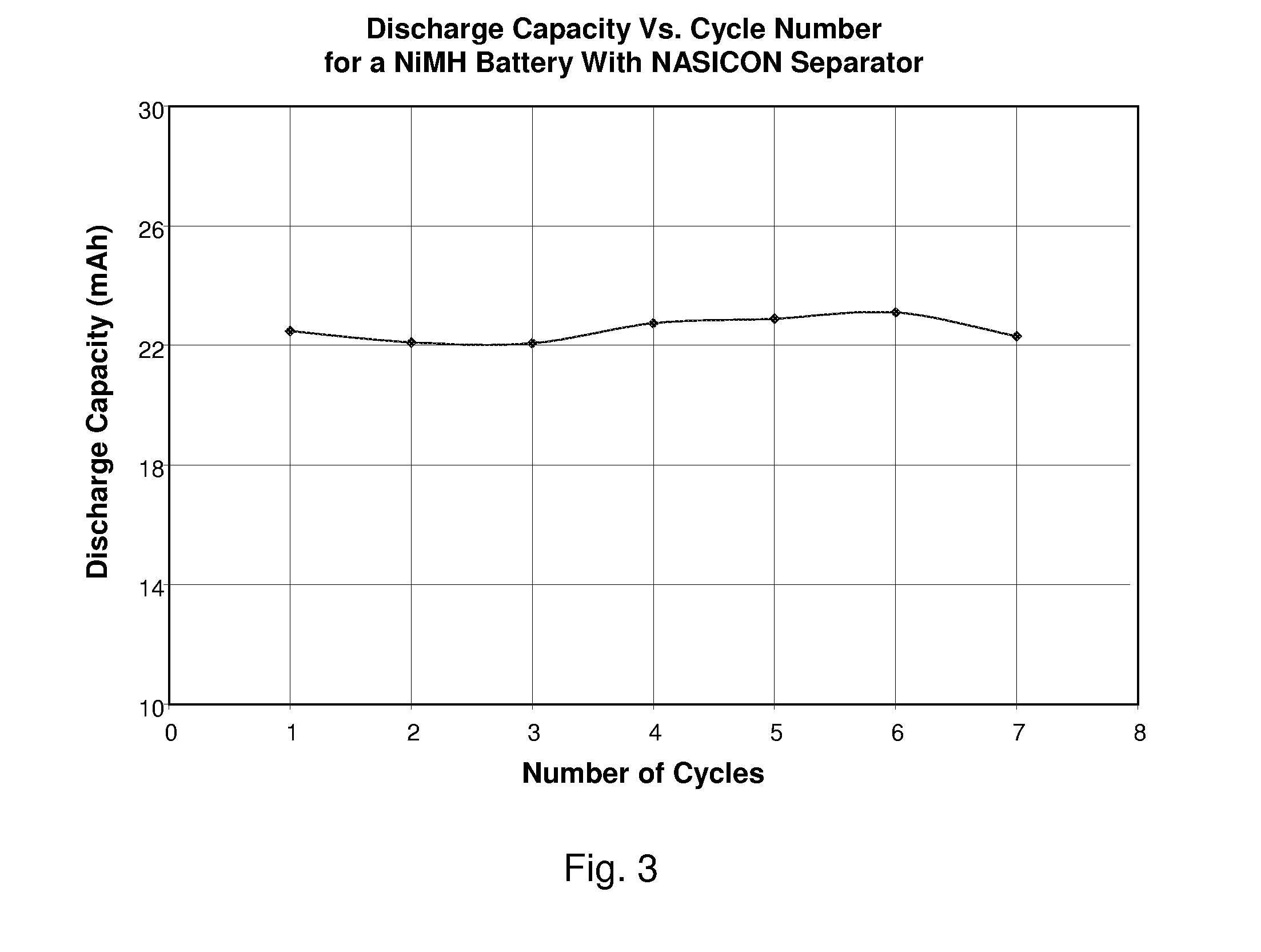

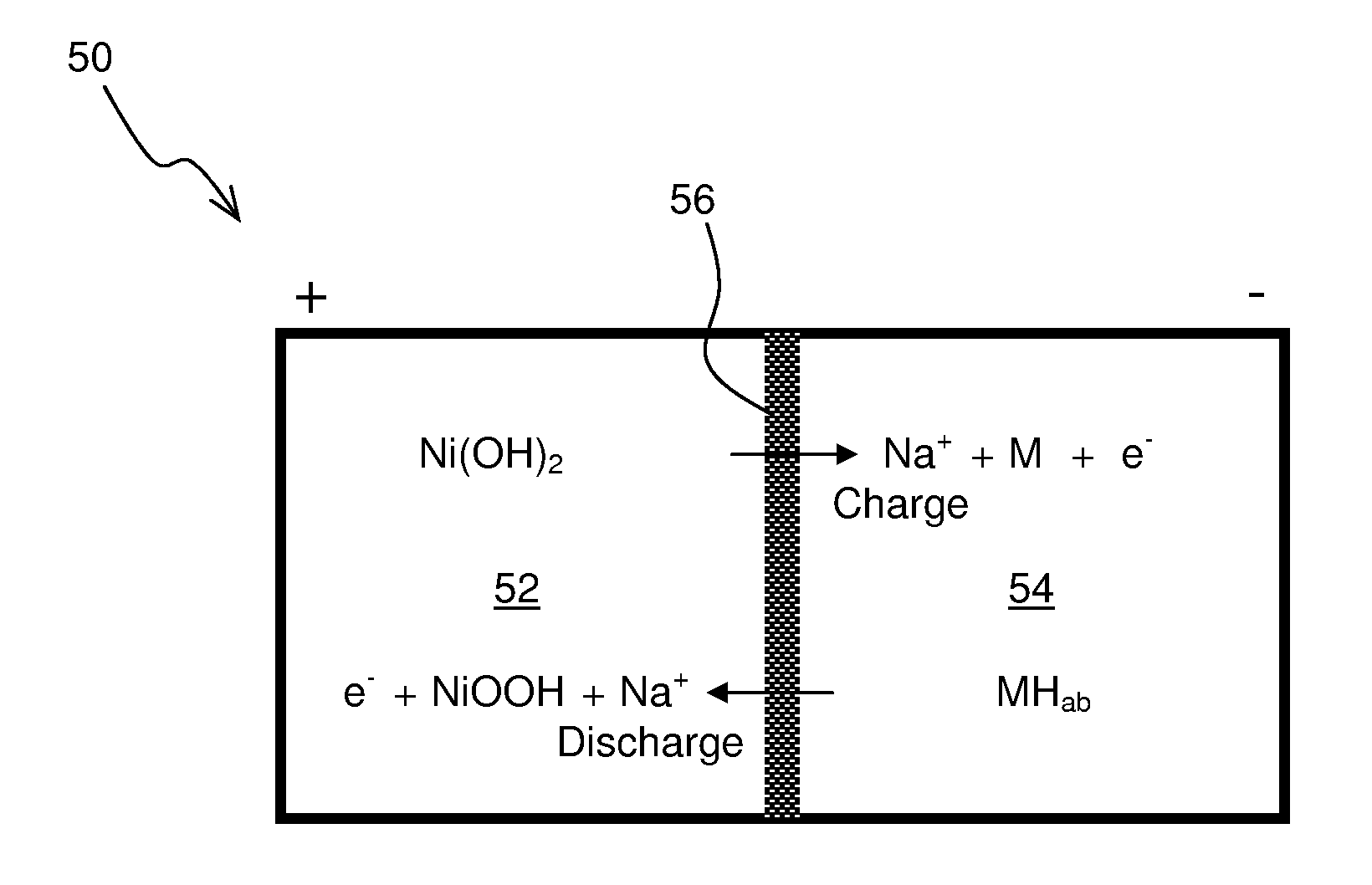

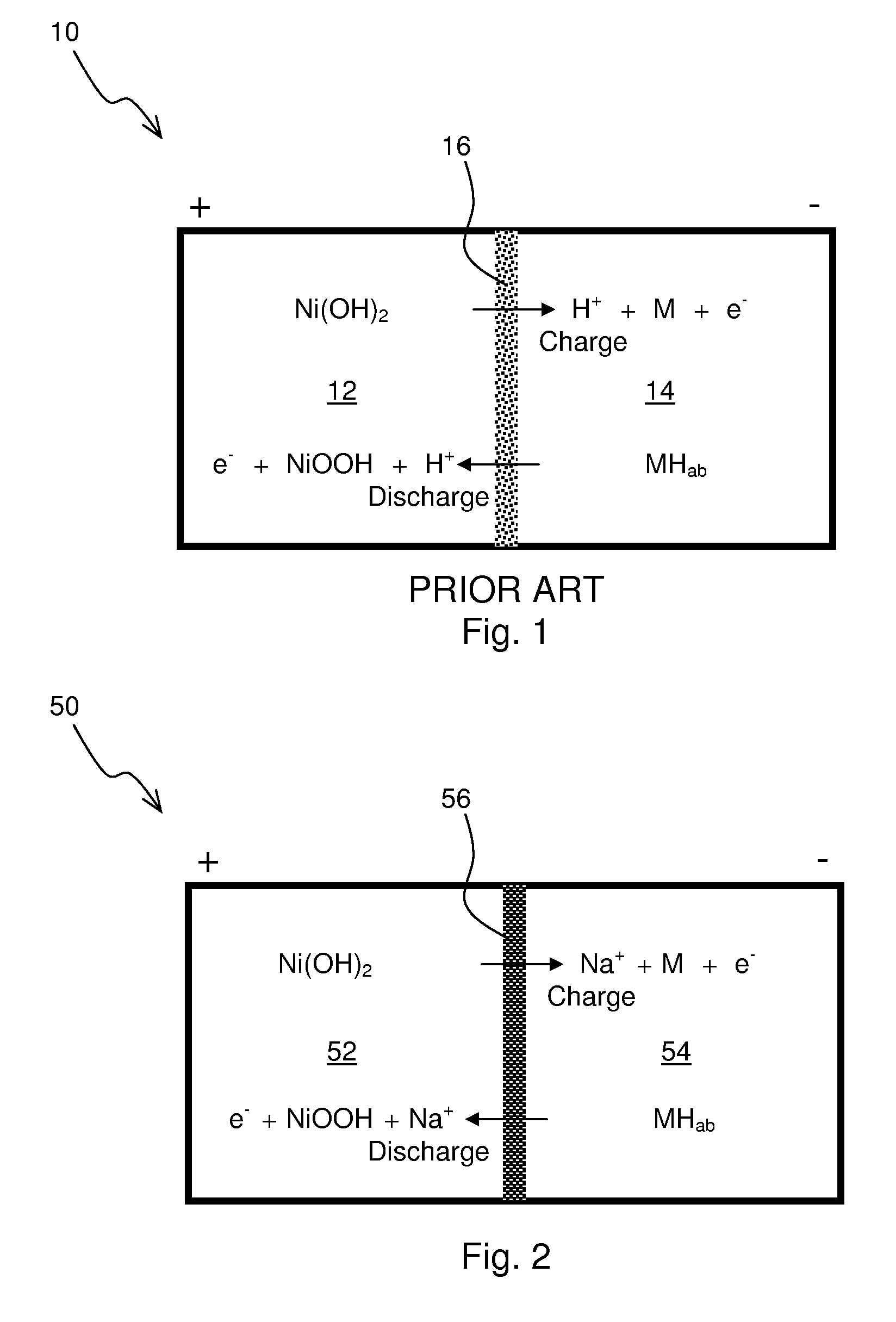

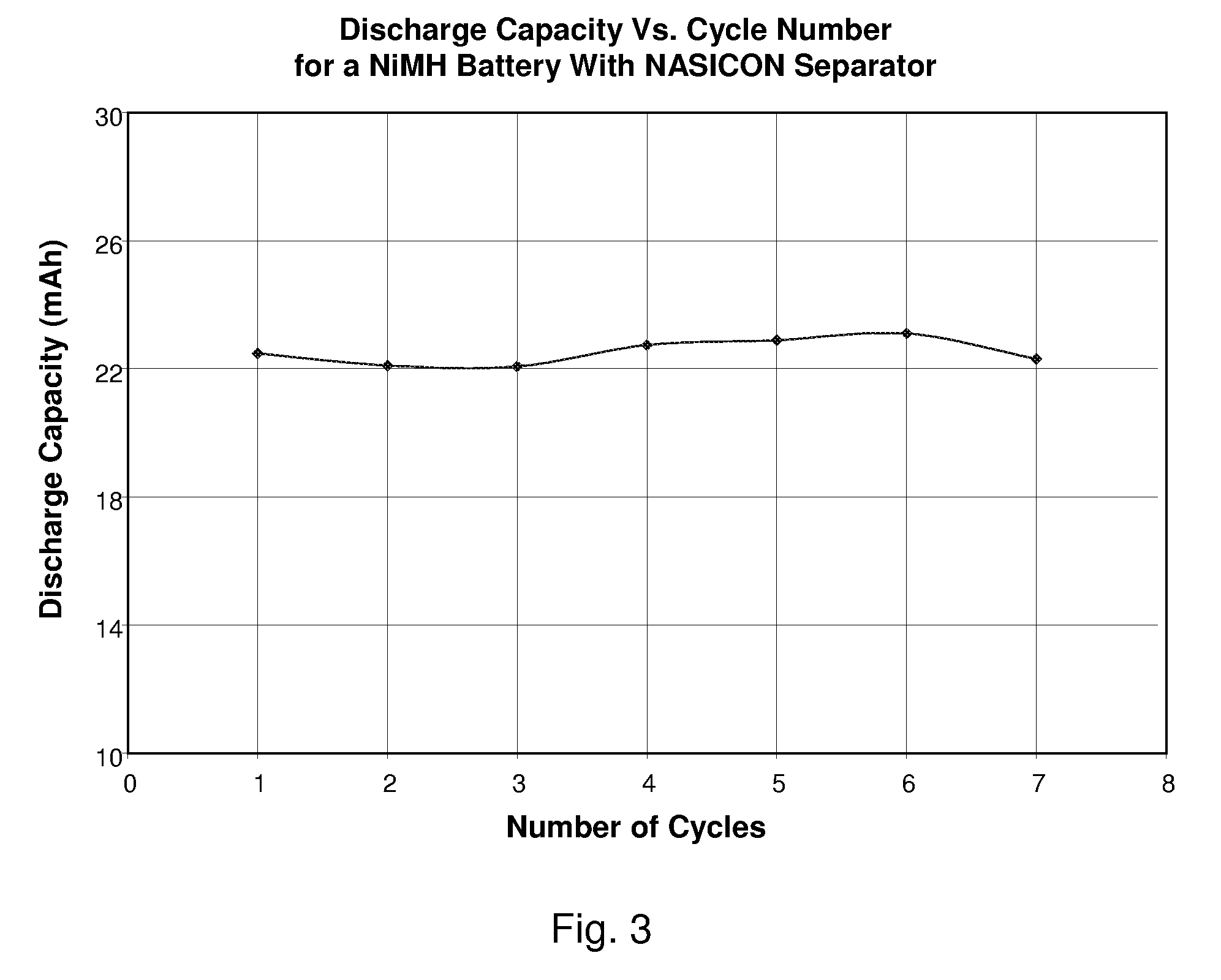

Nickel-Metal Hydride Battery Using Alkali Ion Conducting Separator

ActiveUS20090134842A1Eliminates capacity lossEliminates self dischargeBatteries circuit arrangementsAlkaline accumulatorsAlkali ionsNickel oxide hydroxide

A nickel-metal hydride storage battery comprising a positive electrode containing nickel hydroxide, a negative electrode containing a hydrogen absorbing alloy, an alkaline electrolyte, and an alkali conducting separator provided between the positive electrode and the negative electrode. The alkali conducting separator may be a solid alkali metal ion super ion conducting material, wherein the alkali metal is Na, K, or Li

Owner:FIELD UPGRADING USA INC

Synthesis of higher polyol fatty acid polyesters by transesterification

InactiveUS6504003B1Process economyHigh degree of esterificationEsterified saccharide compoundsSugar derivativesPolyesterTrans esterification

A process for synthesizing polyol fatty acid polyesters comprising the steps of (1) mixing ingredients comprising (a) unesterified first polyol having hydroxyl groups, (b) second polyol esterified with fatty acids, (c) basic catalyst, and (d) emulsifying agent to form a mixture of ingredients; (2) reacting the mixture of ingredients at a temperature sufficient to obtain a transesterification reaction products and by-products; and (3) removing at least a portion of the by-products from the transesterification reaction mixture; and (4) further heating the transesterification reaction products and ingredients from step (3) at a temperature and for a time sufficient to esterify at least about 50% of the hydroxyl groups of the first polyol.

Owner:THE PROCTER & GAMBLE COMPANY

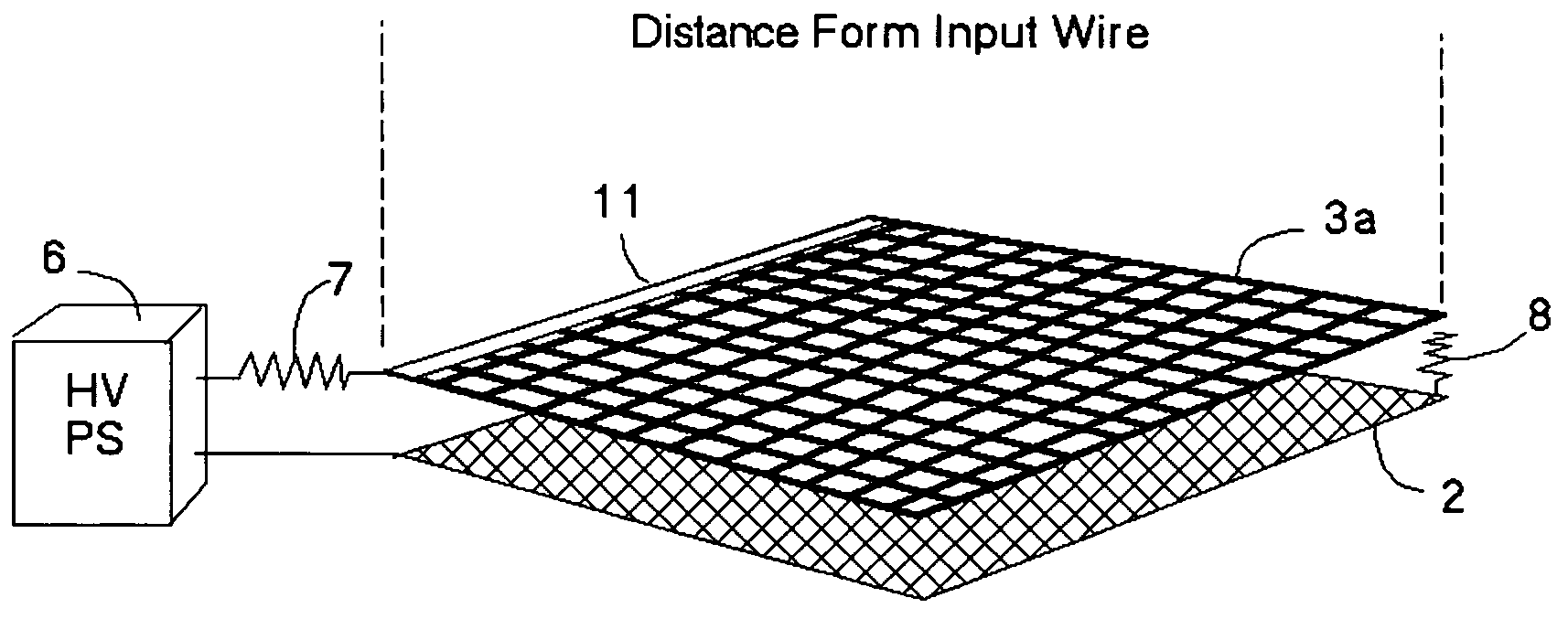

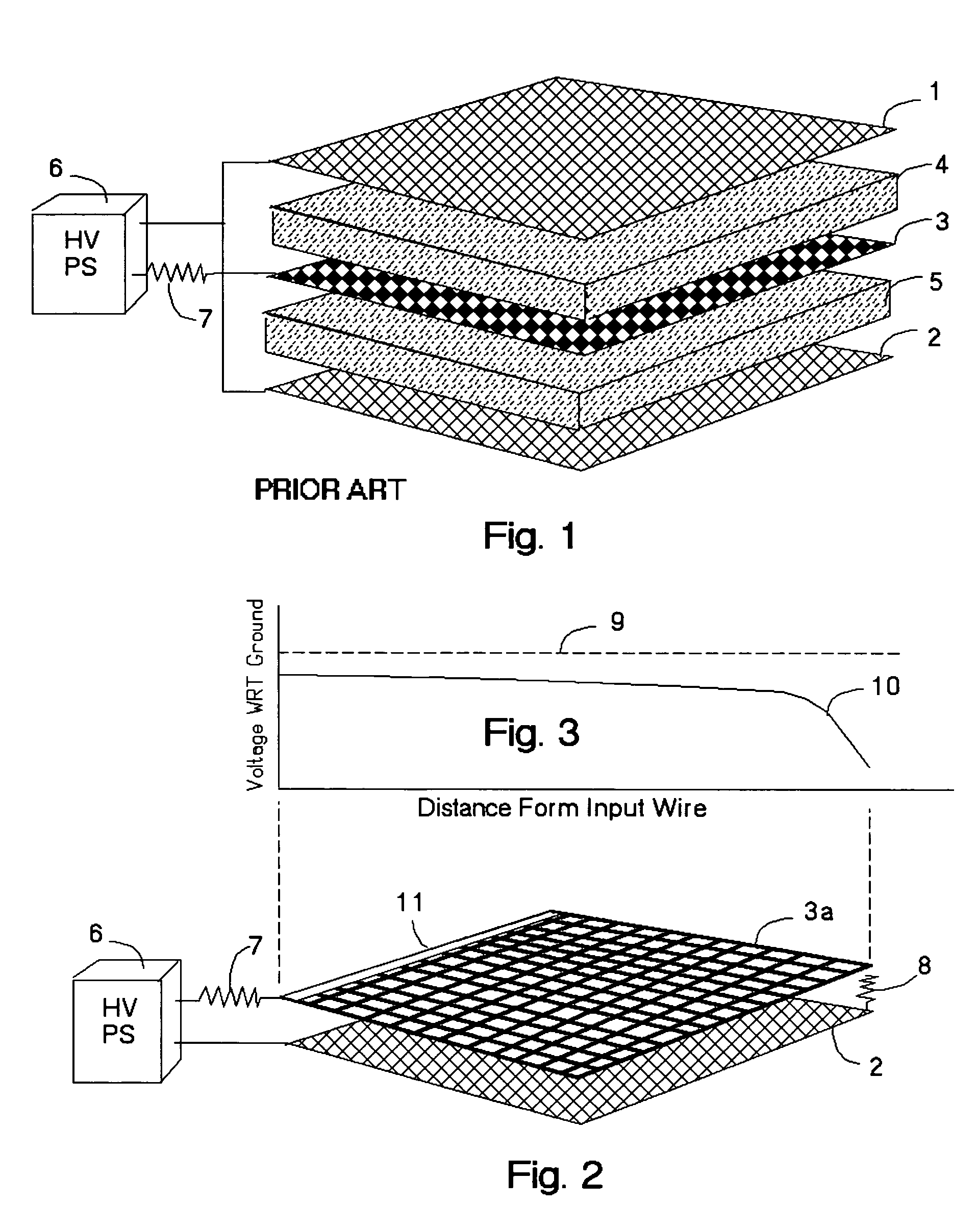

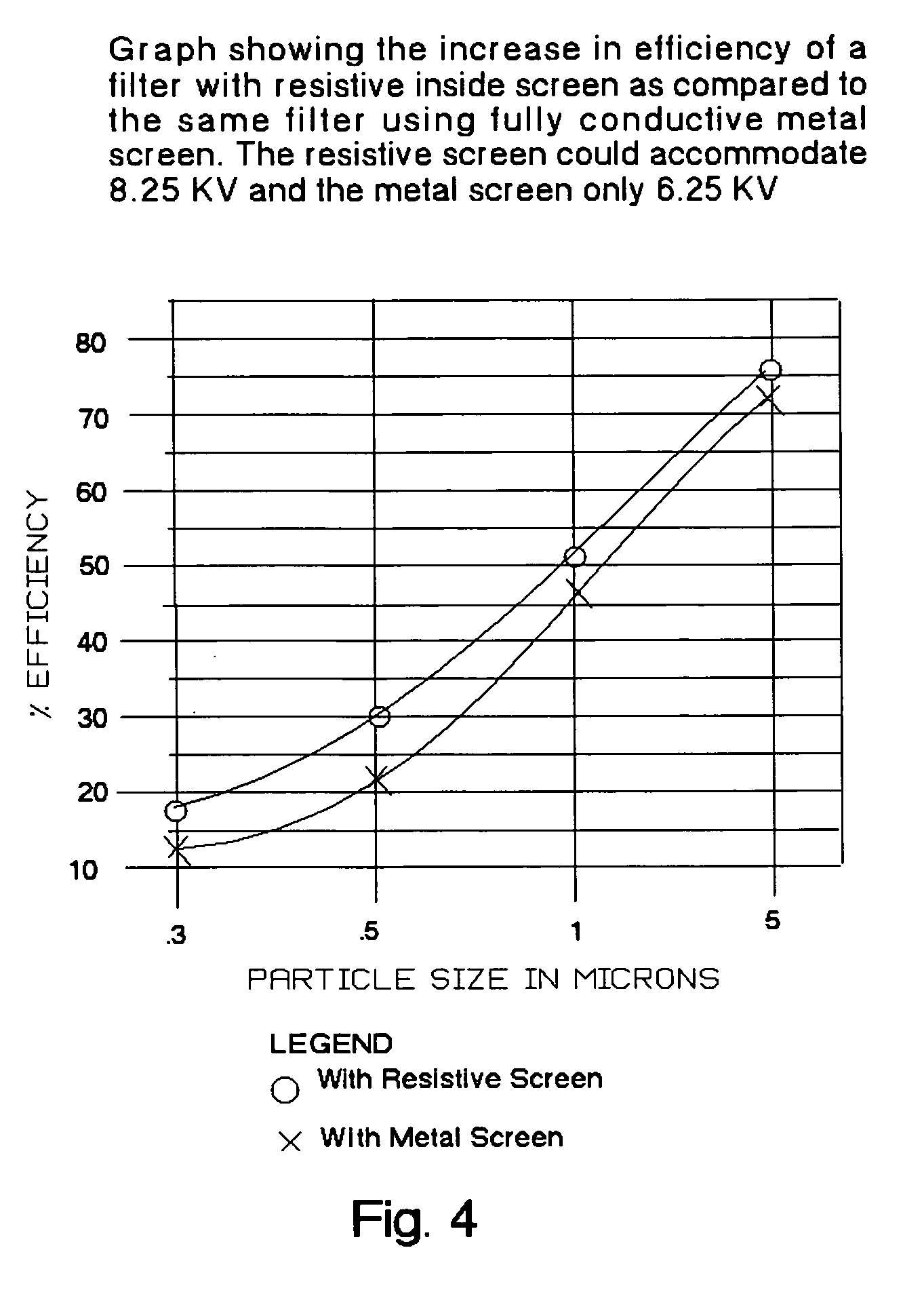

Electronic air filter with resistive screen and electronic modular assembly

InactiveUS20060137527A1Reduce dischargeGood polarizationExternal electric electrostatic seperatorElectrode constructionsElectric arcEngineering

