Preparation method of octanoic acid starch ester and application of octanoic acid starch ester in pesticide microcapsules

A technology of starch esters and microcapsules, which is applied in the preparation and application of natural polymer materials, can solve the problems of good slow-release effect and high embedding rate of pesticide microcapsules, to overcome the low solid content, improve the utilization rate of pesticides, and reduce the loss Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A kind of preparation method of octanoic acid starch ester is to mix starch, esterification agent octanoic acid, auxiliary agent sodium carbonate uniformly, then adopt mechanical activation solid-phase technology, carry out reaction under the condition of rotating speed 300r / min, constant temperature water bath temperature 50 ℃ for 60 Minutes, promptly obtain octanoic acid starch ester; Described octanoic acid quality accounts for 30% of starch dry basis, and described auxiliary agent quality accounts for 2% of starch dry basis; Described starch is tapioca starch.

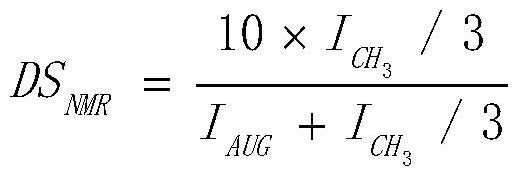

[0033] The substitution degree analysis of the octanoic acid starch ester prepared by the embodiment of the present invention 1

[0034] Adopt nuclear magnetic resonance method to measure caprylic acid starch ester degree of substitution:

[0035] The octanoic acid starch ester product was dissolved in chloroform, and tested with a Bruker (Switzerland) AdvanceШHD 600MHz superconducting nuclear magnetic reson...

Embodiment 2

[0041] A preparation method of octanoic acid starch ester is to mix starch, esterification agent octanoic acid, and auxiliary agent sodium bicarbonate evenly, and then adopt mechanical activation solid-phase technology to react under the conditions of rotating speed 100r / min and constant temperature water bath temperature 100°C In 10 minutes, caprylic acid starch ester was obtained; the quality of the caprylic acid accounted for 25% of the dry basis of the starch, and the quality of the auxiliary agent accounted for 0.5% of the dry basis of the starch; the starch was tapioca starch. The degree of substitution of Example 2 was detected to be 0.26.

Embodiment 3

[0043] A kind of preparation method of octanoic acid starch ester, is to mix starch, esterification agent octanoic acid, auxiliary agent sodium carbonate uniformly, then adopt mechanical activation solid-phase technology, carry out reaction under the condition of rotating speed 500r / min, constant temperature water bath temperature 30 ℃ for 90 Minutes, promptly obtain octanoic acid starch ester; Described octanoic acid quality accounts for 10% of starch dry basis, and described auxiliary agent quality accounts for 10% of starch dry basis; Described starch is tapioca starch. The degree of substitution of Example 3 was detected to be 0.25.

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of substitution | aaaaa | aaaaa |

| degree of substitution | aaaaa | aaaaa |

| embedding rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com