Patents

Literature

42results about How to "High degree of esterification" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing n-3PUFA ocean glycerin ester by enzymatical process

A method for preparing n-3PUFA marine glyceride through adopting enzyme method includes following steps: refined fish oil is made into n-3PUFA condensate through saponification, acidification and urea adduct method; lipase catalyzes the synthesis reaction between n-3PUFA and glycerol; n-3PUFA marine glyceride is extracted and separated; moreover, n-3PUFA is effectively concentrated in glyceride to be made into functional products which can prevent and cure cardiovascular diseases and nourish the brain and improve intelligence. The raw material of the invention, n-3PUFA, is extracted from natural fish oil, thereby being safe and effective; during production, nitrogen protection is adopted without adding synthetic antioxidant, thereby effectively preventing oxidation of n-3PUFA; with scientific and reasonable technique, the invention completes synthesis by means of biological enzyme method along with high esterification degree of reaction, higher utilization rate of raw material and easily controlled reaction process; therefore, the invention has wide market prospect.

Owner:GUANGDONG OCEAN UNIVERSITY

Method for the production of an ester

InactiveUS20060041158A1Improve purification effectHigh degree of esterificationFatty oils/acids recovery from wasteCosmetic preparationsInorganic phosphorus compoundsAlcohol

A process for esterification of carbonyl compounds is provided. The process forms a mixture of a carbonyl compound and an inorganic phosphorous compound. An inorganic base can be added to the mixture. The mixture is filtered and an alcohol and a titanate catalyst are added to the filtrate. The mixture is esterified at an elevated temperature.

Owner:COGNIS DEUT GMBH & CO KG

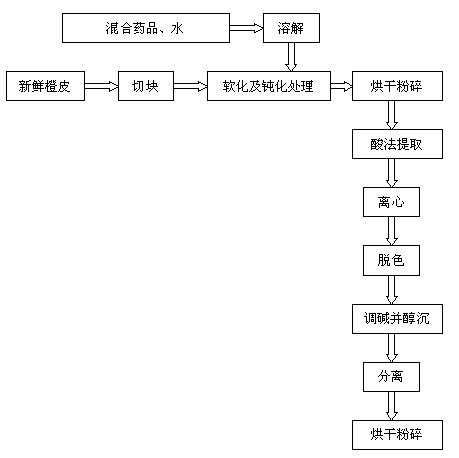

Method for extracting orange peel pectin by softening orange peel and inactivating pectinesterase

The invention discloses a method for extracting orange peel pectin by softening orange peels and inactivating pectinesterase. The method comprises the following step of: soaking fresh orange peels in a mixed solution which is obtained by proportionally mixing sodium hexametaphosphate, citric acid and sodium dihydrogen phosphate, to perform tissue softening treatment and pectinesterase inactivation treatment. The mixed solution contains, per 100 g, 41 g of sodium hexametaphosphate, 40 g of citric acid and 20 g of sodium dihydrogen phosphate. By the above treatments, the molecular weight of the pectin extracted from orange peels is increased and the quality is improved. The orange peel pectin is decolorized by macroporous absorption resin AB-8 to greatly improve the color of the pectin. Besides, during alcohol precipitation, the pH value of the solution is adjusted to 3.5, so as to optimize the sedimentation coefficient of the orange peel pectin and thus to increase the pectin yield.

Owner:NANCHANG UNIV

Preparation method of biobased pentaerythritol fatty acid ester

InactiveCN106748759AAvoid affecting performanceSustainableOrganic compound preparationCarboxylic acid esters preparationIodo fatty acidPentaerythritol

The invention discloses a preparation method of biobased pentaerythritol fatty acid ester, which belongs to the technical field of esterification and synthesis in organic chemistry. Specifically, pentaerythritol is mixed with biobased fatty acid, flowing degassing is performed under a negative pressure condition for an autocatalytic esterification reaction, and refined processes of separation dealcoholization, distillation deacidification and the like are performed, so as to obtain biobased pentaerythritol fatty acid ester. The preparation method has the advantages that a catalyst does not need to be added in the autocatalytic esterification reaction, thereby preventing a residual catalyst existing in a combined-state form in product molecules in a synthesis process of the traditional catalytic esterification technology commonly adopted at present from affecting the overall performance of a product; separation and purification processes are simple, and are controlled easily; the degree of esterification is high, side reaction is less, and the product purity is high; the high-temperature stability of the product is good.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

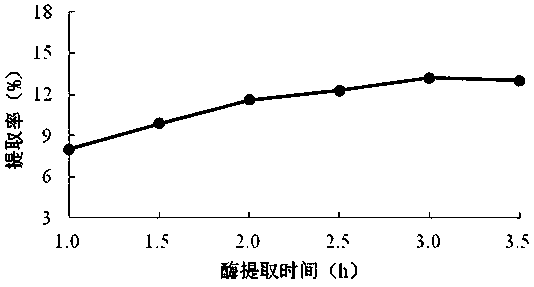

Method for extracting pectin in passiflora edulis peel through microwave-assisted enzymatic method

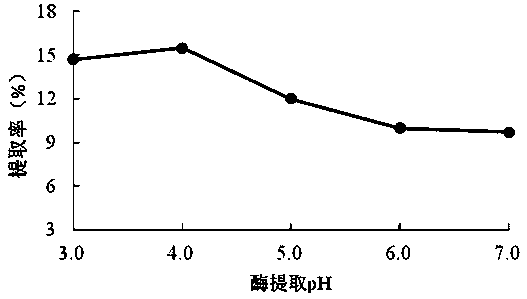

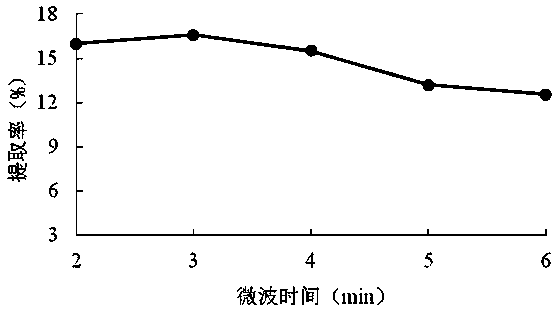

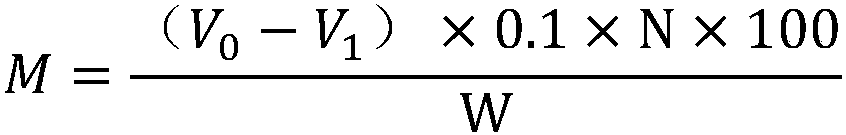

The invention provides a method for extracting pectin in passiflora edulis peel through a microwave-assisted enzymatic method. The method is characterized in that parameters of a technology for extracting the pectin in the passiflora edulis peel by taking passiflora edulis peel as a raw material and adopting the microwave-assisted enzymatic method are as follows: a material-liquid ratio is 1 g / mL:30 g / mL, the microwave time is 3 minutes, the pH (Potential of Hydrogen) of enzyme extraction is 6.0, the concentration of cellulase is 0.4 g / 100 mL, the enzyme extraction temperature is 45 DEG C, andthe enzyme extraction time is 3 hours. The extraction rate, the esterification degree, the total galacturnic acid content, the gelatinous degree, the expansion force and the water-retaining capacityof the pectin extracted through the extraction method are all higher than those of passiflora edulis peel pectin extracted through a traditional acid extraction method, and the pectin belongs to high-ester pectin (the esterification degree is greater than or equal to 50 percent). The pectin is applied to preparation of jelly and fruit soft sweets, and better pectin quality is expressed.

Owner:FUJIAN UNIV OF TRADITIONAL CHINESE MEDICINE

Hard panned coating and confection comprising the same

ActiveUS20160029657A1Good coatingImprove lipophilicityConfectioneryChewing gumChemistryTitanium dioxide

There is provided a hard panned coating, and a hard panned confection comprising an edible core coated with the same. The hard panned coating comprises multiple sugar syrup layers, only some of which further comprise one or more sucrose esters. In some embodiments, titanium dioxide may be excluded from the sugar syrup / sucrose ester layers. In these, and other, embodiments, the hard panned coatings exhibit one or more L*, a* and b* values within 5% of the corresponding value of a colorant overcoat applied over a precoat comprising titanium dioxide. Raw material cost savings are thus provided, while yet providing a confection having enhanced properties.