Owner:JOANNOU CONSTANTINOS J

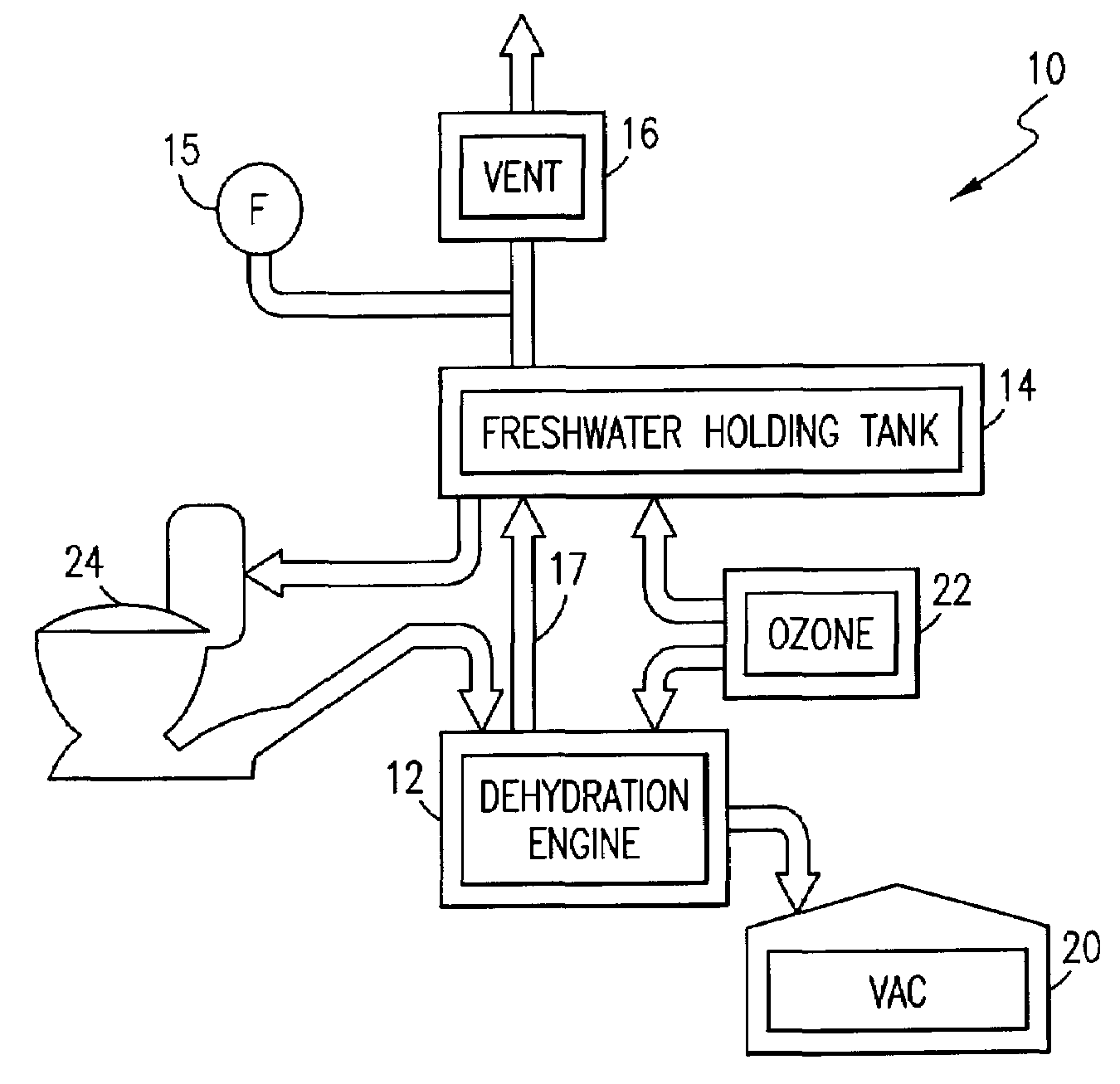

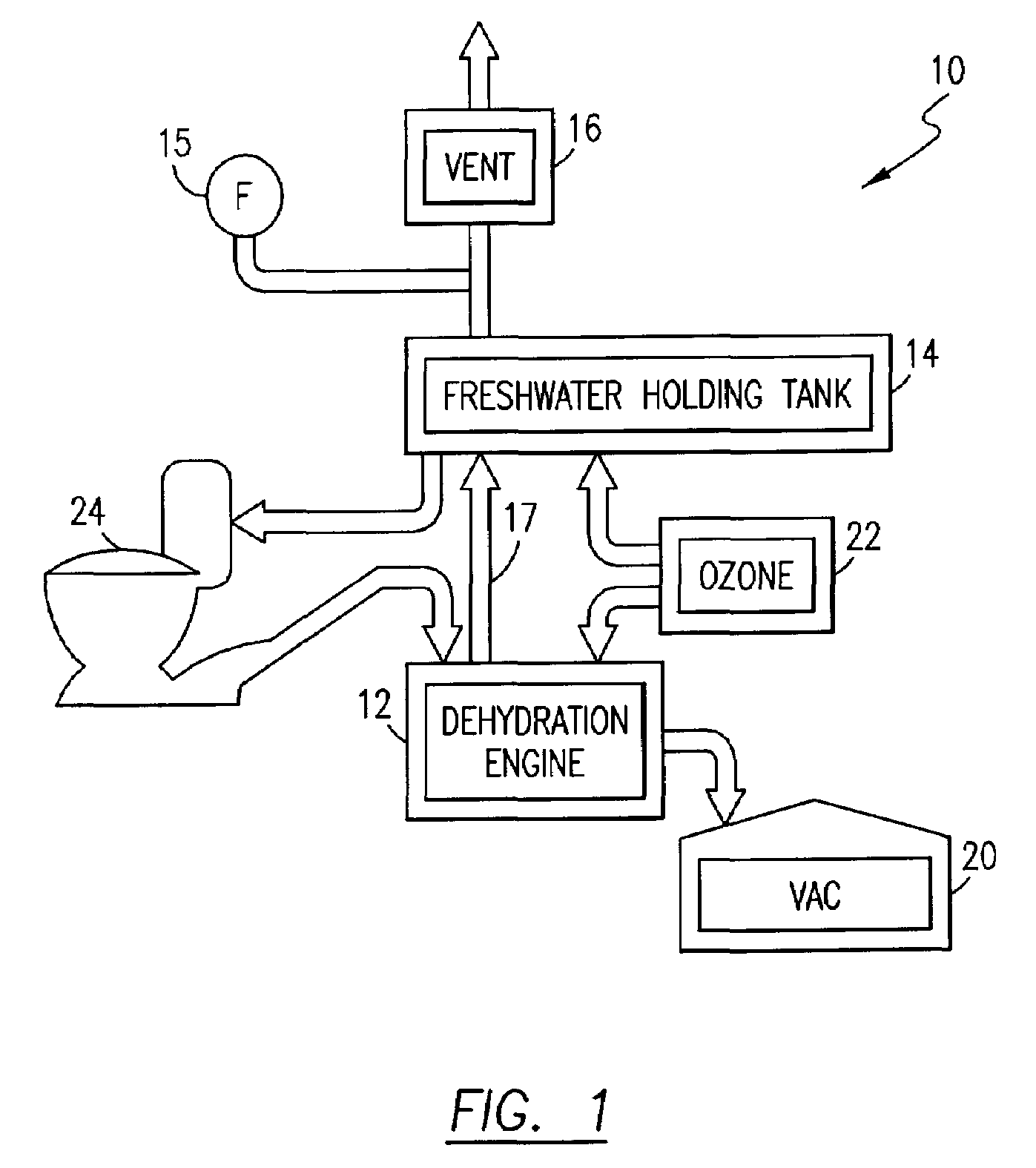

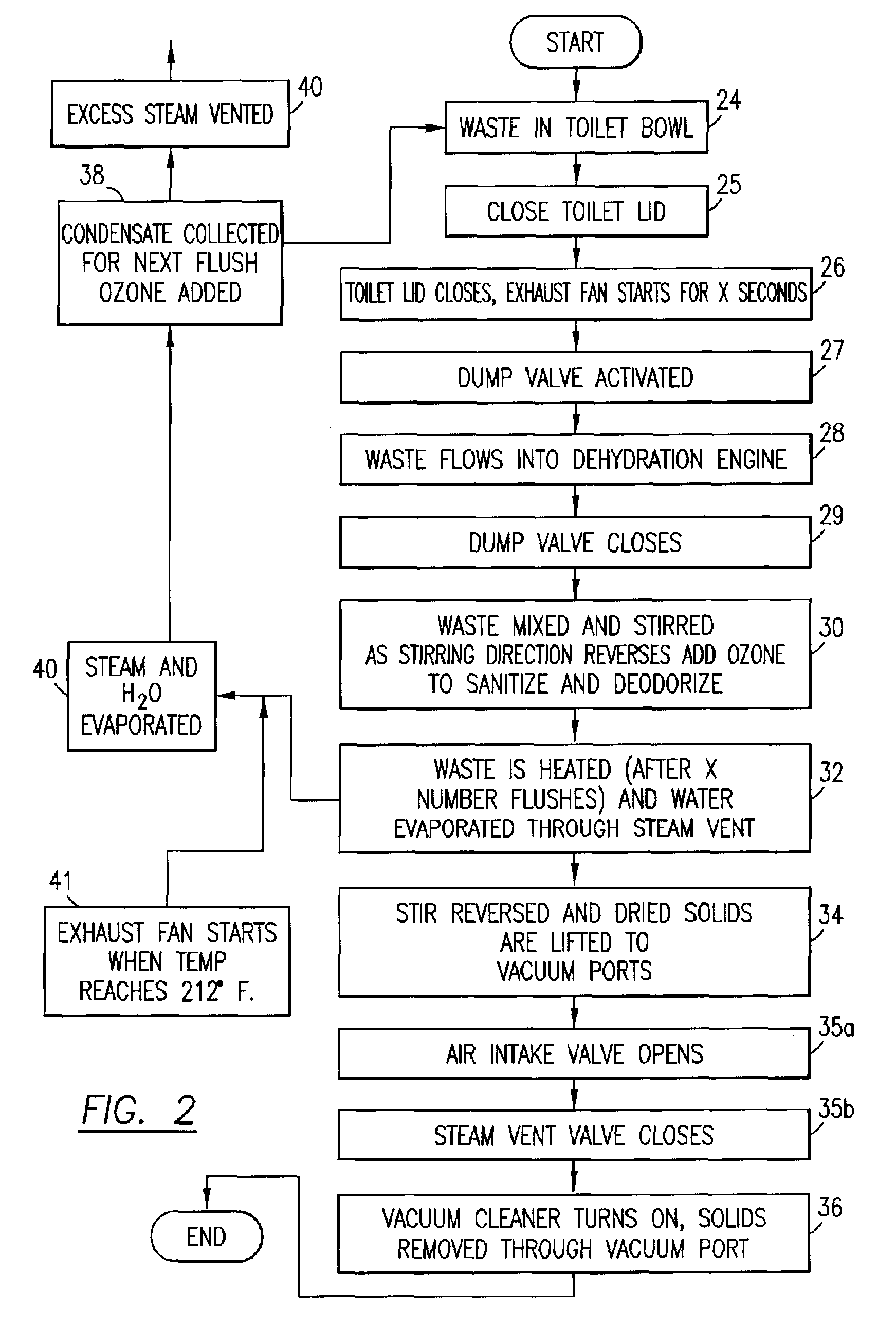

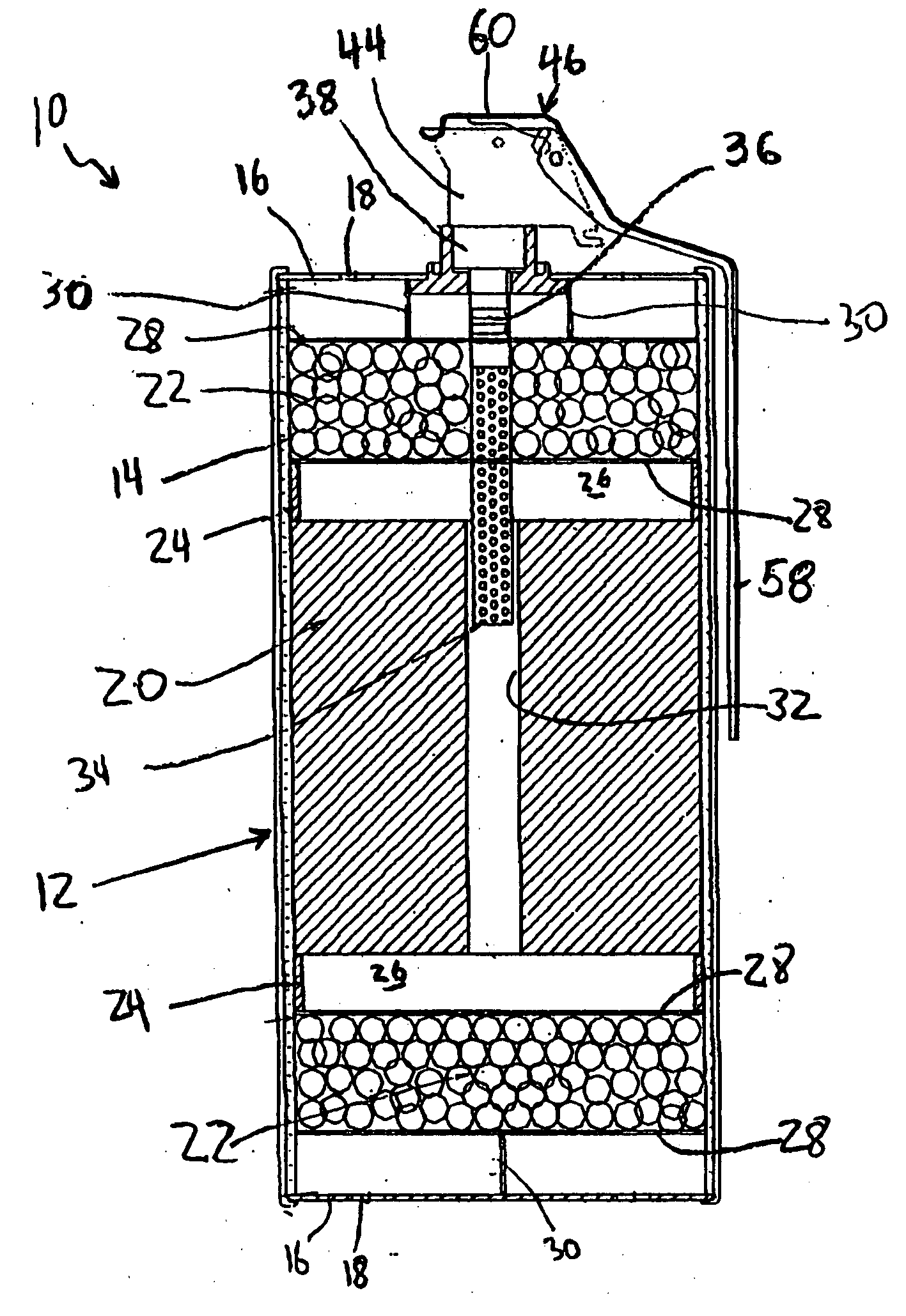

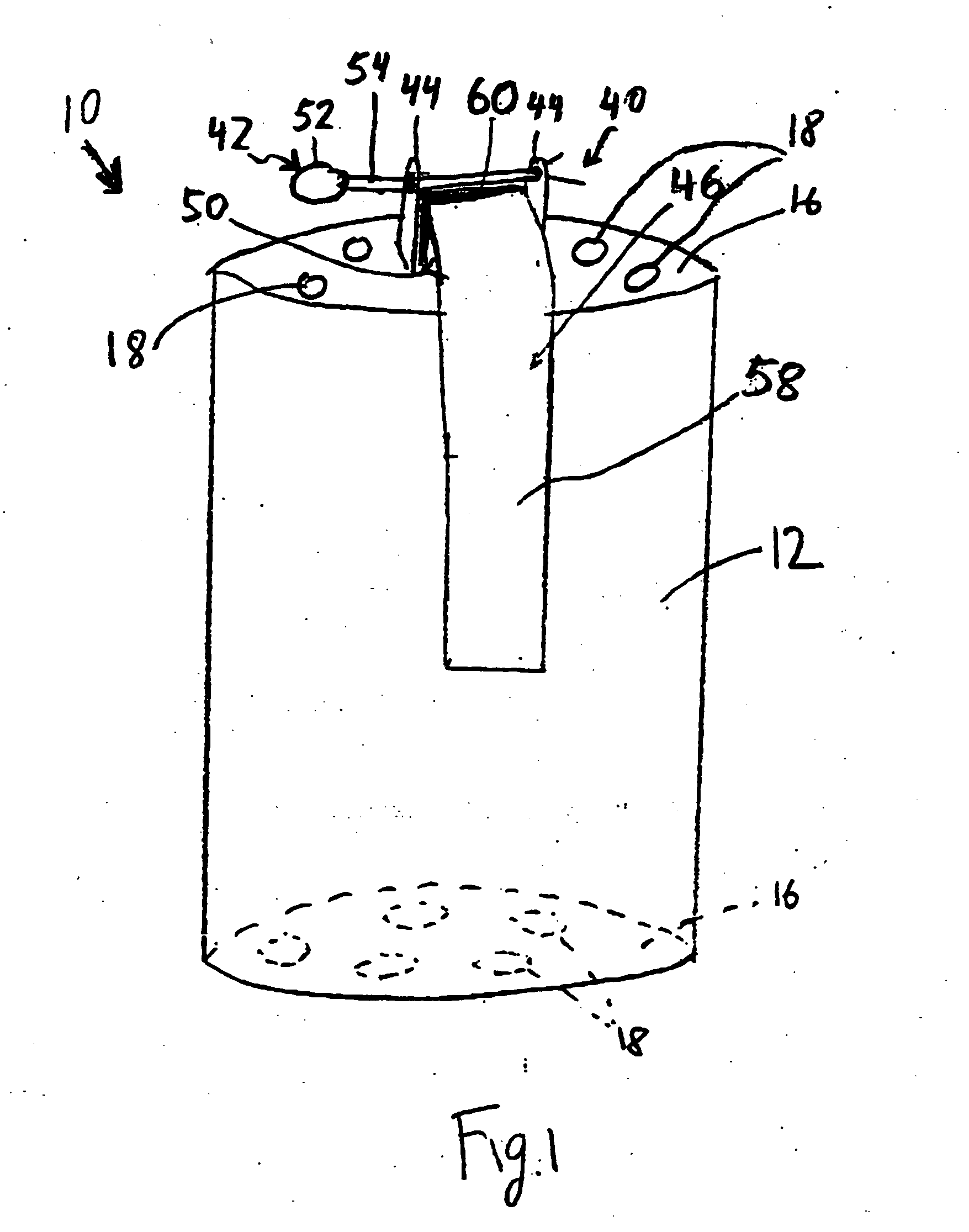

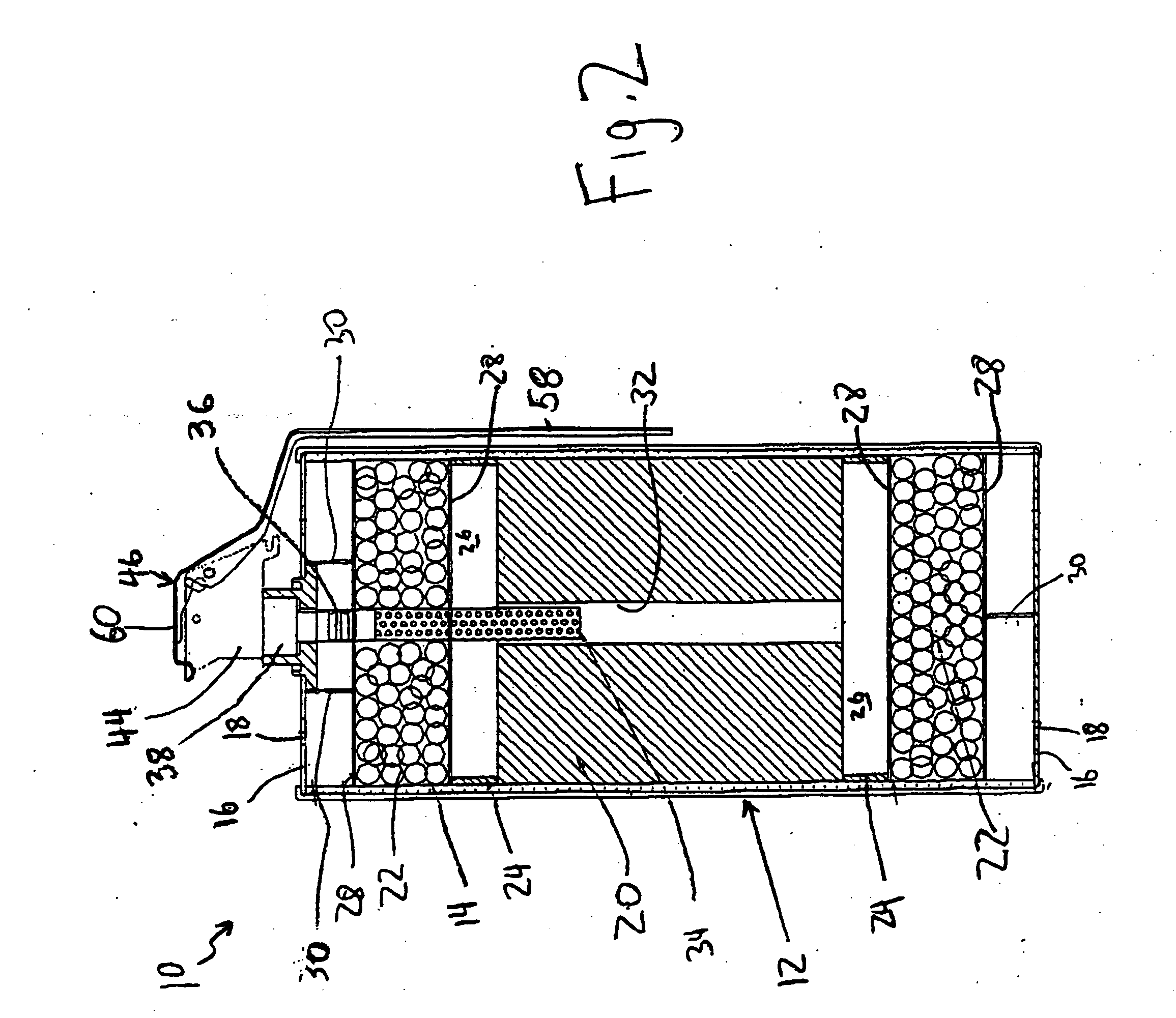

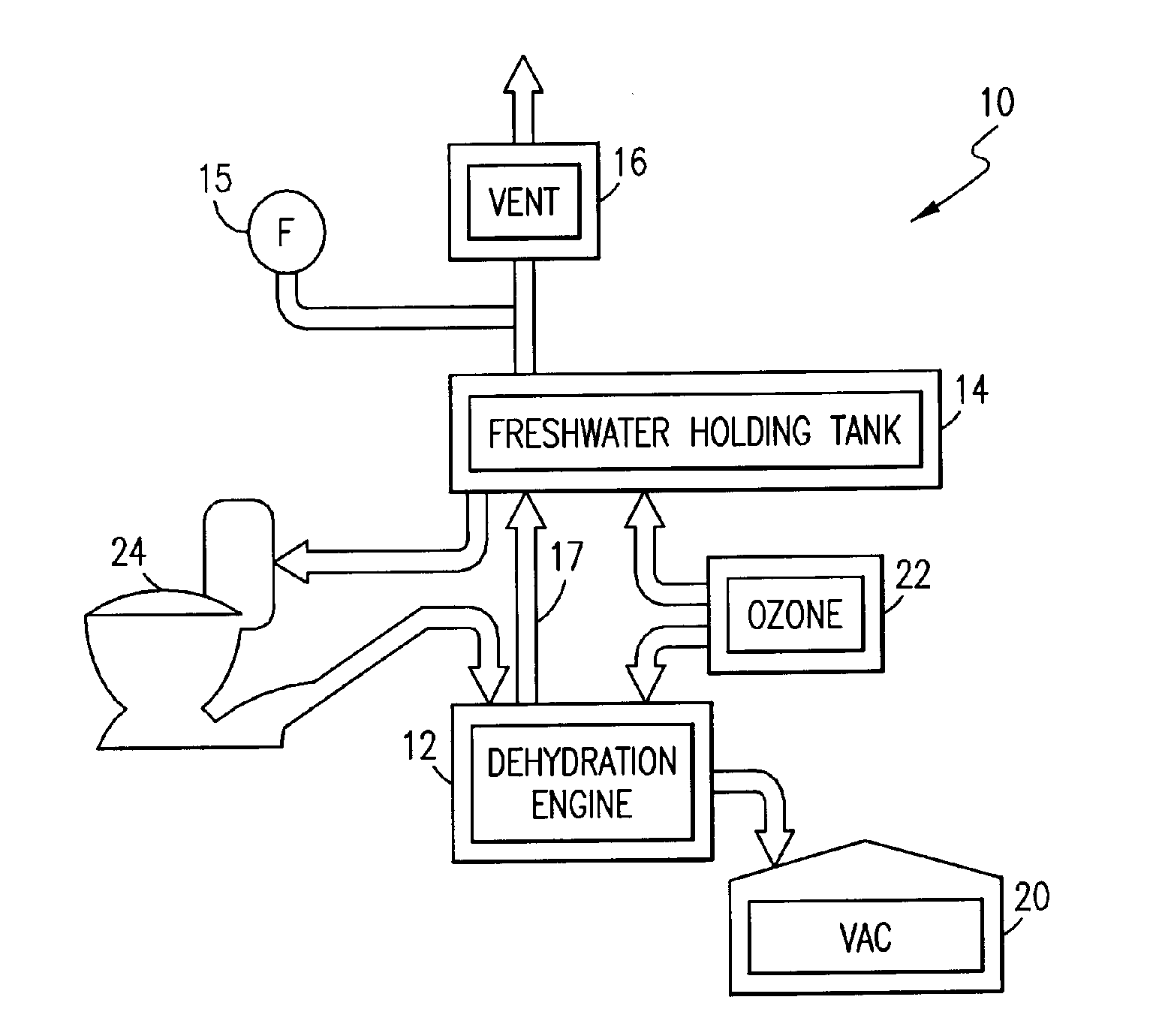

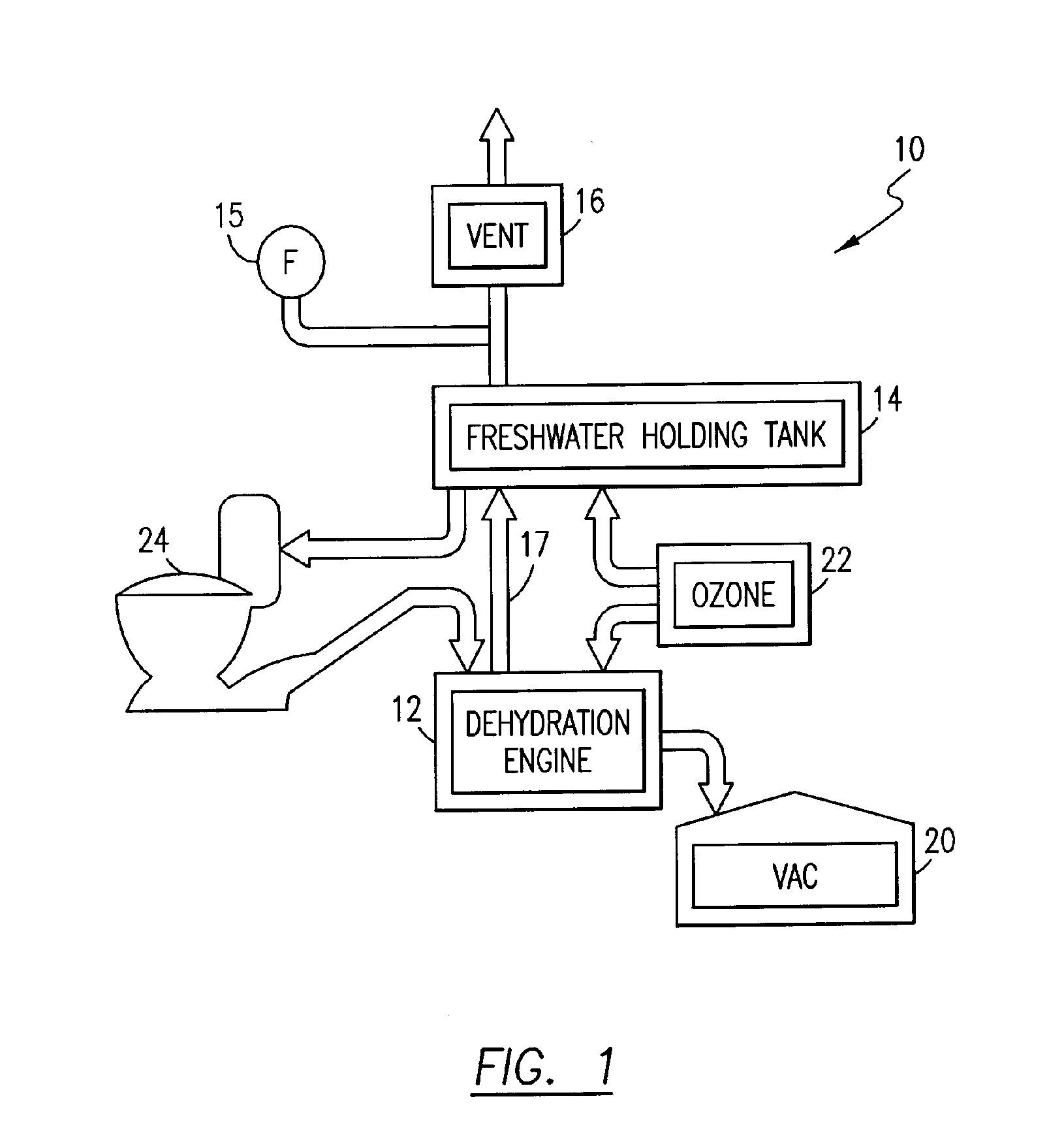

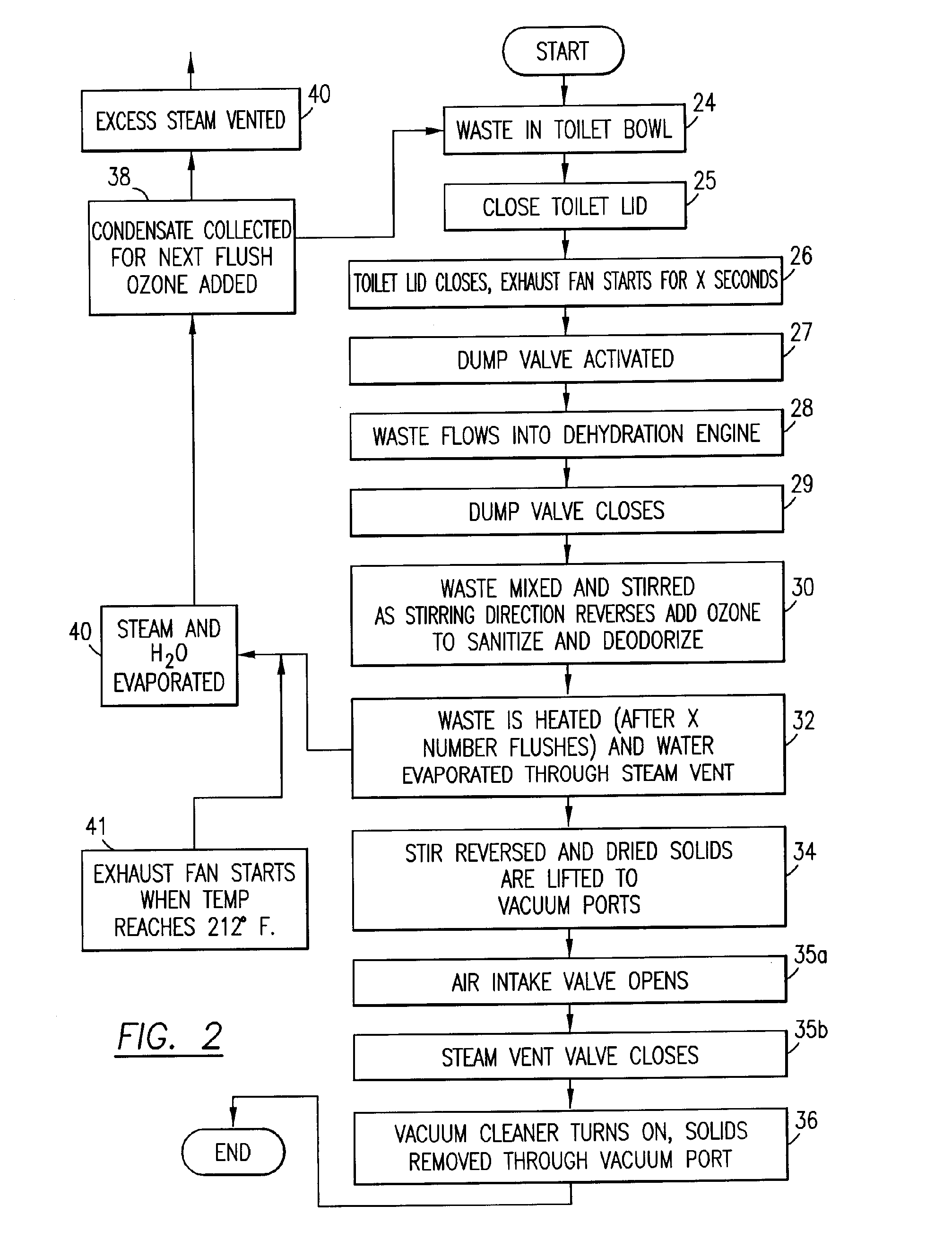

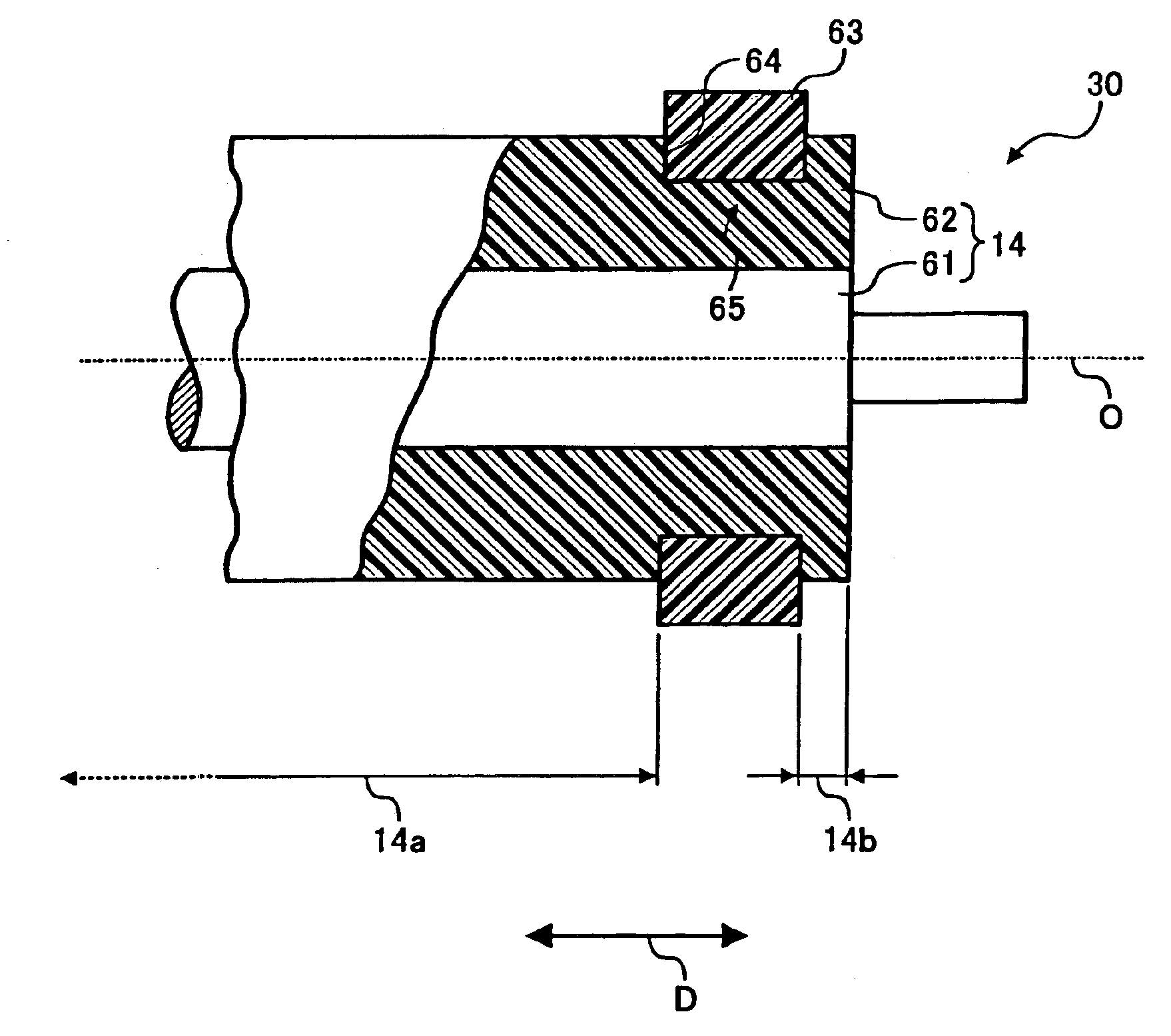

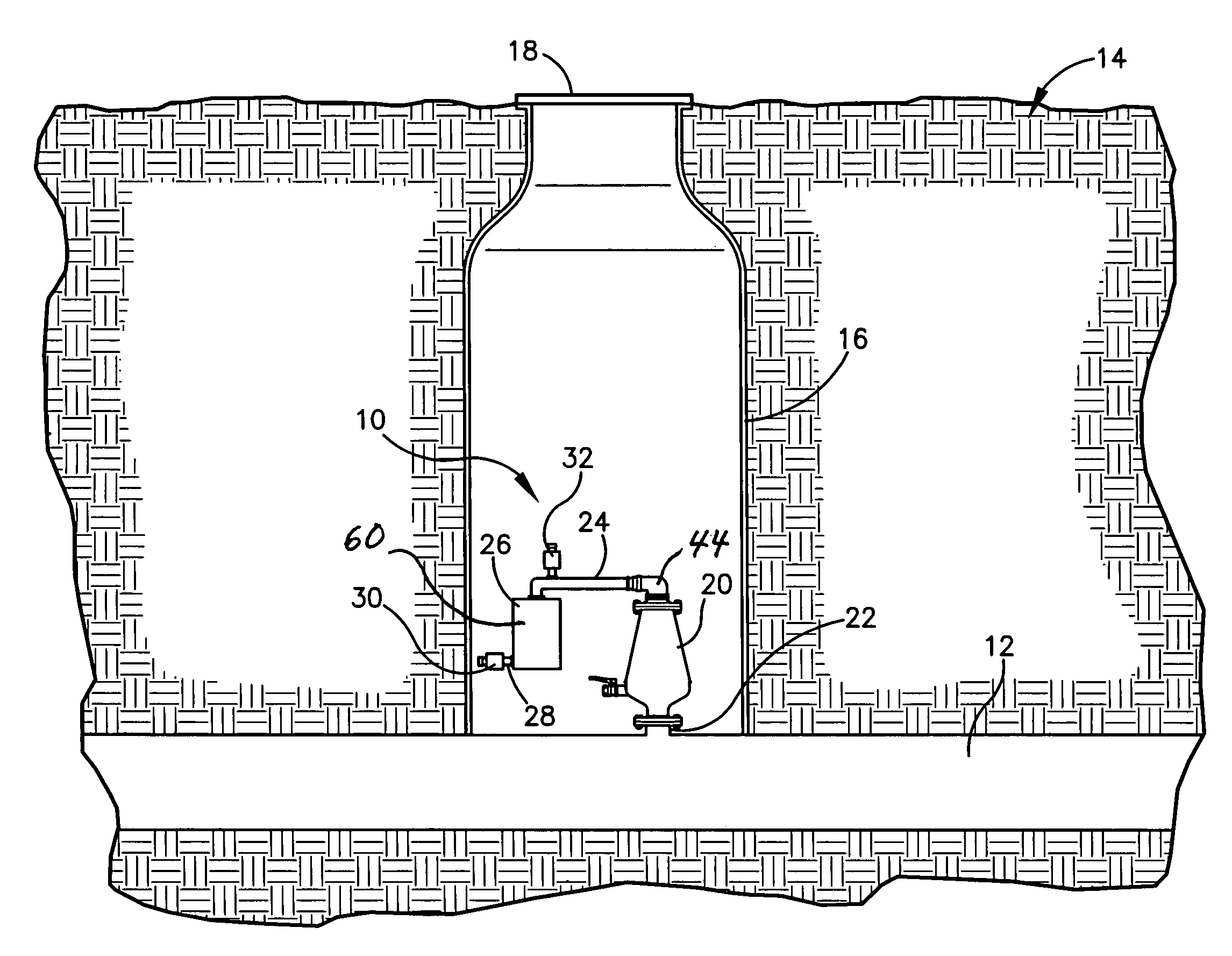

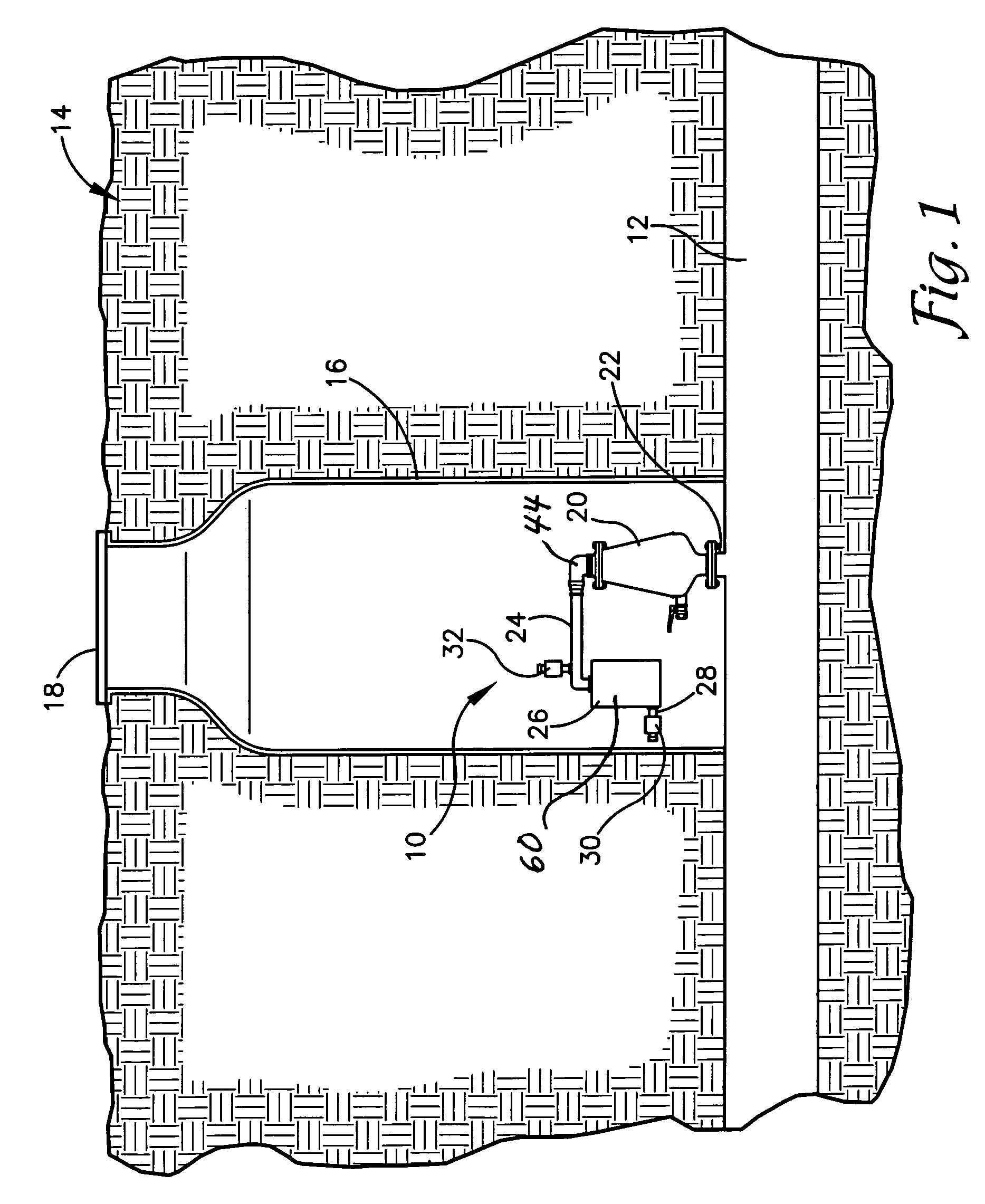

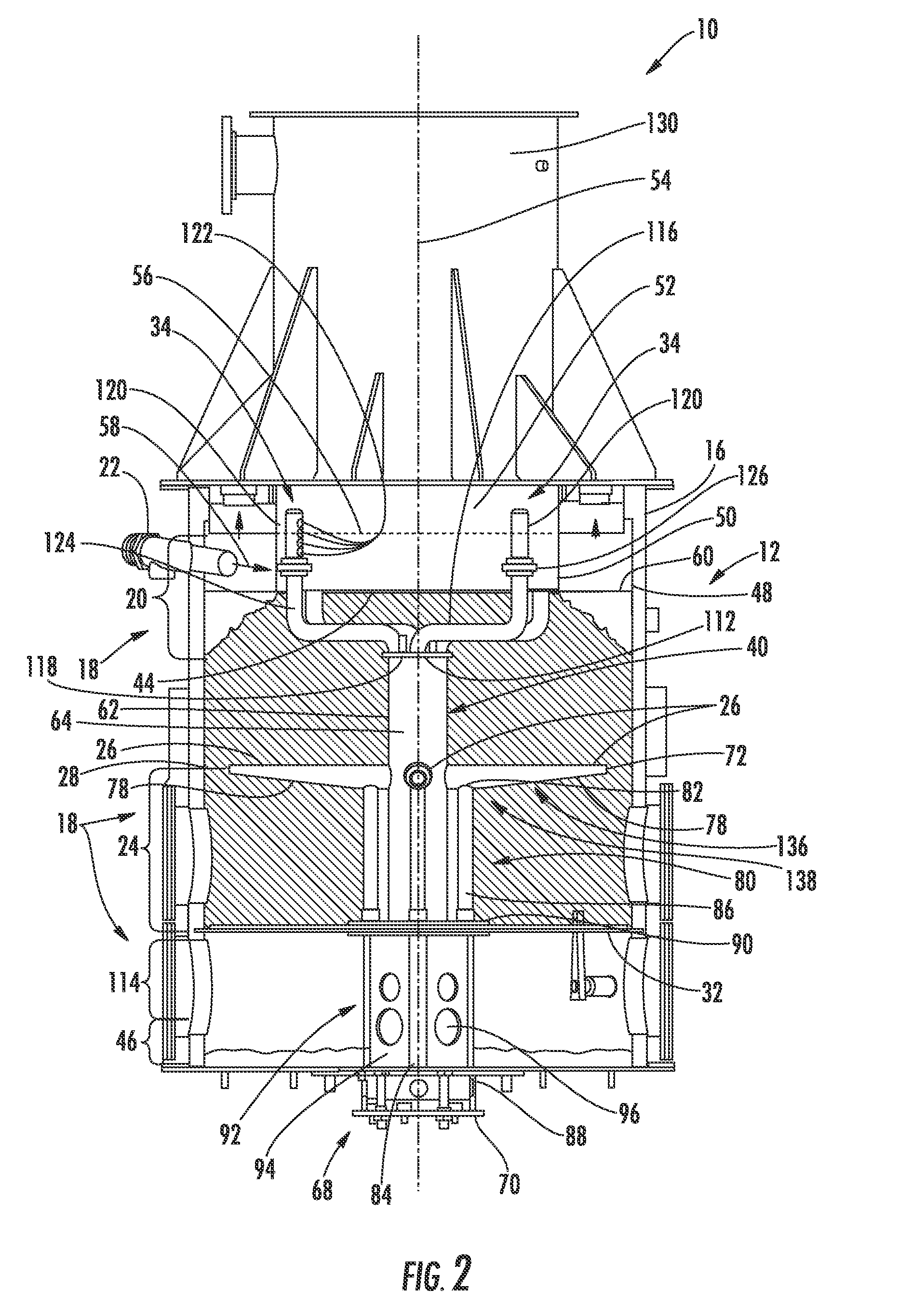

Mobile or stationary modular self-contained dehydration toilet, dehydration engine, and gray water recovery system

InactiveUS7211187B2Reduce solid wasteEliminate dischargeGeneral water supply conservationSustainable biological treatmentHuman wasteWater source

A compact dehydration engine and method for treating human waste and gray water residual electro-coagulants that includes a heated waste dehydration chamber that has low energy consumption and low water consumption in use. The system can be employed in stationary or mobile platforms that include multiple toilets and gray water sources for reclamation.

Owner:ZECO LTD

Nickel-metal hydride battery using alkali ion conducting separator

ActiveUS8012621B2Reduce capacityEliminate dischargeFinal product manufactureAlkaline accumulator electrodesAlkali ionsElectrolyte

A nickel-metal hydride storage battery comprising a positive electrode containing nickel hydroxide, a negative electrode containing a hydrogen absorbing alloy, an alkaline electrolyte, and an alkali conducting separator provided between the positive electrode and the negative electrode. The alkali conducting separator may be a solid alkali metal ion super ion conducting material, wherein the alkali metal is Na, K, or Li.

Owner:FIELD UPGRADING USA INC

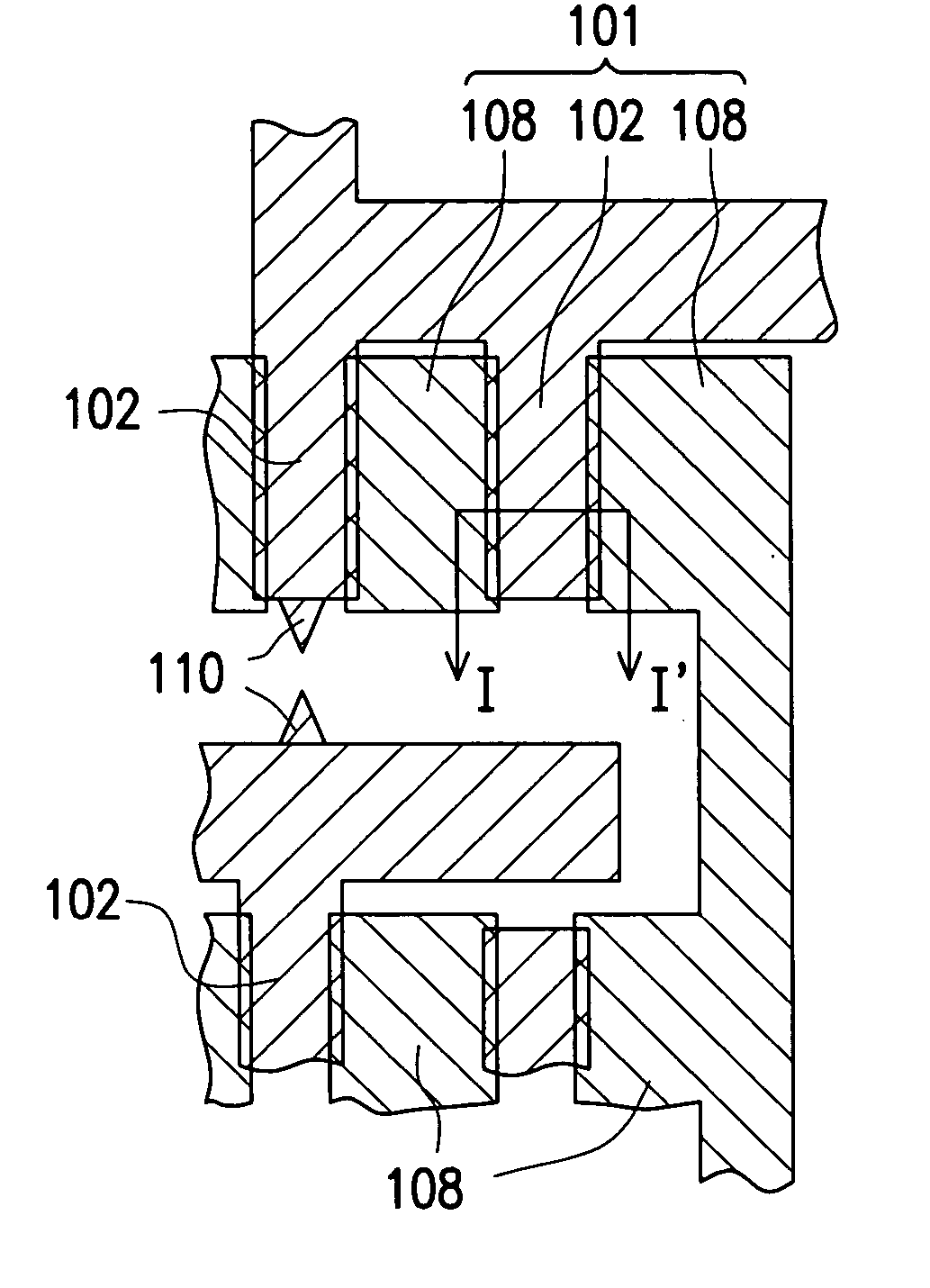

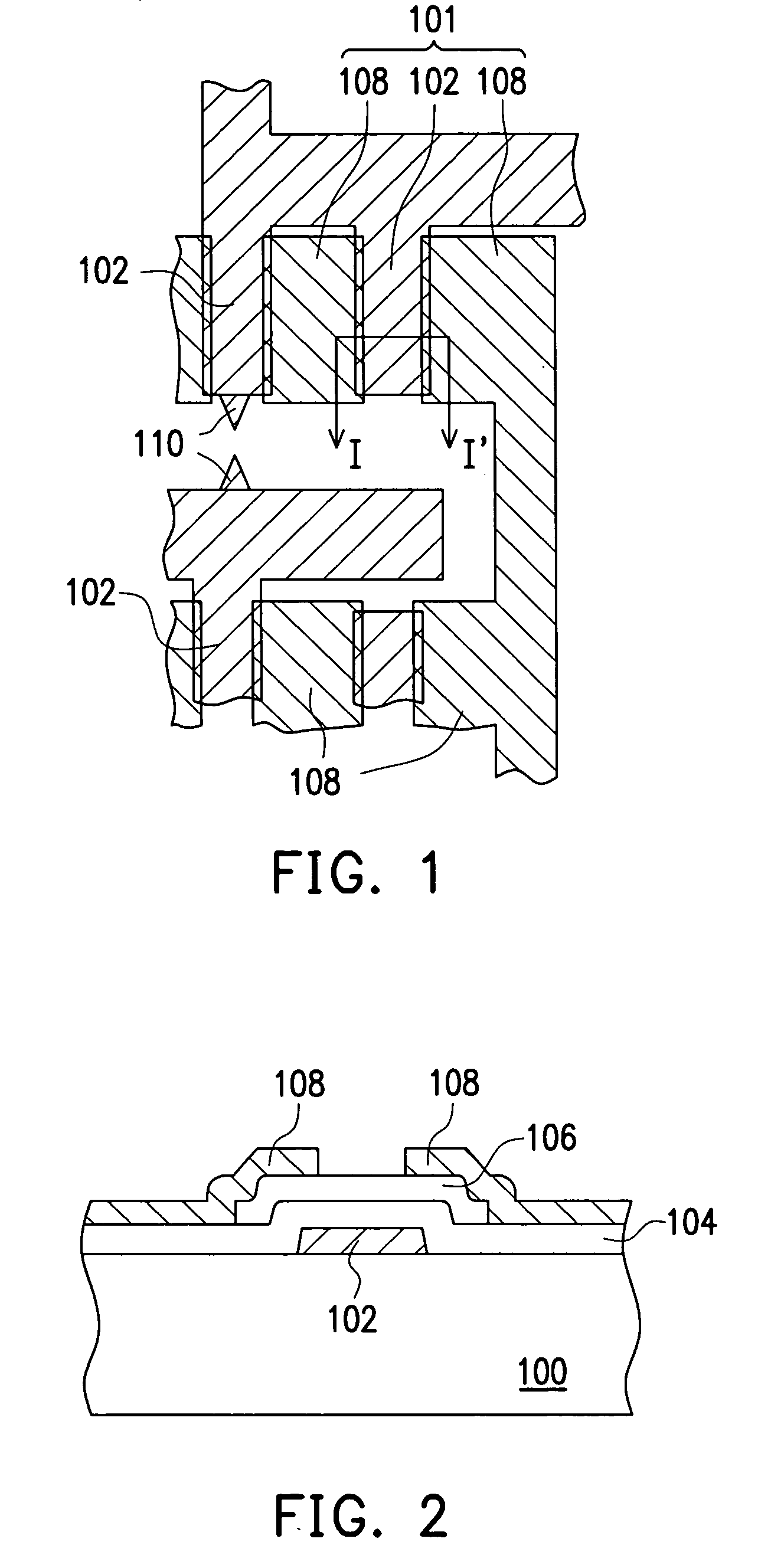

Electrostatic discharge protection circuit

ActiveUS20050023614A1Avoid damageEliminate dischargeTransistorSemiconductor/solid-state device detailsElectrostatic discharge protectionElectrical and Electronics engineering

