Method for extracting pectin in passiflora edulis peel through microwave-assisted enzymatic method

An enzymatic extraction, microwave-assisted technology, applied in the biological field, to achieve the effect of good pectin quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

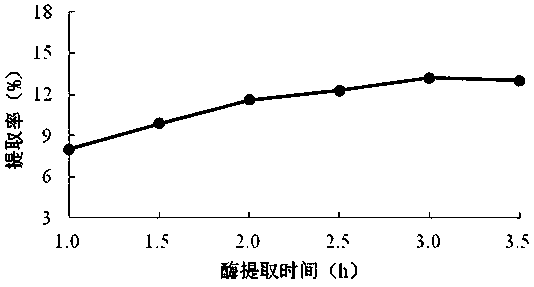

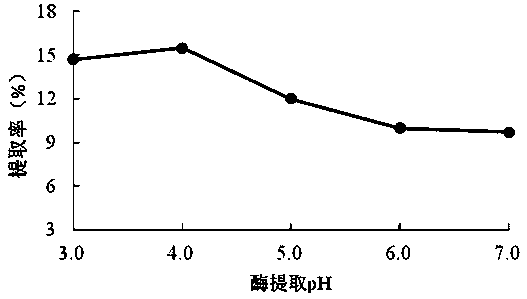

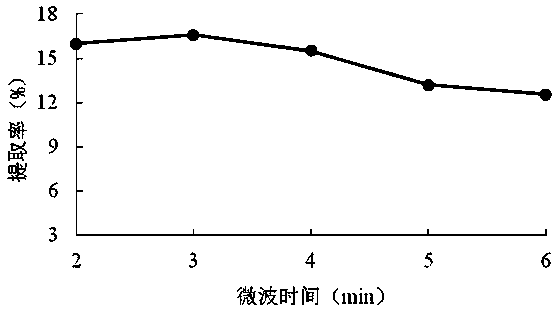

[0023] Single factor experiment of embodiment 1 microwave enzymatic extraction of passion fruit peel pectin

[0024] After cleaning the fresh passion fruit peel, cut it into small pieces, boil it in 100°C water for 4 minutes to inactivate the pectinase activity, then rinse it with distilled water for 4 times until the rinse solution is colorless, drain it with two layers of gauze, and then put it in the Dried in a drying oven at 60°C, put the dried peel in a multi-functional pulverizer, pulverized it, passed through a 100-mesh sieve, and obtained the peel powder for later use.

[0025] The operation is as follows: Weigh the peel powder, add distilled water according to a certain ratio of material to liquid and mix evenly, put it in a microwave oven under acidic conditions and microwave for a certain period of time, take it out, after cooling to room temperature, adjust the pH value with hydrochloric acid, add cellulase, and place After enzymatic hydrolysis in a constant temper...

Embodiment 2

[0053] After cleaning the fresh passion fruit peel, cut it into small pieces, boil it in 100°C water for 4 minutes to inactivate the pectinase activity, then rinse it with distilled water for 4 times until the rinse solution is colorless, drain it with two layers of gauze, and then put it in the Dried in a drying oven at 60°C, put the dried peel in a multifunctional pulverizer, and pulverized it, passed through a 100-mesh sieve, and obtained the peel powder for later use;

[0054] Weigh 1.00 g of peel powder, add distilled water and mix evenly according to the ratio of material to liquid 1:30, put it in a microwave oven for 3 minutes under acidic conditions, take it out, and after cooling to room temperature, adjust the pH value to 6.0 with hydrochloric acid, add cellulase 0.4g / 100mL, put it in a constant temperature water bath at 45°C for 3 hours, inactivate the enzyme in a boiling water bath, and centrifuge and filter while it is hot to obtain a pectin extract, add 95% ethan...

Embodiment 3

[0057] The pectin prepared in Example 2 and the optimal process conditions of the traditional acid extraction method in the reference (reference: Huang Yongchun, Ma Yuefei, Xie Qingruo, et al. Ultrasonic-assisted extraction of pectin from passion fruit peel[J]. Food Science, 2006, (10): 341-344.) The physical and chemical properties of the pectin extracted from the passion fruit peel were analyzed and compared, as shown in Table 3. The results show that the pectin extracted by the two methods is high-ester pectin (esterification degree = 50%), and the total galacturonic acid content is in line with the national food safety standard GB25533-2010 (total galacturonic acid = 65 % ), but the physical and chemical properties of the pectin prepared in Example 3 of the present invention are higher than those of the traditional acid extraction method, and have good pectin properties.

[0058] Table 3 Pectin characteristics of microwave-assisted enzymatic method and traditional acid ext...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com