Owner:MARS INC +1

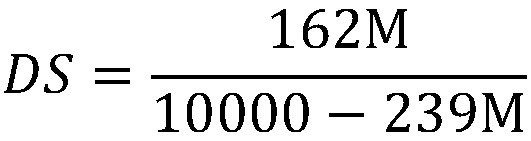

High esterification degree ethyl alginate preparation method

The invention discloses a high esterification degree ethyl alginate preparation method, which comprises: adding alginic acid to anhydrous ethanol, stirring, adding a dehydrating agent having the same molar water content as the alginic acid, adding a catalyst, carrying out stirring heating to achieve a reflux state, adding the remaining dehydrating agent in a dropwise manner when the reflux temperature is achieved, continuously carrying out a reflux reaction for 6-18 h after the remaining dehydrating agent is uniformly added in the dropwise manner within 2-4 h, completing the reaction, cooling to a room temperature, adjusting the pH to 6.5-7.0 with an alkali liquid, filtering, washing the filter cake by using an ethanol aqueous solution with a mass concentration of higher than 60%, and drying at a temperature of 40 DEG C to obtain the ethyl alginate. According to the present invention, with the ethyl alginate preparation method, the esterification degree of the prepared ethyl alginate is higher than 68% and is significantly higher than the esterification degree of the straight chain alkanol ethyl alginate prepared by using the existing technology.

Owner:QINGDAO UNIV

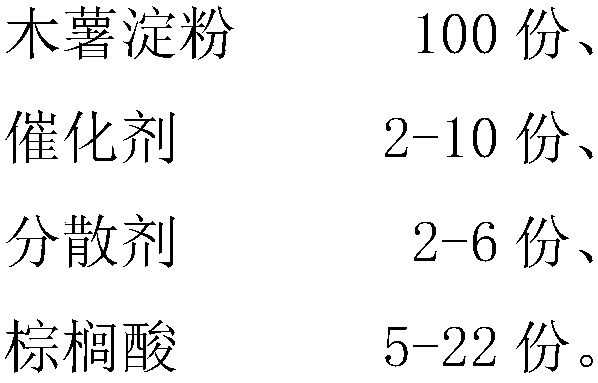

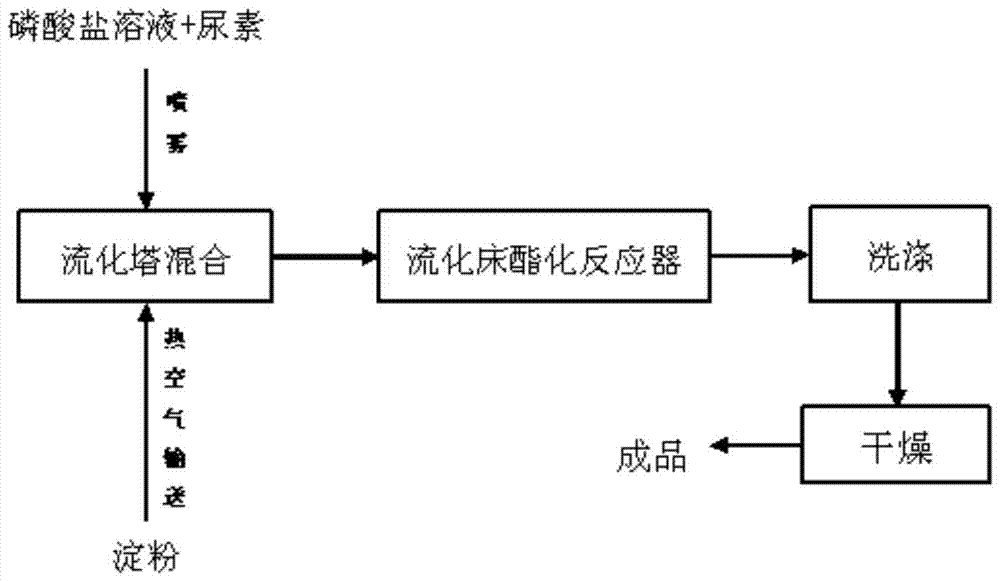

Palmitic acid modified tapioca starch preparation method

InactiveCN109666080AReduce hydrolysis side reactionsImprove the degree of esterification and reaction efficiencyWater contentAlant starch

The invention discloses a palmitic acid modified tapioca starch preparation method, which comprises: adding water to a catalyst, controlling the water content of the system at 15-25%, adding the obtained material to tapioca starch, completely mixing, adding a dispersing agent, and mixing; and adding palmitic acid, carrying out a reaction at a temperature of 105-135 DEG C to obtain the palmitic acid modified tapioca starch. According to the present invention, by using the semi-dry process, the occurrence of hydrolysis side reactions can be effectively reduced so as to greatly improve the esterification degree and the reaction efficiency of starch and palmitic acid, the obtained product has advantages of high grafting rate and high reaction efficiency, and the method has advantages of low production cost, simple operation and the like.

Owner:SHANGHAI DONGSHENG NEW MATERIALS

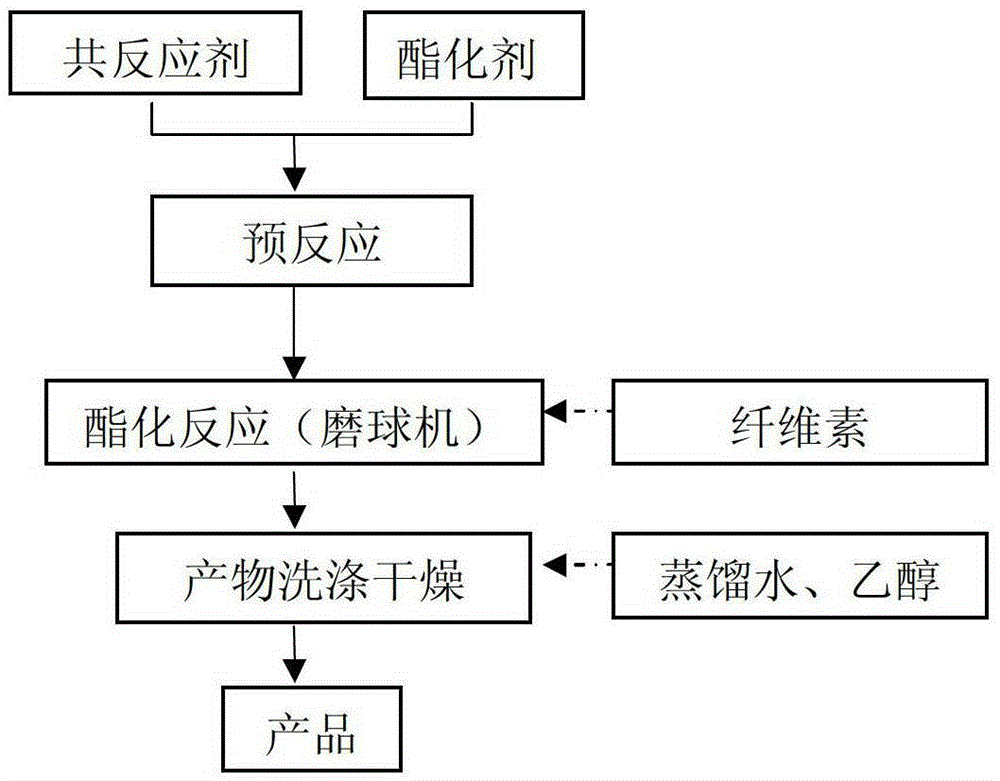

A kind of cellulose fatty acid ester and preparation method thereof

The invention belongs to the field of cellulose modification, and more specifically relates to a cellulose higher fatty acid ester and a preparation method thereof. The weight ratio of cellulose, an esterifying agent and a coreactant, which are the principle raw materials of the cellulose higher fatty acid ester, is 100g:50g-300g:100g-600g. The preparation method comprises steps of pre-reaction and esterification reaction, wherein the esterifying agent and the coreactant are mixed uniformly firstly; the mixture is subjected to pre-reaction for 10 to 30min at a temperature of 50 to 90 DEG C; cellulose is mixed with the mixture uniformly after the pre-reaction, and the mixture is delivered into a ball grinder and is subjected to esterification reaction for 20 to 90min at the temperature of 40 to 90 DEGC with a stirring speed of 100 to 500rmp; and then obtained reaction product is washed and dried so as to obtain the cellulose higher fatty acid ester. Mechanical activation technology is employed so as to increase esterification efficiency of cellulose, shorten reaction time and simplify the processing steps.

Owner:福建鸿燕化工有限公司

Defoamer for fermentation

ActiveUS20140194538A1Inhibited rapidly and continuouslyIncrease productionBacteriaOther chemical processesGlycerolFermentation

Provided is a defoamer for fermentation which has excellent dispersibility in water and forms neither a precipitate nor oil droplets when the dispersion is heated, and which is highly effective in defoaming fermentation media. This defoamer contains a reaction product obtained by mixing a fat or oil having an iodine value of 40 to 130 with glycerin or like in a molar ratio of from 3 / 2 to 1 / 2 to obtain a mixture, causing 4 to 17 mol of propylene oxide to add to 1 mol of the mixture, and then causing 20 to 40 mol of ethylene oxide and 70 to 110 mol of propylene oxide to block-wise add thereto in this order, the reaction product having an ethylene oxide / propylene oxide molar ratio of from 1 / 4 to 2 / 5.