A structure of an electrostatic discharge protection circuit comprises a plurality of thin film transistors and at least a point structure, wherein each of the thin film transistors comprises a gate and a source / drain. The point structure configures at least a portion of a tail or an edge of the gate. In particular, the point structure is located at region apart from the source / drain. The point structures are disposed at prescribed areas apart from devices, and thereby the devices of the electrostatic discharge protection circuit are free from electrostatic discharges.

Owner:AU OPTRONICS CORP

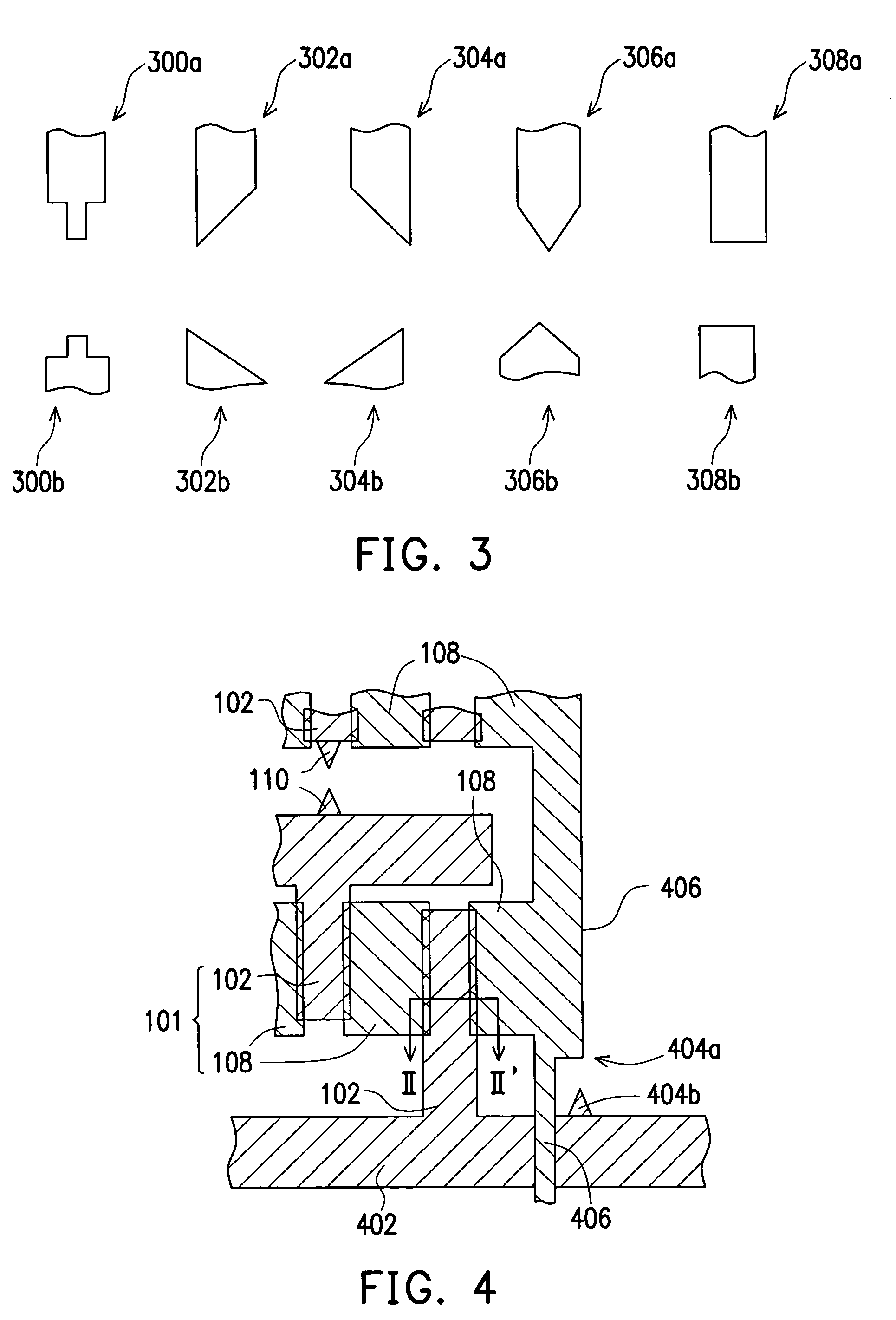

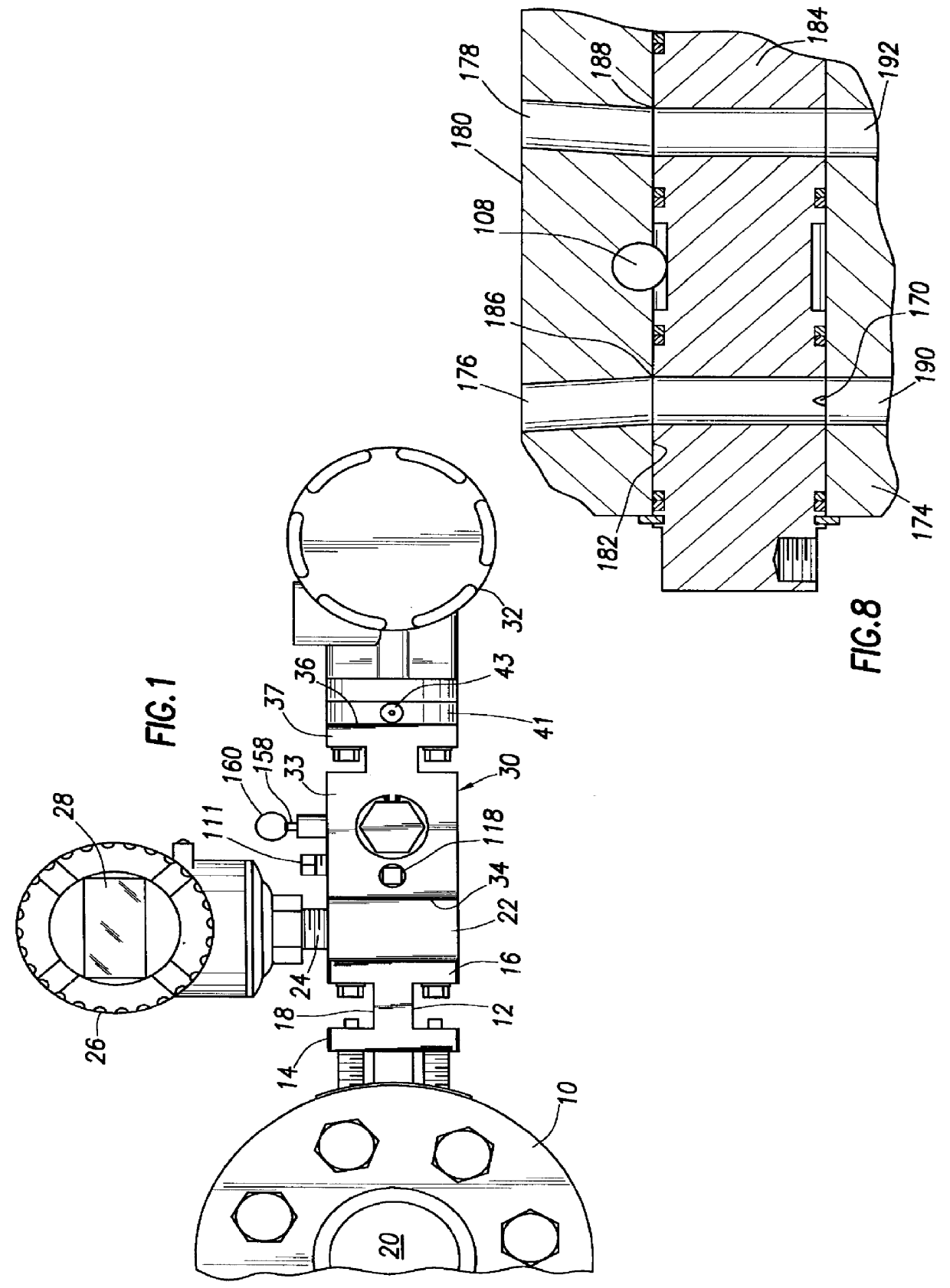

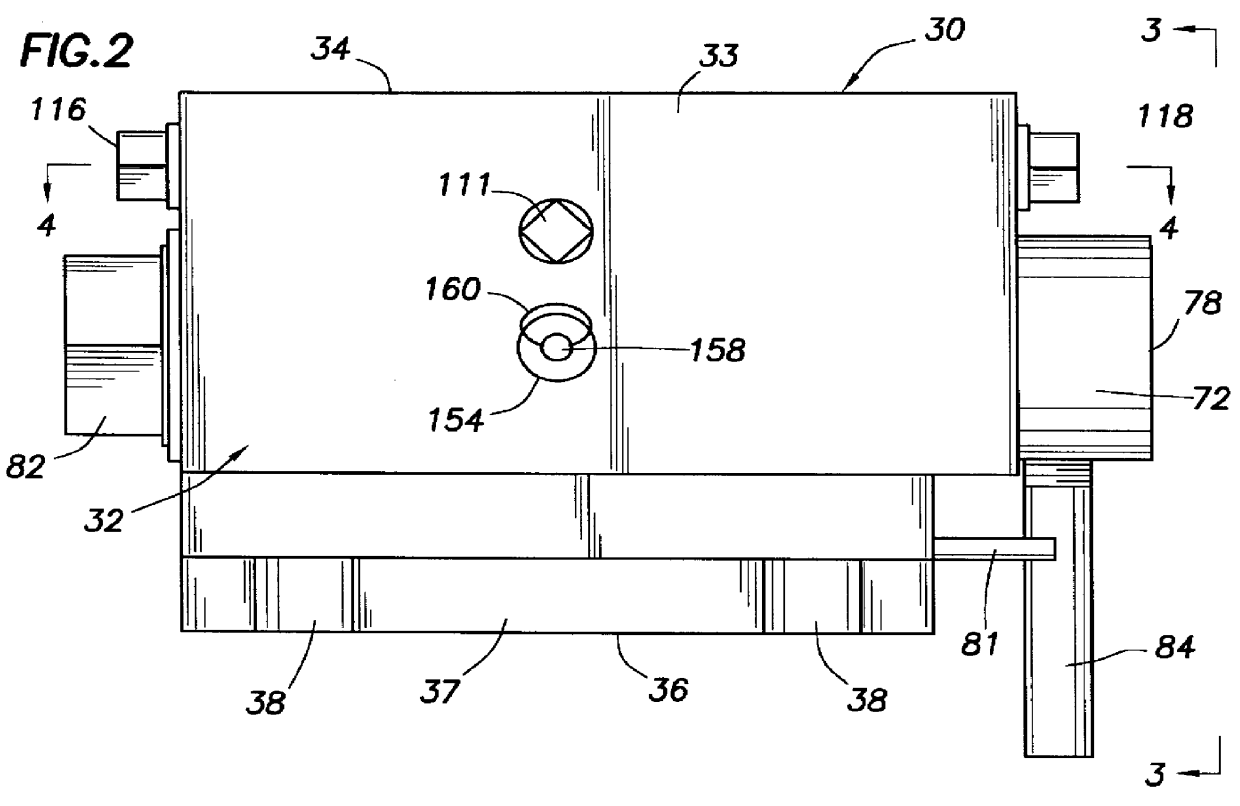

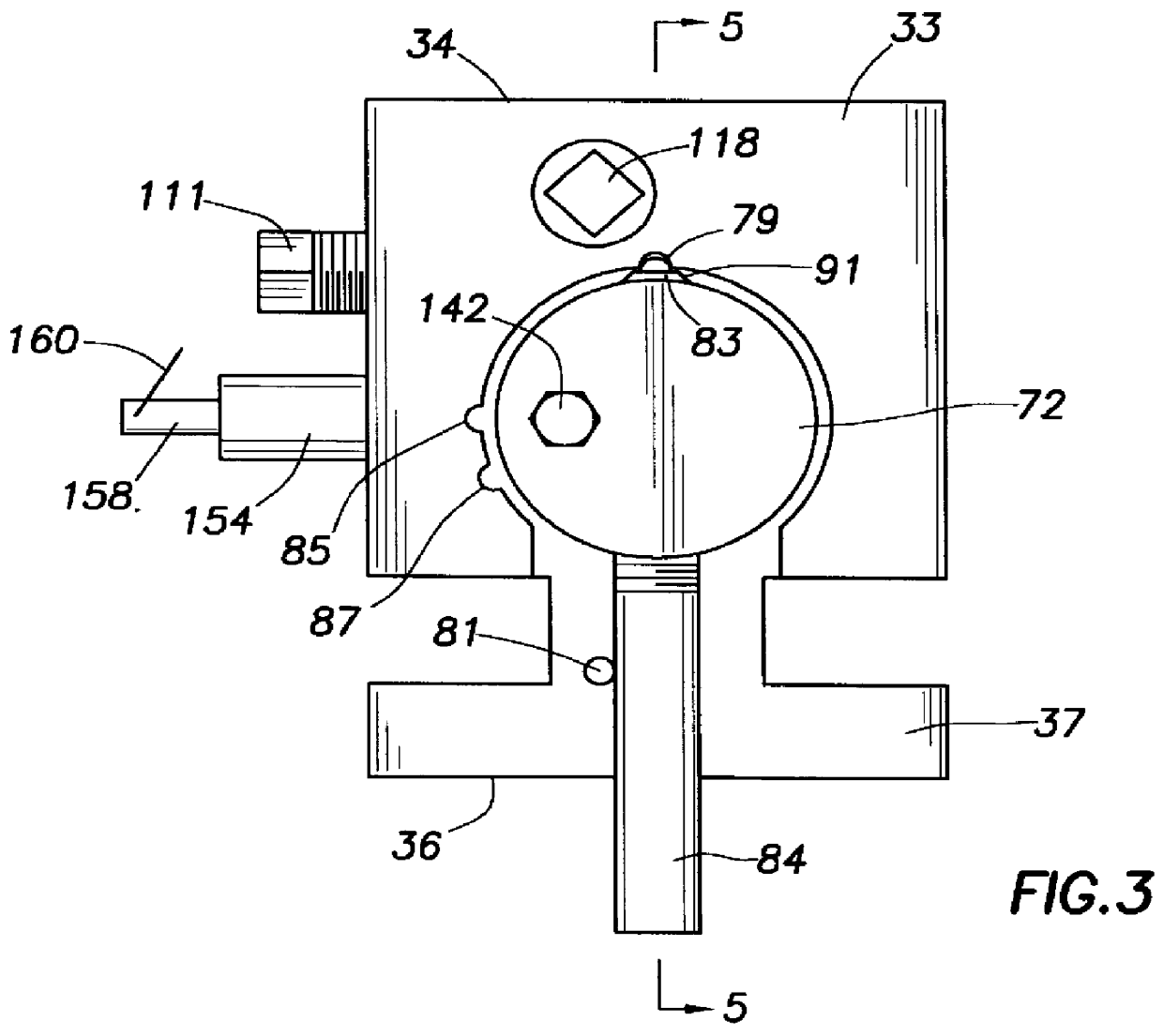

Differential pressure instrument support manifold having rotary mode selection system

InactiveUS6035724AHarming technician and environmentEliminate dischargeFluid pressure measurement by mechanical elementsDifferential pressureSelection system

A spool type differential pressure transmitter support and valving manifold having a manifold body defining a process face and a transmitter face and having a generally cylindrical internal surface defining an open ended spool chamber and having signal inlet and outlet passages intersecting the process and transmitter faces and being in communication with the spool chamber. The manifold body also defines a vent passage which is in communication with said spool chamber. A spool member is positioned for rotation to "run", "zero" and "off" positions within the spool chamber, has ends extending from the open ends of the spool chamber and has a pair of transversely oriented body passages positioned for selective registry with the signal inlet and outlet passages at the "run" position of the spool member. Circumferential seals each preferably comprising an O-ring and a back-up ring establish sealing between the spool member and the manifold body and serve to isolate the signal passages from one another and to prevent leakage of signal pressure at the open ends of the spool chamber. A plurality of mode seal elements are carried by the outer periphery of the spool member and provide for manifold mode selection to the "run", "zero" and "off" positions responsive to rotational positioning of said spool member relative to said manifold body to permit calibration of the differential pressure transmitter with the pressurized process in operation.

