Patents

Literature

95results about How to "Does not affect nature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing liquid wax

ActiveCN103773427AEasy to produceDoes not affect natureHydrocarbon oils refiningParaffin waxHeating system

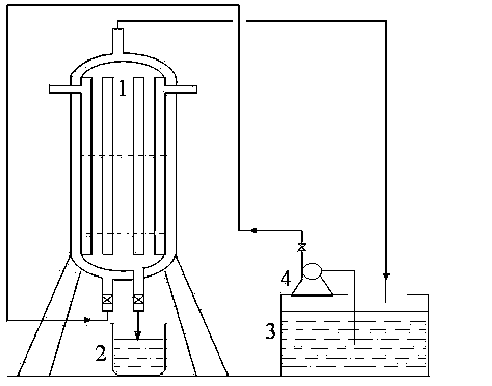

The invention discloses a method for preparing liquid wax. The method comprises the following steps: using straight run diesel oil fractions as raw materials, and adding an additive (alpha-alkene or pentaerythritol), wherein the adding amount of the additive is 50-2,000 mg / g; adopting a paraffin sweating tank connected with a circulating refrigeration / heating system, filling the raw materials containing the additive in the paraffin sweating tank, then starting a refrigeration system, cooling to 10 to -40 DEG C, wherein the temperature is lower than the freezing point of the liquid wax by 15-30 DEG C, and keeping the constant temperature for 4-8 h; starting a heating system to rise the temperature to be lower than the freezing point of the liquid wax by 3-10 DEG C, keeping the constant temperature for 1-8 h, rising the temperature and keeping the constant temperature, at the same time, discharging noncondensing liquid hydrocarbons from the paraffin sweating tank, and finally heating the paraffin sweating tank to melt a solid to be discharged to obtain the liquid wax product. Compared with the prior art, the method has the advantages of simple process, low energy consumption, no environmental pollution, and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing silicon-based oxynitride fluorescent powder

InactiveCN101818063ALow costSynthesis temperature is lowLuminescent compositionsLuminous intensityFluorescence

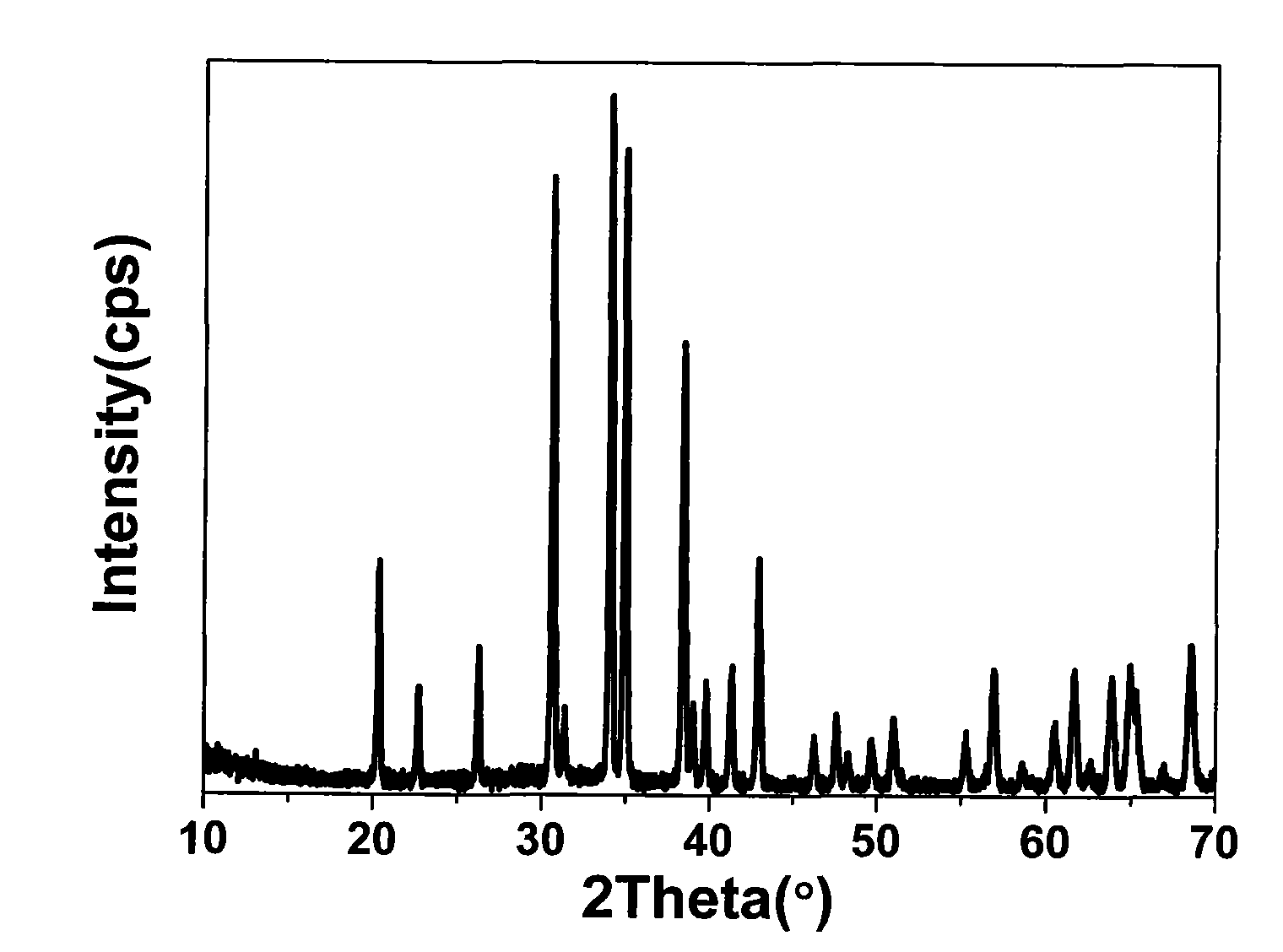

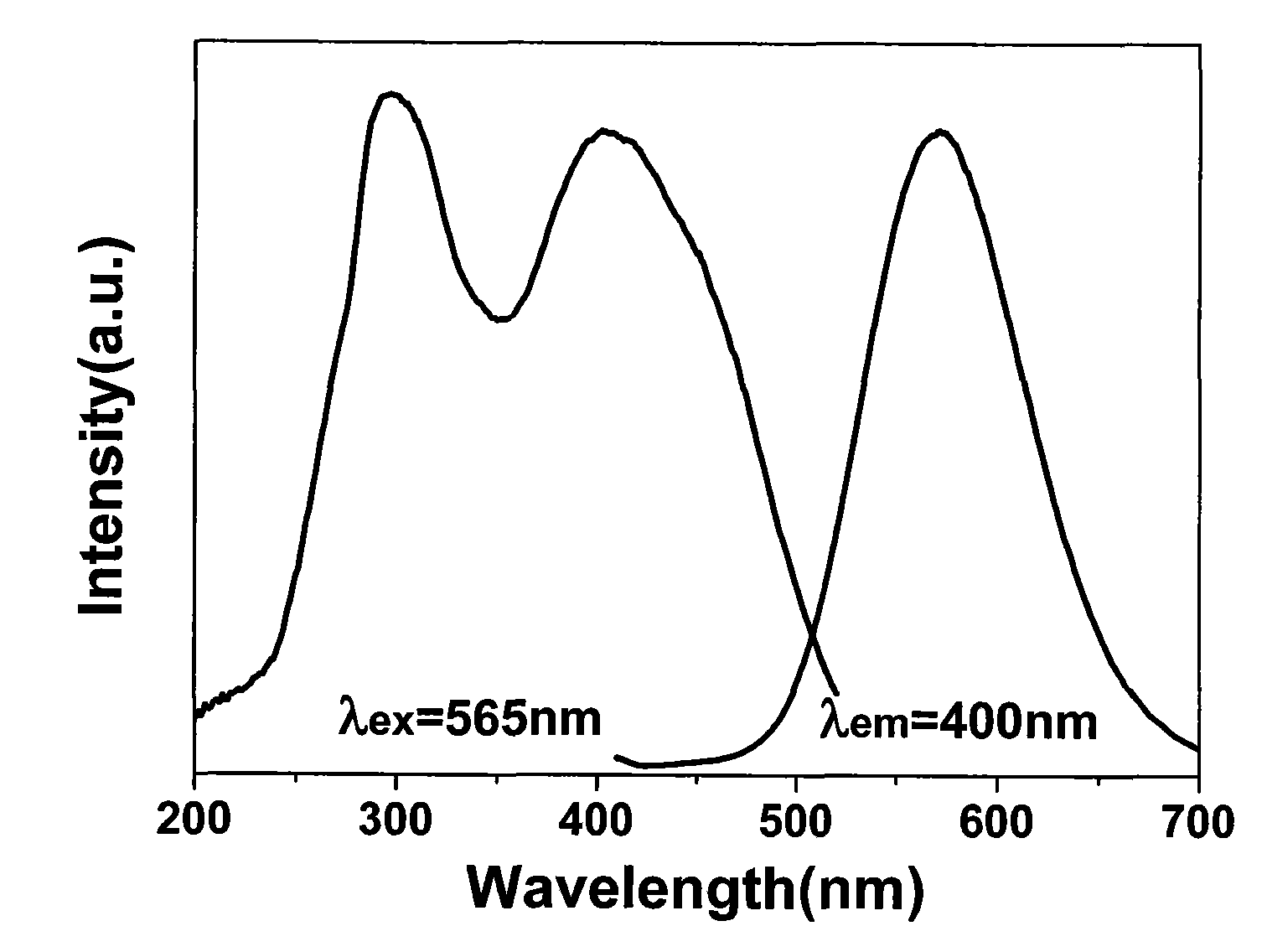

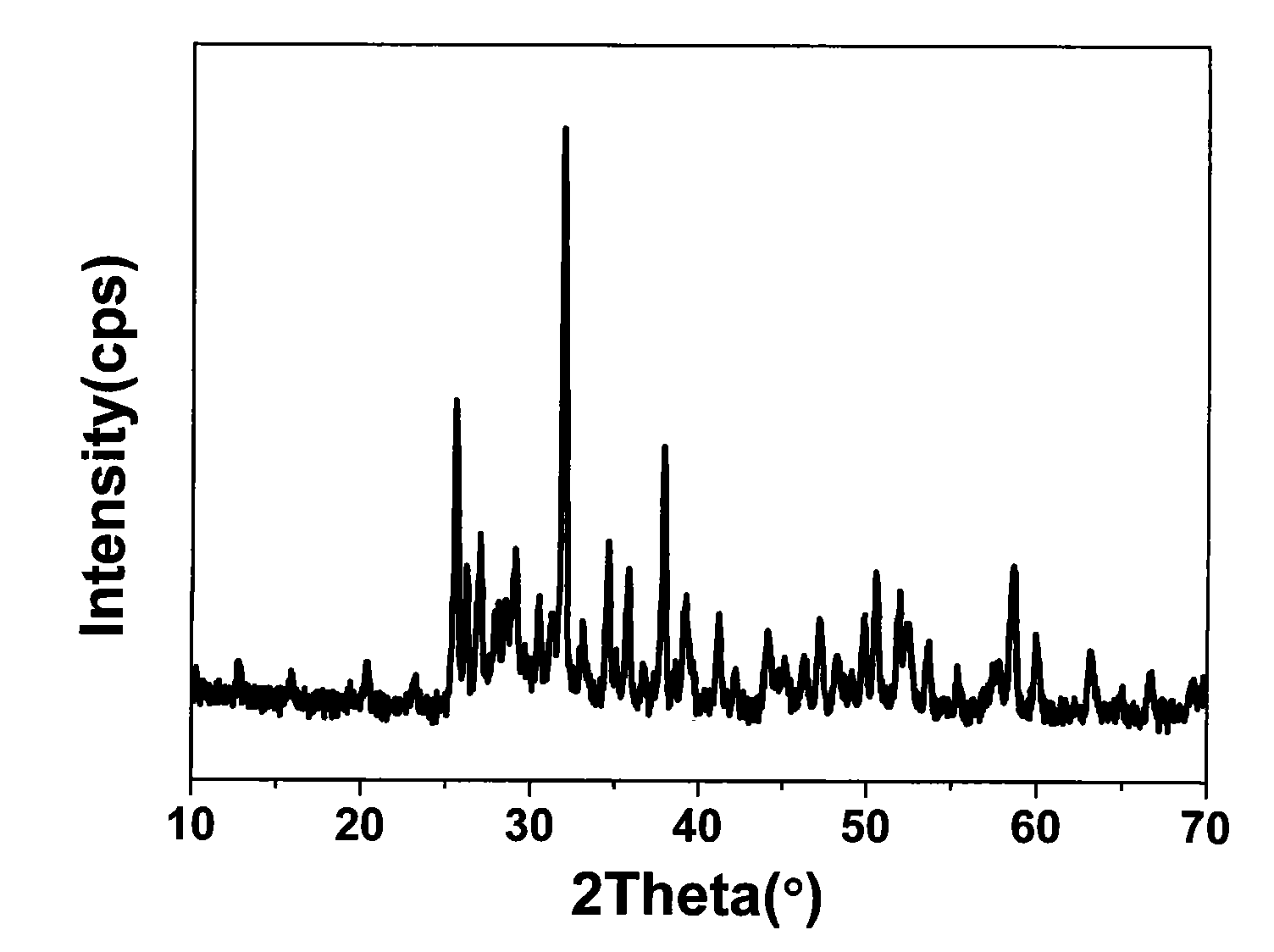

The invention discloses a method for preparing silicon-based oxynitride fluorescent powder, which comprises the following steps of: weighing corresponding raw materials and silica powder based on stoichiometric proportion of each element in the chemical formula of the silicon-based oxynitride fluorescent powder, after uniformly mixing the raw materials and the silica powder, raising the temperature to 800 to 1,000 DEG C under any one of the conditions of condition a to condition c, performing reduction reaction under the condition c or the condition d, and cooling the reaction product to roomtemperature to obtain the silicon-based oxynitride fluorescent powder, wherein the condition a is vacuum; the condition b is the atmosphere of inert gases; the condition c is the atmosphere of nitrogen-containing gases; and the condition d is the atmosphere of reductive gas. The silicon-based oxynitride fluorescent powder doped with various luminescent ions and prepared by the method has bright fluorescence under the excitation of ultraviolet ray, near ultraviolet or visible light. The method has the advantages of low preparation temperature of the product, high phase purity of the product, controllable particle size of the product, good luminous intensity of the product, low cost, simple process and the like, and is easy to enlarge industrialization.