Owner:NOF CORP

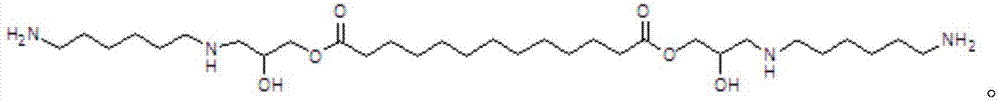

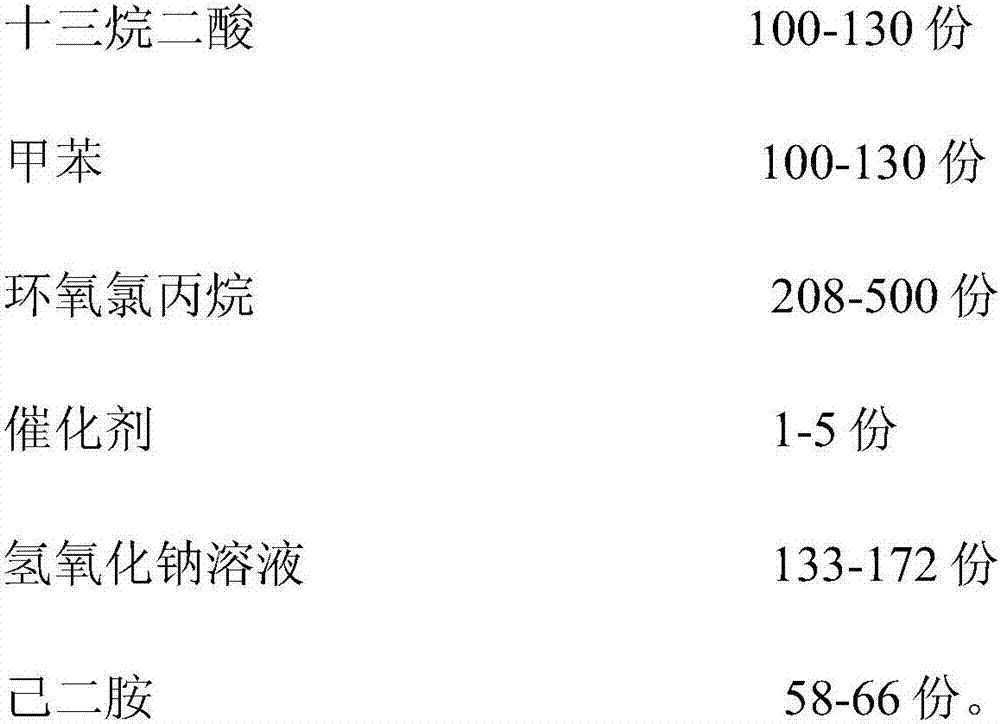

Brassylic acid glycidyl ester modified hexamethylenediamine curing agent and preparation method and applications thereof

ActiveCN107513024AAvoid hydrolysisShort reaction timeOrganic compound preparationAmino-hyroxy compound preparationEpoxyHexamethylenediamine

The invention discloses a brassylic acid glycidyl ester modified hexamethylenediamine curing agent and a preparation method and applications thereof. The preparation method comprises the following steps: at first, carrying out esterification reactions between brassylic acid and epoxy chloropropane under the effect of a catalyst in a toluene solvent at a controlled temperature of 80-110 DEG C to obtain a chloro-alcohol ester intermediate; mixing the chloro-alcohol ester intermediate with a sodium hydroxide water solution, carrying out cyclization reactions at a controlled temperature of 40-85 DEG C to obtain brassylic acid glycidyl ester; and finally, carrying out amination reactions between brassylic acid glycidyl ester and hexamethylenediamine at a temperature of 60 to 75 DEG C to obtain the brassylic acid glycidyl ester modified hexamethylenediamine curing agent. The prepared brassylic acid glycidyl ester modified hexamethylenediamine curing agent has a high amine value, can be used with epoxy resin (epoxy resin E51, for example) to carry out curing, and has an excellent toughening effect on a cured product. The preparation method has the advantages of simple production technology, convenient operation, high output, and suitability for industrial production.

Owner:SHANGHAI RESIN FACTORY

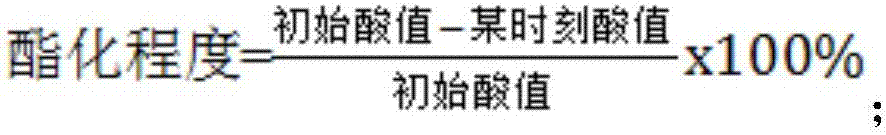

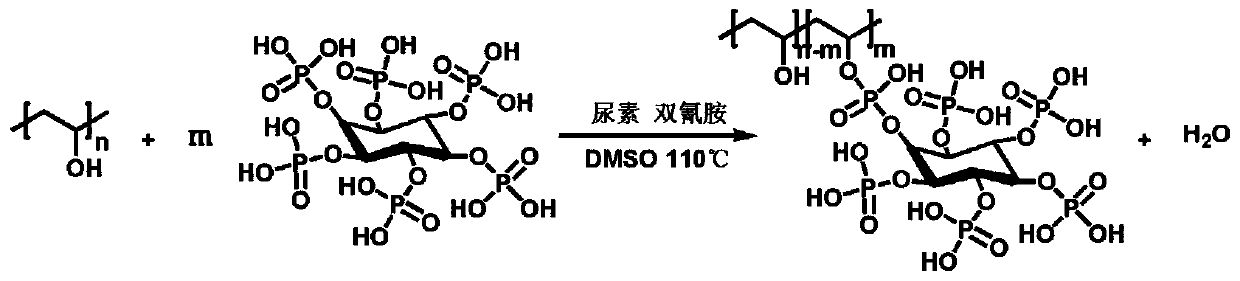

Preparation method of polyvinyl alcohol phytate

InactiveCN110964134AApplication of Enriched Phytic AcidHigh degree of esterificationAlcoholPolyvinyl alcohol

The invention provides a preparation method of polyvinyl alcohol phytate. The preparation method comprises the following steps: adding polyvinyl alcohol solid particles, urea, dicyandiamide and dimethyl sulfoxide into a three-neck flask, building a condensing device and a liquid separation device, carrying out heating and stirring until complete dissolution, dropwise adding a phytic acid solutionand methylbenzene, and after reaction for a period of time, enabling a mixture of methylbenzene and water to flow out of the liquid separation device; and after the reaction is finished, dropwise adding the supernatant part in the three-neck flask into absolute ethyl alcohol, collecting precipitates, carrying out washing with absolute ethyl alcohol and acetone until the pH of filtrate is neutral,and drying the precipitates in vacuum to obtain polyvinyl alcohol phytate. The invention relates to a polyvinyl alcohol and phytic acid modification method, which enriches the application of phytic acid. The invention relates to a method for preparing polyvinyl alcohol phytate through esterification reaction, urea is used as a catalyst, dicyandiamide is used as a dehydrating agent, methylbenzene is used as a water-carrying agent, and the method has higher esterification degree compared with other esterification reactions.

