Brassylic acid glycidyl ester modified hexamethylenediamine curing agent and preparation method and applications thereof

A technology of glycidyl ester and tridecanedioic acid, which is applied in chemical instruments and methods, preparation of organic compounds, preparation of amino hydroxyl compounds, etc., can solve the problems of insufficient impact resistance and high brittleness, and achieve short reaction time, The effect of small temperature fluctuation and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

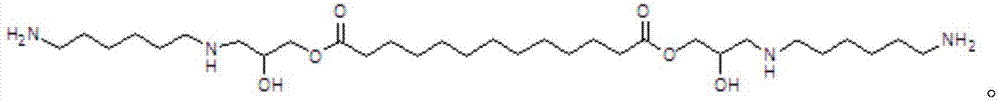

[0048] A kind of tridecanedioic acid glycidyl ester modified amine curing agent, its structural formula is as follows:

[0049] .

[0050] Described tridecanedioic acid glycidyl ester modified amine curing agent is prepared by the method comprising the following steps:

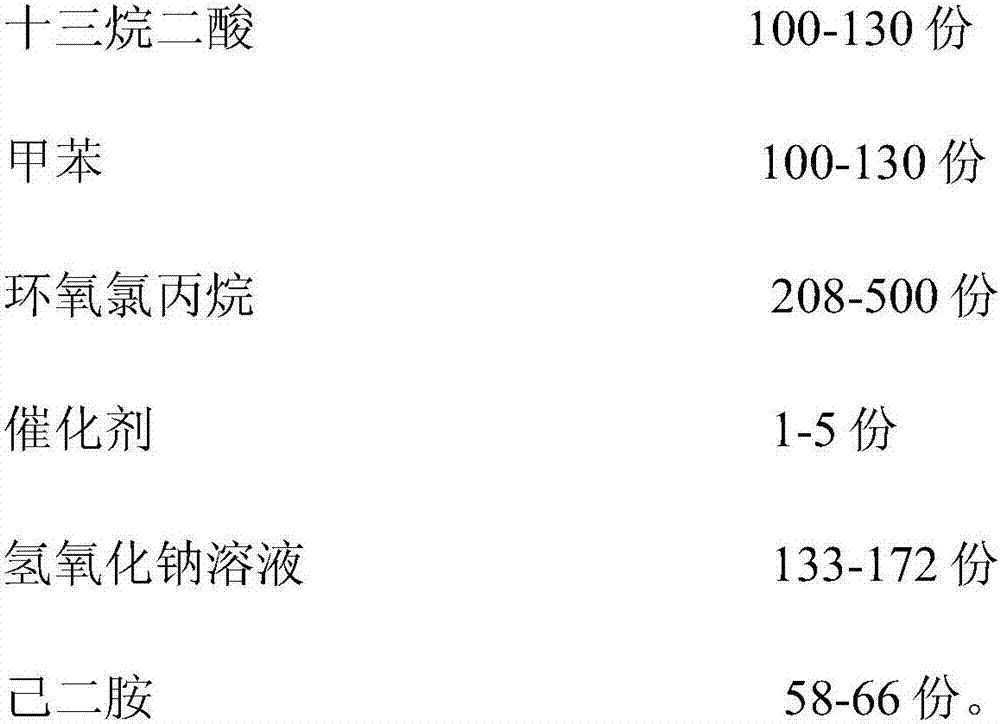

[0051] (1), the preparation of raw material, calculate by weight, the amount of each raw material used for preparation is as follows:

[0052]

[0053] The catalyst is a quaternary phosphine salt, and the quaternary phosphine salt is tetrabutylphosphine chloride;

[0054] Described sodium hydroxide solution is the aqueous sodium hydroxide solution that mass percent concentration is 40%;

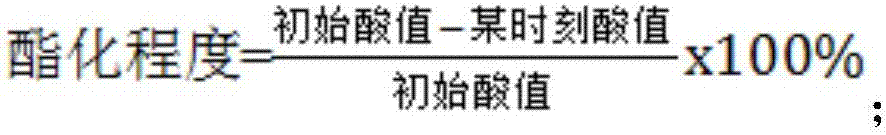

[0055] (2), esterification reaction

[0056] First add 110 parts of tridecanedioic acid and 100 parts of toluene into a four-necked flask equipped with stirring, nitrogen protection, thermometer, and condenser, heat to 70°C and stir evenly, so that tridecanedioic acid is fully dissolved in toluene, Then add 208 parts...

Embodiment 2

[0070] A kind of tridecanedioic acid glycidyl ester modified amine curing agent, its structural formula is as follows:

[0071] .

[0072] Described tridecanedioic acid glycidyl ester modified amine curing agent is prepared by the method comprising the following steps:

[0073] (1), the preparation of raw material, calculate by weight, the amount of each raw material used for preparation is as follows:

[0074]

[0075] Described catalyst is tertiary amine, and described tertiary amine is triethylamine;

[0076] Described sodium hydroxide solution is the aqueous sodium hydroxide solution that mass percent concentration is 40%;

[0077] (2), esterification reaction

[0078] First add 130 parts of tridecanedioic acid and 120 parts of toluene into a four-necked flask equipped with stirring, nitrogen protection, thermometer and condenser, heat to 70°C and stir evenly, so that tridecanedioic acid is fully dissolved in toluene, Then add 345 parts of epichlorohydrin and 5 pa...

Embodiment 3

[0092] A kind of tridecanedioic acid glycidyl ester modified amine curing agent, its structural formula is as follows:

[0093] .

[0094] Described tridecanedioic acid glycidyl ester modified amine curing agent is prepared by the method comprising the following steps:

[0095] (1), the preparation of raw material, calculate by weight, the amount of each raw material used for preparation is as follows:

[0096]

[0097] The catalyst is a quaternary phosphonium salt, and the quaternary phosphonium salt is tetrabutylphosphine bromide;

[0098] Described sodium hydroxide solution is the aqueous sodium hydroxide solution that mass percent concentration is 40%;

[0099] (2), esterification reaction

[0100] First add 100 parts of tridecanedioic acid and 110 parts of toluene into a four-necked flask equipped with stirring, nitrogen protection, thermometer, and condenser, heat to 70°C and stir evenly, so that tridecanedioic acid is fully dissolved in toluene, Then add 341 part...

PUM

| Property | Measurement | Unit |

|---|---|---|

| impact strength | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com