Owner:UNIV OF SCI & TECH OF CHINA

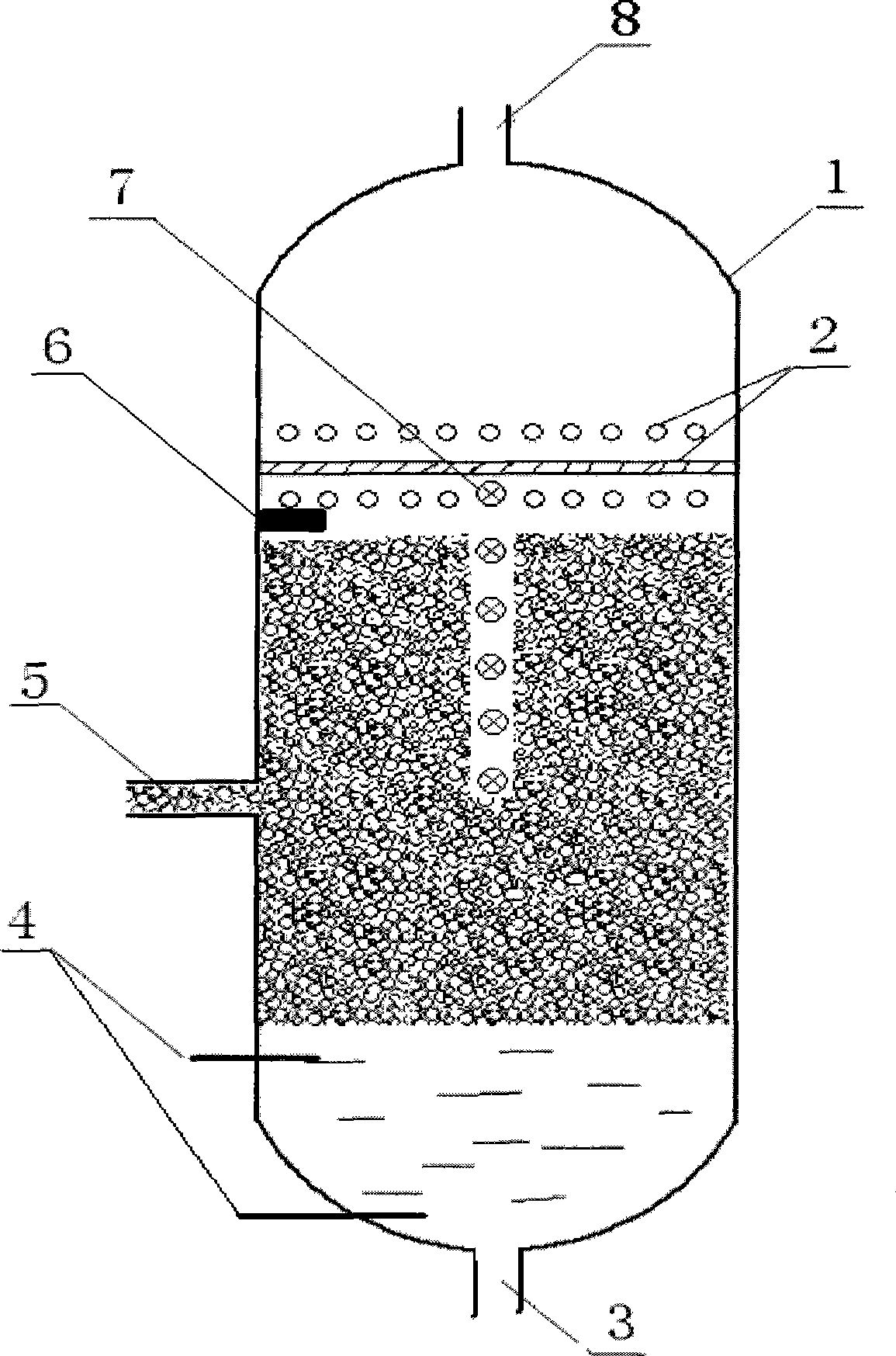

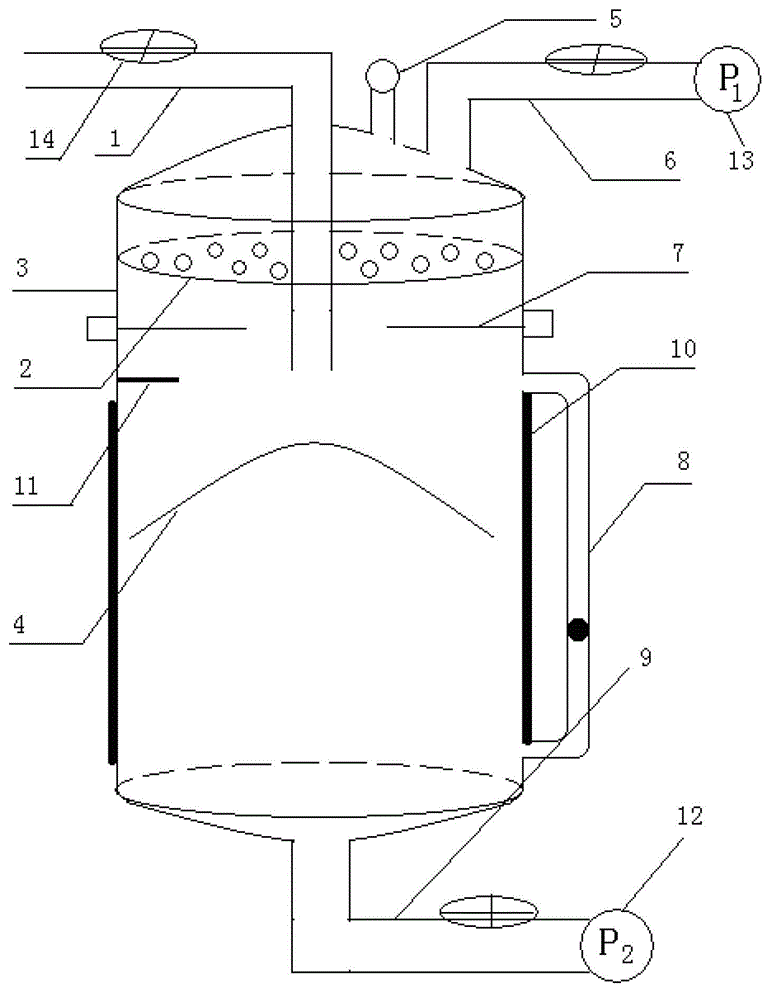

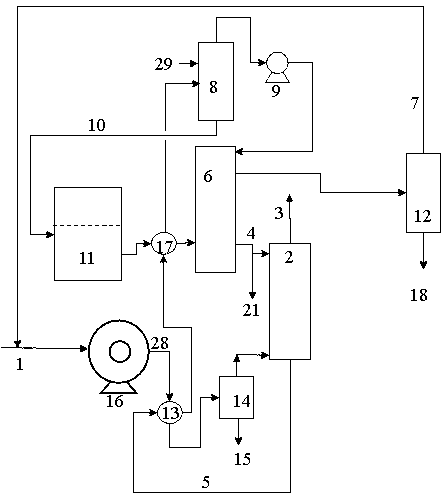

Defoaming method and device for eliminating foam of drilling fluid by thermal radiation

The invention relates to a defoaming method and a deforming device for removing the foam of drilling fluid through thermal radiation, which belong to the technical field of the physical defoaming of the drilling fluid. The defoaming device comprises a cylindrical container. The defoaming device is characterized in that a gas outlet is arranged on the top of the cylindrical container, a fluid and slag outlet is arranged on the bottom of the cylindrical container, a foam inlet is arranged on the side face of the middle lower part of the cylindrical container, a thermal radiation element is arranged on the upper inner wall of the cylindrical container, a temperature sensor is arranged below the thermal radiation element on the cylindrical container, an ultrasonic foam height sensor is also arranged below the thermal radiation element on the cylindrical container, and fluid level sensors are arranged on the middle and lower parts of the inside cylindrical container. The foam flows into the device through the foam inlet, the thermal radiation element on the device gives off thermal radiation to break the foam with low intensity near the device, the separated gas is discharged through the gas outlet, and the foam base fluid and the solid carried by the foam are discharged through the fluid and slag outlet. The defoaming device can quickly remove a great amount of foam discharged from foam drilling and prevent the foam from being accumulated in a mine. In addition, the nature of the foam base fluid is not affected, thereby facilitating the cyclic utilization of the foam base fluid.

Owner:SHANDONG UNIV

Preparation method of high-purity aluminum oxide ceramic

The invention discloses a preparation method of a high-purity aluminum oxide ceramic. According to the preparation method, a nano Al2O3 coating formed on the surfaces of aluminum oxide particles is used as a sintering aid to ensure that a small amount of the sintering aid can be uniformly dispersed in a main phase, so that uniform adding of a small dose of the sintering aid is realized. The preparation method not only ensures the purity and performance of the high-purity aluminum oxide ceramic and meets process requirements for preparation of the aluminum oxide ceramic, but also effectively solves the problem that when the particle size difference of main phase powder and the sintering aid is large, particles of a nano auxiliary agent are gathered in a main phase powder particle gap; and moreover, partial over-firing is avoided, so that the uniformity of sintering of the main phase powder particles and the sintering assisting effect of the sintering aid are effectively improved.

Owner:重庆兀盾纳米科技有限公司

ABO/RhD blood typing detection reagent card and preparation thereof

InactiveCN102707074AEasy to detectReliable test resultsBiological testingMicro columnMonoclonal antibody