Owner:HARBIN ENG UNIV

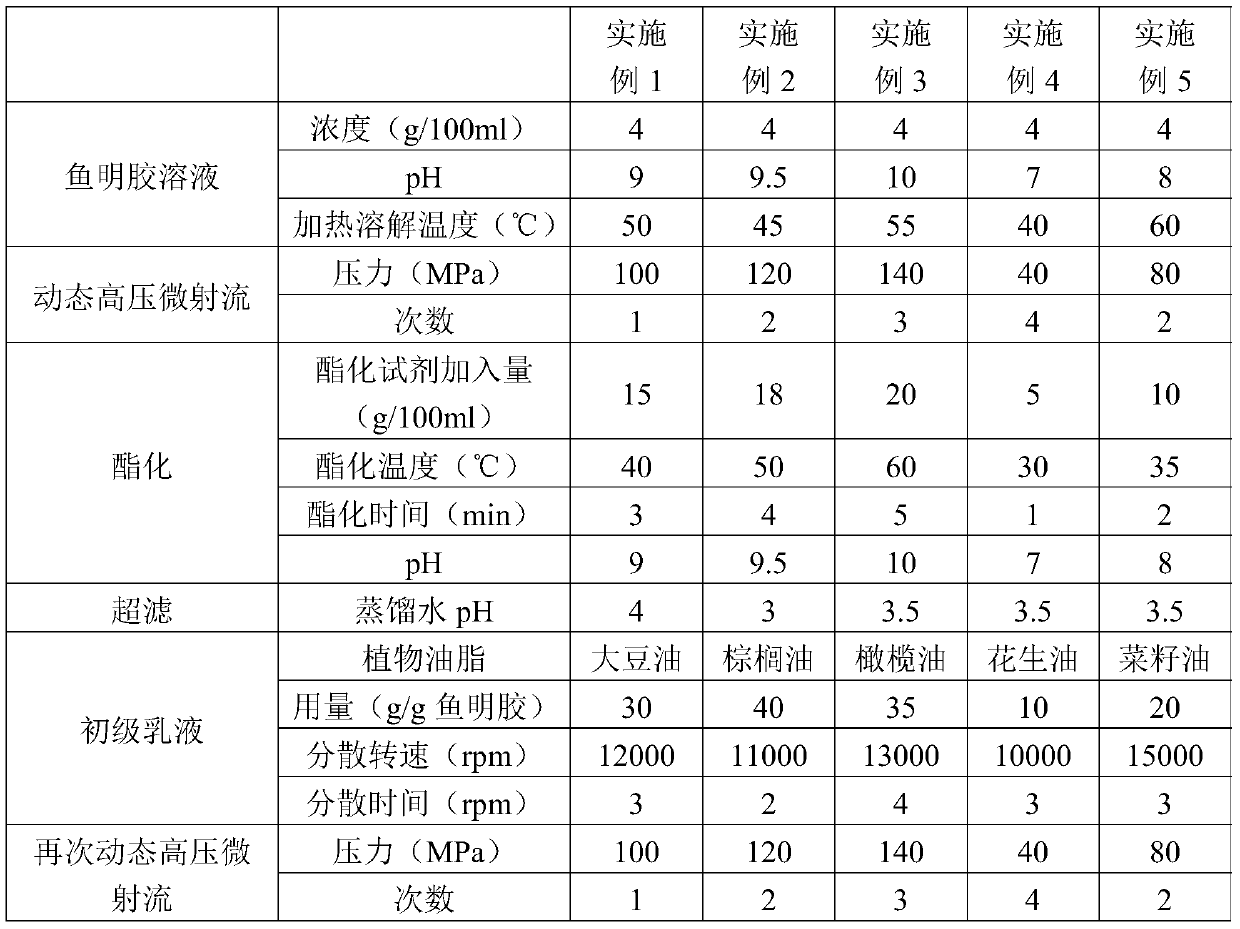

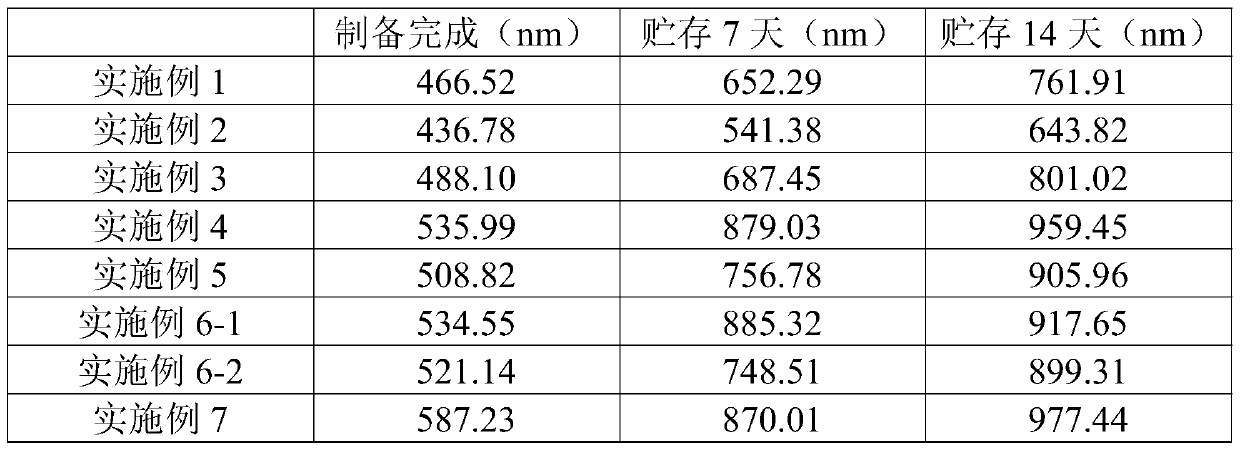

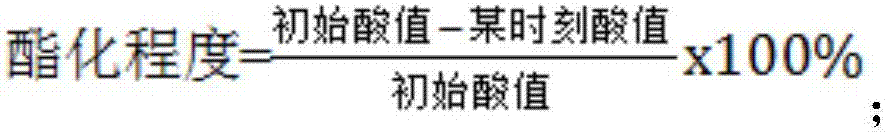

Fish gelatin emulsion and preparation method thereof

The invention relates to the technical field of fish gelatin emulsion, in particular to fish gelatin emulsion and a preparation method thereof. The method comprises the following steps: (1) in a solution state, carrying out dynamic high-pressure micro-jet treatment on fish gelatin to obtain a treated fish gelatin solution; (2) contacting the treated fish gelatin solution with an esterification reagent to esterify the fish gelatin; and (3) mixing the fish gelatin esterified in the step (2) with vegetable fat to obtain the fish gelatin emulsion. The fish gelatin and the esterification reagent are used as raw materials, and the high-stability fish gelatin nano-emulsion is prepared by means of a dynamic high-pressure micro-jet technology and an acylation modification technology. The nano-emulsion prepared by the method is high in stability and can be used for nutrition enhancing food.

Owner:JIANGXI NORMAL UNIV

Method for preparing low ash sucrose fatty acid ester

ActiveCN106243166AGood removal effectOvercome technical issues that cannot be removedEsterified saccharide compoundsSugar derivativesState of artSucrose

The invention discloses a method for preparing a low ash sucrose fatty acid ester, and the method comprises the following steps: A, esterification of fatty acid methyl ester and part of sucrose powder is performed in the presence of an alkaline catalyst, after the reaction is completed, water with the volume equivalent to 0.4-1 time of the volume of the product after the reaction is added for dilution, metal ions in the diluted solution are removed by ion exchange in an ion exchange column, and the alkaline catalyst is an alkaline metal salt or a metal hydroxide; and B, after the ion exchange is completed, water in the ion-exchanged material is removed, and after the removal of the water, sucrose powder is supplemented for continuous reaction. The method has the advantages of low cost and convenient operation, and can solve the problems of low esterification degree, low purity of the sucrose fatty acid ester and high ash content of the product in the prior art.

Owner:ADANA FOOD TECH LIUZHOU

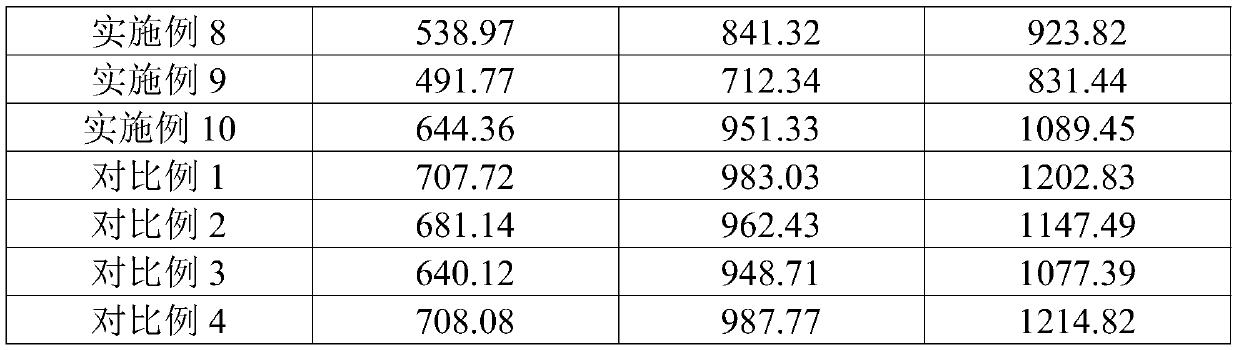

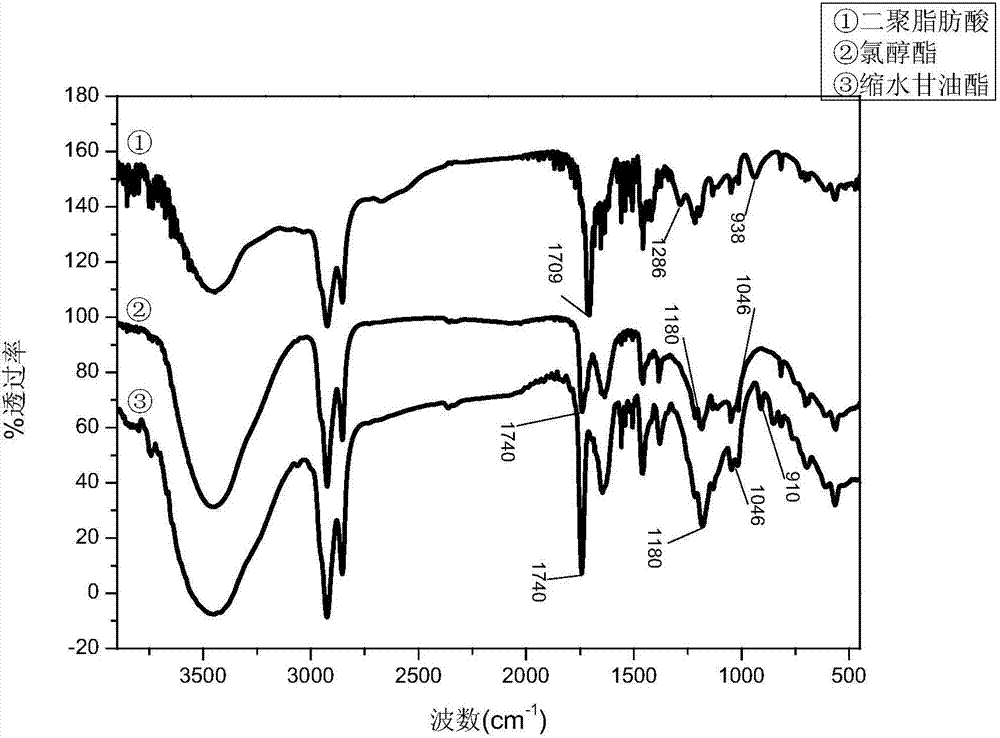

Dimeric fatty acid-diglycidol ester modified amine hardener, preparation method and application