Owner:HEWSON JOHN E

Manually activated, portable fire-extinguishing aerosol generator

InactiveUS20070079972A1Easy to moveSafely thrownFire rescueBoring toolsFire extinguisherBiological activation

Manually activated, portable aerosol fire extinguisher includes a casing having opposed end walls and discharge ports in each end wall, an arrangement for generating fire suppression agent to be discharged through the discharge ports, and an activation system which enables manual activation of the generating arrangement at a safe location a distance from a fire. The activation system includes a firing pin which causes ignition of igniter material upon contact with a primer thereof, a delay column arranged between the primer and igniter material to delay ignition of the igniter material, a safety lever which normally prevents the firing pin from contacting the primer and a manually releasable pull pin which maintains the safety lever in a position preventing the firing pin from contacting the primer. Upon release of the pull pin, the firing pin contacts the primer causing generation of the fire suppression agent.

Owner:FIREAWAY

Mobile or stationary modular self-contained dehydration toilet, dehydration engine, and gray water recovery system

InactiveUS20060091083A1Reduce solid wasteEliminate dischargeGeneral water supply conservationSustainable biological treatmentHuman wasteWater source

A compact dehydration engine and method for treating human waste and gray water residual electro-coagulants that includes a heated waste dehydration chamber that has low energy consumption and low water consumption in use. The system can be employed in stationary or mobile platforms that include multiple toilets and gray water sources for reclamation.

Owner:ZECO LTD

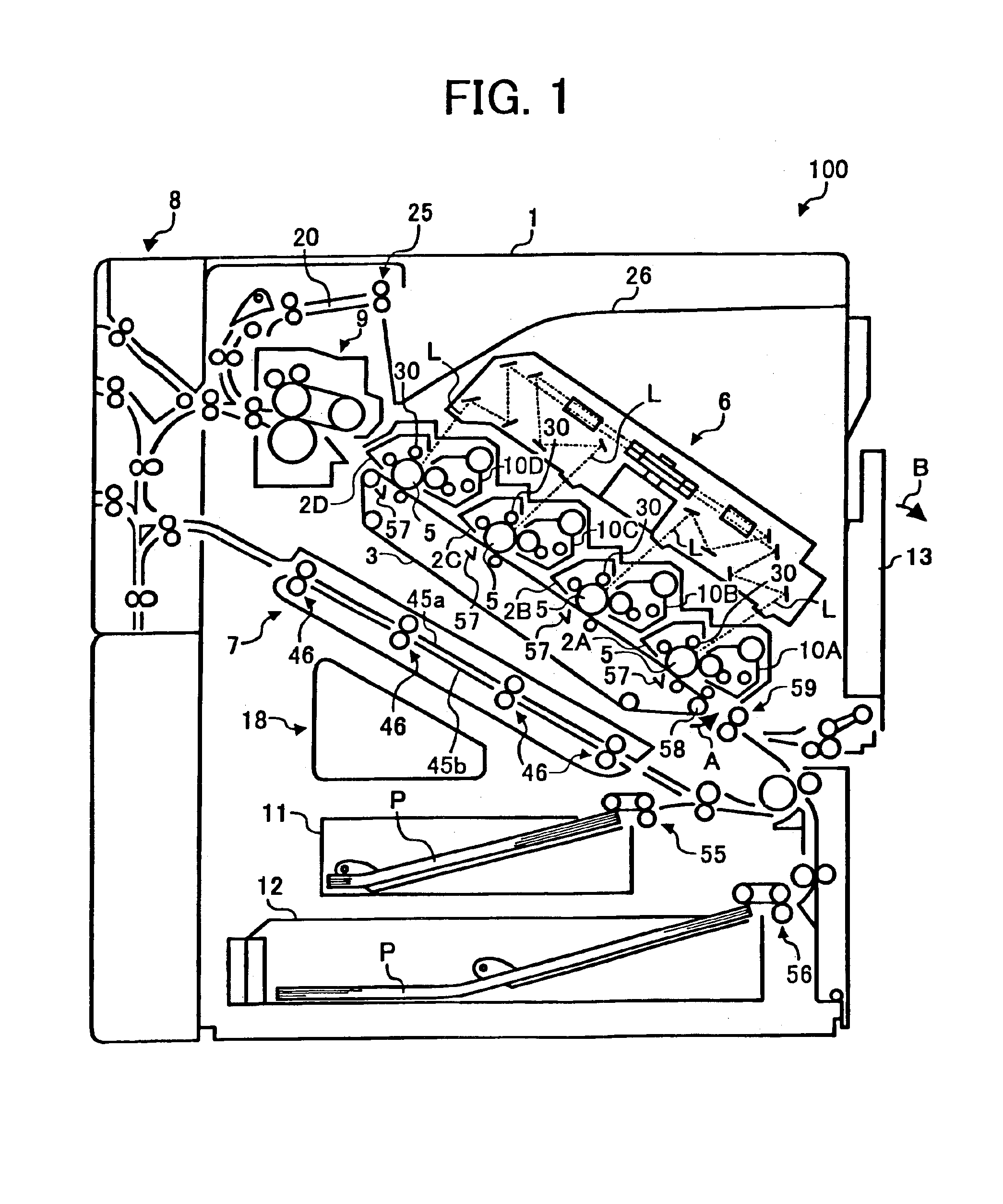

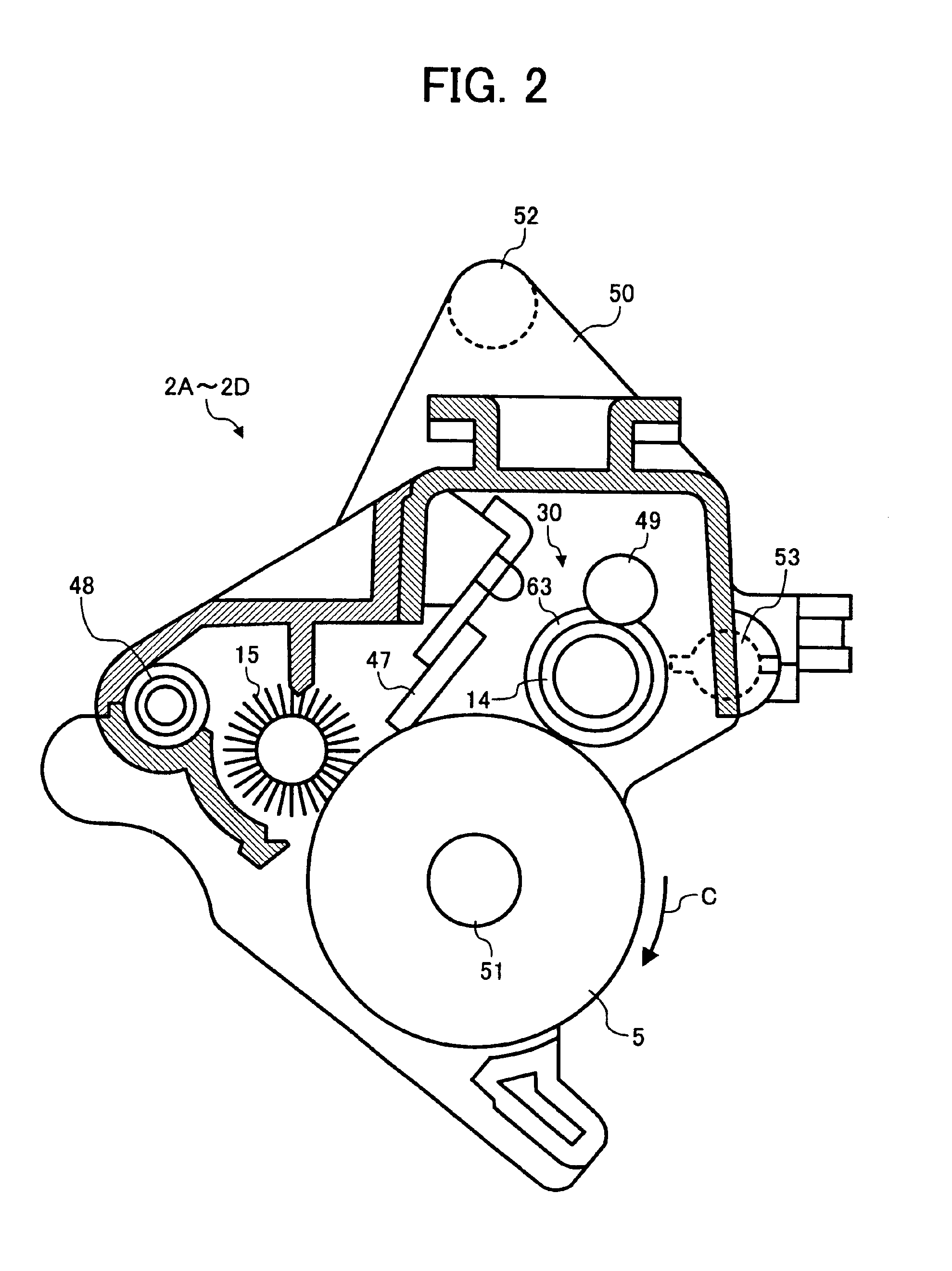

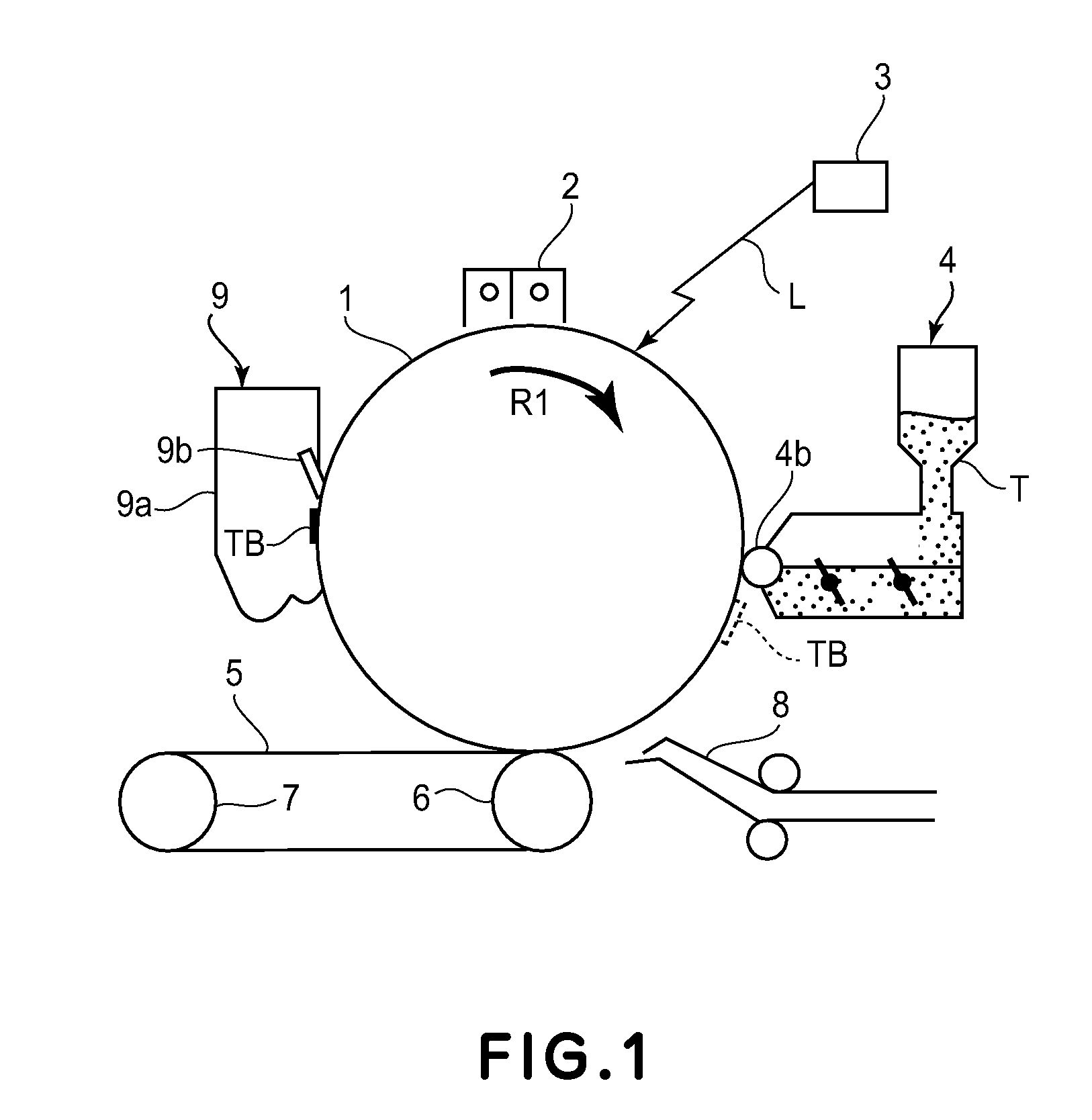

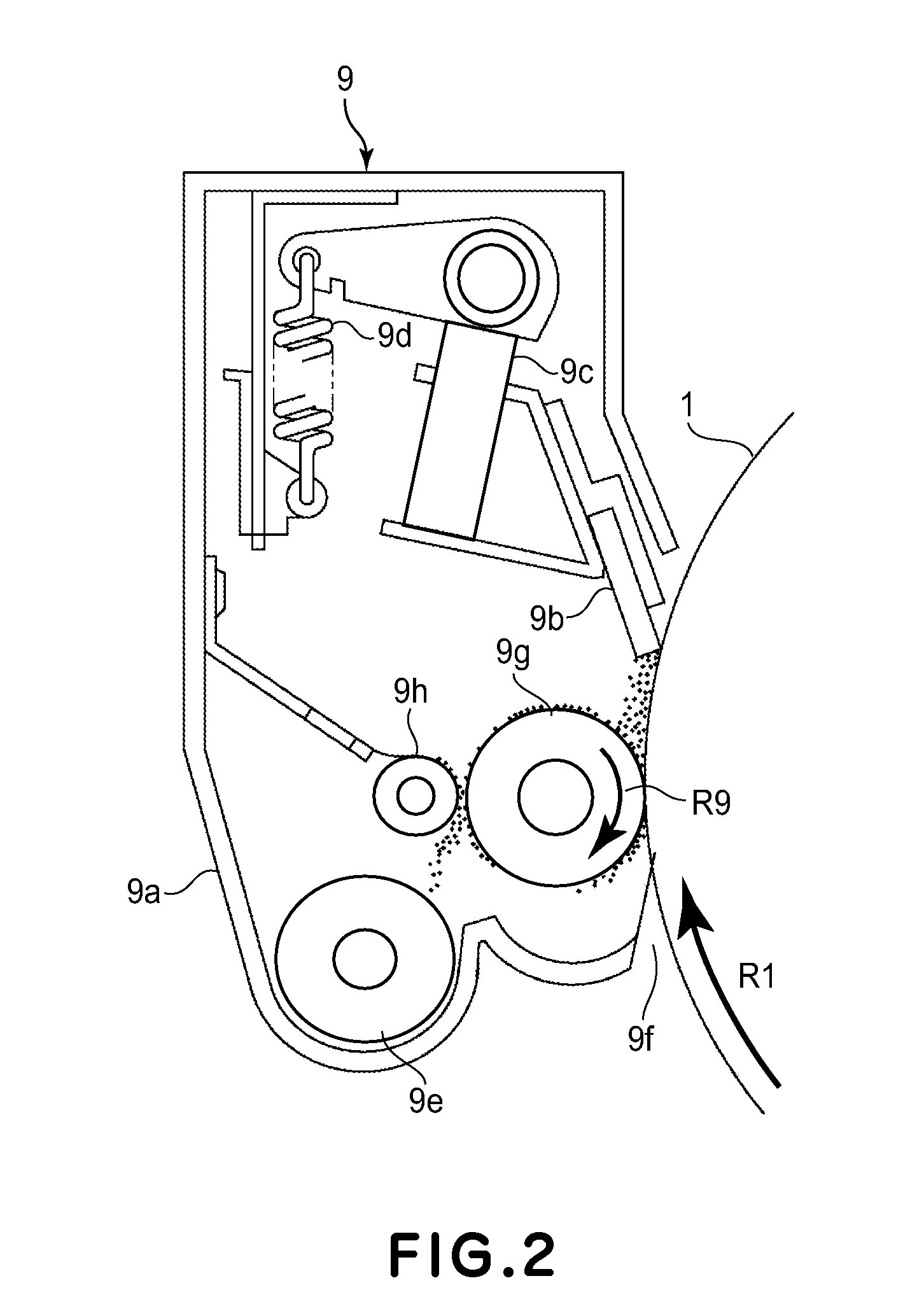

Charging device using a charge roller and image forming apparatus including the same

InactiveUS6961529B2Increased durabilityAvoid gettingElectrographic process apparatusCorona dischargeImage formationEngineering

Owner:RICOH KK

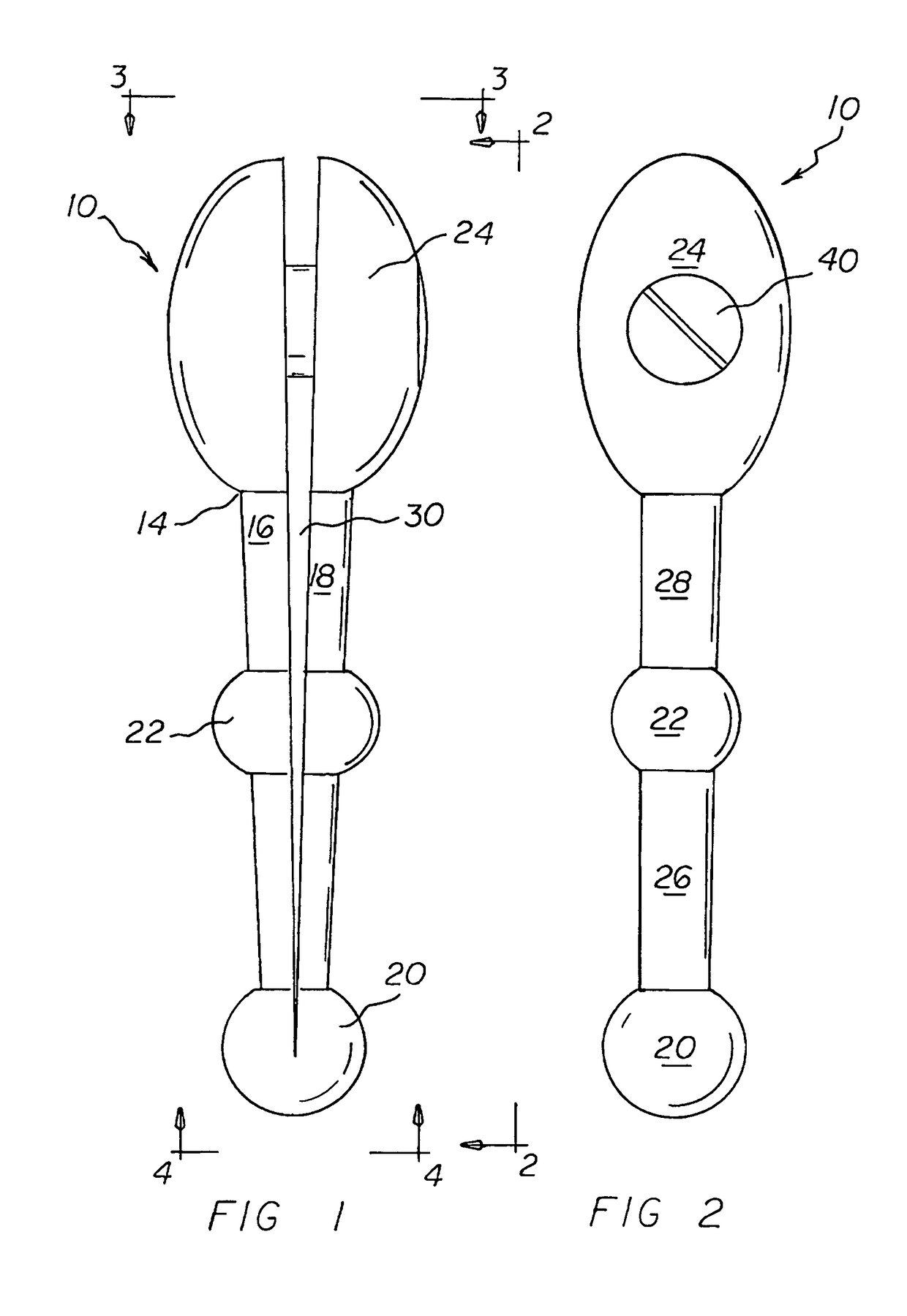

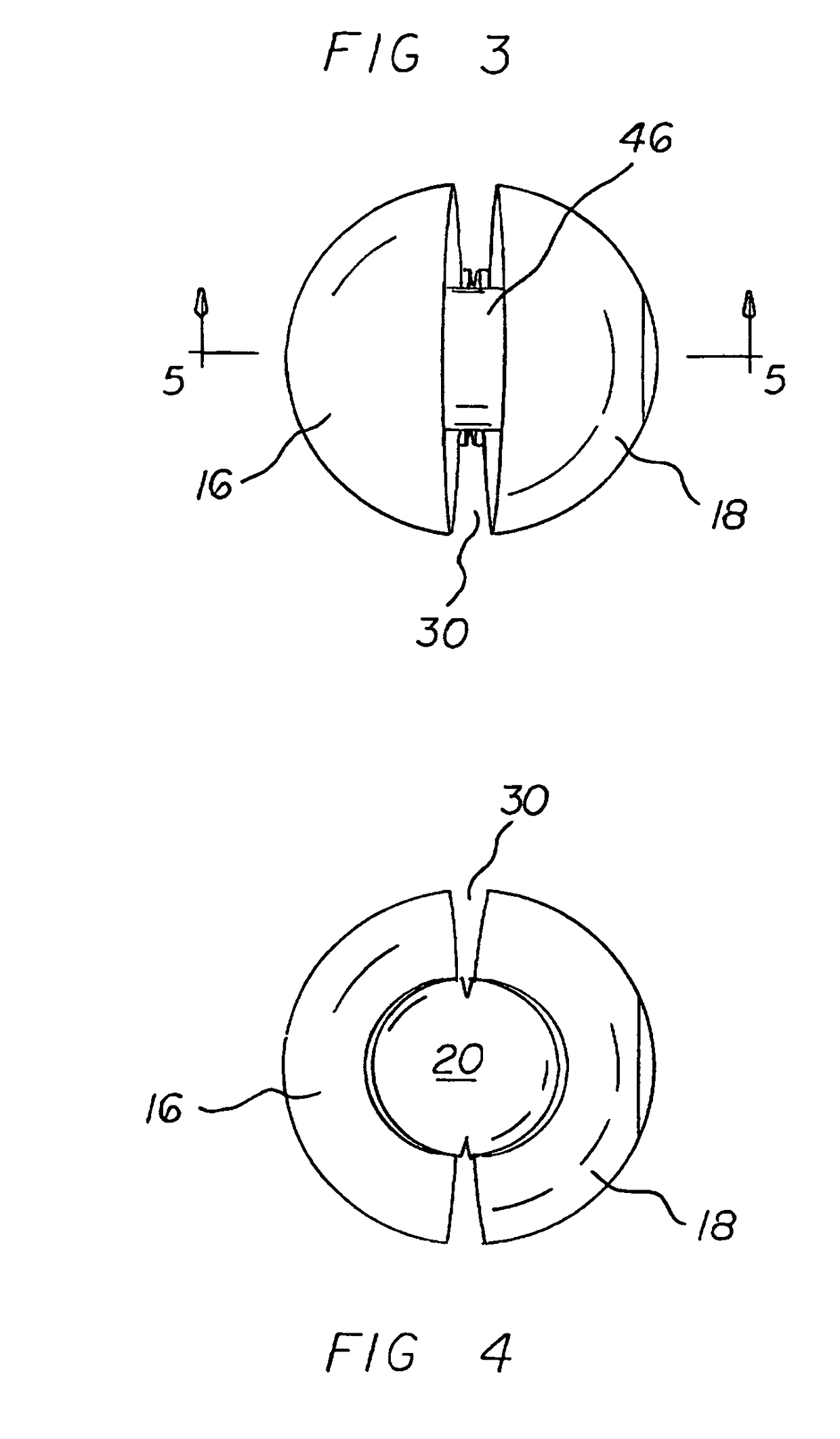

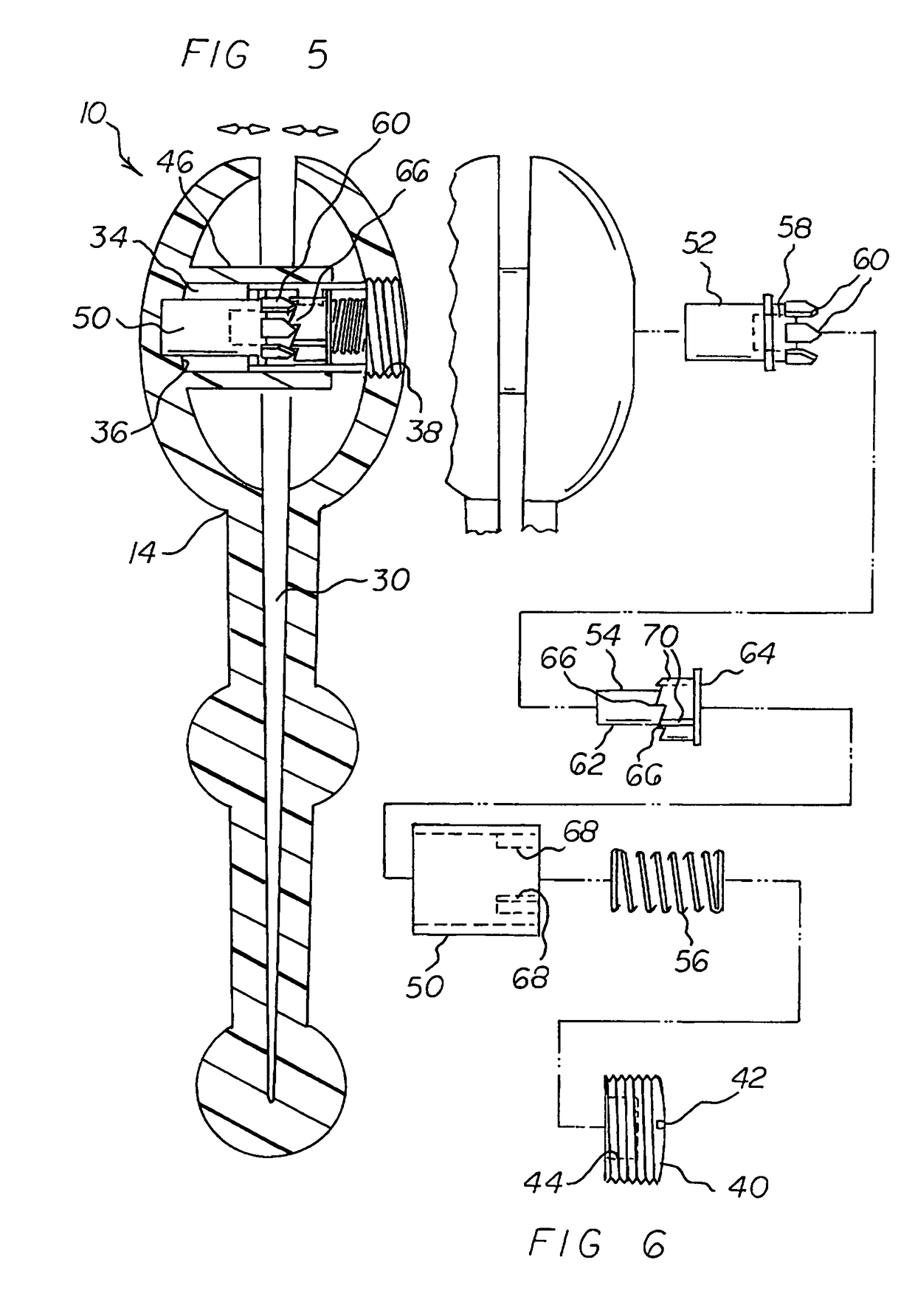

Incontinency abatement system

InactiveUS8118726B1Eliminate dischargeEasy and efficient to manufactureOperating chairsResilient force resistorsEngineeringExternal anal sphincter

A body portion fabricated of an essentially rigid material is formed of similarly configured first and second segments each shaped to include a generally spherical interior enlargement, a generally spherical exterior enlargement, an intermediate section between the enlargements, and a slit extending through the exterior enlargement and the intermediate section. The body portion pivots between a collapsed orientation with the slit at a reduced spacing and an expanded orientation with the slit at an enlarged spacing. An operational zone has a plurality of operational components. Application of a radial force to the second section by a user's external anal sphincter muscle causes axial movement of the segments to both contract and retain expanded segments and expand and retain contracted segments to reorient the system between a collapsed orientation and an expanded orientation.