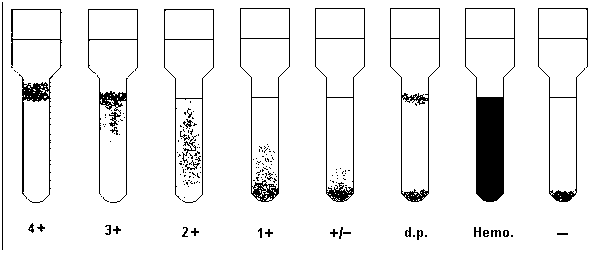

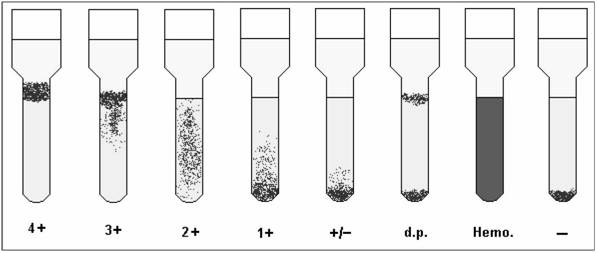

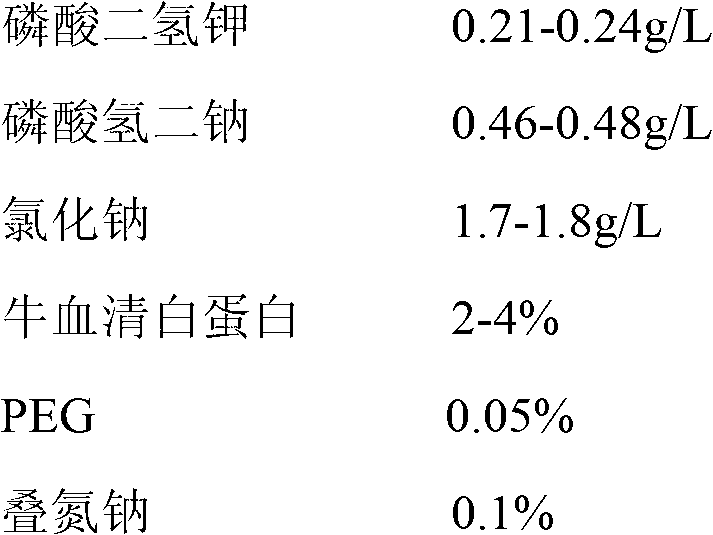

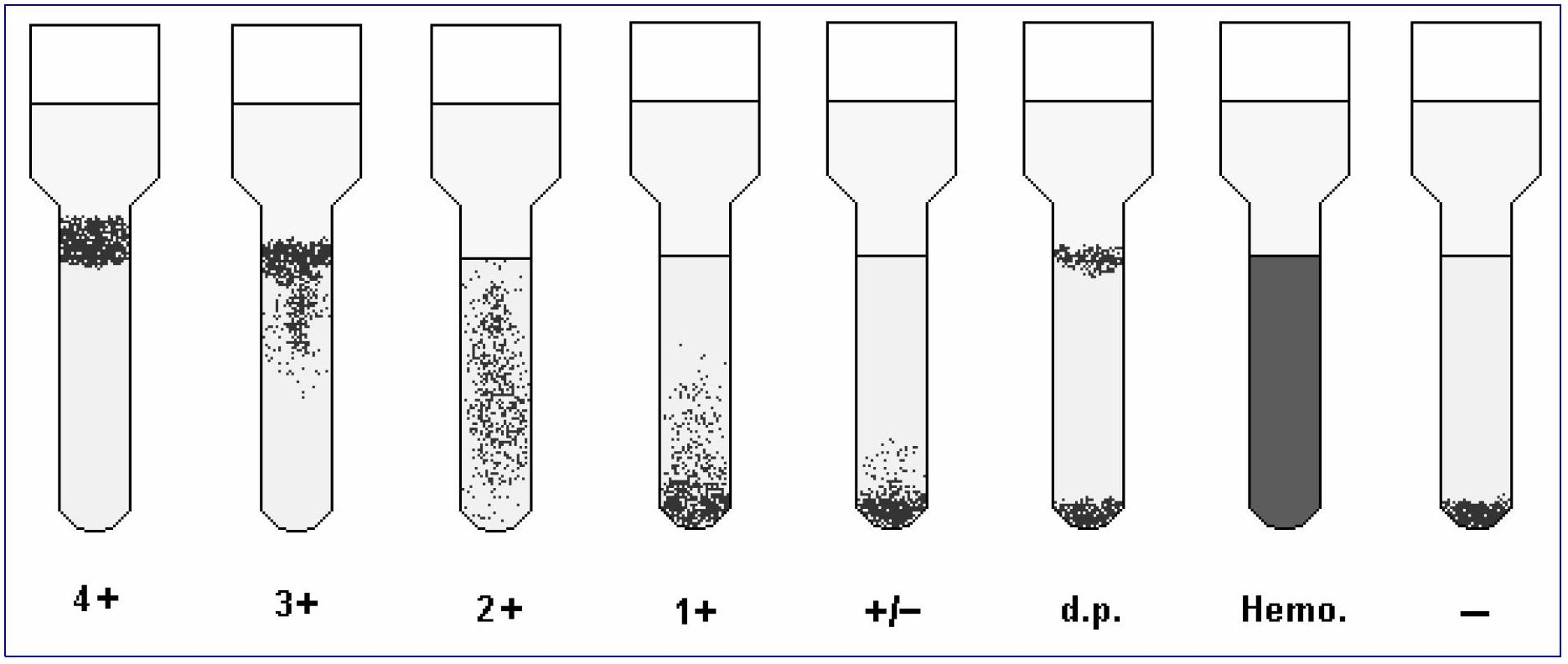

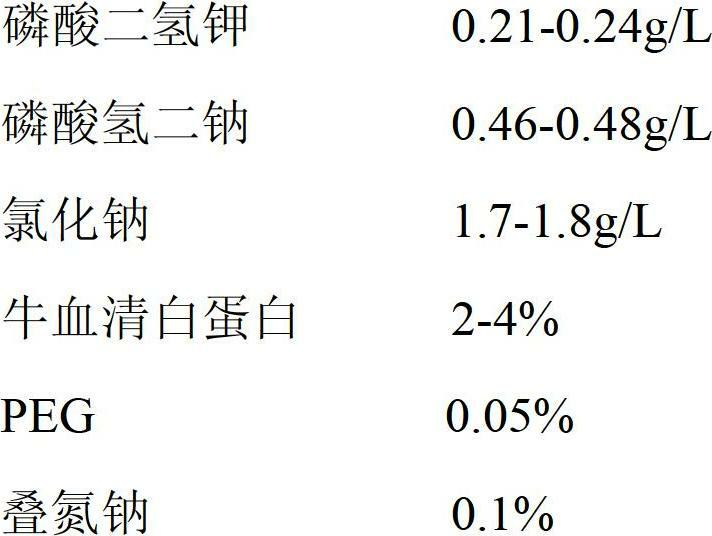

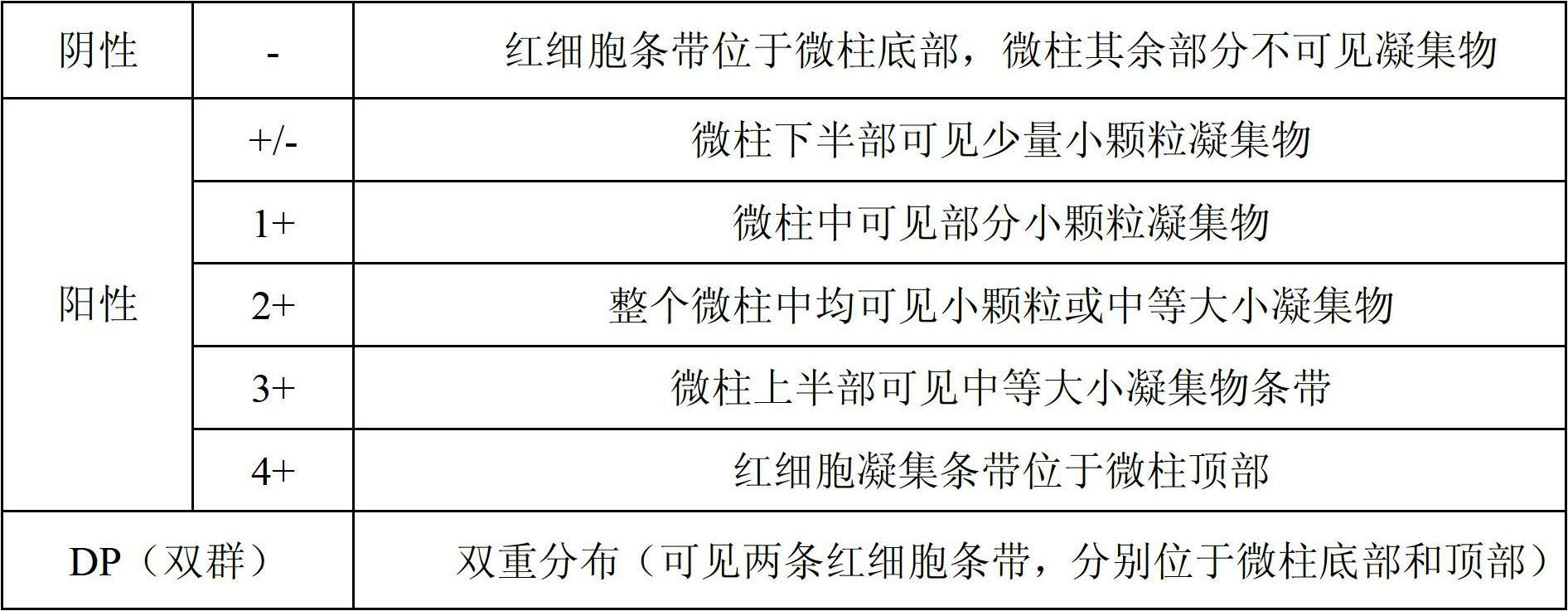

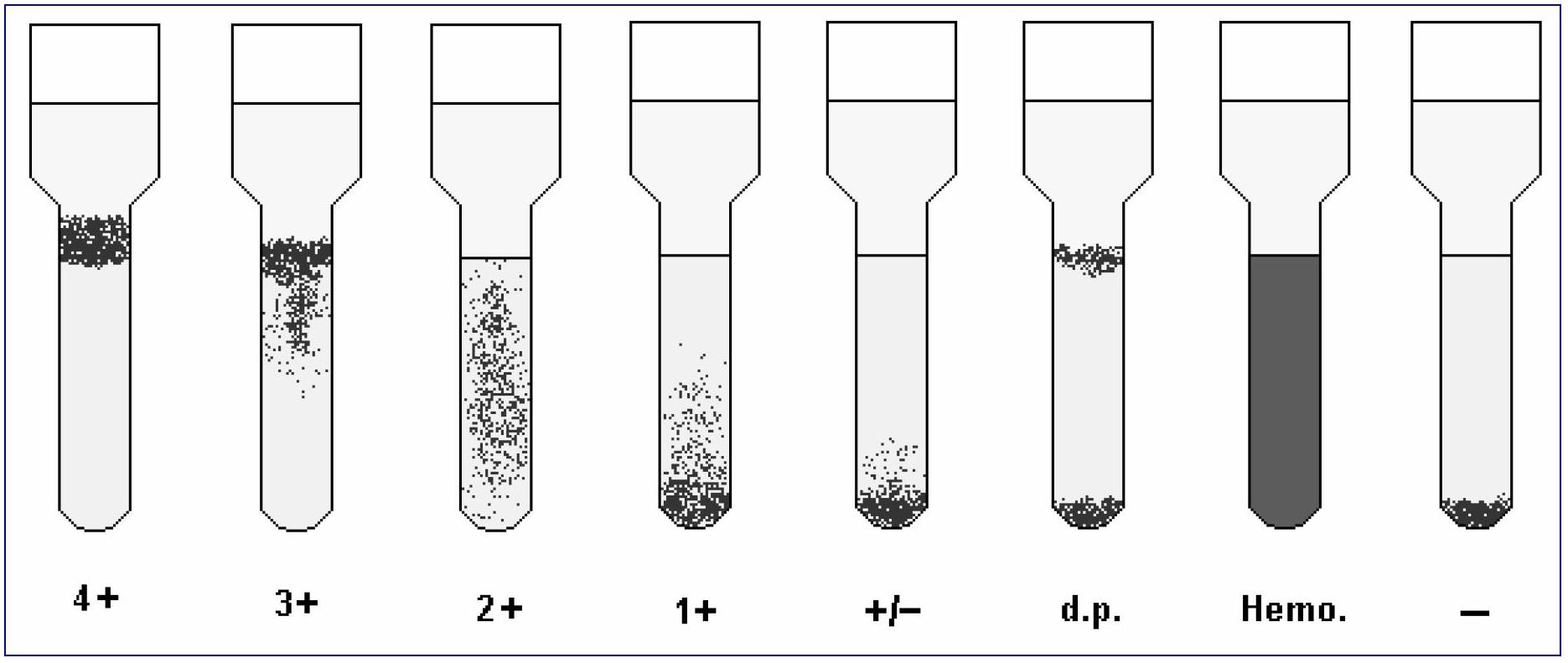

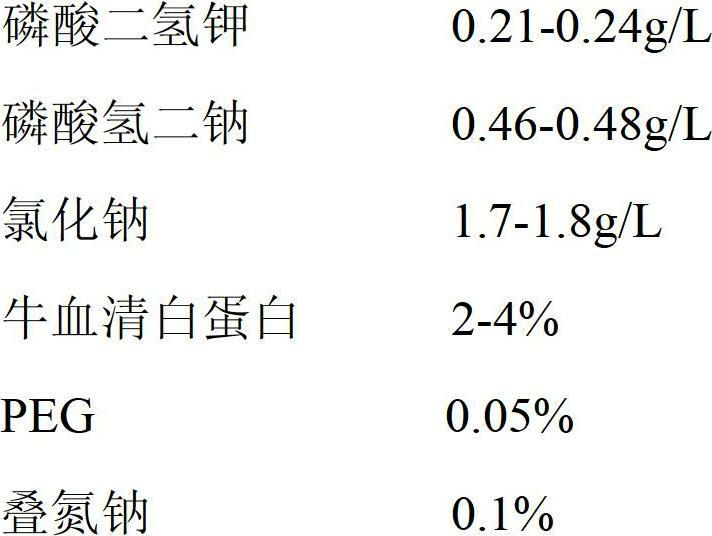

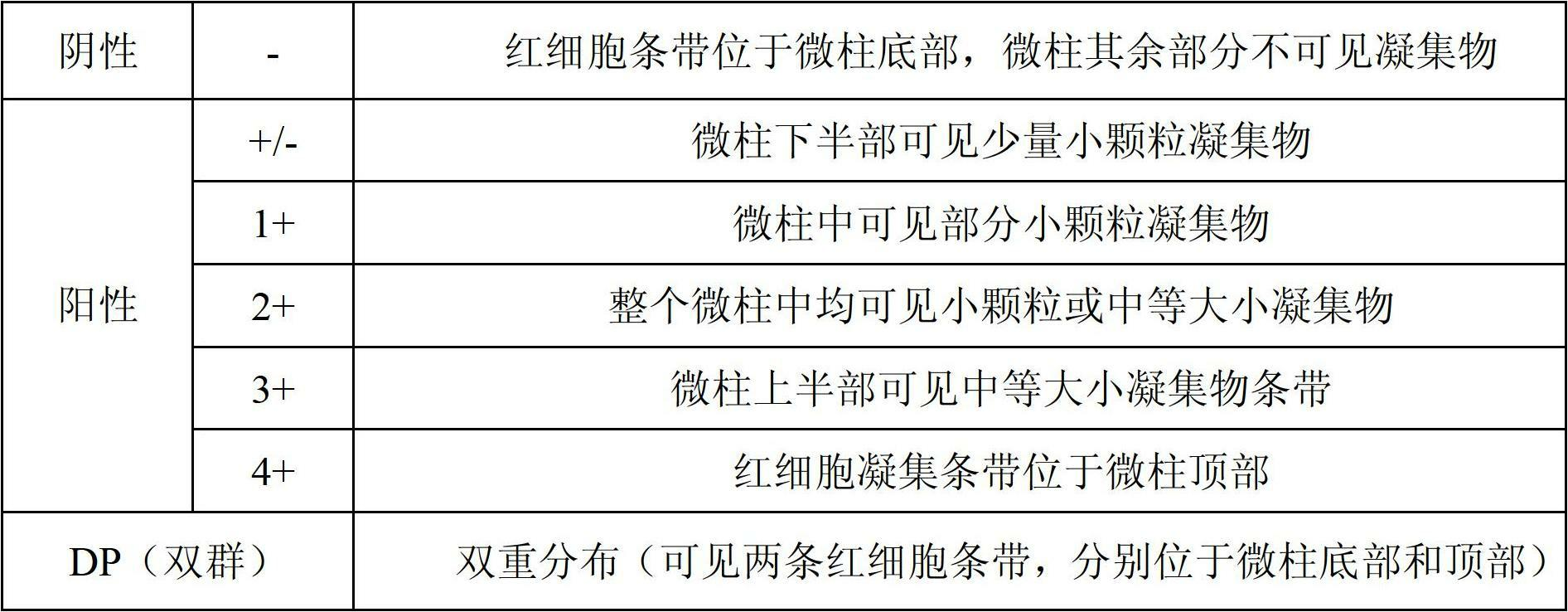

The invention relates to an ABO / RhD blood typing detection reagent card and preparation of the ABO / RhD blood typing detection reagent card. The ABO / RhD blood typing detection reagent card is characterized in that the detection reagent card is provided with 8 micro-column gel tubes, wherein one micro-column gel tube contains gel and an anti-A monoclonal antibody of IgM property, one micro-column gel tube contains gel and an anti-B monoclonal antibody of IgM property, one micro-column gel tube contains gel and an anti-D RhD blood type monoclonal antibody of IgM property, and the rest five gel tubes contain gel suspending medium buffer solutions and gels.

Owner:BEIJING KINGHAWK PHARMA

ABO/RhD blood group antigen detection reagent card and preparation method thereof

InactiveCN102680716AAdded Negative Control AssayAvoid misjudgment of resultsBiological testingMonoclonal antibodyGroup A - blood

The invention relates to a preparation method of an ABO / RhD blood group antigen detection reagent card. Eight microcolumn gel tubes are arranged on the detection reagent card, wherein two gel tubes contain gel and anti-A monoclonal antibodies with an immunoglobulin m (IgM) property, two gel tubes contain gel and anti-B monoclonal antibodies with the IgM property, two gel tubes contain gel and anti-D monoclonal antibodies of RhD blood type with the IgM property, and two gel tubes contain a gel suspending medium buffer solution and gel.

Owner:BEIJING KINGHAWK PHARMA

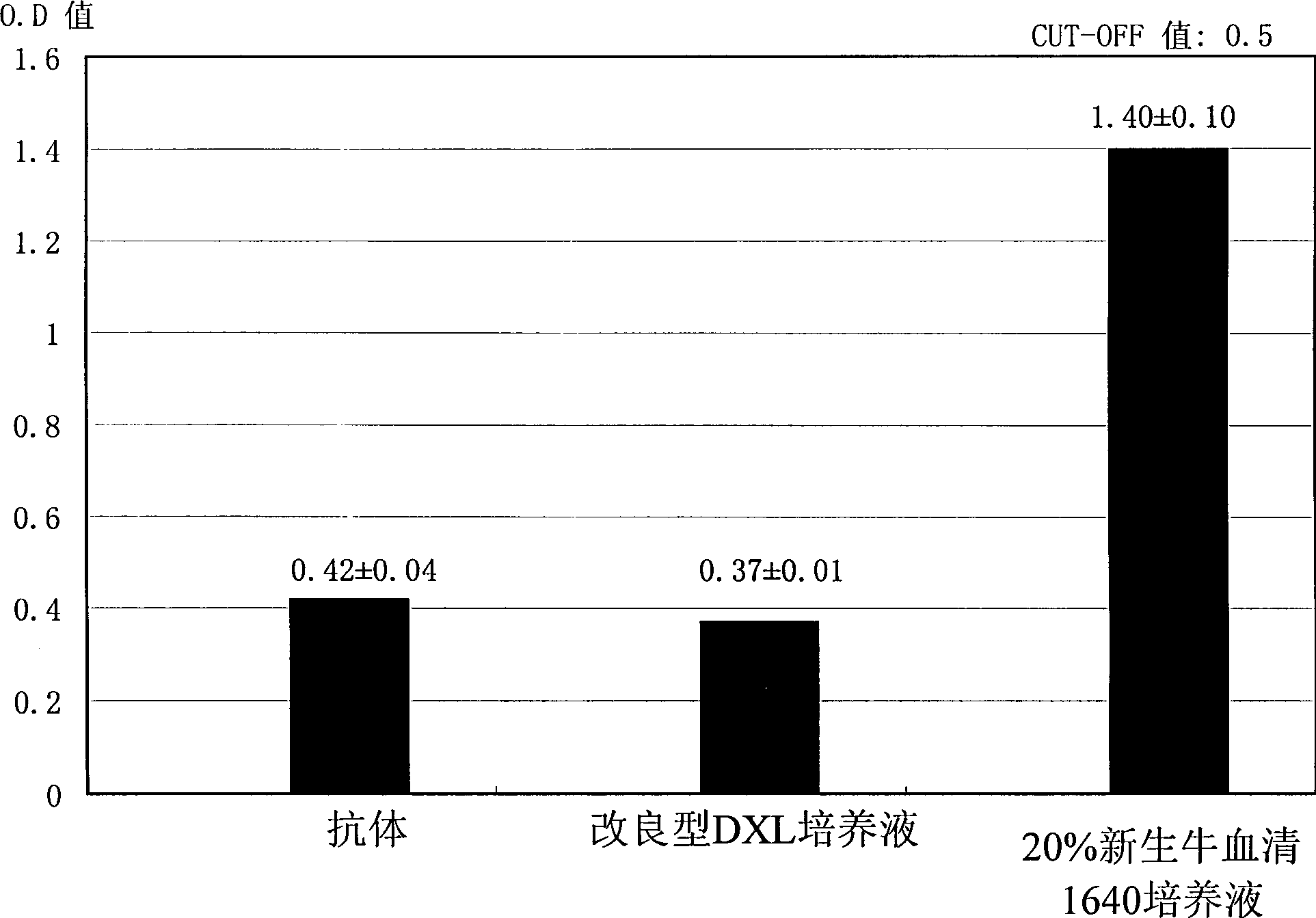

Preprartion method of improved hepatoma murine monoclonal antibody

InactiveCN1367258AReduce slow growthReduce riskMicrobiological testing/measurementTissue cultureSerum free mediaNeural cell

The present invention relates to an improved preparation method of hepatoma murine monoclonal antibody. This invented method uses the improved DXL serum-free medium as culture medium, i.e. various growth factors, such as neural cell growth factor, epidermal growth factor, fibroblast grwoth factor or embyro growth factor are added in the DXL serum-free proteinless medium, and the content is 0.01-0mg / L. This invention adopts packed bed bioreactor to make high-density hybridoma cell continuous culture, and its technological conditions are as follows: temp. is 30-40 deg.c, rotating speed is 300-480 rpm, pH is 6.8-7.25, PO2 is 0.5-1.95 bar, PCO2 is 0.5-1.95 bar, PN2 is 0.5-1.95 bar, air flow rate is 0.1-2 hr. and pressure is 2-5 bar. Its cell density is upt o 10 to the eight power / ml, and theyield of monoclonal antibody of each litre of culture medium can be up to 1000-1500 mg.

Owner:SHANGHAI INST OF BIOLOGICAL SCI CHINESE ACAD OF SCI

Pyrogenic pretreatment method for low-grade laterite nickel mine

InactiveCN101368235ASimple preprocessingStrong raw material adaptabilityWet separationBeneficiationLow graded

The invention relates to a fire pre-processing method for a low-grade lateritic nickel ore which belongs to the field of nonferrous metal. The method includes following steps : the low-tenor lateritic nickel ore mine is cracked; vulcanization pre-processing is carried out; a metal sulfide is generated; the ore concentrate and the tailing of the nickel purite can be obtained through carrying out one time roughing, four time choiceness and three time scavenging on the preprocessed lateritic nickel ore and returning the middling ores in sequence; under a magnetic field intensity of 6000 to 10000 oersted, one time open roughing and three time open choiceness are carried out on the flotation tailing; a magnetic product is iron ore concentrate; the rest products are combined into the total tailing. The technology of the invention has the characteristics of high material suitability, short flow, good vulcanization effect, device investment saving, low production cost, and the like, thus leading the subsequence beneficiation techniques to be greatly simplified and being capable of producing the mixed ore concentrate of nickel and cobalt, the iron ore concentrate and the tailing as well as obtaining a higher metal ore concentrate grade and a high recycling rate.

Owner:KUNMING METALLURGY INST

Purification method of battery-grade graphite fluoride

InactiveCN102602908AEffective dissolutionEasy to cleanCarbon fluoridesHydrogen fluorideHydrofluoric acid

The invention discloses a purification method of ultrasound assisted HF (hydrogen fluoride) washing battery-grade graphite fluoride. The method comprises the following concrete steps of: mixing common graphite fluoride and 20% hydrofluoric acid uniformly; cleaning for 30-60 minutes under ultrasound assistance, and dissolving impurities fully; and then leaching the system above, placing a filter cake in a heat furnace of 150-200 DEG C and drying, thereby obtaining graphite fluoride meeting the battery-grade requirement. The purification method of ultrasound assisted HF washing battery-grade graphite fluoride provided by the invention is not only simple and convenient in process, is low in cost, but also is wide in application range, and is favor of industrial production.

