Plasma process for preparing acid water

A technology of plasma and acid water, applied in the field of water treatment, can solve the problems of limited application of operating conditions and the inability of acid water to exist stably, and achieve the effect of easy preservation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

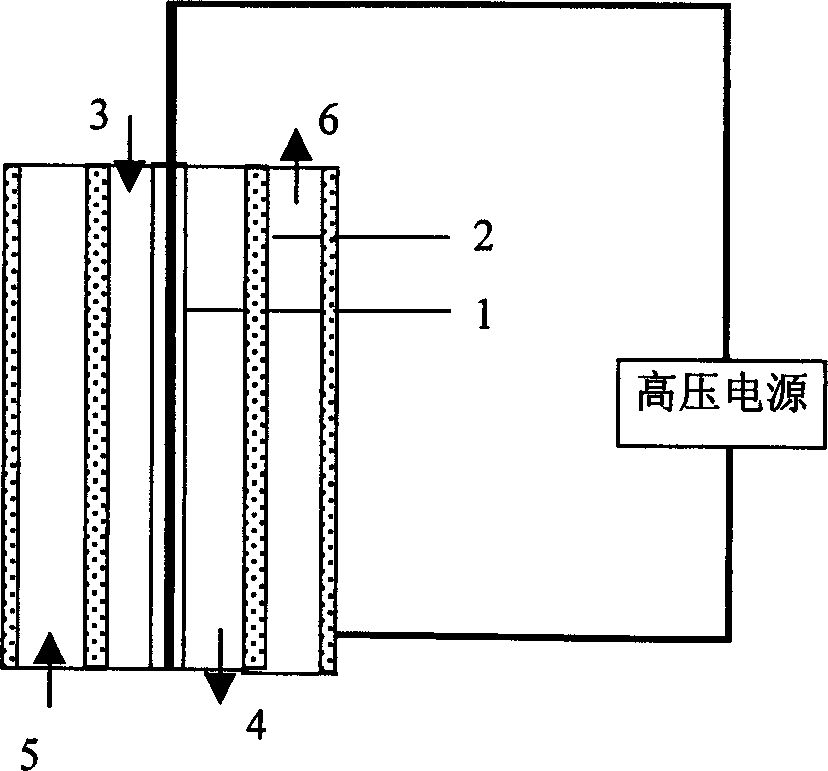

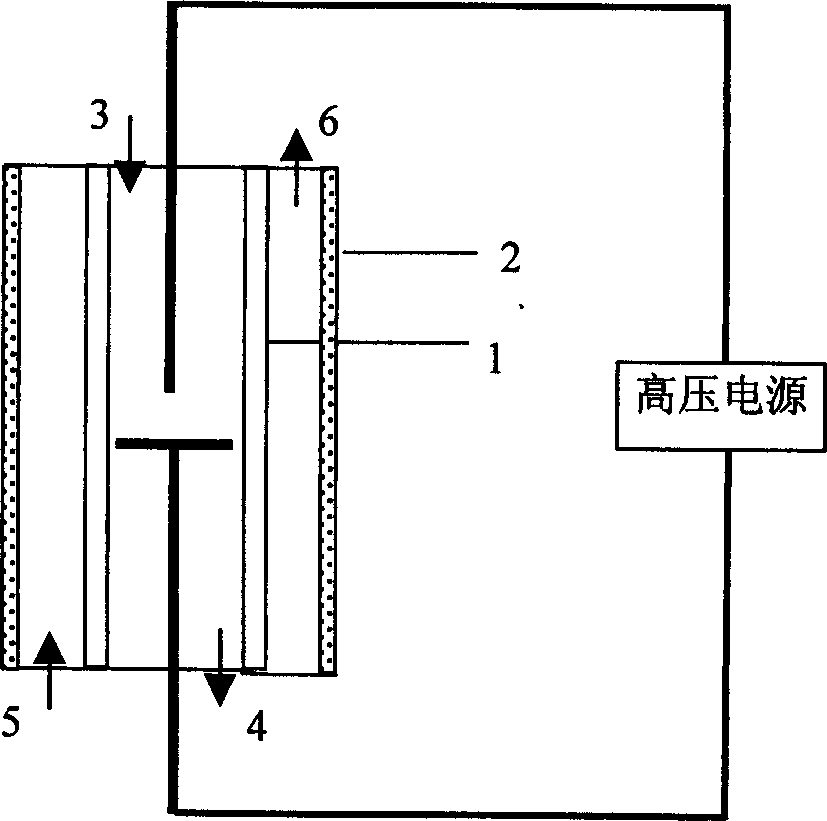

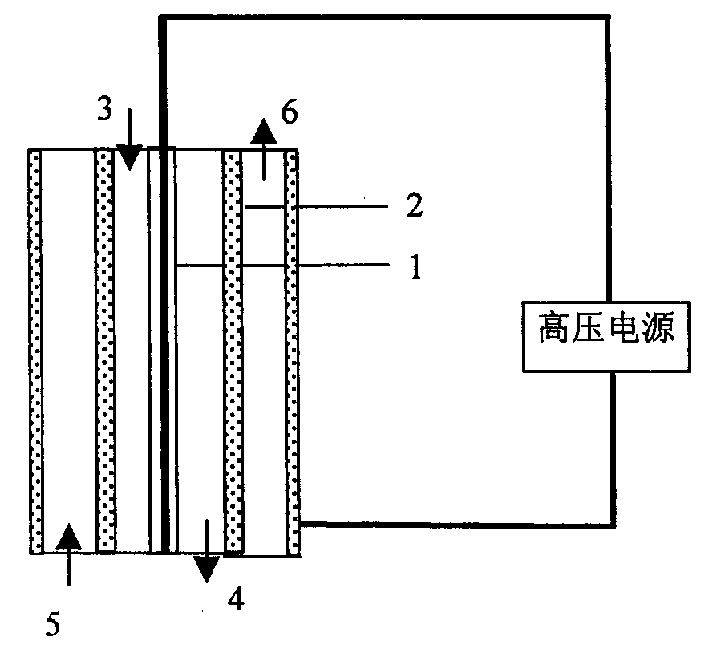

[0011] Such as figure 1 In the shown dielectric barrier plasma generator, the quartz tube 1 containing the positive electrode is placed in the stainless steel tube 2 as the negative electrode, and connected to a high-voltage power supply, and distilled water is placed between the stainless steel tube and the quartz tube. The water enters from the direction of the inlet 3, and the treated acidic water flows out from the direction of the outlet 4. During the treatment, 1000V AC high voltage is applied, and the treatment time is 120 minutes. It flows in from the direction of the inlet 5 and flows out from the direction of the outlet 6 of the jacket, and the temperature is 76°C.

[0012] Using the electric DDS-11A conductivity meter to measure the conductivity of the effluent water, the measured conductivity is 6.10E+03μS / cm, and the conductivity of ordinary distilled water is 3.6μS / cm. It can be seen that after plasma treatment The conductivity increased by 1000 times, indicatin...

Embodiment 2

[0016] The deionized water was treated according to the steps of Example 1, the treatment time was 10 minutes, the treatment voltage was an AC high voltage of 5000V, and the circulating water temperature was 90°C.

[0017] Using the analysis steps in Example 1, the measured conductivity is 3.51E+03 μS / cm, and the pH value is 2.64.

Embodiment 3

[0019] Distilled water was treated according to the steps of Example 1, the treatment time was 30 minutes, the treatment voltage was 3000V AC high voltage, and the circulating water temperature was 82°C.

[0020] Using the analysis steps in Example 1, the measured conductivity is 4.61E+03 μS / cm, and the pH value is 2.24.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com