InactiveCN107573241AAvoid hydrolysisShort reaction timeOrganic compound preparationCarboxylic acid esters preparationEpoxyAqueous sodium hydroxide

The invention discloses a dimeric fatty acid-diglycidol ester modified amine hardener, a preparation method and an application. The preparation method comprises the steps: firstly, subjecting dimericfatty acid and epichlorohydrin to an esterification reaction for 1.5 to 3.0 hours in the presence of a catalyst while controlling a temperature to 80 DEG C to 110 DEG C, so as to obtain a chlorohydrinester intermediate; then, subjecting the chlorohydrin ester intermediate and a sodium hydroxide aqueous solution with the mass percent concentration of 20% to 50% for 2 to 5 hours at the temperatureof 40 DEG C to 85 DEG C, so as to obtain a dimeric fatty acid-diglycidol ester; and finally, subjecting the dimeric fatty acid-diglycidol ester and diethylenetriamine to an amination reaction for 1 to4 hours at the temperature of 60 DEG C to 75 DEG C, thereby obtaining the dimeric fatty acid-diglycidol ester modified amine hardener. The obtained dimeric fatty acid-diglycidol ester modified aminehardener has a relatively high amine number and has excellent toughening performance to the hardening of epoxy resin. The preparation process is simple, and the operation is convenient, so that the preparation method is applicable to large-scale industrial production.

Owner:SHANGHAI INST OF TECH

Method for extracting pectin from lemon peel and keeping aroma in pectin

The invention discloses a method for extracting pectin from lemon peel and keeping aroma in the pectin. The method comprises the following specific steps: (1) taking the lemon peel as a raw material for crushing; (2) washing with water to remove pigments; (3) sealing and performing reduced pressure distillation; (4) placing supernatant liquid collected in the step (3), namely a pectin extraction solution, in a reduced pressure concentration tank to prepare a pectin precipitate mixed solution; and (5) placing the pectin precipitate mixed solution in a plate and frame filter press for filtration. The method disclosed by the invention adopts a sealing, distillation, concentration and extraction way, and can keep the aroma of fruits in the extracted pectin as much as possible and avoid the loss of the aroma.

Owner:ANHUI YUNING PECTIN CO LTD

Preparation method of octanoic acid starch ester and application of octanoic acid starch ester in pesticide microcapsules

InactiveCN111620956AHigh degree of esterificationLipophilicityPlant growth regulatorsBiocideBiotechnologyOctanoic Acids

The invention discloses a preparation method of octanoic acid starch ester and application of octanoic acid starch ester in pesticide microcapsules. The invention belongs to the technical field of preparation and application of natural polymer materials. The octanoic acid starch ester is prepared by adopting starch as a raw material, adding an auxiliary agent and an octanoic acid esterification agent and adopting a mechanical activation solid-phase technology, and the substitution degree of the octanoic acid starch ester is more than 0.25. The obtained octanoic acid starch ester is applied asa wall material to the field of pesticide microcapsules, and the embedding rate of the obtained pesticide microcapsules exceeds 88.6%. The octanoic acid starch ester is prepared by adopting a mechanical activation solid-phase technology, the method is simple, the obtained material has the characteristics of good film-forming property and low viscosity, the defects of high viscosity, poor fluidityand low solid content of traditional starch can be overcome, and the octanoic acid starch ester is applied to the field of pesticide microcapsules, is green and environment-friendly and plays a role in sustained and controlled release, so that the pesticide utilization rate is increased.

Owner:GUANGXI UNIV

Honey vinegar and preparation method thereof

The invention discloses honey vinegar and a preparation method thereof. The honey vinegar contains the following raw materials: honey, water, ammonium sulfate, dipotassium phosphate, bran, rice husk,yeast and acetic acid bacteria. The prepared honey vinegar is reddish brown, glossy, uniform in liquid, mellow, sour and palatable, has no sediment and peculiar smell, has the specific fragrance of honey vinegar and the fragrance of foods such as bran and rice hull and is rich in multiple nutritive values of honey, bran and rice husk and rich in nutrients, the total acid content is 4.5-5.0g / 100mL,the sourness is relatively strong, and the honey vinegar can meet the standard requirements of GB 18187-2000 Brewed Table Vinegar. According to the preparation method, the sugar degree, pH value andnutrients of the honey are adjusted, and the honey vinegar produced sequentially through alcohol liquid fermentation and acetic acid solid fermentation contains rich organic acid, amino acid, vitaminsand mineral substances and is gentle in sourness; and the preparation method is simple and convenient and easy to operate.

Owner:三原县甘露池醋厂

High esterification degree isopropyl alginate preparation method

The invention discloses a high esterification degree isopropyl alginate preparation method, which comprises: adding alginic acid to anhydrous isopropanol, stirring, adding a dehydrating agent having the same molar water content as the alginic acid, adding a catalyst, carrying out stirring heating to achieve a reflux state, adding the remaining dehydrating agent in a dropwise manner when the reflux temperature is achieved, continuously carrying out a reflux reaction for 4-15 h after the remaining dehydrating agent is uniformly added in the dropwise manner within 2-4 h, completing the reaction, cooling to a room temperature, adjusting the pH to 6.5-7.0 with an alkali liquid, filtering, washing the filter cake by using an isopropanol aqueous solution with a mass concentration of higher than 60%, and drying at a temperature of 40 DEG C to obtain the isopropyl alginate. According to the present invention, with the isopropyl alginate preparation method, the esterification degree of the prepared isopropyl alginate is higher than 65% and is significantly higher than the esterification degree of the straight chain alkanol ethyl alginate prepared by using the existing technology.

Owner:QINGDAO UNIV

Method using wine grape residues to prepare leveling agent

InactiveCN108727893ASmall molecular weightHigh degree of esterificationCoatingsCellulose treatment using microorganisms/enzymesEsterification reactionHemicellulose

The invention relates to a method using wine grape residues to prepare a leveling agent. The method includes: extracting cellulose in the wine grape residues, and performing esterification. Celluloseextraction is performed on traditional waste grape residues in a wine brewing process after the impurities such as fat-soluble molecules, lignin and hemicellulose of the grape residues are removed, and the low-molecular-weight cellulose after wine brewing fermentation is used to perform esterification reaction so as to prepare the high-quality leveling agent. The prepared cellulose ester-based leveling agent is widely applicable in fields such as car coating, plastic coating and glass coating and is high in leveling level.

Owner:LUDONG UNIVERSITY

Defoamer for fermentation

ActiveUS9018266B2Inhibited rapidly and continuouslyIncrease productionBioreactor/fermenter combinationsBiological substance pretreatmentsGlycerolFermentation

Provided is a defoamer for fermentation which has excellent dispersibility in water and forms neither a precipitate nor oil droplets when the dispersion is heated, and which is highly effective in defoaming fermentation media. This defoamer contains a reaction product obtained by mixing a fat or oil having an iodine value of 40 to 130 with glycerin or like in a molar ratio of from 3 / 2 to 1 / 2 to obtain a mixture, causing 4 to 17 mol of propylene oxide to add to 1 mol of the mixture, and then causing 20 to 40 mol of ethylene oxide and 70 to 110 mol of propylene oxide to block-wise add thereto in this order, the reaction product having an ethylene oxide / propylene oxide molar ratio of from 1 / 4 to 2 / 5.