Owner:SHANGHAI SCI BIO PHARMA

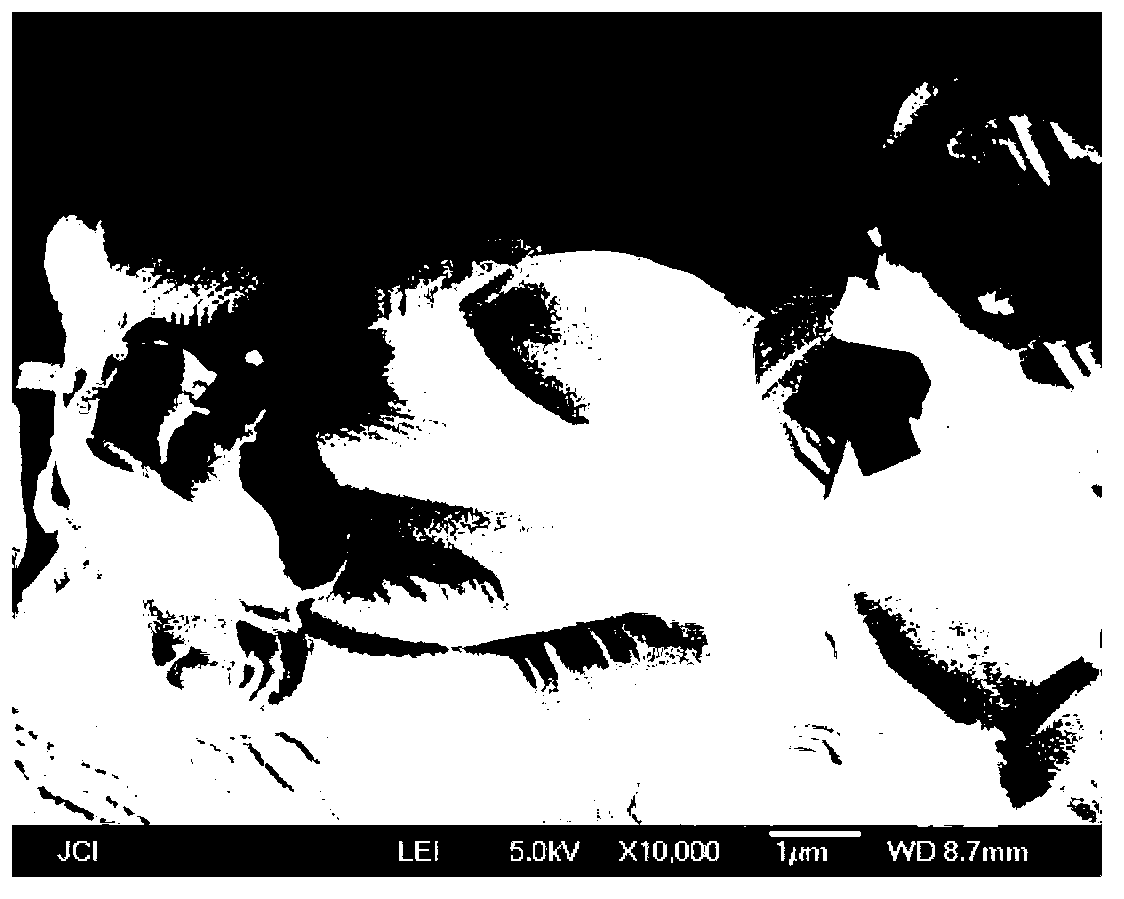

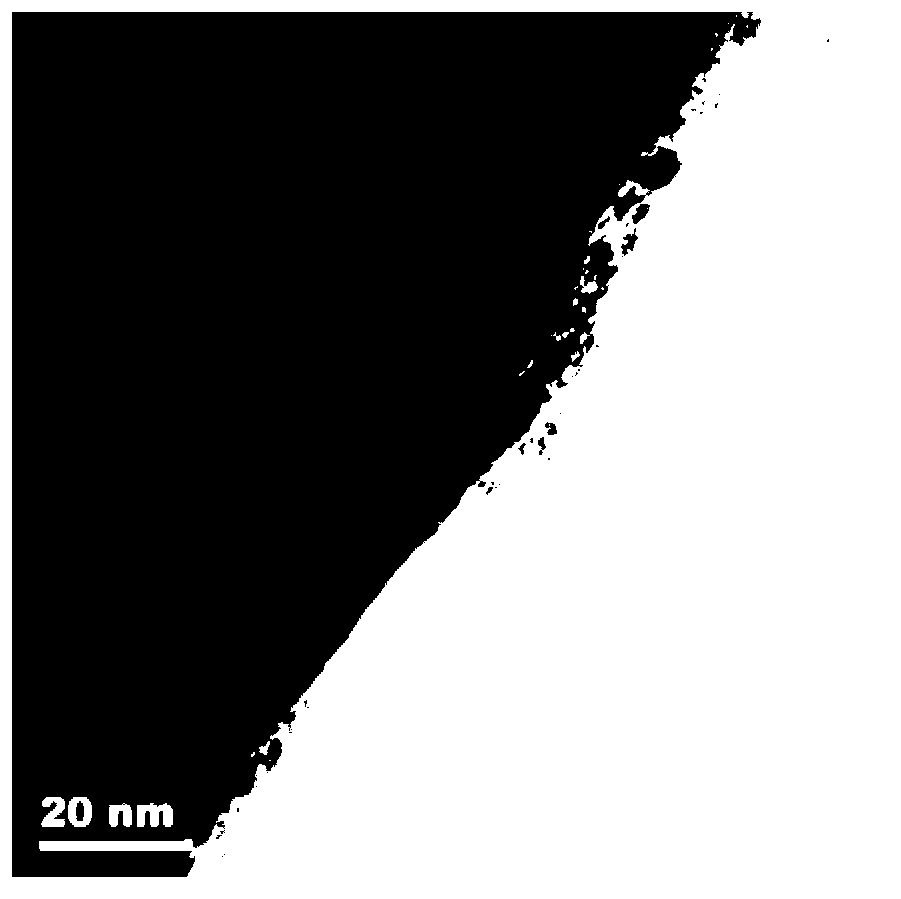

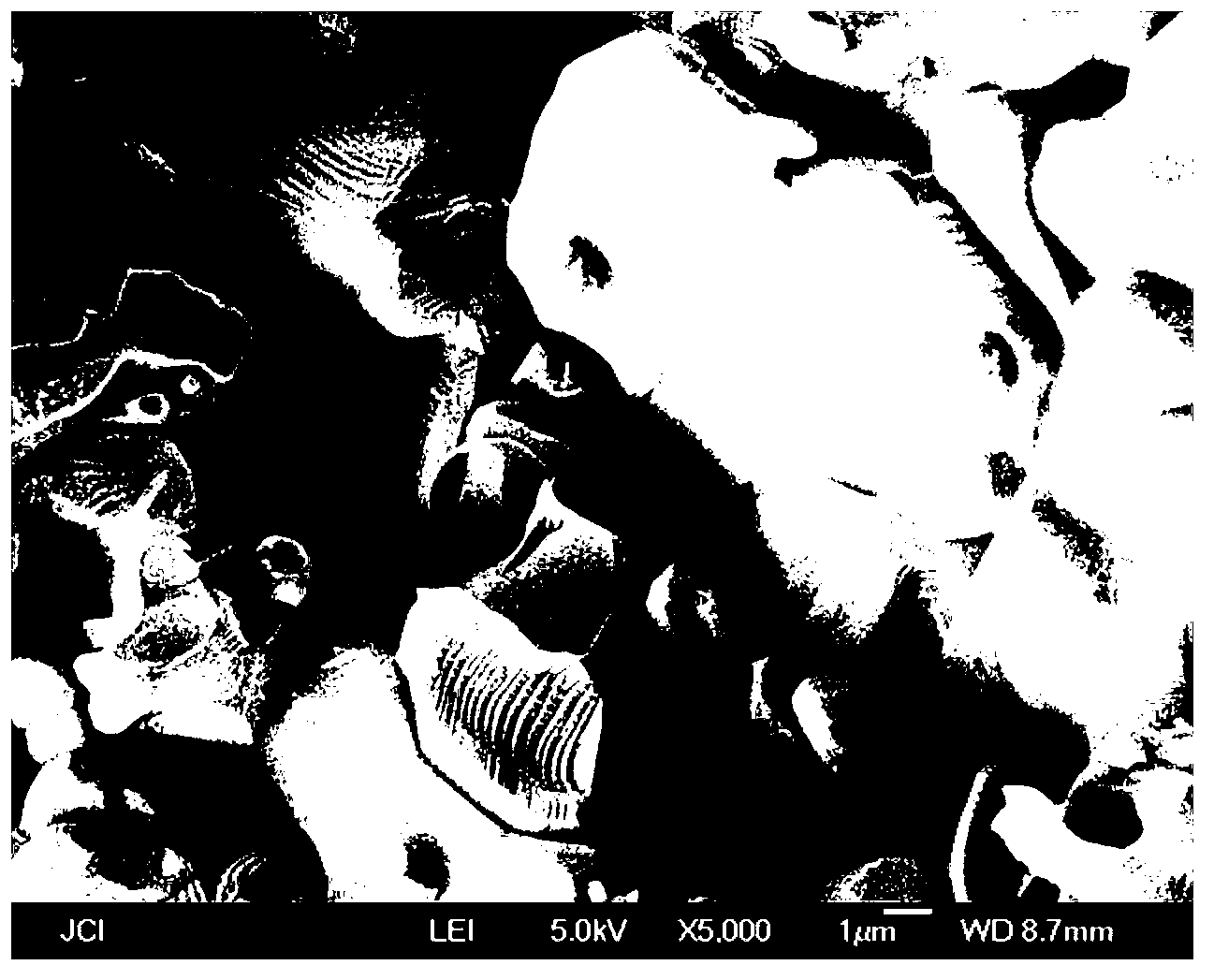

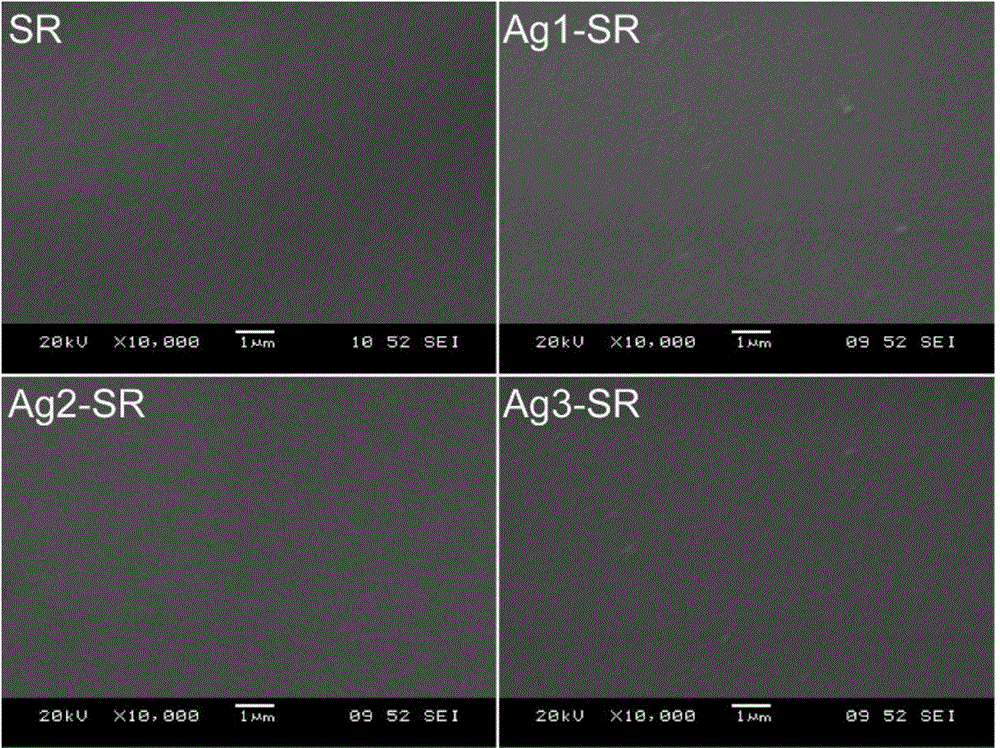

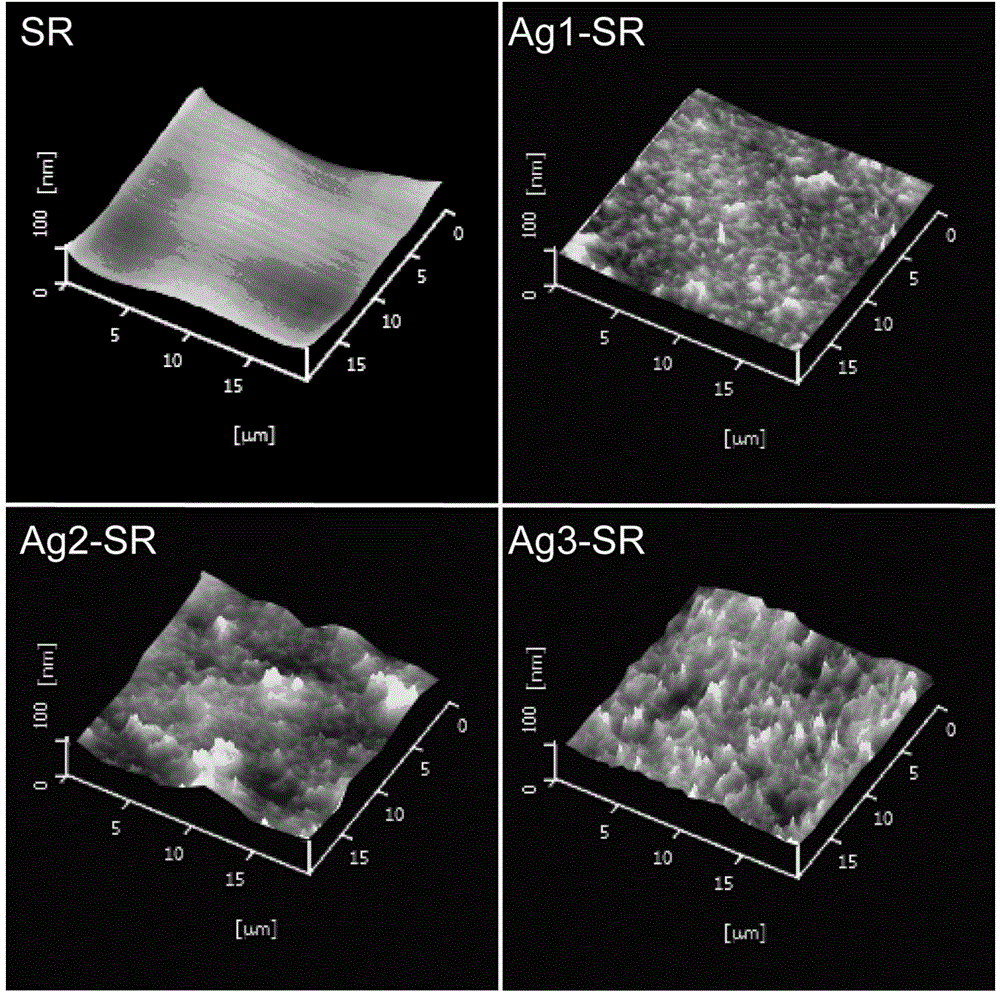

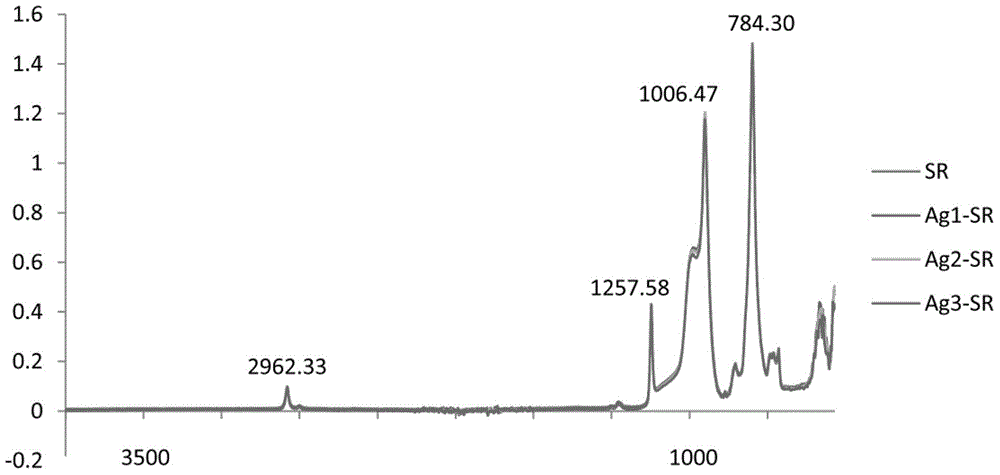

Antibacterial property modification method of silicone rubber

ActiveCN104817711AOperating conditions are easy to controlSimplify operation stepsHydrophilic hydrophobicSurface modification

The invention belongs to the field of medical material modification and specifically relates to an antibacterial property modification method of medical silicone rubber. According to the antibacterial property modification method of silicone rubber, Ag ions are injected into silicone rubber by an ion implantation method so as to obtain the antibacterial silicone rubber. Ion energy of the Ag ions is 10 keV. Injection control conditions of the ions are as follows: ion beam flux density is not more than 1mA / cm<2>, and remnant air pressure is not more than 1*10<-4>Pa. the operation conditions of the method are easy to control; operation steps are simple; and defects such as stripping, poor stability, tedious operation technology and the like existing in plasma processing, graft copolymerization, biomimetic coating and the like in the current surface modification technologies are overcome. In addition, substrate temperature of silicone rubber can be controlled by the method, and properties of the silicone rubber material itself are not influenced. Hydrophilic-hydrophobic property of the silicone rubber obtained is also obviously changed into hydrophilicity. It is verified through cell experiments that biocompatibility of silver ion-injected silicone rubber is also remarkably raised in comparison with biocompatibility of common silicone rubber.

Owner:THE SECOND AFFILIATED HOSPITAL OF THIRD MILITARY MEDICAL UNIV OF PLA

Broad spectrum antihuman globulin reagent assay card and preparation thereof

InactiveCN102692510AAdded Negative Control AssayAvoid misjudgment of resultsBiological testingAntihuman globulinGlobulin

The invention relates to a broad spectrum antihuman globulin reagent assay card and preparation thereof. The assay card is provided with 8 microcolumn gel tubes, wherein broad spectrum IgG (immunoglobulin globulin) and C3D antibody reagents are contained in 8 microcolumn gel tubes.

Owner:BEIJING KINGHAWK PHARMA

Manufacturing method of compound steel

The invention provides a manufacturing method of compound steel, which comprises the following steps: leveling a steel plate and matrix steel, removing an oxide layer on the binding surface of the required steel plate and the matrix steel, and decontaminating so that the binding surface is smooth and flat; superposing the steel plate and the matrix steel, wherein the contact area of the binding surface of the required steel plate and the matrix steel reaches 100%, and no air exists on the binding surface; welding and fixing the transverse seams of the binding surface to obtain a blank; and heating the blank to 950-1000 DEG C in a furnace for 20-30 minutes so that the temperatures inside and outside the blank are uniform, rolling in a hot-rolling mill, and carrying out stress relief annealing by a conventional method, thereby obtaining the compound steel of the invention. The invention has the advantages of simple manufacturing technique, is easy to realize the industrial production and high yield, and enables the yield of compound steel to reach 100% due to the realization of non-oxidation manufacture in the compounding process.

Owner:杨自芬

Method for removing endotoxin in protein

InactiveCN105001299AEfficient removalEasy to operatePeptide preparation methodsUltrafiltrationFiltration

The invention provides a method for removing endotoxin in protein. The method adopts a sequential combination of chromatography, ultrafiltration and common filtration, and accords with a protein purification process flow. With the method, protein purification is realized while endotoxin is effectively removed, and the properties of protein is not influenced. The method is especially suitable to be used in treating various genetically engineered bacteria expressed intracellular and extracellular proteins. With optimized designs of the conditions of filtering mode, filtering pressure, membrane pore size and the like, operation steps and operation time are simplified, such that production cost is reduced, and processing capacity is improved. With the method provided by the invention, the endotoxin content can be reduced to an animal clinical application standard range, and the properties of the product is not influenced while the endotoxin is removed. The method is suitable for large-scale productions and applications.

Owner:TIANJIN RINGPU BIO TECH

Preparation method of trepang oral liquid without fishy odor

The invention discloses a preparation method of trepang oral liquid without fishy smell. The preparation method comprises the steps of removing substances with fishy smell, such as urea, amine and low molecular acid, by adopting a boiling water scalding method, smashing trepang, then adding papain, compound protease and gingerol for mutual enzymolysis, enabling components with fishy smell, such as aldehyde and ketone, to make oxidation reaction, aldolization reaction or esterification reaction, so as to weaken peculiar smell, adding extracting solutions of apple and hawthorn into obtained enzymatic hydrolysate, neutralizing substances with fishy smell, such as methanthiol, by using organic acid in the extracting solutions, and then seasoning by using extracting solutions of medlar, momordica grosvenori and corn. The method is simple, the effect is remarkable, effective components of a product are not affected, most substances with fishy smell are removed, and the oral liquid is better in mouthfeel and low-cost, and meets the requirement of large-scale production.

Owner:山东圣洲海洋生物科技股份有限公司

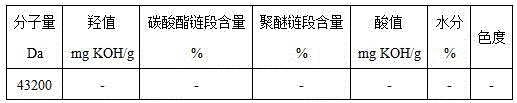

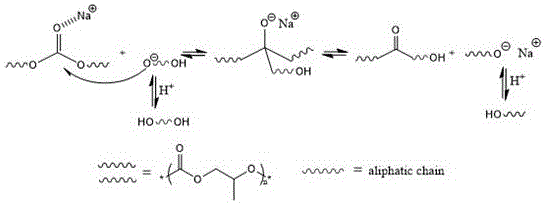

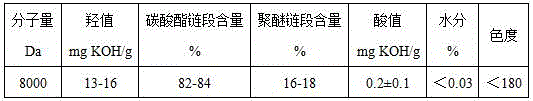

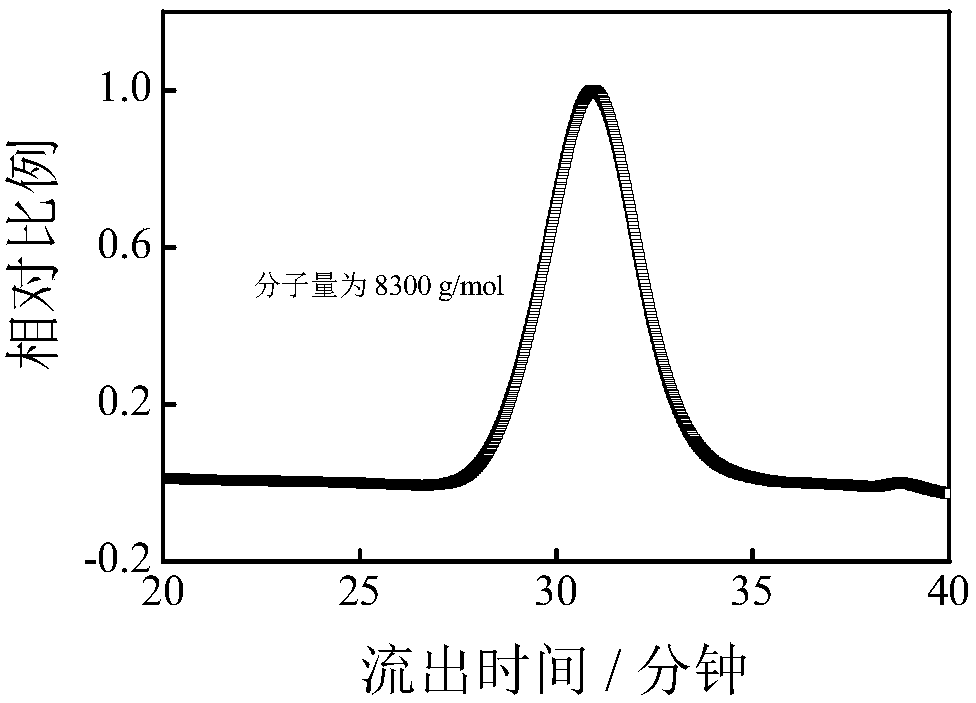

Aliphatic polycarbonate dibasic alcohol and preparation method thereof

The invention relates to the technical field of polymer materials, and discloses an aliphatic polycarbonate dibasic alcohol and a preparation method thereof. The preparation method of the aliphatic polycarbonate dibasic alcohol comprises the following steps: carrying out ester exchange reaction on polymethylethylene carbonate and an aliphatic dibasic alcohol under the condition of a catalyst, and removing impurities, wherein the molecular weight of the polymethylethylene carbonate is greater than 10000Da. The molar weight of the aliphatic dibasic alcohol accounts for 15-100% of that of the polymethylethylene carbonate. The catalyst accounts for 0.01-5% of the molar weight of the polymethylethylene carbonate. The ester exchange reaction is performed by heating to 80-180 DEG C in an inert gas atmosphere and refluxing for 1-30 hours. The invention provides a method for preparing low-molecular-weight aliphatic polycarbonate dibasic alcohol from high-molecular-weight polycarbonate, and widens the applicability of the high-molecular-weight polycarbonate. The molecular weight of the aliphatic polycarbonate dibasic alcohol and the hydroxy functional group degree can be adjusted according to needs, and the primary product of the aliphatic polycarbonate dibasic alcohol is easy for impurity removal.