Owner:BLACKFORD RICHARD

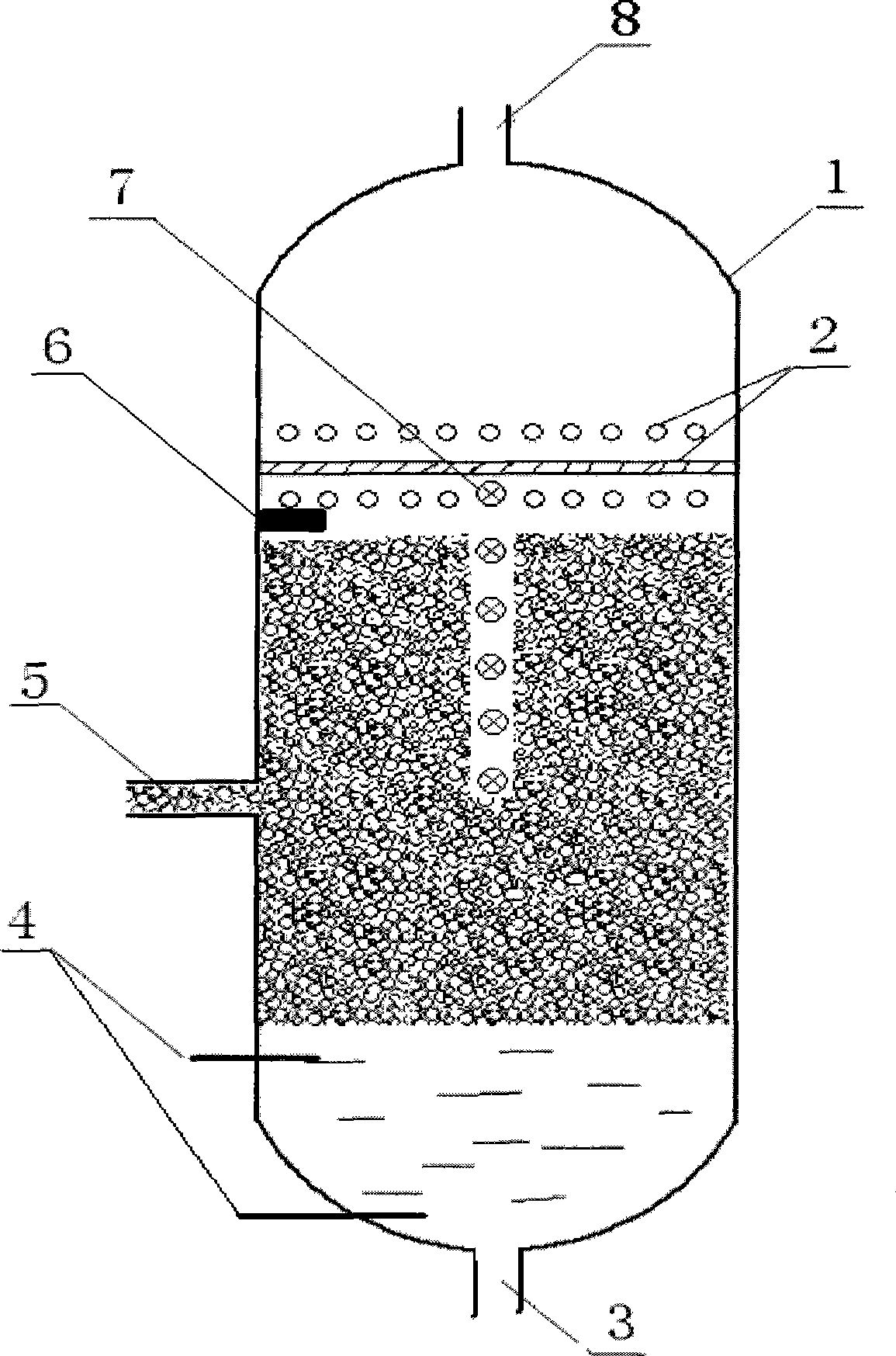

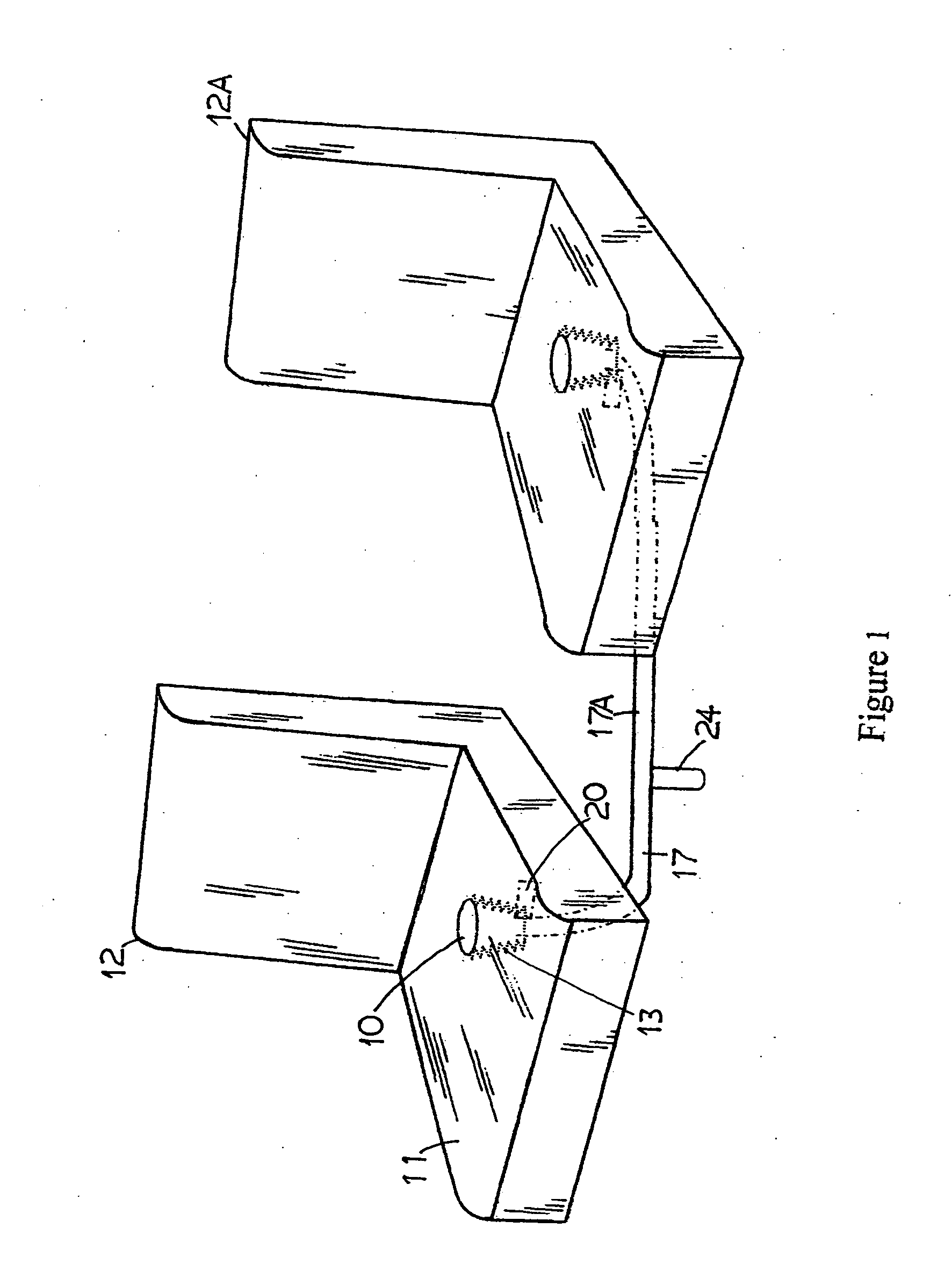

Defoaming method and device for eliminating foam of drilling fluid by thermal radiation

The invention relates to a defoaming method and a deforming device for removing the foam of drilling fluid through thermal radiation, which belong to the technical field of the physical defoaming of the drilling fluid. The defoaming device comprises a cylindrical container. The defoaming device is characterized in that a gas outlet is arranged on the top of the cylindrical container, a fluid and slag outlet is arranged on the bottom of the cylindrical container, a foam inlet is arranged on the side face of the middle lower part of the cylindrical container, a thermal radiation element is arranged on the upper inner wall of the cylindrical container, a temperature sensor is arranged below the thermal radiation element on the cylindrical container, an ultrasonic foam height sensor is also arranged below the thermal radiation element on the cylindrical container, and fluid level sensors are arranged on the middle and lower parts of the inside cylindrical container. The foam flows into the device through the foam inlet, the thermal radiation element on the device gives off thermal radiation to break the foam with low intensity near the device, the separated gas is discharged through the gas outlet, and the foam base fluid and the solid carried by the foam are discharged through the fluid and slag outlet. The defoaming device can quickly remove a great amount of foam discharged from foam drilling and prevent the foam from being accumulated in a mine. In addition, the nature of the foam base fluid is not affected, thereby facilitating the cyclic utilization of the foam base fluid.

Owner:SHANDONG UNIV

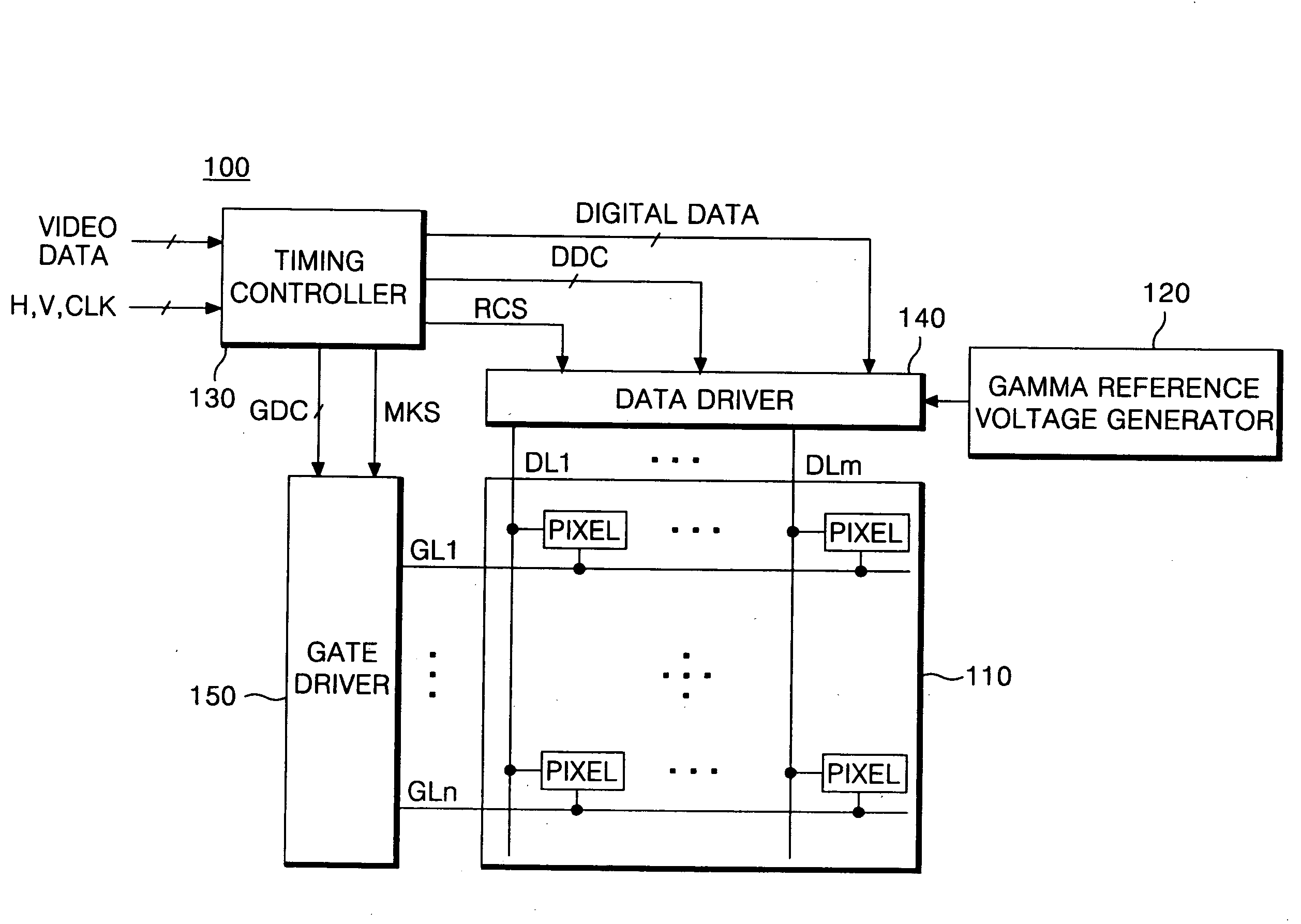

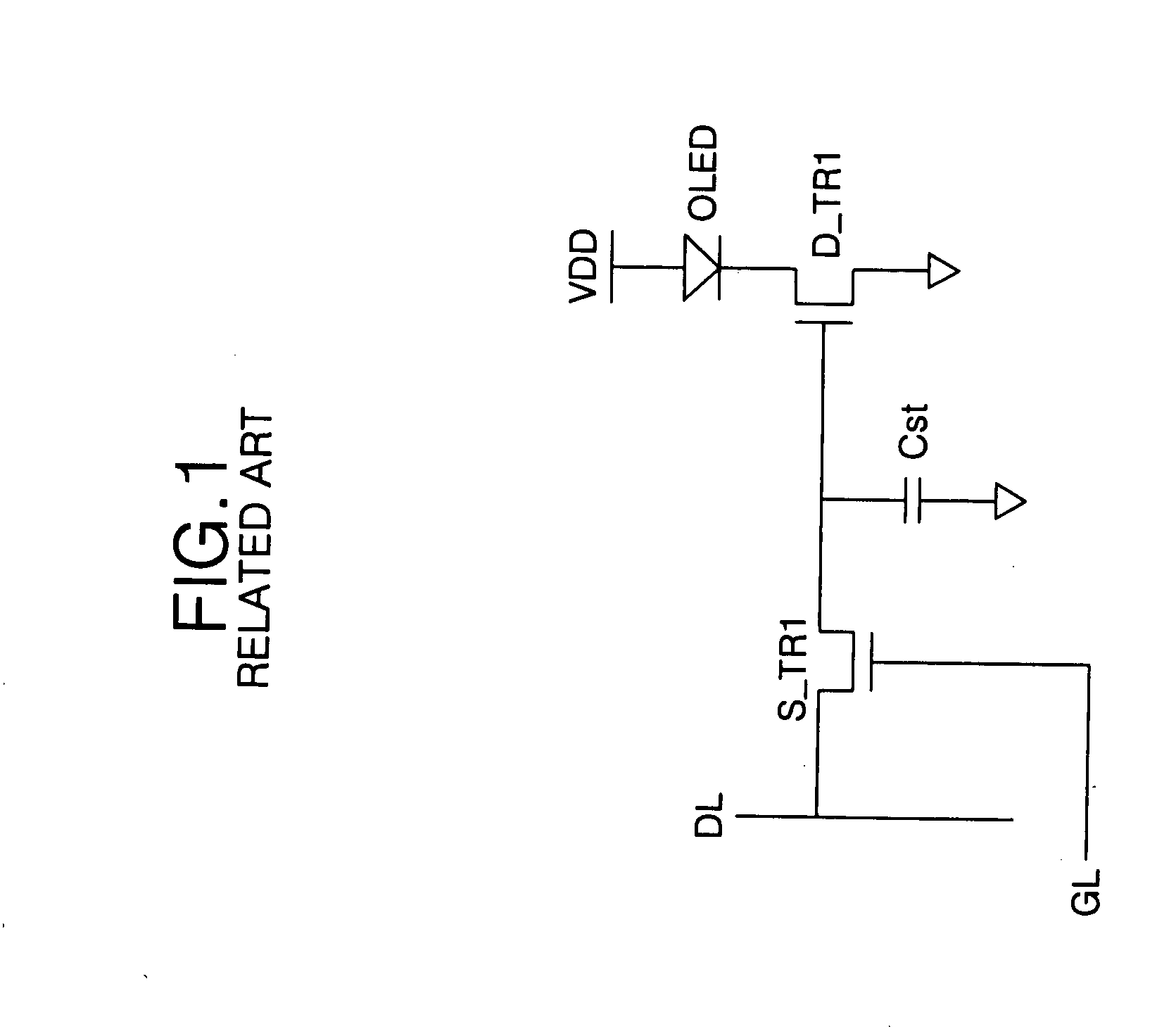

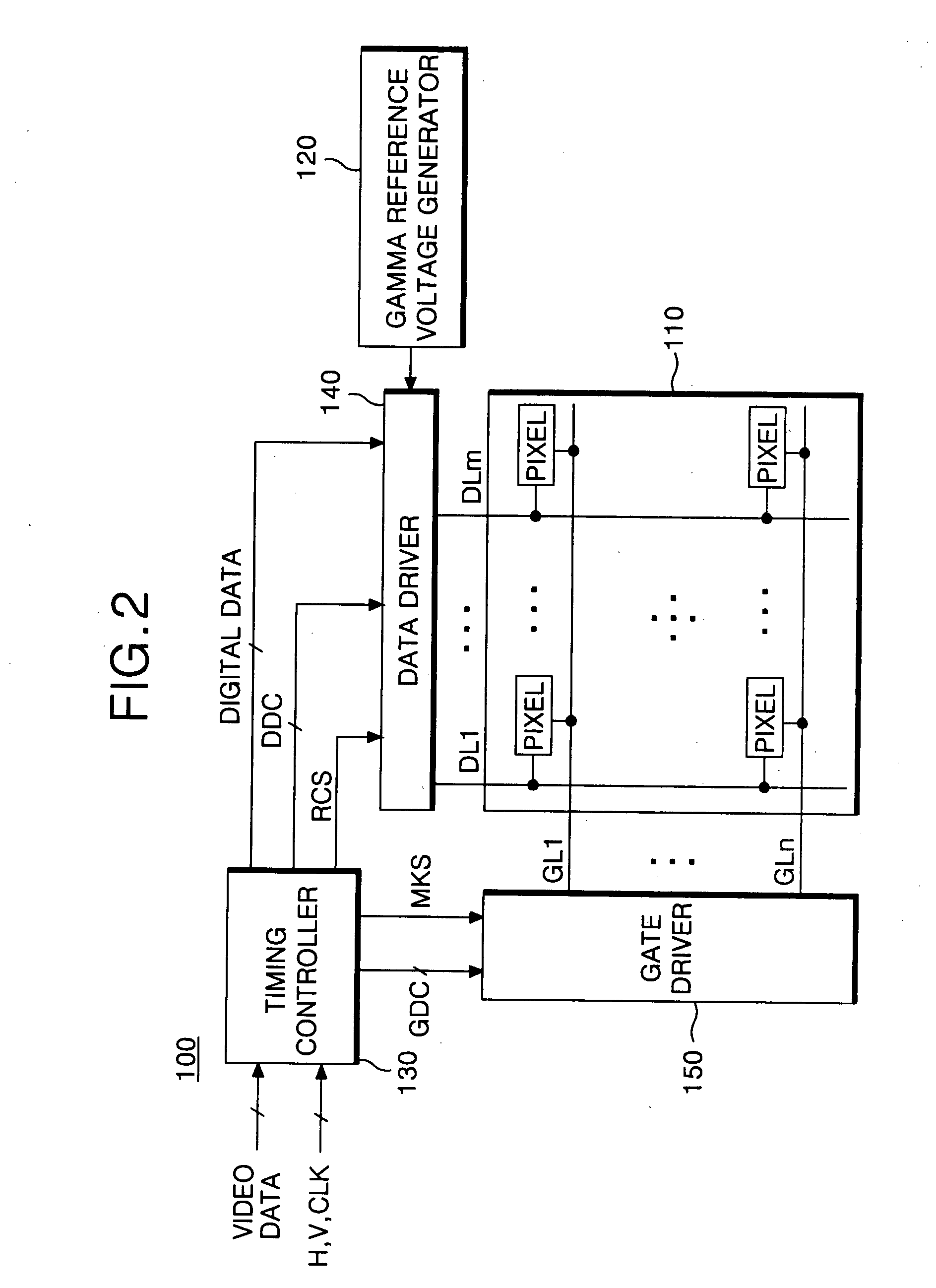

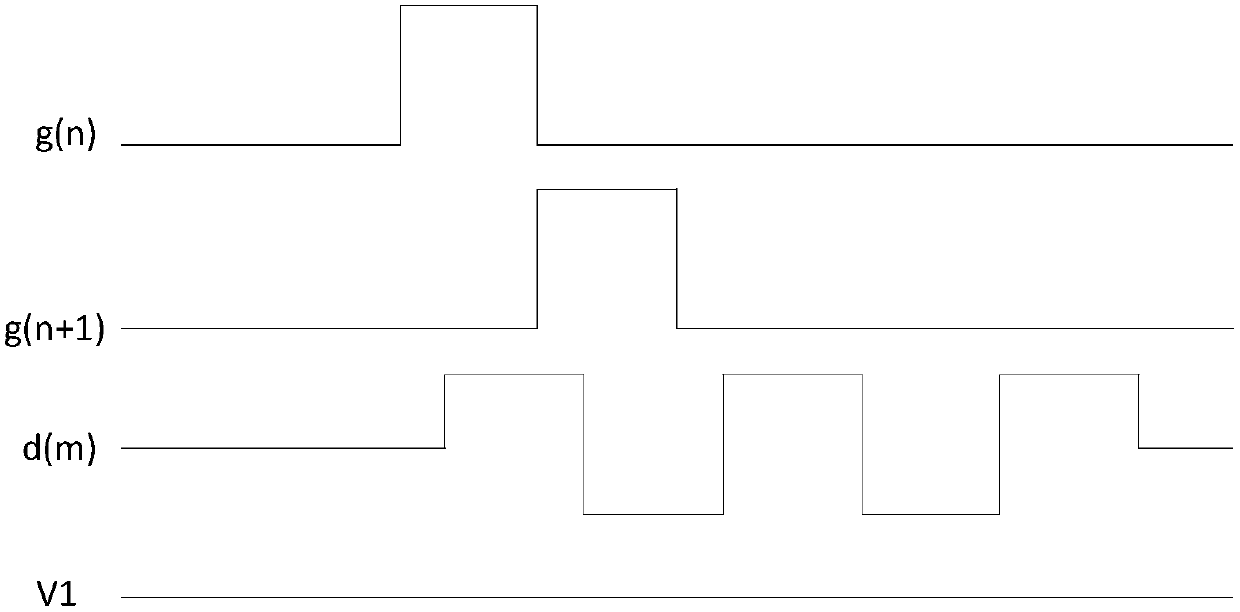

Organic light emitting diode display and driving method thereof

ActiveUS20080001863A1Prevent degradationEliminate dischargeCathode ray tubes/electron beam tubesCathode-ray tube indicatorsDigital dataDisplay device

An organic light emitting diode display for removing a voltage which is charged into a gate electrode of a driving transistor before a current frame is changed to a next frame is disclosed. In the organic light emitting diode display, a display panel has a plurality of pixels that include an organic light emitting diode. A timing controller controls a driving timing of the inputted video data and controls a supply timing of a refresh voltage. A data driver converts a digital data which is outputted from the timing controller for a current frame into an analog data voltage to supply it to the pixels, and then supplies the refresh voltage to pixels which are selected among the pixels in accordance with a control of the timing controller. And a gate driver primarily supplies a scanning pulse for a first horizontal period of a current frame to select the pixels to be supplied with a data, and then secondarily supplies a scanning pulse for a second horizontal period of a current frame to select pixels to be supplied with the refresh voltage among the pixels in accordance with a control of the timing controller.