Owner:NOF CORP

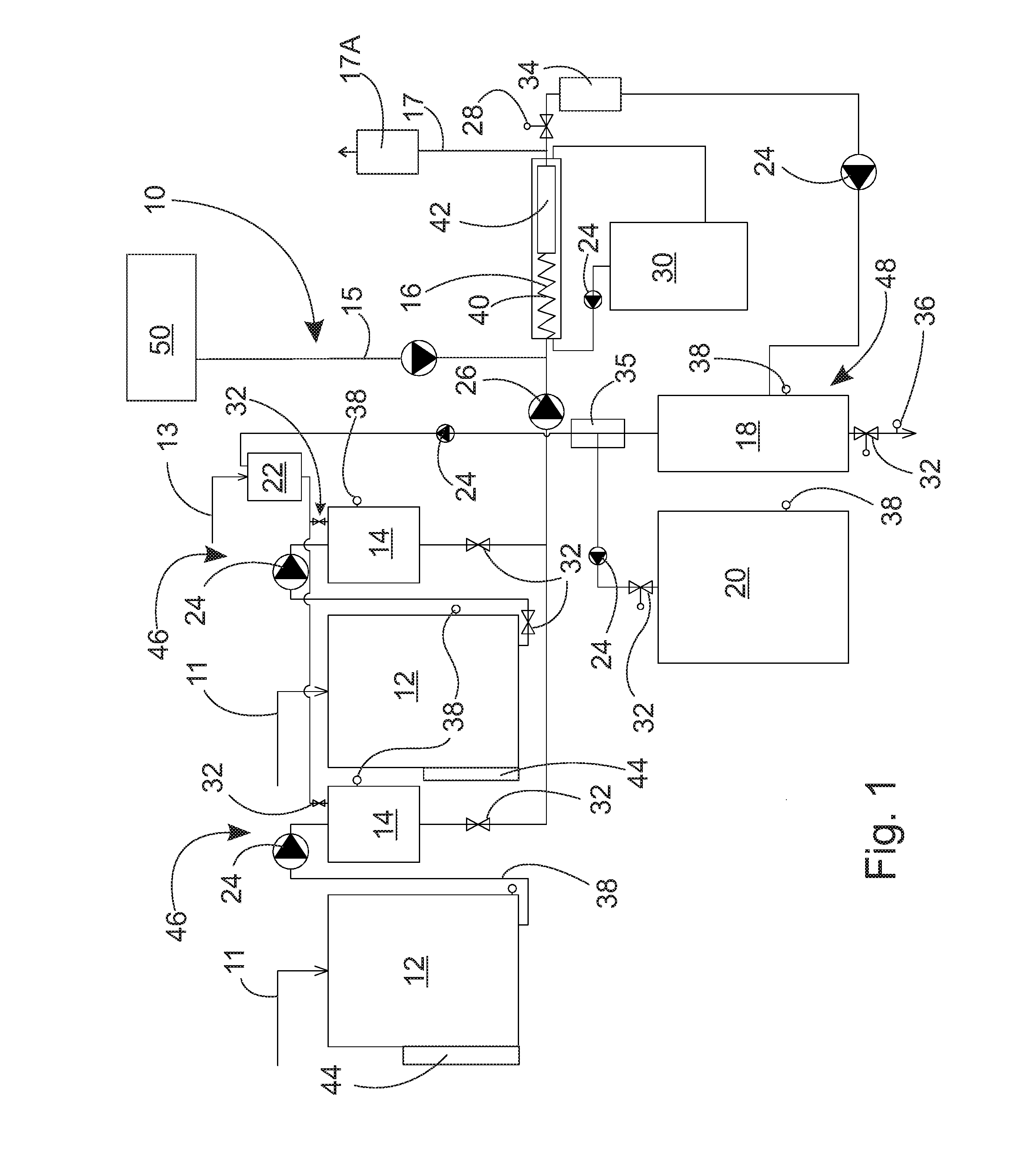

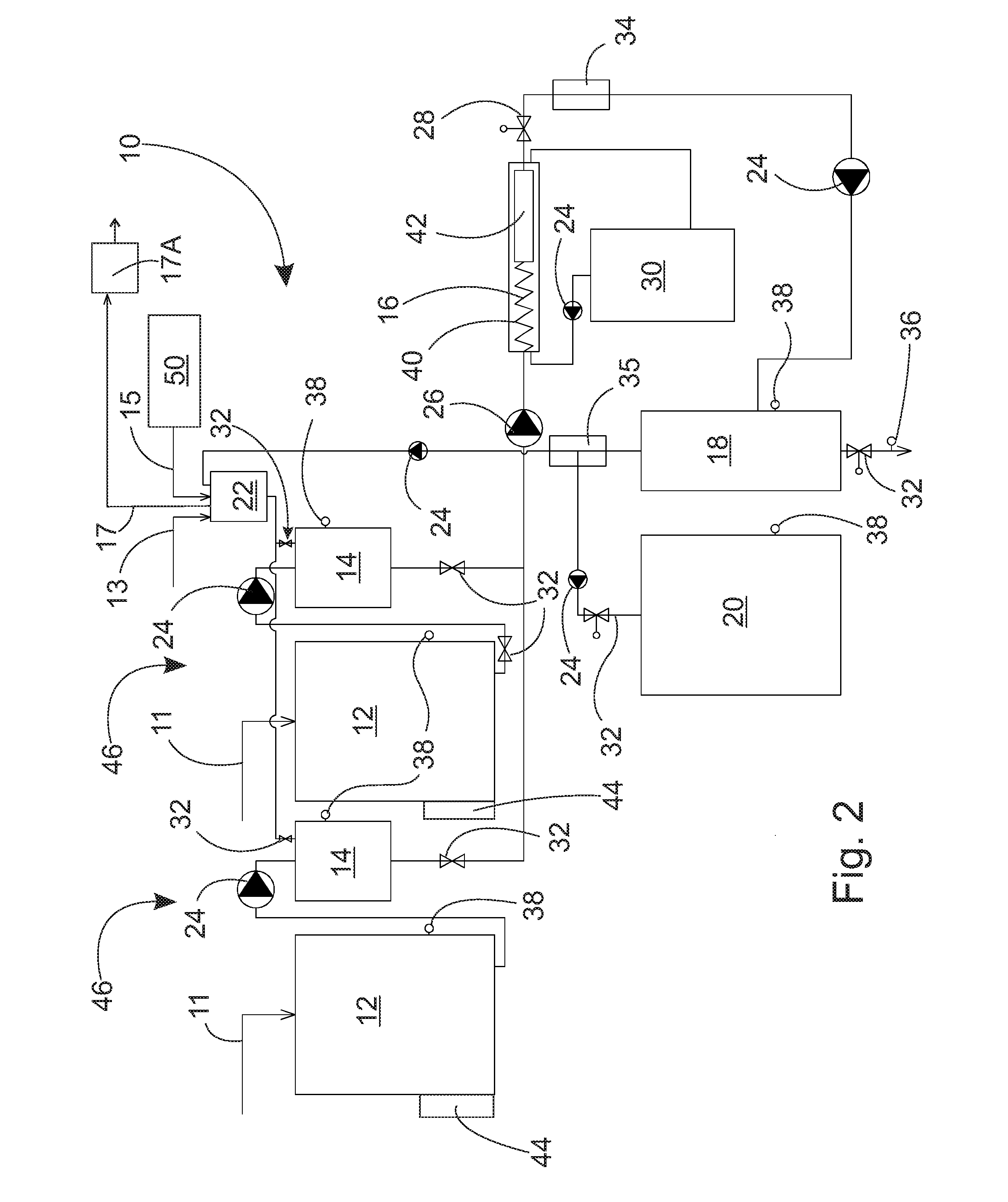

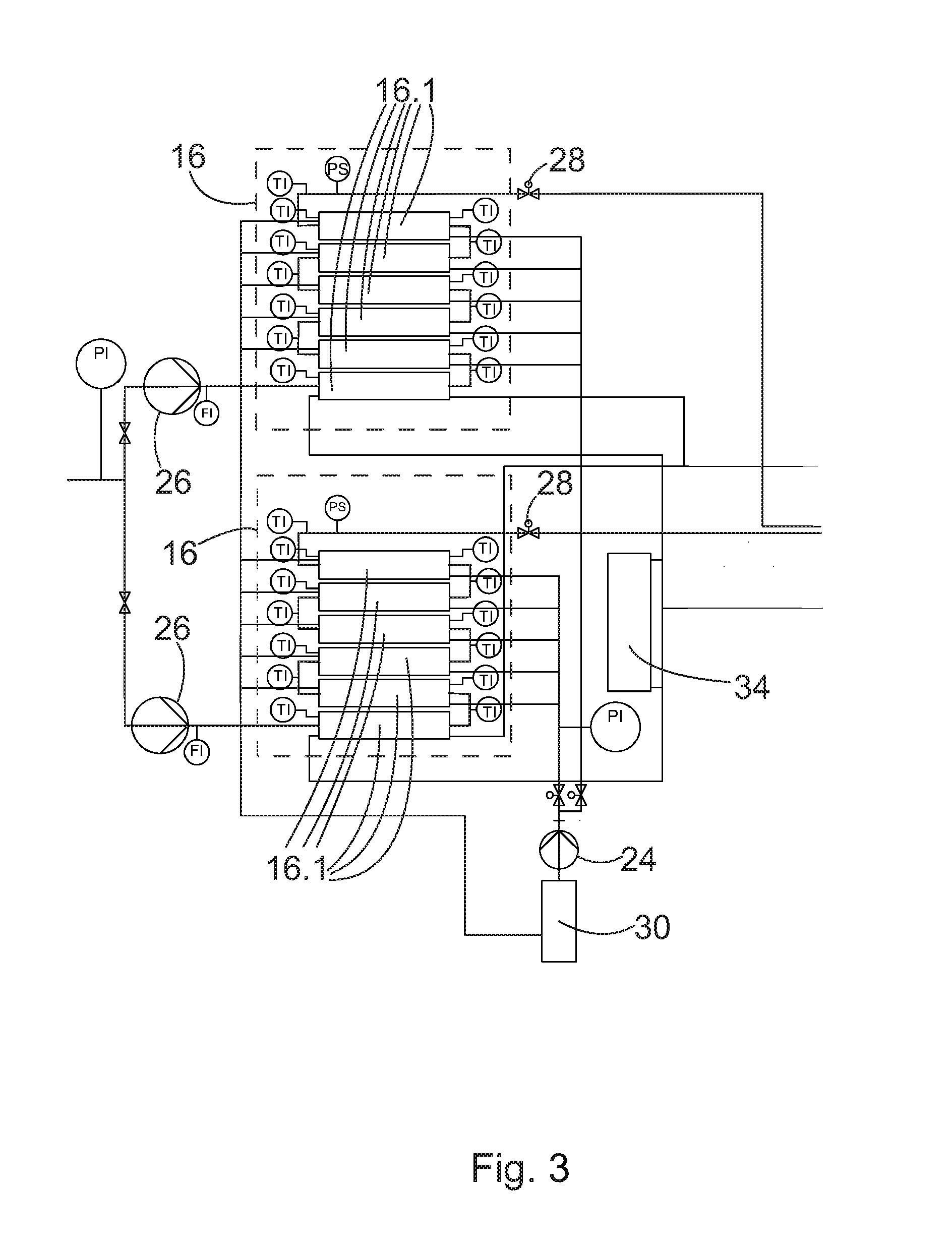

Process and system for producing liquid biofuel from bio-based oils and/or fats

ActiveUS20160281029A1Save global water resourceSuitable for useFatty oils/acids recovery from wasteFatty acid esterificationAlcoholBiofuel

A process for utilizing bio-based oils and / or fats for producing biofuels includes the steps of: mixing alcohol with a raw material for forming a reaction mixture; pumping the reaction mixture to a reactor; mixing biogas as a catalyst with the reaction mixture in a selected process step either before or after the supply of the reaction mixture to a high-pressure pump, the biogas including methane and carbon dioxide; adjusting a temperature and pressure of the reactor so that the reaction mixture achieves a supercritical state; esterifying the reaction mixture to produce liquid biofuel and by-products; separating the by-products including methane and alcohol from the liquid biofuel; and recovering separated methane. An equivalent system for utilizing bio-based oils and / or fats for producing biofuels is also disclosed.

Owner:BIOALL INT GREENTECH CO LTD +1

Preparation method of methyl alginate with high degree of esterification

The invention discloses a preparation method of methyl alginate with high degree of esterification; the preparation method comprises the following steps: in anhydrous methanol, adding alginic acid, starting stirring, adding a dehydrating agent having equal moles to the water content of alginic acid, adding a catalyst, and stirring and heating to reflux; after a reflux temperature is reached, starting to drip the remaining dehydrating agent, and after uniform dripping is completed within 2-4 h, continuing to carry out a reflux reaction for 6-20 h; and finishing the reaction, cooling to room temperature, then adjusting the pH to 6.5-7.0 with an alkali liquor, filtering, washing the filter cake with a methanol aqueous solution with the mass concentration more than 60%, and drying at the temperature of 40 DEG C, to obtain the methyl alginate. With adopting of the preparation method of methyl alginate, the degree of esterification of the prepared methyl alginate is more than 70%, and is obviously more than that of straight-chain alkyl alcohol alginate prepared by the prior art.

Owner:QINGDAO UNIV

Esterification method of pectin

InactiveCN107353359AImprove the efficiency of esterification reactionShorten the reaction time of esterificationChemistryGalacturonic acid

The invention belongs to the technical field of pectin and particularly relates to an esterification method of pectin. The esterification method comprises the steps as follows: firstly, pectin is dissolved in water, vacuum freeze drying is performed, and a pectin solid is obtained; the pectin solid obtained through vacuum freeze drying is dispersed in an alcoholic solution in the solid-liquid ratio being 1:(1-50), inorganic acid is added for an esterification reaction, filtration is performed, and esterified pectin is obtained; the alcoholic solution obtained after filtration can be used for the pectin esterification reaction repeatedly. The esterification method has the advantages that the operation is convenient, the alcoholic solution can be recycled repeatedly, and no pollution is caused. The method can be used for preparing pectin esterified products with the esterification degree being 20%-95%, and esterification groups linked with galacturonic acid units correspond to used alcohol types.