Owner:SUN YAT SEN UNIV

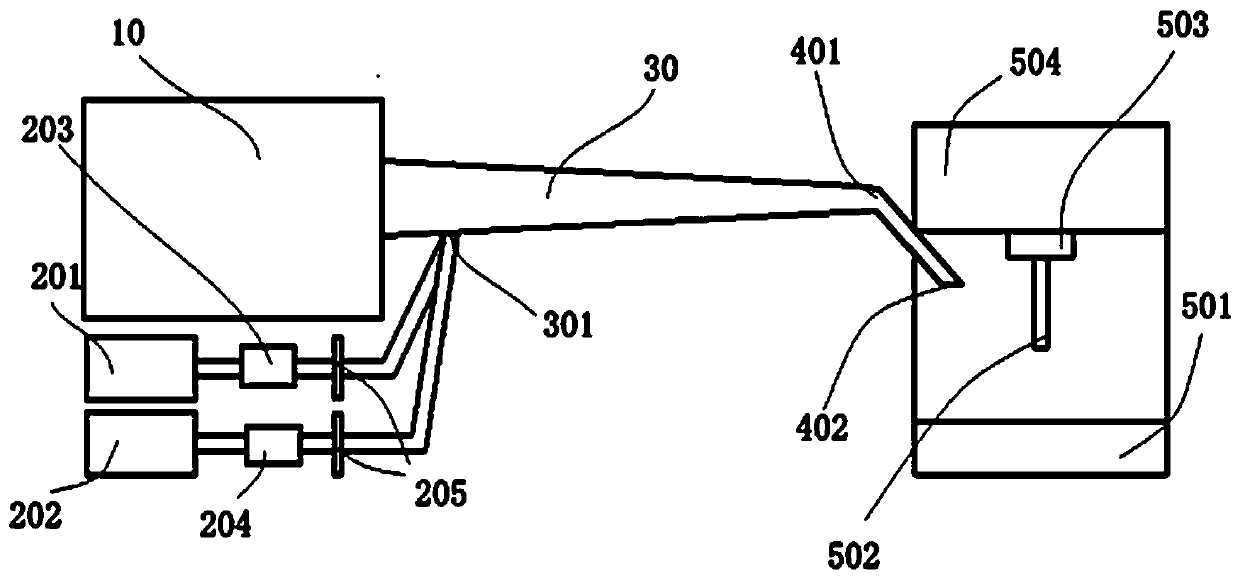

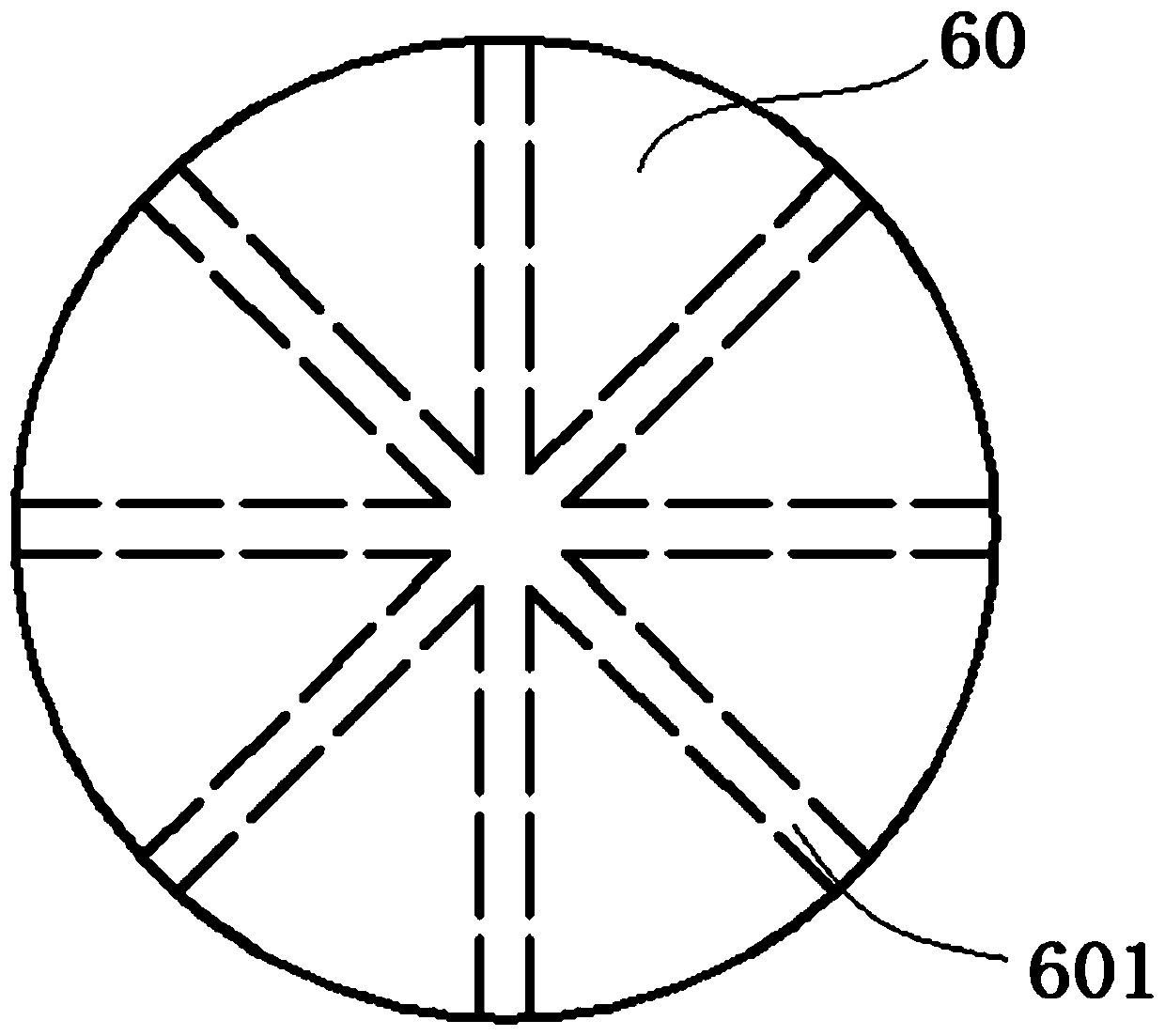

Stainless steel workpiece cutting device

InactiveCN107639465AReduce the temperatureFully moistenedMaintainance and safety accessoriesCooling effectLubrication

The invention provides a stainless steel workpiece cutting device. The device comprises water-oil mixing assembly, a conveying pipe, a low-temperature gas generating assembly, a nozzle and a machine tool; the conveying pipe is of a pipe structure of which the two ends are opening, a through hole is formed in the wall of the conveying pipe, and a water pump and an oil pump are connected with the pipeline of an output pipe at the through hole; the low-temperature gas generating assembly is connected to the pipeline of the conveying pipe at one end of the output pipe; the nozzle comprises a liquid inlet and a sprayer, wherein the liquid inlet is connected to the pipeline at the other end of the output pipe; the machine tool comprises a work platform, a cutter, a main shaft and a rack, one endof the main shaft is connected to the rack movably, the other end of the main shaft is connected to the cutter, the work platform is arranged at the lower portion of the cutter point of the cutter, the side face of the nozzle is fixedly connected to the rack, and the sprayer is opposite to the cutter point of the cutter. The stainless steel workpiece cutting device is good in lubrication effect and cooling effect and prevents filing accumulation.

Owner:ZHAOQING HI TECH ZONE GUOZHUAN TECH CO LTD

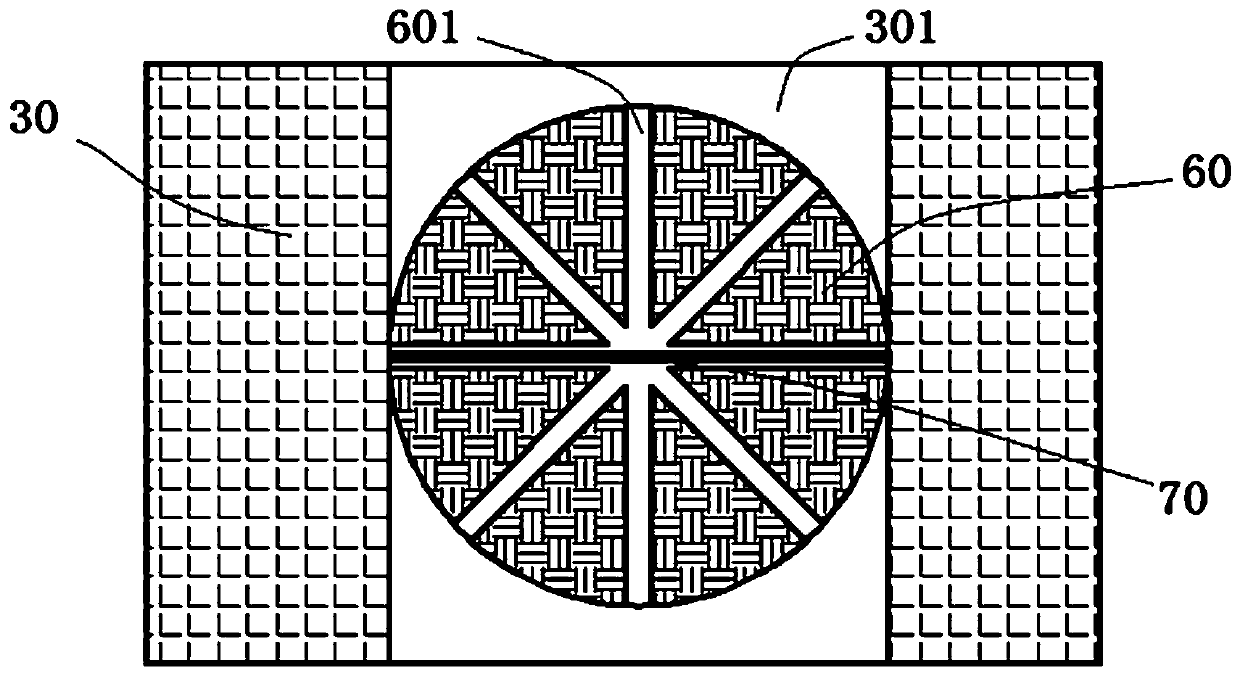

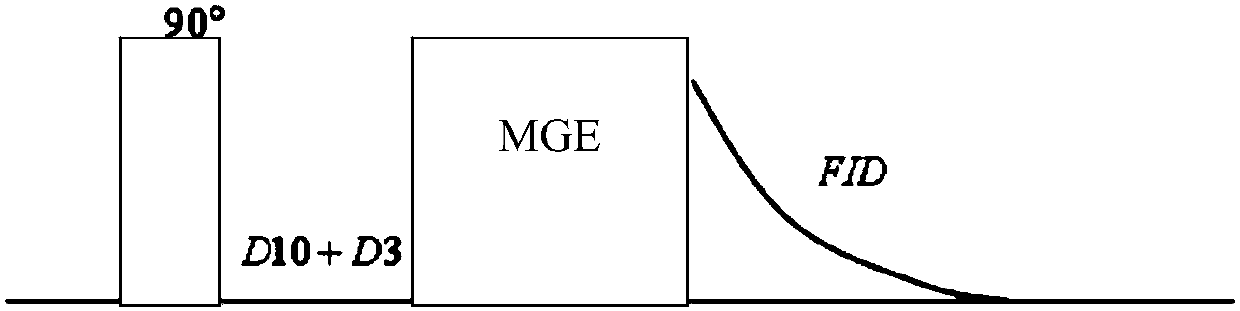

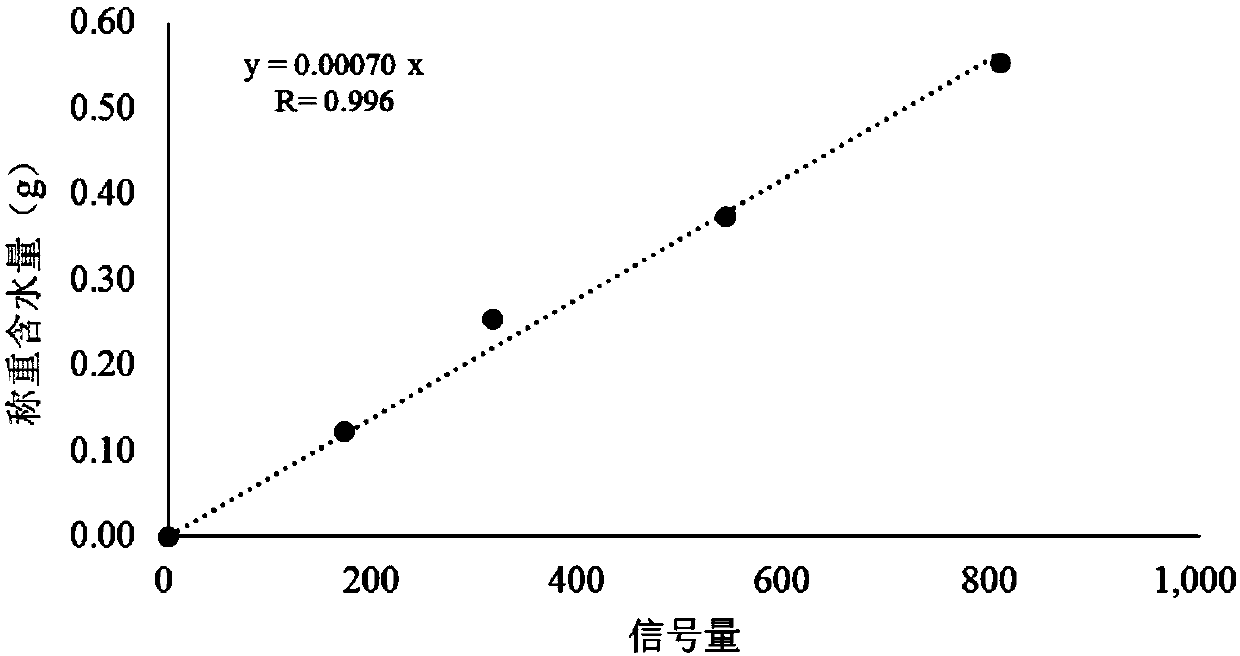

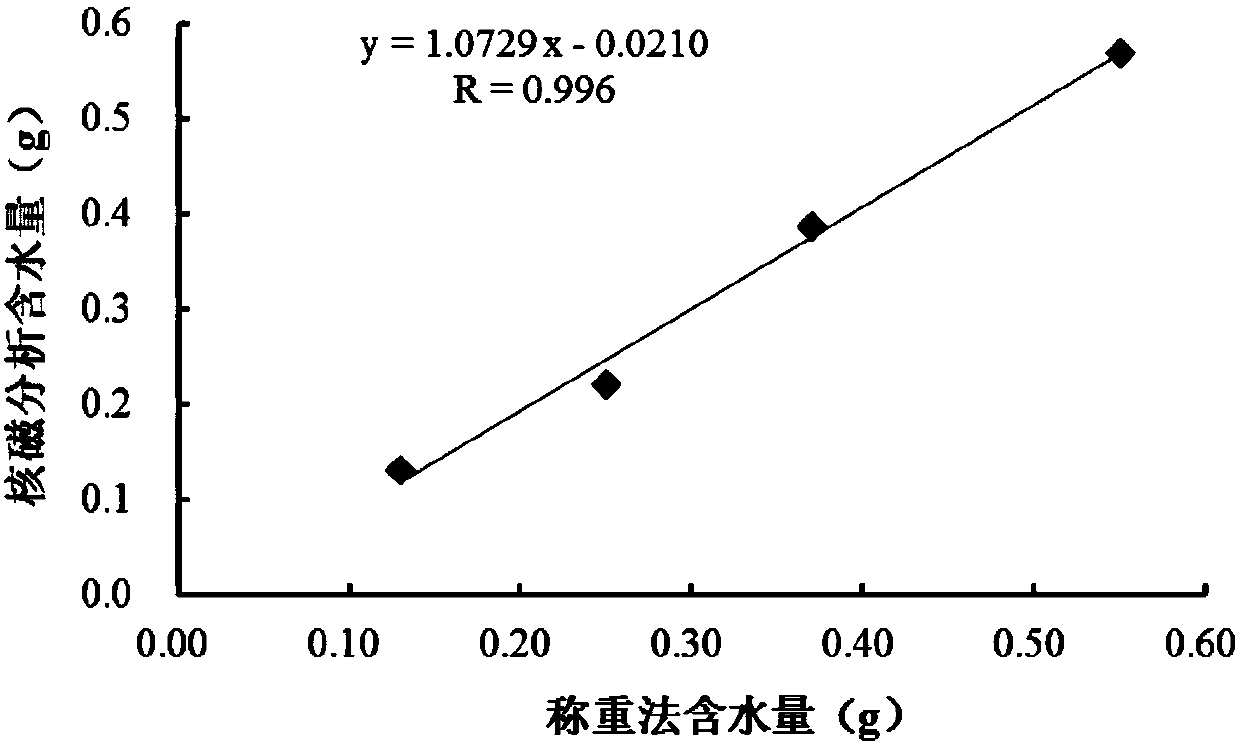

Method for nondestructive testing of source rock water content based on magnetic resonance imaging

ActiveCN107655922ADoes not affect natureMake up for the inability to accurately measure the water content of source rocksWater resource assessmentAnalysis using nuclear magnetic resonanceWater contentSource rock

The invention provides a method for nondestructive testing of source rock water content based on magnetic resonance imaging, which includes steps of a, sequence selection: using a magnetic resonance imaging analyzer, and applying an S-MGE sequence to selectively collect a signal of proton in hydrone in a source rock sample, wherein the collecting process of the S-MGE sequence includes steps of applying multiple impulses at 90 degrees to magnetic resonance imaging signals of all hydrogen cores of a saturated source rock sample to form an exciting echo during the recovery process of the magneticresonance imaging signals of the hydrogen core, so as to acquire magnetic resonance imaging relaxing information of the hydrogen core in a water molecule in the source rock sample; finally, acquiringthe magnetic resonance imaging signal intensity of the hydrogen core in the water molecule in the source rock sample; b, building a standard curve; c, testing water content in the to-be-tested sampleof the source rock; d, calculating the water content of the to-be-tested sample of the source rock.