Owner:LG DISPLAY CO LTD

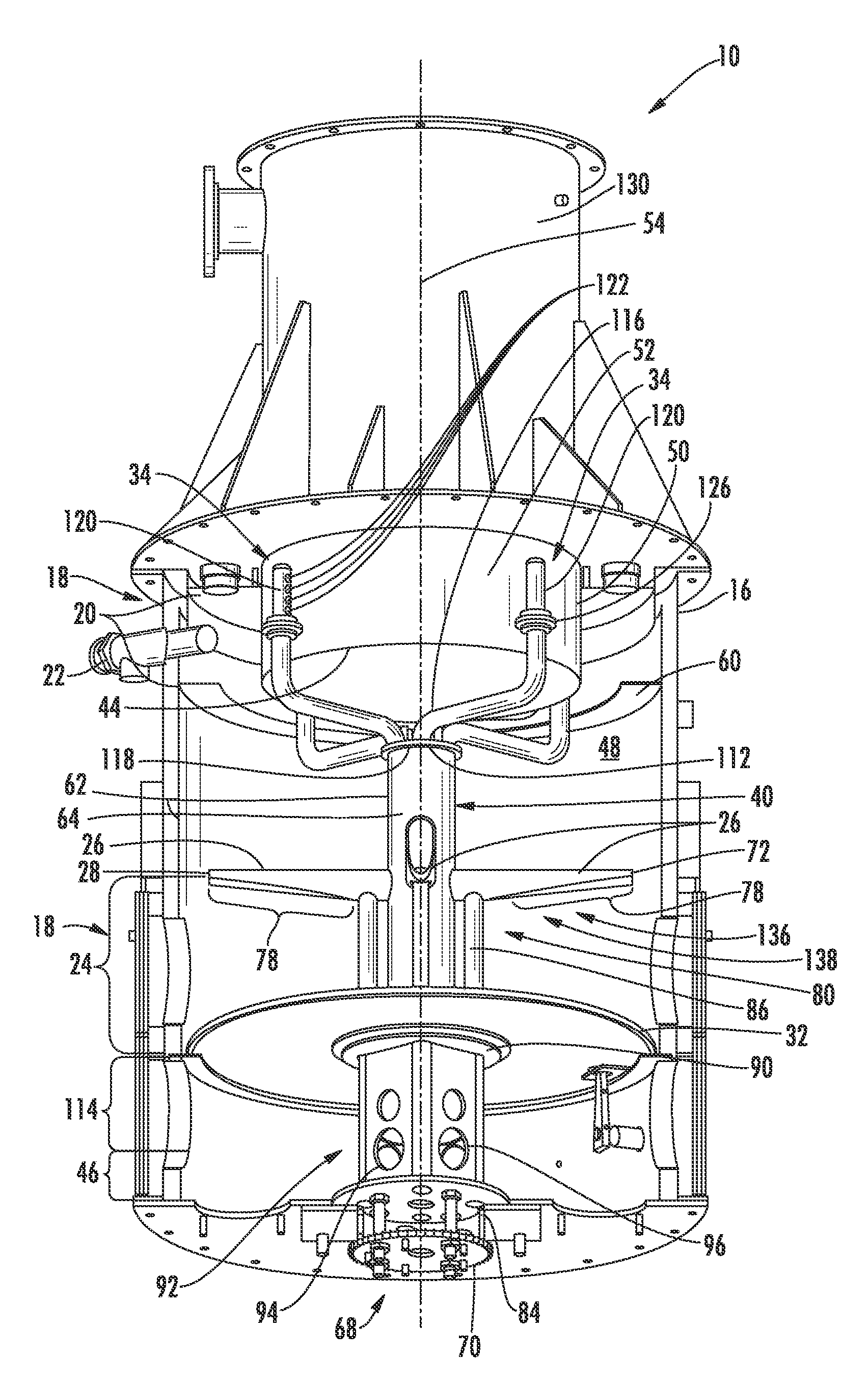

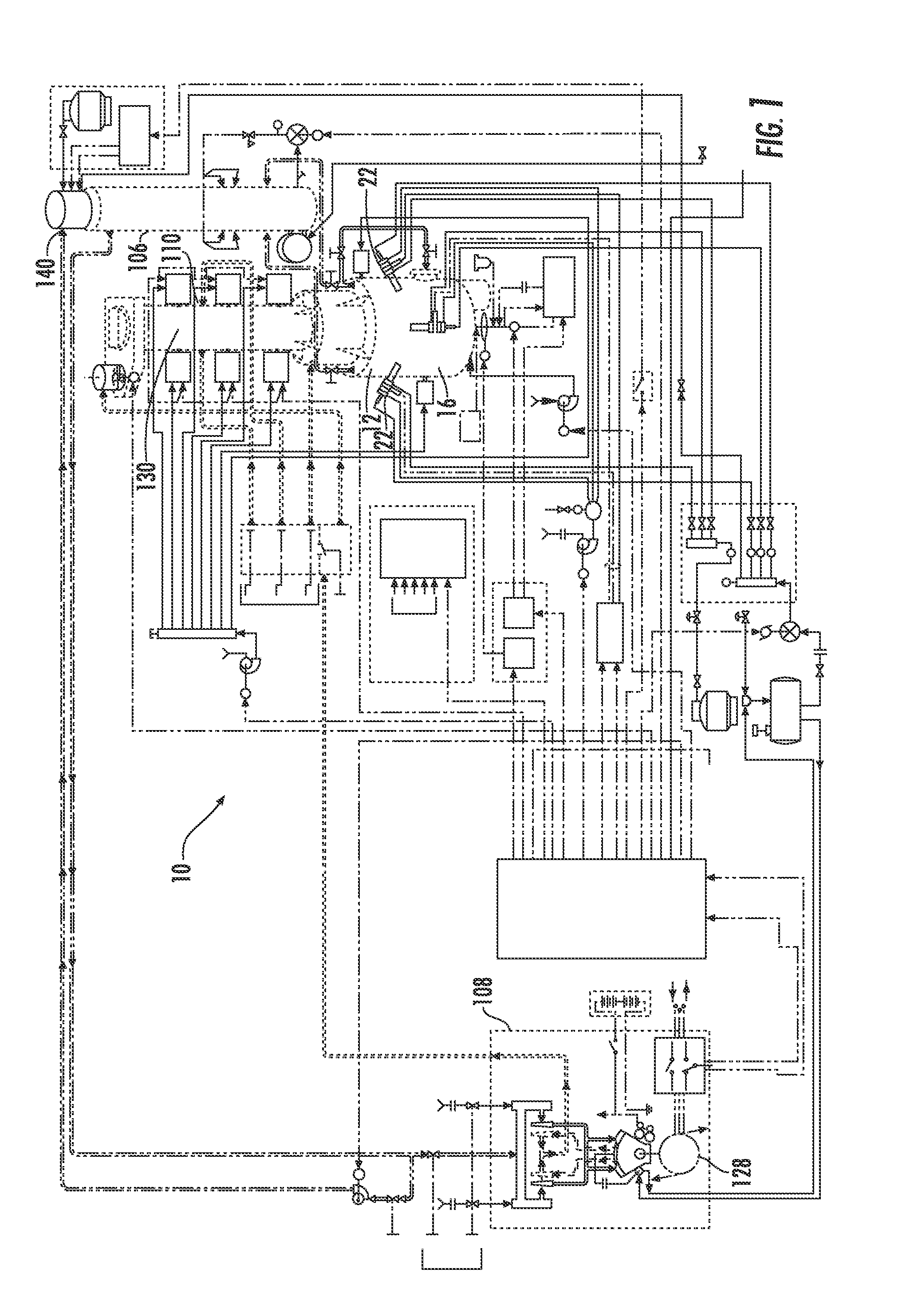

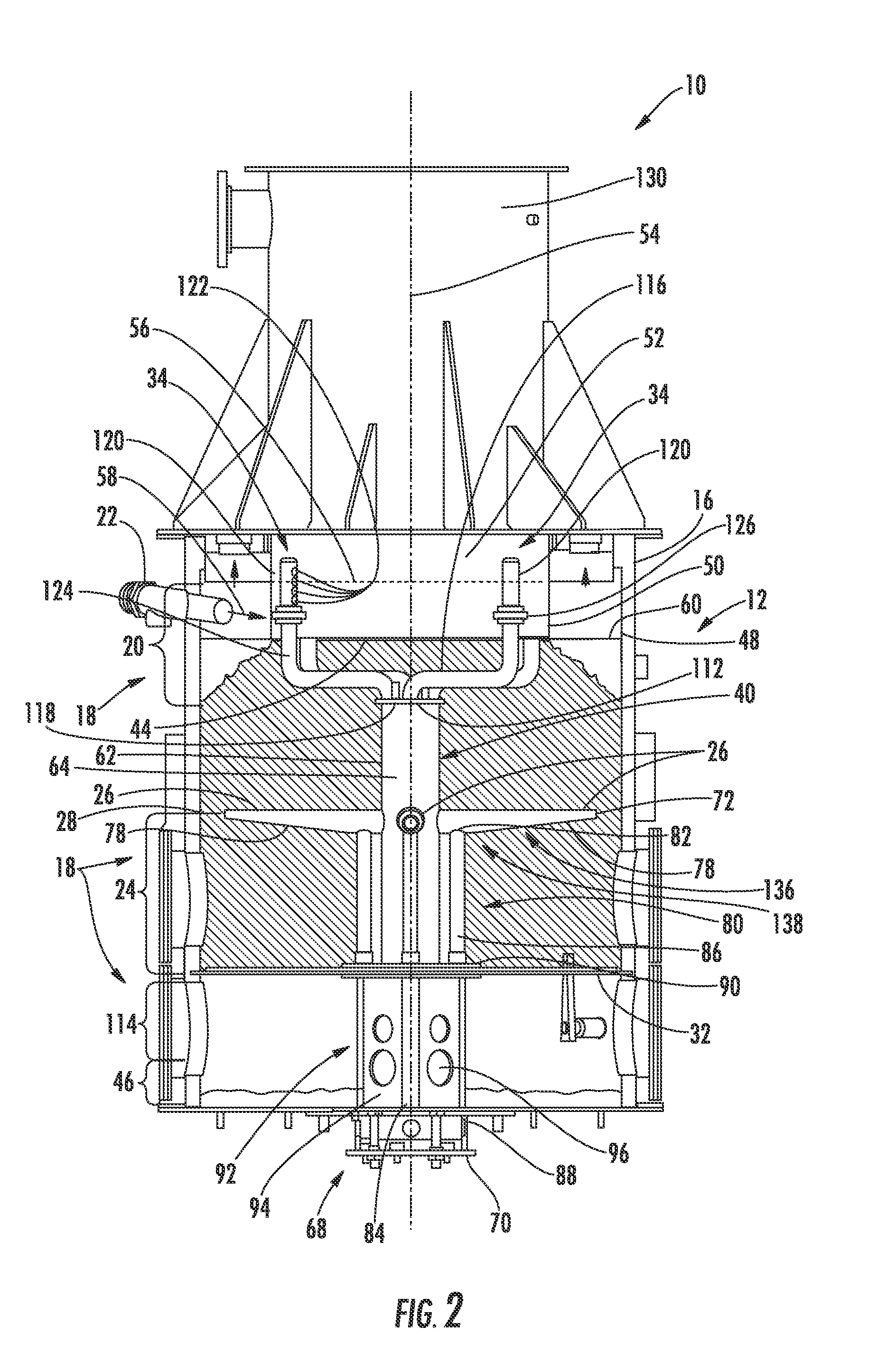

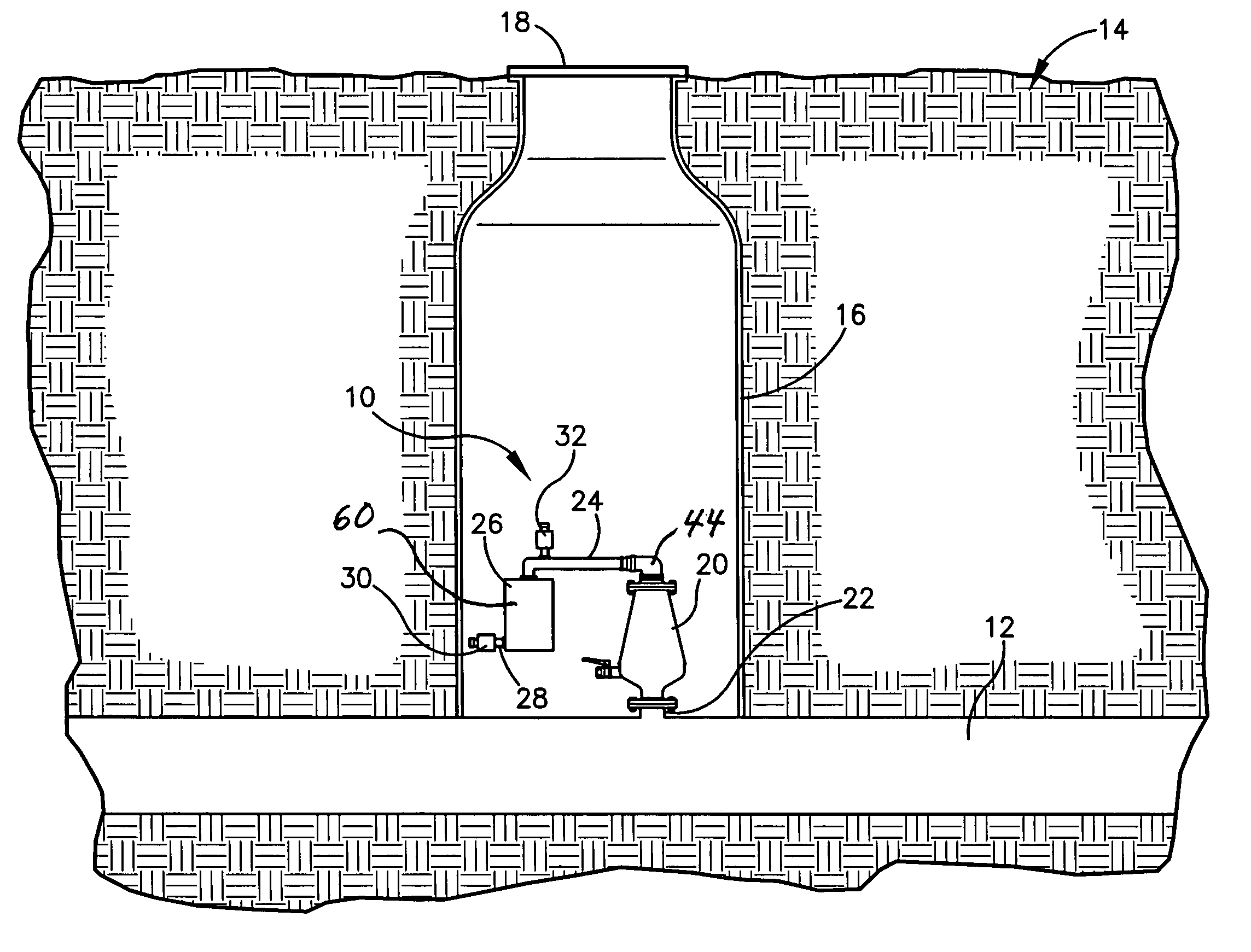

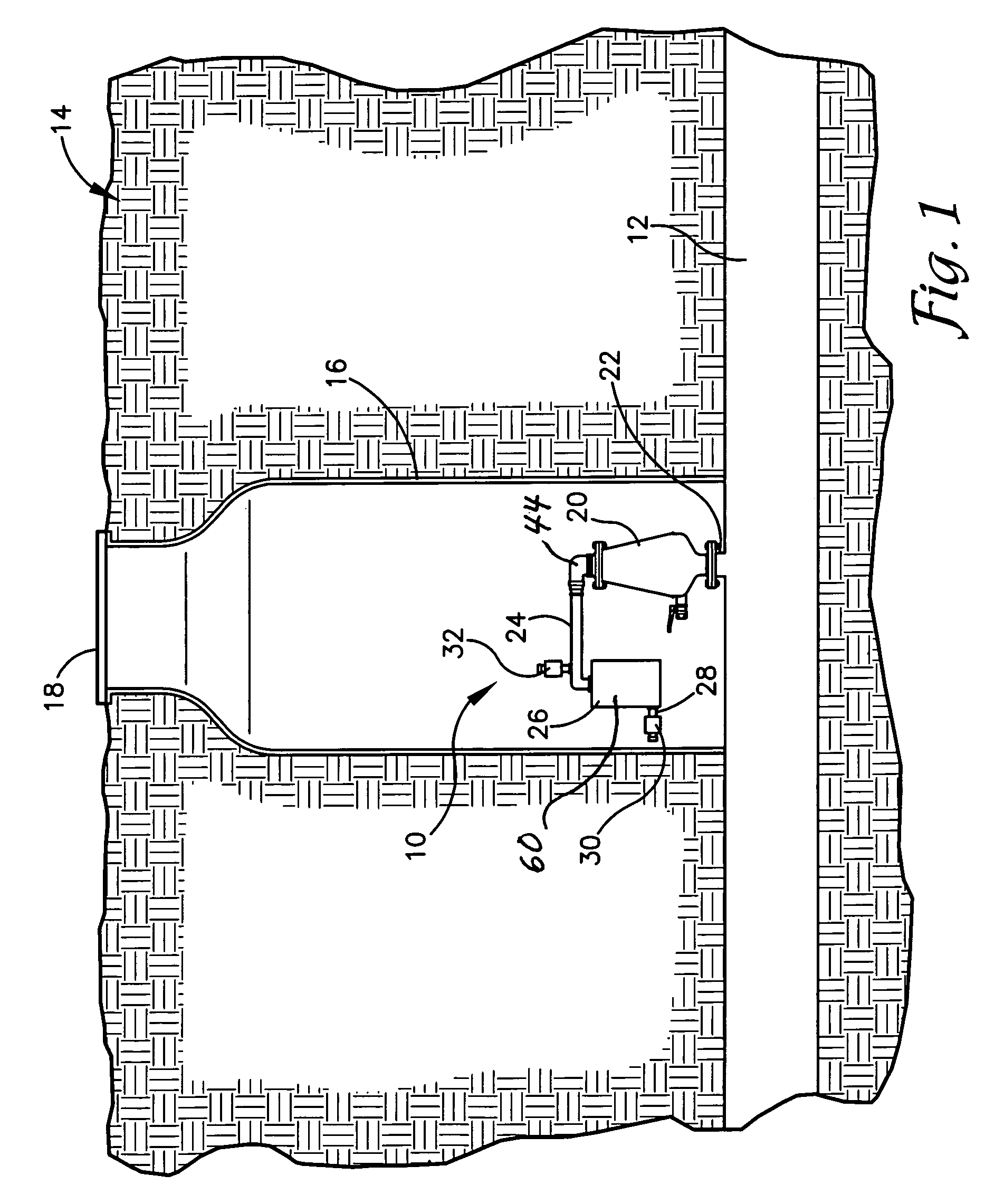

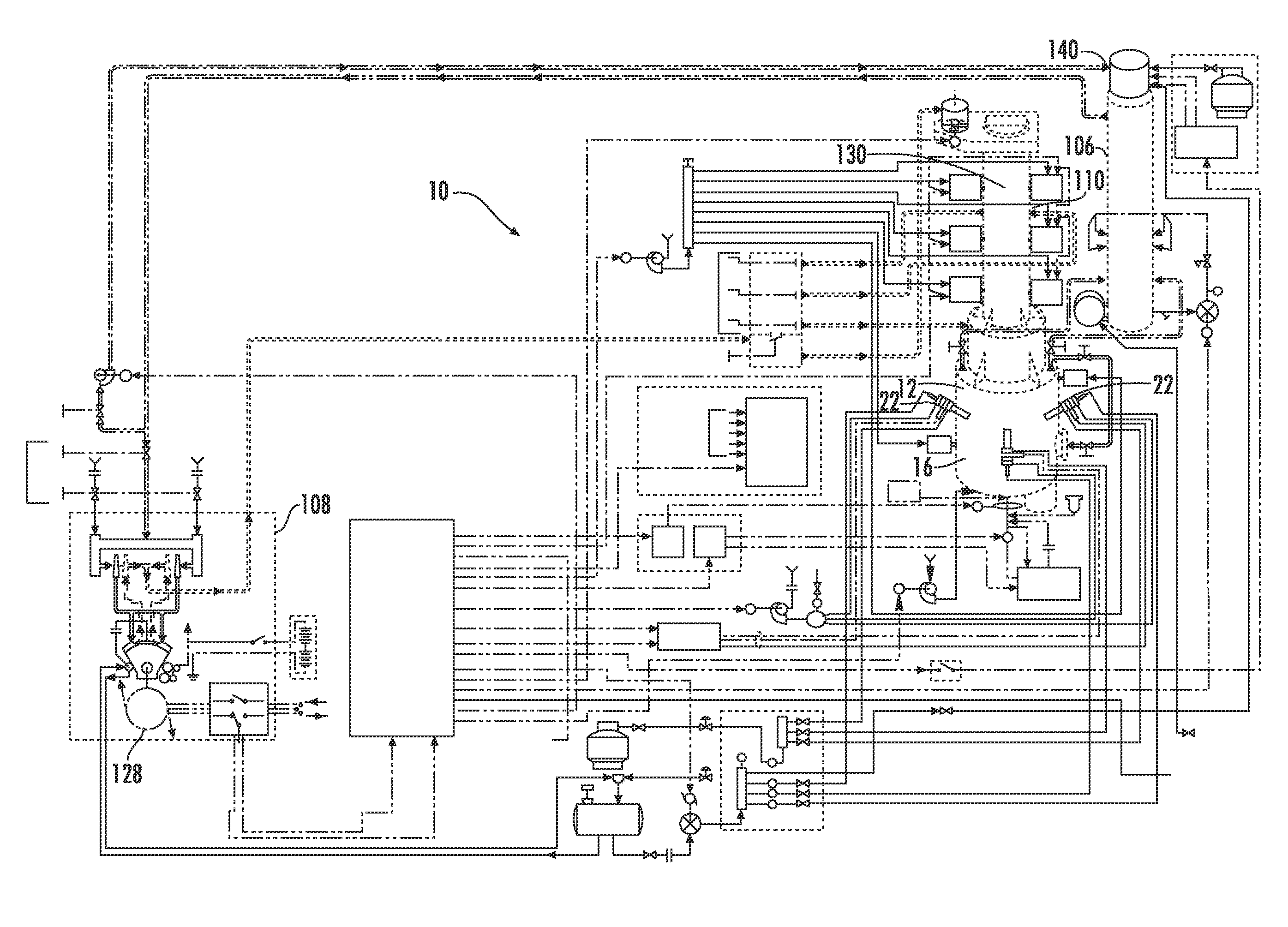

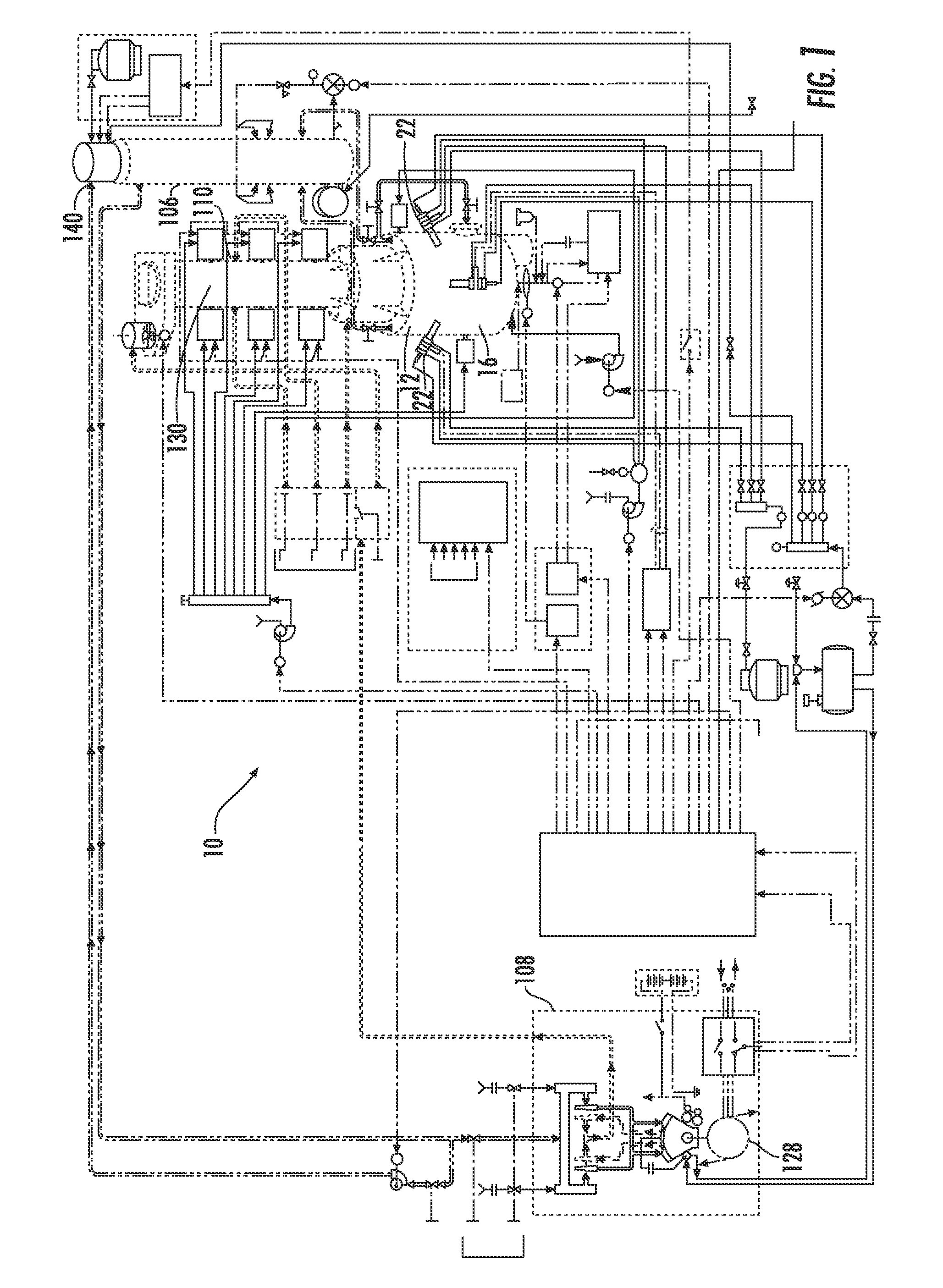

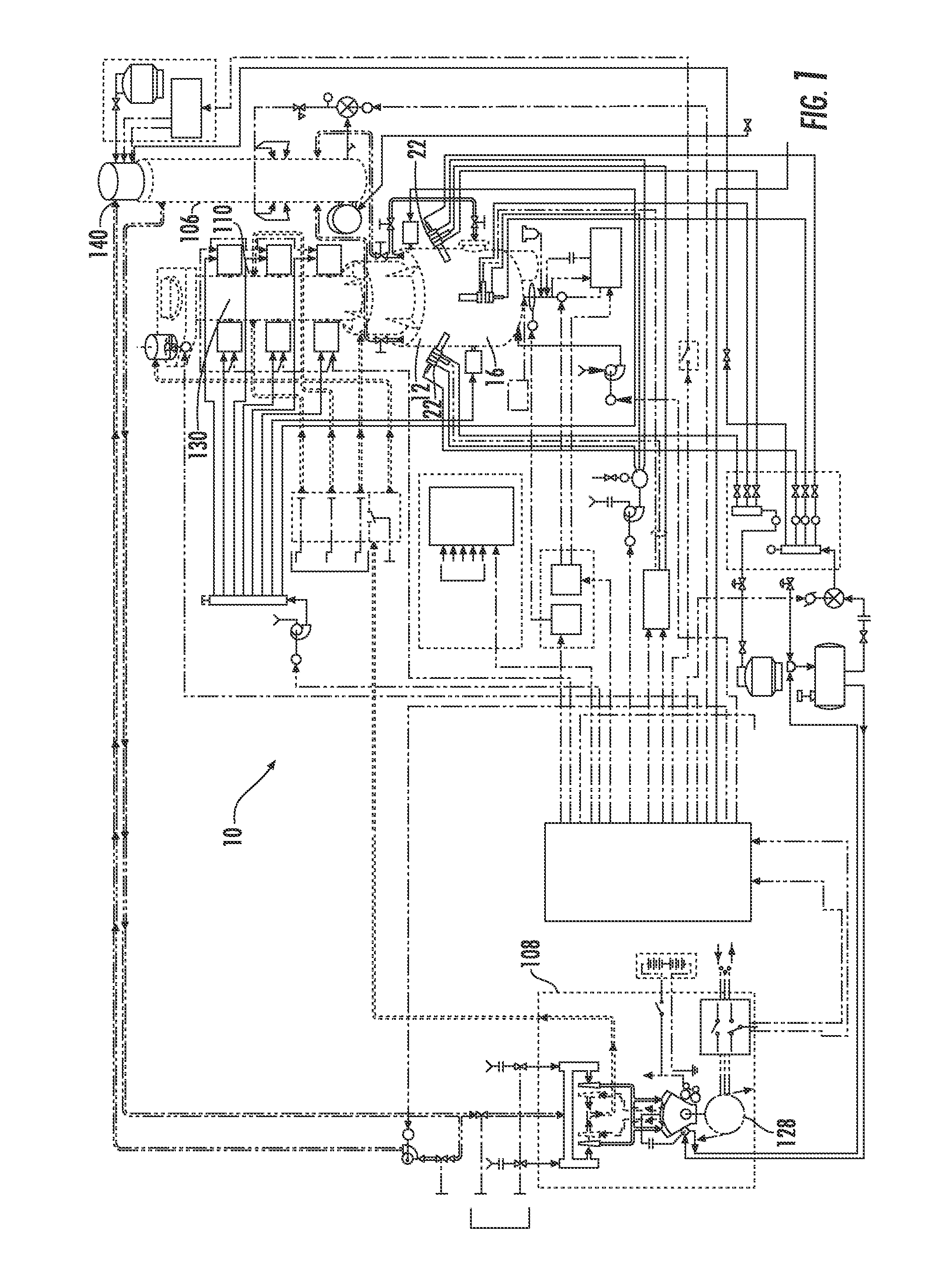

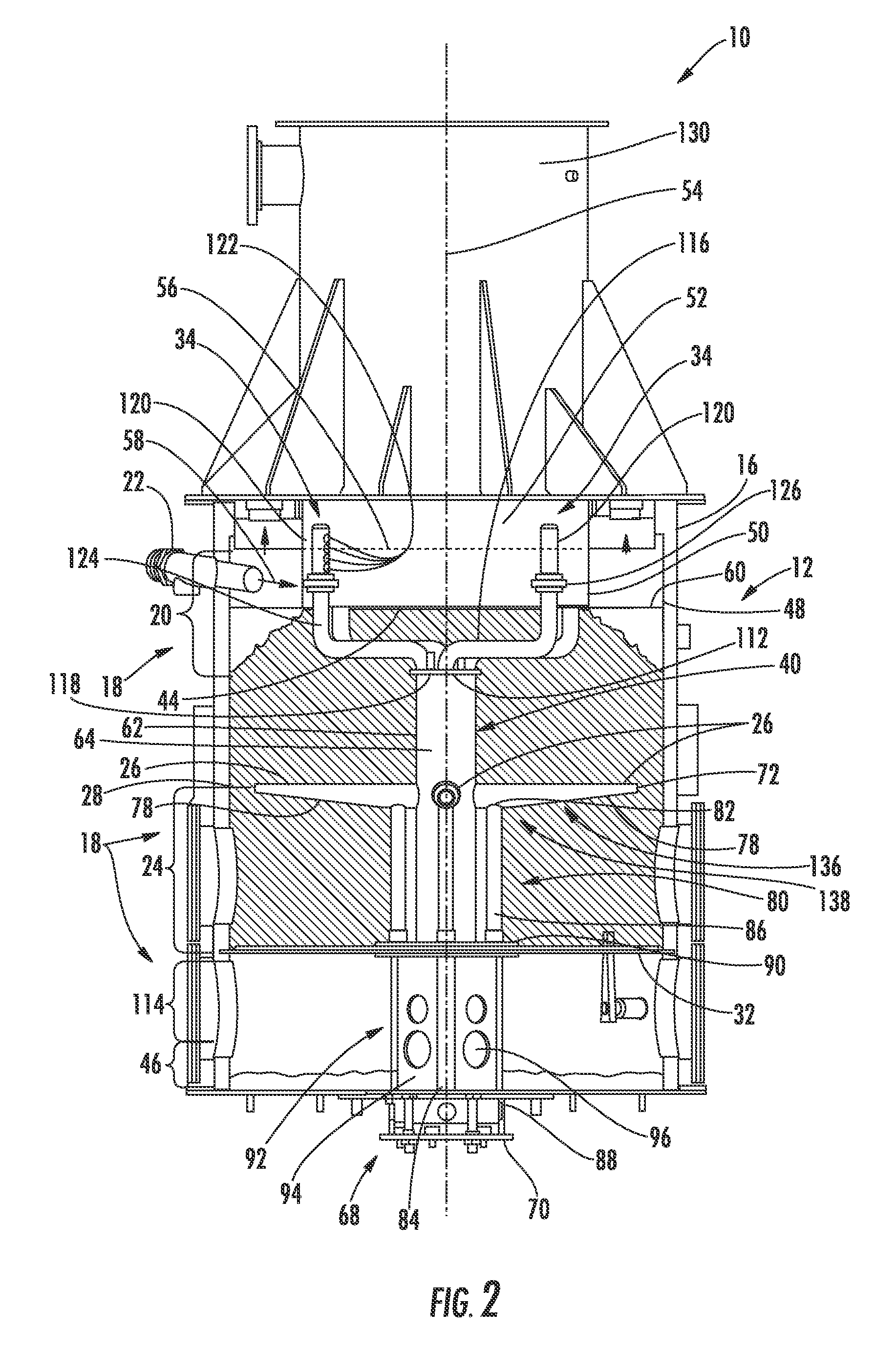

Plasma assisted gasification system

InactiveUS20120117876A1Convenient shipmentEasy to transportElectric discharge heatingMuffle furnacesSyngasCarbon layer

A controlled zone gasification reactor for a plasma assisted gasification reaction system is disclosed for converting fuel, such as, but not limited to, biomass, to syngas to replace petroleum based fuels used in power generation. The system may be a modular system housed within a frame facilitating relatively easy transportation. The system may include a reactor vessel with distinct reaction zones that facilitate greater control and a more efficient system. The system may include a syngas heater channeling syngas collected downstream of the carbon layer support and to the pyrolysis reaction zone. The system may also include a syngas separation chamber configured to produce clean syngas, thereby requiring less filtering. The system may further include an agitator drive assembly that prevents formation of burn channels with in the fuel.

Owner:ADAPTIVEARC

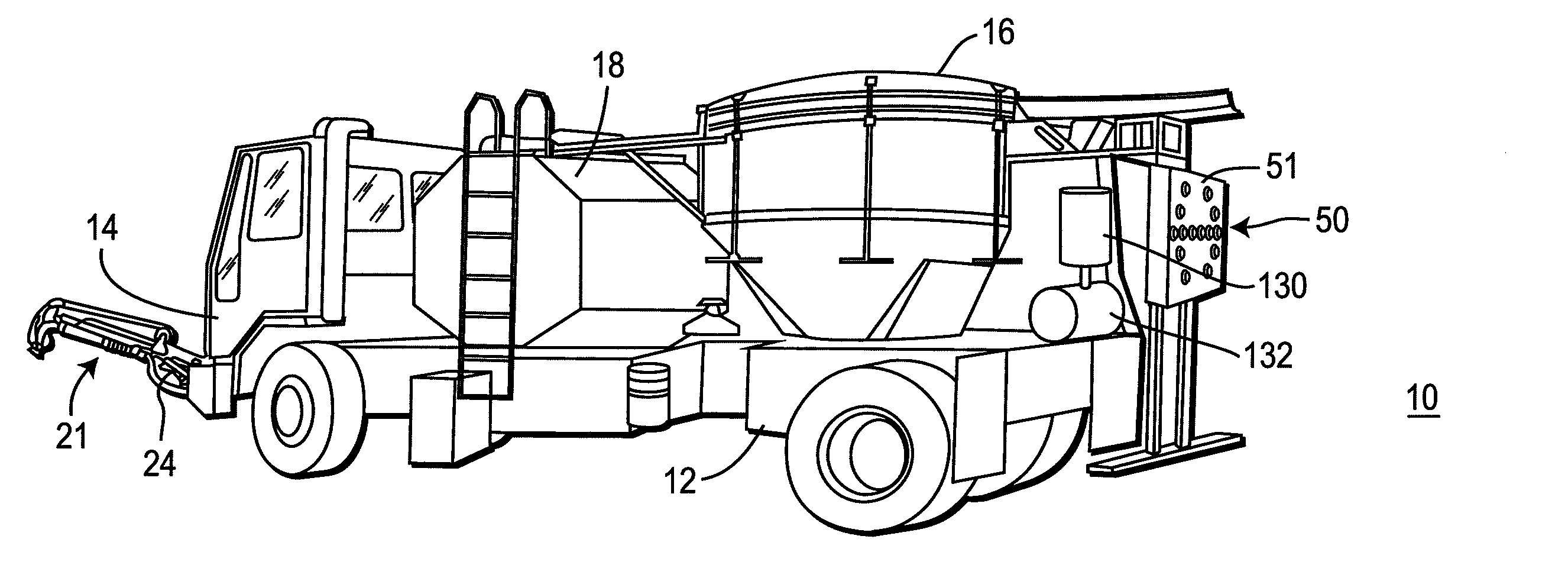

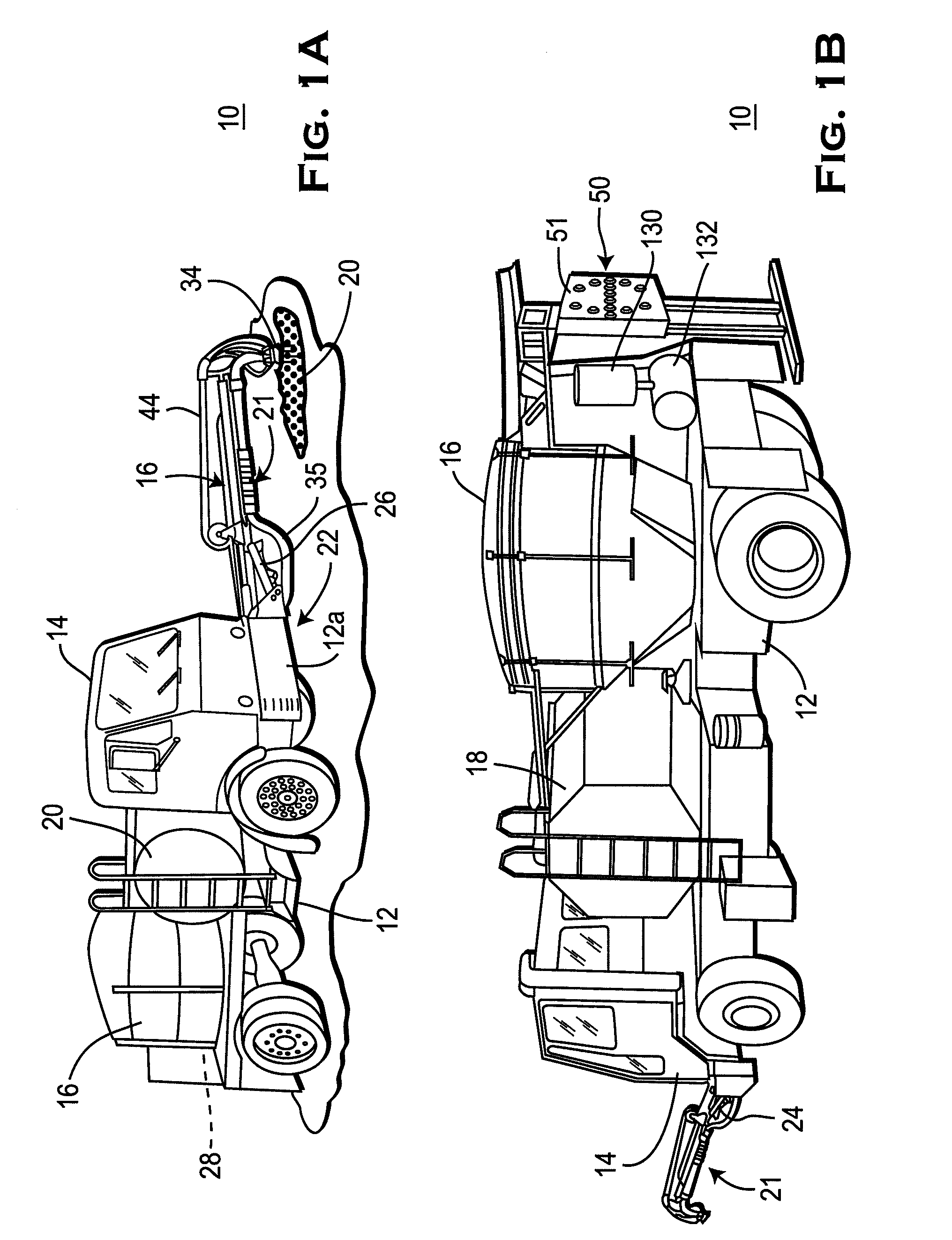

Method and apparatus for repairing potholes and the like

A vehicle mounted patching system for patching potholes and the like and incorporating method and apparatus for feeding materials used in patching operations as well as removing and flushing asphalt emulsion from the feed lines of the patcher vehicle to completely recycle the cleaning agent used to flush the feed lines after a patching operation, as well as preventing any external discharge of potentially toxic materials. Dry particulate is used to coat a pothole patch to permit immediate use. Rubber particulate impregnated with a fibrous material is used to assure bonding with the emulsion. A hydraulically-driven feeder feeds particulate into a pressurized conduit through a one-way air lock. A hydraulic pump provides mechanical power to the feeder and an air blower which pressurizes the conduit carrying the particulate to a dispensing head. A spray assembly is provided to spray fibrous material entering the feeder.

Owner:PATCH MANAGEMENT

Ohmic defroster for foods and process

InactiveUS20120228283A1Less energy consumptionReduce material lossOhmic-resistance heating detailsHigh frequency current welding apparatusElectric energyOhm

The defrosting apparatus of the present invention uses ohmic heating as operating principle, circulating an electric current through blocks of food. In the particular case of foods, electric current conduction capacity is low, which means that energy is dissipated into the material in the form of heat, thereby heating same. In this case, the block of frozen food acts as a resistor in the electrical circuit which opposes the passage of the current. The defrosting apparatus of the present invention generally comprises a plurality of compartments for receiving blocks of frozen food and for connecting said blocks to an electrical circuit by means of electrodes. In addition, the apparatus includes a plurality of heating modules, a module for controlling and monitoring variables, a plurality of power modules for supplying the necessary electrical energy, and a plurality of pneumatic modules for guaranteeing contact between the blocks of food and the electrodes of the power system. The heating modules are designed to receive the frozen blocks of food and to supply the electrical energy necessary to heat the material and to obtain the required temperature. The defrosting apparatus comprises a plurality of heating modules, depending on the capacity required and on the geometry of the blocks of food to be defrosted, and the number of modules may be between four and eight, but is not limited thereto. The module for controlling and monitoring variables is designed to record the behaviour of the variables that play a role in the defrosting process and the operation of the equipment. The equipment includes a single system that governs the entire operation thereof. The defrosting process for blocks of frozen foods is characterized by (i) placing the block of frozen food in a plurality of compartments, (ii) connecting said block to an electrical circuit by means of electrodes, (iii) guaranteeing contact between the frozen block of food and the electrodes, and (iv) circulating an electric current through the block of frozen food. Said electric current is that which is necessary to heat the frozen block of food and to obtain the necessary temperature.