Owner:JIANGNAN UNIV

Method for preparing adipic acid dimaltitol ester

ActiveCN102977408BSimple processShort processSugar derivativesSugar derivatives preparationTosylic acidBenzene

The invention relates to a method for preparing adipic acid dimaltitol ester, which belongs to the field of plasticizers and auxiliary heat stabilizers for polyvinyl chloride processing. Adipic acid and maltitol are mixed with each other to be subjected to esterificated reaction under the action of a catalyst at 140-165 DEG C. Cyclohexane, benzene and toluene are takes as water-carrying agents to separate water out during the reaction process, so that the esterification rate is increased. Concentrated sulphuric acid and p-toluenesulfonic acid are taken as the catalysts, and the usage amount of the catalysts accounts for 20-30% of the mass of the adipic acid. The easterification reaction time is between 4 and 5 hours, and the faint yellow oily adipic acid dimaltitol ester is obtained after the reaction is completed. The prepared adipic acid dimaltitol ester has high esterification degree, the preparation method is simple, the catalysts and unreacted adipic acid and maltitol do not need to be separated out after the esterification is completed, and the product can be directly used as a polyvinyl chloride (PVC) processing agent. Through adding CaO, a powdery product can also be obtained, and the use of adipic acid dimaltitol ester is benefited.

Owner:慧科高新科技股份有限公司

A kind of method of oxidation-esterification composite modified starch

The invention relates to a preparation method of oxidation-esterification composite modified starch. There are many starch modification methods, and the composite modification can combine the advantages of the two modified starches. Adding nanocellulose in the starch modification process can promote starch modification. It improves the performance and application range of starch, and performs oxidation-esterification modification of starch. It has the advantages of both oxidized starch and esterified starch, and is more widely used in various fields of production and life.

Owner:QILU UNIV OF TECH

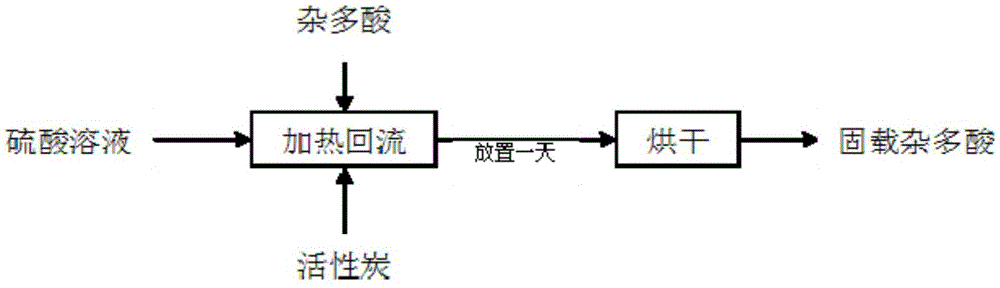

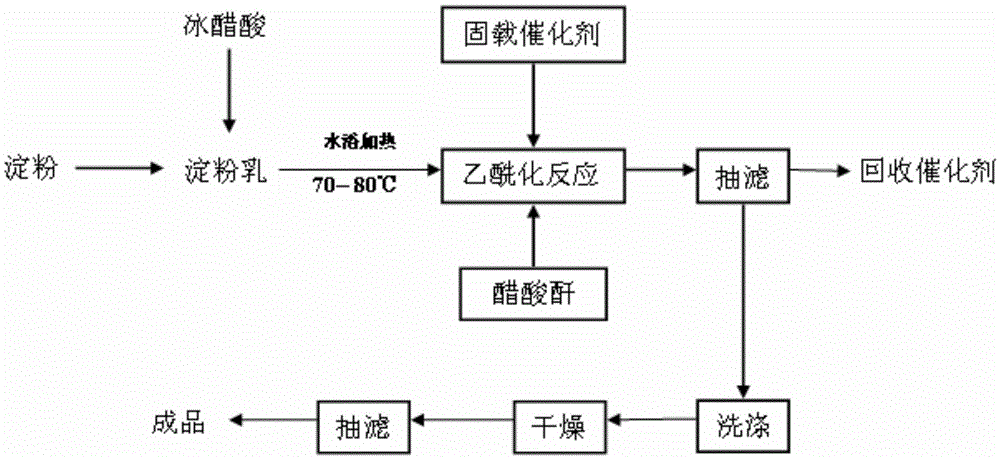

A kind of method for preparing rice starch acetate catalyzed by immobilized heteropolyacid

The invention discloses a method for preparing rice starch acetate catalyzed by a solid-carrying heteropolyacid. The method mainly includes the following steps: preparation of activated carbon immobilized heteropolyacid catalyst; using glacial acetic acid as solvent and acetic anhydride as esterification agent, under the catalysis of immobilized heteropolyacid, at a temperature of 70-80°C and react for 2 to 3 hours; the first suction filtration recovers the immobilized heteropolyacid; the filtrate is poured into a large amount of distilled water for washing, and the second suction filtration obtains the product, which is then dried in a vacuum environment, ground, and filtered Sieve to obtain rice starch acetate with a degree of substitution of more than 2.5 and a high degree of substitution up to 2.7. The method of the invention has the characteristics of high reaction efficiency, recyclable and reusable catalyst, green safety and the like.