Owner:PETROCHINA CO LTD

Preparation method of fusible multilayer composite asphalt filling bag

InactiveCN103231519AAvoid pollutionAvoid problems such as recycling difficultiesBlow moldingPolymer science

The invention discloses a preparation method of a fusible multilayer composite asphalt filling bag. The method is characterized in that the method comprises the following steps: utilizing polyolefin, a modified polyolefin material and a compounding agent to prepare a fusible multilayer composite asphalt filling bag film blowing material, carrying out blow molding of the film blowing material and processing master batches through adopting a film blowing set to form a fusible multilayer composite asphalt filling bag body having a thickness of 20-100mum, and carrying out slitting and heat sealing to prepare the fusible multilayer composite asphalt filling bag. The processing master batches are a fusion compound comprising a polyethylene resin and a processing assistant. The fusible multilayer composite asphalt filling bag has the characteristics of high temperature filling resistance, realization of complete mixed fusion with asphalt, no edge leakage, no seepage, high heat sealing strength, wide range of the use temperature, ultraviolet resistance, weather resistance, strong designability, and relative low price. The fusible multilayer composite asphalt filling bag is used for the high and low temperature filling of pavement asphalt and various modified asphalts, and can be widely used in the petroleum field and the building field.

Owner:宁波江东晟利工业产品设计有限公司 +2

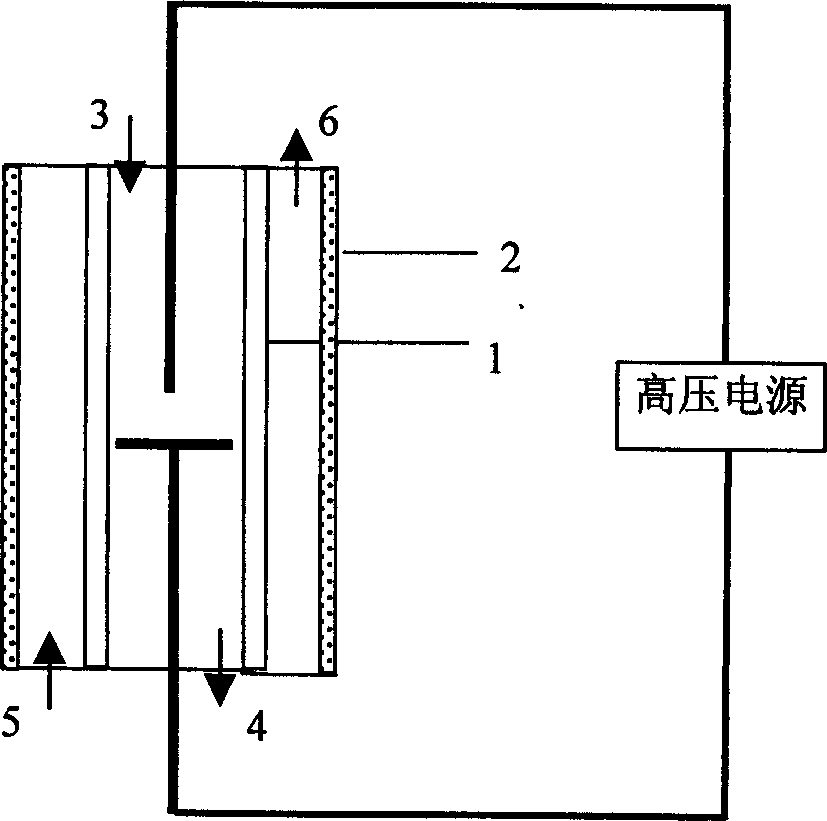

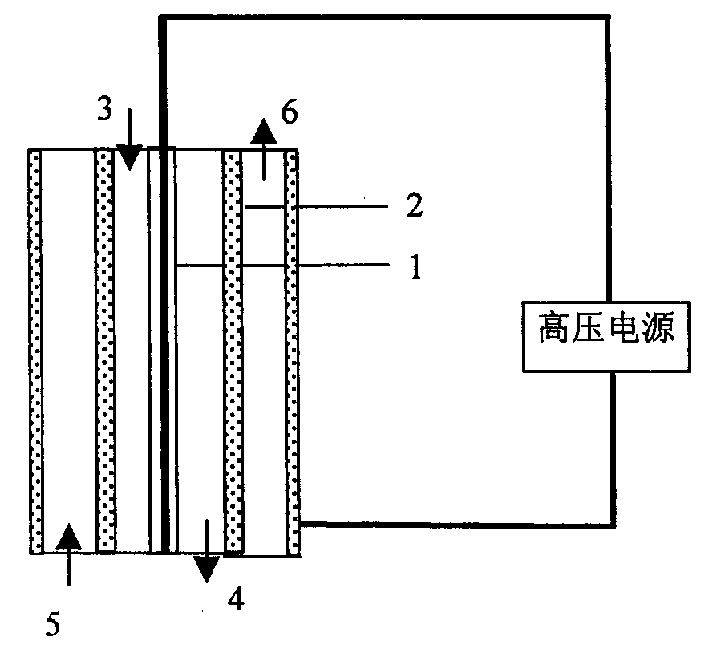

Plasma process for preparing acid water

InactiveCN1491899AProcess stabilityDoes not affect natureWater/sewage treatment by magnetic/electric fieldsAcid waterPlasma generator

The present invention relates to a kind of acid water preparing process. Neutral water or its vapor is set inside plasma generator, and DC or AC voltage of 300-5000 V is applied across the electrodes for reaction of 10-300 min. The plasma generator may be one of dielectric blocking discharge or corona discharge. The acid water prepared through the plasma process has conductivity 10-2000 times higher than that of common water, and pH value up to 1.89. The acid water may be preserved for long period and has property not affected by freezing and heating. The acid water may be used as efficient and clean acid to replace inorganic acid with serious pollution for wide use.

Owner:TIANJIN UNIV

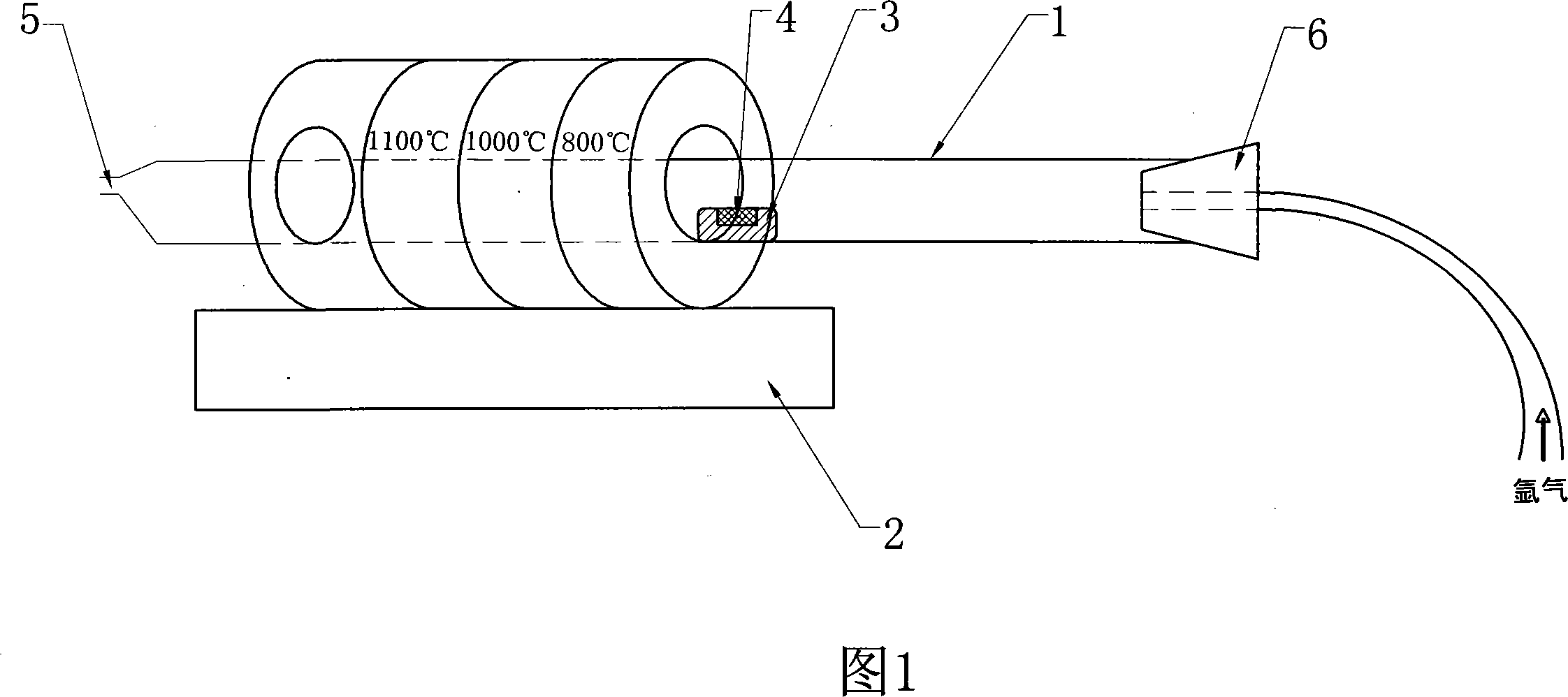

Method for determining un-voltatile residue and relative carbon-content in solid sample

InactiveCN101067594AFully expelledDoes not affect natureWeighing by removing componentSpecial data processing applicationsIsolation effectSilicon alloy

The invention relates to a method of testing the no volatilized residuum and the relative carbon amount in the solid test specimen, puts the test specimen into the heat-resisting vessel and under the isolation air condition after separately heats the certain time with the heater in the 750-850 deg,950-1050 deg, 1050-1150 deg three temperature areas weighing and computing the no volatilized residuum and the relative carbon amount according to the following formula; the method has good isolation effect with air and the long heat time, can fully drive out the volatile matter but not to affect the residuum character, the three temperature areas tubular heat up structure is simple, operation simple bright and is easy to make the processing, the observation data reduction mathematical formula simply, is easy to grasp, the test entire process and the atmosphere even more approach the stove return original state process of the electric heating to smelt the aluminum silicon alloy, the obtained result has a better instruction.

Owner:登封电厂集团铝合金有限公司

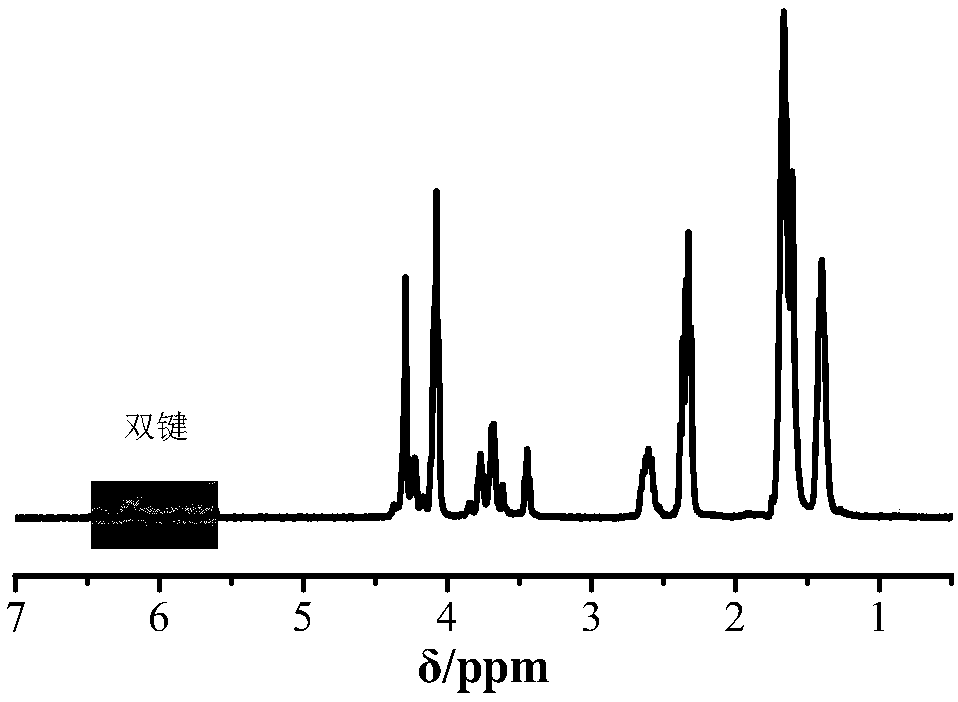

Synthesis method of copolyester

The invention belongs to the field of synthesis of copolyester, and particularly relates to a synthesis method of the copolyester. The synthesis method comprises the step of catalyzing copolymerization reaction of two monomers such as a hydroxyl acrylate-containing monomer and a cyclic monomer through small organic molecules to obtain the degradable copolyester with a brand-new structure. The hydroxyl acrylate-containing monomer comprises hydroxyethyl acrylate and hydroxyethyl methylacrylate as well as a derivative thereof; the cyclic monomer comprises an epoxy monomer and a lactone monomer. The epoxy monomer comprises ethylene oxide, epoxypropane, allyl glycidyl ether and the like; the lactone monomer comprises butyrolactone, caprolactone, lactide and the like. A polymerization mode for hydroxyl acrylate in the method is carried out in a proton transfer manner instead of conventional vinyl addition, thereby obtaining polyester with a special structure. Raw materials used in the methodare readily available and are economical and environmentally friendly; reaction conditions are mild, and the reaction rate is high; different functional groups can be introduced into the polyester, so that the application range is expanded; the method has an extremely good application prospect.

Owner:CHANGZHOU UNIV

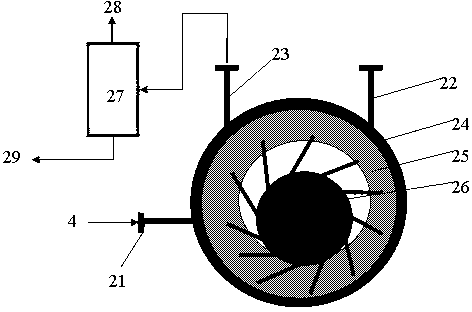

Defoaming device and defoaming method for removing foam of drilling fluid by means of linkage of negative pressure and thermal radiation

A defoaming device and a defoaming method for removing foam of drilling fluid by means of linkage of negative pressure and thermal radiation belong to the technical field of physical defoaming of drilling fluid. The device comprises a cylinder tank body and is characterized in that a thermal radiation part is arranged in the tank body, a vacuum pump and a water pump are connected to the outer side of the tank body, and the whole set of device comprises a pressure sensor, a temperature sensor, a liquid level sensor, and the like. The core thought of the device provided by the invention is to adopt the mode of combining the negative pressure and thermal radiation technologies. Firstly, the foam is guided into the closed tank body, a container is vacuumed by the vacuum pump to make internal and external pressure difference for the foam, in addition, the thermal radiation part is used to heat to enable the gas in the foam in the tank body to expand, then the foam is rapidly removed under the actions of the vacuum pump and the thermal radiation part, and the foam base solution and solids carried by the foam are discharged from a liquid and slag discharge port. According to the defoaming device, a large amount of foam discharged from foam drilling is quickly removed, the foam is prevented from being accumulated in a mine field, and the foam base solution is not affected and can be recycled.

