Method for extracting orange peel pectin by softening orange peel and inactivating pectinesterase

A technology of pectin esterase and orange peel fruit, applied in the field of food processing, can solve the problems of high cost, strong pH value conditions, difficult to act on orange peel and the like, and achieves low production cost, simple operation and high molecular weight of pectin. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

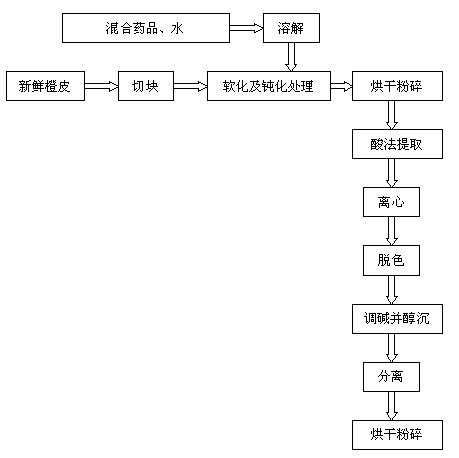

Image

Examples

Embodiment 1

[0023] Weigh 50g of mixed medicine, dissolve in 10L of tap water, and mix well. Then cut 10kg of fresh orange peel into small pieces, put it in a container, pour in the mixed solution prepared above that is 3 times the volume of the orange peel, stir for 15 minutes, remove and drain, and repeat this 3 times. Put the pretreated orange peel into an oven, dry it at 65°C for 10 hours, take it out, pulverize it, pass through a 60-mesh sieve to obtain orange peel powder, and store it under dry conditions.

[0024] Weigh 1kg of orange peel powder and add it to a container containing 25L of distilled water at a ratio of 1:25, add 0.2M hydrochloric acid solution to adjust the pH value of the solution to 1.7, put the container in a constant temperature water bath heater at 85°C, stir and extract 100min. After taking out the extract, put it in a centrifuge at 4800r, centrifuge for 20min, and take the upper liquid as a pectin solution.

[0025] Pump the pectin solution obtained after ce...

Embodiment 2

[0028] Weigh 50g of mixed medicine, dissolve in 10L of tap water, and mix well. Then cut 10kg of fresh orange peel into small pieces, put it in a container, pour in the mixed solution prepared above which is 3 times the volume of the orange peel, stir for 30 minutes, remove and drain, and repeat this twice. Put the orange peel treated in step (2) into an oven, dry at 65°C for 10 hours, take it out, pulverize it, pass through a 60-mesh sieve to obtain orange peel powder, and store it under dry conditions.

[0029] Weigh 1kg of orange peel powder and add it to a container containing 25L of distilled water at a ratio of 1:25, add 0.2M hydrochloric acid solution to adjust the pH value of the solution to 1.7, put the container in a constant temperature water bath heater at 85°C, and stir Extract for 100min. After taking out the extract, put it in a centrifuge at 4800r, centrifuge for 20min, and take the upper liquid as a pectin solution.

[0030] Pump the pectin solution obtained...

Embodiment 3

[0033] Weigh 50g of mixed medicine, dissolve in 10L of tap water, and mix well. Then cut 10kg of fresh orange peel into small pieces, put it in a container, pour 3 times the volume of orange peel into the above-prepared mixed solution, stir for 90 minutes, remove and drain, and repeat this once. Put the pretreated orange peel into an oven, dry it at 65°C for 10 hours, take it out, pulverize it, pass through a 60-mesh sieve to obtain orange peel powder, and store it under dry conditions.

[0034] Weigh 1kg of orange peel powder and add it to a container containing 25L of distilled water at a ratio of 1:25, add 0.2M hydrochloric acid solution to adjust the pH value of the solution to 1.7, put the container in a constant temperature water bath heater at 85°C, stir and extract 100min. After taking out the extract, put it in a centrifuge at 4800r, centrifuge for 20min, and take the upper liquid as a pectin solution.

[0035] Pump the pectin solution obtained after centrifugation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com