Owner:INDA DE ALIMENTOS ZENUS S

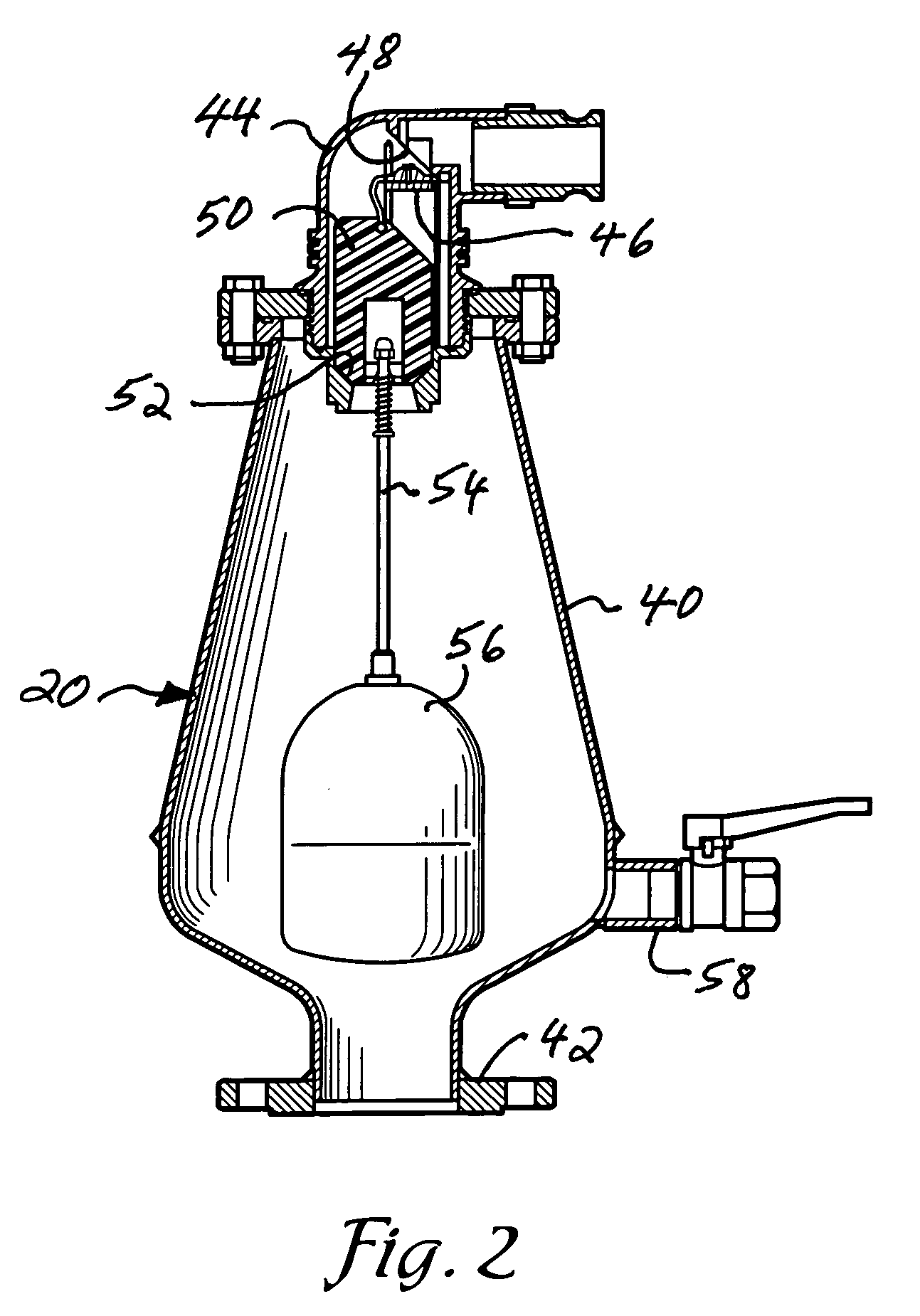

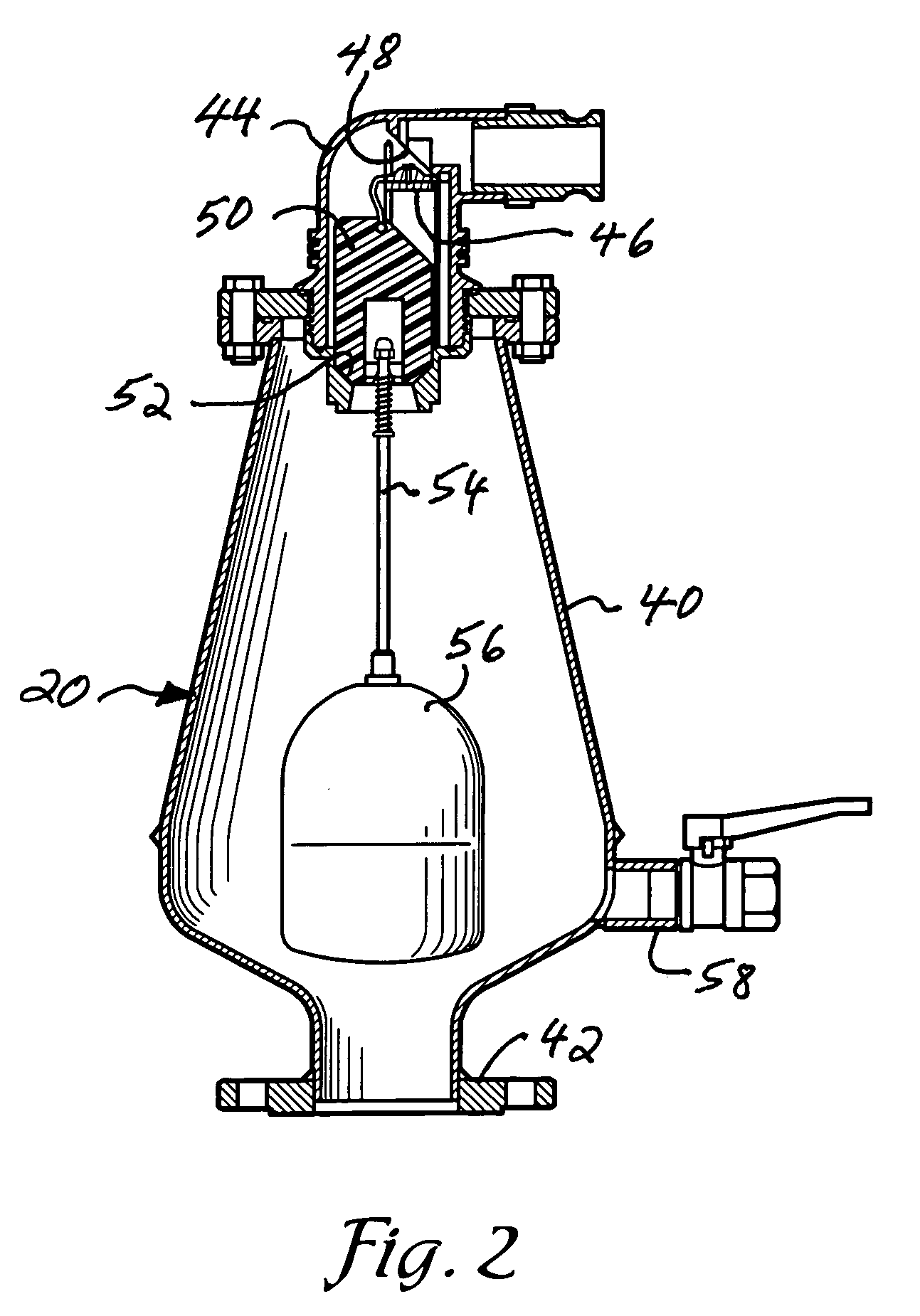

Sewer pipe gas exhaust filter apparatus

ActiveUS20070033719A1Avoid dischargeProlong lifeOperating means/releasing devices for valvesSewerage structuresFilter mediaVALVE PORT

A sewer pipe gas exhaust filter apparatus includes a sewer vent valve unit connected to a sewer pipe and including a valve member moved into and out of engagement with a valve seat by a float member, a gas filter unit connected to the sewer vent valve unit and including a gas filter medium, and a gas flow valve arrangement to cause gases from the sewer to flow through the filter medium while bypassing air drawn into the sewer pipe past the gas filter unit. The filter medium of the gas filter unit removes chemical components from air and gas exhausted from the sewer pipe, thereby improving the odor of such exhausted gases.

Owner:ODOR CONTROL SPECIALTIES

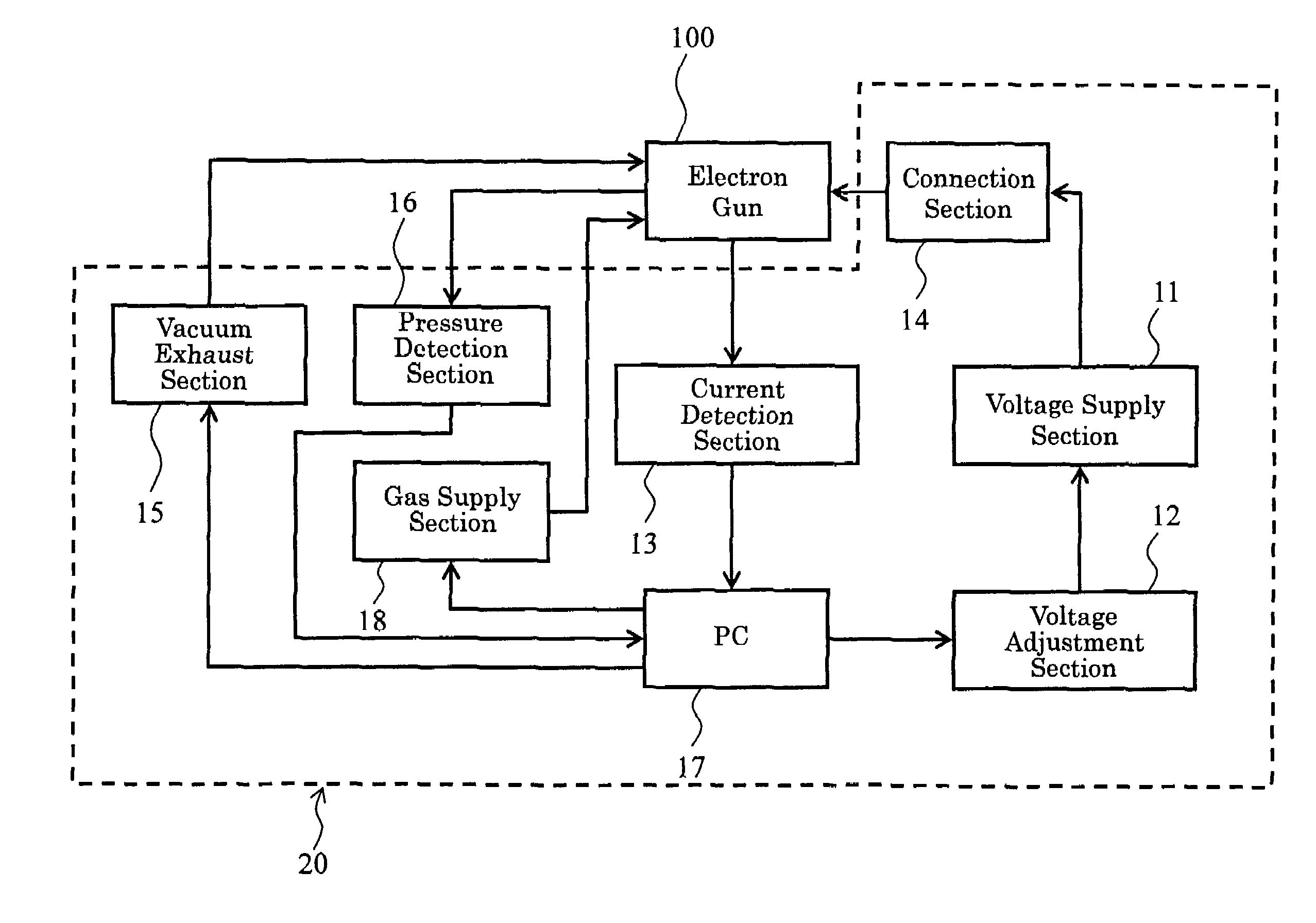

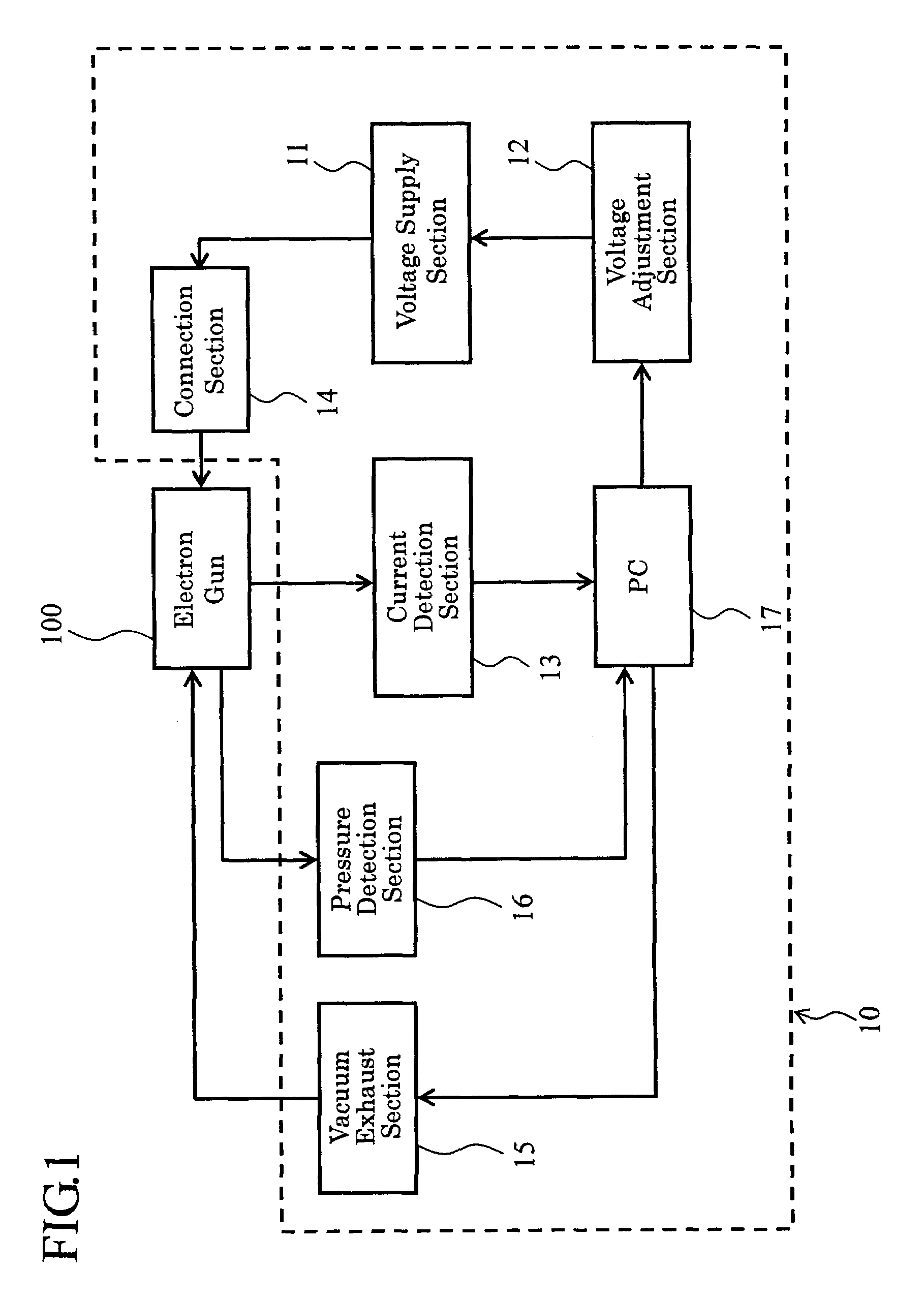

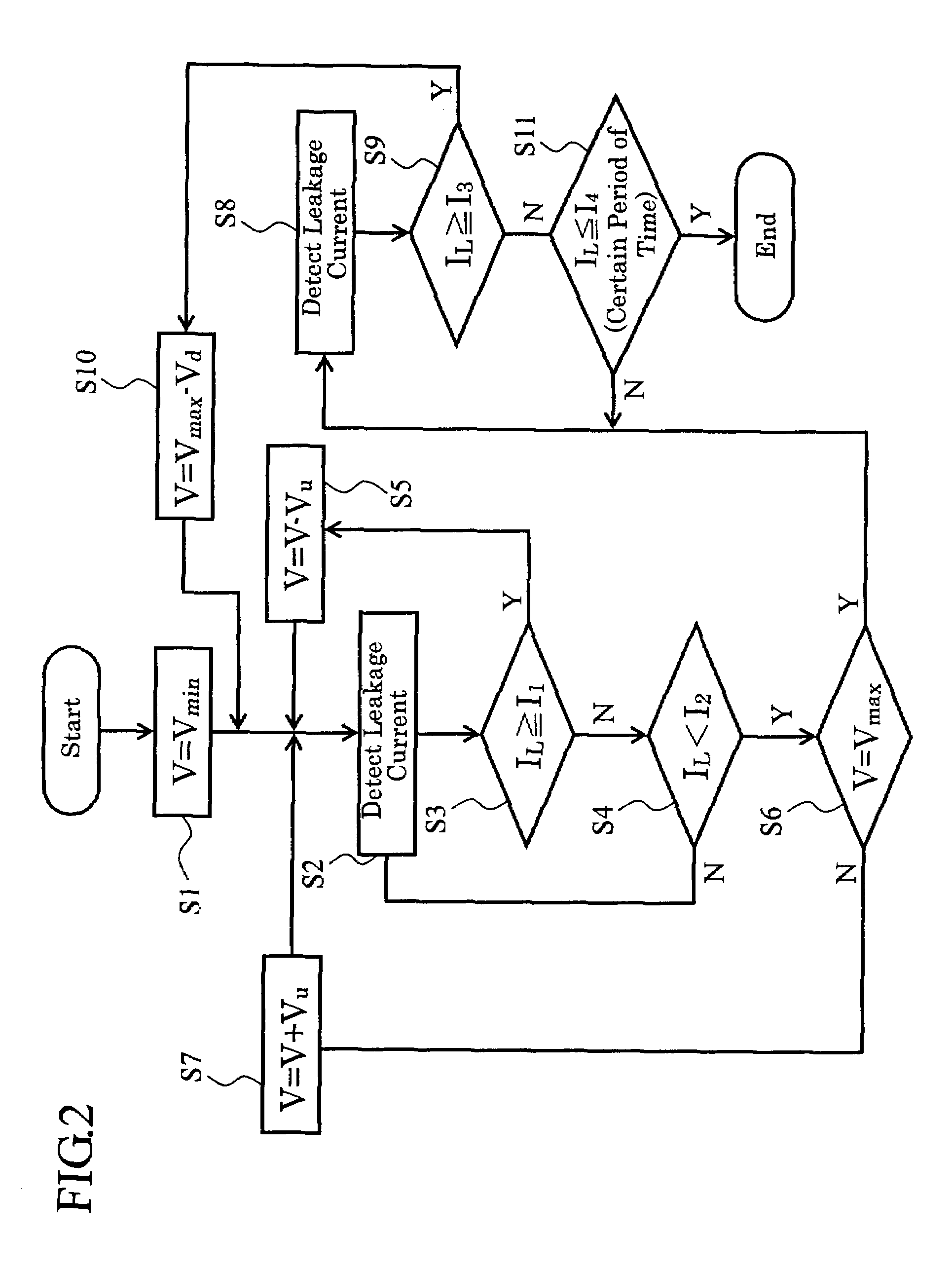

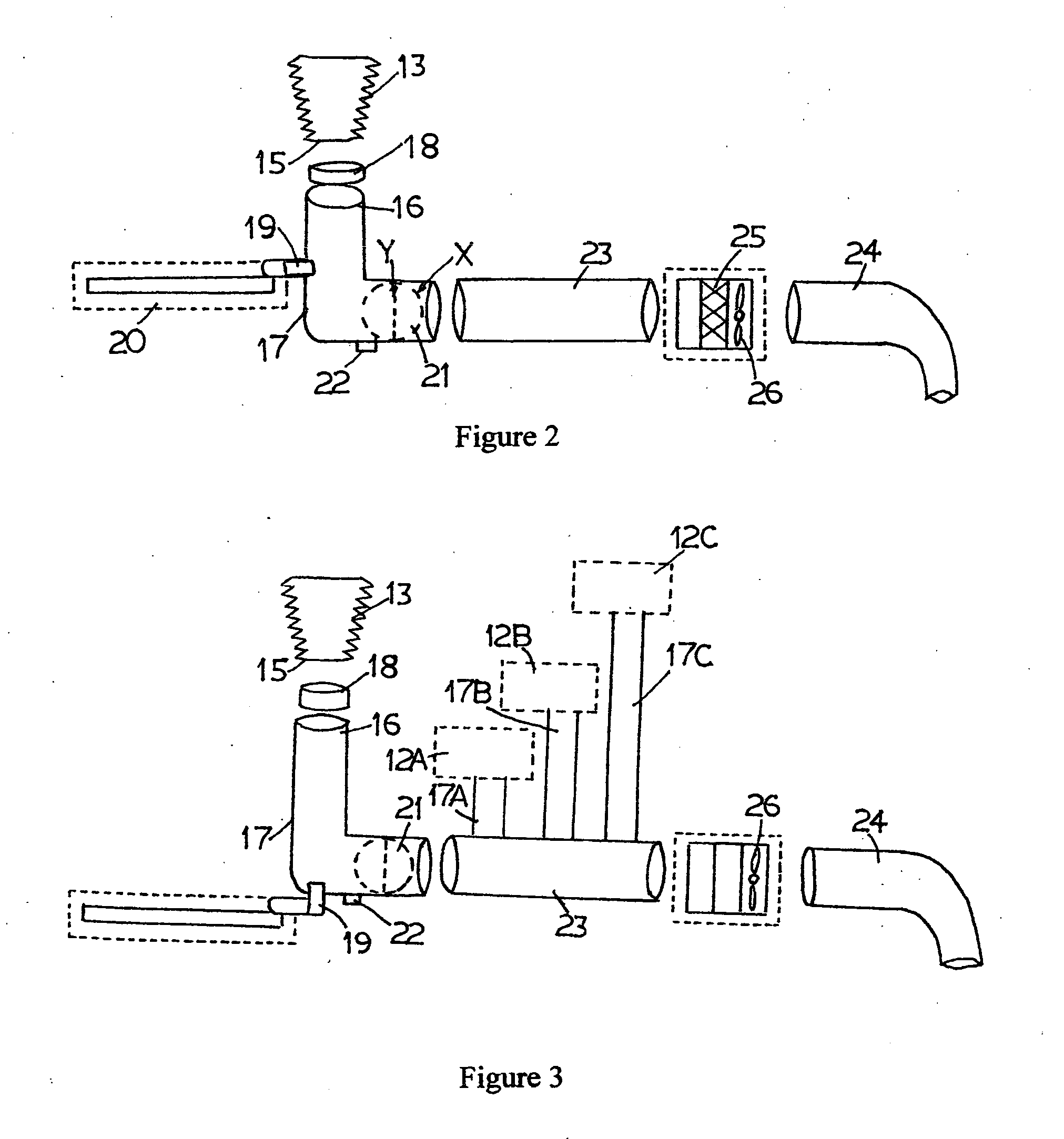

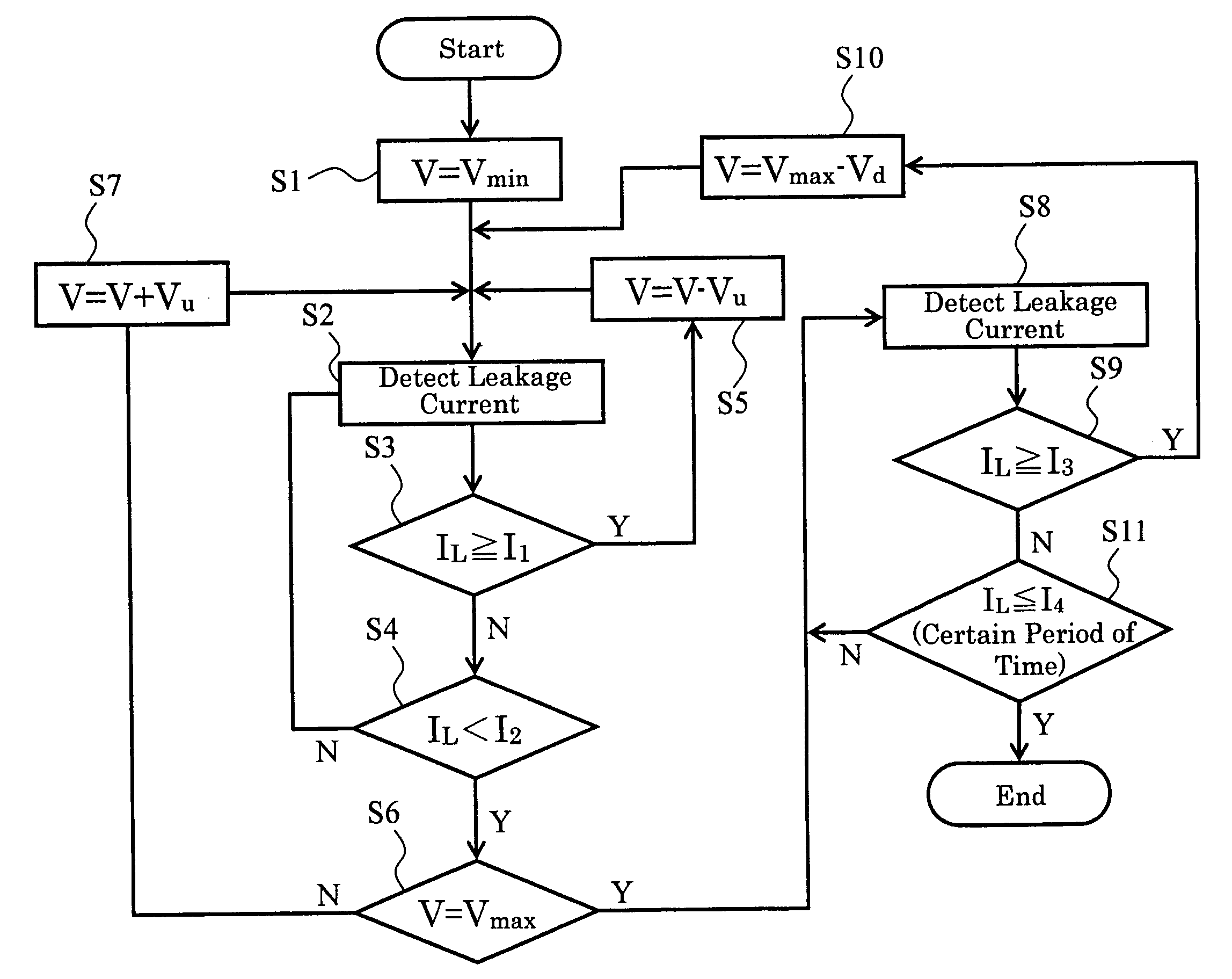

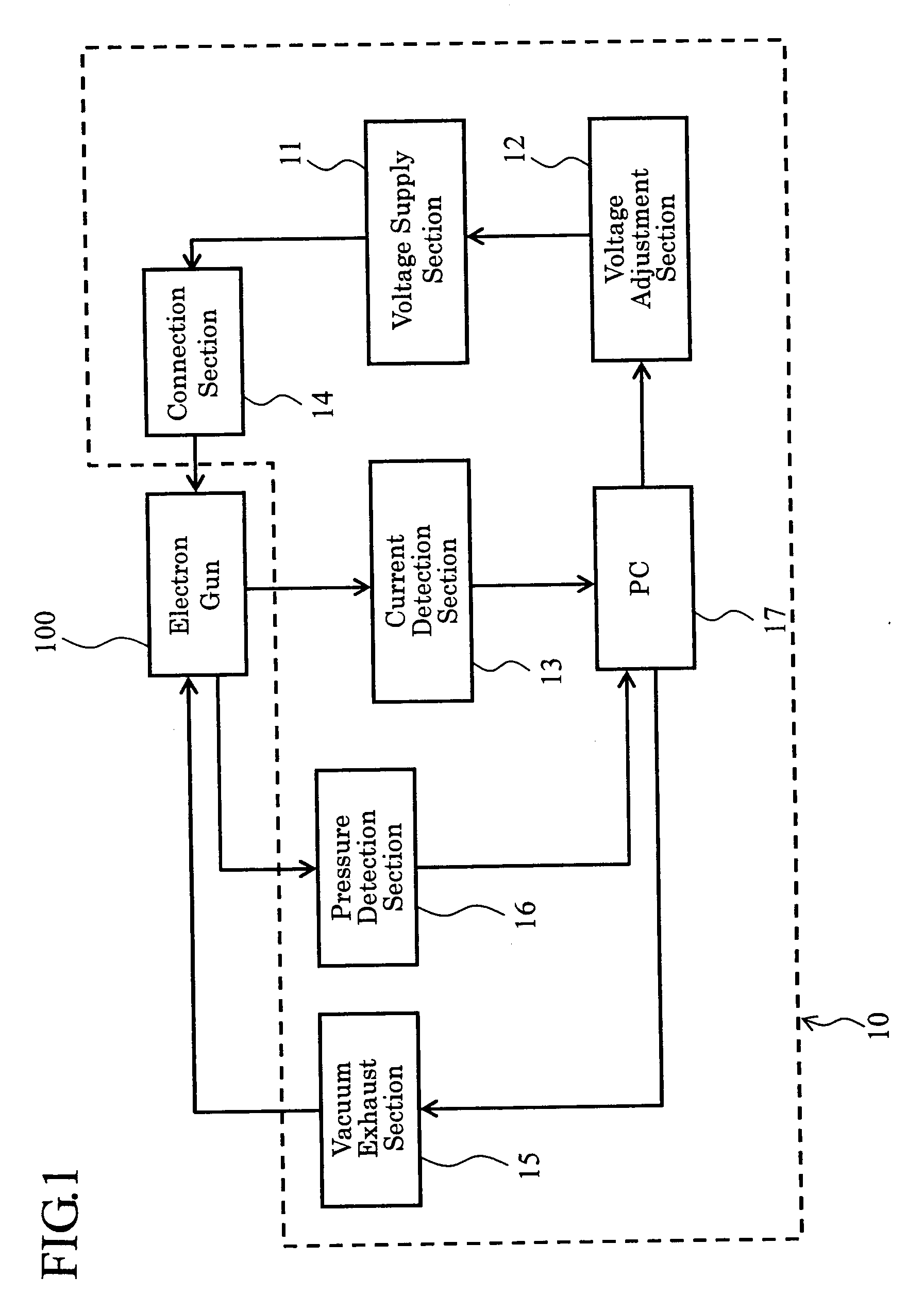

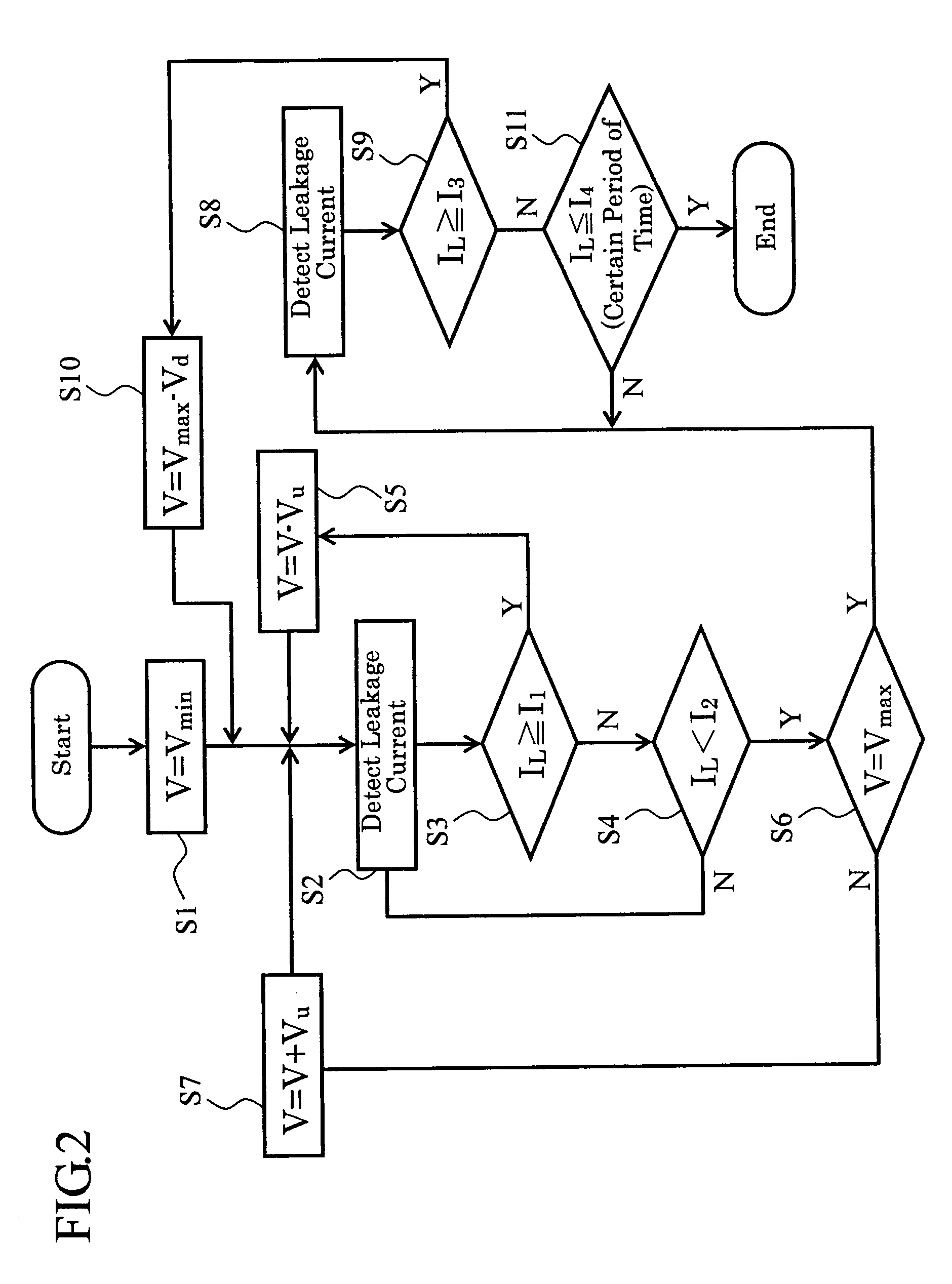

Processing method and processing device of conditioning electron gun

ActiveUS7683551B2Improve pressure resistanceEliminate dischargeNanoinformaticsTube/lamp factory adjustmentVoltage regulationEngineering

Discharge factors existing on a surface of an electrode or an insulator forming an electron gun are removed efficiently and effectively, thus simply and easily enhancing the withstand voltage property of the electron gun. A conditioning processing device of an electron gun is provided with a voltage supply section, a voltage adjusting section for adjusting the output voltage of the voltage supply section, and a current detection section for detecting a leakage current flowing between the electrodes of the electron gun. Further, there are attached a vacuum exhaust section for adjusting the inside of the electron gun in a reduced pressure condition and a pressure detection section. Further, it is arranged that a personal computer (PC), for example, performs data processing based on the leakage current detected by the current detection section or comparison with a reference value thereof to control the voltage, which is applied between the electrodes from the voltage supply section via a connection section, via the voltage adjustment section.

