Preparation method of biobased pentaerythritol fatty acid ester

A technology for pentaerythritol and fatty acid ester, which is applied in the field of esterification synthesis in organic chemistry, can solve the problems of long reaction time, reduced catalyst usage, cumbersome process, etc., and achieves good biodegradation performance, short time consumption, separation and purification process simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Embodiment 1: Prepare stearic acid and oleic acid with waste oil as raw material

[0025] Put the waste oil and water that have been treated by the waste oil treatment plant after removing impurities into the high-pressure reactor, close the reactor, adjust the stirring speed to mix the materials evenly, add water vapor to increase the pressure of the system to 3.5MPa, and heat up Heat at 220°C, heat-preserve and hydrolyze for 6 hours. After the reaction, the reaction solution is centrifuged to obtain the upper crude fatty acid phase and the lower glycerol aqueous phase. The obtained crude fatty acid is refined by molecular distillation, and different fractions are collected to obtain pure stearic acid and oil respectively. Sour pure.

Embodiment 2

[0026] Embodiment 2: take palm oil as raw material to prepare palmitic acid

[0027] Add palm oil and water into the autoclave, close the autoclave, adjust the stirring speed to mix the materials evenly, add water vapor to pressurize the system to raise the pressure to 4.5MPa, and heat up to 210°C, heat preservation and hydrolysis for 4 hours, and react after reaction The upper layer of crude fatty acid phase and the lower layer of glycerin aqueous phase were obtained by liquid centrifugal separation, and the obtained crude fatty acid was refined by molecular distillation to obtain pure palmitic acid.

Embodiment 3

[0028] Embodiment 3: the preparation of pentaerythritol stearate

[0029] 100 grams of stearic acid (C 18:0 ) and 8 grams of pentaerythritol were added to the reaction kettle, the reaction kettle was closed, the stirring speed was adjusted to mix the materials uniformly, the system pressure was maintained at 0.04MPa by vacuuming, and the temperature was raised to 230° C., and the flow degassing and heat preservation reaction was carried out for 4 hours. After the reaction, the temperature of the reaction solution is lowered to 80°C, and the unreacted pentaerythritol solid and liquid reaction products are separated by natural sedimentation or suction filtration, and the pentaerythritol can be reused after being separated and recovered. The liquid reaction product is separated and purified by molecular distillation, and the heavy component collected is the pentaerythritol stearate product. The product yield is 95.2%, the acid value is 1.9mgKOH / g, and the degree of esterification...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

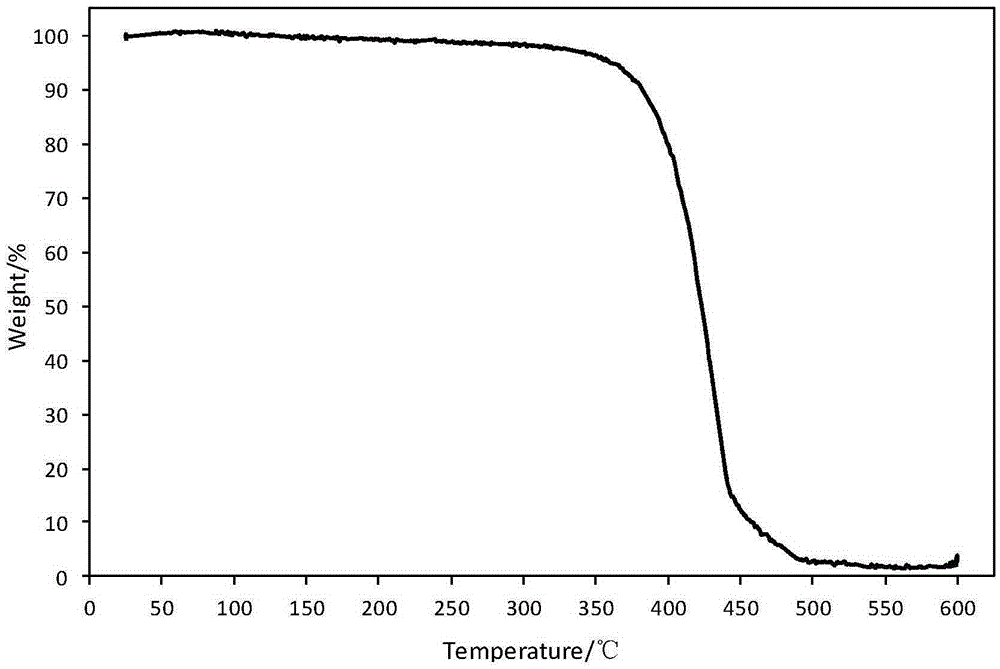

| thermal stability | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com