Owner:广西利佰兴食品集团有限公司

A kind of preparation method of low-ash sucrose fatty acid ester

ActiveCN106243166BGood removal effectOvercome technical issues that cannot be removedEsterified saccharide compoundsSugar derivativesSucroseMaterial removal

The invention discloses a method for preparing a low ash sucrose fatty acid ester, and the method comprises the following steps: A, esterification of fatty acid methyl ester and part of sucrose powder is performed in the presence of an alkaline catalyst, after the reaction is completed, water with the volume equivalent to 0.4-1 time of the volume of the product after the reaction is added for dilution, metal ions in the diluted solution are removed by ion exchange in an ion exchange column, and the alkaline catalyst is an alkaline metal salt or a metal hydroxide; and B, after the ion exchange is completed, water in the ion-exchanged material is removed, and after the removal of the water, sucrose powder is supplemented for continuous reaction. The method has the advantages of low cost and convenient operation, and can solve the problems of low esterification degree, low purity of the sucrose fatty acid ester and high ash content of the product in the prior art.

Owner:ADANA FOOD TECH LIUZHOU

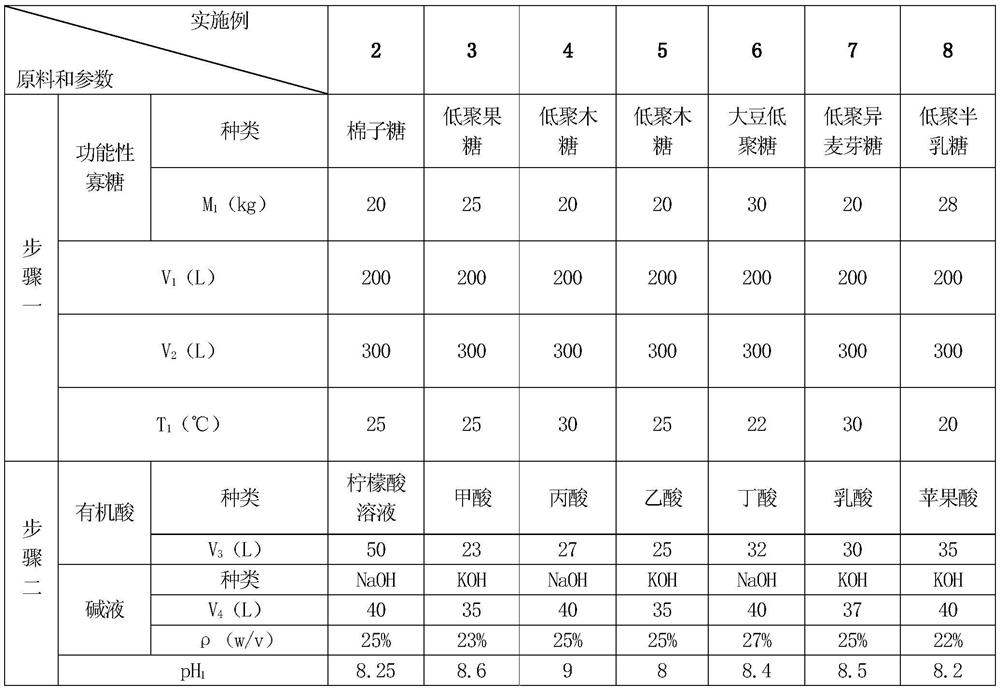

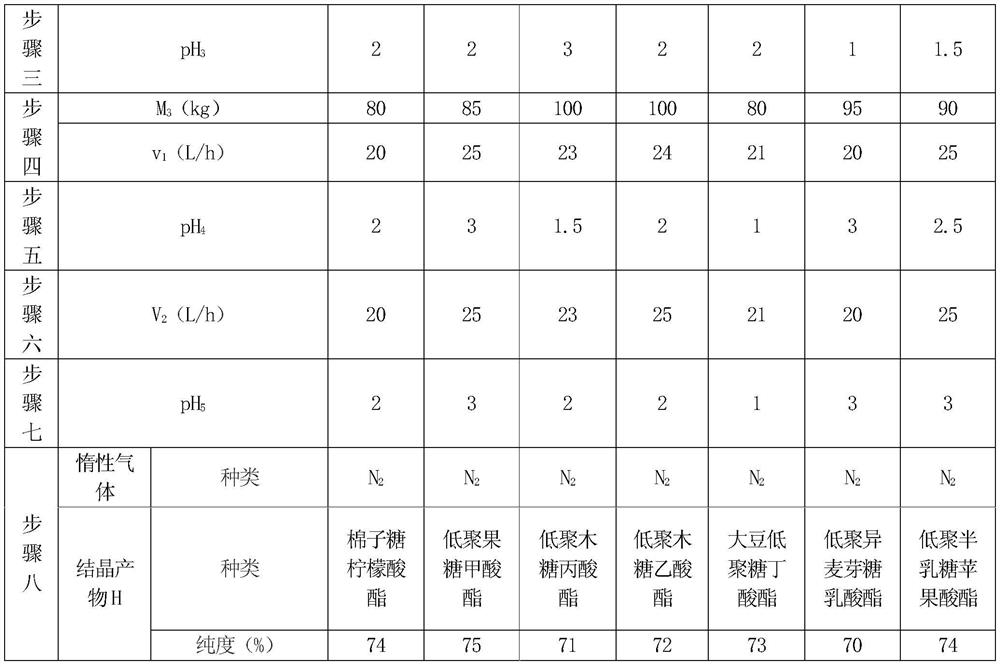

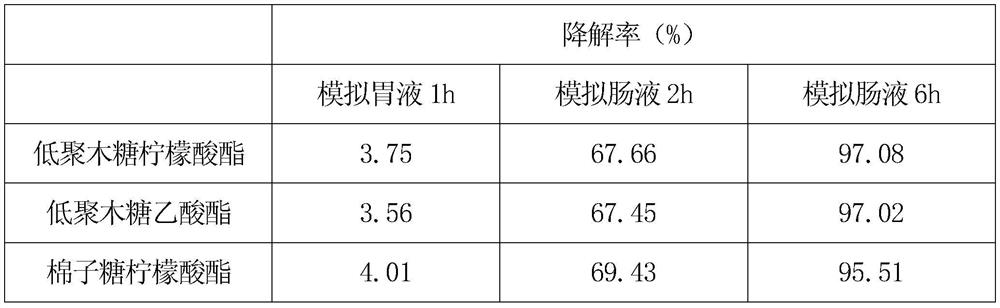

Preparation method and application of functional oligosaccharide glycoside ester

ActiveCN113072601AEasy to useGood for healthEsterified saccharide compoundsSugar derivativesGlycosideOrganic acid

The invention discloses a preparation method of functional oligosaccharide glycoside ester. According to the method, functional oligosaccharide and organic acid are subjected to an esterification reaction to generate the functional oligosaccharide glycoside ester. The invention also discloses application of the functional oligosaccharide glycoside ester. According to the functional oligosaccharide glycoside ester prepared by the invention, the organic acid and the functional oligosaccharide can pass through the stomach and the small intestine together to reach the large intestine, and then the intestinal tract releases the oligosaccharide and the organic acid, so that the utilization rate and the use effect of the functional oligosaccharide and the organic acid are improved; and by adding the functional oligosaccharide glycoside ester into an animal daily ration, the feed cost can be reduced, meanwhile, the intestinal health condition of animals is improved, and potential threats to animal health, which is caused by excessive consumption of the organic acid, are reduced. The invention belongs to the technical field of animal feeds, and is used for improving the utilization rate of the functional oligosaccharide and the organic acid in the animal feed.

Owner:固安君德同创生物工程有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com