Owner:SHANDONG UNIV

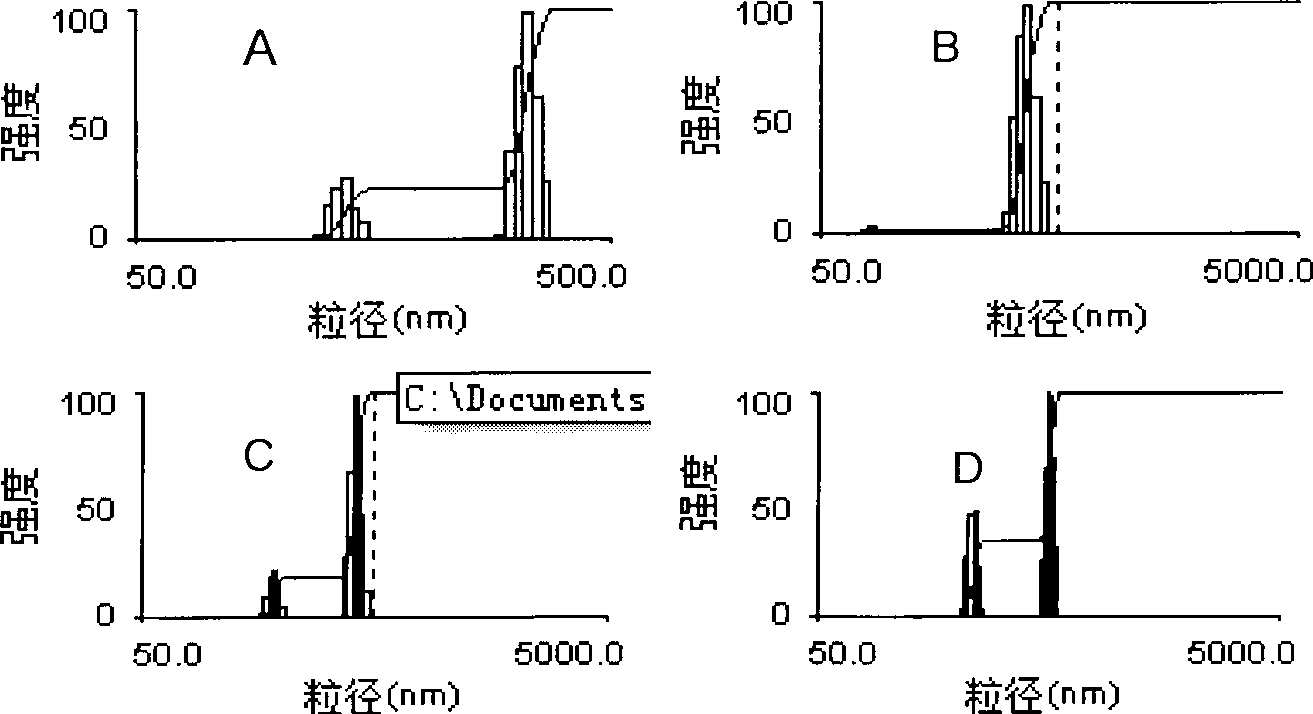

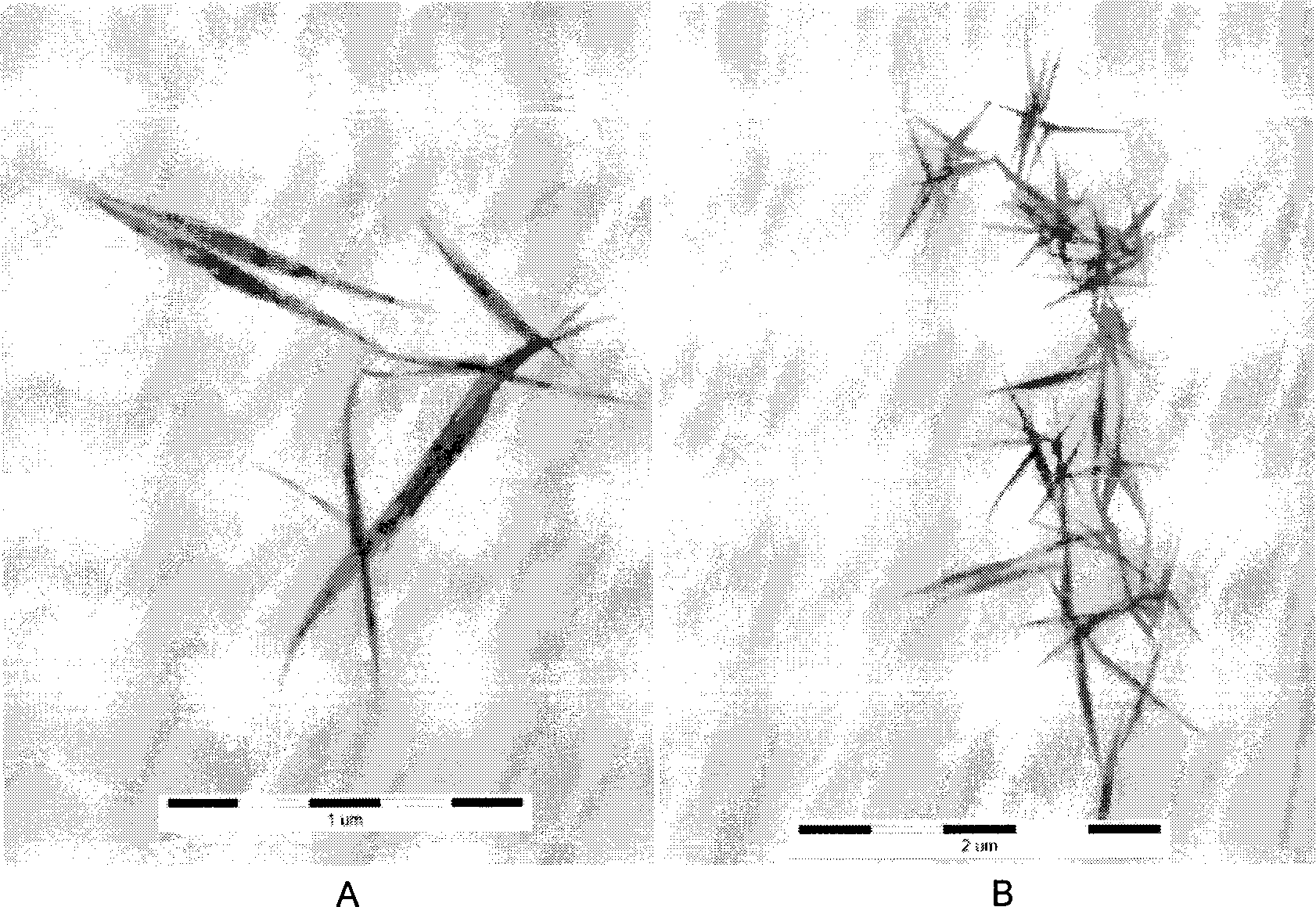

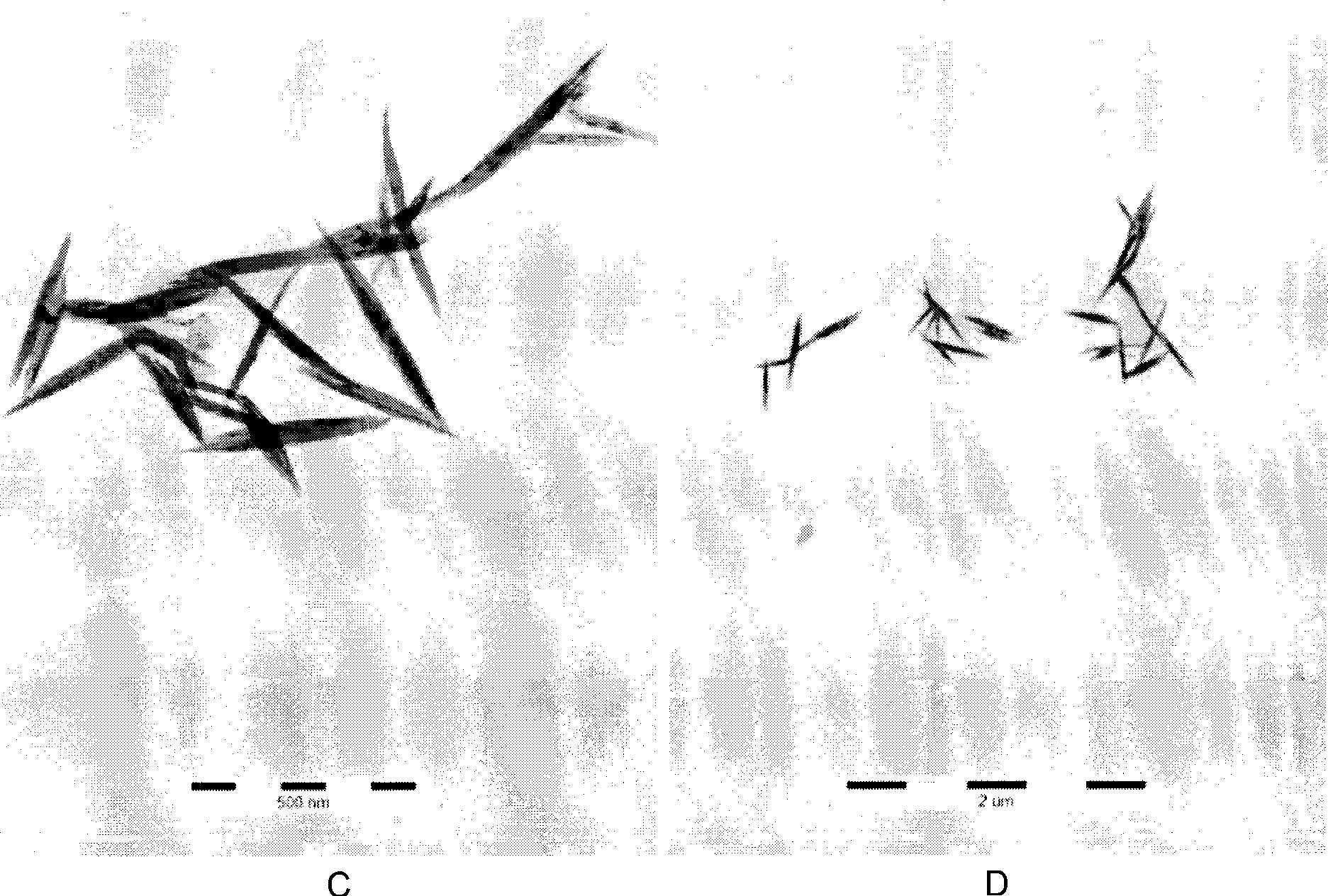

Liquid-phase sugar nano tellurium and preparation method thereof as well as method for storing nano tellurium in liquid phase

InactiveCN101445221ASimple manufacturing methodEasy to operateElemental selenium/telluriumAqueous solutionLiquid phase

The invention discloses a liquid-phase sugar nano tellurium and a preparation method thereof. The liquid-phase sugar nano tellurium is a compound of sugar and nano tellurium obtained by reacting tellurite aqueous solution with the sugar by heating in the present of a reducing agent. The method comprises the following steps: adding the sugar to the tellurite solution, adding the reducing agent which is 50-100 times of the molar weight of the tellurite, and heating for reacting to obtain a product. The method is simple and feasible, and is applicable to industrialized production. The obtained product is more stable at normal temperature, thus realizing the storage of a nano tellurium elementary substance in a liquid phase, greatly widening the application range of the existing solid nano tellurium and reducing the use restriction thereof.

Owner:JINAN UNIVERSITY

Technology for producing hard alloy woodworking blade by means of fine-particle return scraps

InactiveCN105642881ADoes not affect natureImprove wear resistanceTransportation and packagingMetal-working apparatusHeat resistanceHardness

The invention discloses a technology for producing a hard alloy woodworking blade by means of fine-particle return scraps. The technology comprises the following steps that S1, the fine-particle return scraps produced in the bar production process are recycled and dewaxed; S2, the return scrap treated in the step S1 are added into a rotary mill with hard alloy serving as a grinding body; and S3, spray particles are formed through a precision press and sintered in a pressure sintering furnace. The dewaxing technology is adjusted, so that it is guaranteed that dewaxing is carried out completely, and the property of the fine-particle return scraps is not influenced; the proper ball milling carbon addition technology is determined; by means of testing of the forming performance of various forming agents, a pressing test is carried out, the proper forming agents are screened out, and it is ensured that the pressing performance of a hard alloy woodworking cutter produced through the fine-particle return scraps is stable, and the forming agents are reasonable in ratio; and the wear resistance and heat resisting strength of the hard alloy woodworking blade manufactured through the technology are remarkably improved, hardness is reasonable, and the manufacturing cost is greatly reduced.

Owner:江西耀升钨业股份有限公司

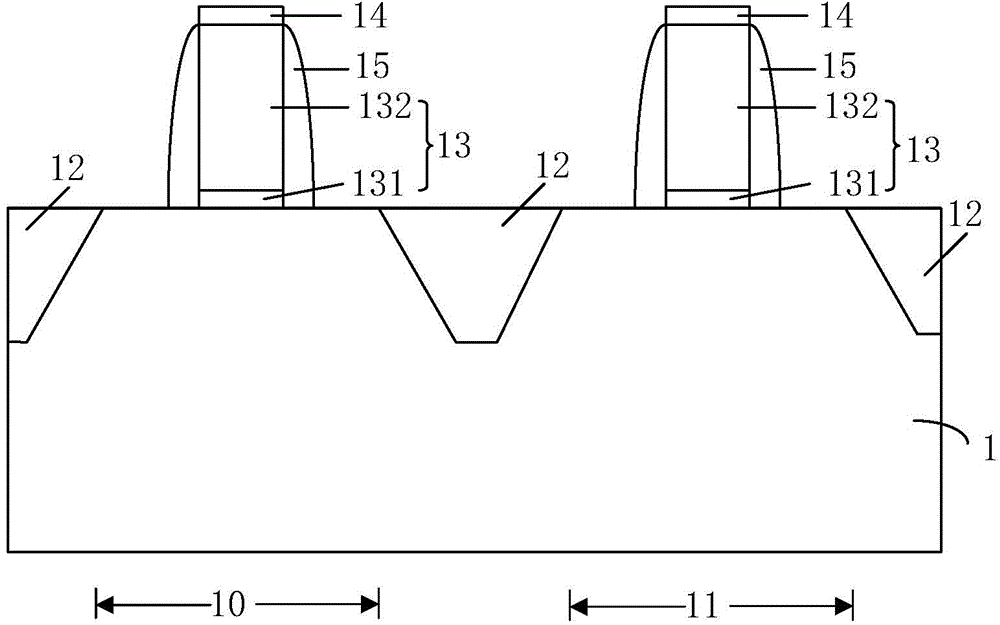

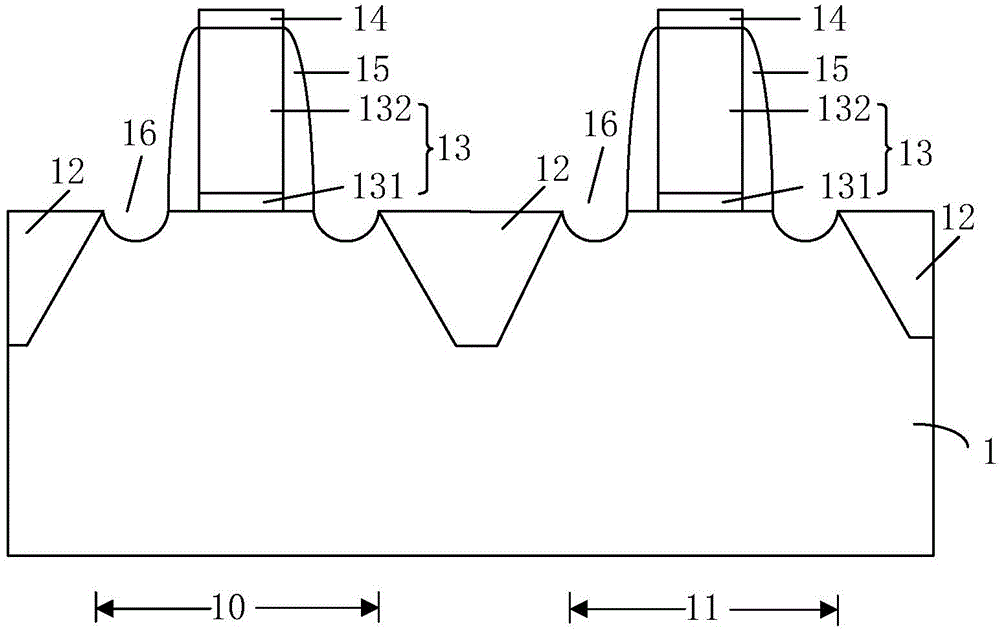

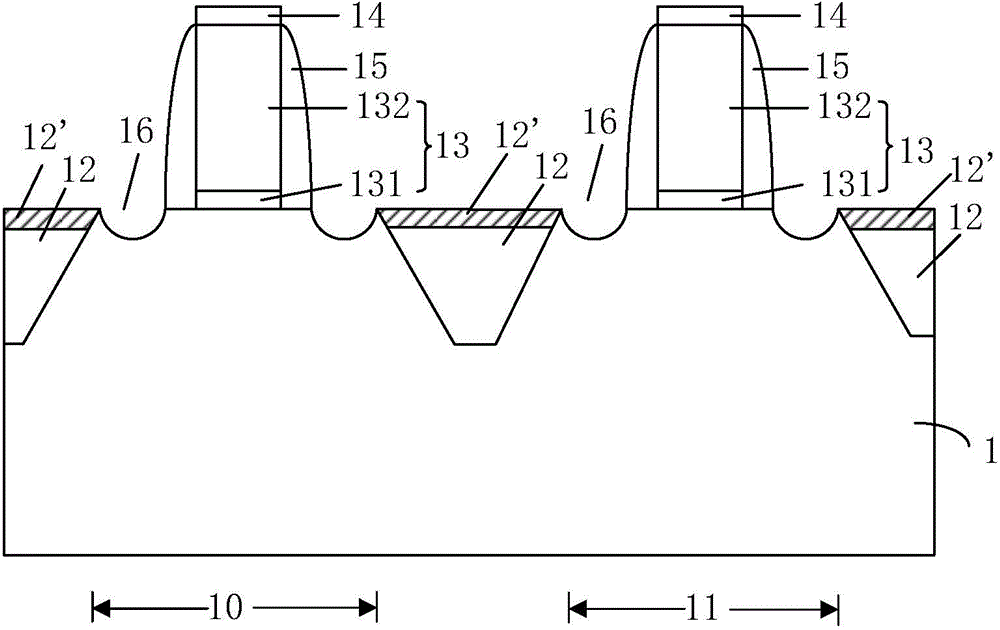

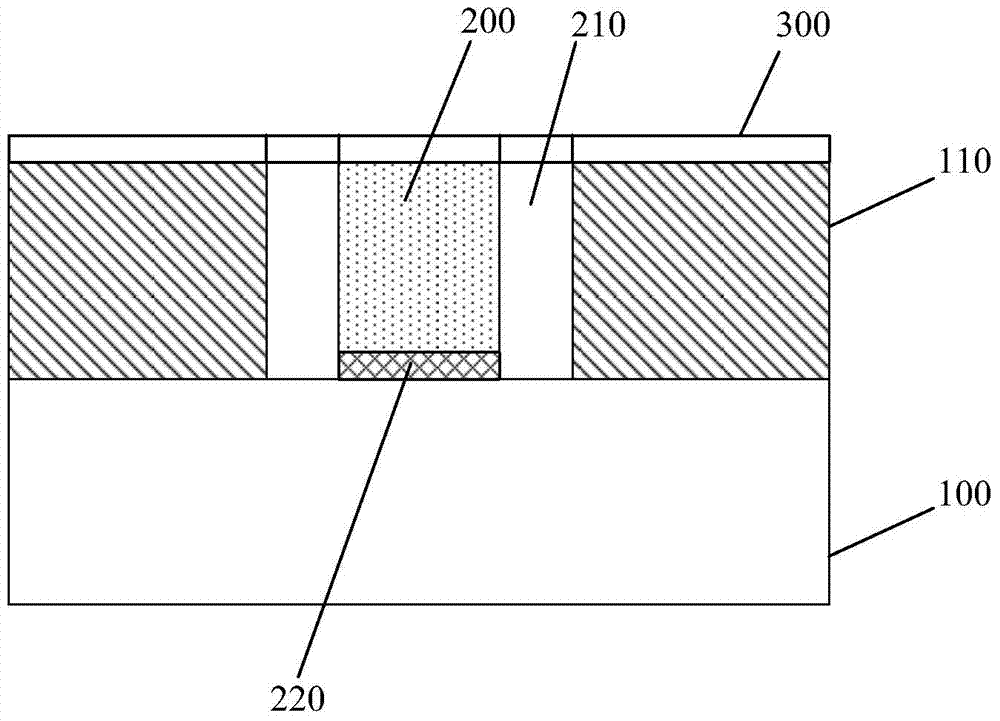

MOS transistor forming method

InactiveCN105632928AAvoid corrosionImprove insulation performanceSemiconductor/solid-state device manufacturingEngineeringTension stress

The invention discloses an MOS transistor forming method, and the method comprises the steps: firstly carrying out the dry etching of active regions at two sides of a grid structure and forming bowl-shaped grooves; secondly corroding a semiconductor substrate through employing HF acid solution, and then corroding the bowl-shaped grooves through employing alkaline solution to form sigma grooves, wherein a modified region is formed on the surface of a shallow trench isolation structure playing a role in isolating the adjacent active regions at least before the HF acid solution corrodes the semiconductor substrate. Therefore, the modified region can avoid the corrosion of the shallow trench isolation structure when the HF acid solution corrodes the semiconductor substrate, thereby avoiding a condition that a material is still filled ion a conductor source-drain region formed at the placed of the corroded removed shallow trench isolation structure when a hold appears on the shallow trench isolation structure or a pressure stress material or a pull stress material is filled in the sigma grooves so as to form the source-drain region, finally improving the insulation of the shallow trench isolation structure, and avoiding mutual interference between the manufactured adjacent MOS transistors.