Owner:NUFLARE TECH INC

Sewer pipe gas exhaust filter apparatus

ActiveUS7866334B2Avoid dischargeProlong lifeOperating means/releasing devices for valvesSewerage structuresExhaust valveFilter media

A sewer pipe gas exhaust filter apparatus includes a sewer vent valve unit connected to a sewer pipe and including a valve member moved into and out of engagement with a valve seat by a float member, a gas filter unit connected to the sewer vent valve unit and including a gas filter medium, and a gas flow valve arrangement to cause gases from the sewer to flow through the filter medium while bypassing air drawn into the sewer pipe past the gas filter unit. The filter medium of the gas filter unit removes chemical components from air and gas exhausted from the sewer pipe, thereby improving the odor of such exhausted gases.

Owner:ODOR CONTROL SPECIALTIES

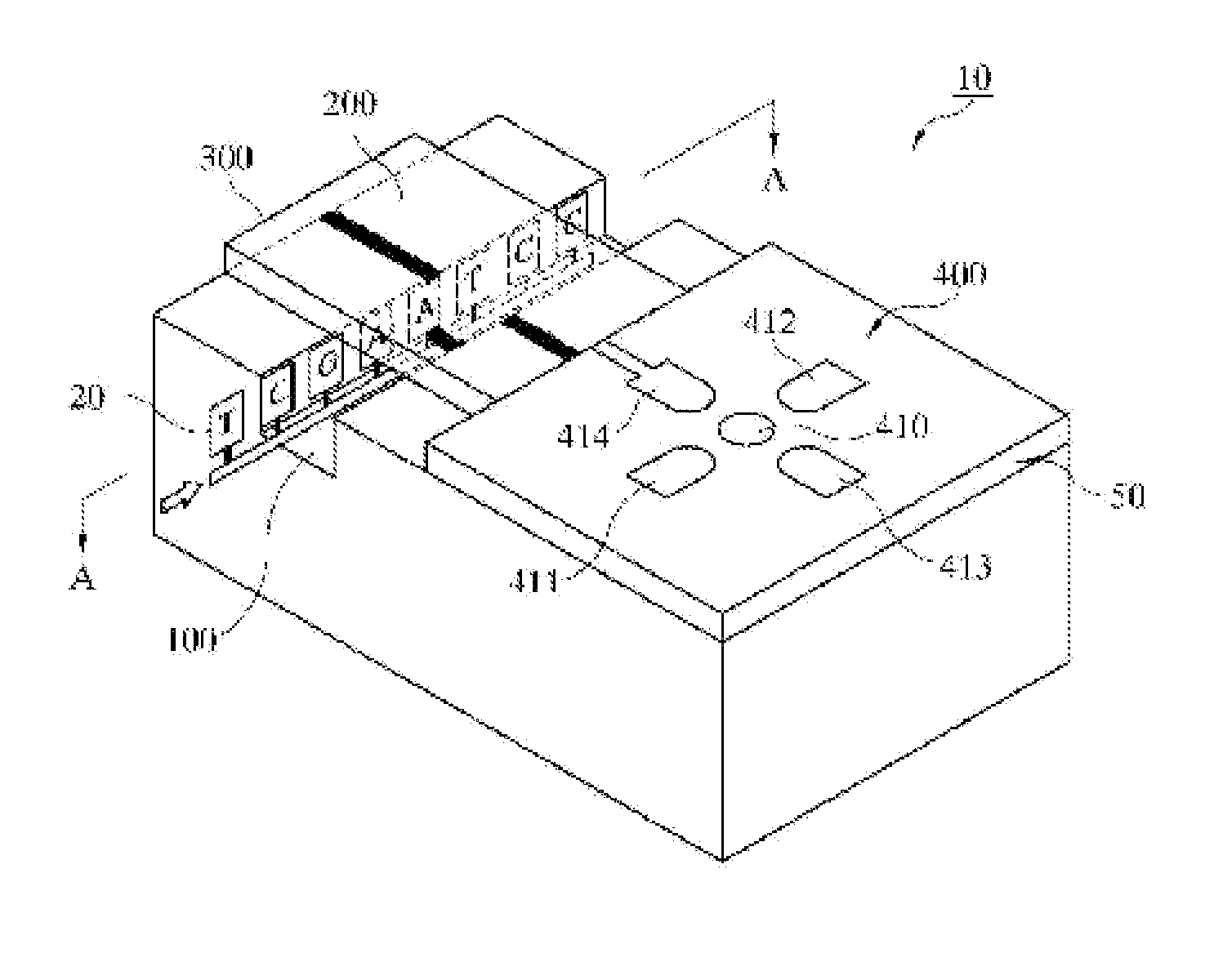

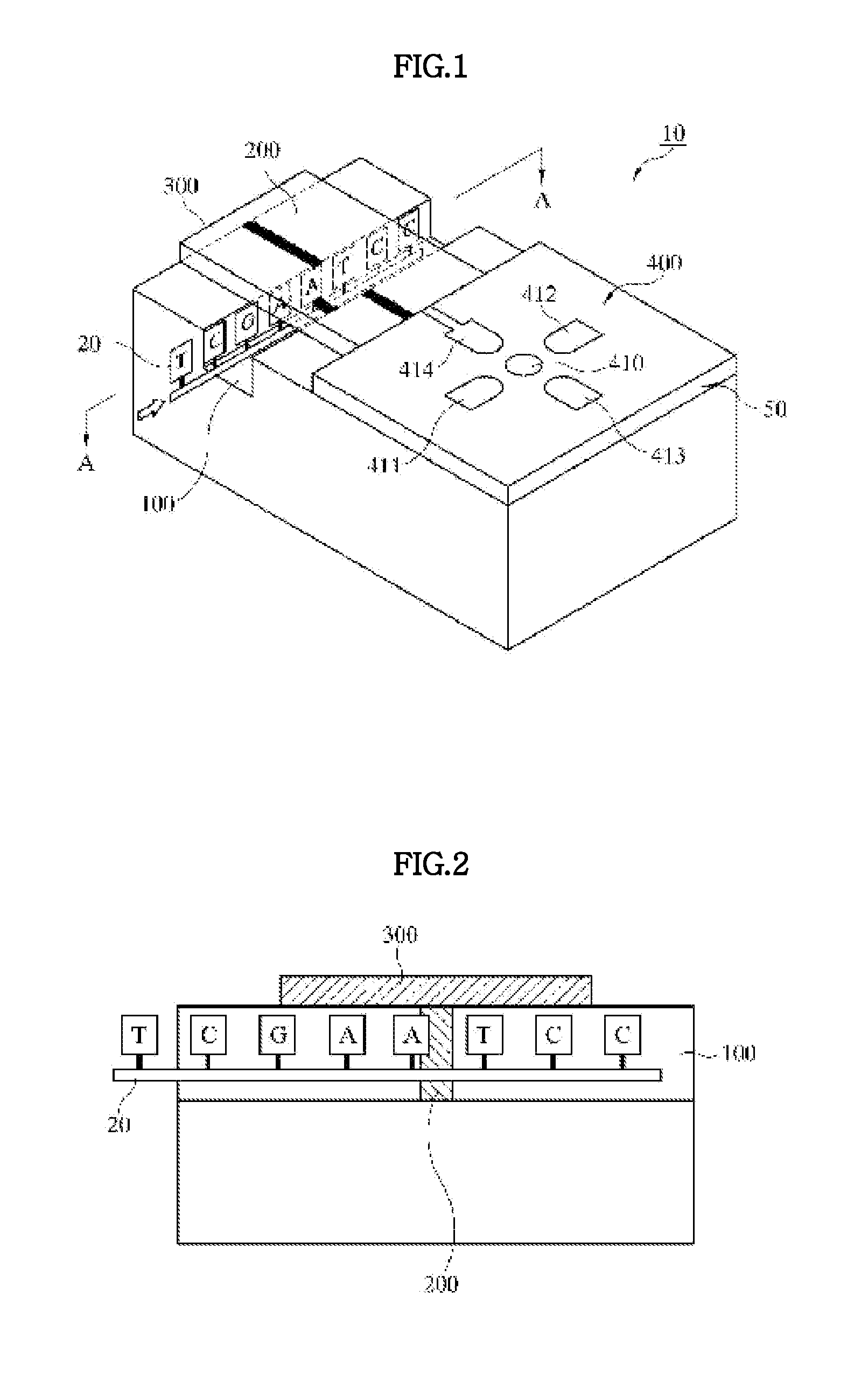

System and method for real-time analysis of molecular sequences using nanochannels

InactiveUS20150316529A1Excessive timeEliminates dischargeSludge treatmentVolume/mass flow measurementDirectivityMoving speed

The present invention relates to a system for analyzing molecular sequences, which is capable of decoding unit molecules constituting various biopolymers on a real-time basis using nanochannels. A control electrode serves to control the unit molecules passing along the channel such that the velocity of movement, arrangement, and directivity of the unit molecules can be rendered uniform. Particularly, at least four probe electrodes are separately formed in the case of decoding ss-DNA base molecules. Each probe electrode is coated with four different types of DNA base molecules to maximize detection efficiency through the interaction with complementary base molecules moving along the inside of the channel.

Owner:CHUNGBUK NAT UNIV IND ACADEMIC COOPERATION FOUND

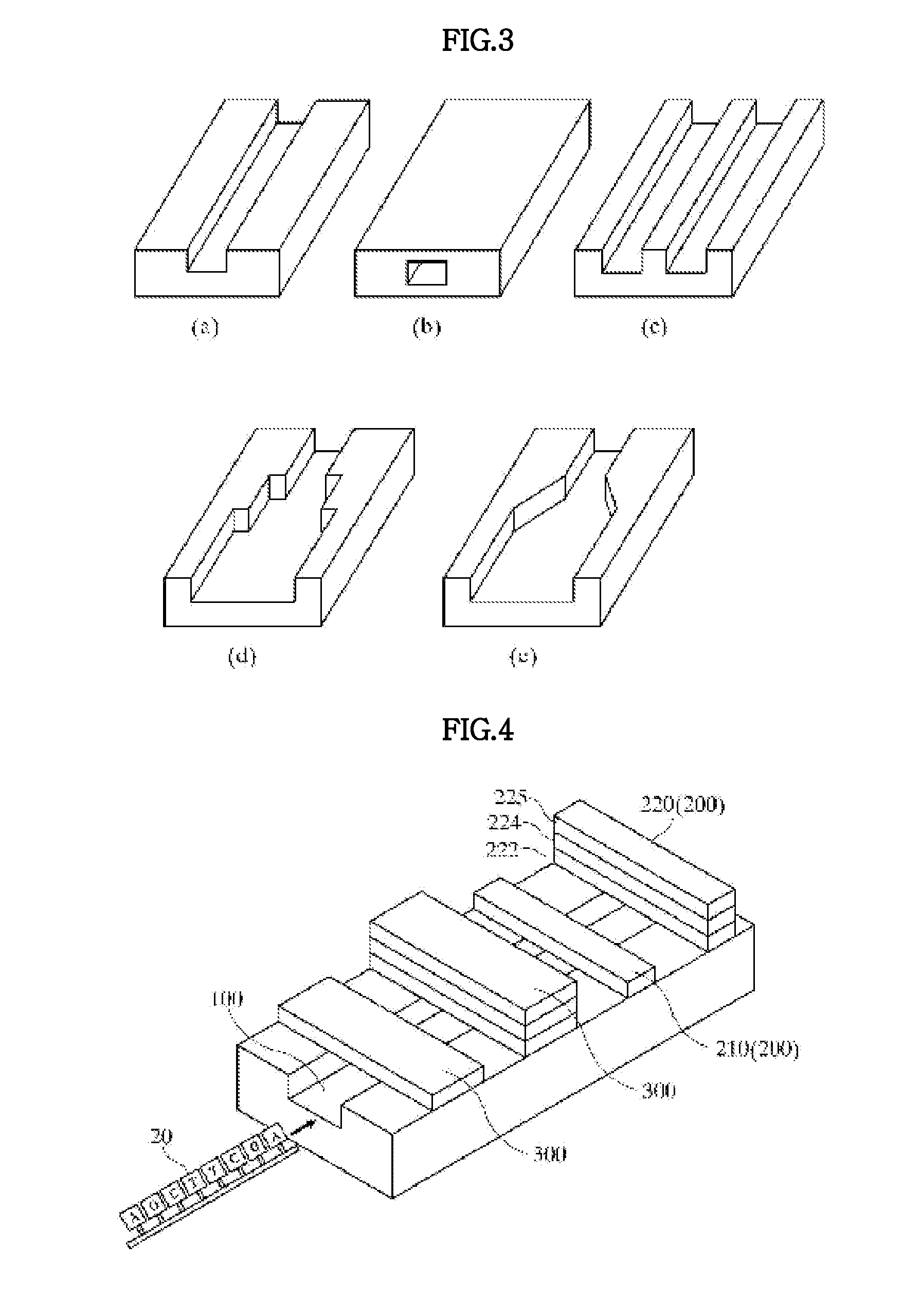

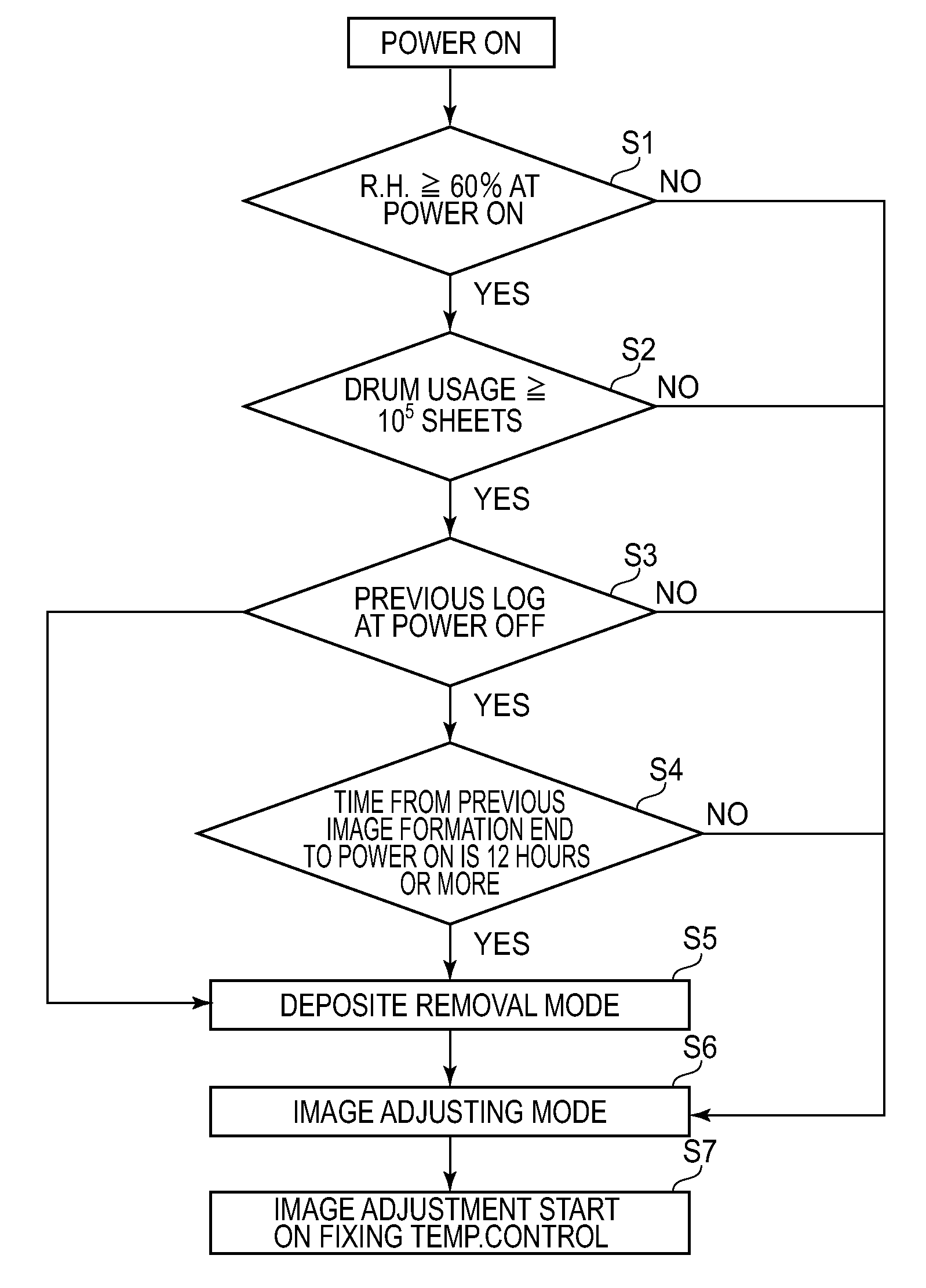

Image forming method

InactiveUS20070212082A1Eliminate dischargeSuppressing an occurrence of image flow in a short timeElectrographic process apparatusEngineeringImage formation

Owner:CANON KK

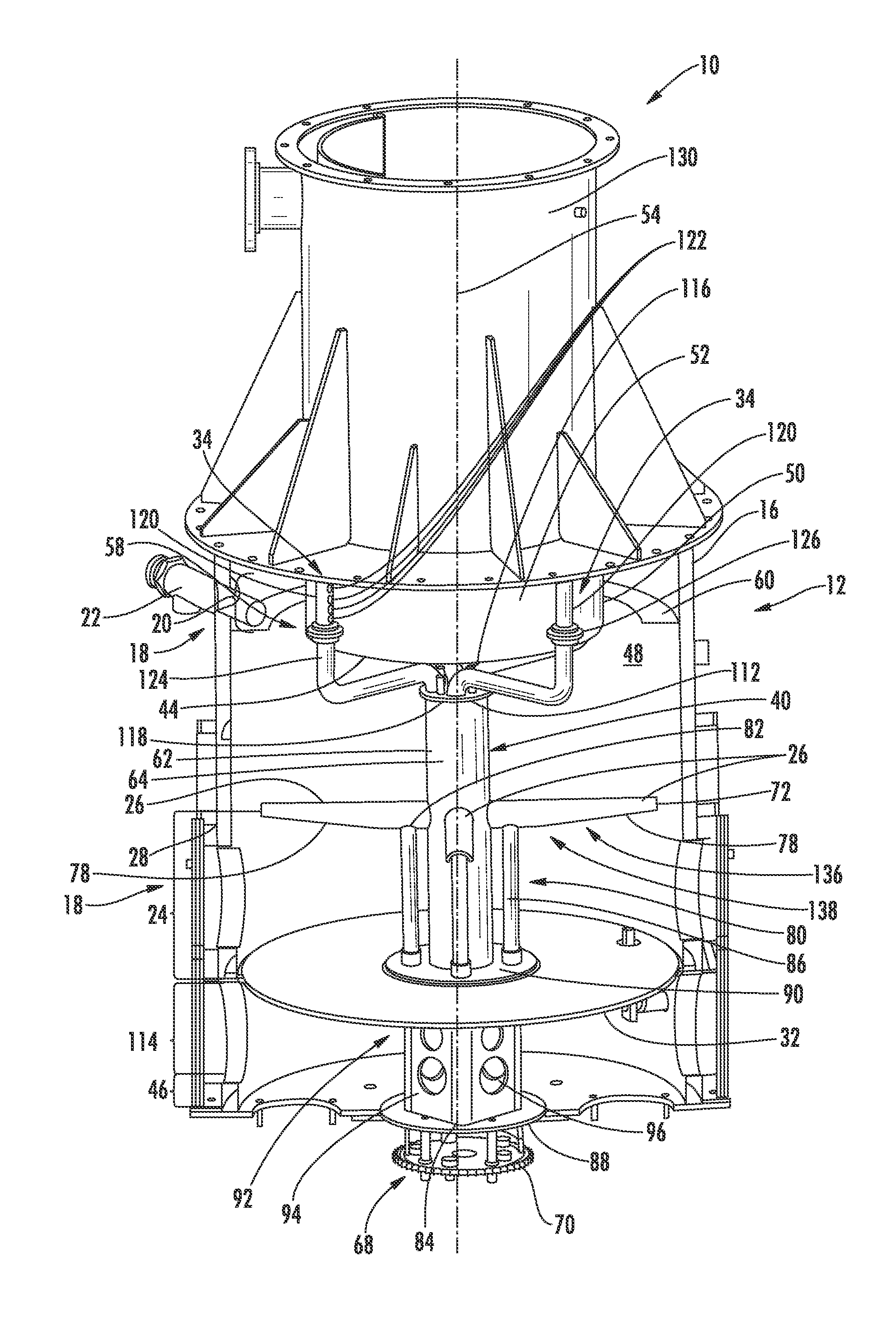

Modular plasma assisted gasification system

InactiveUS20120117980A1Convenient shipmentEasy to transportBiofuelsCombustion enginesCarbon layerSyngas

A modular gasification reactor for a plasma assisted gasification reaction system is disclosed for converting fuel, such as, but not limited to, biomass, to syngas to replace petroleum based fuels used in power generation. The system may be a modular system housed within a frame facilitating relatively easy transportation. The system may include a reactor vessel with distinct reaction zones that facilitate greater control and a more efficient system. The system may include a syngas heater channeling syngas collected downstream of the carbon layer support and to the pyrolysis reaction zone. The system may also include a syngas separation chamber configured to produce clean syngas, thereby requiring less filtering. The system may further include an agitator drive assembly that prevents formation of burn channels within the fuel.

Owner:ADAPTIVEARC

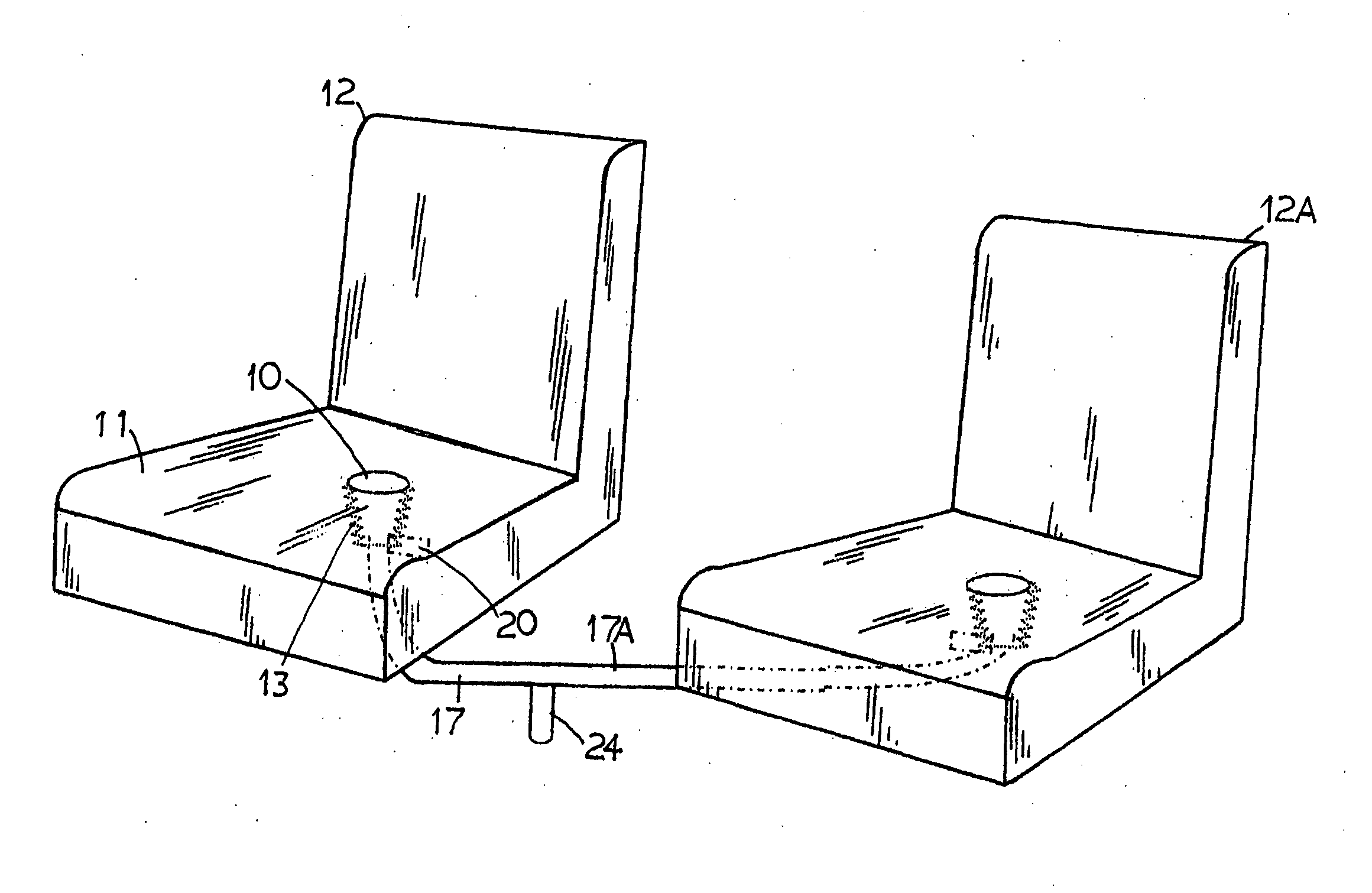

Malodor air exhaust system

InactiveUS20110319004A1Readily and easily incorporatedEasily and readily removedVehicle seatsAir-treating devicesFlatulenceWaste management

The exhaust system is for removing malodor flatulence air expelled by a person sitting in a seat. The gas sensor and the control module are provided in the form an integral unit removably mounted to a manifold incorporated in or under the seat. The gas sensor is removably mounted either to the side wall or at a bottom portion of the manifold. A sensor fan is provided close to the intake opening of the manifold for drawing the flatulence air into the system as soon as it is expelled by the person.

Owner:ROBERT BOSCH GMBH

Processing method and processing device of conditioning electron gun

ActiveUS20080153376A1Improve pressure resistanceEliminate dischargeNanoinformaticsTube/lamp factory adjustmentVoltage regulationPersonal computer

Discharge factors existing on a surface of an electrode or an insulator forming an electron gun are removed efficiently and effectively, thus simply and easily enhancing the withstand voltage property of the electron gun. A conditioning processing device of an electron gun is provided with a voltage supply section, a voltage adjusting section for adjusting the output voltage of the voltage supply section, and a current detection section for detecting a leakage current flowing between the electrodes of the electron gun. Further, there are attached a vacuum exhaust section for adjusting the inside of the electron gun in a reduced pressure condition and a pressure detection section. Further, it is arranged that a personal computer (PC), for example, performs data processing based on the leakage current detected by the current detection section or comparison with a reference value thereof to control the voltage, which is applied between the electrodes from the voltage supply section via a connection section, via the voltage adjustment section.

Owner:NUFLARE TECH INC

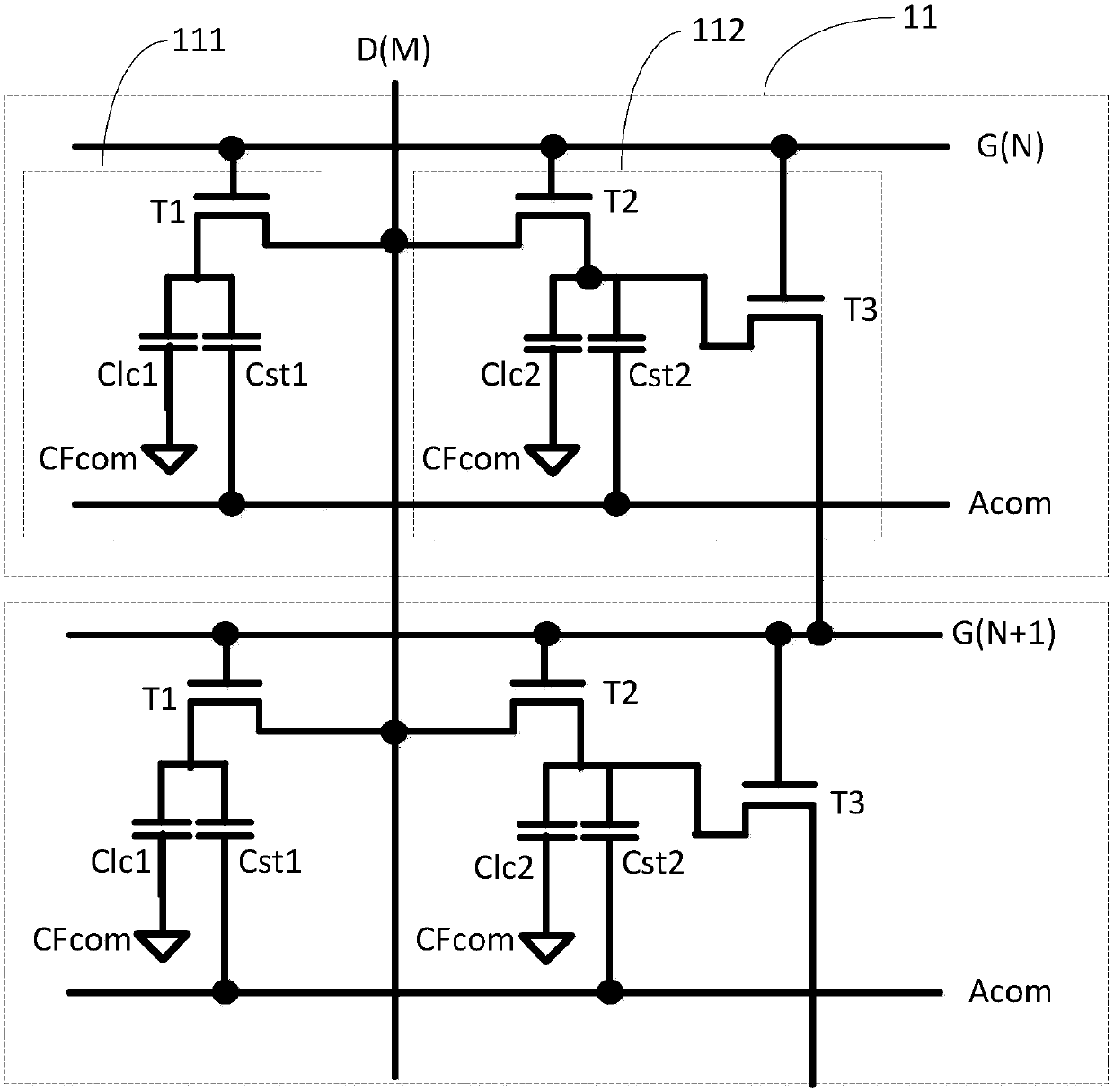

Pixel structure, array substrate and display panel

InactiveCN107643639AEliminate dischargeEliminate horizontal crosstalk issuesNon-linear opticsVoltageData lines

The invention discloses a pixel structure, an array substrate and a display panel. The pixel structure comprises a plurality of pixel units. The pixel units are arranged to form matrixes, and each pixel unit comprises a master pixel unit and a slave pixel unit; the master pixel units in the N row and M columns are used for receiving scanning signals from N scanning lines, and further can receive data signals from M data lines to have master pixel voltages; sub-pixel units in the N row and the M columns are used for receiving the scanning signals of the N scanning lines, further can receive the data signals from the M data lines and can have sub-pixel voltages by means of electric discharge of N+1 data lines. Owing to the mode, the pixel structure, the array substrate and the display panel have the advantage that the problem of horizontal crosstalk due to electric discharge of existing sub-pixel units on voltage stabilization lines can be solved by the aid of the pixel structure, the array substrate and the display panel.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

Plasma assisted gasification system with agitator drive assembly in reactor vessel

InactiveUS20120117875A1Convenient shipmentEasy to transportElectric discharge heatingInternal combustion piston enginesSyngasReaction zone

A controlled zone gasification reactor with an agitator drive assembly for a plasma assisted gasification reaction system is disclosed for converting fuel, such as, but not limited to, biomass, to syngas to replace petroleum based fuels used in power generation. The agitator drive assembly that prevents formation of burn channels with in the fuel. The agitator drive assembly may include a syngas separation chamber configured to produce clean syngas, thereby requiring less filtering. The syngas separation chamber may feed syngas downstream to a syngas heater in a pyrolysis reaction zone in the reactor vessel.

Owner:ADAPTIVEARC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com