Owner:SEMICON MFG INT (SHANGHAI) CORP

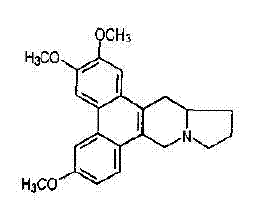

Method for extracting antofine

InactiveCN102391265AReduce dissolutionPromote dissolutionOrganic chemistryFiltration membraneUltraviolet

The invention discloses a method for extracting antofine. The method comprises the following steps of: crushing a cynanchum komarovii raw material, adding 0.5 to 1 percent aqueous solution of hydrochloric acid or sulfuric acid, extracting, regulating the pH of the extract to be between 7.5 and 8.5, adding an ultra-filtration membrane for ultra-filtration, adding a nano-filtration membrane for nano-filtration, regulating the pH of the concentrate to be between 9.5 and 11, extracting the concentrate by using chloroform, separating the concentrated extract by adopting preparative liquid chromatography, performing ultraviolet on-line detection, collecting the target component, drying the target component at a low temperature, and thus obtaining the antofine product. The method is low in energy consumption, low in pollution and high in product content (which can reach over 95 percent), is suitable for small experiments, and can also be used for industrialized production.

Owner:NANJING ZELANG MEDICAL TECH

Method for comprehensive oil gas recovery

ActiveCN102911704AEfficient recyclingReduce operating loadLiquid hydrocarbon mixture recoveryDispersed particle separationRecovery methodGas exchange

The present invention discloses a method for comprehensive oil gas recovery, including an oil gas absorption process and a rich absorbent regeneration process. Commercial diesel oil is used as the oil gas absorbent for the oil gas absorption process. The temperature of the absorbent entering an absorption tower is -20 to 20 DEG C. The oil gas is compressed to 0.2-1MPa via a liquid ring compressor. The liquid ring compressor-pressurized oil gas exchanges heat with the rich absorbent discharged from the absorption tower for cooling. Oil gas condensed to be liquid phase is recovered, while un-condensed oil gas is fed into the absorption tower and in countercurrent contact with the absorbent in the absorption tower. The rich absorbent absorbed the oil gas is discharged from the absorption tower; and is desorbed after being heated via heat exchange. Commercial diesel oil is used as operating fluid for the liquid ring compressor, and the operating fluid is once-through. The operating fluid discharged from the liquid ring compressor, together with the rich absorbent discharged from the absorption tower, is desorbed by means of appropriate vacuum, and then is fed into a commercial diesel tank. Compared with the prior art, the method of the present invention has advantages of a reasonable technological process, high oil gas recovery efficiency, low investment in equipment and operating costs, etc.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of preparation method of sinomenine

InactiveCN102267945AReduce dissolutionPromote dissolutionOrganic chemistryUv detectionUltrafiltration

The invention discloses a preparation method of sinomenine, which comprises the following steps: crushing the stems and leaves of dried pueraria puerariae, adding 0.5-1% hydrochloric acid or sulfuric acid aqueous solution to extract, adjusting the pH of the extract to 7.5-8.5, adding an ultrafiltration membrane for ultrafiltration, Then add nanofiltration membrane and nanofiltration, adjust the pH of the concentrated solution to 9.5-11, extract with chloroform, concentrate the extract, and then use preparative liquid chromatography to separate, ultraviolet on-line detection, collect the target components, and dry at low temperature to obtain the sinomenine product . The invention has low energy consumption, less pollution and high product content, which can reach more than 98%, and is not only suitable for small-scale experiments, but also can be used for industrial production.

Owner:NANJING ZELANG MEDICAL TECH

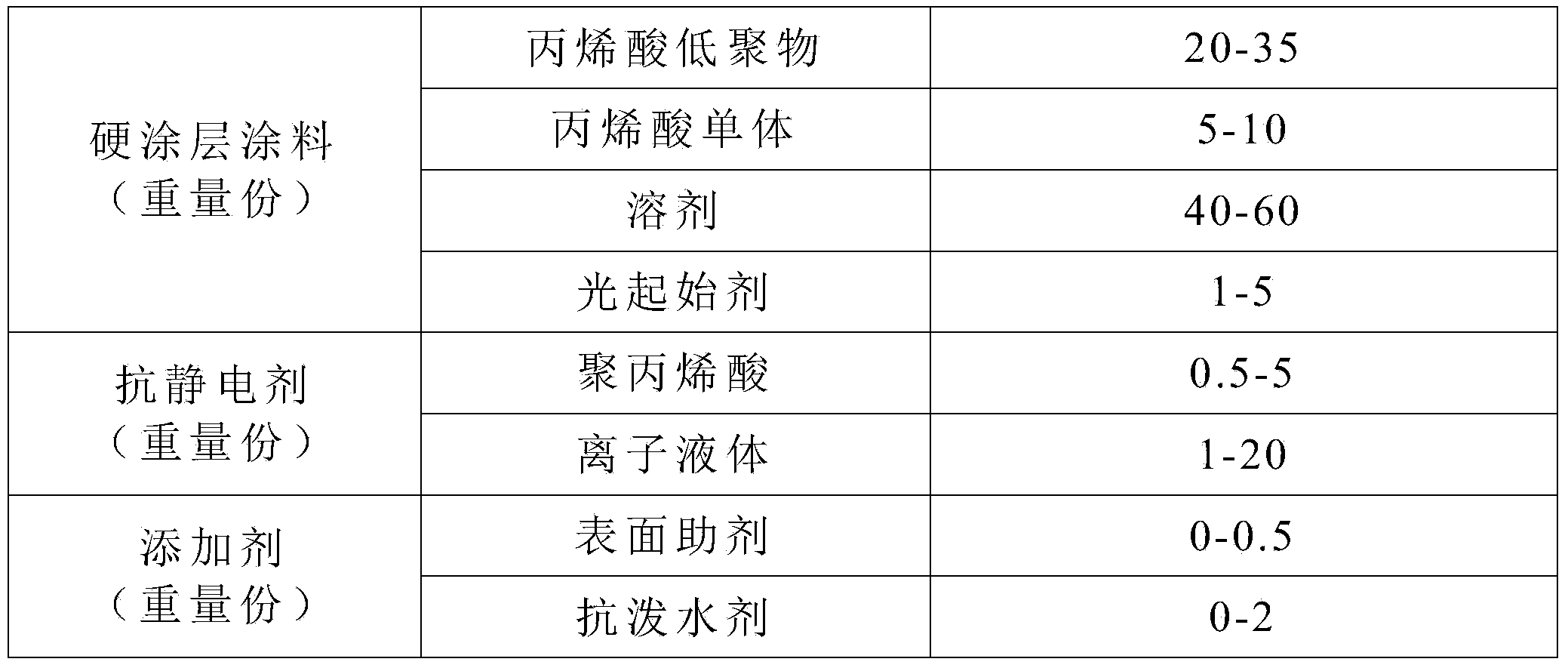

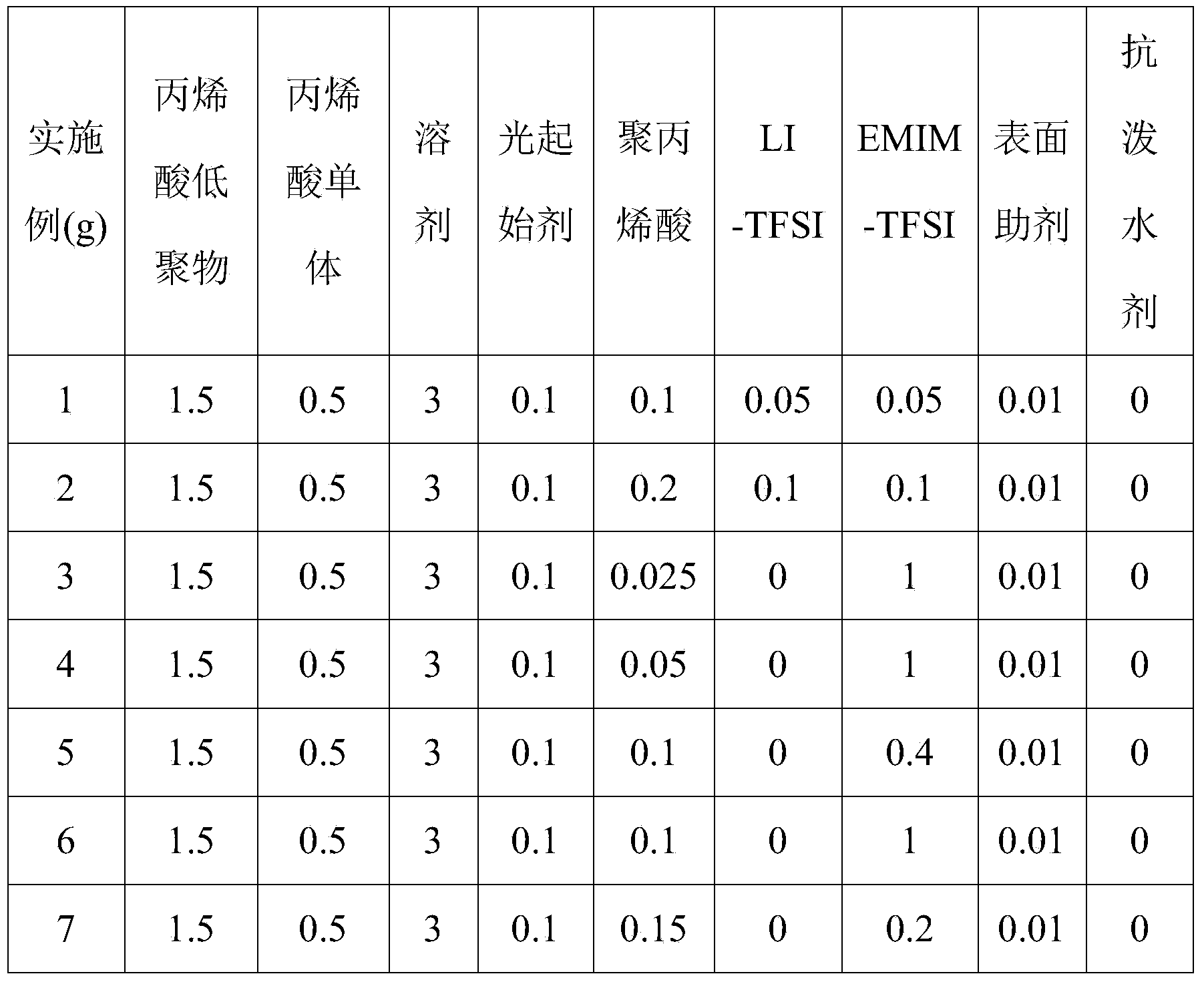

Antistatic paint, antistatic thin film and preparation method of the antistatic thin film

The invention provides an antistatic paint, an antistatic thin film and a preparation method of the antistatic thin film. The antistatic paint comprises a hard coating paint and an antistatic agent. The hard coating paint comprises the following components by weight: 20 to 35 parts of acrylic oligomer, 5 to 10 parts of acrylic monomer, 40 to 60 parts of a solvent and 1 to 5 parts of a photoinitiator. The antistatic agent comprises the following components by weight: 0.5 to 5 parts of polyacrylic acid and 1 to 20 parts of an ionic liquid. The surface pencil hardness of the antistatic thin film formed by coating the antistatic paint provided by the invention reaches 2H, the initial surface resistivity can reach 10<8> to 10<11> ohm / sq., the surface resistivity can be still 10<10> to 10<12> ohm / sq. after the thin film is wiped by the solvent, and therefore the antistatic thin film has the characteristics of high weathering resistance, high hardness, low surface resistance and good optical effects.

Owner:BENQ MATERIALS +1

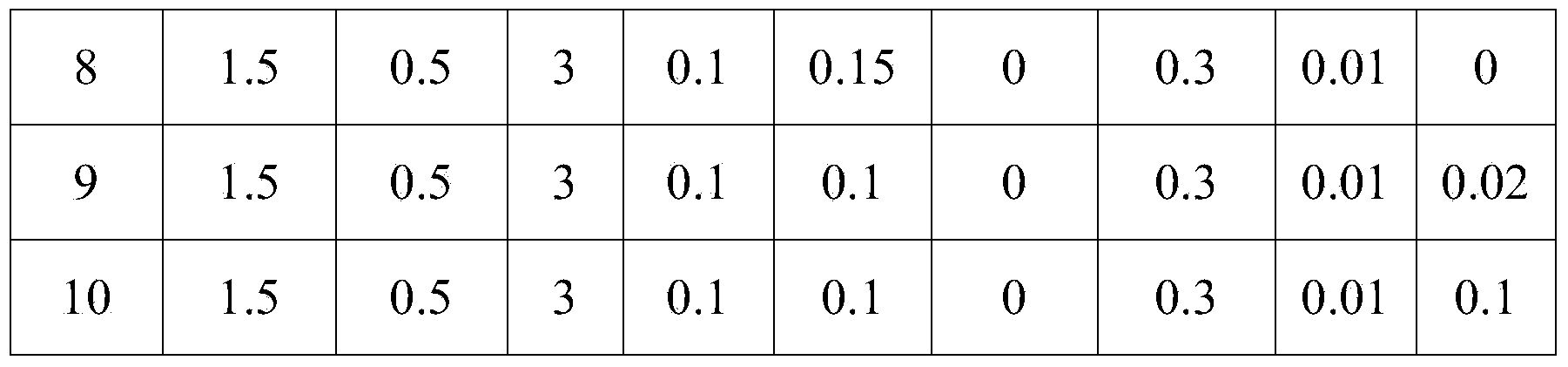

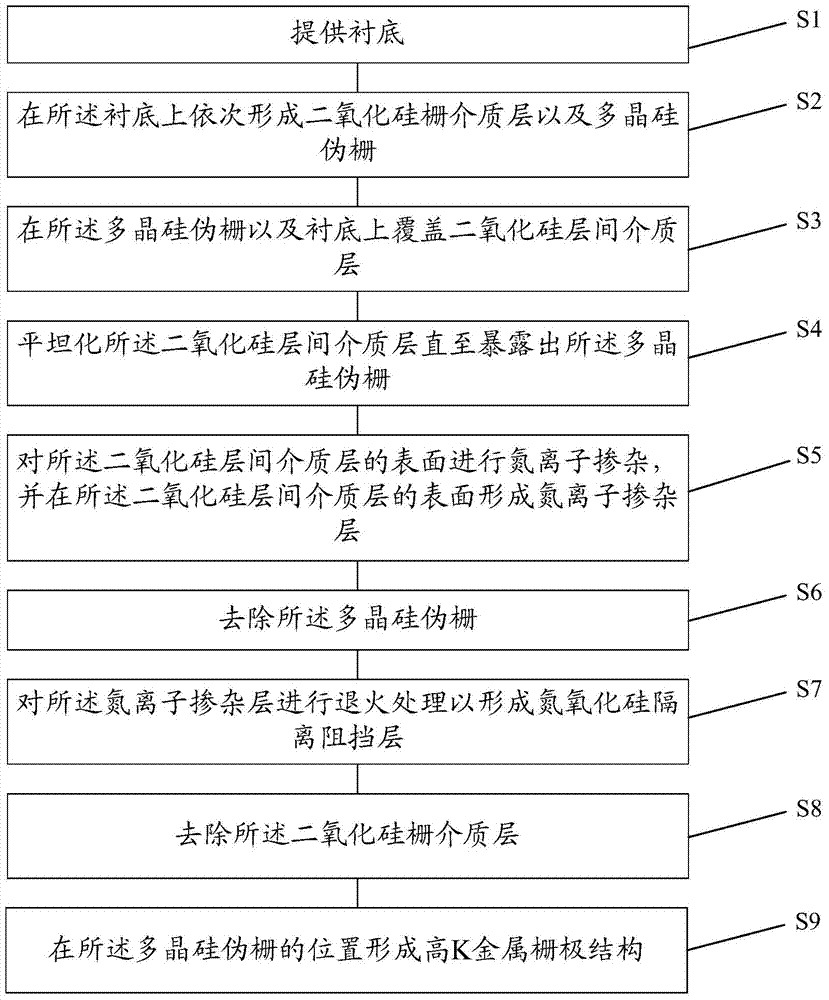

Semiconductor device and forming method thereof

InactiveCN104733294AIncreasing the thicknessReduce consumptionSemiconductor devicesGate dielectricSurface loss

A semiconductor device forming method comprises steps: a substrate is provided, and a gate dielectric layer and a pseudo gate; an interlayer dielectric layer flush with the pseudo gate is formed on the substrate; ion doping is carried out on the surface of the interlayer dielectric layer so as to form a doping layer on the surface of the interlayer dielectric layer; the gate dielectric layer and the pseudo gate are removed; and a gate electrode structure is formed at the pseudo gate position. The invention also provides a semiconductor device, which comprises the substrate, the gate electrode, the interlayer dielectric layer and an isolation layer arranged on the surface of the interlayer dielectric layer. The semiconductor device and the forming method thereof have the beneficial effects that through carrying out ion doping on the surface of the interlayer dielectric layer and the surface of the exposed pseudo gate and forming the doping layers on the surface of the interlayer dielectric layer and the surface of the pseudo gate, the doping layers can well block influences on the interlayer dielectric layer by the subsequent pseudo gate removal step, surface losses of the interlayer dielectric layer are further reduced, and the height of the gate electrode formed subsequently can be ensured.

Owner:SEMICON MFG INT (SHANGHAI) CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com